Alginate/Gelatin Hydrogels Reinforced with TiO2 and β-TCP Fabricated by Microextrusion-based Printing for Tissue Regeneration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Methodology

2.1.1. Materials

2.1.2. Pre-Crosslinked Hydrogel Solution Preparation and Characterization

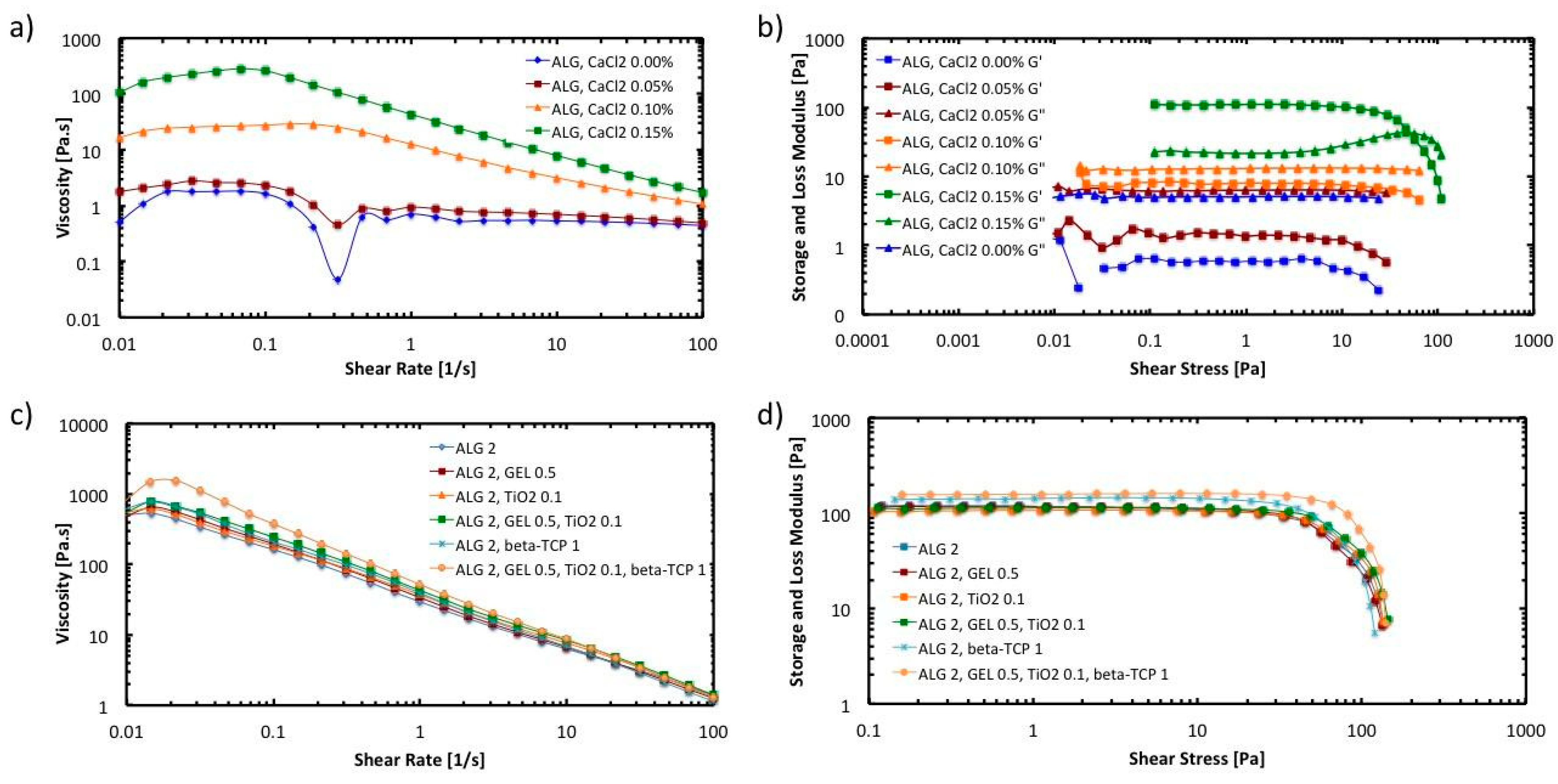

2.1.3. Rheology

2.1.4. Crosslinked Hydrogel Preparation

2.1.5. X-ray Diffraction

2.1.6. FTIR

2.1.7. Pore Size Analysis and Microscopy

2.1.8. Mechanical Tests

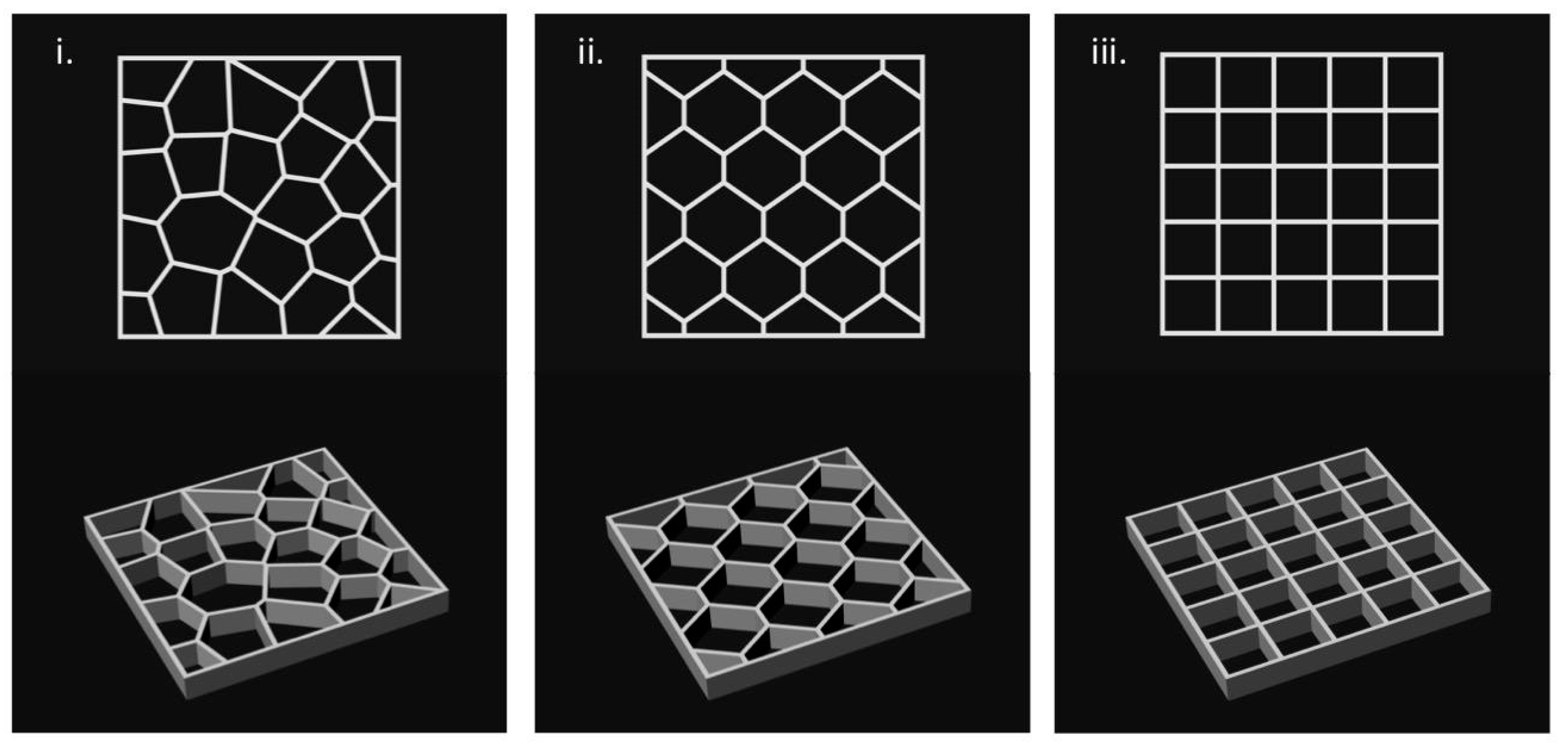

2.2. Design and Manufacturing Process

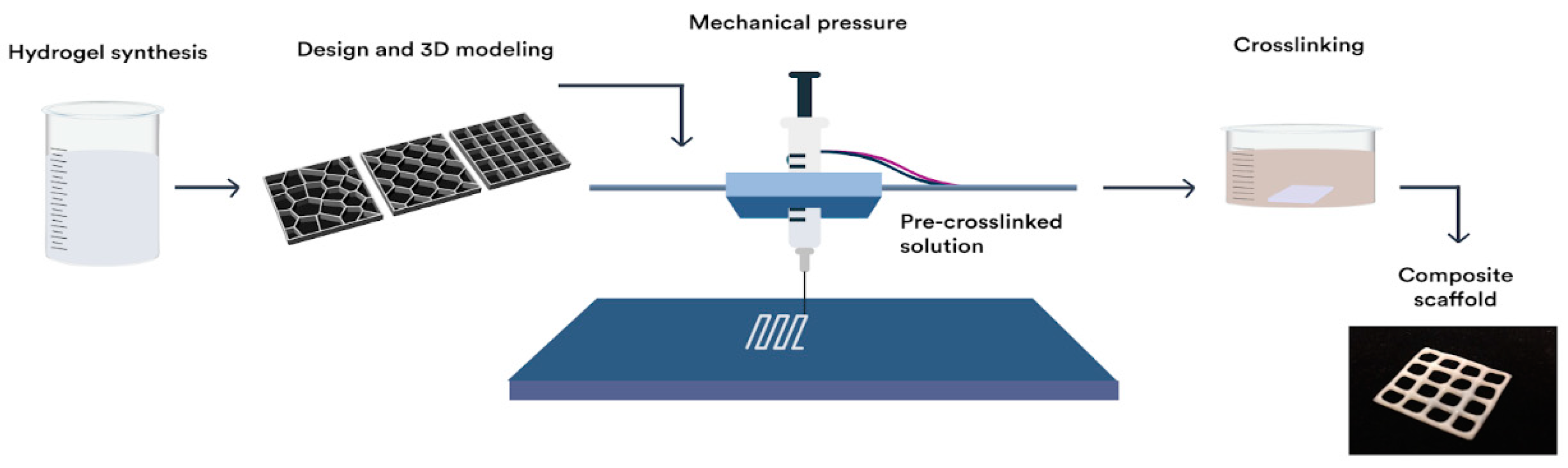

2.2.1. Design Models

