A Misalignment Optical Guiding Module for Power Generation Enhancement of Fixed-Type Photovoltaic Systems

Abstract

:1. Introduction

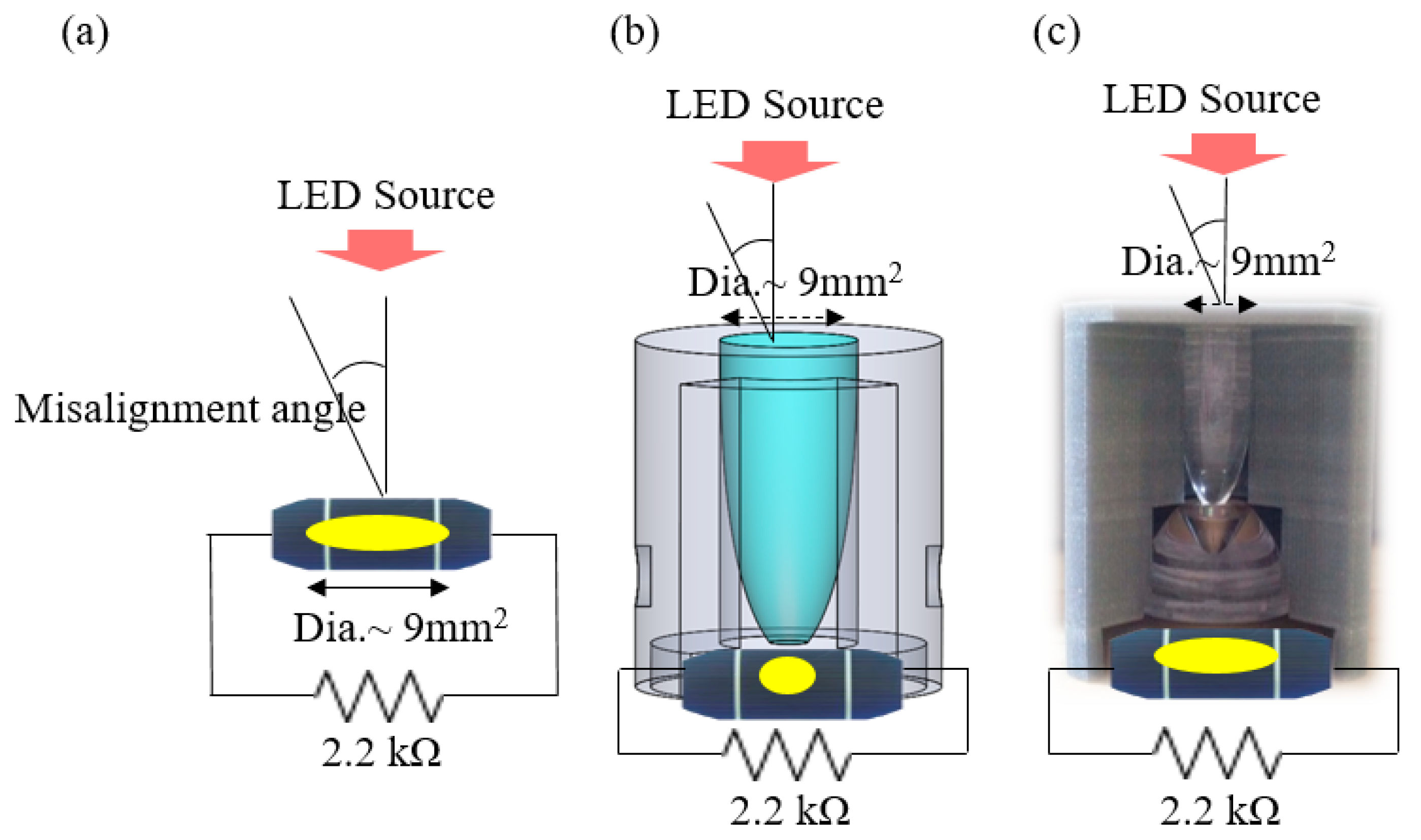

2. Experimental Methods

