Abstract

The development of rare-earth-free permanent magnets represents a strategic direction in advanced magnetic materials research. Among the most promising candidates, the metastable α″-Fe16N2 phase stands out due to its exceptionally high saturation magnetization. In this work, α″-Fe16N2 powders produced by gas atomization followed by nitriding were consolidated via Spark Plasma Sintering (SPS). The effects of sintering temperature (498–598 K) and pressure (40–80 MPa) on phase evolution, densification, microstructure, and magnetic properties have been systematically investigated. Optimal processing conditions were identified at 548 K and 60 MPa, providing a balance between densification (~80% of the theoretical density), phase stability, and magnetic performance. X-ray diffraction revealed that the α″-Fe16N2 phase remains stable up to ~523 K, while its decomposition into α-Fe and γ′-Fe4N becomes significant at higher temperatures. The consolidated samples exhibited a saturation magnetization of ~230 Am2/kg, a maximum coercivity of ~86.5 kA/m, and a Mr/Ms ratio of 0.42. δM curve analysis indicated a transition from magnetostatic interactions (at low pressures) to exchange-dominated coupling (at intermediate and high pressures). These findings demonstrate the potential of SPS processing to preserve the α″-Fe16N2 phase and produce rare-earth-free magnetic compacts with competitive magnetic performance, providing a basis for further process optimization.

1. Introduction

The request for high-performance permanent magnets free of critical rare-earth elements has intensified significantly in recent decades, marking an important trend in advanced materials science and technology. This increase is largely attributed to evolving sustainability goals, alongside the need for innovative green technologies. These vital technologies encompass a wide range of applications, such as electric vehicles and wind turbines, which play essential roles in the shift towards renewable energy sources. Although Nd-Fe-B magnets continue to be the predominant choice for various high-performance applications due to their outstanding magnetic properties, growing concerns about supply chain vulnerabilities in addition to the environmental footprint related to rare earth mining have stimulated focused research aimed at discovering alternative magnets that do not depend on rare earth elements (REEs) [,,].

Among the various investigated alternatives, one of the most promising candidates is the metastable α″-Fe16N2 phase, which has attracted attention in both academia and industry due to its exceptional theoretical values of the magnetic properties, such as high saturation magnetization (~2.9 T) exceedingly even that of Nd-Fe-B magnets [,]. Recent advances in powder and nanopowder synthesis techniques, including low-temperature nitriding of Fe nanoparticles obtained by chemical reduction [], mechanical ball milling with a solid nitrogen source NH4NO3 [,], and hydrogen reduction of iron oxides [,], allowed the production of α″-Fe16N2 powder with high phase purity and controlled morphology. Despite these advances in powder synthesis, their consolidation into dense magnets remains particularly challenging. A significant obstacle encountered in the fabrication of α″-Fe16N2-based magnets is the phase decomposition that occurs beyond 473 K under ambient pressure conditions [,,]. This critical temperature threshold is particularly important because nitrogen desorption can unfortunately lead to the formation of undesired phases, such as α-Fe and γ′-Fe4N, which are detrimental to magnetic performance.

From the technological perspective, the challenge of consolidating metastable powders, such as α″-Fe16N2, must be considered in the context of developing scalable and industrially viable sintering methods. Conventional methods, such as hot pressing (HP) and hot isostatic pressing (HIP), are well established for densifying powders. However, the long sintering times (tens of minutes to hours) and high temperatures involved in these processes, typically over 973 K [,,], are fundamentally incompatible with the narrow thermal stability range of the α″-Fe16N2 phase. Thus, the HP technique, based on direct heating of the mold and on the application of uniaxial pressure, allows a satisfactory control of densification, but also generates significant thermal gradients and prolonged temperature exposures, favoring nitrogen desorption and decomposition of the α″-Fe16N2 phase. On the other hand, the HIP method offers superior homogeneity due to isostatic gas pressure but requires also processing cycles at high temperatures and extended durations (over 1 h), which makes it unsuitable for metastable phases in the Fe-N system [,]. It should be noted that high-pressure sintering experiments performed at the GPa scale have demonstrated partial retention of α″-Fe16N2 at temperatures near 200 °C []. However, such extreme-pressure conditions are limited to small-scale laboratory setups and are not representative for the pressure and temperature ranges in industrial HIP or HP systems.

More recently used methods, such as fast sintering (FS), have dramatically shortened processing times (which would be advantageous for consolidating metastable phases or materials in inequilibrium []), achieving densification within seconds by directly applying electrical fields to the sample [,,]. However, FS has been mainly optimized for ceramics and semiconductors, as its fundamental mechanism is based on a sudden increase in electrical conductivity with temperature, a prominent effect in materials with high resistivity, such as ZrO2, Al2O3, or SiC [,,,].

In contrast, metal powders exhibit high electrical conductivity even at room temperature, which leads to a uniform electrical field distribution and prevents the formation of localized gradients necessary for rapid activation of electrical discharge. Therefore, in metallic systems such as Fe-N, uncontrolled current flow often causes surface melting, oxidation or nitrogen desorption, rather than a controlled densification. It should be noted that the term “uncontrolled current flow” does not refer to the absence of settings of the equipment, but to the self-accelerating and spatially non-uniform distribution of the current that occurs during the flash event, due to thermal runaway. In recent years, hybrid approaches have emerged, such as Flash Spark Plasma Sintering (FSPS) and Dynamic SPS, proposed to alleviate these problems by combining the pulsed current control with uniaxial pressure in order to achieve transient localized heating while preserving structural integrity [,,]. However, control of the flash phenomenon and its applicability to metal nitride powders, without nitrogen loss, remain research challenges.

In contrast to these hybrid approaches, the conventional Spark Plasma Sintering (SPS) technique remains particularly relevant, as it employs a precisely controlled pulsed direct current within a closed electrical circuit. This configuration enables extremely high heating rates (up to 103 K/min), uniform Joule heating throughout the compact, as well as rapid densification with holding times of only a few minutes at relatively low temperatures (typically 573–873 K) [,]. Owing to its controllability, repeatability, and compatibility with large-scale equipment, SPS is already recognized as an industrially scalable consolidation route. Recent discoveries in metastable materials processed with SPS, such as high-entropy carbides [,] and Mn-Al-C magnets [,], demonstrate their ability to preserve phase purity and nanoscale microstructures. These research reports indicate that carefully optimized SPS protocols offer a promising pathway for the compaction of metastable α″-Fe16N2 powders into bulk magnets via this industrially scalable technique.

