Top-Down Design Approach of Lightweight Composite Battery Pack Enclosure for Electric Vehicles Based on Numerical Modeling and Topology Optimization

Abstract

1. Introduction

2. Materials and Methods

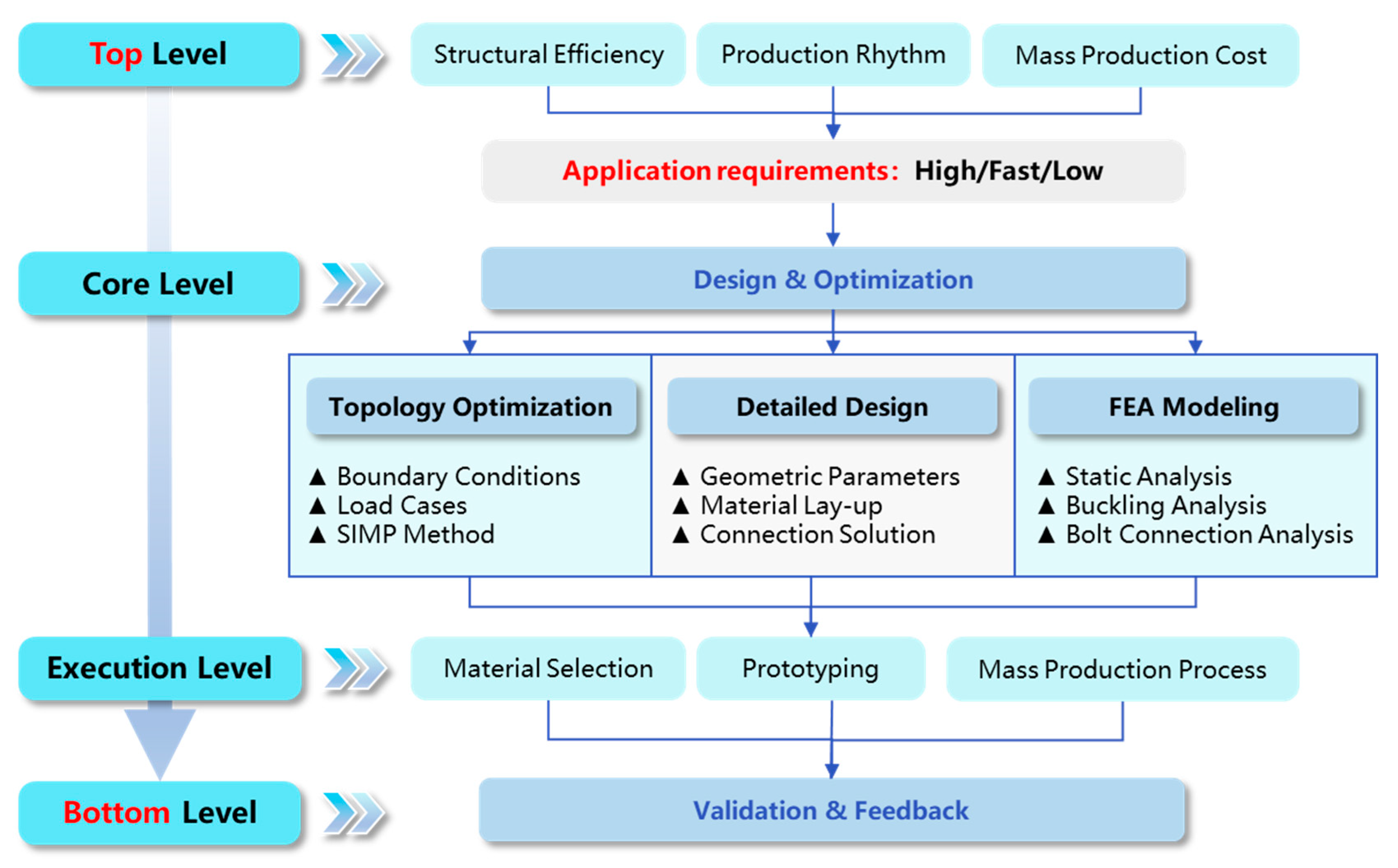

2.1. Top-Down Design Approach

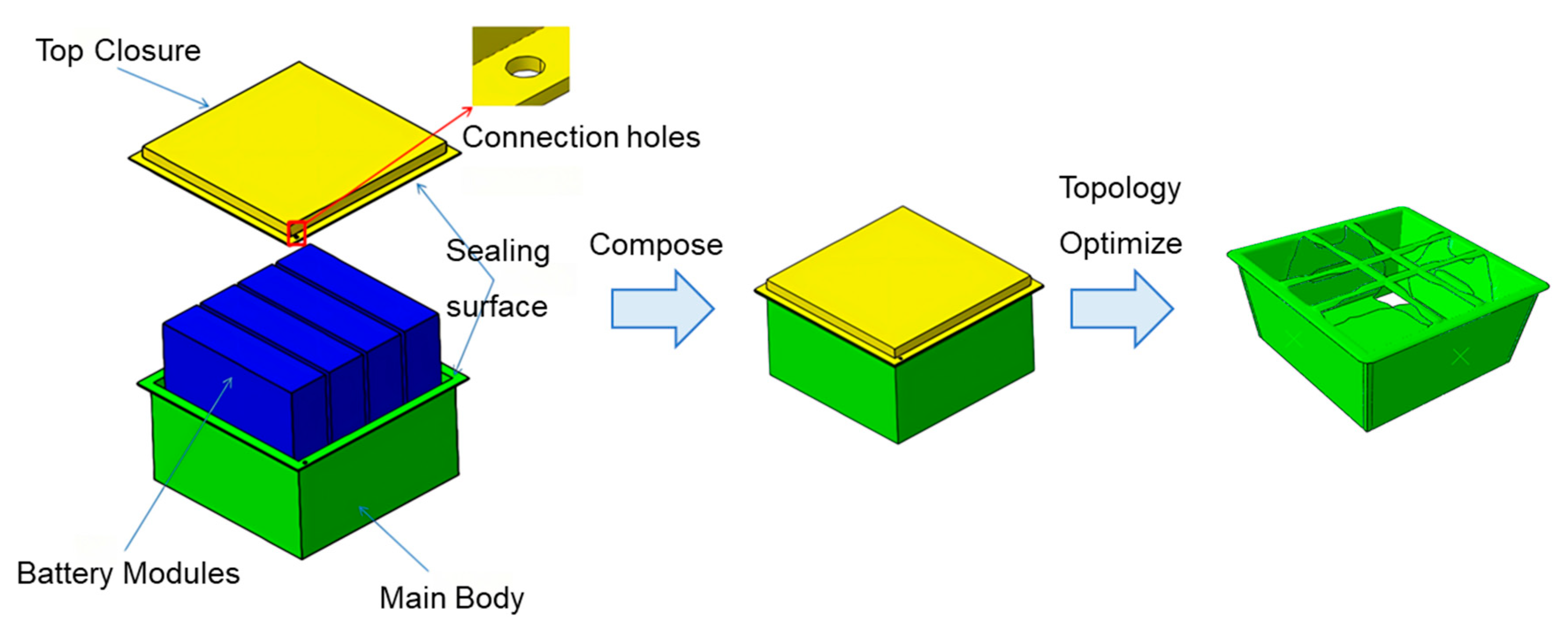

2.2. Topology Optimization

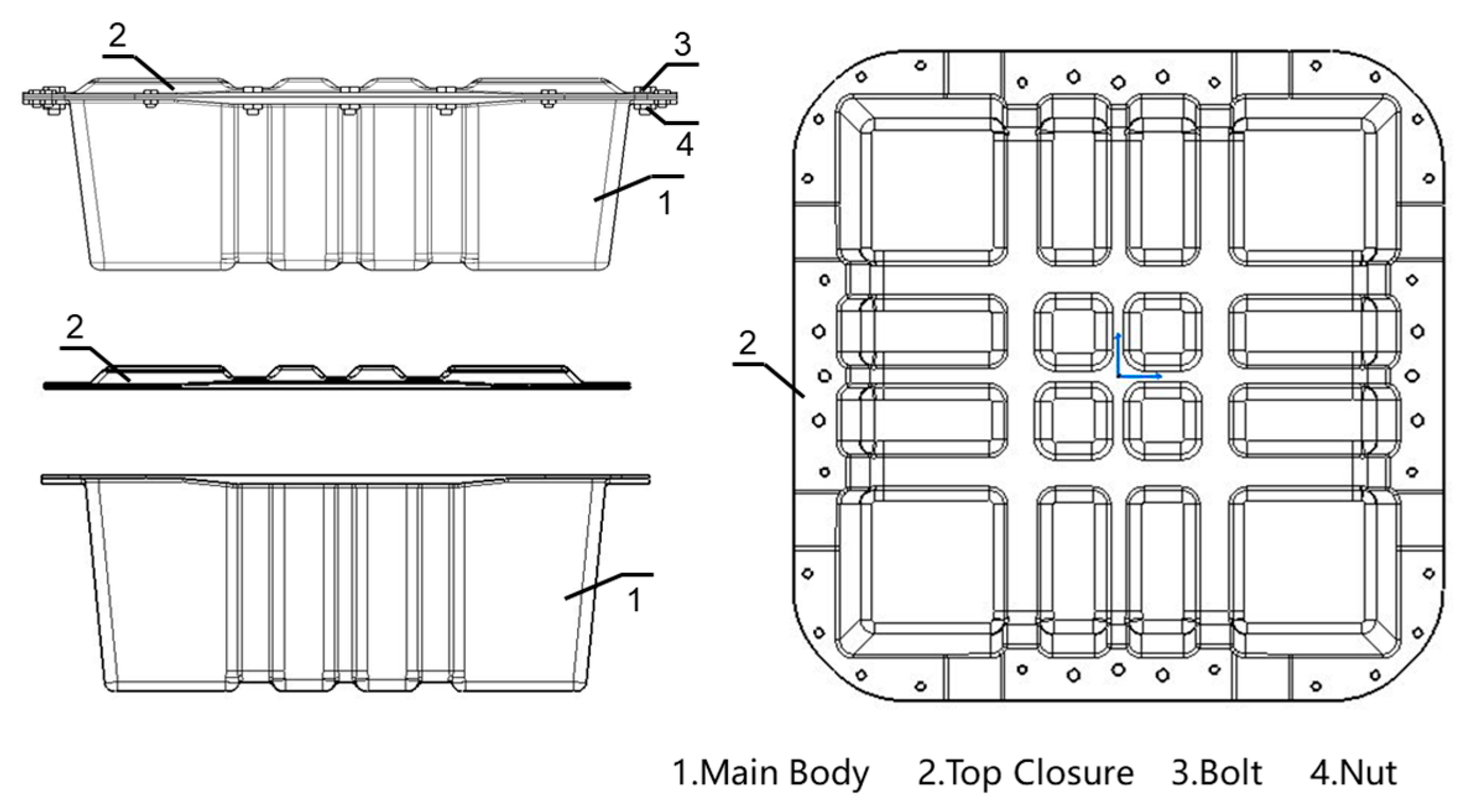

2.3. Structural Design

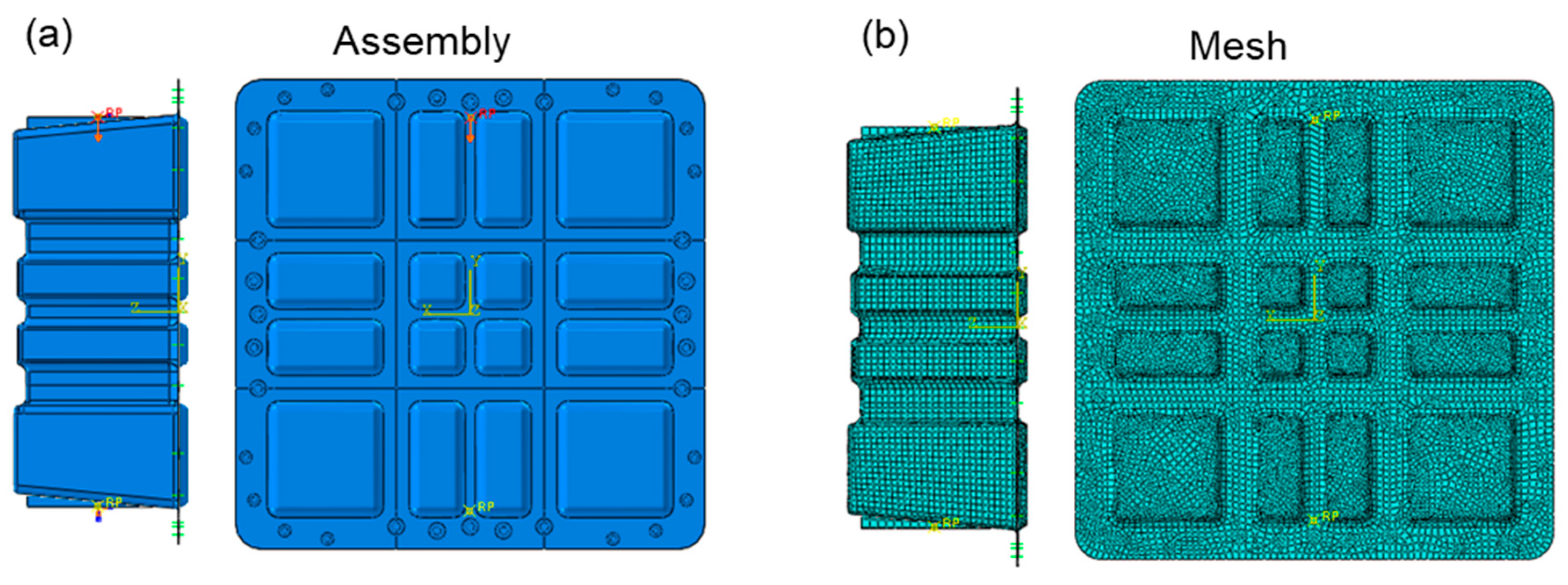

2.4. Finite Element Modeling

2.4.1. Suspended In-Plane Static Bottom Compression Modeling

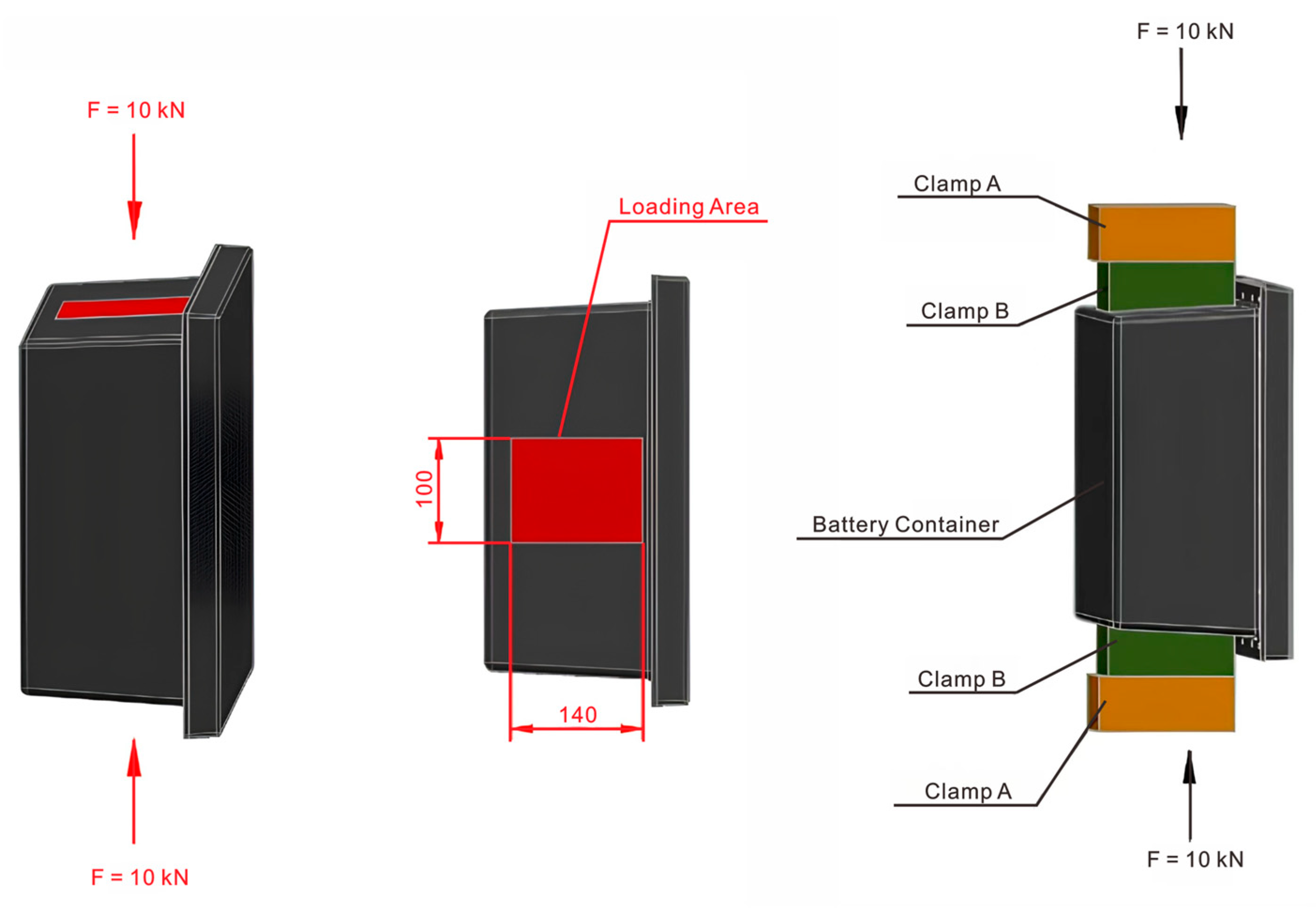