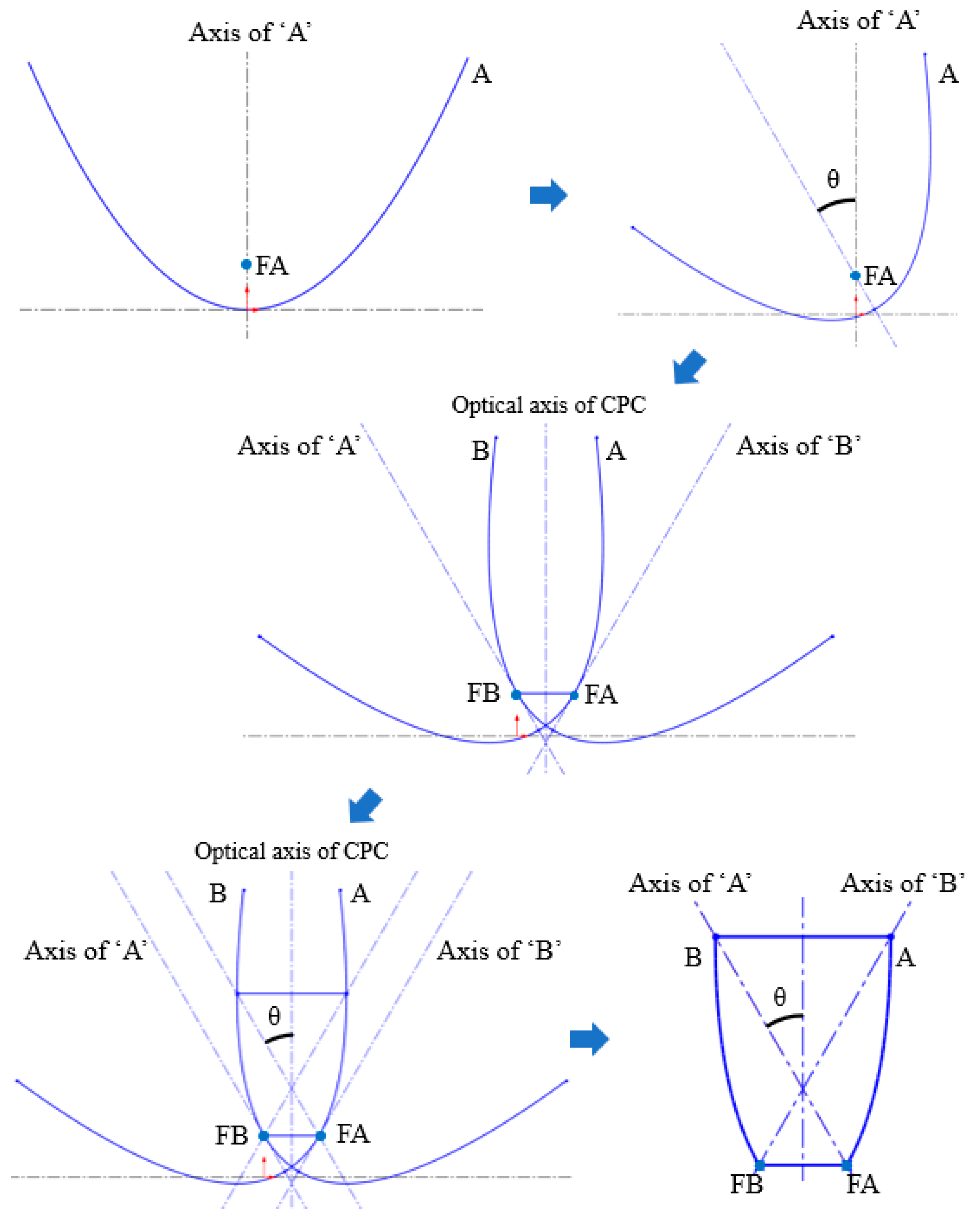

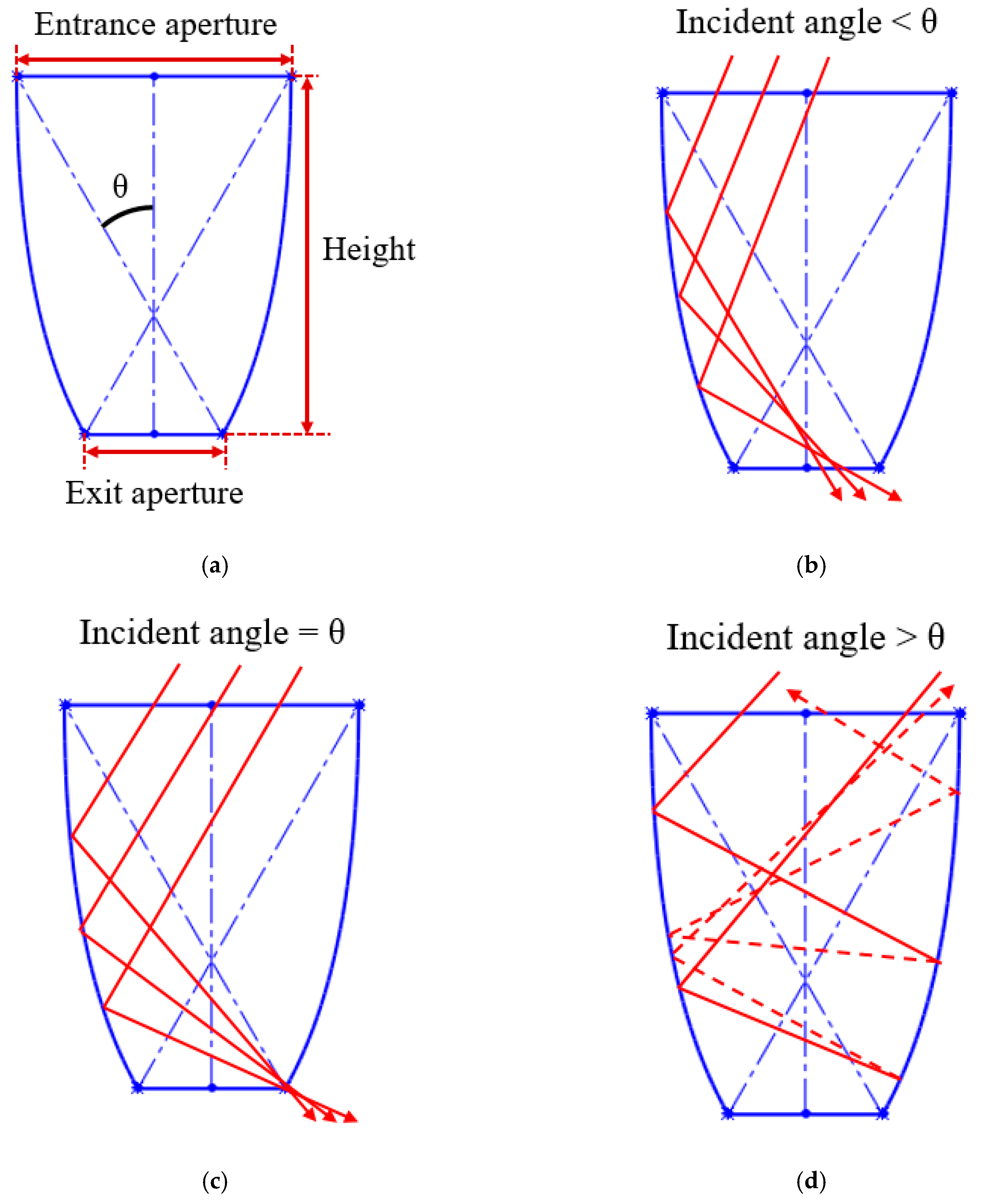

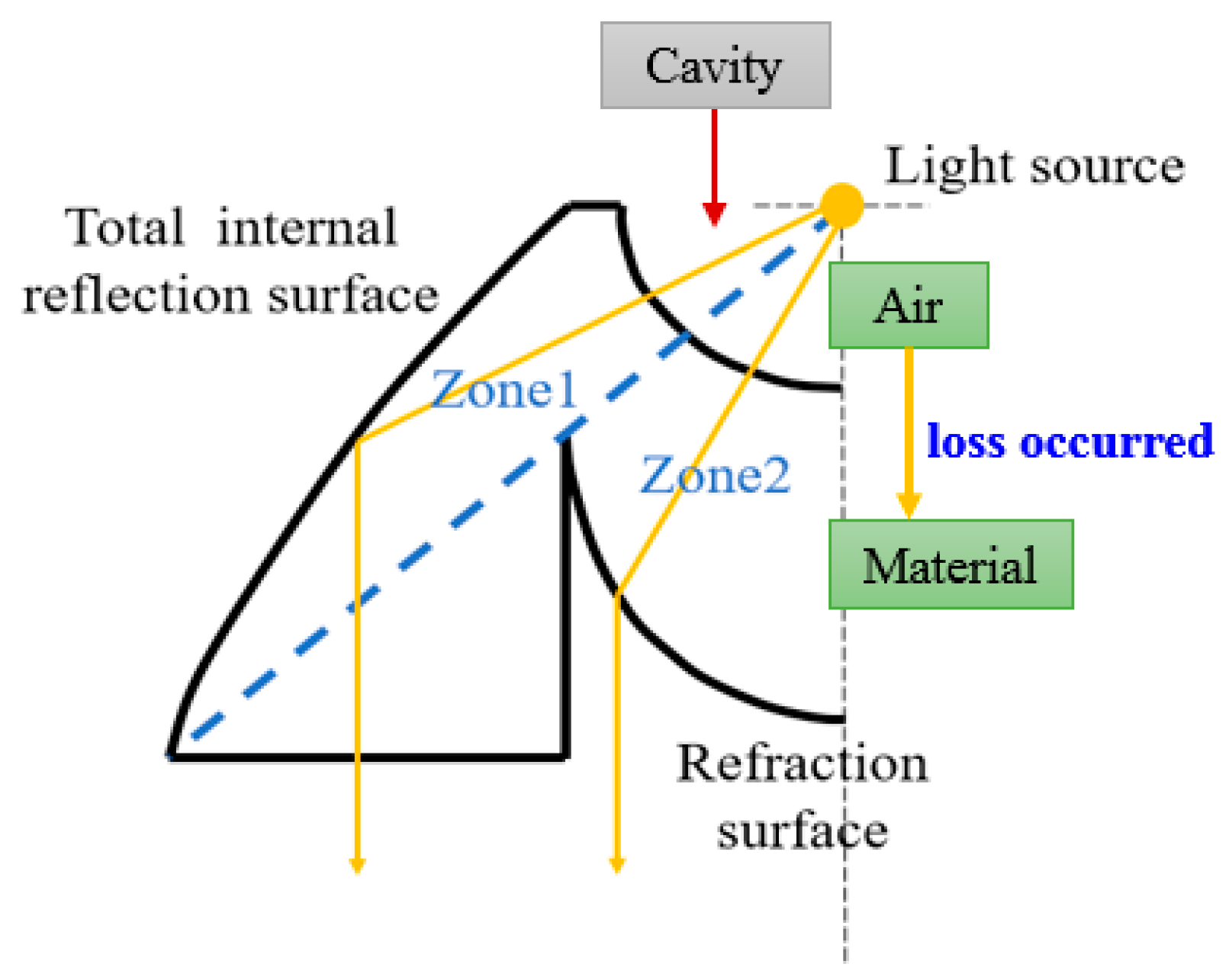

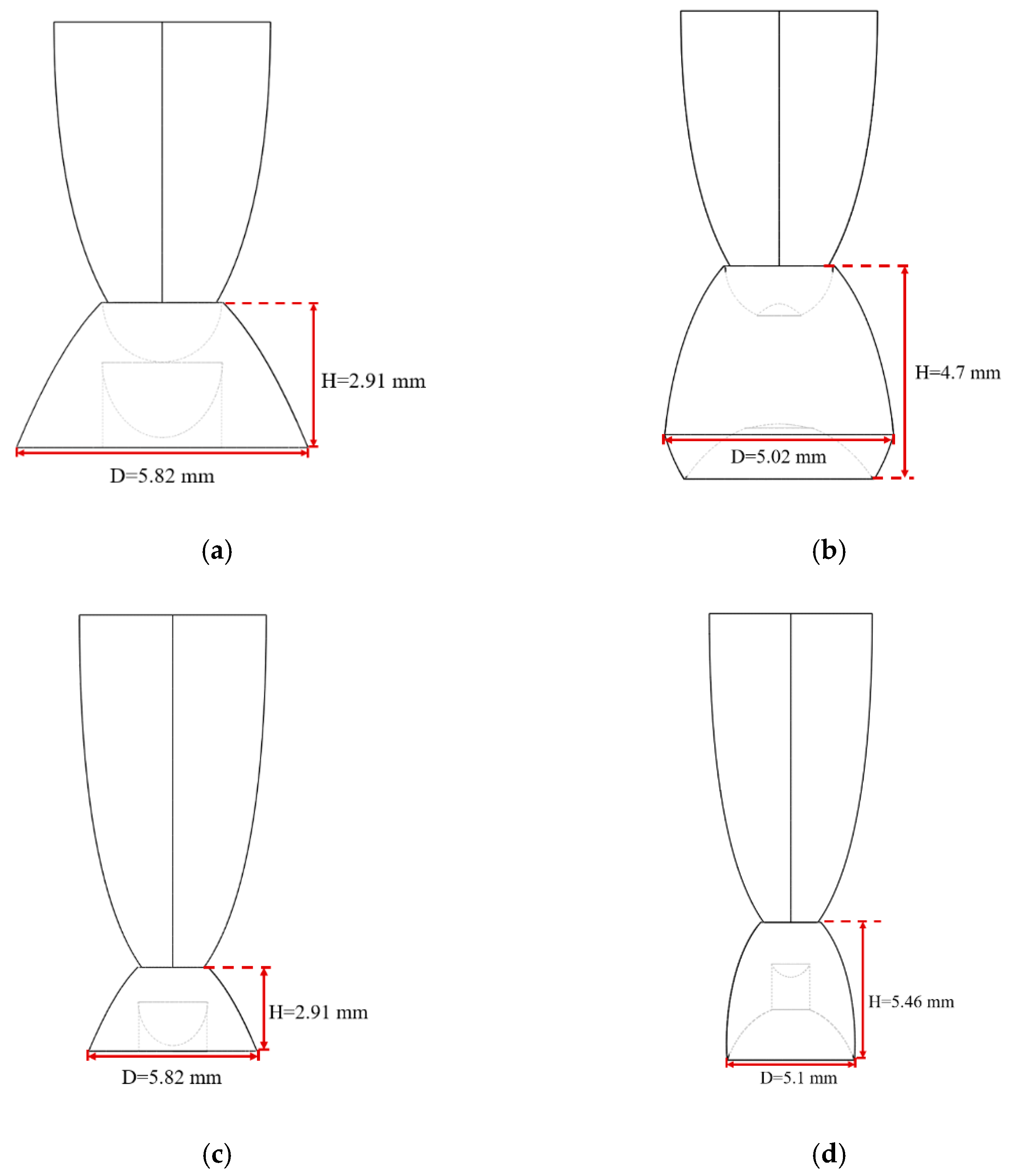