Building on our previous research focused on synthesizing Fe–N-based powders [,], the present study systematically investigates the consolidation of α″-Fe16N2 through SPS, with emphasis on the interrelation among sintering parameters, densification, phase evolution, and magnetic performance. The main goal is to establish optimal processing conditions in order to maximize the magnetic properties while minimizing phase degradation. This work thus provides new insights into the thermal stability and consolidation mechanisms of α″-Fe16N2 and lays a technological foundation for scaling up rare-earth-free permanent magnets for next-generation energy applications.

2. Materials and Methods

α″-Fe16N2 powders were synthesized through a two-step route combining gas atomization and subsequent gas-phase nitridation, as described in our previous studies [,]. The resulting nitrided α″-Fe16N2 powders have been subsequently compacted using a SPS system (FCT Systeme GmbH, Frankenblick, Germany) under vacuum conditions (~10−2 Pa). Approximately 2 g of powders were loaded into a 10 mm graphite die lined with graphite foil to prevent contamination. Sintering was conducted under a uniaxial pressure of 40–80 MPa, with the temperature varying between 498 K and 598 K and sintering times ranging from 3 to 8 min. A heating rate of 100 K/min was applied to minimize nitrogen desorption and microstructural coarsening. Temperature control was achieved via a thermocouple embedded in the die wall. Phase composition and structural evolution before and after SPS were analyzed by X-ray diffraction (XRD) using a Bruker AXS D8 Advance diffractometer (Bruker AXS, GmbH, Mannheim, Germany) equipped with Cu Kα radiation (λ = 1.5406 Å). Diffraction patterns were collected over the angular range 20–90° (2θ), with a step size of 0.02° and a counting time of 2 s per step. Quantitative phase analysis was performed through Rietveld refinement using the MAUD software package version 2.92, with an estimated uncertainty of approximately ±3% in the relative phase fractions. Microstructural characterization was carried out using a focused ion beam/scanning electron microscope (FIB/FE-SEM CrossBeam Carl Zeiss NEON 40 EsB, Oberkochen, Germany). All magnetic measurements were performed at room temperature (300 K) using a vibrating sample magnetometer (VSM, Lake Shore Model 7410, Westerville, OH, USA) under a maximum applied magnetic field of about 1600 kA/m. Density measurements were conducted using the Archimedes method, and porosity was estimated relative to the theoretical density of α″-Fe16N2 (7.46 g/cm3).

3. Results and Discussion

3.1. Phase Evolution

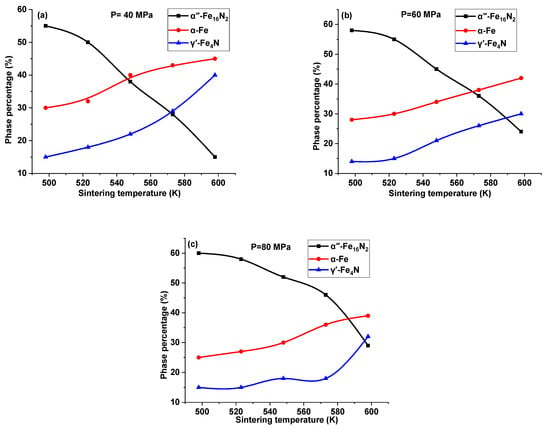

The phase evolution and densification behaviour of α″-Fe16N2 compacts prepared by SPS have been systematically investigated as a function of temperature and applied pressure. Particular attention was given to identify the processing window that ensures efficient consolidation while minimizing the thermal decomposition of the α″-Fe16N2 phase. The precursor powders used in this study have approximately 57% α″-Fe16N2 phase, as confirmed by previous XRD analyses []. In the present study, XRD analyses performed on the sintered compacts, processed at temperatures between 498 and 598 K and pressures between 40 and 80 MPa, enabled quantitative evaluation of the main structural phases. The quantitative phase analysis, derived from XRD patterns (see Figure S1 in the Supplementary Information for a representative example), revealed the evolution of the relative phase fractions of α″-Fe16N2, of α-Fe, and of the γ′-Fe4N as a function of sintering temperature for the three investigated pressure levels, as illustrated in Figure 1.

Figure 1.

The variation of the relative phase fractions, α″-Fe16N2, α-Fe, and γ′-Fe4N, as a function of sintering temperature for the three values of the applied pressures (40, 60, and 80 MPa).

The results indicate that the Fe–N system is highly sensitive to both temperature and applied pressure. The increase in the sintering temperature promotes the partial decomposition of the metastable α″-Fe16N2 phase into α-Fe and γ′-Fe4N, evidencing the narrow thermal stability range of α″-Fe16N2. For all pressure values, the increase in the temperature results in a gradual decrease of the α″-Fe16N2 fraction, accompanied by a corresponding increase in the α-Fe and γ′-Fe4N phases, confirming the inherently metastable nature of α″-Fe16N2.

At 40 MPa, the α″-Fe16N2 content significantly decreases from 55% at the temperature of 498 K to a considerably lower value of only 15% at an increased temperature of 598 K. In contrast, the fractions of both α-Fe and γ′-Fe4N are increasing simultaneously during this process, ultimately reaching a combined fraction of approximately 85% at this higher temperature. Similarly, the α″-Fe16N2 fraction decreases from 58% to 24% at 60 MPa at a temperature of 598 K. However, it is important to note that the higher pressure noticeably slows down the occurring degradation process. Finally, at 80 MPa, the α″-Fe16N2 phase retention is observed to be the most effective. The α″-Fe16N2 fraction takes values of above 52% at a temperature of 548 K and only drops to approximately 30% at a higher temperature of 598 K. This evident pressure dependence indicates that higher mechanical loading inhibits nitrogen diffusion and promotes the preservation of the metastable phase.

The γ′-Fe4N phase, which is recognized as a key partial decomposition product of α″-Fe16N2, exhibits a significant increase at temperatures that are equal to or are exceeding 548 K. Under 60 MPa applied pressure, the concentration of γ′-Fe4N grows progressively, reaching about 30% at 598 K, while at 40 MPa its formation is noticeably faster and begins at lower temperatures, suggesting that lower pressures enhances nitrogen mobility and accelerates the α″-Fe16N2 → γ′-Fe4N transformation. The α-Fe phase, the final product of thermal degradation, is present under all sintering conditions but becomes dominant only at high temperatures and low pressures. For instance, at a temperature of 598 K and a pressure of 40 MPa, the α-Fe phase reaches a notable concentration of 45%, which significantly surpasses the concentrations of other phases.