2.2.2. Manufacturing Process

2.2.3. Die Swell Behavior

3. Results and Discussion

3.1. Study of the Rheological Properties of the Hydrogel Ink

3.2. FTIR and XRD Characterizations

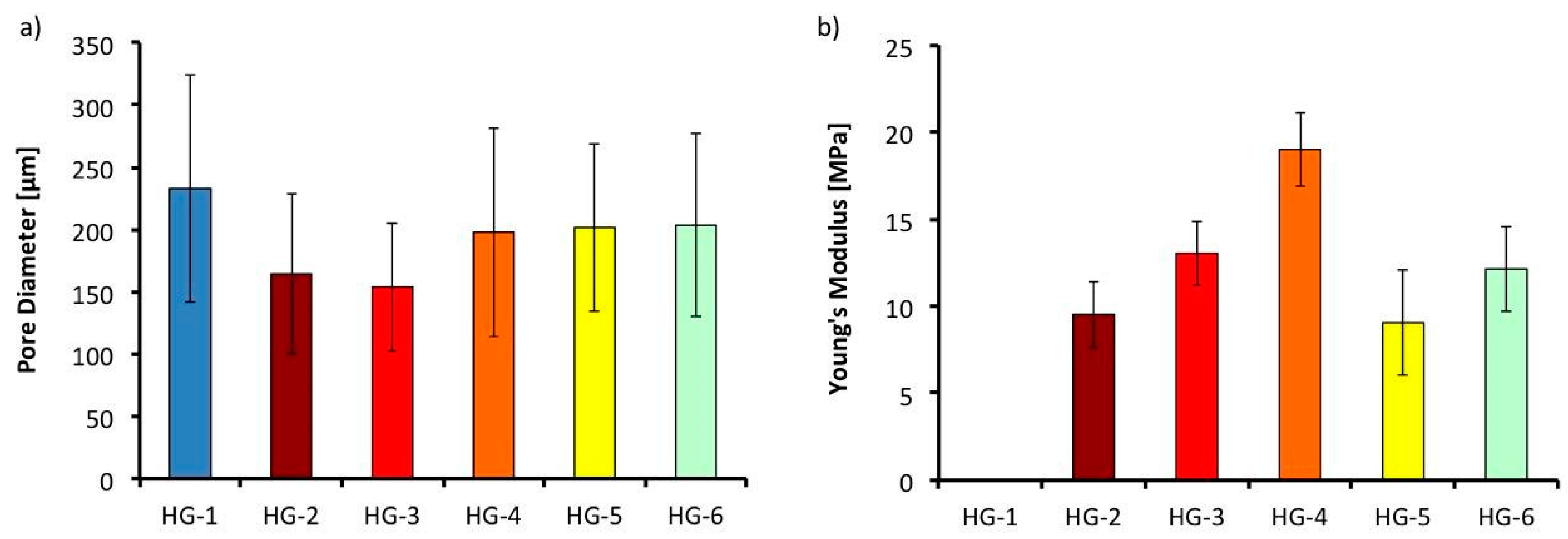

3.3. Porosity and Structure

3.4. Mechanical Test

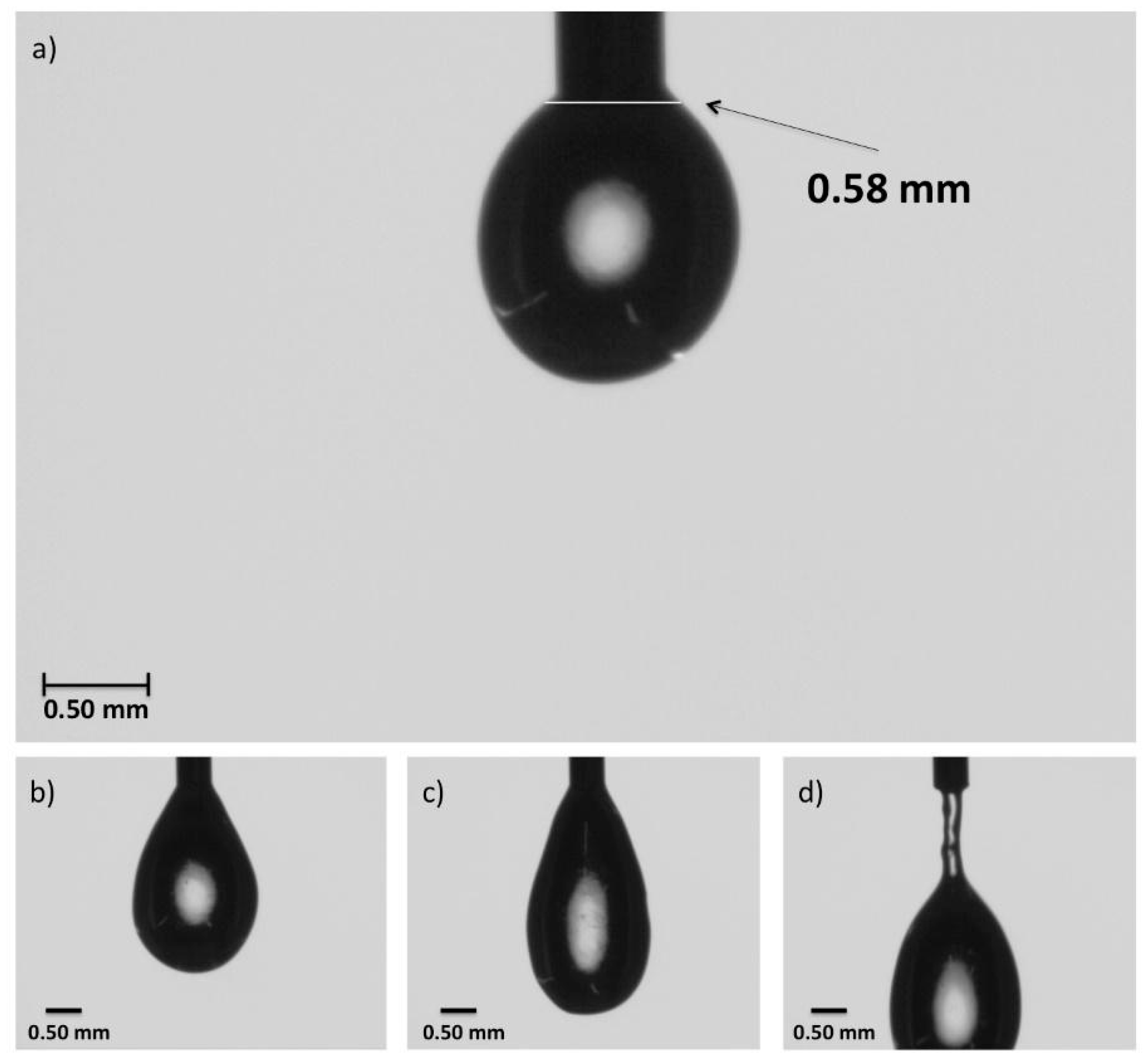

3.5. Die Swell Behavior

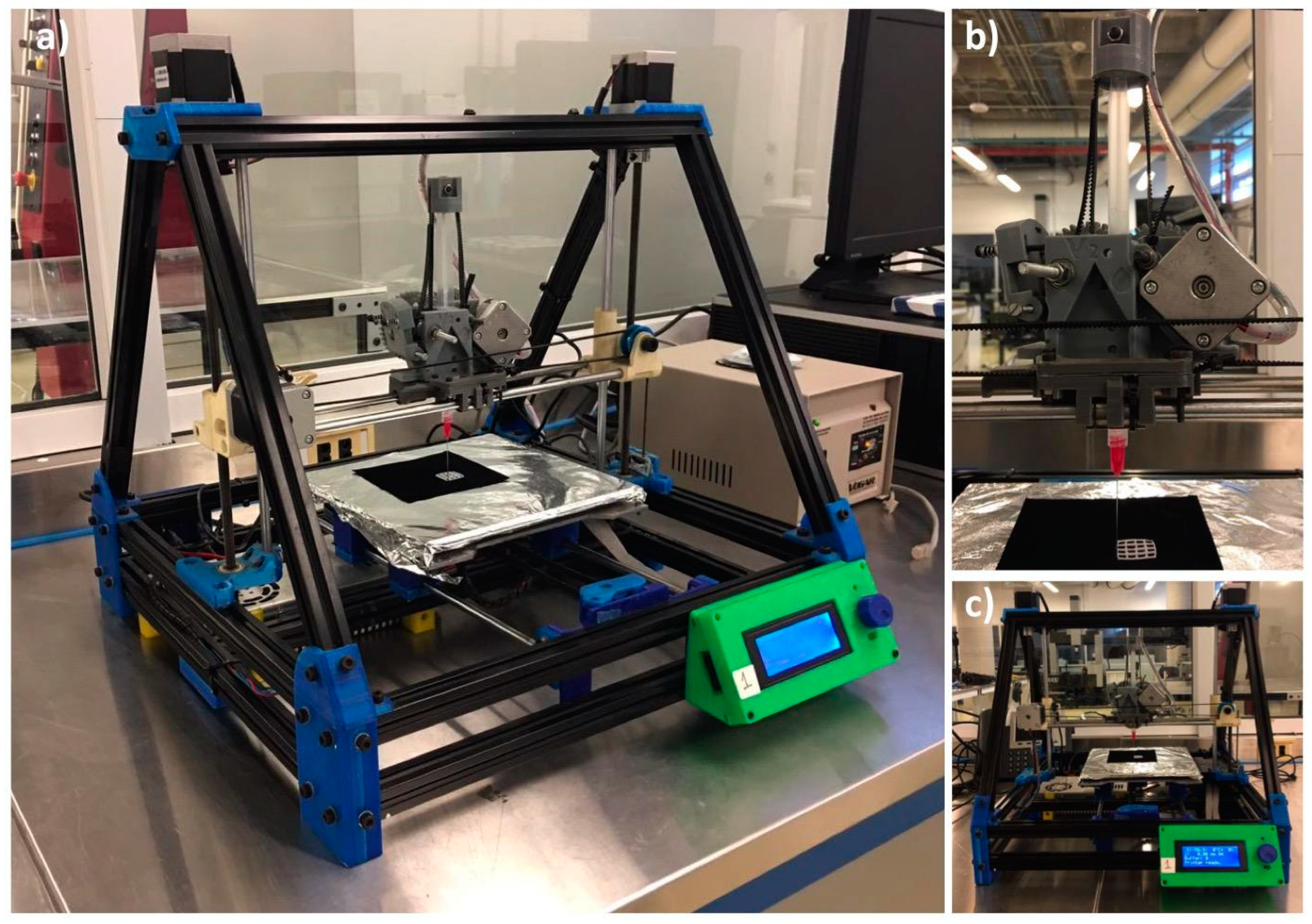

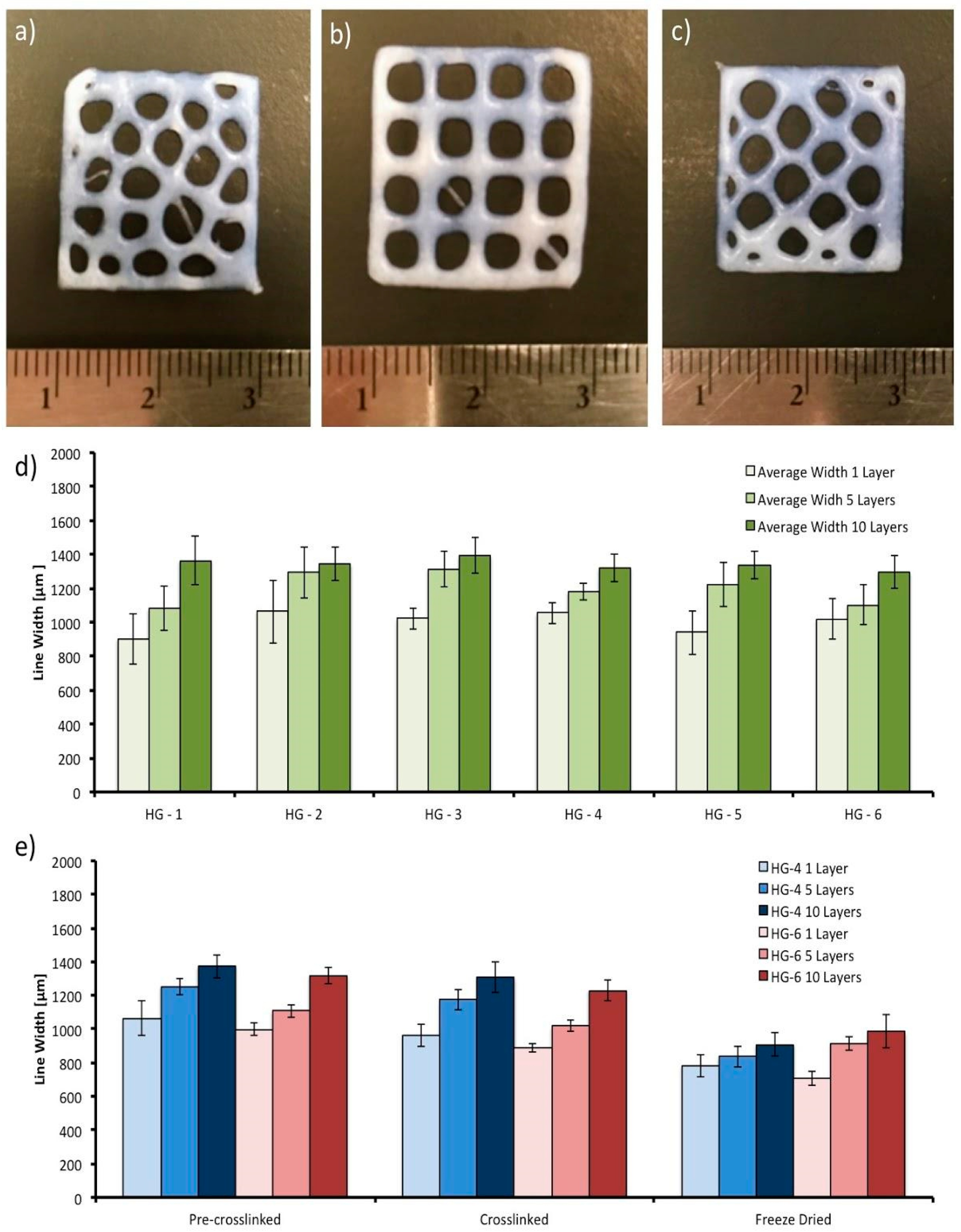

3.6. Extrusion Test and Printing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jensen, S.S.; Terheyden, H. Bone augmentation procedures in localized defects in the alveolar ridge: Clinical results with different bone grafts