Developing Fall-impact Protection Pad with 3D Mesh Curved Surface Structure using 3D Printing Technology

Abstract

:1. Introduction

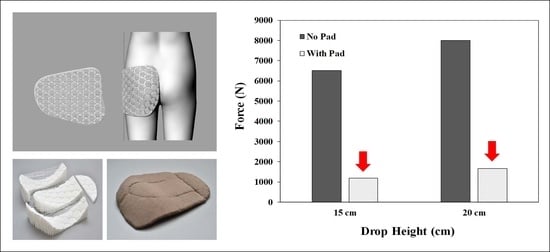

2. Experimental Methods

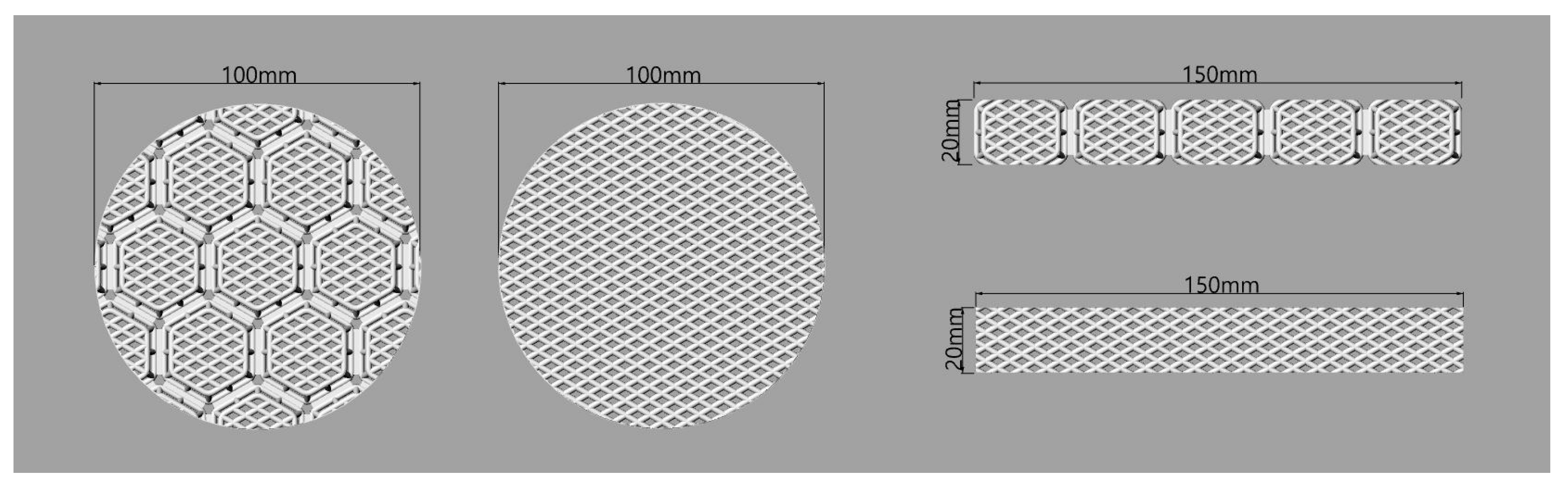

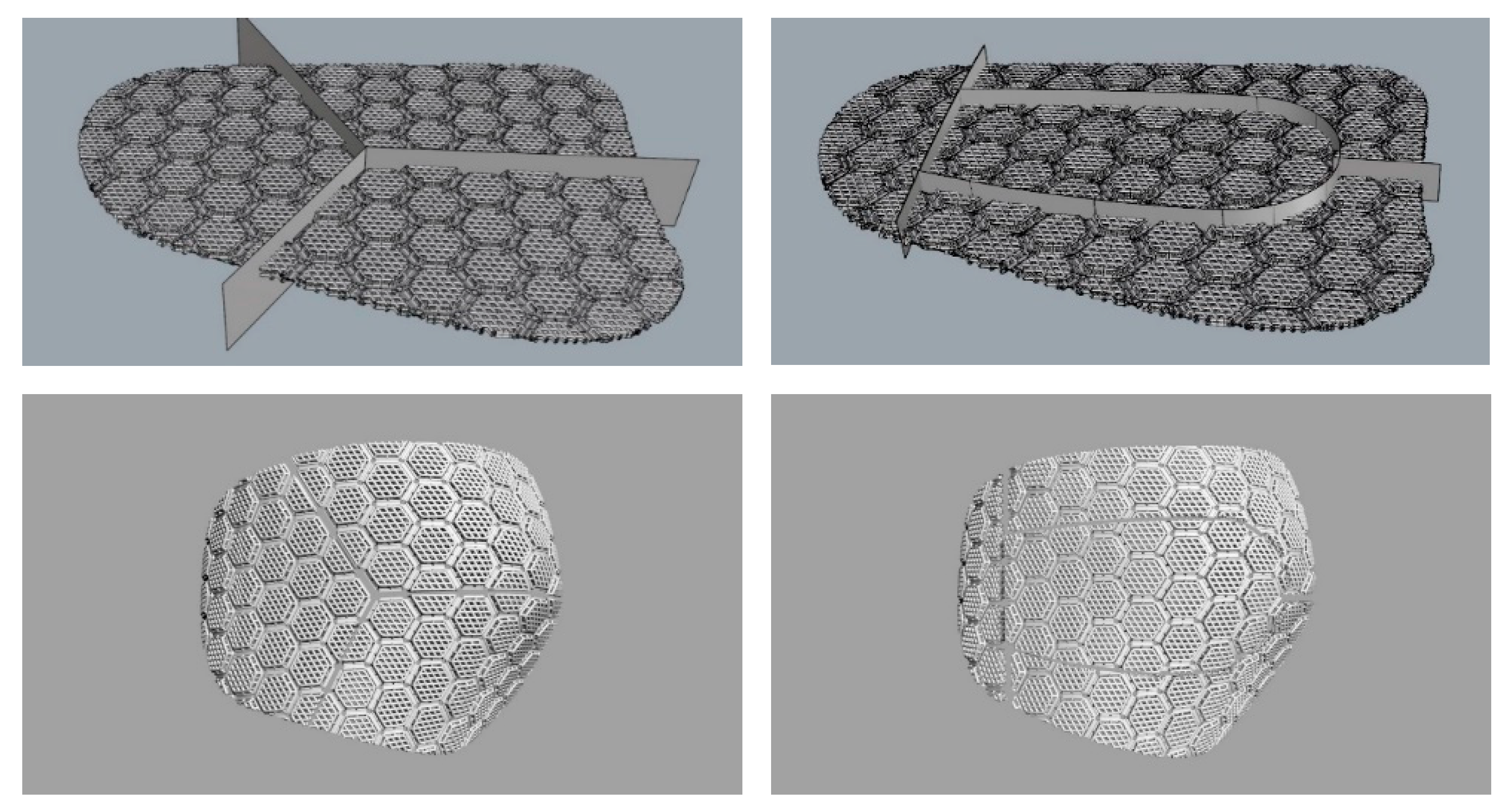

2.1. 3D Modeling

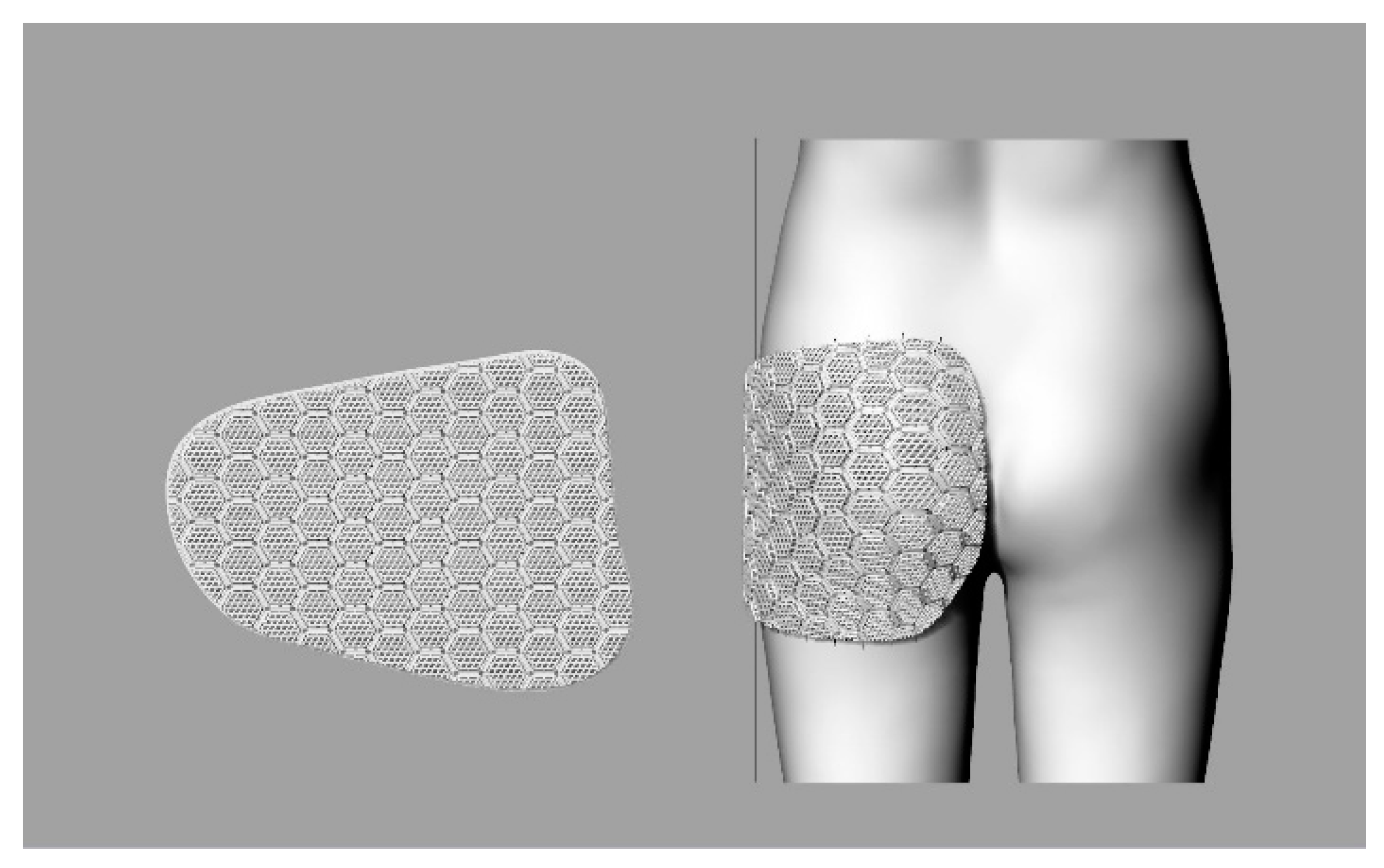

- Curved surface pad fitted to 3D human shape.

- A pad outline with shape properly outlining the impact protection area.