Although previous studies have reported that α″-Fe16N2 usually decomposes at temperatures exceeding 473–539 K in inert atmospheres or in vacuum [,,], the specific and unique features of the SPS process, such as the remarkably fast heating rate of about 100 K per minute and the exceptionally short residence time (typically between 3 and 8 min), play a significant and critical role in effectively suppressing nitrogen diffusion and consequently slowing down the decomposition kinetics. This behavior is in line with reports in the SPS literature, i.e., a review on reactive SPS emphasizes that high heating rates (hundreds of K per minute) and short dwell times inhibit grain growth and diffusion-driven transformations []. In the same way, a recent study on the effect of SPS heating rate demonstrates that faster heating suppresses undesired phase changes and maintains structural integrity of sensitive materials []. Guillon et al. discuss the way the SPS technique, via its field-assisted heating, enables densification at lower working temperatures and shorter maintaining durations, thereby limiting diffusion-driven degradation as compared to conventional methods []. In agreement with these reports, our results show that the degradation of the α″-Fe16N2 phase is effectively suppressed at lower sintering temperatures, particularly under high applied pressures (e.g., 80 MPa). A distinct transition in phase stability is observed around 548 K, marking the onset of accelerated decomposition. Below this temperature, a substantial fraction of α″-Fe16N2 remains stable and well preserved, whereas above 548 K, the phase deteriorates rapidly. Between 573 and 598 K, the α″-Fe16N2 phase fraction drops below 30%, accompanied by a pronounced increase in both α-Fe and γ′-Fe4N.

It is evident that applying higher pressure during sintering exerts a favorable influence on the stability of α″-Fe16N2. The stability improvement can be attributed to a probable reduction in porosity and intergranular spacing, which effectively limits the outward diffusion of nitrogen. Furthermore, elevated pressures may significantly increase the nitrogen partial pressure in the microcavities existent within the material, thereby inhibiting the process of degassing. The use of a pressure of 80 MPa clearly demonstrates these beneficial effects, supporting the idea that moderate temperatures combined with high pressures create an optimal balance between densification and phase preservation.

In summary, maintaining a high content of the α″-Fe16N2 phase throughout the sintering process is indeed achievable, largely due to the important synergy that exists between rapid heating, applied pressures, and short times during the procedure. However, it is crucial to note that the stability of this phase remains constrained to a relatively narrow thermal window. Exceeding ~548 K leads to a progressive loss of the magnetic α″-Fe16N2 phase and to the emergence of α-Fe and γ′-Fe4N, which are leading to the deterioration of the magnetic performance.

3.2. Density

The relative density is a critical indicator of the efficiency of the sintering process and has a direct impact on the magnetic and structural properties of the consolidated materials. The density of the SPS-sintered samples was determined by the volumetric method, which entailed measuring both the mass and the geometric volume of the cylindrical specimens. The relative density was then calculated based on the theoretical density of α″-Fe16N2 (7.44 g/cm3) [], allowing an indirect estimation of residual porosity.

The density measurements for the investigated temperature and pressure ranges are summarized in Table 1. A systematic increase in density is observed with the increase in the sintering temperature and pressure. This increase can be attributed to the synergistic effects of plastic and diffusional densification mechanisms that become increasingly pronounced at elevated temperatures, in conjunction with improved particle rearrangement that occurs under high compressive forces.

Table 1.

Evolution of density as a function of sintering temperature and pres.

For a sintering temperature of 548 K, the sample consolidated at 40 MPa reached a density of 5.45 g/cm3, corresponding to a relative density of approximately 73.2% of the theoretical maximum. When the samples were subjected to a higher pressure of 80 MPa, the density notably rose to 6.10 g/cm3, which corresponds to a relative density of 81.9%. These values indicate that higher pressures are significantly reducing the residual porosity and are enhancing the intergranular connectivity among the particles. While an increase in the density beyond 548 K is observed, this benefit is counterbalanced by the progressive degradation of the α″-Fe16N2 phase. Therefore, the combination of moderate temperature (548 K) and high pressure (80 MPa) provides an optimal balance for achieving maximum densification while still maintaining the metastable α″-Fe16N2 phase. However, as it will be discussed later, slightly lower pressures (~60 MPa) yield superior magnetic performance due to a more favorable balance between intergranular exchange coupling and domain wall pinning.

The residual porosity inferred from these measurements ranges between 18–27%, which is consistent with the microstructural observations that showed a transition from loosely packed particles at low pressure to a more compact and interconnected network at high pressures. This residual porosity, while modest, is sufficient to influence the coercivity and magnetic connectivity, as it will be discussed in the following sections.

3.3. Microstructural Evolution

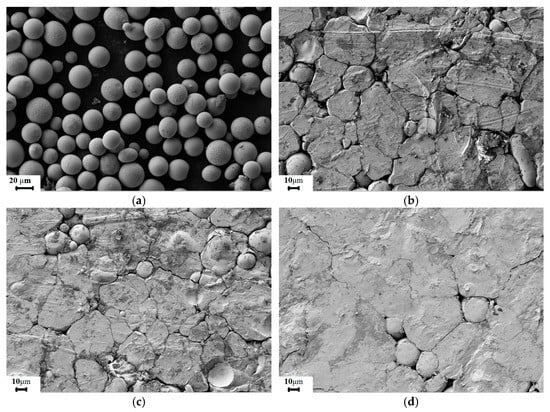

It is well known that the microstructure has a direct influence on the final magnetic performance of consolidated magnets. In this context, to elucidate the influence of sintering pressure, scanning electron microscopy (SEM) was performed on samples sintered at 548 K under three representative pressures: 40, 60, and 80 MPa (Figure 2b–d). This temperature value was selected as reference point since it provides an optimal balance between efficient densification and retention of the α″-Fe16N2 phase, as discussed previously. The precursor powders, produced by nitrogen gas atomization followed by nitriding, exhibit a spherical morphology with particle sizes below 32 µm (Figure 2a). This initial microstructure provides good compressibility, while introducing at the same time local compositional heterogeneity that influences sintering behavior.

Figure 2.

