High Lateral Breakdown Voltage in Thin Channel AlGaN/GaN High Electron Mobility Transistors on AlN/Sapphire Templates

Abstract

:1. Introduction

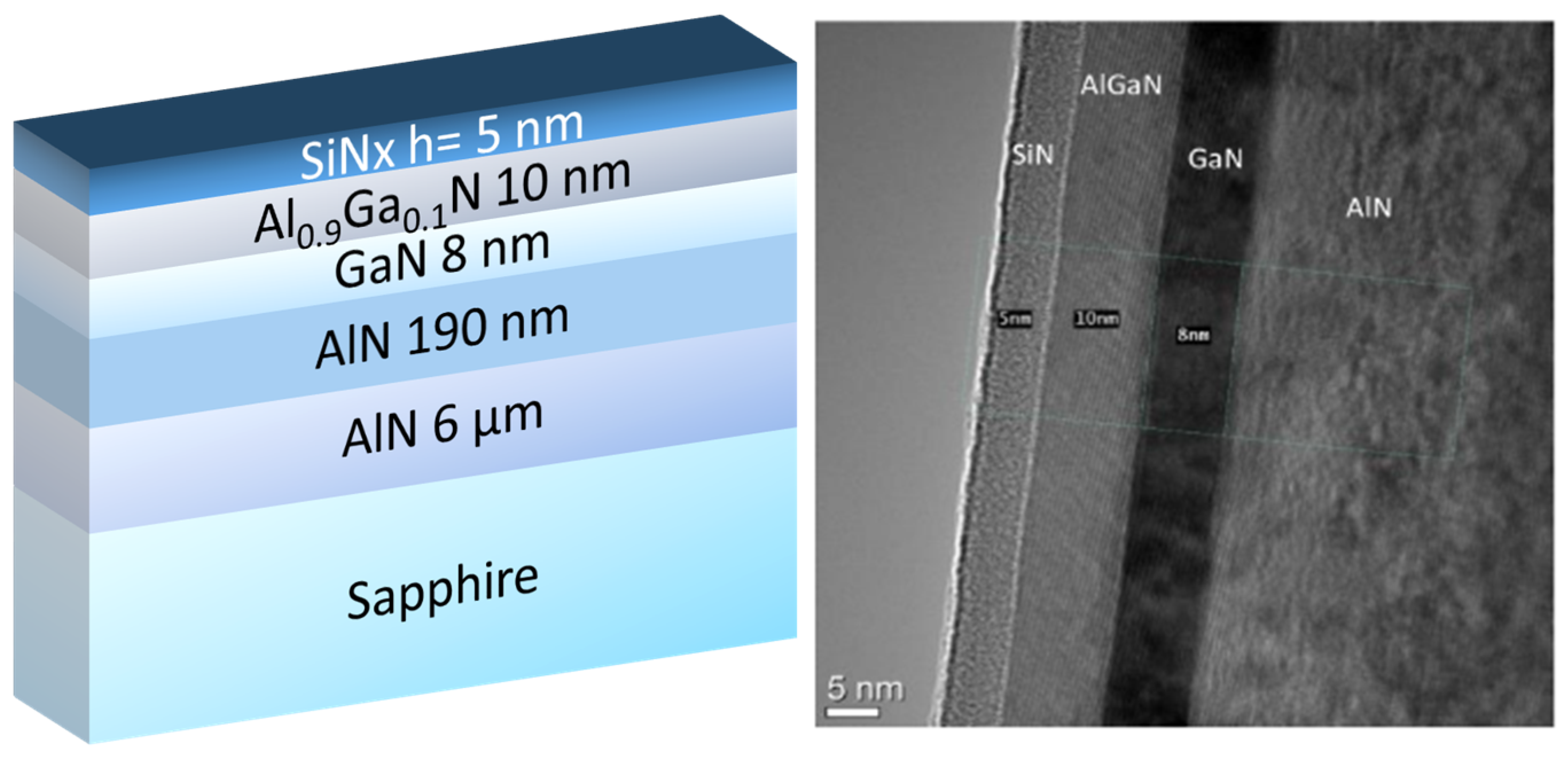

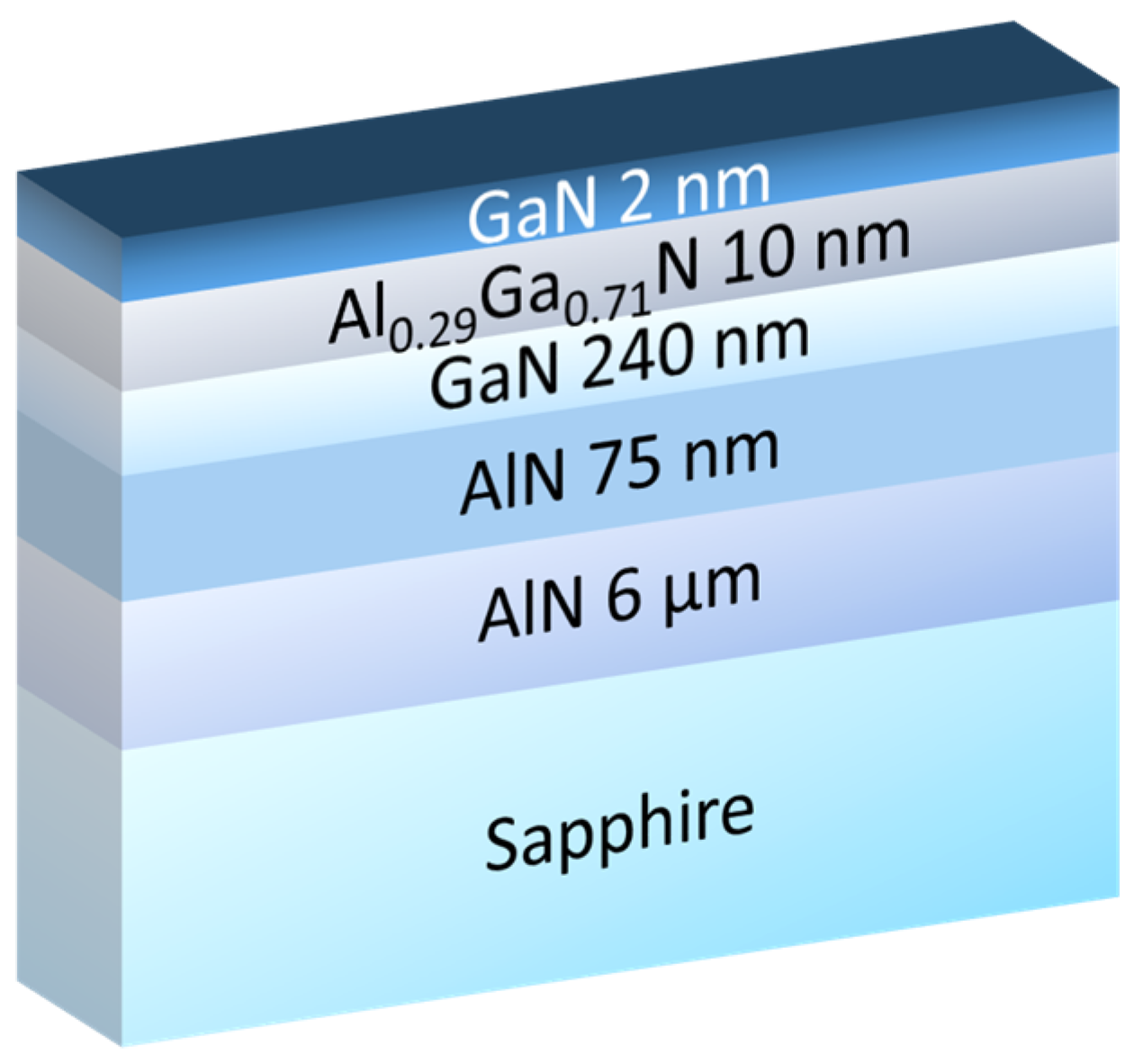

2. Material Description and Device Fabrication

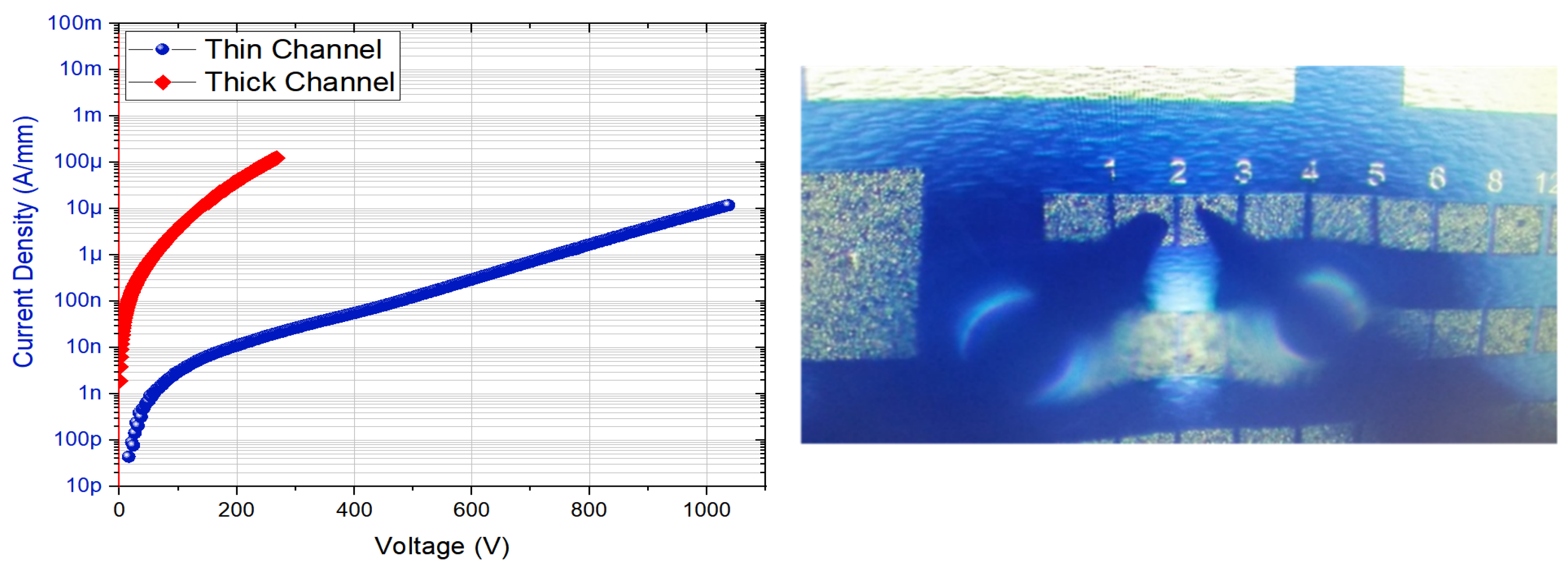