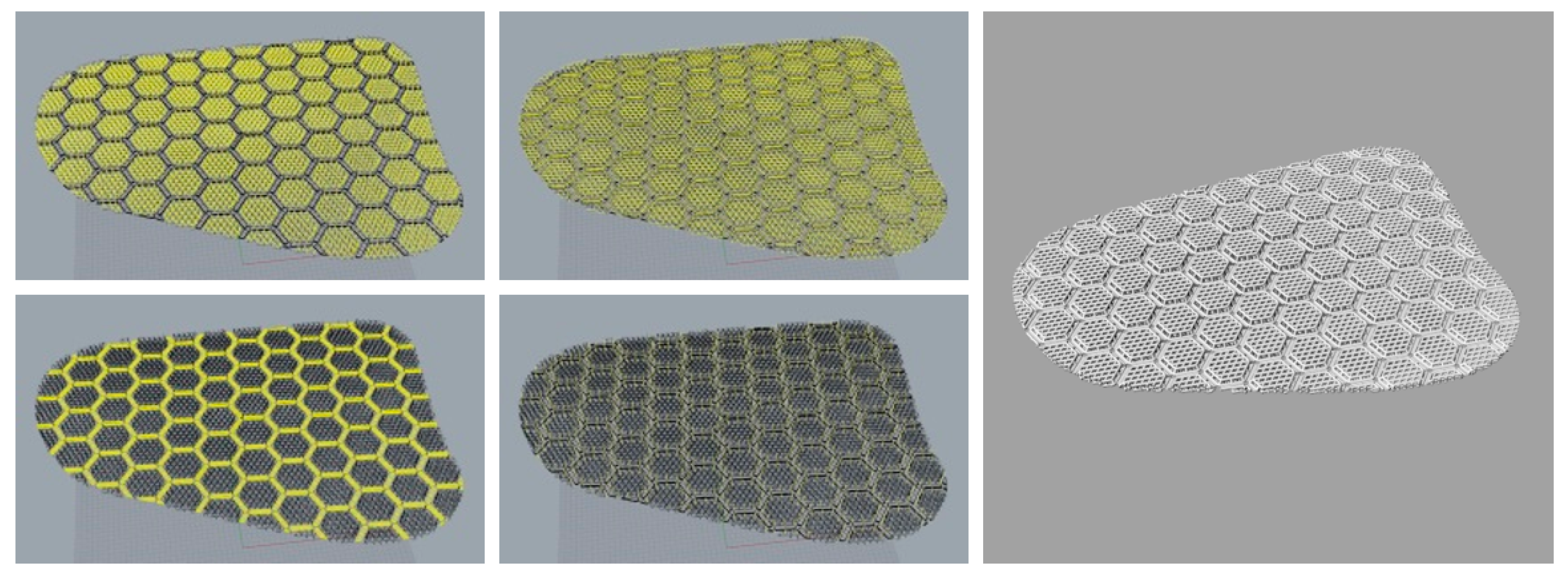

- A hexagonal three-dimensional unit that is closely connected in honeycomb form, maintaining flexibility due to the connection of each structural unit by thin plate.

- A hexagonal, three-dimensional unit structure composed of a surface layer and a spacer layer with an impact-absorbing property similar to that of the spacer fabric.

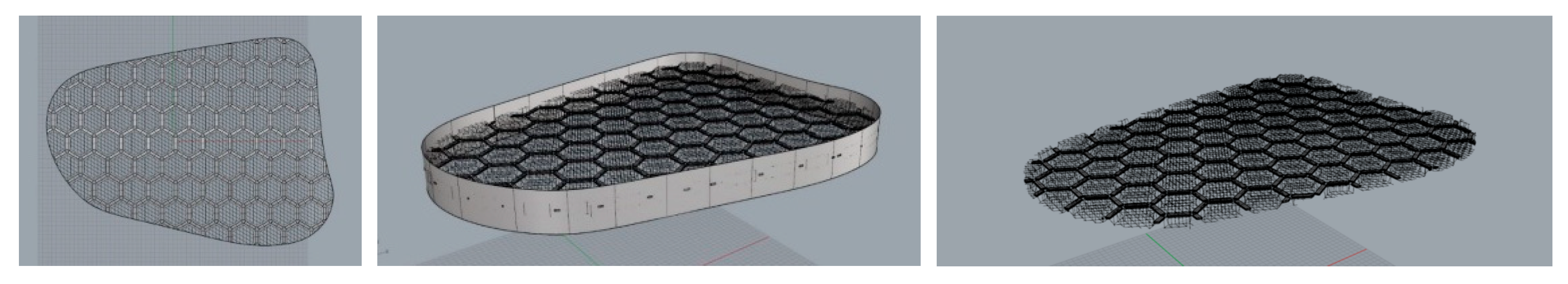

- Setting a baseline over the human 3D body scan data (base surface).