SEM images of the precursor powders (a) and the surfaces of the compacts processed at 548 K under different pressures: 40 MPa (b), 60 MPa (c), and 80 MPa (d).

As shown in Figure 2, the SEM micrographs reveal a clear and progressive evolution of the microstructure with increasing sintering pressure. At 40 MPa, the morphology is characterized by weak interparticle contact and significant porosity, with large intergranular voids. Many individual particles in this state retain their original spherical shape, and they exhibit clearly defined boundaries. This observation indicates a limited degree of plastic deformation or diffusion occurring at the contact points between the particles, suggesting that the process is not yet advanced at this level of pressure. At 60 MPa, the structure exhibits enhanced compaction, with a noticeable reduction in interparticle spacing. The surface becomes continuous and uniform, while signs of localized diffusion are detected, as well as of intergranular plastic deformation that starts to become evident. However, numerous particle boundaries and small agglomerates or deposits at interfaces are still visible. At 80 MPa, the SEM micrograph displays a significantly compact microstructure, characterized by strong particle bonding, as well as a considerable reduction in porosity levels. The contours of the particles are now nearly entirely blurred, leading to a more homogeneous surface texture that enhances overall material integrity. However, it is important to note that isolated pores are still present, along with the development of fine surface microcracks, indicating potential high internal stresses within the material structure.

This microstructural evolution is consistent with the above-mentioned increase in density (6.10 g/cm3, ~82% of the theoretical value), confirming the effectiveness of SPS in promoting rapid densification at moderate temperatures. The observed transition from a porous, particle-separated structure to a highly interconnected one, with minimal voids, underscores the dominant role of pressure in achieving strong intergranular bonding.

Furthermore, the reduction of porosity and the formation of continuous necks are expected to enhance magnetic coupling between particles, minimizing the demagnetizing field and facilitating more efficient magnetic flux transfer throughout the bulk.

These observations support the conclusion that microstructural optimization through controlled SPS pressure is critical not only for achieving mechanical integrity but also for tailoring the balance between magnetic exchange interactions and domain wall pinning, which ultimately governs the macroscopic magnetic behavior of the compacts.

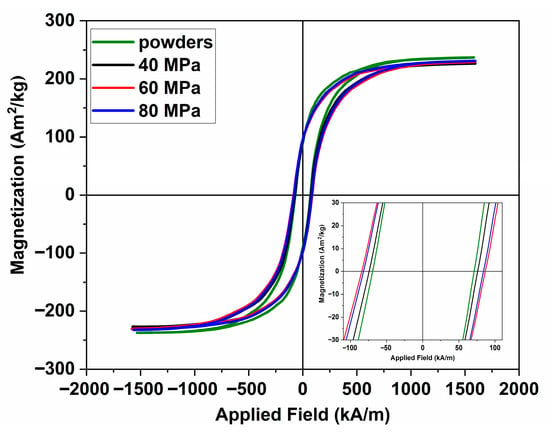

3.4. Magnetic Properties

The hysteresis measurements shown in Figure 3 for samples sintered at 548 K under applied pressures of 40, 60, and 80 MPa reveal distinct variations in the saturation magnetization (Ms), coercivity (Hc), and remanence-to-saturation ratio (Mr/Ms), highlighting the influence of sintering conditions on the magnetic properties. For reference, the hysteresis loop of the precursor α″-Fe16N2 powders is also shown in Figure 3, allowing direct comparison between the precursor and the SPS-consolidated compacts.

Figure 3.

Hysteresis curves for the α″-Fe16N2 powder and for the compacts processed at 548 K under different pressures: 40 MPa, 60 MPa, and 80 MPa, measured at room temperature (300 K).

Table 2 summarizes the characteristic magnetic parameters (Ms, Mr, Hc, (BH)max) extracted from the hysteresis curves measured at room temperature (300 K) for samples sintered at 548 K under different pressures. The corresponding B(H) and (BH)(H) curves used to determine the (BH)max values reported in Table 2 are provided in Figures S2 and S3 of the Supplementary Information.

Table 2.

Magnetic parameters as a function of sintering pressure.

The behavior exhibited by saturation magnetization (Ms) and coercivity (Hc) in relation to sintering pressure significantly reflects the complex interplay that exists among the microstructure, retention of the α″-Fe16N2 phase, and densification processes that occur during the fabrication. A nearly monotonic increase in the saturation magnetization (Ms) is observed with increasing pressure, which can be primarily attributed to factors such as reduced porosity, enhanced intergranular contact, and improved retention of the α″-Fe16N2 phase at higher pressures (consistent with the XRD results). The increase in Ms remains modest, suggesting that the coexistence of α-Fe and γ′-Fe4N phases limits the overall magnetization.

The evolution of coercivity (Hc) is more complex. At a pressure of 40 MPa, Hc reaches 78.2 kA/m (a value slightly higher than that of the starting powder, 70.14 kA/m), associated with a porous microstructure characterized by weak interparticle contact. This morphology greatly restricts exchange interactions between the particles and results in a considerable reduction in the effectiveness of various pinning mechanisms. Consequently, this situation allows for relatively easy and unhindered domain wall motion in the particle. However, as we move to 60 MPa, coercivity reaches a maximum value (86.5 kA/m), indicating an optimal balance between structural connectivity and the defect density. The improved densification at this pressure enhances magnetic coupling between particles, which facilitates the alignment of magnetic moments. Despite this enhancement, the microstructure still retains a significant number of defects, numerous grain boundaries, and residual internal stresses that act as effective pinning centers, collectively leading to higher coercivity for this case. At 80 MPa, it can be observed that Hc experiences a slight decrease from 86.5 down to 83 kA/m. This reduction can be traced back to the higher level of densification of compacts that occurs at this pressure, which leads to a lowering of defect density. As a result, the overall effectiveness of domain wall pinning diminishes. Simultaneously, exchange interactions become well developed, promoting a more coherent motion of domains. This combination of factors contributes to the modest reduction in coercivity that can be observed at this pressure level.

The remanence (Mr) follows a similar trend, increasing with pressure up to 60 MPa and then slightly decreasing at 80 MPa. This variation reflects the balance between magnetic coupling and defect-induced pinning. The highest Mr/Ms ratio (0.42) and maximum energy product (BH)max = 15.71 kJ/m3 were obtained for the compact processed at 60 MPa, confirming that this intermediate pressure provides optimal conditions for exchange-coupled interactions between adjacent α″-Fe16N2 particles formed during SPS consolidation.