and bone-substitute materials. Int. J. Oral Maxillofac. Implants 2009, 24, 218–236. [Google Scholar] [PubMed]

- Silva, F.M.S.; Cortez, A.L.V.; Moreira, R.W.F.; Mazzonetto, R. Complications of intraoral donor site for bone grafting prior to implant placement. Implant Dent. 2006, 15, 420–426. [Google Scholar] [CrossRef] [PubMed]

- Holtzclaw, D.; Toscano, N.; Eisenlohr, L.; Callan, D. The Safety of Bone Allografts Used in Dentistry: A Review. J. Am. Dent. Assoc. 2008, 139, 1192–1199. [Google Scholar] [CrossRef] [PubMed]

- Fisher, J.P.; Reddi, A.H. Functional tissue engineering of bone: Signals and scaffolds. Top. Tissue Eng. 2003, 1, 1–29. [Google Scholar]

- Zhu, J.; Marchant, R.E. Design properties of hydrogel tissue-engineering scaffolds. Expert Rev. Med. Devices 2011, 8, 607–626. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Advert. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Sherbiny, I.M.; Yacoub, M.H. Hydrogel scaffolds for tissue engineering: Progress and challenges. Glob. Cardiol. Sci. Pract. 2013, 2013, 316–342. [Google Scholar] [CrossRef] [PubMed]

- Murphy, C.M.; O’Brien, F.J. Understanding the effect of mean pore size on cell activity in collagen-glycosaminoglycan scaffolds. Cell Adhes. Migr. 2010, 4, 377–381. [Google Scholar] [CrossRef] [Green Version]