- Creating a pad outline, and using it to create a flat surface.

- Placing a pad outline along the body surface, and using it to create a curved surface (target surface) that reflects the body shape.

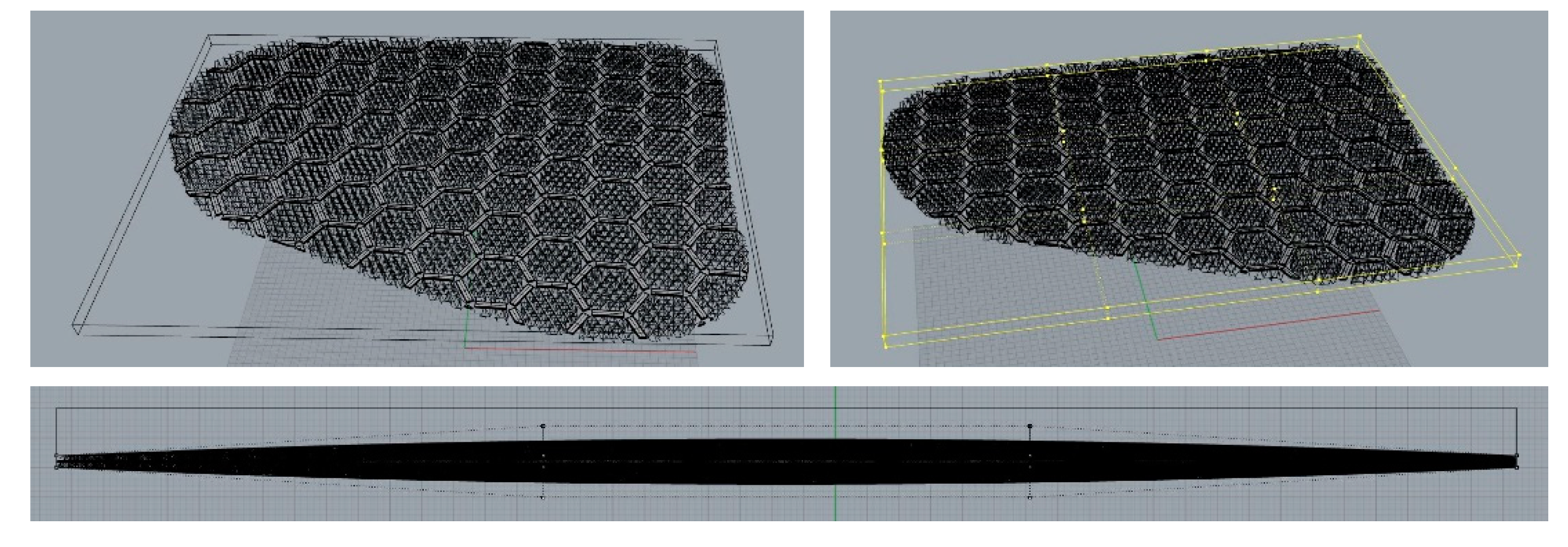

- Designing a hexagonal mesh structure and extracting a flat pad shape conforming to the pad outline (flat pad with structural information).

- Completing the curved surface protective pad by transforming the pad of the flat hexagonal mesh structure (flat pad with structural information) according to the human body’s curved surface contours (target curved surface) through the base curved surface.