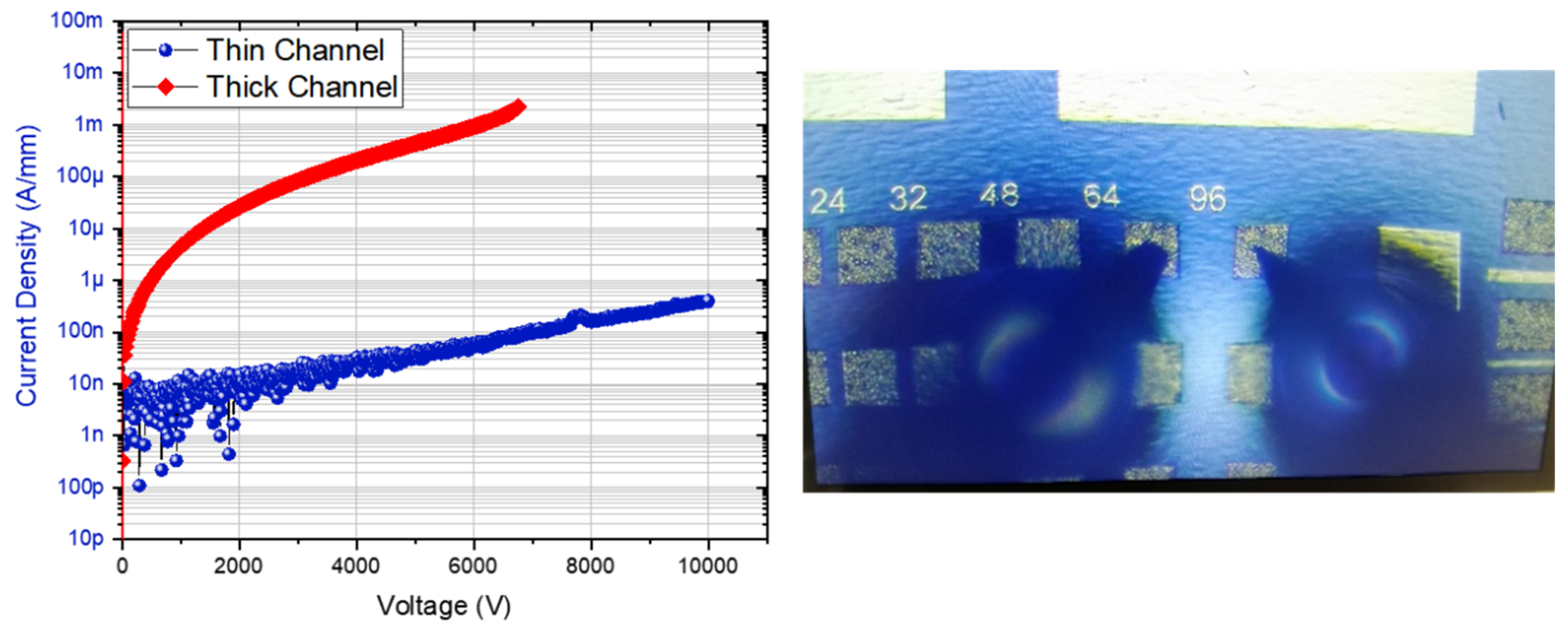

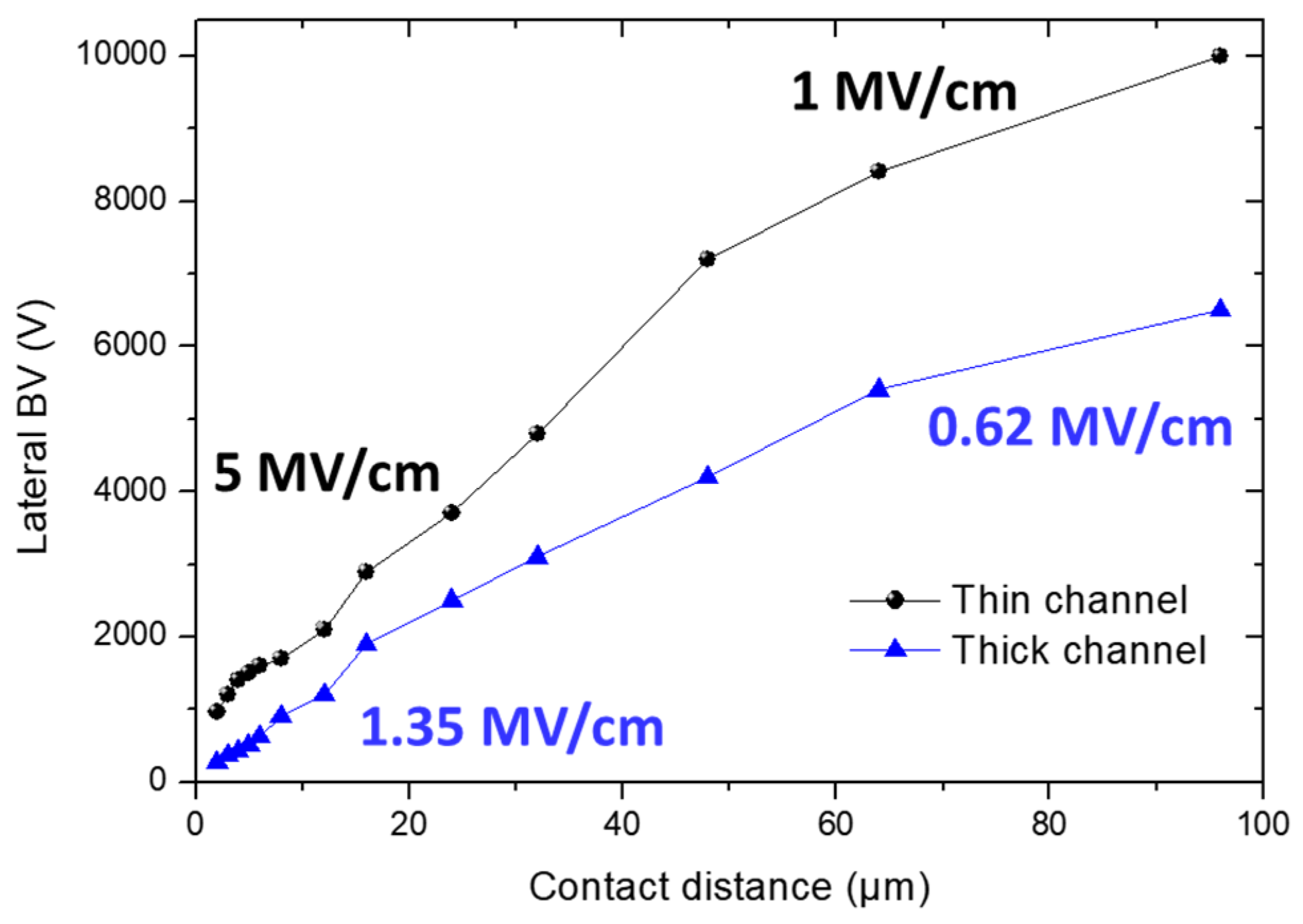

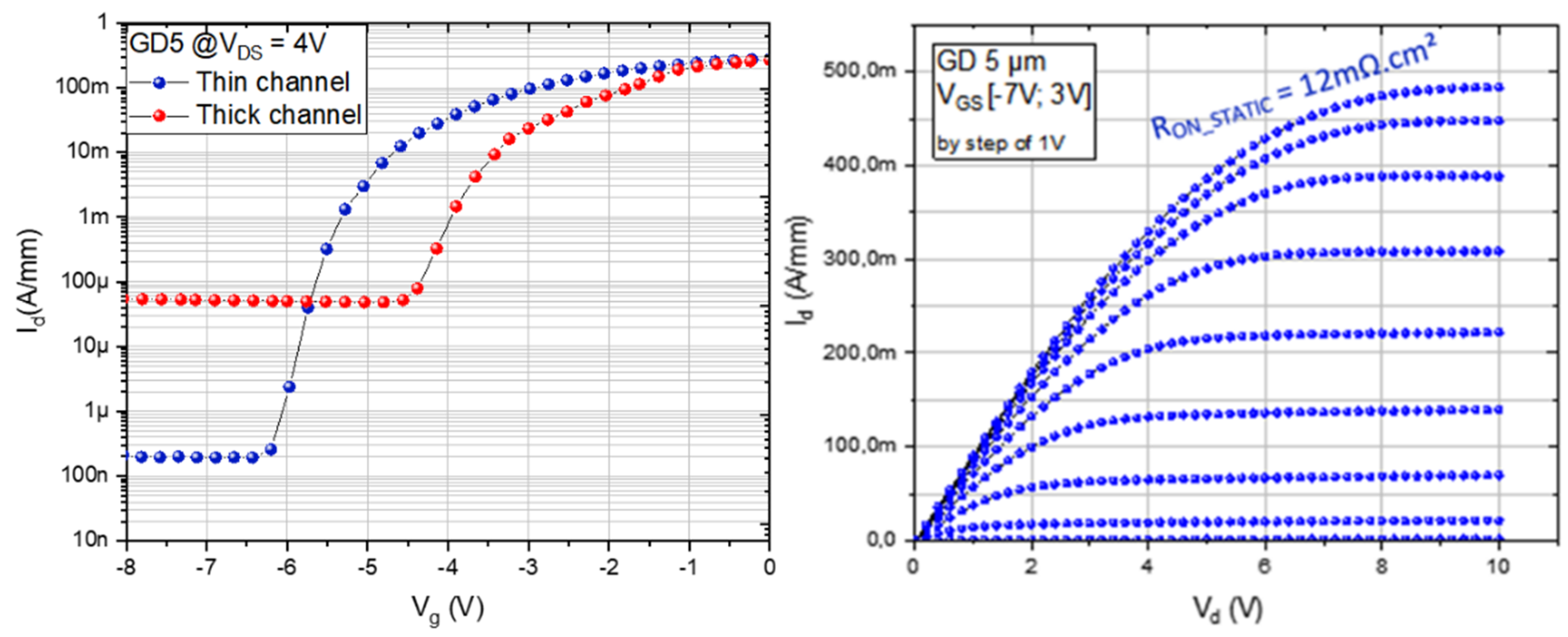

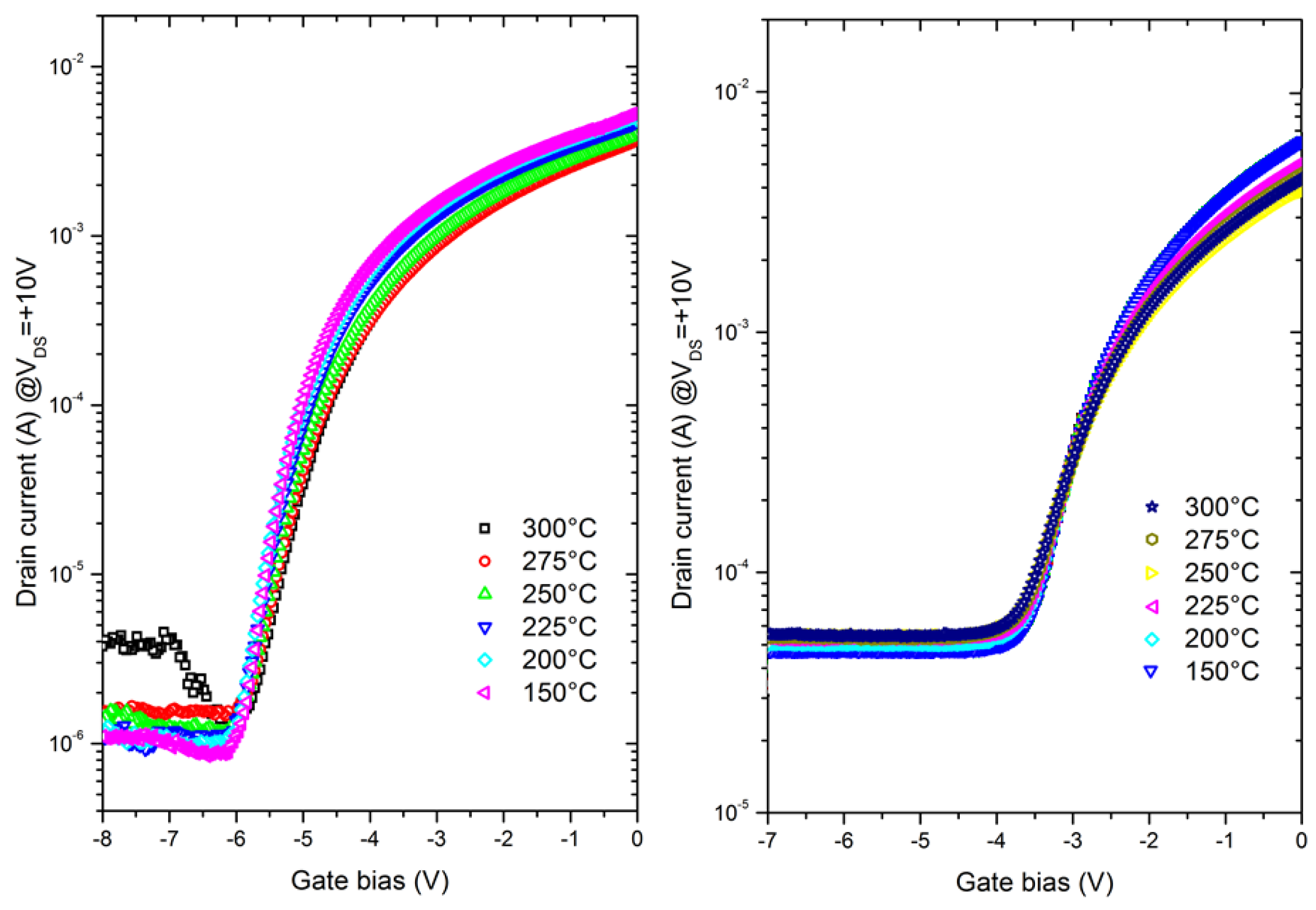

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Saito, W. Reliability of GaN-HEMTs for high-voltage switching applications. In Proceedings of the International Reliability Physics Symposium, Monterey, CA, USA, 10–14 April 2011. [Google Scholar]

- Dogmus, E.; Zegaoui, M.; Medjdoub, F. GaN-on-silicon high-electron-mobility transistor technology with ultra-low leakage up to 3000 V using local substrate removal and AlN ultra-wide bandgap. Appl. Phys. Express 2018, 11, 034102. [Google Scholar] [CrossRef]