2.1. Non-Axisymmetric Compound Parabolic Curve Design

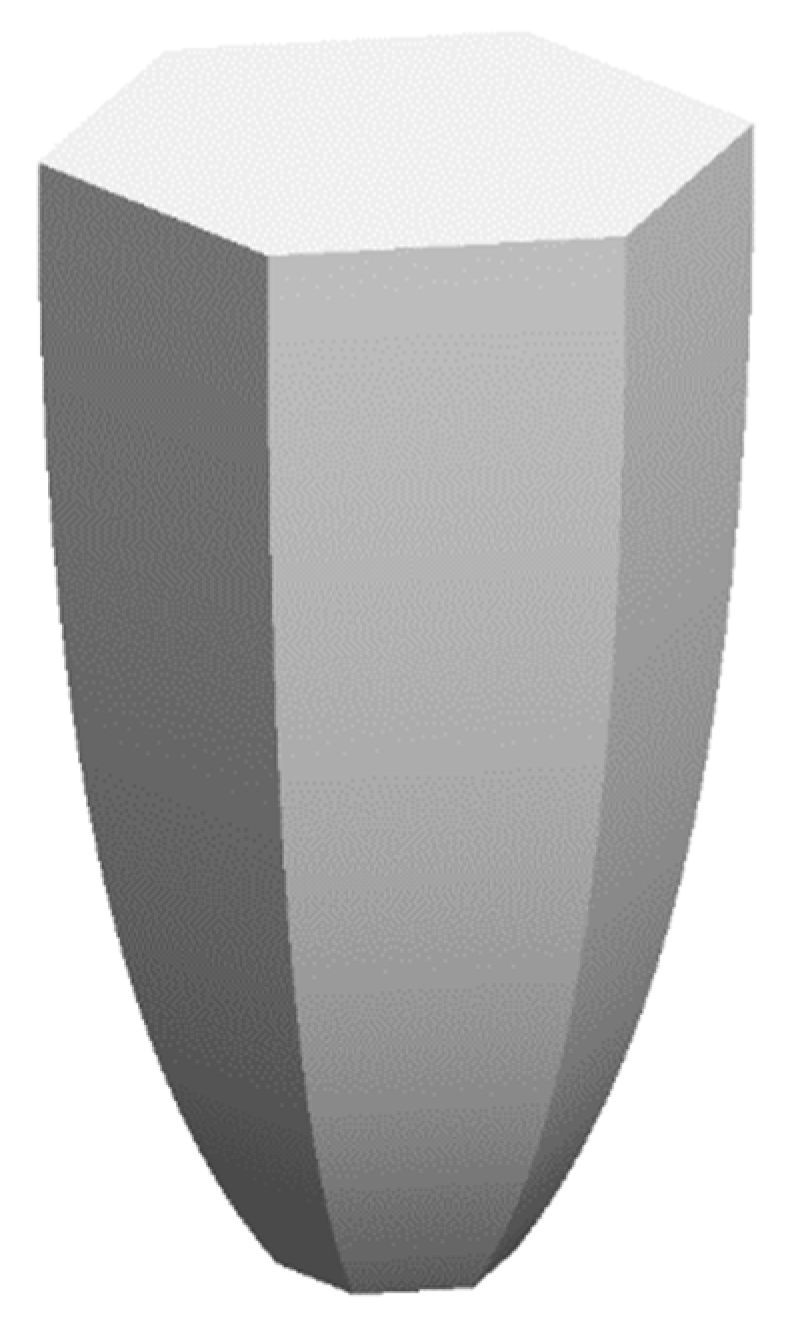

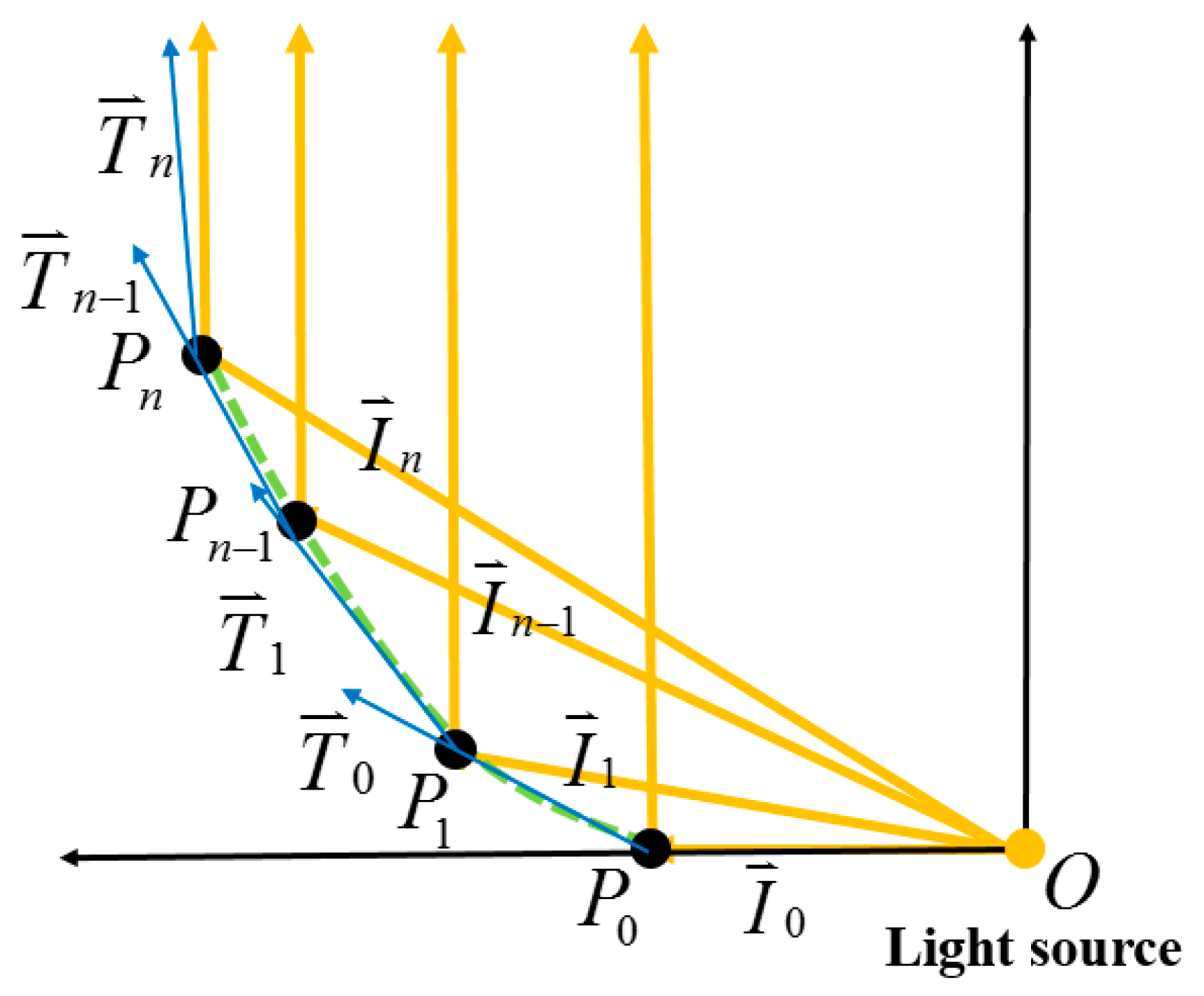

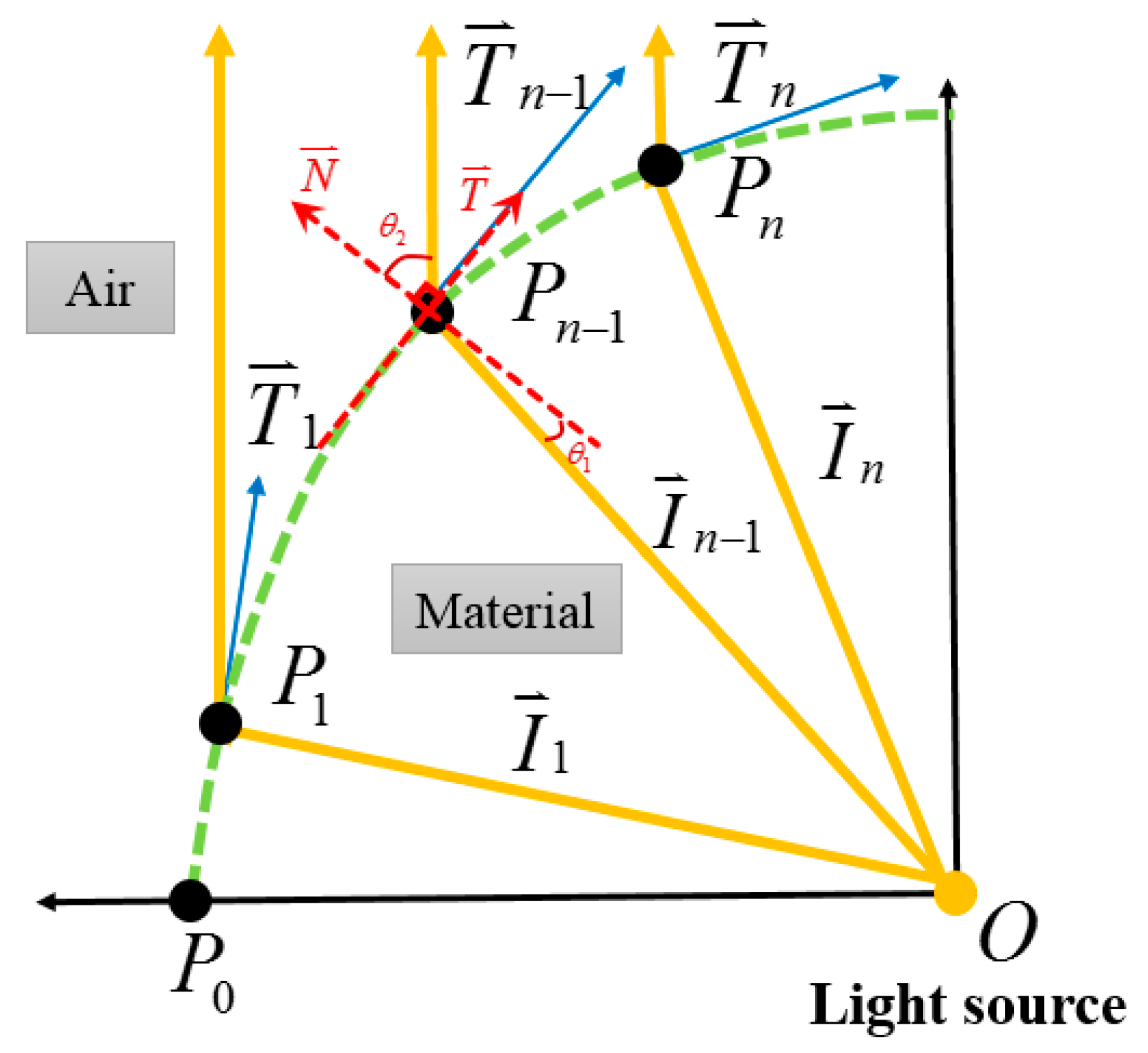

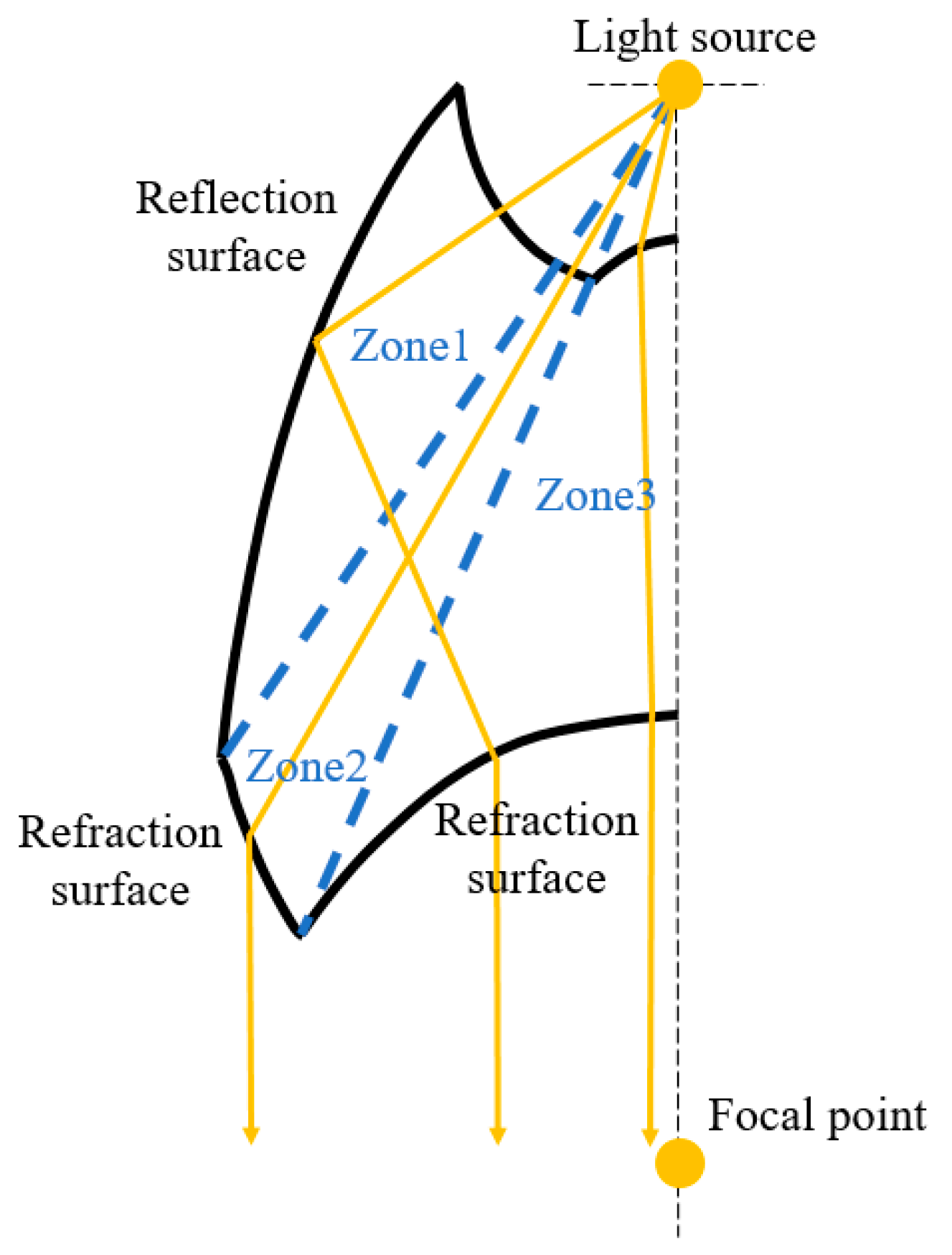