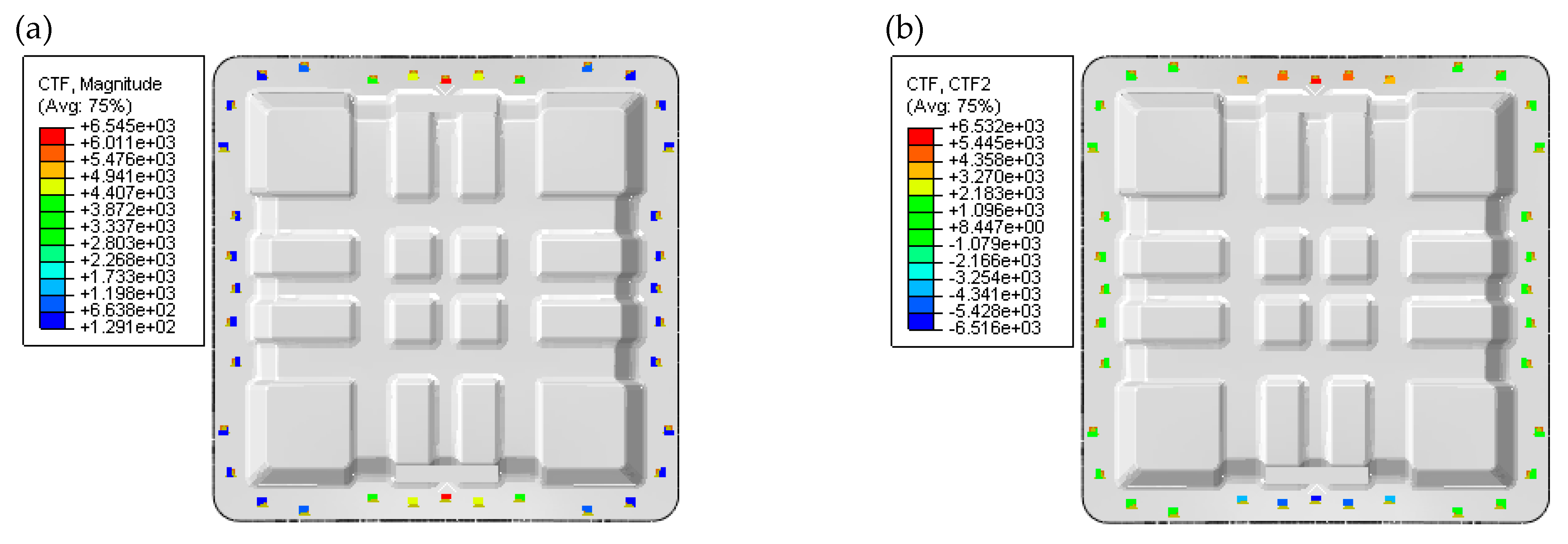

2.4.2. Lateral Compression Modeling

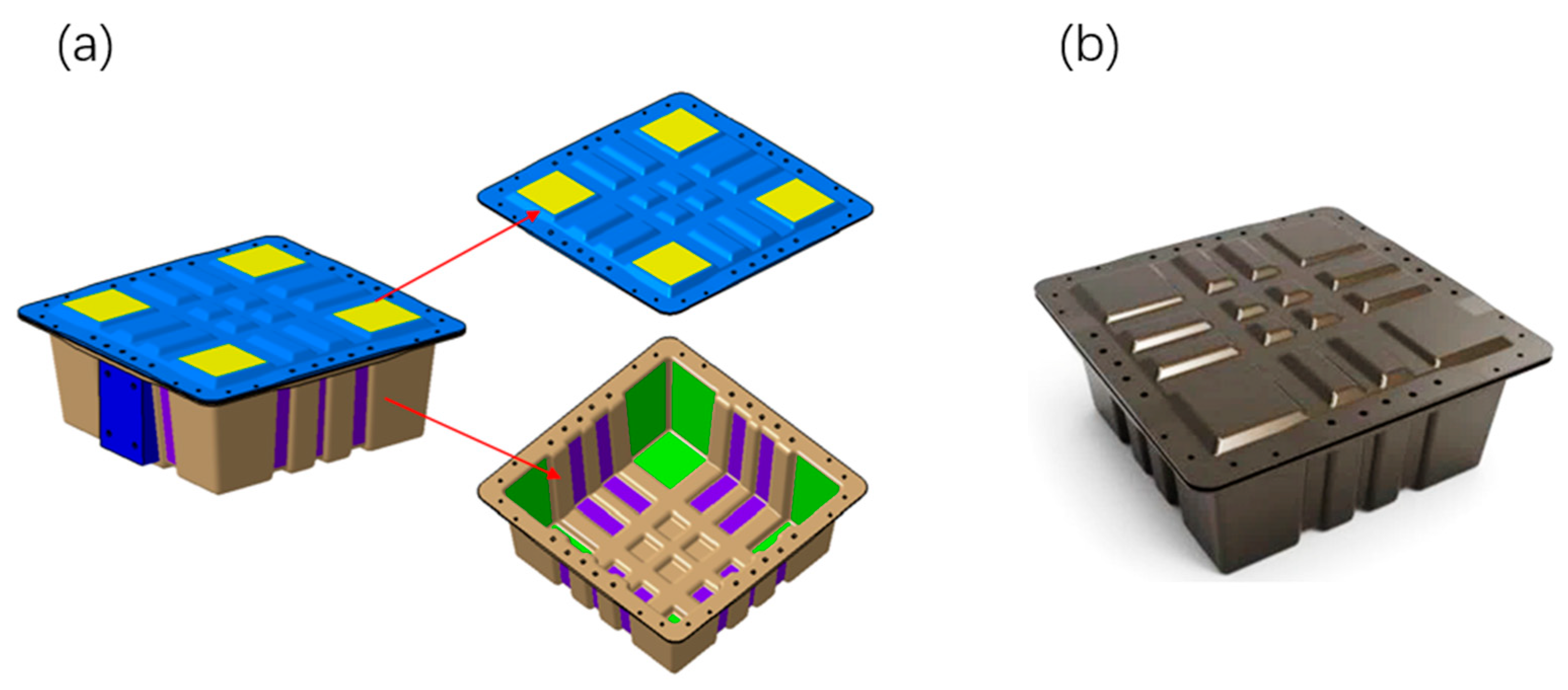

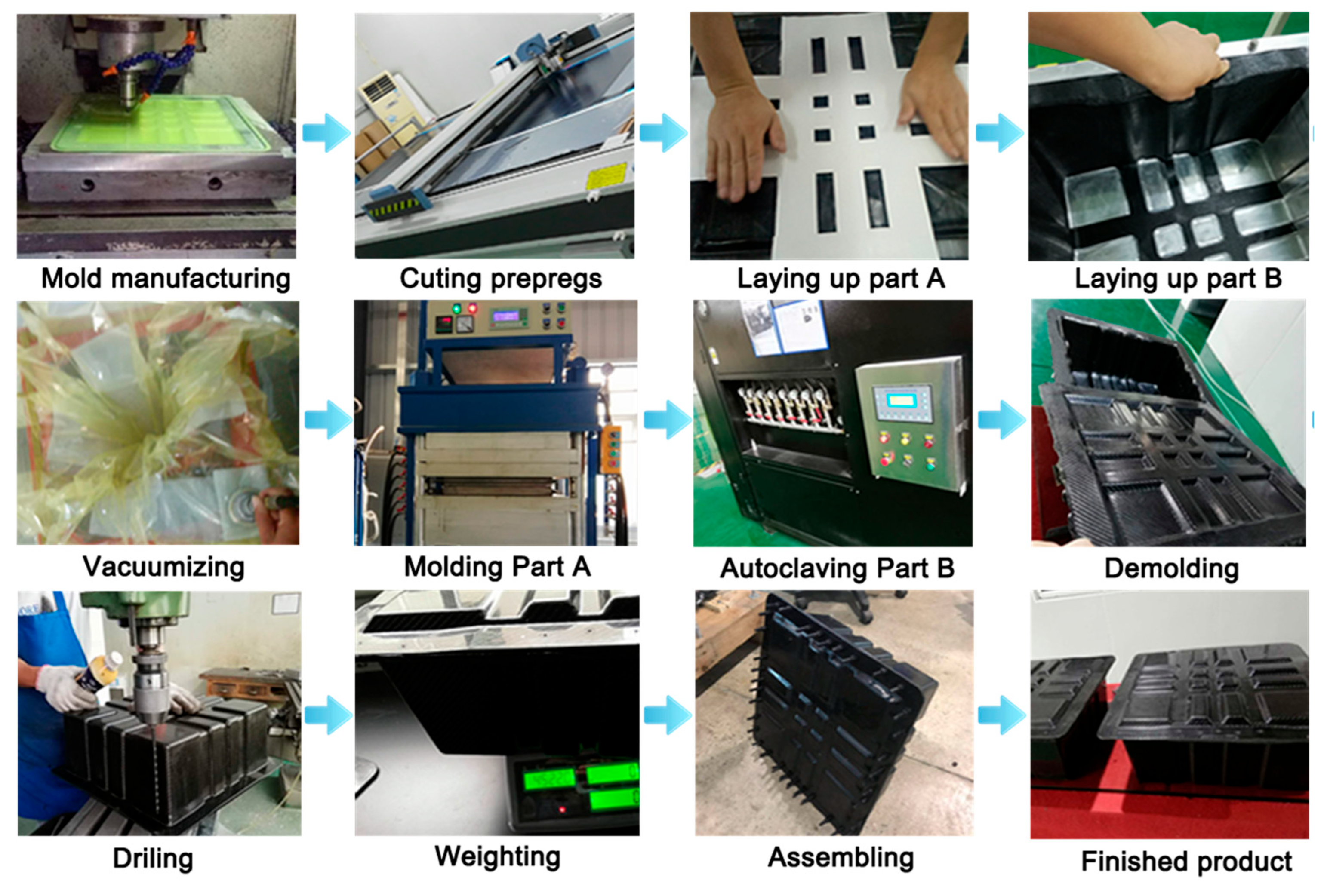

2.5. Fabrication Procedure

2.5.1. Materials

2.5.2. Fabrication of Prototype Product

2.5.3. Mass Production Process

2.6. Experimental Test

2.6.1. Suspended In-Plane Static Bottom Compression Test

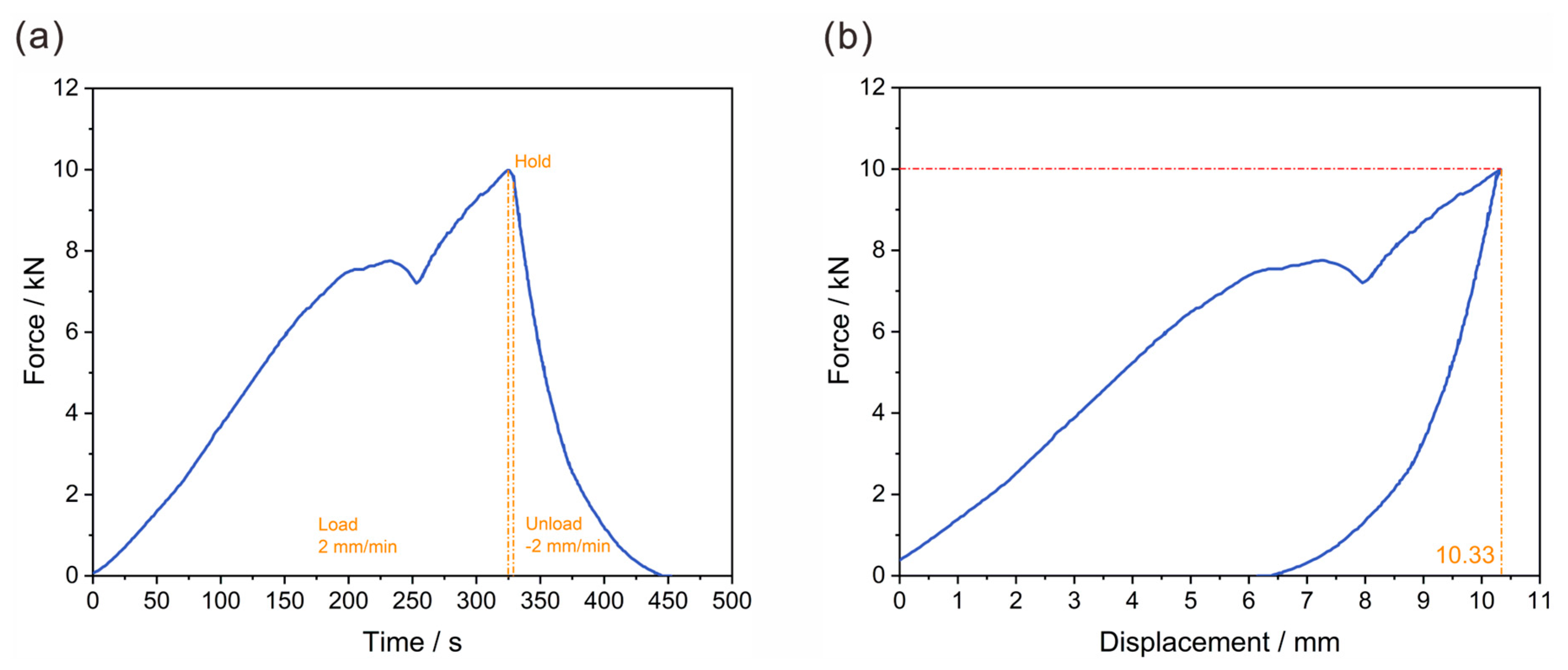

2.6.2. Static Lateral Compression Test

3. Results and Discussion

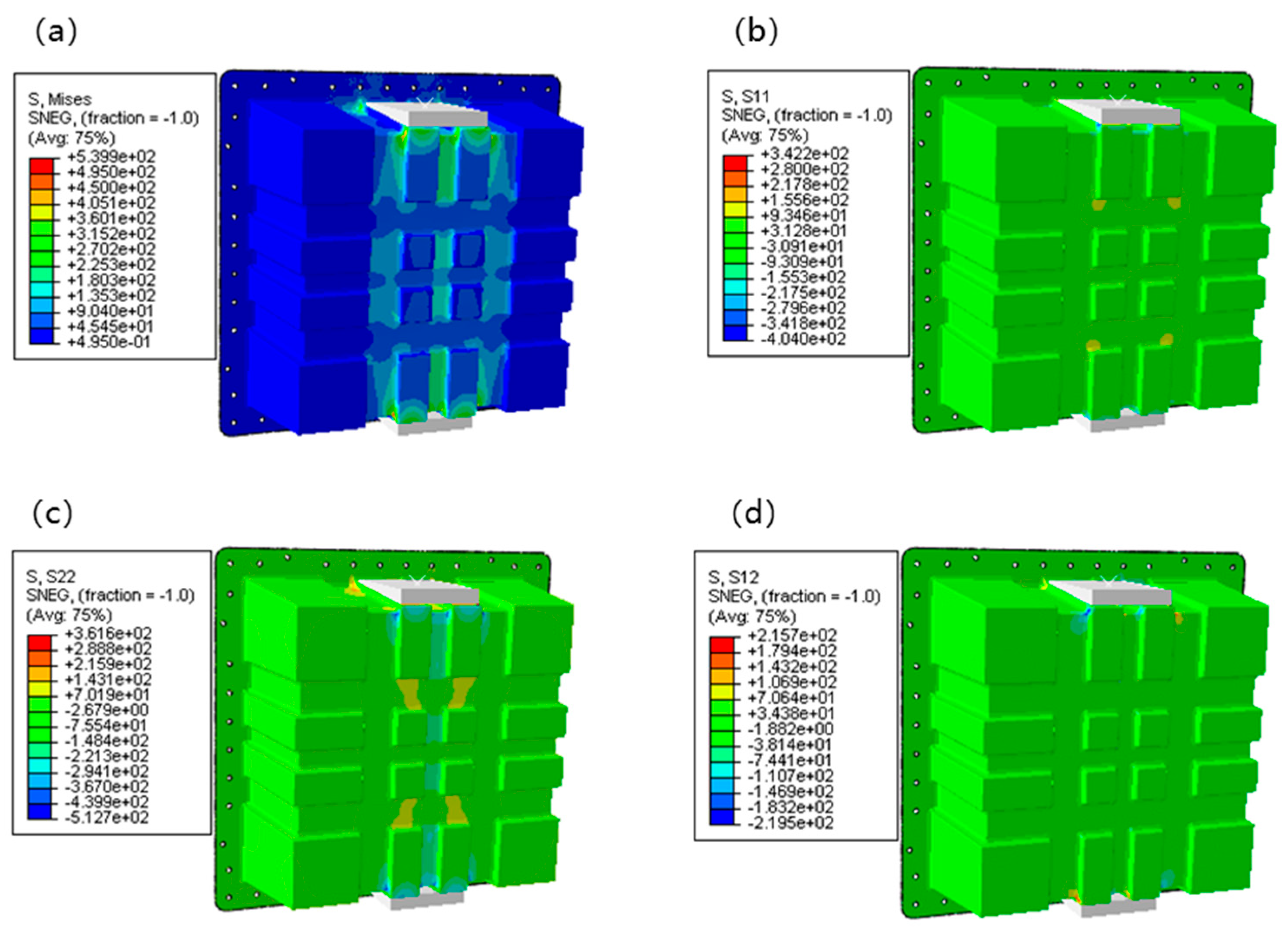

3.1. Results of Suspended Static Bottom Loading Condition

