A Facile Fabrication Route of Poly(Ethylene Glycol Phenyl Ether Acrylate) Photopolymers with Efficient Optical Response for Holographic Storage

Abstract

:1. Introduction

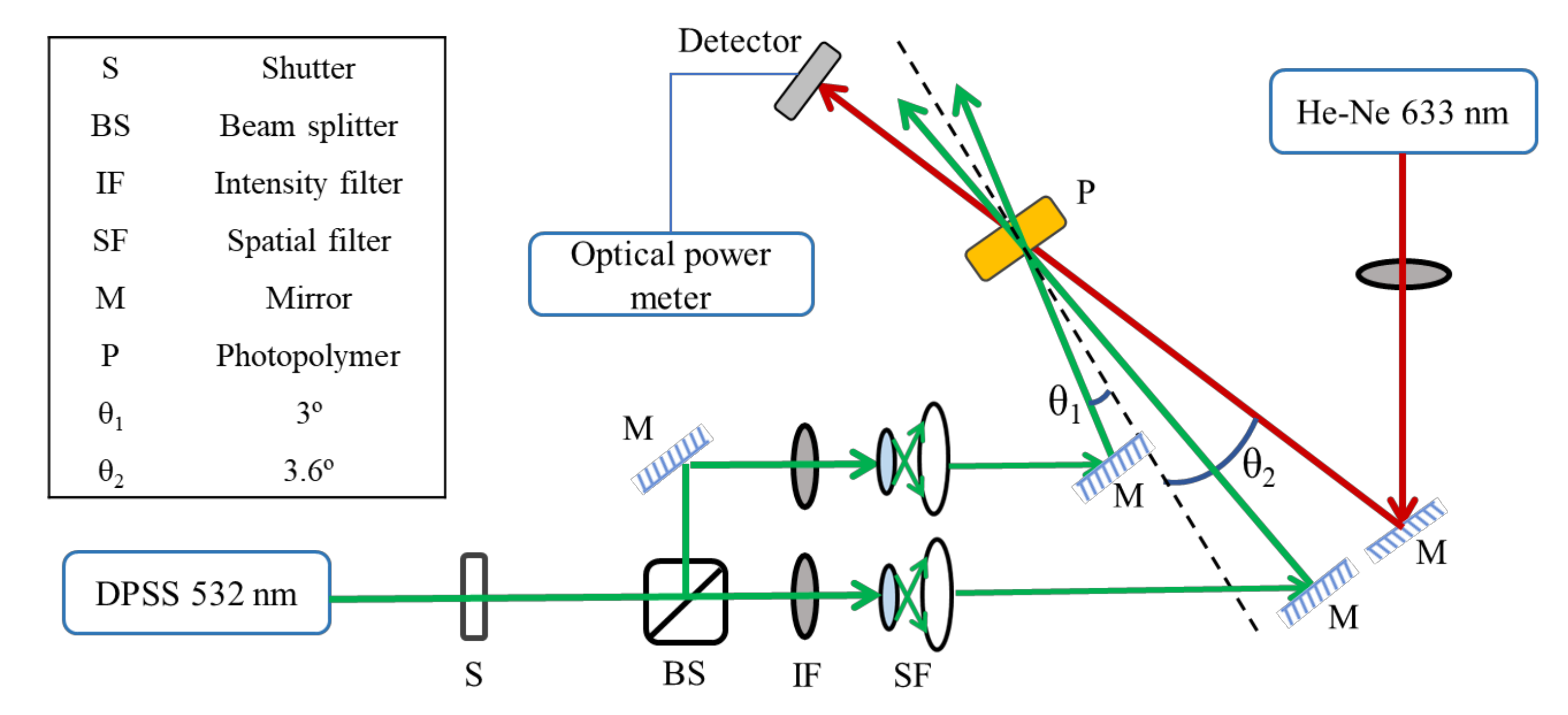

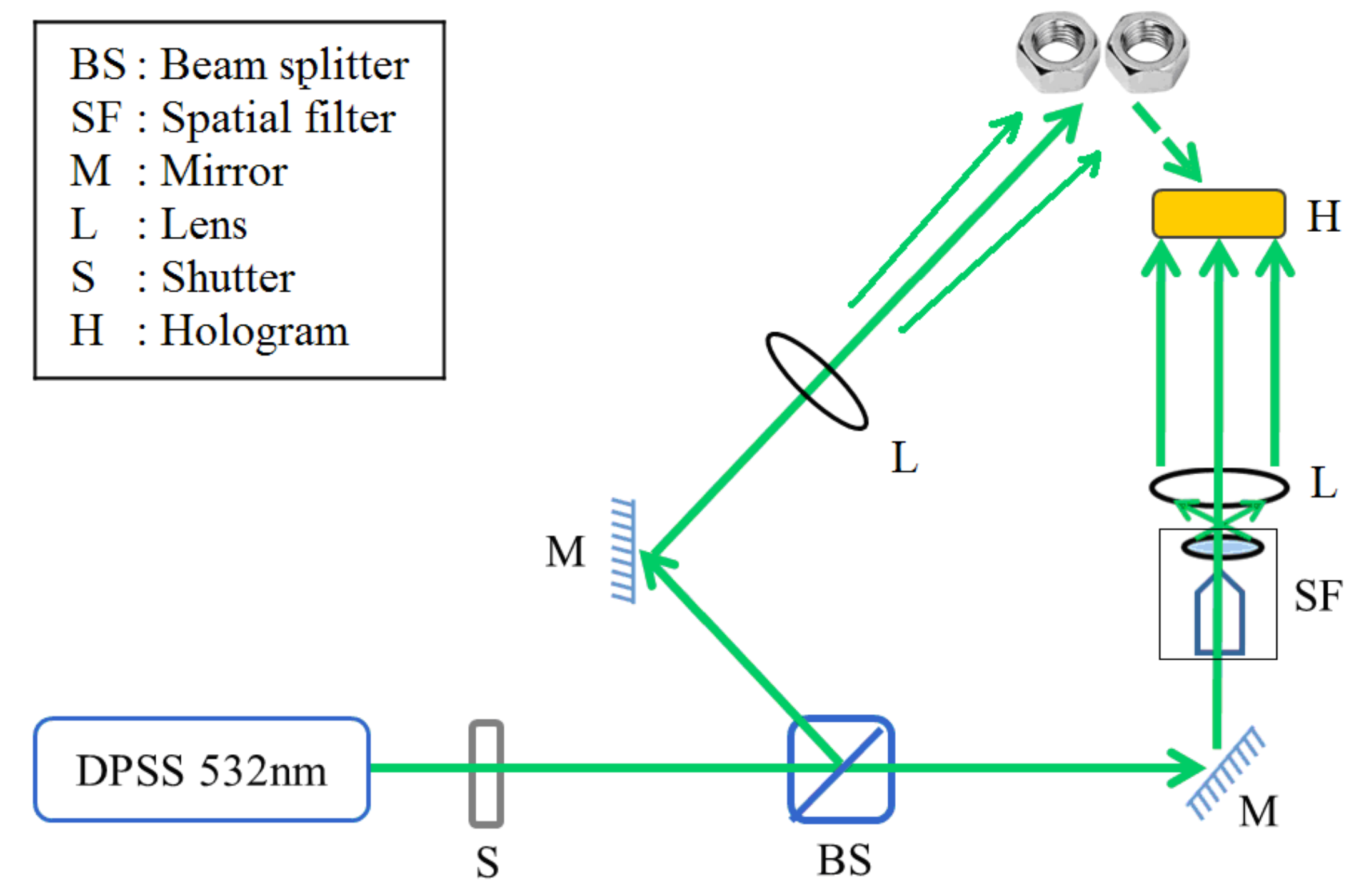

2. Materials and Optical Measurement

3. Results and Discussion

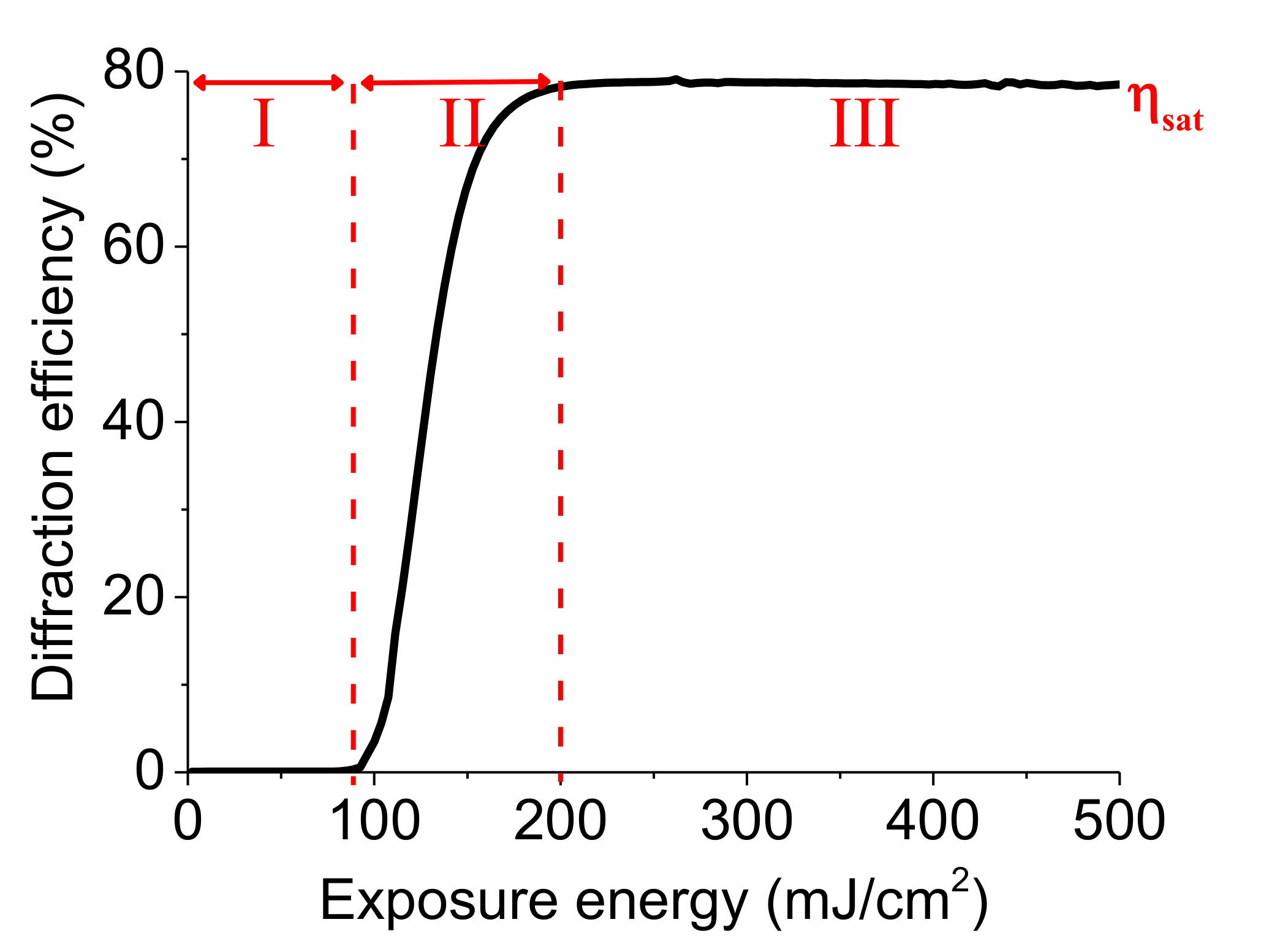

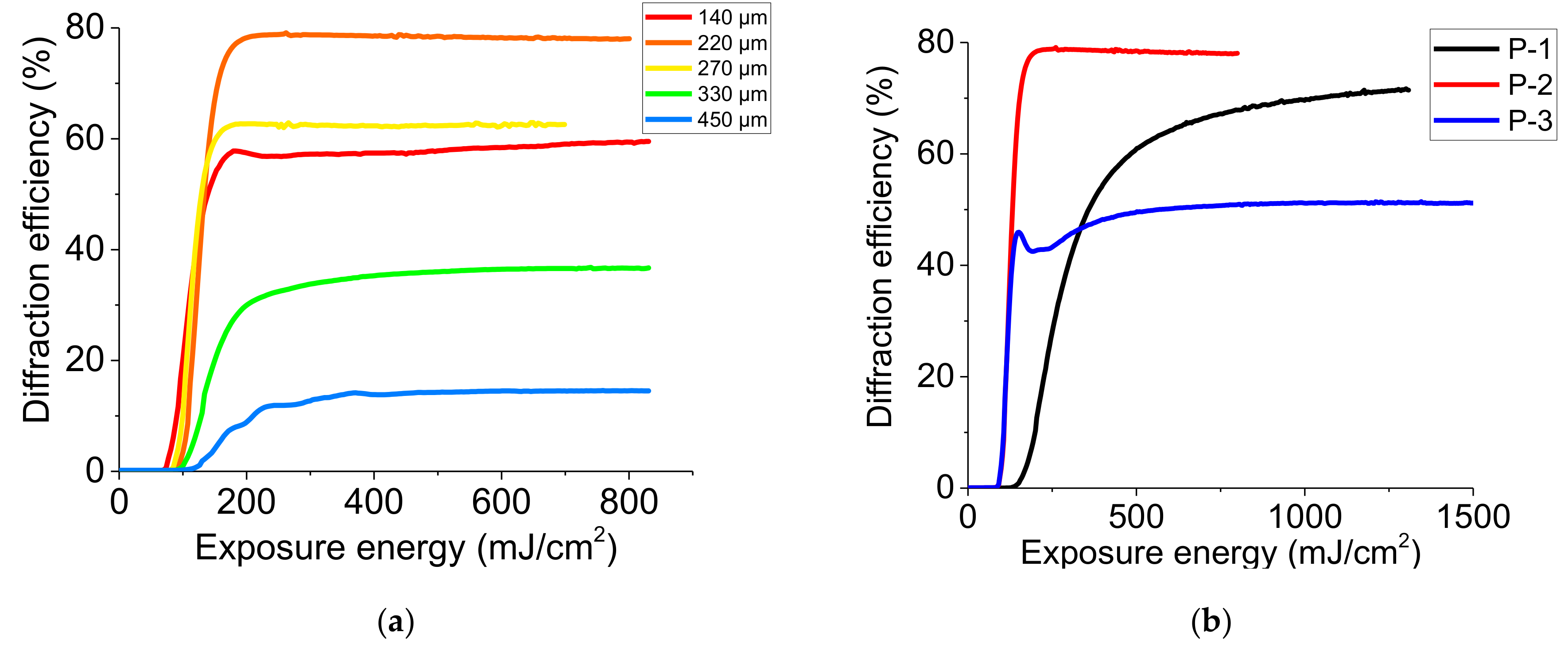

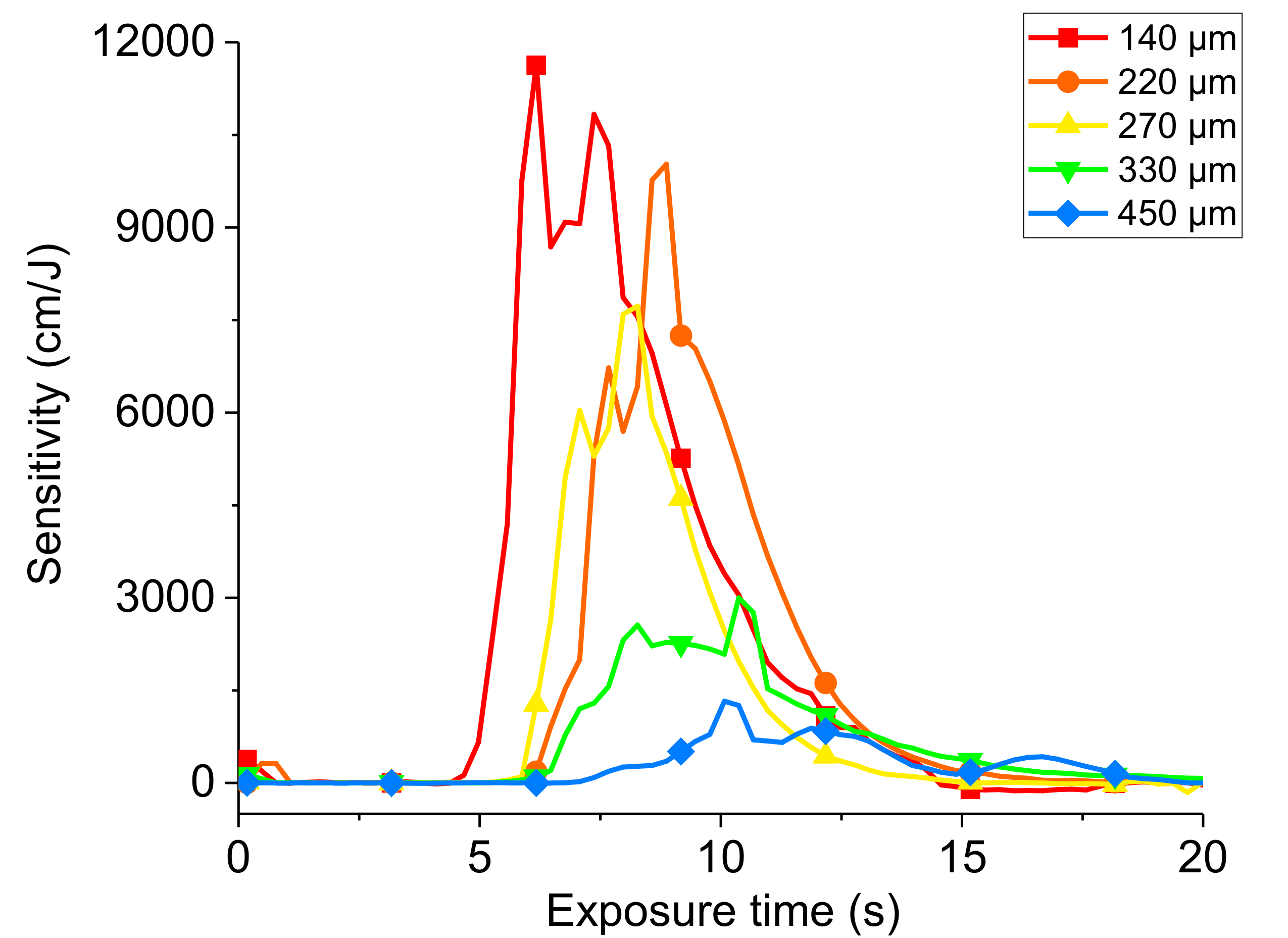

3.1. Optical Efficiency of EGPEA/PMMA Photopolymers