- Maiti, B.; Díaz Díaz, D. 3D Printed Polymeric Hydrogels for Nerve Regeneration. Polymers 2018, 10, 1041. [Google Scholar] [CrossRef]

- Josef, E.; Zilberman, M.; Bianco-Peled, H. Composite alginate hydrogels: An innovative approach for the controlled release of hydrophobic drugs. Acta Biomater. 2010, 6, 4642–4649. [Google Scholar] [CrossRef] [PubMed]

- Webber, R.E.; Shull, K.R. Strain Dependence of the Viscoelastic Properties of Alginate Hydrogels. Macromolecules 2004, 37, 6153–6160. [Google Scholar] [CrossRef]

- Sarker, B.; Singh, R.; Silva, R.; Roether, J.A.; Kaschta, J.; Detsch, R.; Schubert, D.W.; Cicha, I.; Boccaccini, A.R. Evaluation of fibroblasts adhesion and proliferation on alginate-gelatin crosslinked hydrogel. PLoS ONE 2014, 9, e107952. [Google Scholar] [CrossRef] [PubMed]

- Contessi Negrini, N.; Bonnetier, M.; Giatsidis, G.; Orgill, D.P.; Farè, S.; Marelli, B. Tissue-mimicking gelatin scaffolds by alginate sacrificial templates for adipose tissue engineering. Acta Biomater. 2019. [Google Scholar] [CrossRef] [PubMed]

- You, F.; Wu, X.; Chen, X. 3D printing of porous alginate/gelatin hydrogel scaffolds and their mechanical property characterization. Int. J. Polym. Mater. Polym. Biomater. 2017, 66, 299–306. [Google Scholar] [CrossRef]