3.2. Results of Lateral Loading Condition

3.3. Results of Experimental Verification

4. Conclusions

- An optimized lightweight structural design was successfully developed and validated. Guided by load path analysis, the process involved topology optimization followed by detailed configuration design, which led to the implementation of a cross-rib stiffened structure. The resulting design met all stringent performance criteria, including static strength, stability, and bolt connection integrity under various operational loads, and achieved a total battery box mass of 4.78 kg.

- The prototype demonstrated excellent mechanical performance under critical loading conditions. Experimental tests confirmed the structural robustness, with a deformation of 10.33 mm under a severe 10 kN lateral crush load and a minimal deformation of 0.56 mm when subjected to a 1200 N static pressure on the base.

- A high-efficiency and cost-effective manufacturing strategy was established for industrial mass production of the CFRP battery-pack enclosure. It was achieved by selecting fast-curing prepregs and optimizing design to achieve a rapid curing cycle of 10–15 min. Furthermore, rigorous cost-control measures across production stages ensured that the target cost per unit was below ¥1000, which guarantees its commercial market.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AFP | Automated fiber placement |

| ATL | Automated tape laying |

| BMC | Bulk molding compound |

| CAE | Computer-aided engineering |

| CFRP | Carbon fiber reinforced plastic |

| C3D10M | Modified quadratic tetrahedral element |

| EVs | Electric vehicles |

| FEA | Finite element analysis |

| FRP | Fiber reinforced plastic |

| GFRP | Glass fiber reinforced plastic |

| HP-RTM | High-pressure resin transfer molding |

| OOA | Out-of-autoclave |

| PCM | Prepreg compression molding |

| RP | Reference point |

| RTM | Resin transfer molding |

| SIMP | Solid isotropic material with penalization |

| SMC | Sheet molding compound |

References

- Kumar, R.; Kanwal, A.; Asim, M.; Pervez, M.; Mujtaba, M.A.; Fouad, Y.; Kalam, M.A. Transforming the transportation sector: Mitigating greenhouse gas emissions through electric vehicles (EVs) and exploring sustainable pathways. AIP Adv. 2024, 14, 035320. [Google Scholar] [CrossRef]