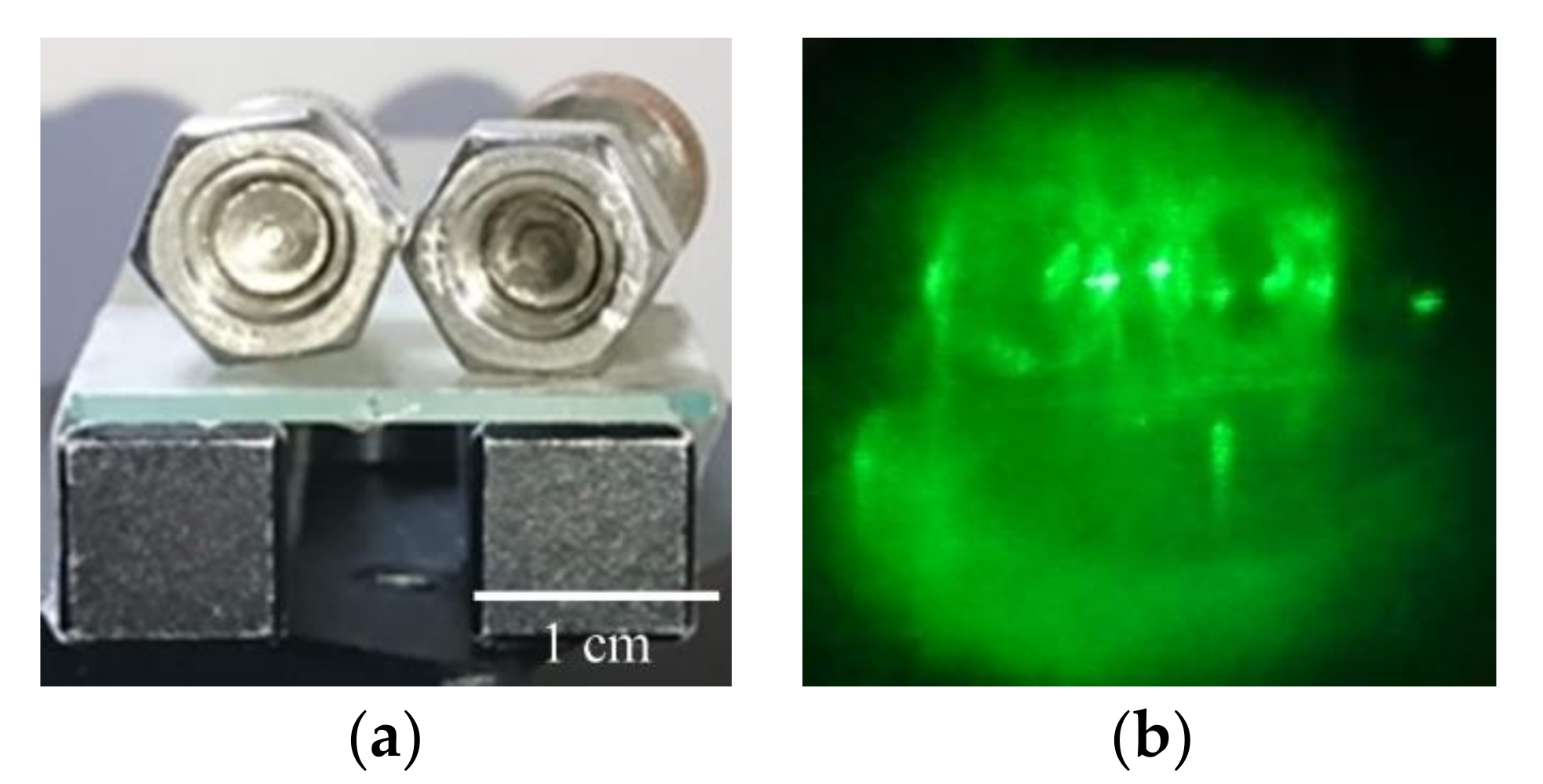

3.2. Holographic Image Recording on an EPGEA-Based Hologram

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lin, S.-H.; Lin, J.H.; Chen, P.L.; Shiao, Y.N.; Hsu, K.-Y. Doped poly(methyl methacrylate) photopolymers for holographic data storage. J. Nonlinear Opt. Phys. Mater. 2006, 15, 239–252. [Google Scholar] [CrossRef]

- Lin, S.-H.; Chen, P.-L.; Hsiao, Y.-N.; Whang, W.