- Gnanaprakasam Thankam, F.; Muthu, J. Alginate based hybrid copolymer hydrogels—Influence of pore morphology on cell–material interaction. Carbohydr. Polym. 2014, 112, 235–244. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Li, Q.; Xu, S.; Zheng, Q.; Cao, X. Preparation and Properties of 3D Printed Alginate–Chitosan Polyion Complex Hydrogels for Tissue Engineering. Polymers 2018, 10, 664. [Google Scholar] [CrossRef]

- Kühn, P.; Rozenbaum, R.; Perrels, E.; Sharma, P.; van Rijn, P. Anti-Microbial Biopolymer Hydrogel Scaffolds for Stem Cell Encapsulation. Polymers 2017, 9, 149. [Google Scholar] [CrossRef]

- Luo, Y.; Lode, A.; Akkineni, A.R.; Gelinsky, M. Concentrated gelatin/alginate composites for fabrication of predesigned scaffolds with a favorable cell response by 3D plotting. RSC Adv. 2015, 5, 43480–43488. [Google Scholar] [CrossRef]

- Giannitelli, S.; Mozetic, P.; Trombetta, M.; Rainer, A. Additive Manufacturing of Pluronic/Alginate Composite Thermogels for Drug and Cell Delivery. In Additive Manufacturing; CRC Press: Boca Raton, FL, USA, 2015; pp. 403–412. ISBN 978-1-49-871477-8. [Google Scholar]

- Izadifar, Z.; Chang, T.; Kulyk, W.; Chen, X.; Eames, B.F. Analyzing Biological Performance of 3D-Printed, Cell-Impregnated Hybrid Constructs for Cartilage Tissue Engineering. Tissue Eng. Part C Methods 2016, 22, 173–188. [Google Scholar] [CrossRef] [PubMed]

- Bendtsen, S.T.; Quinnell, S.P.; Wei, M. Development of a novel alginate-polyvinyl alcohol-hydroxyapatite hydrogel for 3D bioprinting bone tissue engineered scaffolds. J. Biomed. Mater. Res. A 2017, 105, 1457–1468. [Google Scholar] [CrossRef] [PubMed]

- Barradas, A.M.C.; Yuan, H.; van Blitterswijk, C.A.; Habibovic, P. Osteoinductive biomaterials: Current knowledge of properties, experimental models and biological mechanisms. Eur. Cell. Mater. 2011, 21, 407–429. [Google Scholar] [CrossRef] [PubMed]

- Zazakowny, K.; Lewandowska-Łańcucka, J.; Mastalska-Popławska, J.; Kamiński, K.; Kusior, A.; Radecka, M.; Nowakowska, M. Biopolymeric hydrogels—Nanostructured TiO2 hybrid materials as potential injectable scaffolds for bone regeneration. Colloids Surf. B Biointerfaces 2016, 148, 607–614. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-Y.; Bark, C.W.; Van Quy, H.; Seo, S.-J.; Lim, J.-H.; Lee, J.-M.; Suh, J.-Y.; Lee, Y.; Um, H.-S.; Kim, Y.-G. Photofunctionalizing effects of hydroxyapatite combined with TiO2 on bone regeneration in rabbit calvarial defects. J. Biomed. Mater. Res. B Appl. Biomater. 2018. [Google Scholar] [CrossRef] [PubMed]

- Tiainen, H.; Wohlfahrt, J.C.; Verket, A.; Lyngstadaas, S.P.; Haugen, H.J. Bone formation in TiO2 bone scaffolds in extraction sockets of minipigs. Acta Biomater. 2012, 8, 2384–2391. [Google Scholar] [CrossRef] [PubMed]

- Shirai, R.; Miura, T.; Yoshida, A.; Yoshino, F.; Ito, T.; Yoshinari, M.; Yajima, Y. Antimicrobial effect of titanium dioxide after ultraviolet irradiation against periodontal pathogen. Dent. Mater. J. 2016, 35, 511–516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, J.-P.; Cheng, T.-H. Bone regeneration using 3D hyaluronic acid and chitosan-containing thermo-reversible hydrogel and canine mesenchymal stem cells. J. Biotechnol. 2008, 136, S128–S129. [Google Scholar] [CrossRef]

- Jose, R.R.; Rodriguez, M.J.; Dixon, T.A.; Omenetto, F.; Kaplan, D.L. Evolution of Bioinks and Additive Manufacturing Technologies for 3D Bioprinting. ACS Biomater. Sci. Eng. 2016, 2, 1662–1678. [Google Scholar] [CrossRef]

- Yanagawa, F.; Sugiura, S.; Kanamori, T. Hydrogel microfabrication technology toward three dimensional tissue engineering. Regen. Ther. 2016, 3, 45–57. [Google Scholar] [CrossRef] [Green Version]

- Day, M. Rhino Grasshopper, AEC Magazine; X3DMedia: Santa Clara, CA, USA, 2009. [Google Scholar]