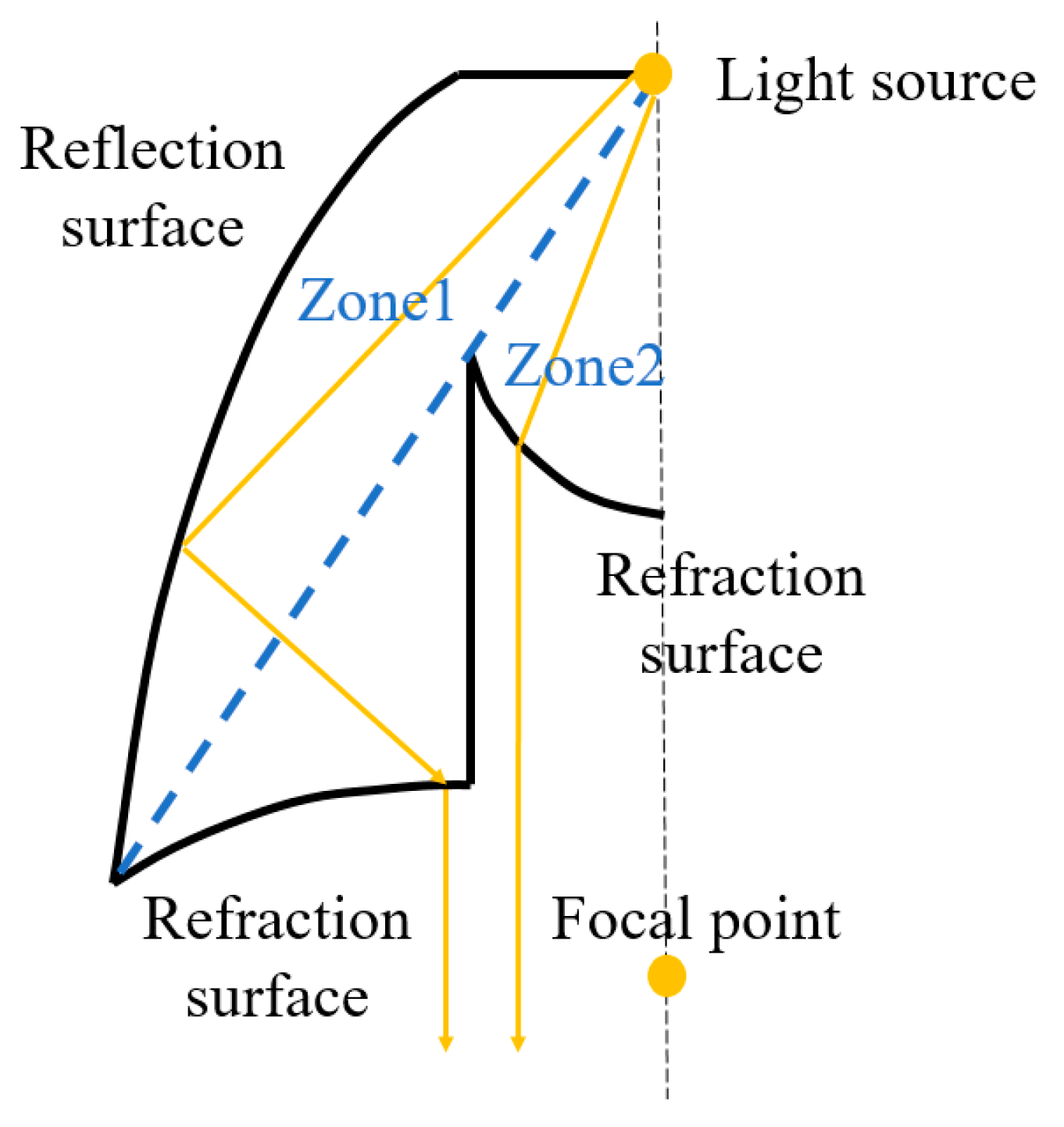

2.2. Freeform Surface Collimator Design

3. Results and Discussion

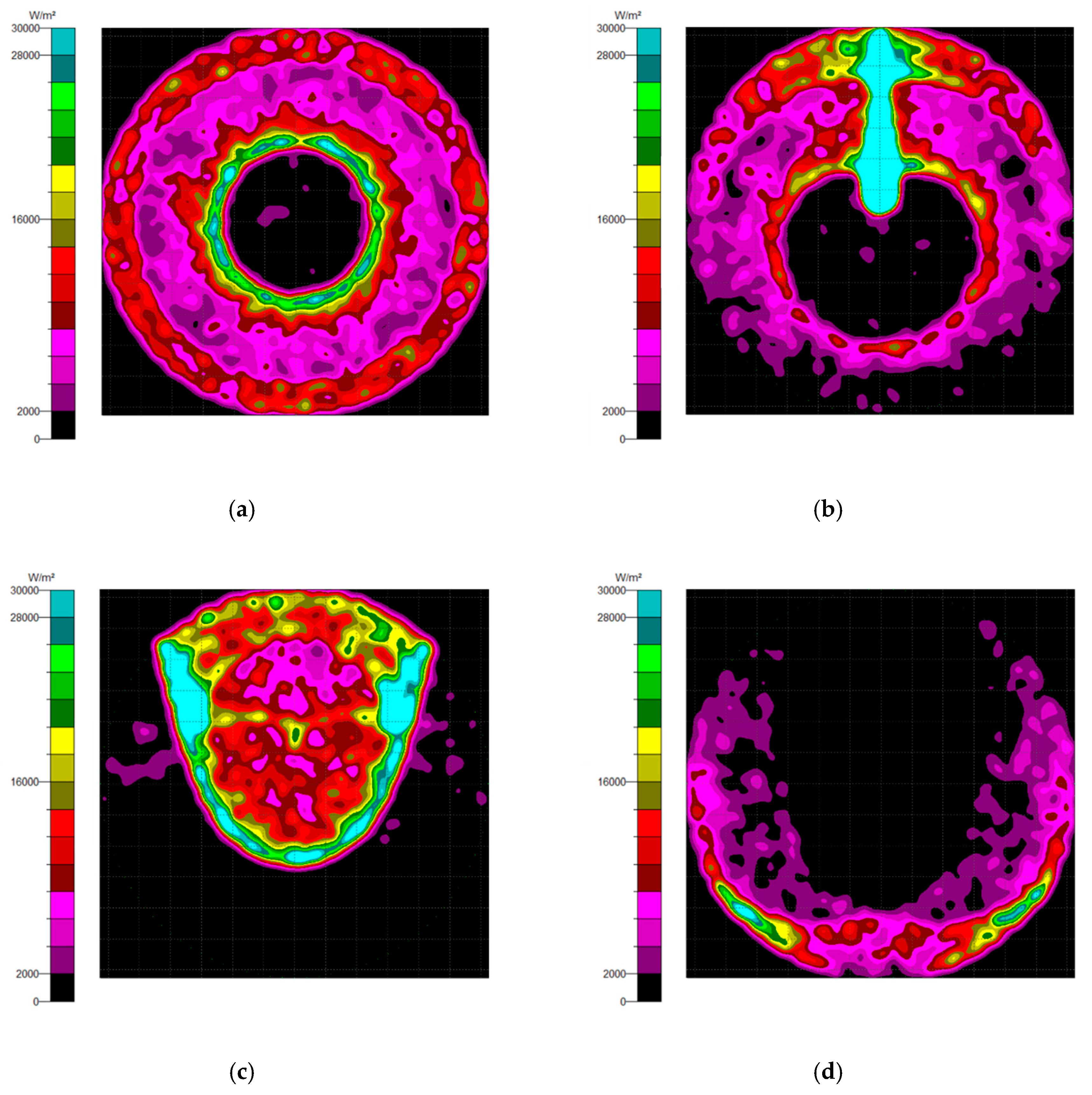

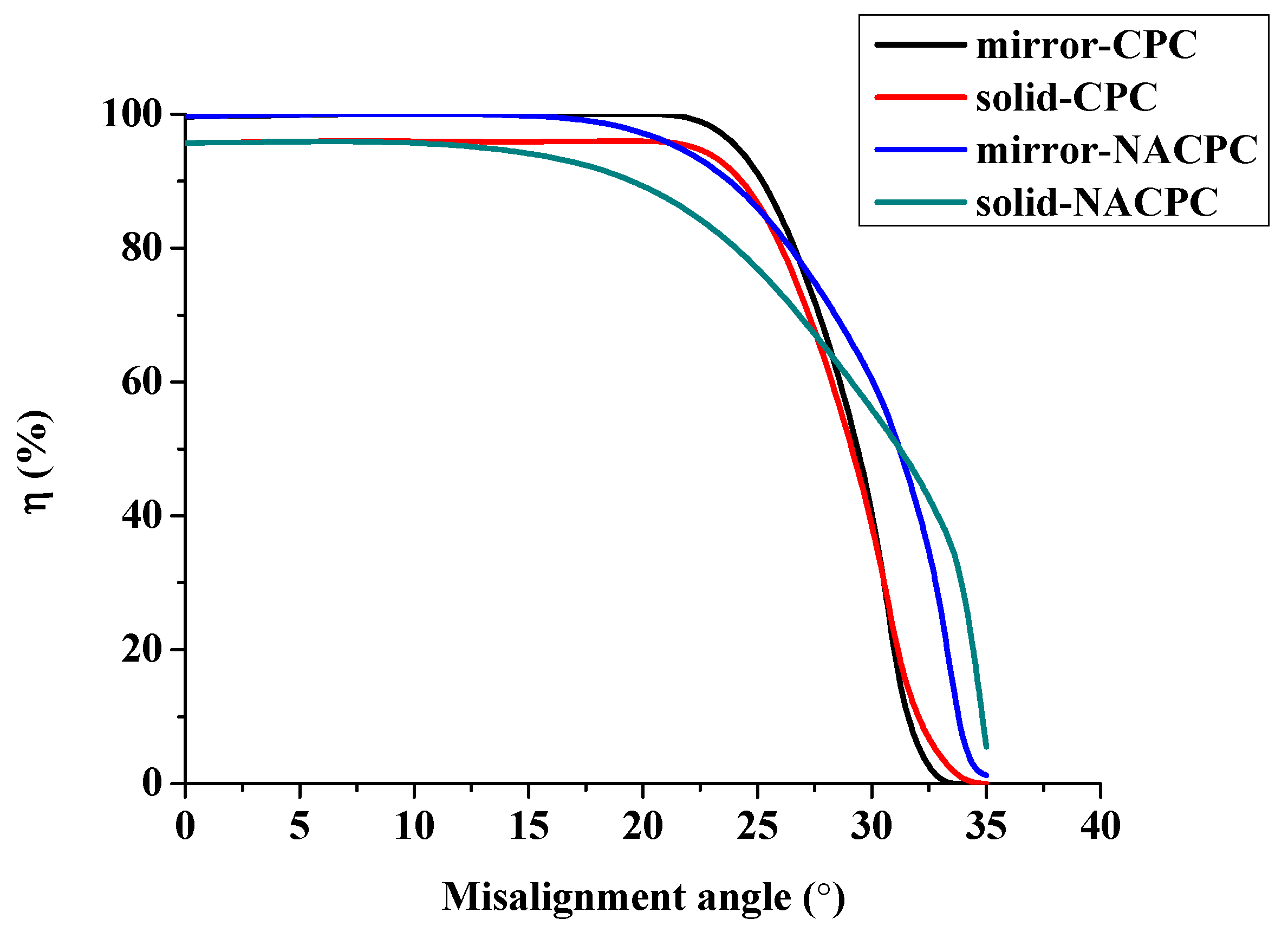