- Kumar, A. A comprehensive review of an electric vehicle based on the existing technologies and challenges. Energy Storage 2024, 6, e70000. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, F.; Geng, J.; Hao, H.; Liu, Z. Comprehensive assessment for different ranges of battery electric vehicles: Is it necessary to develop an ultra-long range battery electric vehicle? Iscience 2023, 26, 106654. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Xiong, Y.; Wu, L.; Diao, K.; Guo, W. Lightweight design of an automotive battery-pack enclosure via advanced high-strength steels and size optimization. Int. J. Automot. Technol. 2021, 22, 1279–1290. [Google Scholar] [CrossRef]

- Haghbin, S.; Larijani, M.R.; Zolghadri, M.; Kia, S.H. Automotive battery pack standards and design characteristics: A review. Discov. Appl. Sci. 2025, 7, 731. [Google Scholar] [CrossRef]

- Naumanen, M.; Uusitalo, T.; Huttunen-Saarivirta, E.; van der Have, R. Development strategies for heavy duty electric battery vehicles: Comparison between China, EU, Japan and USA. Resour. Conserv. Recycl. 2019, 151, 104413. [Google Scholar] [CrossRef]

- Murugan, M.; Elumalai, P.V.; Vijayakumar, K.; Babu, M.; Kumar, K.S.; Ganesh, M.; Kuang, L.; Prabhakar, S. A Comprehensive Review of Thermal Management Methods and Ideal System Design for Improved Electric Vehicle Battery Pack Performance and Safety. Energy Sci. Eng. 2025, 13, 1011–1036. [Google Scholar] [CrossRef]

- Dhoke, A.; Dalavi, A. A critical review on lightweight design of battery pack enclosure for electric vehicles. Int. J. Sustain. Transp. Technol. 2021, 4, 53–62. [Google Scholar] [CrossRef]

- Kulkarni, S.S.; Hale, F.; Taufique, M.F.; Soulami, A.; Devanathan, R. Investigation of crashworthiness of carbon fibre-based electric vehicle battery enclosure using finite element analysis. Appl. Compos. Mater. 2023, 30, 1689–1715. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, X.; Han, Y.; Tian, Y.; Zhang, D.; Yan, L. Failure mechanisms and process defects of 3D-printed continuous carbon fibre-reinforced composite circular honeycomb structures with different stacking directions. Aerosp. Sci. Technol. 2024, 148, 109075. [Google Scholar] [CrossRef]

- Ma, Q.; Sahu, S.K.; Badgayan, N.D.; Rejab, M.R.M. Experimental and numerical investigations on tensile properties of carbon fibre-reinforced plastic and self-reinforced polypropylene composites. J. Mech. Behav. Mater. 2024, 33, 20240021. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing technologies of carbon/glass fibre-reinforced polymer composites and their properties: A review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, X.; Song, L.; Tian, Y.; Zhang, D.; Yan, L. Compressive properties and failure mechanisms of 3D-printed continuous carbon fibre-reinforced auxetic structures. Compos. Commun. 2023, 43, 101744. [Google Scholar] [CrossRef]

- Azzopardi, B.; Hapid, A.; Kaleg, S.; Sudirja; Onggo, D.; Budiman, A.C. Recent advances in battery pack polymer composites. Energies 2023, 16, 6223. [Google Scholar] [CrossRef]

- Galos, J.; Pattarakunnan, K.; Best, A.S.; Kyratzis, I.L.; Wang, C.; Mouritz, A.P. Energy storage structural composites with integrated lithium-ion batteries: A review. Adv. Mater. Technol. 2021, 6, 2001059. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, D.; Zhang, T.; Li, H.; Zhang, B.; Zhang, Z. Preparation and multifunctional performance of carbon fibre-reinforced plastic composites for laminated structural batteries. Polym. Compos. 2020, 41, 3023–3033. [Google Scholar] [CrossRef]

- Nieduzak, T.B.; Tronci, E.M.; Zhou, T.; Demo, L.B.; Feng, M.Q.; Aitharaju, V. Heat transfer model for temperature-sensing polymer composite EV battery enclosure. Compos. Part B Eng. 2025, 296, 112258. [Google Scholar] [CrossRef]

- Budiman, A.C.; Azzopardi, B.; Sudirja; Perdana, M.A.P.; Kaleg, S.; Hadiastuti, F.S.; Hasyim, B.A.; Amin; Ristiana, R.; Muharam, A.; et al. Phase change material composite battery module for thermal protection of electric vehicles: An experimental observation. Energies 2023, 16, 3896. [Google Scholar] [CrossRef]

- Nie, B.; Lim, J.; Liu, T.; Kovalenko, I.; Guo, K.; Liang, J.; Zhu, J.; Sun, H. Multifunctional composite designs for structural energy storage. Battery Energy 2023, 2, 20230023. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, P.; Zhang, Y.; Wang, F.; Tu, Y.; Ma, Y.; Zhang, C. Design and optimization of 3D-printed variable cross-section I-beams reinforced with continuous and short fibres. Polymers 2024, 16, 684. [Google Scholar] [CrossRef]

- Ma, Q.-H.; Dong, F.; Qin, X.-Y.; Gan, X.-H.; Cai, M. Parallel optimization of design and manufacturing—Carbon fibre battery pack for electric vehicles. Mech. Adv. Mater. Struct. 2024, 31, 2289–2306. [Google Scholar] [CrossRef]

- Shui, L.; Chen, F.; Garg, A.; Peng, X.; Bao, N.; Zhang, J. Design optimization of battery pack enclosure for electric vehicle. Struct. Multidiscip. Optim. 2018, 58, 331–347. [Google Scholar] [CrossRef]

- Chen, X.; Li, M.; Li, S.; Jin, J.; Zhang, C. Design optimization of multi-material battery enclosure for electric vehicle. In Society of Automotive Engineers (SAE)-China Congress; Springer: Singapore, 2017. [Google Scholar]