The Mr/Ms ratio provides additional insight into the complex nature of magnetic interactions within the intricate microstructure of materials. The observed increase in the Mr/Ms ratio from 0.38 at 40 MPa pressure to 0.42 at a pressure of 60 MPa confirms that exchange interactions become increasingly effective as densification of the system progresses, resulting in an enhanced retention of the magnetic moment once the external magnetic field is removed. However, at 80 MPa, a slight decrease in the ratio to 0.40 MPa can be attributed to internal stress relaxation and to a reduced density of active pinning defects, which facilitate domain wall movement and lowers the magnetic remanence retention.

Compared to the precursor α″-Fe16N2 powder (Ms = 235 A·m2/kg, Hc = 70.1 kA/m, Mr/Ms = 0.37), all SPS-consolidated samples exhibit slightly reduced Ms values, reflecting the partial decomposition of α″-Fe16N2 and the presence of α-Fe and γ′-Fe4N phases, as revealed by XRD. In contrast, both Hc and Mr/Ms increase after consolidation, indicating that the improved interparticle connectivity promotes stronger exchange coupling and domain wall pinning.

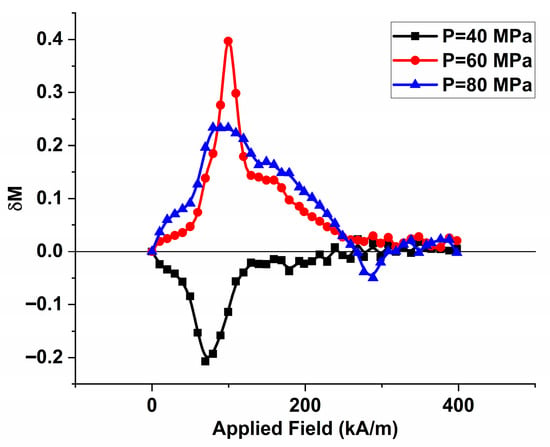

To gain a much deeper and comprehensive understanding of the complex intergranular magnetic interactions taking place, the δM(H) curves were employed, defined as: , where is the reduced remanence determined after demagnetization while is the reduced remanence determined after magnetization.

The δM(H) analysis was performed using the isothermal remanence magnetization (IRM) and direct current demagnetization (DCD) curves obtained at room temperature. Positive values of δM(H) indicate exchange interactions (short-range), whereas negative values correspond to magnetostatic (dipolar) interactions (long-range). This approach provides a sensitive means of distinguishing between the evolutions of magnetic coupling mechanisms during SPS consolidation. Figure 4 shows the δM curves of the compacts, processed at 548 K under different pressures: 40 MPa, 60 MPa, and 80 MPa, measured at room temperature (300 K).

Figure 4.

δM curves for the compacts, processed at 548 K under different pressures: 40 MPa, 60 MPa, and 80 MPa, measured at room temperature (300 K).

The evolution of the δM(H) curves shows a direct correlation with the observed microstructural changes and magnetic parameters. Specifically, the sample that was sintered at 40 MPa exhibits a negative δM, which indicates that dipolar magnetostatic interactions are indeed the dominant factor. This finding is consistent with the high level of porosity present in the material and the limited connectivity of the particles. This explains the lower Ms and Mr/Ms values, as well as the observed moderate Hc. At a pressure of 60 MPa the value of δM becomes positive (δMmax ≈ +0.39), which indicates the clear emergence of regions that are interconnected through the mechanism of exchange coupling. Concurrently, the structural defects that remain in the material serve as effective pinning centers. These pinning centers contribute to the maximum coercivity observed in the material and also enhance the Mr/Ms ratio, leading to improved overall magnetic properties. At a pressure of 80 MPa, δM stays positive. However, it presents a notably reduced amplitude. This behavior indicates a more homogeneous magnetic structure along with a partial relaxation of the involved pinning centers. Consequently, this change leads to an increase in Ms, but with a slight decrease in Hc. This behavior is consistent with the development of stronger exchange interactions, alongside a reduction in internal stresses in the material.

In summary, the magnetic parameters (Ms, Hc, and Mr/Ms) and the δM(H) evolution clearly indicate that intermediate sintering pressures (~60 MPa) yield the best magnetic performance by balancing densification, α″-Fe16N2 phase stability, and the interplay between exchange coupling and domain wall pinning.

3.5. Thermomagnetic Behavior (M vs. T)

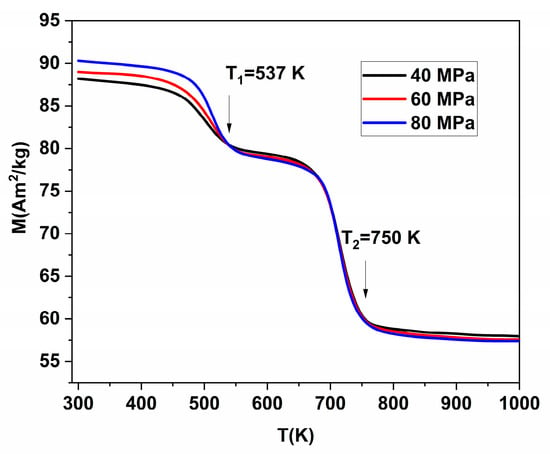

The thermomagnetic measurements provide information on the thermal stability and magnetic phase transformations of the consolidated compacts. Therefore, these measurements are complementary to the structural (XRD) and magnetic (M vs. H) investigations discussed above, allowing the evaluation of phase stability under heating conditions similar to those encountered during the potential use of the compacts. The thermomagnetic M(T) curves measured at an applied field of 7.958 kA/m (100 Oe) for samples sintered at 548 K at 40, 60, and 80 MPa (as shown in Figure 5) exhibit similar general trends, with small but systematic differences in the magnitude of magnetization and in the transition temperatures.

Figure 5.

Thermomagnetic M(T) curves for samples sintered at 548 K under different pressures (40, 60, and 80 MPa), under an applied magnetic field of 7.958 kA/m.