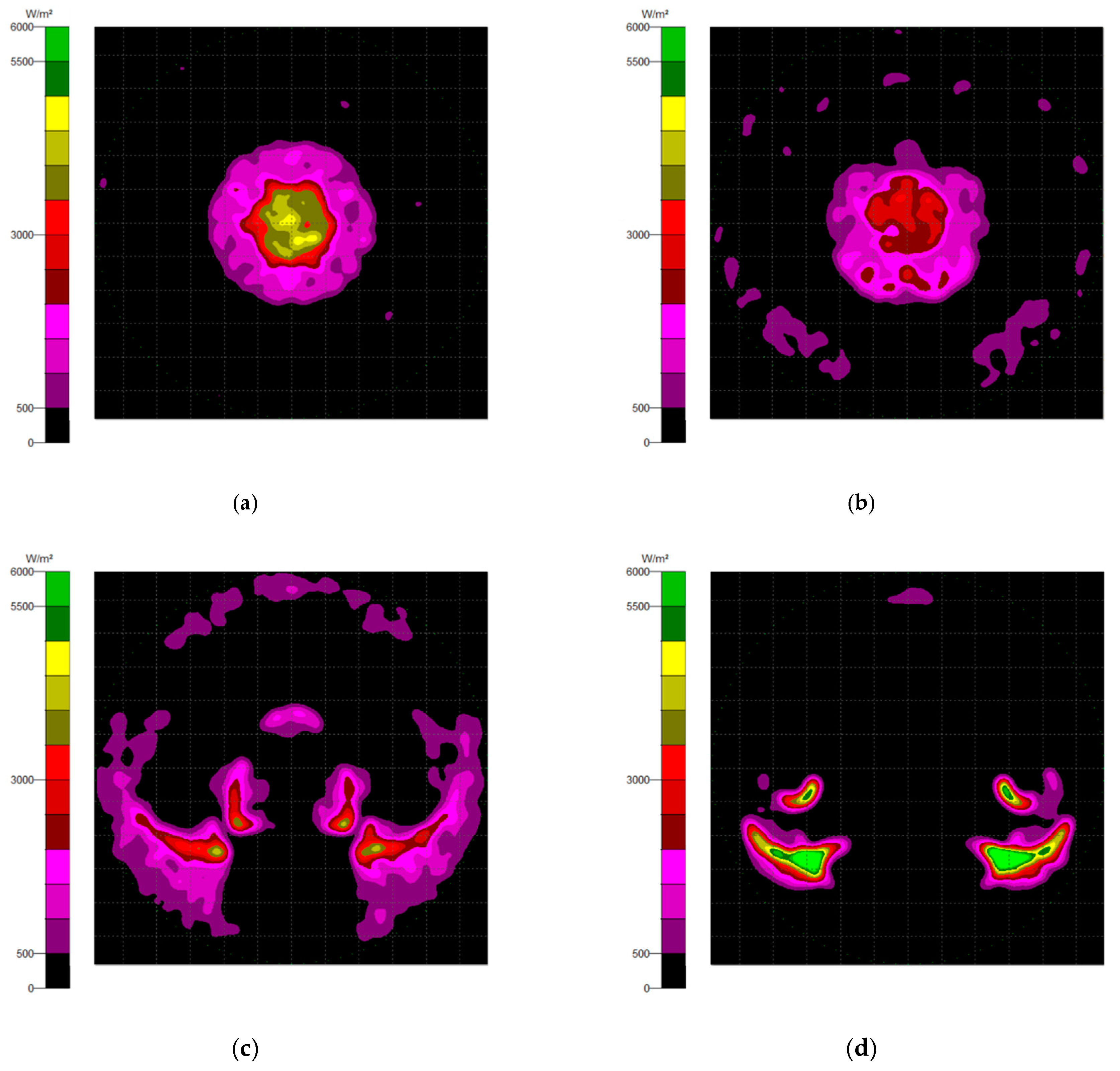

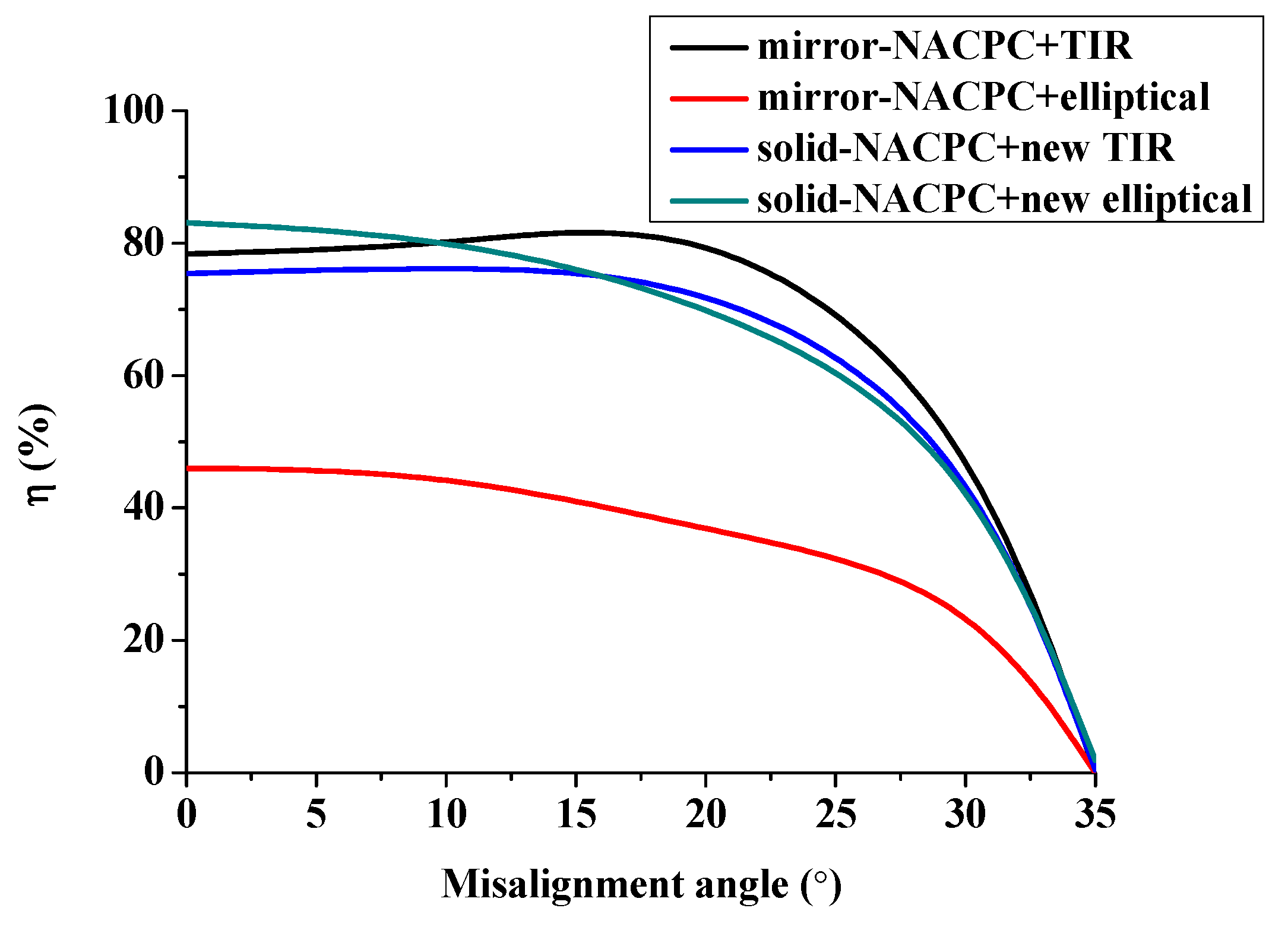

3.1. The Simulation Results of the NACPC

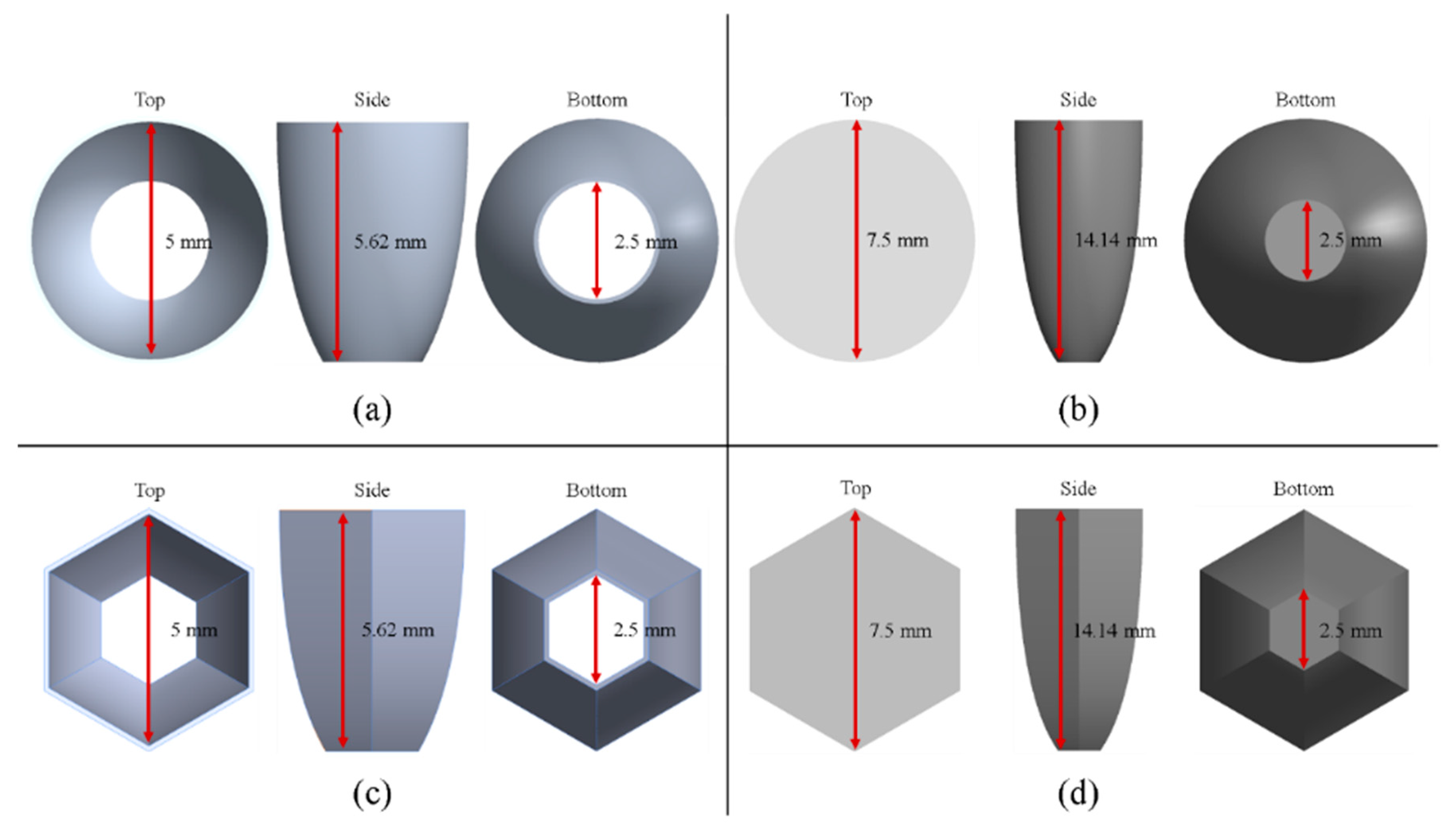

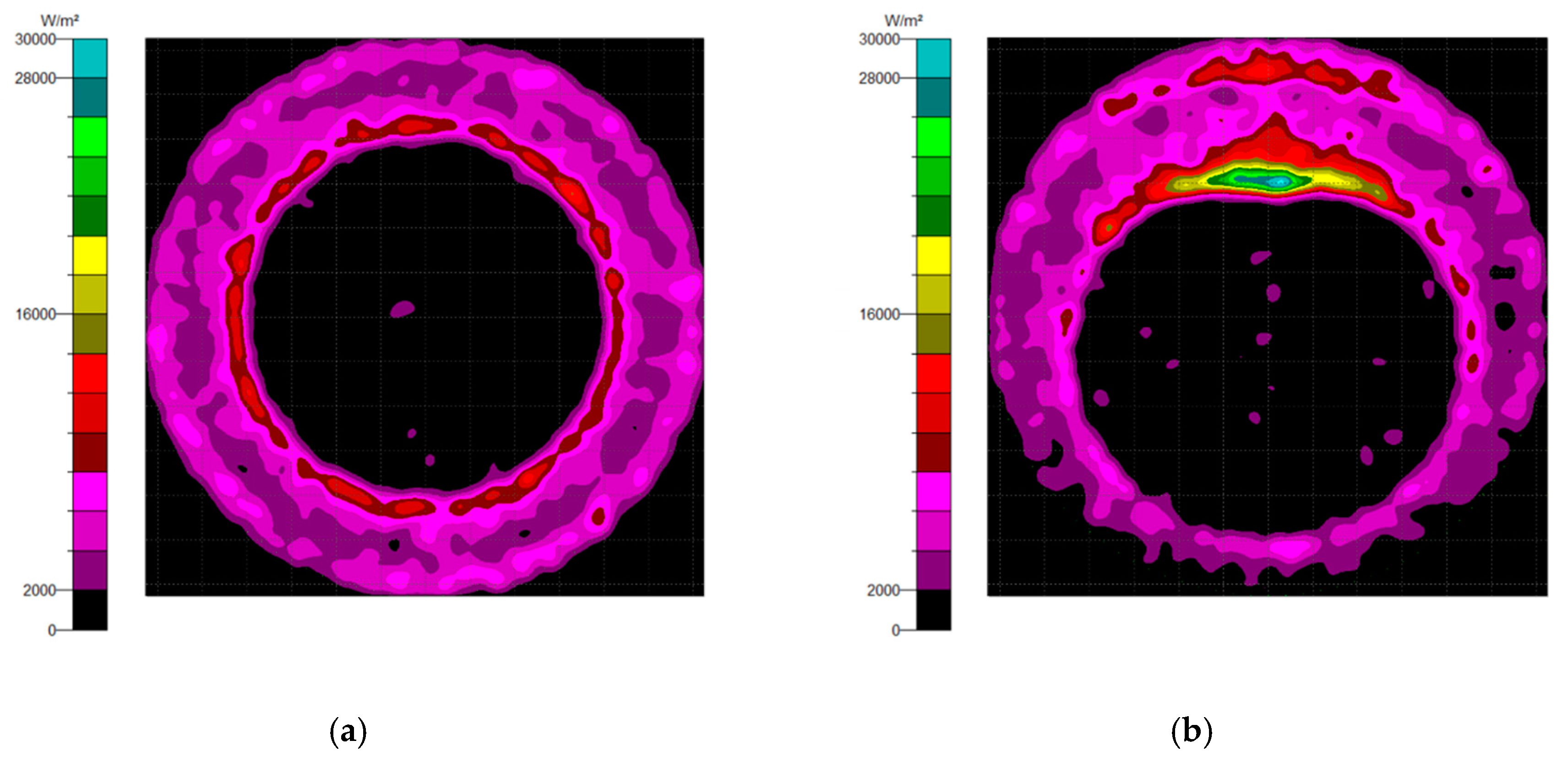