- Fragassa, C.; Pavlovic, A.; Minak, G. On the structural behaviour of a CFRP safety cage in a solar powered electric vehicle. Compos. Struct. 2020, 252, 112698. [Google Scholar] [CrossRef]

- Campos, B.M.; Bourbigot, S.; Fontaine, G.; Bonnet, F. Thermoplastic matrix-based composites produced by resin transfer molding: A review. Polym. Compos. 2022, 43, 2485–2506. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, G.; Xu, J.; Shi, X.P.; Wang, X. Review of curing deformation control methods for carbon fibre reinforced resin composites. Polym. Compos. 2022, 43, 3350–3370. [Google Scholar] [CrossRef]

- Bere, P.; Dudescu, M.; Neamțu, C.; Cocian, C. Design, manufacturing and test of CFRP front hood concepts for a lightweight vehicle. Polymers 2021, 13, 1374. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Fan, Y.; Gao, Q.; Wang, H. Multi-objective lightweight design of automotive battery pack box for crashworthiness. Int. J. Crashworthiness 2024, 29, 292–307. [Google Scholar] [CrossRef]

- Zhang, G.; Li, X.; Li, J.; Zhou, X.; Zhou, Y. Optimization design of battery bracket for new energy vehicles based on 3D printing technology. Sci. Rep. 2024, 14, 13461. [Google Scholar] [CrossRef]

- Lian, F.; Wang, D.; Xu, W.; Zhang, X.; Kong, D.; Huang, L. Multi-objective optimization design of a battery pack system for crashworthiness and lightweight based on a submodel and hybrid weighting method. Eng. Optim. 2025, 57, 1–19. [Google Scholar] [CrossRef]

- Liu, J.; Xu, L.; Yan, M.; Zhang, H.; Deng, H. Digital Twin-based AAHP/CFRP Battery Enclosure Hybrid Optimization Lightweight Design Method. ASME J. Risk Uncertain. Part B 2025, 12, 1–38. [Google Scholar] [CrossRef]

- Dabasa, T.; Lemu, H.G.; Regassa, Y. A Review on the Crashworthiness of Bio-Inspired Cellular Structures for Electric Vehicle Battery Pack Protection. Computation 2025, 13, 217. [Google Scholar] [CrossRef]

- Li, P.; Yan, Z.; Yang, Y. Progress in automobile body processing technology: Multi-material and lightweight strategies for saving energy and reducing emissions. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 324. [Google Scholar] [CrossRef]

- Arslan, M.; Karamangil, M.İ. Comprehensive Optimization and Design of an Electric Vehicle Battery Box Side Profile for Lightweight and Crashworthiness Using a Novel Hybrid Structure. Appl. Sci. 2025, 15, 2037. [Google Scholar] [CrossRef]

- Pan, Y.; Xiong, Y.; Dai, W.; Diao, K.; Wu, L.; Wang, J. Crush and crash analysis of an automotive battery-pack enclosure for lightweight design. Int. J. Crashworthiness 2022, 27, 500–509. [Google Scholar] [CrossRef]

| Parameters | Steel (e.g., Mild Steel) | Aluminum (e.g., Al 6061) | GFRP | CFRP |

|---|---|---|---|---|

| Costs (¥/kg) | Low (~10–20) | Medium (~30–50) | Medium (~40–70) | High (~200–400) |

| Manufacturing cost | Low | Medium | Medium | High, but reducible |

| Manufacturing speed | Very high | Very high | High | Medium |

| Scalability for mass production | Very high | Very high | Medium | Medium to High |

| Thermal conductivity (W/m·K) | High (~50) | Very high (~200) | Low (~0.2–0.5) | Moderate |

| Mechanical properties | Low | Medium | Medium | Very high |

| Corrosion resistance | Low | Medium | High | High |

| Weight saving | Baseline | ~40–50% lighter | ~50% lighter | ~60% or more lighter |

| Structural Parameter | Value |

|---|---|

| Length × width × height/mm | 460 × 460 × 180 |

| Angle of main enclosure body/° | 5.5 |

| Angle of slot/° | 10 |

| Angle of cover/° | 10 |

| Height × width of stiffener/mm | 9 × 15 |

| Spacing of stiffeners/mm | 25 |

| Diameter of rounding/mm | 3/10 |

| Diameter of bolt/mm | 6/8 |

| Edge distance of bolt/mm | 18 |

| Properties | /MPa | /MPa | /MPa | /MPa | /MPa | |

|---|---|---|---|---|---|---|

| CFRP | 131,000 | 8180 | 0.3 | 5320 | 5320 | 3476 |

| GFRP | 22,800 | 22,800 | 0.142 | 3800 | 3800 | 3000 |

| Equivalent Properties | /MPa | /MPa | /MPa | /MPa | /MPa | |

|---|---|---|---|---|---|---|

| Composite laminates | 50,771 | 50,771 | 0.3 | 19,538 | 4560 | 4560 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Lin, Q.; Xiao, Y.; Jia, L.; Yang, T.; Wang, L.; Ma, Q.; Wang, B. Top-Down Design Approach of Lightweight Composite Battery Pack Enclosure for Electric Vehicles Based on Numerical Modeling and Topology Optimization. Polymers 2025, 17, 2897. https://doi.org/10.3390/polym17212897

Zhang X, Lin Q, Xiao Y, Jia L, Yang T, Wang L, Ma Q, Wang B. Top-Down Design Approach of Lightweight Composite Battery Pack Enclosure for Electric Vehicles Based on Numerical Modeling and Topology Optimization. Polymers. 2025; 17(21):2897. https://doi.org/10.3390/polym17212897

Chicago/Turabian StyleZhang, Xin, Qiang Lin, Ying Xiao, Liyong Jia, Tiantian Yang, Lei Wang, Quanjin Ma, and Bing Wang. 2025. "Top-Down Design Approach of Lightweight Composite Battery Pack Enclosure for Electric Vehicles Based on Numerical Modeling and Topology Optimization" Polymers 17, no. 21: 2897. https://doi.org/10.3390/polym17212897

APA StyleZhang, X., Lin, Q., Xiao, Y., Jia, L., Yang, T., Wang, L., Ma, Q., & Wang, B. (2025). Top-Down Design Approach of Lightweight Composite Battery Pack Enclosure for Electric Vehicles Based on Numerical Modeling and Topology Optimization. Polymers, 17(21), 2897. https://doi.org/10.3390/polym17212897