2.2. 3D Printing of Protective Pads

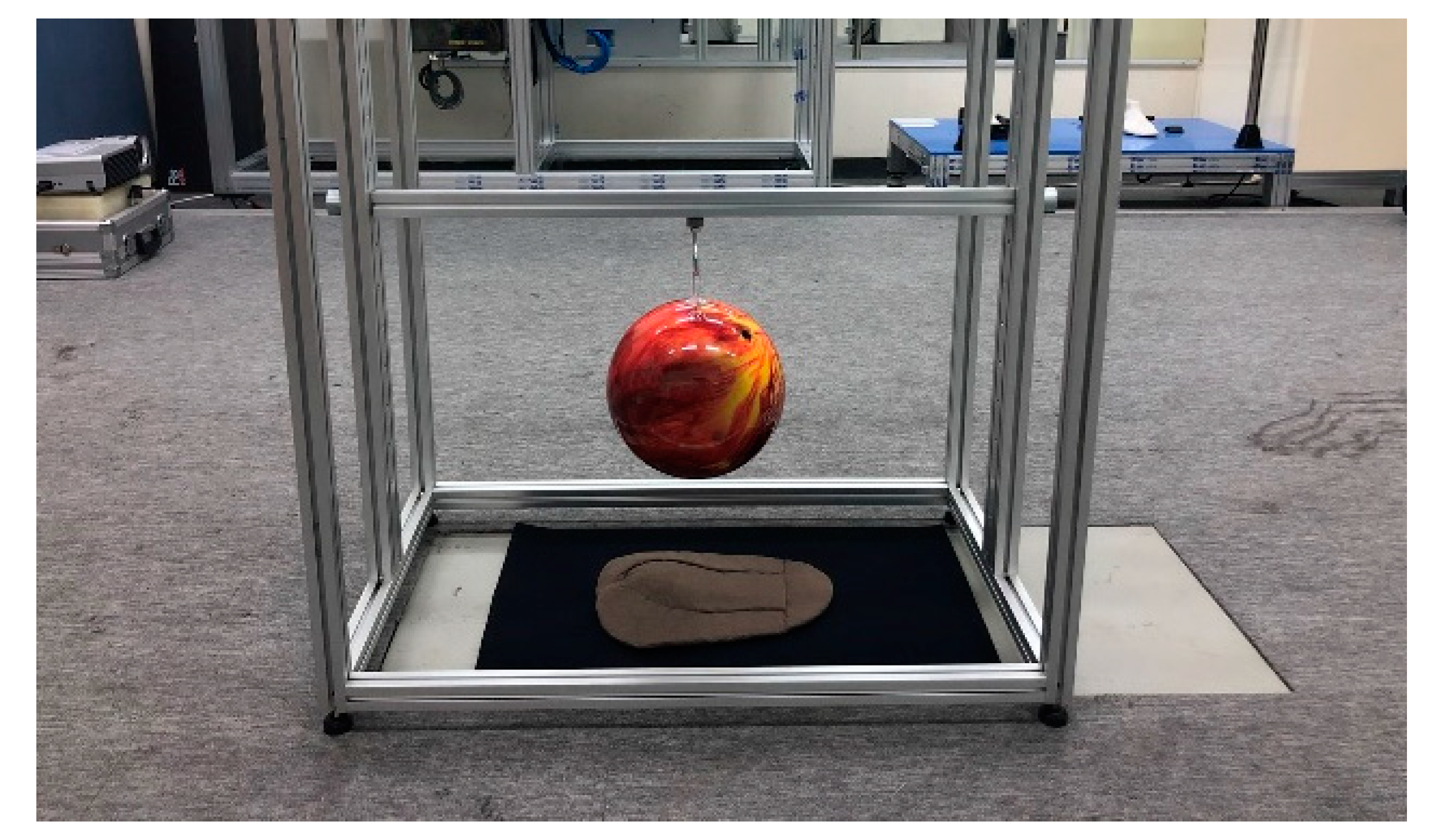

2.3. Evaluation of Impact Protection Performance

2.4. Evaluation of Flexural Stiffness

2.5. Evaluation of Elongation Rate

3. Results and Discussion

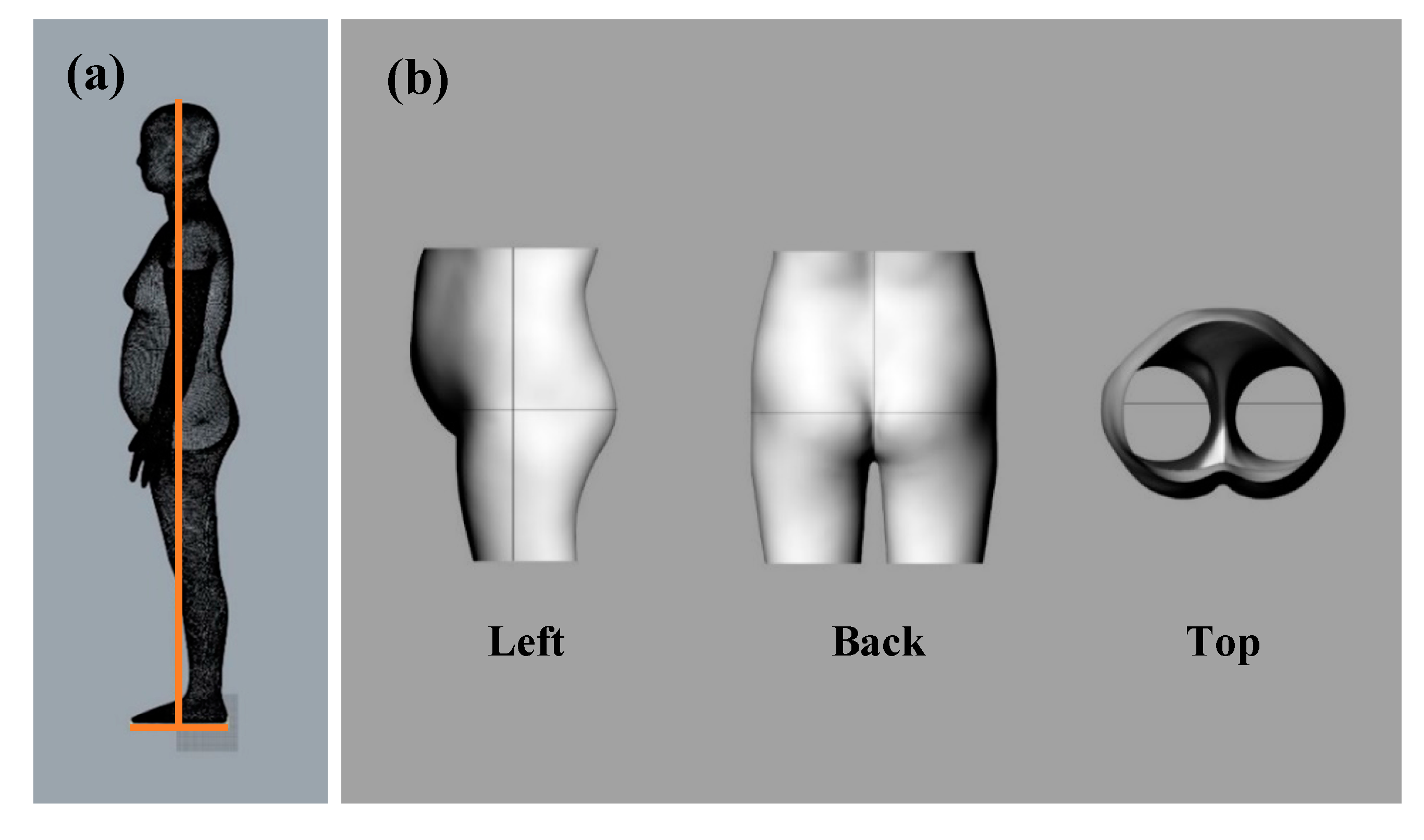