- Malda, J.; Visser, J.; Melchels, F.P.; Jüngst, T.; Hennink, W.E.; Dhert, W.J.A.; Groll, J.; Hutmacher, D.W. 25th anniversary article: Engineering hydrogels for biofabrication. Adv. Mater. 2013, 25, 5011–5028. [Google Scholar] [CrossRef] [PubMed]

- Guvendiren, M.; Lu, H.D.; Burdick, J.A. Shear-thinning hydrogels for biomedical applications. Soft Matter 2011, 8, 260–272. [Google Scholar] [CrossRef]

- Schuurman, W.; Levett, P.A.; Pot, M.W.; van Weeren, P.R.; Dhert, W.J.A.; Hutmacher, D.W.; Melchels, F.P.W.; Klein, T.J.; Malda, J. Gelatin-methacrylamide hydrogels as potential biomaterials for fabrication of tissue-engineered cartilage constructs. Macromol. Biosci. 2013, 13, 551–561. [Google Scholar] [CrossRef] [PubMed]

- Aguado, B.A.; Mulyasasmita, W.; Su, J.; Lampe, K.J.; Heilshorn, S.C. Improving viability of stem cells during syringe needle flow through the design of hydrogel cell carriers. Tissue Eng. Part A 2012, 18, 806–815. [Google Scholar] [CrossRef] [PubMed]

- Macosko, C.W. Rheology: Principles, Measurements, and Applications; Wiley: Hoboken, NJ, USA, 1994; ISBN 978-0-47-118575-8. [Google Scholar]

- Das, D.; Bang, S.; Zhang, S.; Noh, I. Bioactive Molecules Release and Cellular Responses of Alginate-Tricalcium Phosphate Particles Hybrid Gel. Nanomaterials 2017, 7, 389. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Feng, L.; Li, Z.; Fu, Y.; Zhang, X.; Wei, J.; Wei, S. Preparation, characterization and photocatalytic degradation properties of a TiO2/calcium alginate composite film and the recovery of TiO2 nanoparticles. RSC Adv. 2014, 4, 51321–51329. [Google Scholar] [CrossRef]

- Dong, Z.; Wang, Q.; Du, Y. Alginate/gelatin blend films and their properties for drug controlled release. J. Membr. Sci. 2006, 280, 37–44. [Google Scholar] [CrossRef]

- McKee, C.T.; Last, J.A.; Russell, P.; Murphy, C.J. Indentation versus tensile measurements of Young’s modulus for soft biological tissues. Tissue Eng. Part B Rev. 2011, 17, 155–164. [Google Scholar] [CrossRef] [PubMed]

- Goktas, S.; Dmytryk, J.J.; McFetridge, P.S. Biomechanical behavior of oral soft tissues. J. Periodontol. 2011, 82, 1178–1186. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Yang, F.; Zhao, H.; Gao, Q.; Xia, B.; Fu, J. Research on the printability of hydrogels in 3D bioprinting. Sci. Rep. 2016, 6, 29977. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Hydrogel | ALG [w/v %] | GEL [w/v %] | TiO2 [w/v %] | TCP [w/v %] | CaCl2 [w/v %] |

|---|---|---|---|---|---|

| HG-1 | 2.0 | - | - | - | 0.2 |

| HG-2 | 2.0 | 0.5 | - | - | 0.2 |

| HG-3 | 2.0 | - | 0.1 | - | 0.2 |

| HG-4 | 2.0 | 0.5 | 0.1 | - | 0.2 |

| HG-5 | 2.0 | 0.5 | - | 1.0 | 0.2 |

| HG-6 | 2.0 | 0.5 | 0.1 | 1.0 | 0.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urruela-Barrios, R.; Ramírez-Cedillo, E.; Díaz de León, A.; Alvarez, A.J.; Ortega-Lara, W. Alginate/Gelatin Hydrogels Reinforced with TiO2 and β-TCP Fabricated by Microextrusion-based Printing for Tissue Regeneration. Polymers 2019, 11, 457. https://doi.org/10.3390/polym11030457

Urruela-Barrios R, Ramírez-Cedillo E, Díaz de León A, Alvarez AJ, Ortega-Lara W. Alginate/Gelatin Hydrogels Reinforced with TiO2 and β-TCP Fabricated by Microextrusion-based Printing for Tissue Regeneration. Polymers. 2019; 11(3):457. https://doi.org/10.3390/polym11030457

Chicago/Turabian StyleUrruela-Barrios, Rodrigo, Erick Ramírez-Cedillo, A. Díaz de León, Alejandro J. Alvarez, and Wendy Ortega-Lara. 2019. "Alginate/Gelatin Hydrogels Reinforced with TiO2 and β-TCP Fabricated by Microextrusion-based Printing for Tissue Regeneration" Polymers 11, no. 3: 457. https://doi.org/10.3390/polym11030457