- Mishra, U.K.; Parikh, P.; Wu, Y.F. AlGaN/GaN HEMTs: An overview of device operation and applications. Proc. IEEE 2002, 90, 1022–1031. [Google Scholar] [CrossRef]

- Roccaforte, F.; Greco, G.; Fiorenza, P.; Iucolano, F. An Overview of Normally-Off GaN-Based High Electron Mobility Transistors. Materials 2019, 12, 1599. [Google Scholar] [CrossRef] [PubMed]

- Baliga, B.J. Gallium nitride devices for power electronic applications. Semicond. Sci. Technol. 2013, 28, 074011. [Google Scholar] [CrossRef]

- Pavlidis, G.; Kim, S.H.; Abid, I.; Zegaoui, M.; Medjdoub, F.; Graham, S. The Effects of AlN and Copper Back Side Deposition on the Performance of Etched Back GaN/Si HEMTs. IEEE Electron Device Lett. 2019, 40, 1060–1063. [Google Scholar] [CrossRef]

- Ikeda, N.; Niiyama, Y.; Kambayashi, H.; Sato, Y.; Nomura, T.; Kato, S.; Yoshida, S. GaN Power Transistors on Si Substrates for Switching Applications. Proc. IEEE 2010, 98, 1151–1161. [Google Scholar] [CrossRef]

- Kambayashi, H.; Satoh, Y.; Ootomo, S.; Kokawa, T.; Nomura, T.; Kato, S.; Chow, T.S. Over 100 A operation normally-off AlGaN/GaN hybrid MOS-HFET on Si substrate with high-breakdown voltage. Solid-State Electron. 2010, 54, 660–664. [Google Scholar] [CrossRef]

- Herbecq, N.; Roch-Jeune, I.; Rolland, N.; Visalli, D.; Derluyn, J.; Degroote, S.; Germain, M.; Medjdoub, F. 1900 V, 1.6 mΩ cm2 AlN/GaN-on-Si power devices realized by local substrate removal. Appl. Phys. Express 2014, 7, 034103. [Google Scholar] [CrossRef]

- Tsao, J.Y.; Chowdhury, S.; Hollis, M.A.; Jena, D.; Johnson, N.M.; Jones, K.A.; Kaplar, R.J.; Rajan, S.; Van de Walle, C.G.; Bellotti, E.; et al. Ultrawide-Bandgap Semiconductors: Research Opportunities and Challenges. Adv. Electron. Mater. 2018, 1, 1600501. [Google Scholar] [CrossRef]

- Kaplar, R.J.; Allerman, A.A.; Armstrong, A.M.; Crawford, M.H.; Dickerson, J.R.; Fischer, A.J.; Baca, A.G.; Douglas, E.A. Review-Ultra-Wide-Bandgap AlGaN Power Electronic Devices. ECS J. Solid State Sci. Technol. 2017, 6, Q3061. [Google Scholar] [CrossRef]

- Razzak, T.; Xue, H.; Xia, Z.; Hwang, S.; Khan, A.; Lu, W.; Rajan, S. Ultra-wide band gap materials for high frequency applications. In Proceedings of the IEEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes for RF and THz Applications (IMWS-AMP), Ann Arbor, MI, USA, 16–18 July 2018. [Google Scholar]

- Anderson, T.J.; Hite, J.K.; Ren, F. Ultra-Wide Bandgap Materials and Device. ECS J. Solid State Sci. Technol. 2017, 6, Y1. [Google Scholar] [CrossRef]

- Shealy, J.R.; Kaper, V.; Tilak, V.; Prunty, T.; Smart, J.A.; Green, B.; Eastman, L.F. An AlGaN/GaN high-electron-mobility transistor with an AlN sub-buffer layer. J. Phys. Condens. Matter 2002, 14, 3499. [Google Scholar] [CrossRef]

- Yafune, N.; Hashimoto, S.; Akita, K.; Yamamoto, Y.; Tokuda, H.; Kuzuhara, M. AlN/AlGaN HEMTs on AlN substrate for stable high-temperature operation. Electron. Lett. 2014, 50, 211–212. [Google Scholar] [CrossRef]

- Wu, Y.F.; Kapolnek, D.; Ibbetson, J.P.; Parikh, P.; Keller, B.P.; Mishra, U.K. Very-high power density AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2001, 48, 586–590. [Google Scholar]