3.1. Processing of Body Scan Data

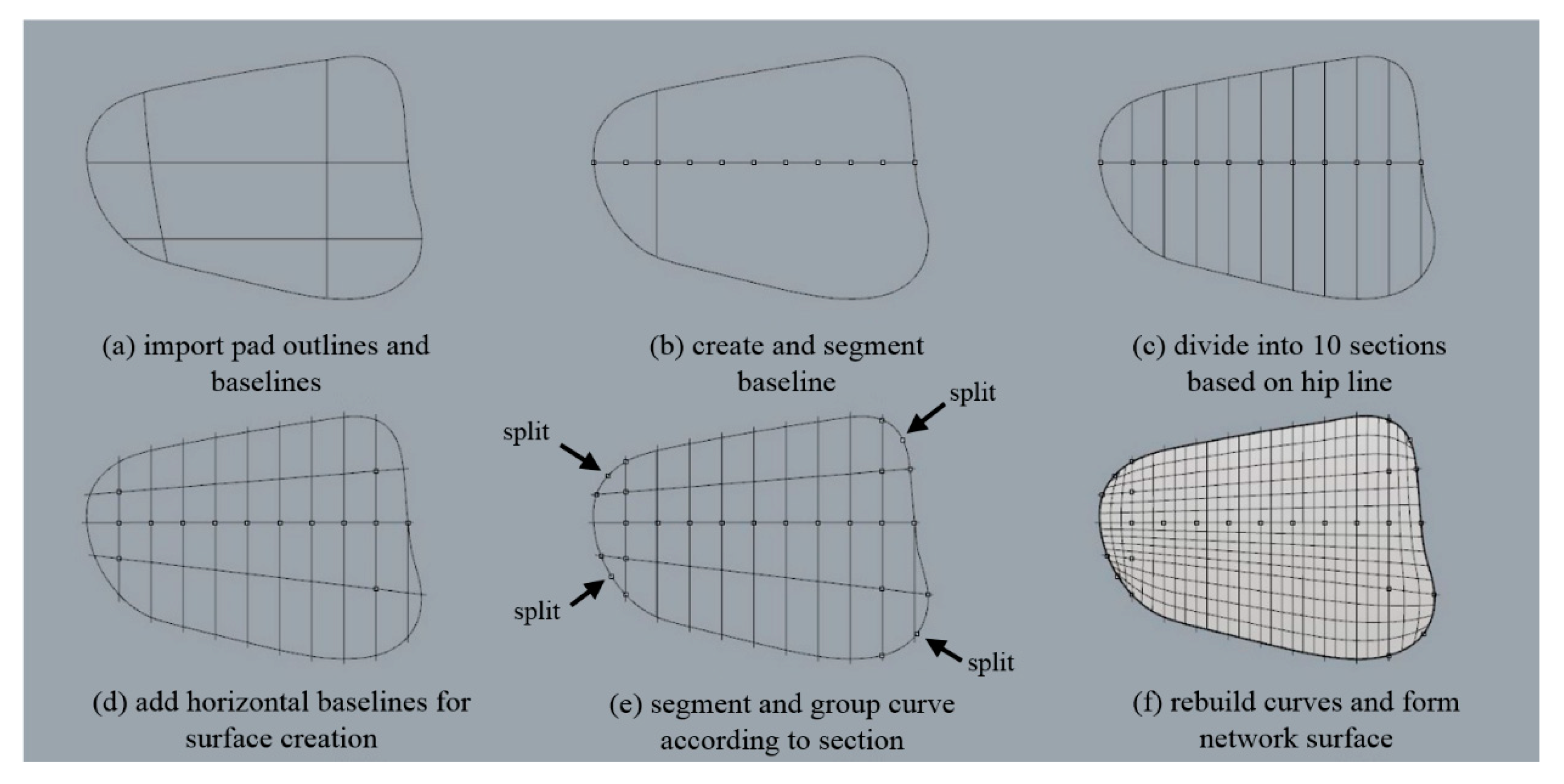

3.2. Creation of Pad Outline and Base Surface

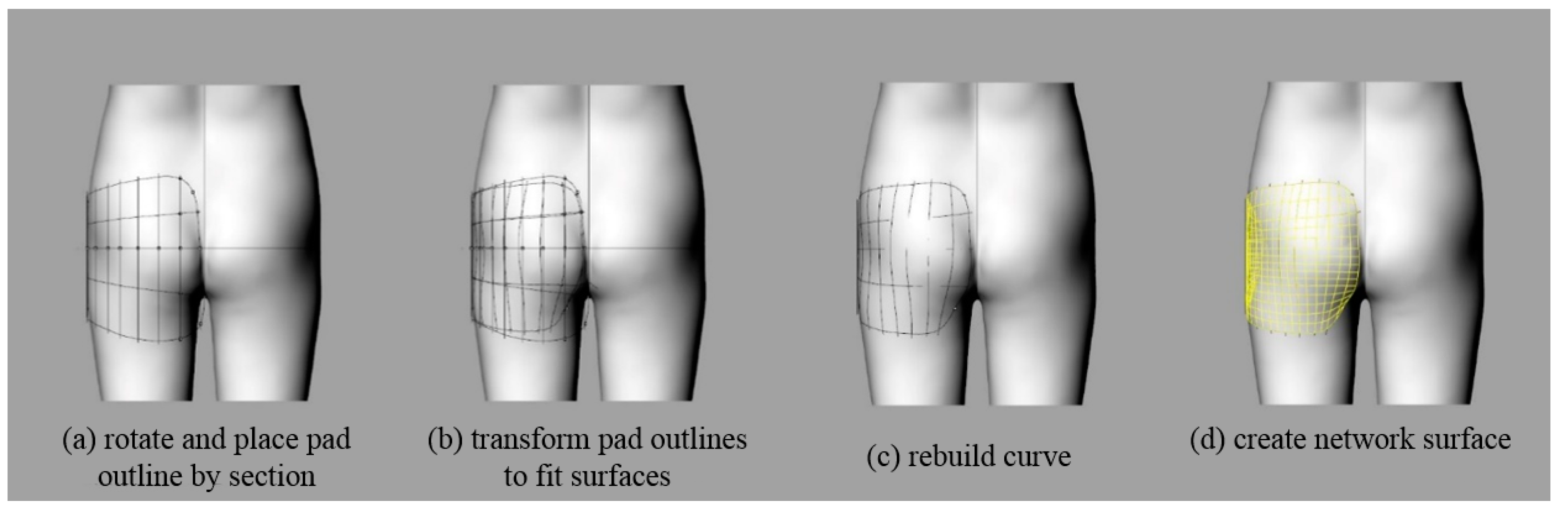

3.3. Formation of Pad Surface on the Body Surface

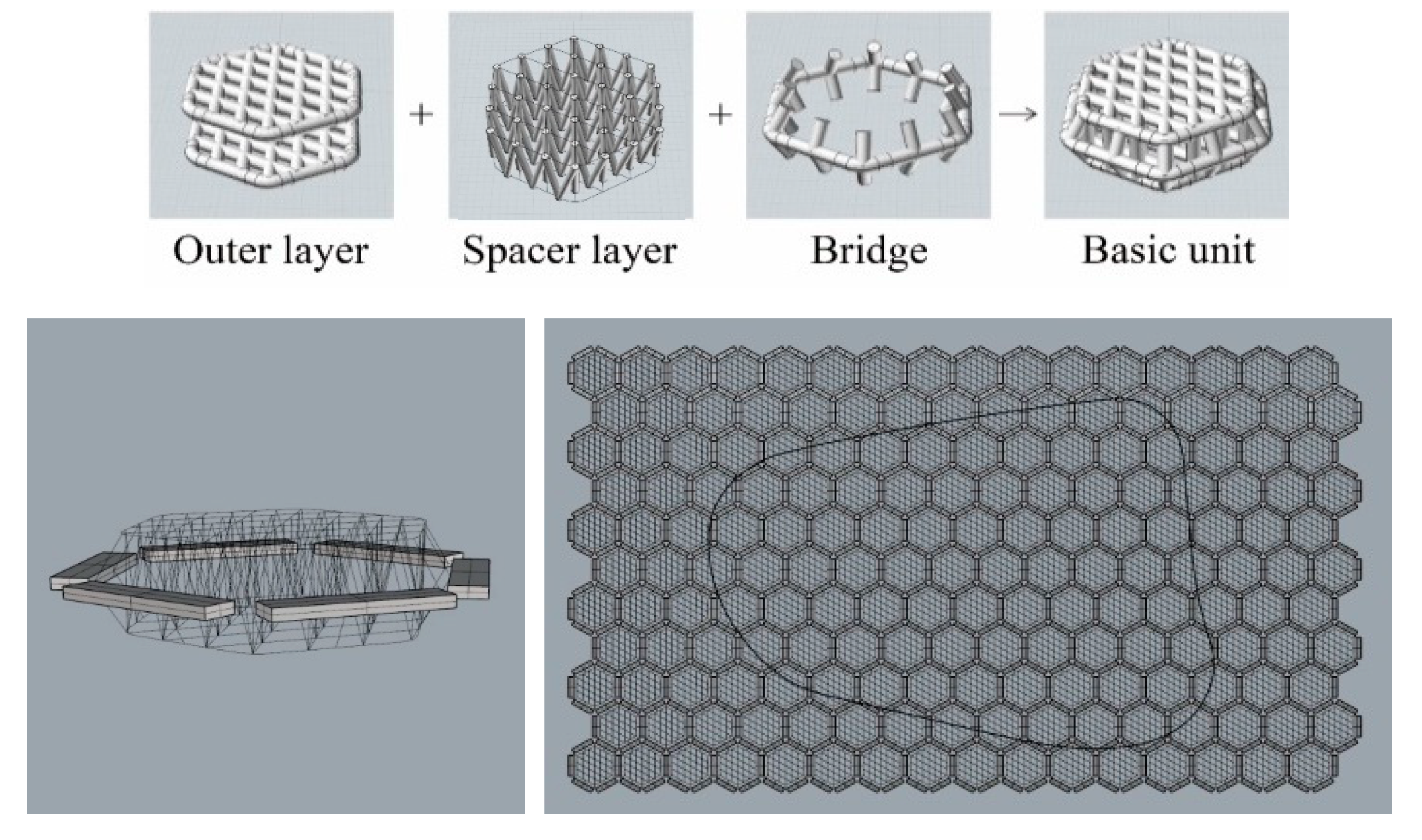

3.4. Formation of Three-Dimensional Mesh Structure Planar Pad