Differences that reflect both the variable content of the α″-Fe16N2 phase and the different grades of densification. Two clear events are observed: a gradual decrease in magnetization in the range T1 ≈ 530–537 K, followed by a more pronounced decrease around T2 ≈ 743–750 K. Since thermomagnetic measurements are usually performed with a relatively slow heating rate (1–2 K/min), nitrogen desorption and phase transformations can be activated during the run, thus placing the T1 transition at temperatures considerably lower than the intrinsic Curie temperature, Tc, predicted by theoretical models (>700 K) [,]. Therefore, T1 should be considered a decomposition /transformation temperature of the metastable α″-Fe16N2 phase into α-Fe and γ′-Fe4N, rather than the intrinsic TC of the α″-Fe16N2 phase. This interpretation is consistent with XRD/Rietveld quantification, which shows a progressive loss of α″-Fe16N2 concomitant with the formation of α-Fe and γ′-Fe4N at high temperatures and with the kinetic sensitivity of α″-Fe16N2 upon slow heating and with some literature reports [,,]. The high-temperature transition (T2) corresponds to the Curie temperature range of the γ′-Fe4N phase reported in the literature (≈750 K) [], while the residual magnetization beyond T2 is attributed to the α-Fe phase (Tc ≈ 1043 K).

3.6. Brief Comparison with Other Rare-Earth-Free Permanent Magnets

In order to contextualize the magnetic performance of the consolidated α″-Fe16N2 compacts prepared in this study, a comparison with other representative non-rare-earth permanent magnets such as AlNiCo, Mn-Al-C, MnBi, and FePt, is presented.

AlNiCo magnets typically exhibit high saturation magnetization but only moderate coercivity, resulting in reported (BH)max values of approximately 30–80 kJ/m3 [,]. Mn-Al-C magnets are promising due to their low cost and reasonable coercivity, although their metastable τ phase limits performance. Bulk MnAl(C) magnets typically reach (BH)max ≈ 7.5 MGOe (≈60 kJ/m3) with Hc ≈ 3 kOe (≈238 kA/m), while textured films or nanostructures can approach (BH)max ≈ 16.8 MGOe (≈134 kJ/m3) [,]. MnBi alloys show comparable behavior, with (BH)max in bulk ≈ 8.7 MGOe and in films up to 16 MGOe, although their very low decomposition temperature (≈535 K) limits densification []. In contrast, FePt (L10) represents a highly anisotropy magnetic phase whose optimized nanostructure can, in principle, reach or exceed hundreds of kJ/m3, but its high cost and limited scalability currently restrict its practical applications [,].

The experimentally determined energy product (BH)max for our samples ranges from 13.5 to 15.71 kJ/m3. These values, though smaller than those of fully optimized AlNiCo or Mn-based magnets, are remarkable for a metastable Fe–N system processed below 550 K without rare-earth elements. Overall, this comparison highlights the potential use of α″-Fe16N2 as a free-rare-earth, high-magnetization material and justifies further optimization aimed at increasing the α″ phase fraction and bulk density to enhance (BH)max values.

4. Conclusions

This work has successfully demonstrated the feasibility of consolidating metastable α″-Fe16N2 powders into dense bulk compacts using SPS, providing a viable pathway towards the development of high-performance, rare-earth-free permanent magnets.

A systematic investigation of compacts versus SPS parameters (temperature and pressure) revealed a critical trade-off between densification and magnetic phase stability. Temperature was identified as the dominant factor controlling α″-Fe16N2 phase stability. While the relative density increased continuously with temperature, the α″ phase could be retained only up to approximately 548 K. Beyond this limit, accelerated decomposition led to the predominant formation of α-Fe and γ′-Fe4N. Applying a higher pressure (80 MPa) a significant beneficial effect was observed, improving thus both densification and α″-phase retention, most likely due to reduced porosity and inhibited nitrogen diffusion.

Microstructural observations have confirmed that the increase in the pressure results in progressive compaction, with significant porosity reduction and enhanced intergranular bonding, without major phase degradation under optimized conditions.

This structural evolution has directly influenced the magnetic behavior. The saturation magnetization (Ms) is increasing with pressure, which is consistent with improved density and α″-Fe16N2 phase preservation, while the coercivity (Hc) has reached a maximum at an intermediate pressure of 60 MPa due to an optimal balance between exchange coupling and domain-wall pinning. The δM(H) analysis corroborate these findings, showing a transition from magnetostatic to exchange-dominated interactions while the pressure is increasing.

Overall, this work highlights the potential of SPS technology to overcome key challenges in processing metastable magnetic materials and represents a significant step towards the practical realization of bulk, rare-earth-free α″-Fe16N2-based magnets for future applications.

Future work will focus on increasing the α″-Fe16N2 phase fraction through optimization of the nitriding process parameters (temperature, gas composition, and duration), as well as on tailoring microstructural characteristics to enhance magnetic stability and performance.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/cryst15110969/s1.

Author Contributions

Conceptualization, resources, investigation, result discussion, writing—original draft, M.G.; sample preparation, experimental design, data analysis, writing—original draft, M.L.; investigation, data analysis, results discussion, M.P.; data curation, formal analysis, investigation, equipment assistance, G.S.; funding acquisition, supervision, methodology, results discussion, N.L. All authors have read and agreed to the published version of the manuscript.

Funding

Financial support from NUCLEU Programme, Contract No.18N/01.01.2023 (Project PN 23 11 01 01) is highly acknowledged.

Data Availability Statement

Data supporting the reported results are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Amato, A.; Becci, A.; Bollero, A.; Cerrillo-Gonzalez, M.d.M.; Cuesta-Lopez, S.; Ener, S.; Dirba, I.; Gutfleisch, O.; Innocenzi, V.; Montes, M.; et al. Life Cycle Assessment of Rare Earth Elements-Free Permanent Magnet Alternatives: Sintered Ferrite and Mn-Al-C. ACS Sustain. Chem. Eng. 2023, 11, 13374–13386. [Google Scholar] [CrossRef]

- Kuz’min, M.D.; Skokov, K.P.; Jian, H.; Radulov, I.; Gutfleisch, O. Towards high-performance permanent magnets without rare earths. J. Phys. Condens. Matter 2014, 26, 064205. [Google Scholar] [CrossRef]

- Popa, D.-C.; Szabó, L. Securing Rare Earth Permanent Magnet Needs for Sustainable Energy Initiatives. Materials 2024, 17, 5442. [Google Scholar] [CrossRef]

- Wang, J.-P. Environment-friendly bulk Fe16N2 permanent magnet: Review and prospective. J. Magn. Magn. Mater. 2020, 497, 165962. [Google Scholar] [CrossRef]