- Kinoshita, T.; Nagashima, T.; Obata, T.; Takashima, S.; Yamamoto, R.; Togashi, R.; Kumagai, Y.; Schlesser, R.; Collazo, R.; Koukitu, A.; et al. Fabrication of vertical Schottky barrier diodes on n-type freestanding AlN substrates grown by hydride vapor phase epitaxy. Appl. Phys. Exp. 2015, 8, 061003. [Google Scholar] [CrossRef]

- Cahill, D.G. Analysis of heat flow in layered structures for time-domain thermoreflectance. Rev. Sci. Instrum. 2004, 75, 5119–5122. [Google Scholar] [CrossRef]

- Choi, S.R.; Kim, D.; Choa, S.H.; Lee, S.H.; Kim, J.K. Thermal Conductivity of AlN and SiC Thin Films. Int. J. Thermophys. 2006, 27, 896–905. [Google Scholar] [CrossRef]

- Strite, S.; Morkoç, H. GaN, AlN, and InN: A review. J. Vac. Sci. Technol. B 1992, 10, 1237. [Google Scholar] [CrossRef]

- Cordier, Y.; Pruvost, F.; Semond, F.; Massies, J.; Leroux, M.; Lorenzini, P.; Chaix, C. Quality and uniformity assessment of AlGaN/GaN Quantum Wells and HEMT heterostructures grown by molecular beam epitaxy with ammonia source. Phys. Stat. Sol. C 2006, 3, 2325–2328. [Google Scholar] [CrossRef]

- Cordier, Y. Al(Ga)N/GaN high electron mobility transistors on silicon. Phys. Status Solidi A 2015, 212, 1049–1058. [Google Scholar] [CrossRef]

- Baron, N.; Cordier, Y.; Chenot, S.; Vennéguès, P.; Tottereau, O.; Leroux, M.; Semond, F.; Massies, J. The critical role of growth temperature on the structural and electrical properties of AlGaN/GaN high electron mobility transistor heterostructures grown on Si (111). J. Appl. Phys. 2009, 105, 033701. [Google Scholar] [CrossRef]

- Rowena, I.B.; Selvaraj, S.L.; Egawa, T. Buffer thickness contribution to suppress vertical leakage current with high breakdown field (2.3 MV/cm) for GaN on Si. IEEE Electron Device Lett. 2011, 32, 1534–1536. [Google Scholar] [CrossRef]

- Khan, M.N.; Ahmed, U.F.; Ahmed, M.M.; Rehman, S. An improved model to assess temperature-dependent DC characteristics of submicron GaN HEMTs. J. Comput. Electron. 2018, 17, 653–662. [Google Scholar] [CrossRef]

- Razeeb, K.M.; Dalton, E.; Cross, G.L.; Robinson, A.J. Present and future thermal interface materials for electronic devices. Int. Mater. Rev. 2017, 63, 1–21. [Google Scholar] [CrossRef]

- Cho, J.; Bozorg-Grayeli, E.; Altman, D.H.; Asheghi, M.; Goodson, K.E. Low Thermal Resistances at GaN–SiC Interfaces for HEMT Technology. IEEE Trans. Electron Devices Lett. 2012, 33, 378–380. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abid, I.; Kabouche, R.; Bougerol, C.; Pernot, J.; Masante, C.; Comyn, R.; Cordier, Y.; Medjdoub, F. High Lateral Breakdown Voltage in Thin Channel AlGaN/GaN High Electron Mobility Transistors on AlN/Sapphire Templates. Micromachines 2019, 10, 690. https://doi.org/10.3390/mi10100690

Abid I, Kabouche R, Bougerol C, Pernot J, Masante C, Comyn R, Cordier Y, Medjdoub F. High Lateral Breakdown Voltage in Thin Channel AlGaN/GaN High Electron Mobility Transistors on AlN/Sapphire Templates. Micromachines. 2019; 10(10):690. https://doi.org/10.3390/mi10100690

Chicago/Turabian StyleAbid, Idriss, Riad Kabouche, Catherine Bougerol, Julien Pernot, Cedric Masante, Remi Comyn, Yvon Cordier, and Farid Medjdoub. 2019. "High Lateral Breakdown Voltage in Thin Channel AlGaN/GaN High Electron Mobility Transistors on AlN/Sapphire Templates" Micromachines 10, no. 10: 690. https://doi.org/10.3390/mi10100690