-T. Fabrication and characterization of poly(methyl methacrylate) photopolymer doped with 9,10-phenanthrenequinone (PQ) based derivatives for volume holographic data storage. Opt. Commun. 2008, 281, 559–566. [Google Scholar] [CrossRef]

- Luo, Y.; Russo, J.M.; Kostuk, R.K.; Barbastathis, G. Silicon oxide nanoparticles doped PQ-PMMA for volume holographic imaging filters. Opt. Lett. 2010, 35, 1269–1271. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Gelsinger, P.J.; Barton, J.K.; Barbastathis, G.; Kostuk, R.K. Spectral-spatial depth sectioning of biological samples using silicon oxide nano-particles doped PQ-PMMA. In Advances in Imaging; OSA Technical Digest (CD); DTuB5; Optical Society of America: Washington, DC, USA, 2009. [Google Scholar]

- Lin, S.H.; Hsu, K.Y.; Chen, W.-Z.; Whang, W.T. Phenanthrenequinone-doped poly(methyl methacrylate) photopolymer bulk for volume holographic data storage. Opt. Lett. 2000, 25, 451–453. [Google Scholar] [CrossRef]

- Bruder, F.-K.; Hagen, R.; Rölle, T.; Weiser, M.-S.; Fäcke, T. From the Surface to Volume: Concepts for the Next Generation of Optical–Holographic Data-Storage Materials. Angew. Chem. Int. Ed. 2011, 50, 4552–4573. [Google Scholar] [CrossRef] [PubMed]

- Sukhanov, V.I. 3-dimensional deep holograms and meterials for recording them. J. Opt. Technol. 1994, 61, 49–56. [Google Scholar]

- Steckman, G.J.; Solomatine, I.; Zhou, G.; Psaltis, D. Characterization of phenanthrenequinone-doped poly(methyl methacrylate) for holographic memory. Opt. Lett. 1998, 23, 1310–1312. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hsu, K.Y.; Lin, S.-H. Holographic Data Storage Using Photopolymer. In Optical Science and Technology, SPIE’s 48th Annual Meeting; SPIE: Bellingham, WA, USA, 2003; Volume 5206. [Google Scholar]

- Hsu, K.Y.; Lin, S.-H.; Hsiao, Y.-N.; Whang, W.-T. Experimental characterization of phenanthrenequinone-doped poly(methyl methacrylate) photopolymer for volume holographic storage. Opt. Eng. 2003, 42, 1390–1396. [Google Scholar]