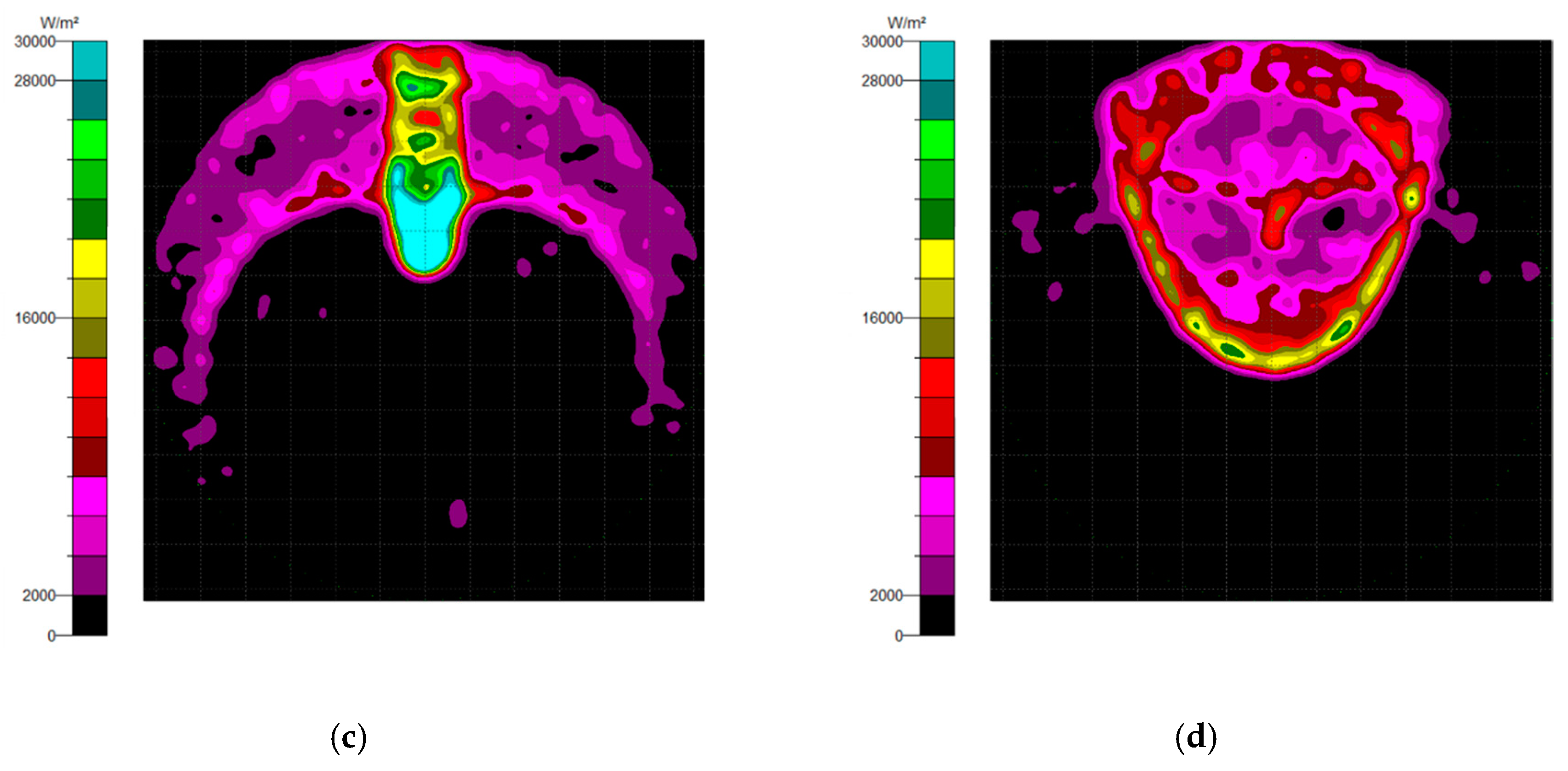

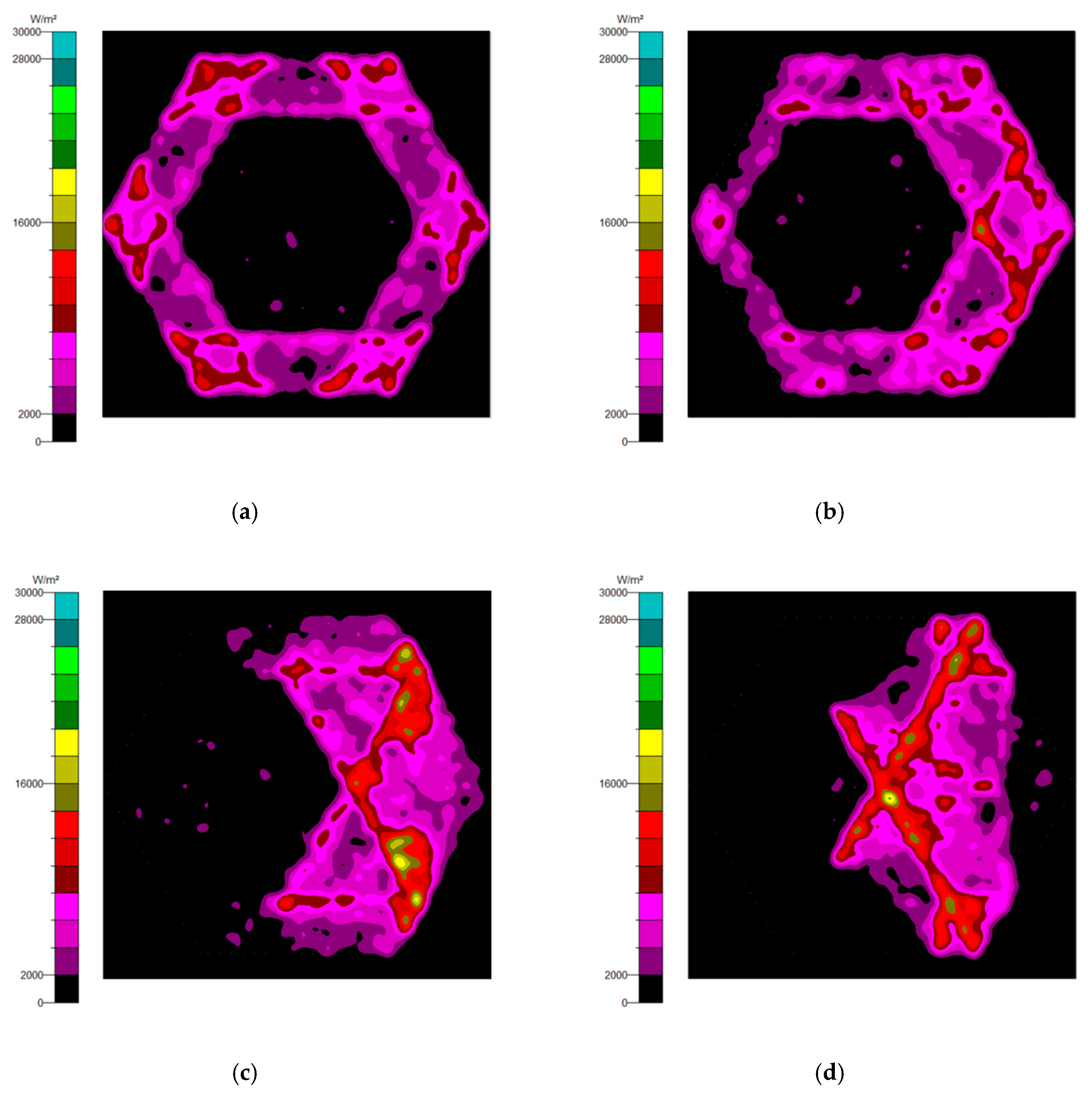

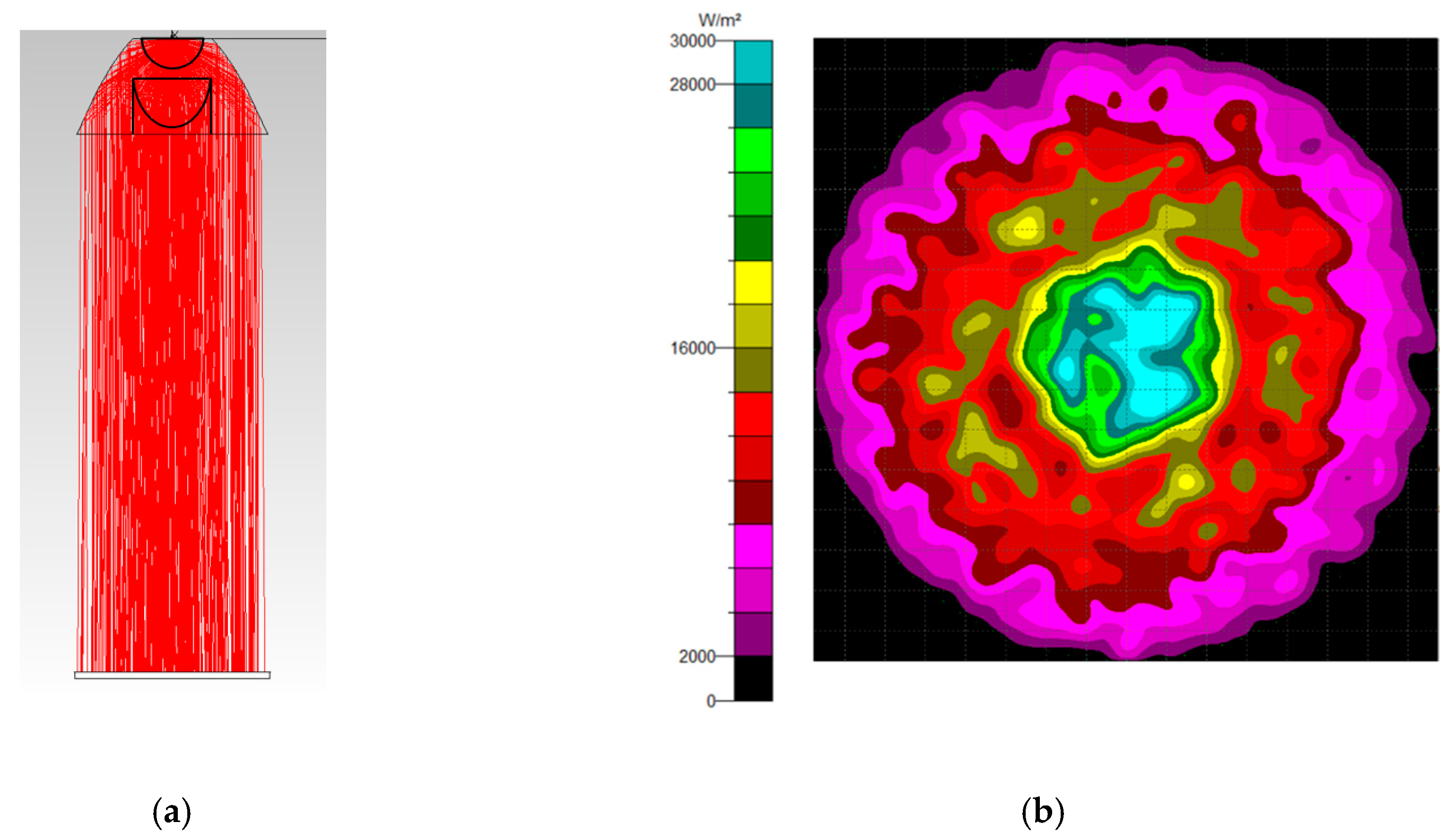

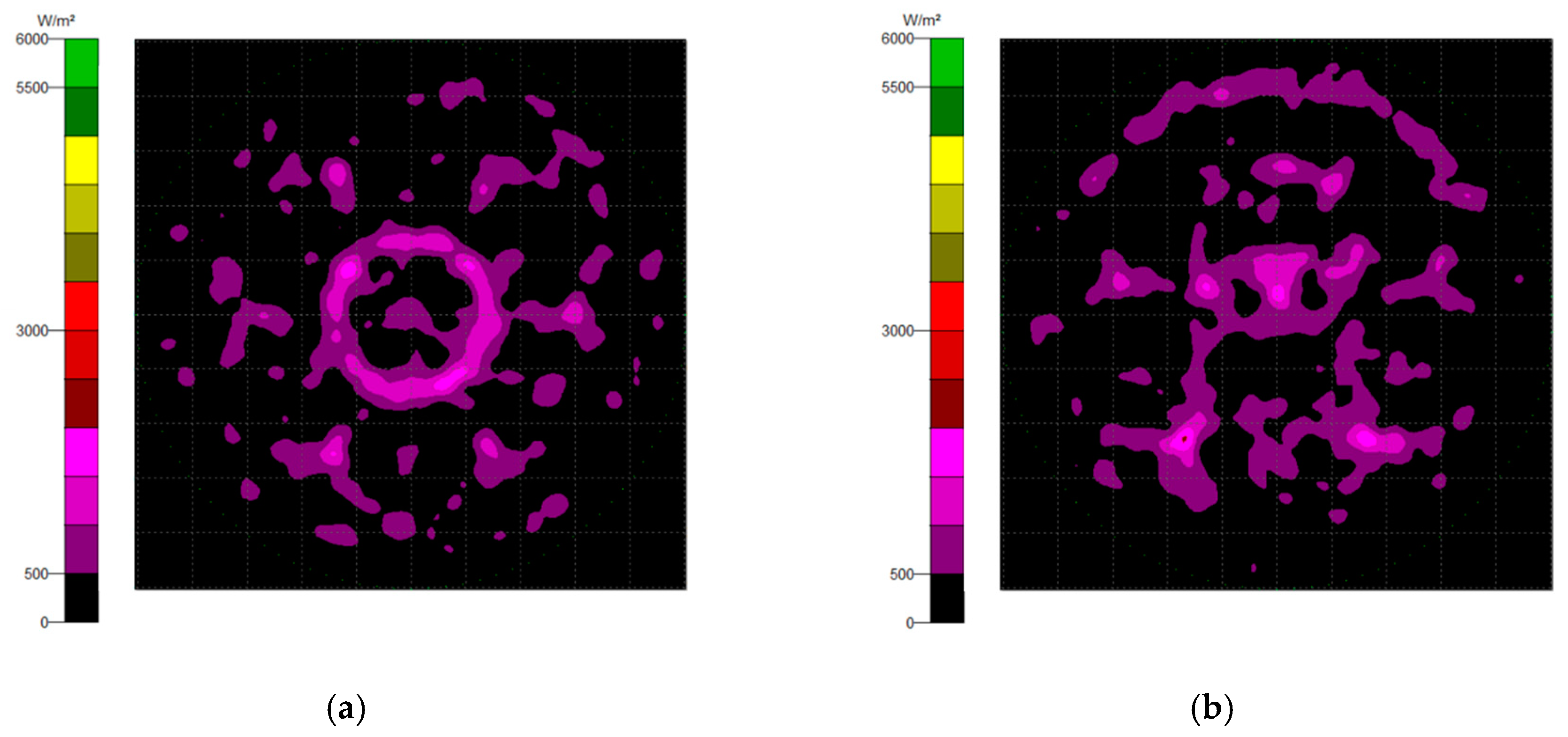