- Stoeckl, P.; Wang, J.-P. Theoretical study of thermal stability range of α″-Fe16N2 within the iron nitride binary phase diagram. AIP Adv. 2025, 15, 035209. [Google Scholar] [CrossRef]

- Zheng, J.; Mao, Z.; Zhang, X.; Yue, P.; Zheng, J.; Cai, W.; Chen, H.; Qiao, L.; Ying, Y.; Li, W.; et al. Preparation and characterization of submicron porous α″-Fe16N2 powders composed of nano-units by spray pyrolysis. J. Alloys Compd. 2025, 1010, 177260. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, J.; Suri, P.K.; Kennedy, G.; Thadhani, N.N.; Flannigan, D.J.; Wang, J.-P. Preparation of an α″-Fe16N2 magnet via a ball milling and shock compaction approach. Adv. Eng. Mater. 2016, 18, 1009–1016. [Google Scholar] [CrossRef]

- Kim, J.; Hwang, J.; Yi, S. Iron nitride based magnetic powder synthesized by mechanical alloying of Fe-based glassy powders and solid nitrogen compounds. J. Magn. Magn. Mater. 2021, 539, 168329. [Google Scholar] [CrossRef]

- Tobise, M.; Saito, S. Synthesis of α″-(Fe,M)16N2 nanoparticles obtained by hydrogen reduction and subsequent nitridation starting from α-(Fe,M)OOH (M=Co,Al). IEEE Trans. Magn. 2022, 58, 1–5. [Google Scholar] [CrossRef]

- Ogawa, T.; Ogata, Y.; Gallage, R.; Kobayashi, N.; Hayashi, N.; Kusano, Y.; Yamamoto, S.; Kohara, K.; Doi, M.; Takano, M.; et al. Challenge to the synthesis of α″-Fe16N2compound nanoparticle with high saturation magnetization for rare earth free new permanent magnetic material. Appl. Phys. Express 2013, 6, 073007. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, M.; Jiang, Y.; Allard, L.F.; Wang, J.-P. Thermal stability of partially ordered Fe16N2 film on non-magnetic Ag under layer. J. Appl. Phys. 2014, 115, 17A767. [Google Scholar] [CrossRef]

- Yamamoto, S.; Gallage, R.; Ogata, Y.; Kusano, Y.; Kobayashi, N.; Ogawa, T.; Hayashi, N.; Kohara, K.; Takahashi, M.; Takano, M. Quantitative understanding of thermal stability of α′′-Fe16N2. Chem. Commun. 2013, 49, 7708. [Google Scholar] [CrossRef] [PubMed]

- Saito, T.; Yamamoto, H. Hard magnetic properties of Fe16N2 magnets. AIP Adv. 2024, 14, 015149. [Google Scholar] [CrossRef]

- Yang, F.; Wang, H.; You, L.; Volinsky, A.A.; Zhang, C.; Guo, Z.; Sui, Y. Performance of Nd-Fe-B Magnets Fabricated by Hot Isostatic Pressing and Low-Temperature Sintering. J. Mater. Eng. Perform. 2019, 28, 273. [Google Scholar] [CrossRef]

- Yoo, J.-G.; Kim, T.-H.; Cha, H.-R.; Kim, Y.-D.; Lee, J.-G. Design of High-Remanence Nd-Fe-B Hot-Pressed Magnets by Manipulating Coercivity of Hydrogenation-Disproportionation-Desorption-Recombination Treated Anisotropic Precursors. Materials 2023, 16, 7599. [Google Scholar] [CrossRef]

- Li, J.; Sepehri-Amin, H.; Sasaki, T.; Ohkubo, T.; Hono, K. Most frequently asked questions about the coercivity of Nd-Fe-B permanent magnets. Sci. Technol. Adv. Mater. 2021, 22, 386–403. [Google Scholar] [CrossRef] [PubMed]

- Ashby, M.F.; Jones, D.R.H. Engineering Materials 2: An Introduction to Microstructures, Processing and Design; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar] [CrossRef]

- ZFu, Z.; Xu, J.; Zhou, B.; He, J.; Chen, H.; Liu, X.; Huang, Y.; Chen, Q. Microstructure evolution, magnetic domain dynamics and magnetic properties of gradient-annealed Fe-based nanocrystalline soft magnetic alloys under hot isostatic pressing. J. Alloys Compd. 2025, 1044, 184538. [Google Scholar] [CrossRef]

- Takagi, K.; Akada, M.; Ozaki, K.; Kobayashi, N.; Ogawa, T.; Ogata, Y.; Takahashi, M. High-pressure sintering behavior of α″-Fe16N2 nanopowder. J. Appl. Phys. 2014, 115, 103905. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-assisted sintering technology/spark plasma sintering: Mechanisms, materials, and technology developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Biesuz, M.; Sglavo, V.M. Flash sintering of ceramics. J. Eur. Ceram. Soc. 2019, 39, 115–143. [Google Scholar] [CrossRef]

- Cologna, M.; Rashkova, B.; Raj, R. Flash sintering of nanograin zirconia in <5 s at 850 °C. J. Am. Ceram. Soc. 2011, 94, 316–319. [Google Scholar] [CrossRef]

- Manière, C.; Lee, G.; Olevsky, E.A. All-Materials-Inclusive Flash Spark Plasma Sintering. Sci Rep. 2017, 7, 15071. [Google Scholar] [CrossRef]

- Singh, C.; Yadav, D. Mechanical properties of flash sintered 3YSZ. Ceram. Int. 2025, 51 Pt B, 37201–37208. [Google Scholar] [CrossRef]

- Yao, S.; Liu, Y.; Liu, D.; Zhao, K.; Liu, J. Flash sintering of Al2O3–ZrO2 ceramics under alternating current electric field. Ceram. Int. 2022, 48, 36764–36772. [Google Scholar] [CrossRef]

- Gibson, A.; Li, Y.; Bonilla, R.S.; Todd, R.I. Pressureless flash sintering of α-SiC: Electrical characteristics and densification. Acta Mater. 2022, 241, 118362. [Google Scholar] [CrossRef]

- Zhou, H.; Li, X.; Zhu, Y.; Liu, J.; Wu, A.; Ma, G.; Wang, X.; Jia, Z.; Wang, L. Review of flash sintering with strong electric field. High Volt. 2022, 7, 1–11. [Google Scholar] [CrossRef]