- Chen, Y.-F.; Lin, J.-H.; Lin, S.H.; Hsu, K.Y.; Whang, W.-T. PQ:DMNA/PMMA photopolymer having amazing volume holographic recording at wavelength of insignificant absorption. Opt. Lett. 2013, 38, 2056–2058. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.H.; Hsiao, Y.N.; Hsu, K.Y. Preparation and characterization of Irgacure 784 doped photopolymers for holographic data storage at 532 nm. J. Opt. A Pure Appl. Opt. 2009, 11, 024012. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, F.; Hong, Y.; Zang, J.; Kang, G.; Tan, X. Volume holographic recording in Irgacure 784-doped PMMA photopolymer. Opt. Express 2017, 25, 20654–20662. [Google Scholar] [CrossRef]

- Zhao, G.; Mouroulis, P. Diffusion Model of Hologram Formation in Dry Photopolymer Materials. J. Mod. Opt. 1994, 41, 1929–1939. [Google Scholar] [CrossRef]

- Colburn, W.S.; Haines, K.A. Volume Hologram Formation in Photopolymer Materials. Appl. Opt. 1971, 10, 1636–1641. [Google Scholar] [CrossRef]

- Sabol, D.; Gleeson, M.R.; Liu, S.; Sheridan, J.T. Photoinitiation study of Irgacure 784 in an epoxy resin photopolymer. J. Appl. Phys. 2010, 107, 053113. [Google Scholar] [CrossRef]

- Oh, H.; Kim, J.; Kim, E. Holographic Recording on Photopolymers Containing Pyrene for Enhanced Fluorescence Intensity. Macromolecules 2008, 41, 7160–7165. [Google Scholar] [CrossRef]

| Sample | I-784 (wt %) | Thickness (μm) | ηsat (%) | tsat (s) |

|---|---|---|---|---|

| P-1 | 0.37 | 110 | 24 | 46 |

| 140 | 27 | 61 | ||

| 230 | 68 | 70 | ||

| 460 | 74 | 24 | ||

| 520 | 56 | 20 | ||

| P-2 | 0.39 | 140 | 57 | 14 |

| 220 | 80 | 16 | ||

| 270 | 63 | 12 | ||

| 330 | 34 | 39 | ||

| 450 | 14 | 28 | ||

| P-3 | 0.41 | 100 | 58 | 15 |

| 170 | 42 | 54 | ||

| 230 | 48 | 30 | ||

| 380 | 61 | 21 | ||

| 520 | 33 | 13 |

| Monomer | Matrix | Wavelength (nm) | I-784 (%) | η (%) | Expo. Energy (mJ/cm2) | Year/Ref |

|---|---|---|---|---|---|---|

| EGPEA + DT | PES | 491 | 1.00 | 70.0 | 17.6 | 2008/[17] |

| MMA | PMMA | 532 | 1.00 | 13.6 | 32821 | 2017/[13] |

| MMA | PMMA | 532 | 3.00 | 32.9 | 54466 | 2017/[13] |

| MMA | PMMA | 532 | 5.00 | 52.2 | 127323 | 2017/[13] |

| MMA | PMMA | 532 | 7.00 | 52.2 | 127323 | 2017/[13] |

| EGPEA | PMMA | 532 | 0.39 | 80.0 | 200 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, F.-Y.; Wang, X.-J.; Su, W.-H.; Hsu, T.-C. A Facile Fabrication Route of Poly(Ethylene Glycol Phenyl Ether Acrylate) Photopolymers with Efficient Optical Response for Holographic Storage. Crystals 2020, 10, 935. https://doi.org/10.3390/cryst10100935

Lee F-Y, Wang X-J, Su W-H, Hsu T-C. A Facile Fabrication Route of Poly(Ethylene Glycol Phenyl Ether Acrylate) Photopolymers with Efficient Optical Response for Holographic Storage. Crystals. 2020; 10(10):935. https://doi.org/10.3390/cryst10100935

Chicago/Turabian StyleLee, Fang-Yong, Xin-Jin Wang, Wei-Hung Su, and Tzu-Chien Hsu. 2020. "A Facile Fabrication Route of Poly(Ethylene Glycol Phenyl Ether Acrylate) Photopolymers with Efficient Optical Response for Holographic Storage" Crystals 10, no. 10: 935. https://doi.org/10.3390/cryst10100935