3.2. Simulation Results of the Freeform Surface Collimator

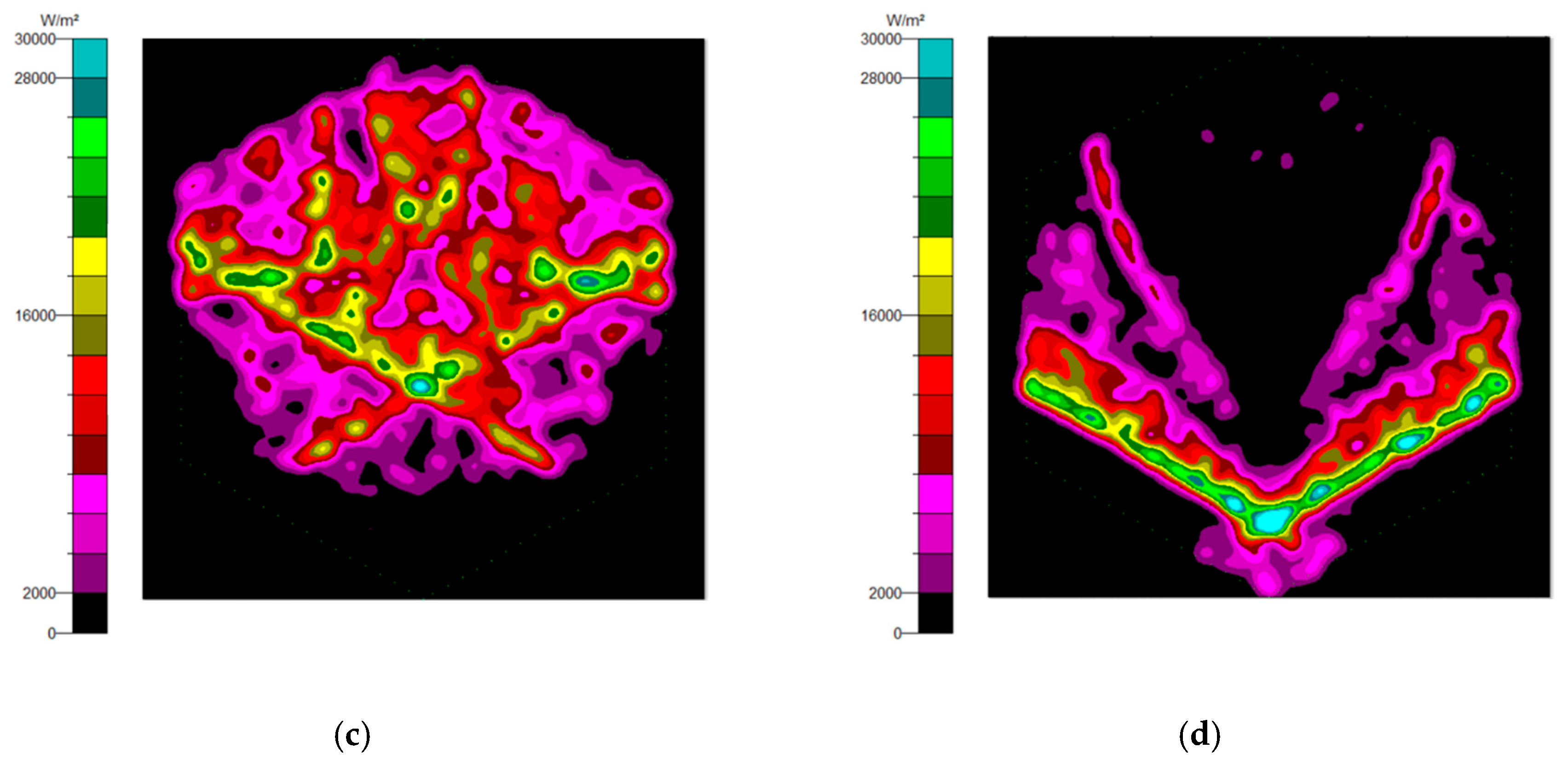

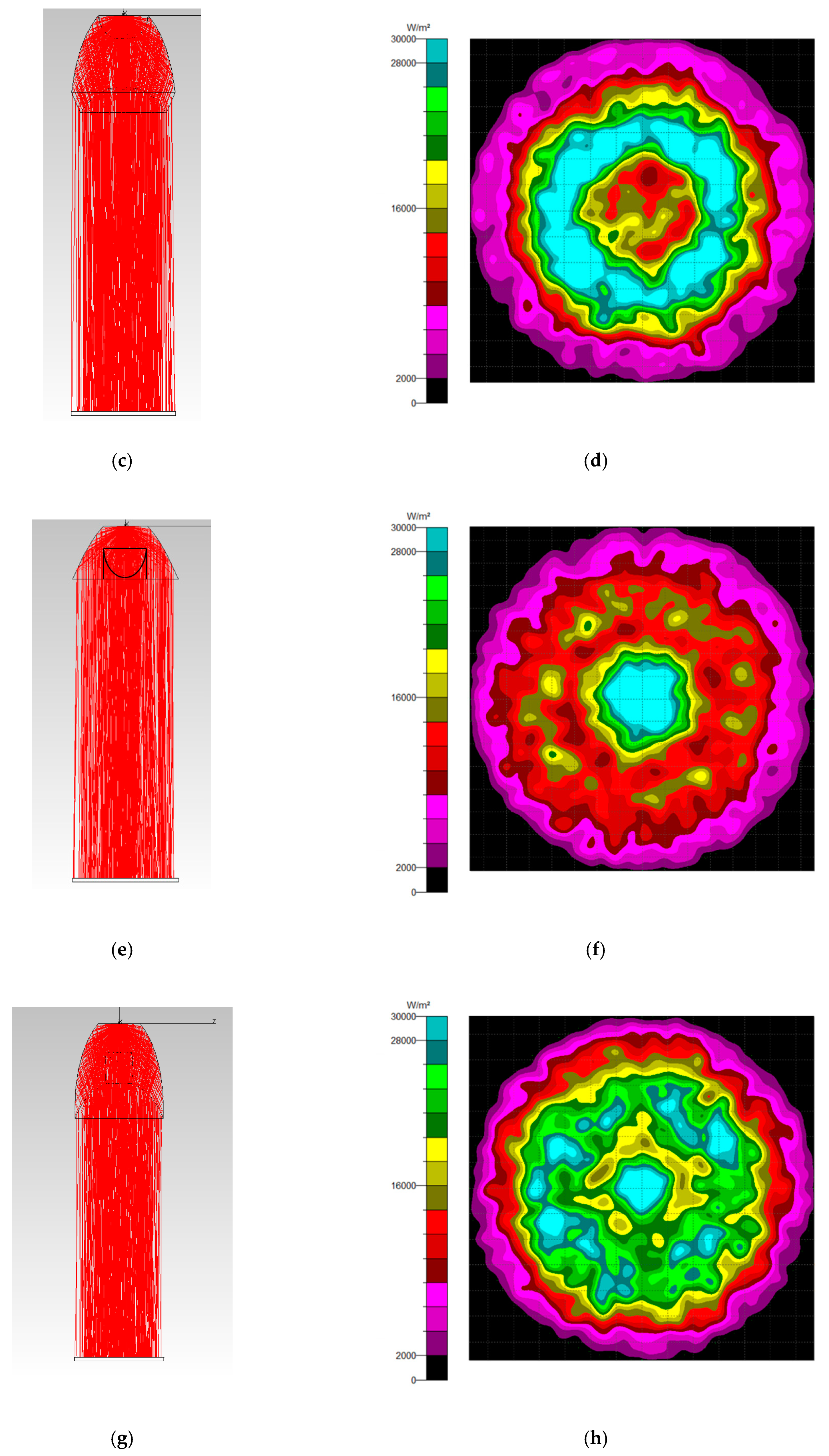

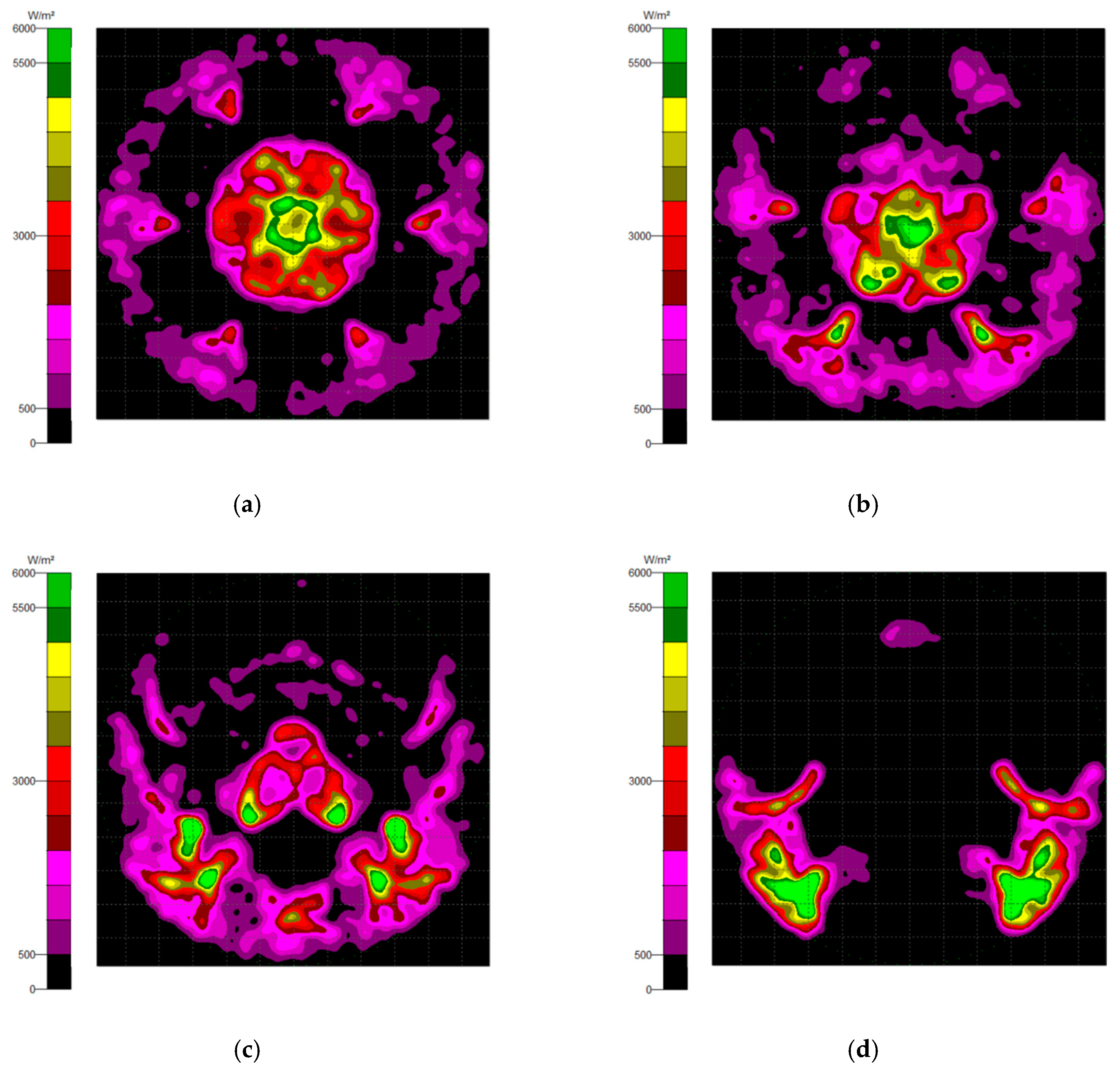

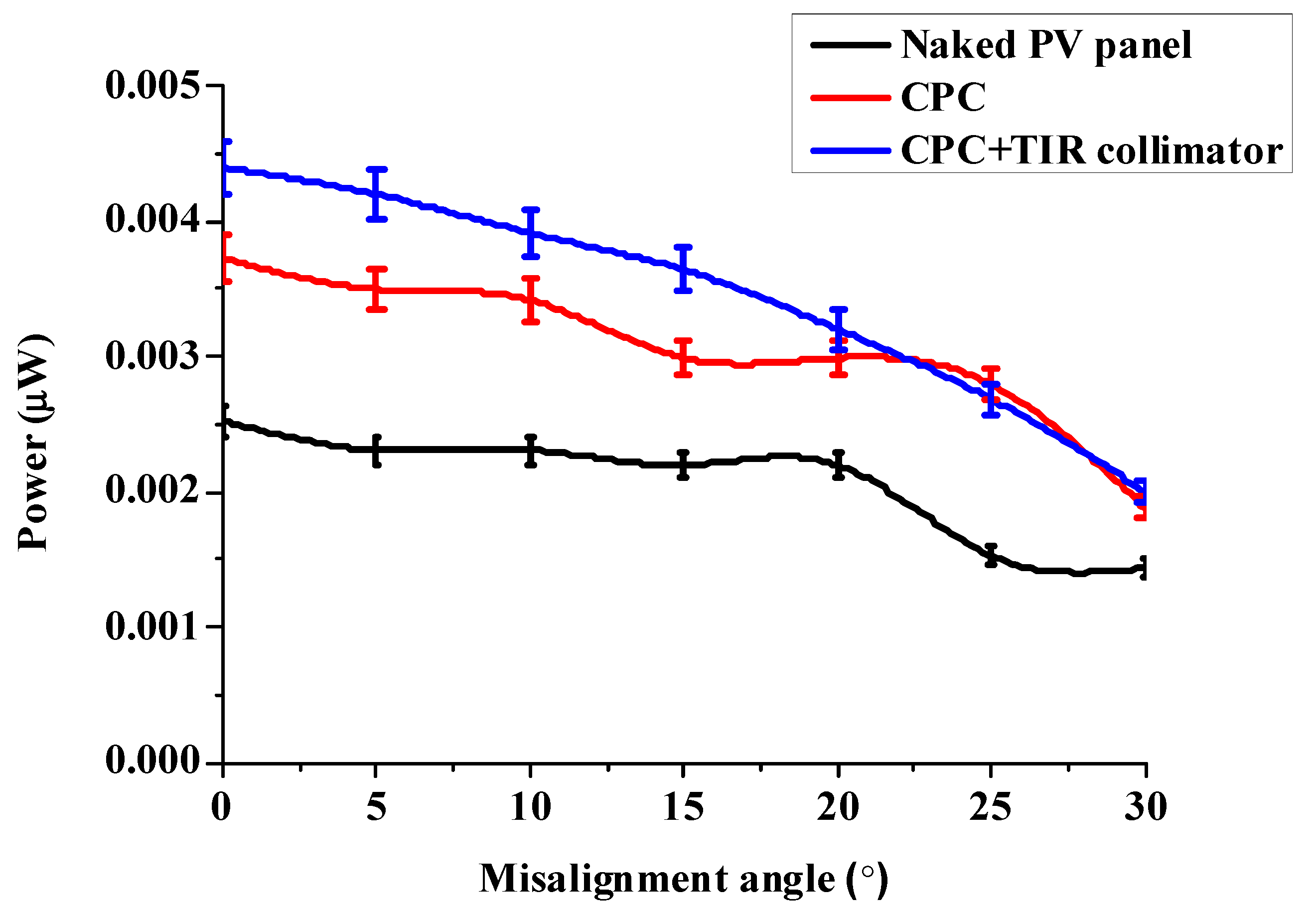