- Maccari, F.; Mishra, T.P.; Keszler, M.; Braun, T.; Adabifiroozjaei, E.; Radulov, I.; Jiang, T.; Bruder, E.; Guillon, O.; Molina-Luna, L.; et al. Nanocrystalline Nd–Fe–B Anisotropic Magnets by Flash Spark Plasma Sintering. Adv. Eng. Mater. 2023, 25, 2300252. [Google Scholar] [CrossRef]

- Keszler, M.; Radulov, I.A.; Maccari, F.; Mutuk, T.; Krengel, M.; Guillon, O.; Gutfleisch, O.; Bram, M. Field assisted sintering and spark plasma texturing of Nd–Fe–B magnets with anisotropic magnetic properties. Powder Metall. 2025, 68, 179–196. [Google Scholar] [CrossRef]

- Saito, T.; Yamamoto, H.; Nishio-Hamane, D. Production of Rare-Earth-Free Iron Nitride Magnets (α′′-Fe16N2). Metals 2024, 14, 734. [Google Scholar] [CrossRef]

- Mukasyan, A.; Rogachev, A.; Moskovskikh, D.; Yermekova, Z. Reactive spark plasma sintering of exothermic systems: A critical review. Ceram. Int. 2022, 48, 2988–2998. [Google Scholar] [CrossRef]

- Hussein, M.A.; Ogunlakin, N.O.; Kumar, A.M.; Azeem, M.A. Effect of Spark Plasma Sintering Heating Rate on the Mechanical and In Vitro Corrosion Behavior of Biomedical Ti-Zr-Nb-Ta-Ag High-Entropy Alloy in Simulated Body Fluid. Adv. Eng. Mater. 2025, 20, e2501012. [Google Scholar] [CrossRef]

- Le Godec, Y.; Le Floch, S. Recent Developments of High-Pressure Spark Plasma Sintering: An Overview of Current Applications, Challenges and Future Directions. Materials 2023, 16, 997. [Google Scholar] [CrossRef]

- Martin, P.; Aguilar, C.; Cabrera, J. A review on mechanical alloying and spark plasma sintering of refractory high-entropy alloys: Challenges, microstructures, and mechanical behavior. J. Mater. Res. Technol. 2024, 30, 1900–1928. [Google Scholar] [CrossRef]

- Maccari, F.; Aubert, A.; Ener, S.; Bruder, E.; Radulov, I.; Skokov, K.; Gutfleisch, O. Formation of pure τ-phase in Mn–Al–C by fast annealing using spark plasma sintering. J. Mater. Sci. 2022, 57, 6056–6065. [Google Scholar] [CrossRef]

- Pasko, A.; LoBue, M.; Fazakas, E.; Varga, L.K.; Mazaleyrat, F. Spark plasma sintering of Mn-Al-C hard magnets. J. Phys. Condens. Matter 2014, 26, 064203. [Google Scholar] [CrossRef]

- Grigoras, M.; Lostun, M.; Stoian, G.; Ababei, G.; Porcescu, M.; Lupu, N. The Influence of Preparation Parameters on the Morphology and Magnetic Properties of Fe-N Powders Obtained by the Gas Atomization Method. Appl. Sci. 2023, 13, 11529. [Google Scholar] [CrossRef]

- Grigoras, M.; Lostun, M.; Porcescu, M.; Stoian, G.; Ababei, G.; Lupu, N. Innovative Method for the Mass Preparation of α′′-Fe16N2 Powders via Gas Atomization. Crystals 2023, 13, 1578. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Lee, S.-C. First-principles study of the complex magnetism in Fe16N2. Sci. Rep. 2019, 9, 8381. [Google Scholar] [CrossRef] [PubMed]

- Ke, L.; Belashchenko, K.D.; van Schilfgaarde, M.; Kotani, T.; Antropov, V.P. Effects of alloying and strain on the magnetic properties of Fe16N2. Phys. Rev. B 2013, 88, 024404. [Google Scholar] [CrossRef]

- Li, Y.; Kuang, Q.; Men, X.; Wang, S.; Li, D.; Choi, C.; Zhang, Z. Anisotropic Growth and Magnetic Properties of α″-Fe16N2 @C Nanocones. Nanomaterials 2021, 11, 890. [Google Scholar] [CrossRef]

- Wriedt, H.A.; Gokcen, N.A.; Nafziger, R.H. The Fe-N (Iron- Nitrogen) system. Bull. Alloy Phase Diagr. 1987, 8, 355–377. [Google Scholar] [CrossRef]

- Skomski, R.; Coey, J.M.D. Permanent Magnetism; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Coey, J.M.D. Magnetism and Magnetic Materials; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar] [CrossRef]

- Cui, J.; Kramer, M.; Zhou, L.; Liu, F.; Gabay, A.; Hadjipanayis, G.; Balasubramanian, B.; Sellmyer, D. Current progress and future challenges in rare-earth-free permanent magnets. Acta Mater. 2018, 158, 118–137. [Google Scholar] [CrossRef]

- Keller, T.; Yang, W.; Chen, W.; Baker, I. Additive manufacturing of Mn-Al permanent magnets via laser powder bed fusion. Materialia 2024, 33, 101978. [Google Scholar] [CrossRef]

- Cui, J.; Choi, J.P.; Li, G.; Polikarpov, E.; Darsell, J.; Overman, N.; Olszta, M.; Schreiber, D.; Bowden, M.; Droubay, T. Thermal stability of MnBi magnetic materials. J. Phys. Condens. Matter 2016, 26, 064212. [Google Scholar] [CrossRef] [PubMed]

- Pousthomis, M.; Garnero, C.; Marcelot, C.; Blon, T.; Cayez, S.; Cassignol, C.; Du, V.; Krispin, M.; Arenal, R.; Soulantica, K.; et al. 1 On the advantages of spring magnets compared to pure FePt: Strategy for rare-earth free permanent magnets following a bottom-up approach. J. Magn. Magn. Mater. 2017, 424, 304–313. [Google Scholar] [CrossRef]

- Yanai, T.; Omagari, Y.; Furutani, S.; Yamashita, A.; Fujita, N.; Morimura, T.; Nakano, M.; Fukunaga, H. High-temperature properties of Fe-Pt film-magnets prepared by electroplating method. AIP Adv. 2020, 10, 015149. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).