3.5. Formation of Curved Pad of Three-Dimensional Mesh Structure

3.6. Dividing Pad

3.7. 3D Printing of Final Product

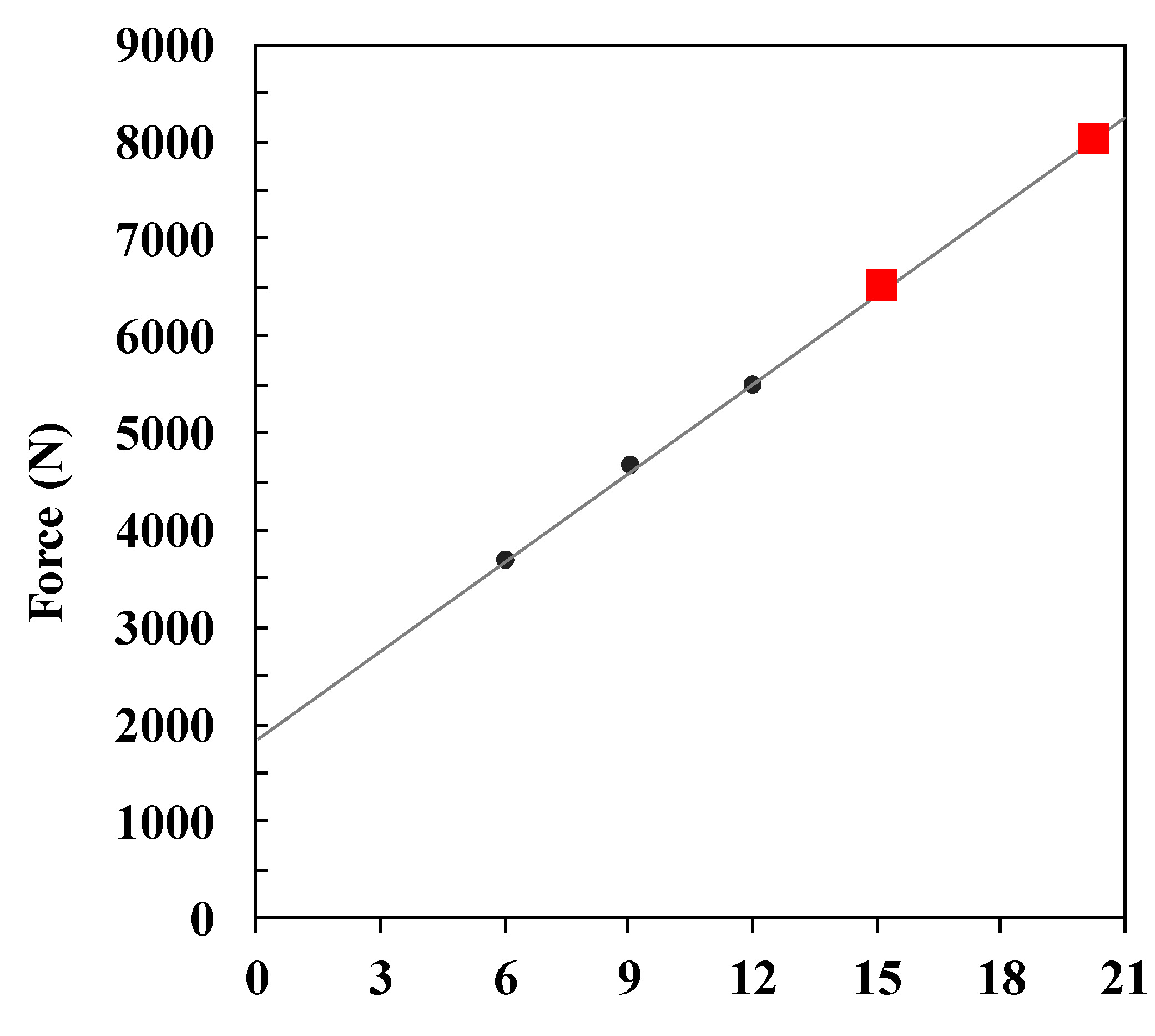

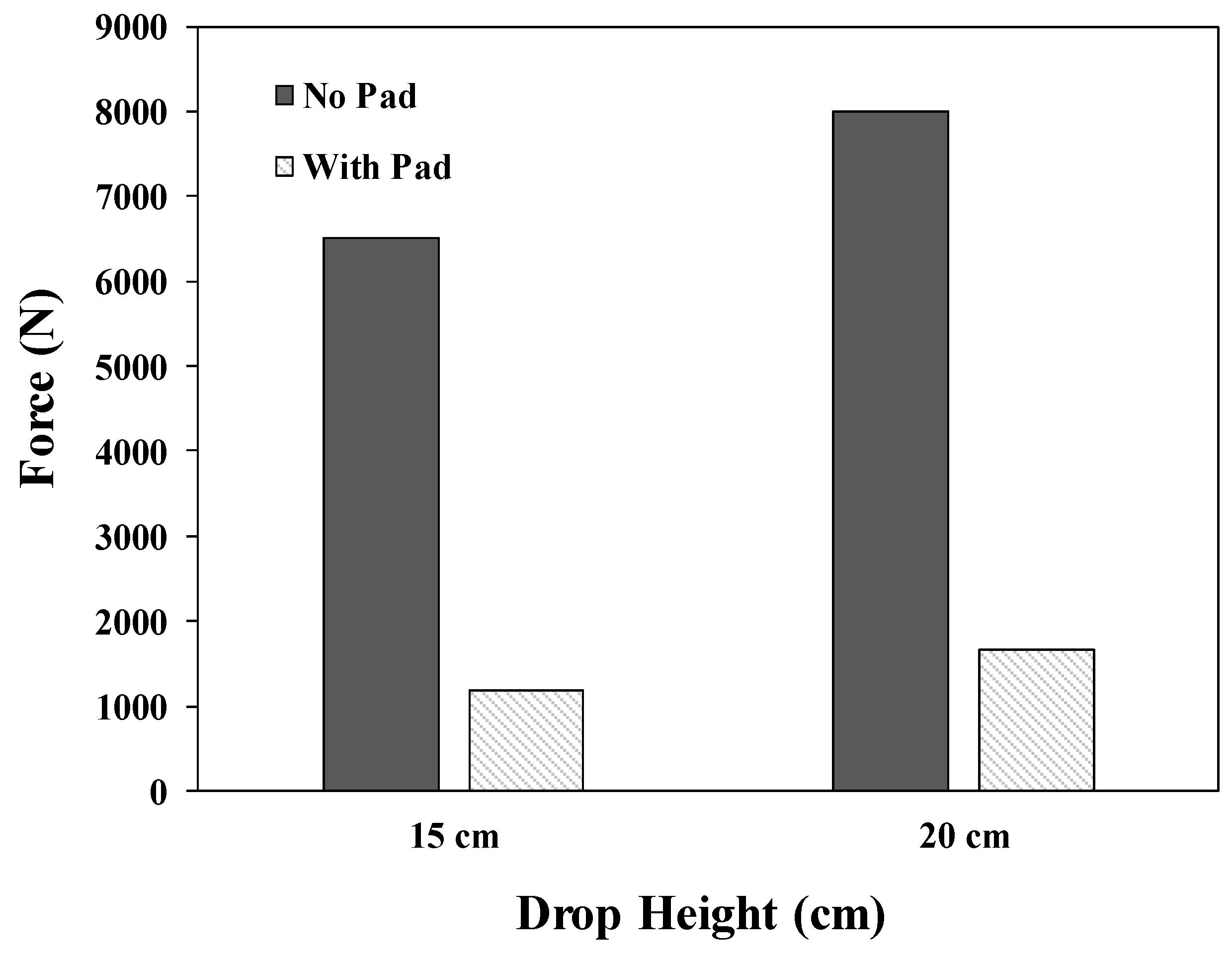

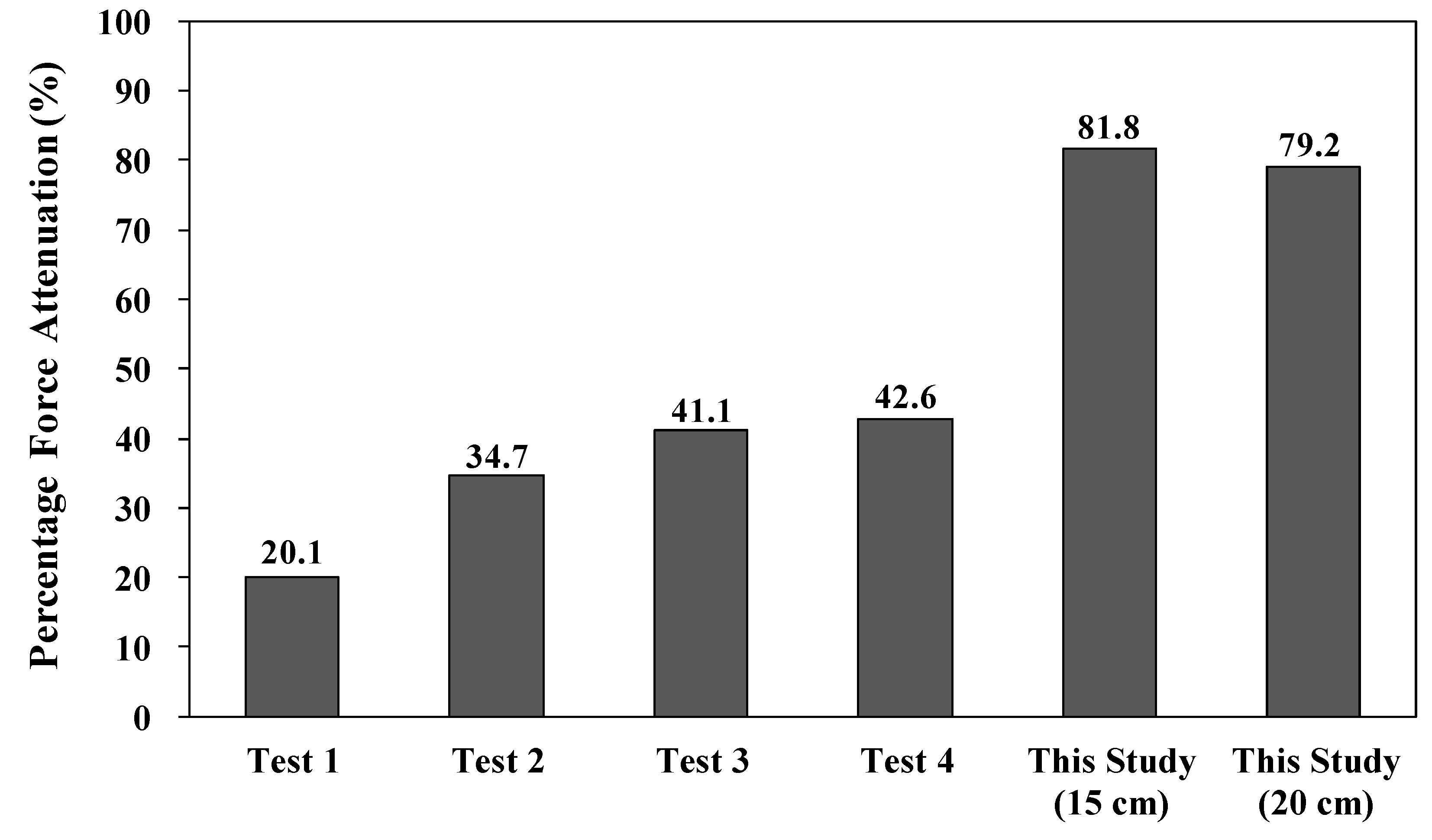

3.8. Impact Protection Performance

3.9. Flexural Stiffness

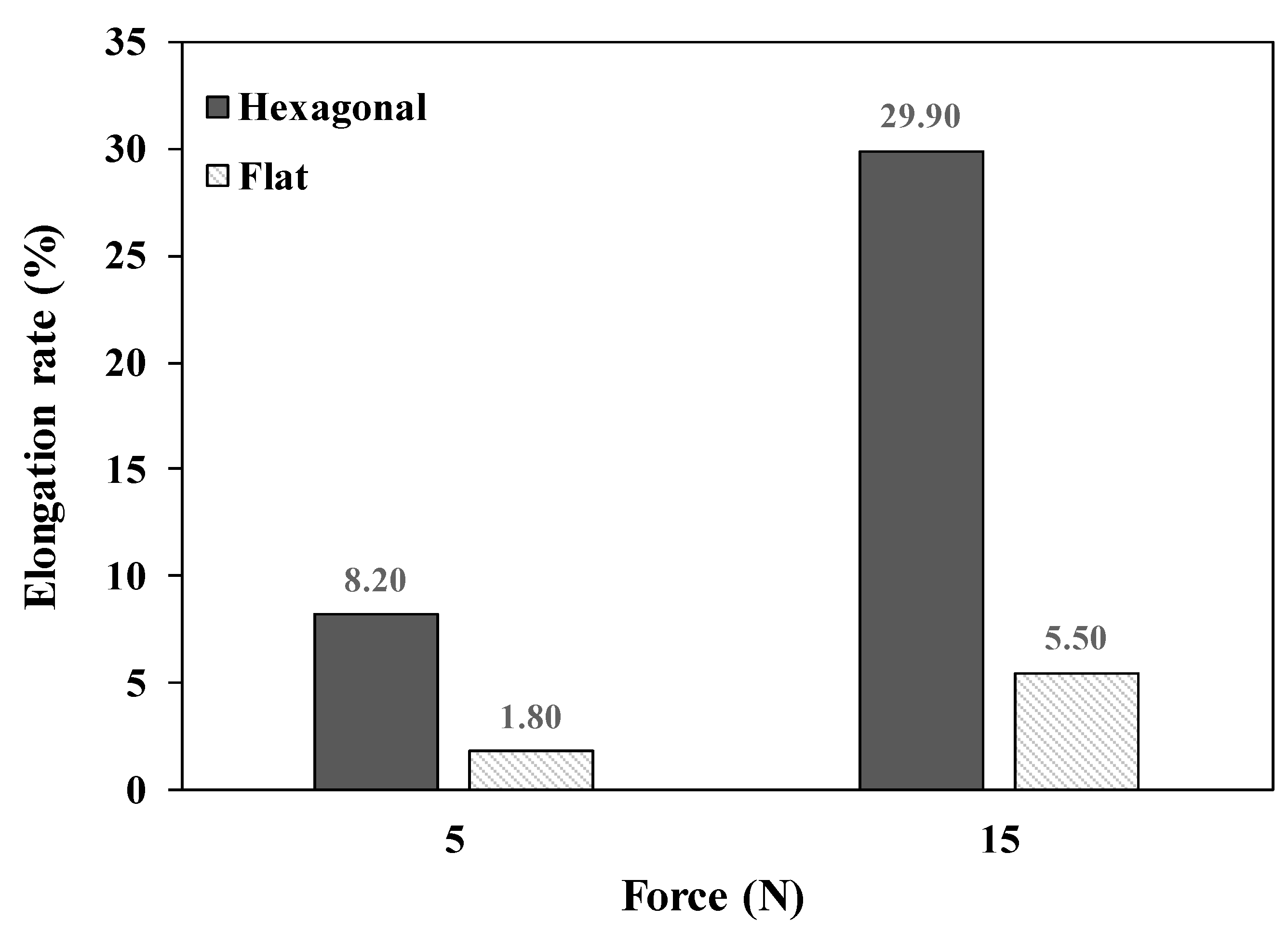

3.10. Elongation Rate

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Monthly Health Report (Jan. 2019), Falling Accidents; Korea Centers for Disease Control & Prevention: Osong, Korea, 2019.

- Choi, W.J.; Hoffer, J.A.; Robinovitch, S.N. Effect of hip protectors, falling angle and body mass index on pressure distribution over the hip during simulated falls. Clin. Biomech. 2010, 25, 63–69. [Google Scholar] [CrossRef] [PubMed]

- Laing, A.C.; Robinovitch, S.N. Effect of soft shell hip protectors on pressure distribution to the hip during sideways falls. Osteoporos. Int. 2008, 19, 1067–1075. [Google Scholar] [CrossRef] [PubMed]

- Van Schoor, N.M.; van der Veen, A.J.; Schaap, L.A.; Smit, T.H.; Lips, P. Biomechanical comparison of hard and soft hip protectors, and the influence of soft tissue. Bone 2006, 39, 401–407. [Google Scholar] [CrossRef] [PubMed]

- Harada, A. Prevention of Fractures Caused by Falls in Elderly Persons. Jpn. Med. Assoc. J. 2001, 44, 306–311. [Google Scholar]

- Minns, R.J.; Marsh, A.M.; Chuck, A.; Todd, J. Are hip protectors correctly positioned in use? Age Ageing 2007, 36, 140–144. [Google Scholar] [CrossRef] [Green Version]

- O’Halloran, P.D.; Murray, L.J.; Cran, G.W.; Dunlop, L.; Kernohan, G.; Beringer, T.R.O. The effect of type of hip protector and resident characteristics on adherence to use of hip protectors in nursing and residential homes—An exploratory study. Int. J. Nurs. Stud. 2005, 42, 387–397. [Google Scholar] [CrossRef]

- Spahiu, T.; Grimmelsmann, N.; Ehrmann, A.; Shehi, E.; Piperi, E. On the possible use of 3D printing for clothing and shoe manufacture. In Proceedings of the 7th International Conference of Textile, Tirana, Albania, 10–11 November 2016. [Google Scholar]

- Halassi, S.; Semeijn, J.; Kiratli, N. From consumer to prosumer: A supply chain revolution in 3D printing. Int. J. Phys. Distr. Log. 2019, 49, 200–216. [Google Scholar] [CrossRef]

- Vanderploeg, A.; Lee, S.-E.; Mamp, M. The application of 3D printing technology in the fashion industry. Int. J. Fash. Des. Technol. Educ. 2017, 10, 170–179. [Google Scholar] [CrossRef]

- Ratto, M.; Ree, R. Materializing information: 3D printing and social change. First Monday 2012, 17. [Google Scholar] [CrossRef]

- Gebler, M.; Uiterkamp, A.J.S.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Rengier, F.; Mehndiratta, A.; Von Tengg-Kobligk, H.; Zechmann, C.M.; Unterhinninghofen, R.; Kauczor, H.-U.; Giesel, F.L. 3D printing based on imaging data: Review of medical applications. Int. J. Comput. Assist. Radiol. Surg. 2010, 5, 335–341. [Google Scholar] [CrossRef] [PubMed]

- Araujo, M.R.P.; Sa-Barreto, L.L.; Gratieri, T.; Gelfuso, G.M.; Cunha, M. The Digital Pharmacies Era: How 3D Printing Technology Using Fused Deposition Modeling Can Become a Reality. Pharmaceutics 2019, 11, 128. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.Y.; Lin, S.W.; Xie, Q.G.; Ouyang, W.W.; Tan, T.B.; Li, J.H.; Chen, Z.Y.; Yang, J.L.; Wu, H.Y.; Pan, J.; et al. Impact of 3D printing technology on the comprehension of surgical liver anatomy. Surg. Endosc. 2019, 33, 411–417. [Google Scholar] [CrossRef]

- Vithani, K.; Goyanes, A.; Jannin, V.; Basit, A.W.; Gaisford, S.; Boyd, B.J. An Overview of 3D Printing Technologies for Soft Materials and Potential Opportunities for Lipid-based Drug Delivery Systems. Pharm. Res. 2019, 36, 4. [Google Scholar] [CrossRef]

- Hehr, A.; Wenning, J.; Norfolk, M.; Sheridan, J.; Newman, J.A.; Domack, M. Selective Reinforcement of Aerospace Structures Using Ultrasonic Additive Manufacturing. J. Mater. Eng. Perform. 2019, 28, 633–640. [Google Scholar] [CrossRef]

- Liu, Z.G.; Wang, Y.Q.; Wu, B.C.; Cui, C.Z.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Ventola, C.L. Medical applications for 3D printing: Current and projected uses. Pharm. Ther. 2014, 39, 704. [Google Scholar]

- Wei, P.Q.; Yang, X.; Cao, Z.M.; Guo, X.L.; Jiang, H.L.; Chen, Y.; Morikado, M.; Qiu, X.B.; Yu, D.L. Flexible and Stretchable Electronic Skin with High Durability and Shock Resistance via Embedded 3D Printing Technology for Human Activity Monitoring and Personal Healthcare. Adv. Mater. Technol. 2019, 4, 1900315. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Tavitov, A.G.; Urzhumtsev, O.D.; Mikhalin, M.V.; Solonin, A.N. Design and Fabrication of Strong Parts from Poly (Lactic Acid) with a Desktop 3D Printer: A Case with Interrupted Shell. Polymers 2019, 11, 760. [Google Scholar] [CrossRef]

- Sun, L.; Zhao, L. Envisioning the era of 3D printing: A conceptual model for the fashion industry. Fash. Text. 2017, 4, 25. [Google Scholar] [CrossRef]

- Pasricha, A.; Greeninger, R. Exploration of 3D printing to create zero-waste sustainable fashion notions and jewelry. Fash. Text. 2018, 5, 30. [Google Scholar] [CrossRef]

- Valtas, A.; Sun, D. 3D printing for garments production: An exploratory study. J. Fash. Technol. Text. Eng. 2016, 4, 1–4. [Google Scholar] [CrossRef]

- Eom, R.-I.; Lee, H.; Lee, Y. Evaluation of Thermal Properties of 3D Spacer Technical Materials in Cold Environments using 3D Printing Technology. Polymers 2019, 11, 1438. [Google Scholar] [CrossRef] [PubMed]

- Pei, E.; Shen, J.; Watling, J. Direct 3D printing of polymers onto textiles: Experimental studies and applications. Rapid Prototyp. J. 2015, 21, 556–571. [Google Scholar] [CrossRef]

- Sanatgar, R.H.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Melnikova, R.; Ehrmann, A.; Finsterbusch, K. 3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials. IOP Conf. Ser. Mater. Sci. Eng. 2014, 62, 012018. [Google Scholar] [CrossRef]

- Li, N.; Tsushima, E.; Tsushima, H. Comparison of impact force attenuation by various combinations of hip protector and flooring material using a simplified fall-impact simulation device. J. Biomech. 2013, 46, 1140–1146. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.H.; Lee, J.R. Developing Fall-impact Protection Pad with 3D Mesh Curved Surface Structure using 3D Printing Technology. Polymers 2019, 11, 1800. https://doi.org/10.3390/polym11111800

Park JH, Lee JR. Developing Fall-impact Protection Pad with 3D Mesh Curved Surface Structure using 3D Printing Technology. Polymers. 2019; 11(11):1800. https://doi.org/10.3390/polym11111800

Chicago/Turabian StylePark, Jung Hyun, and Jeong Ran Lee. 2019. "Developing Fall-impact Protection Pad with 3D Mesh Curved Surface Structure using 3D Printing Technology" Polymers 11, no. 11: 1800. https://doi.org/10.3390/polym11111800