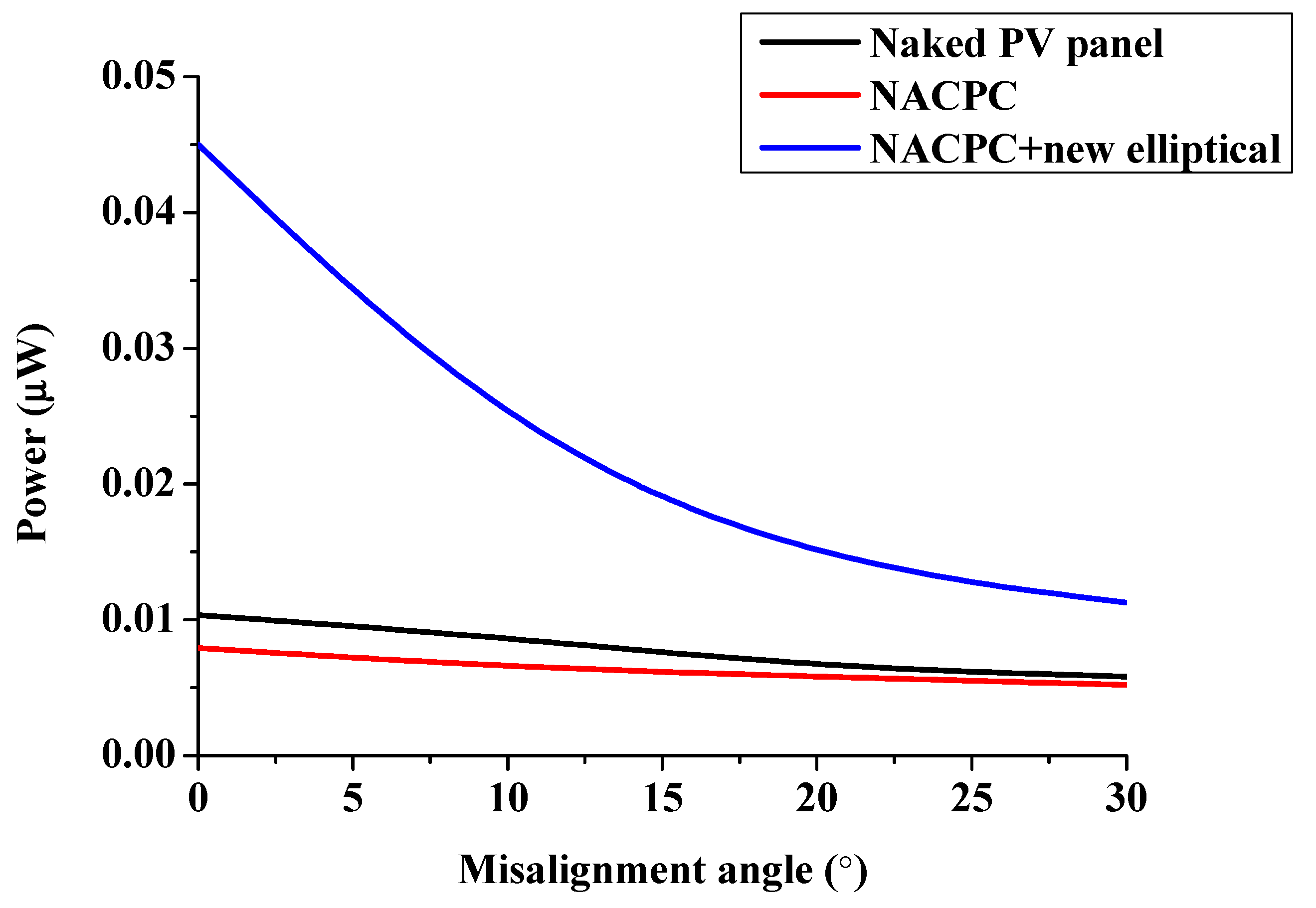

3.3. Analysis of the Misalignment Light-Guiding Unit

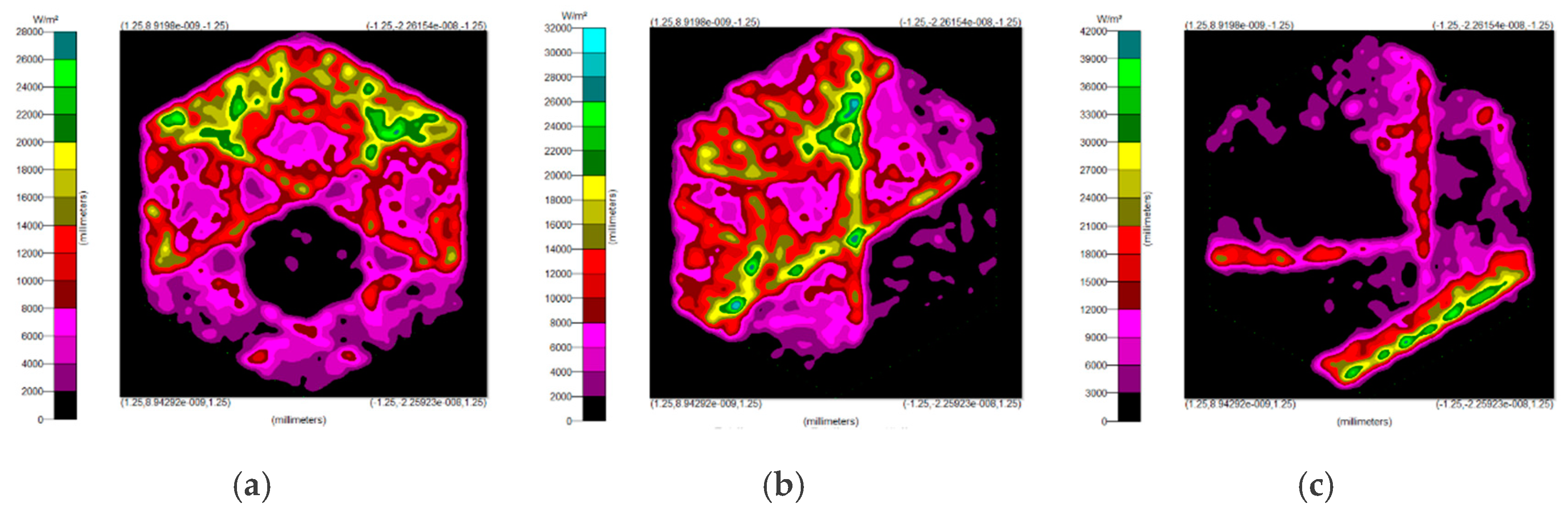

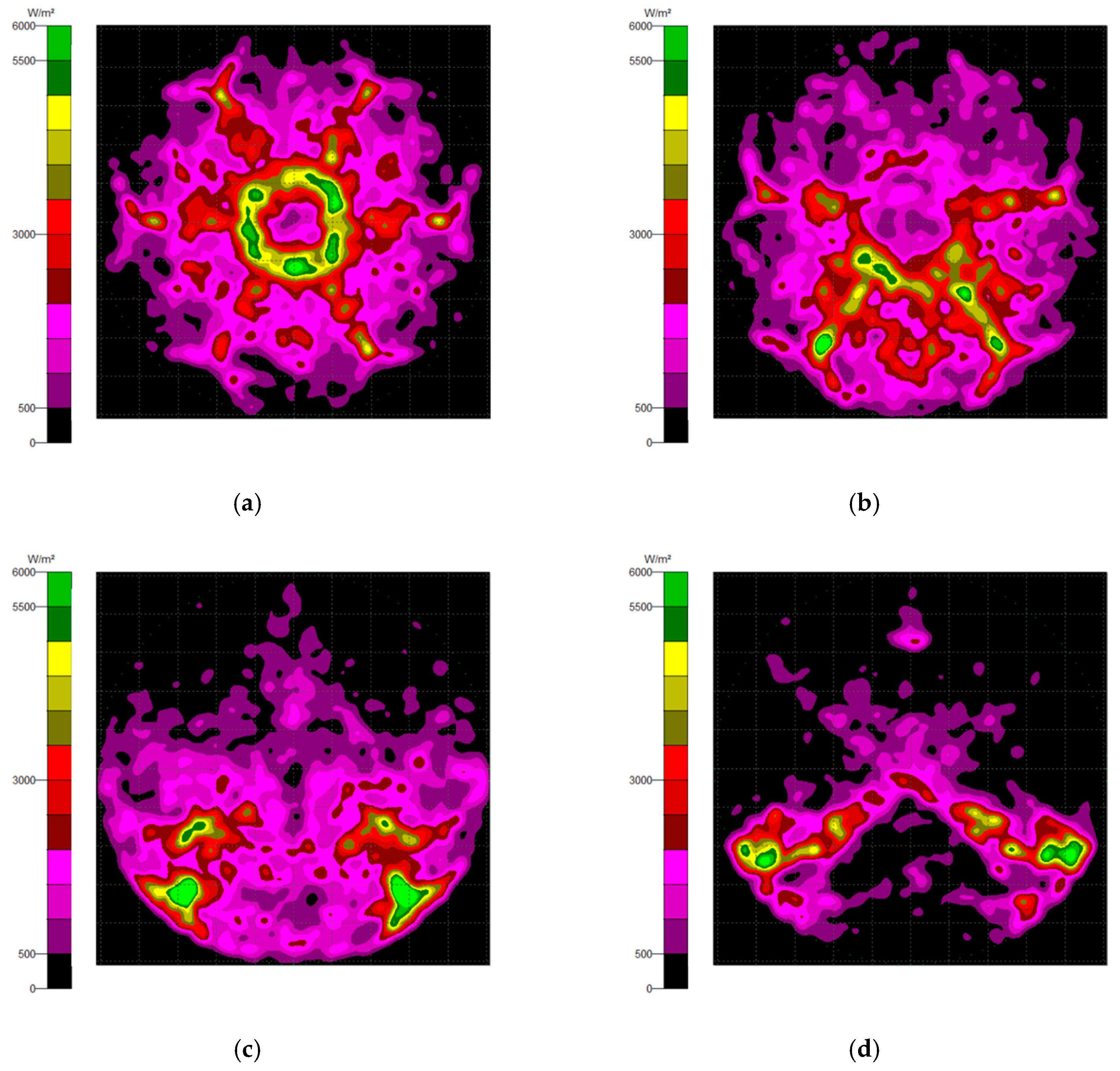

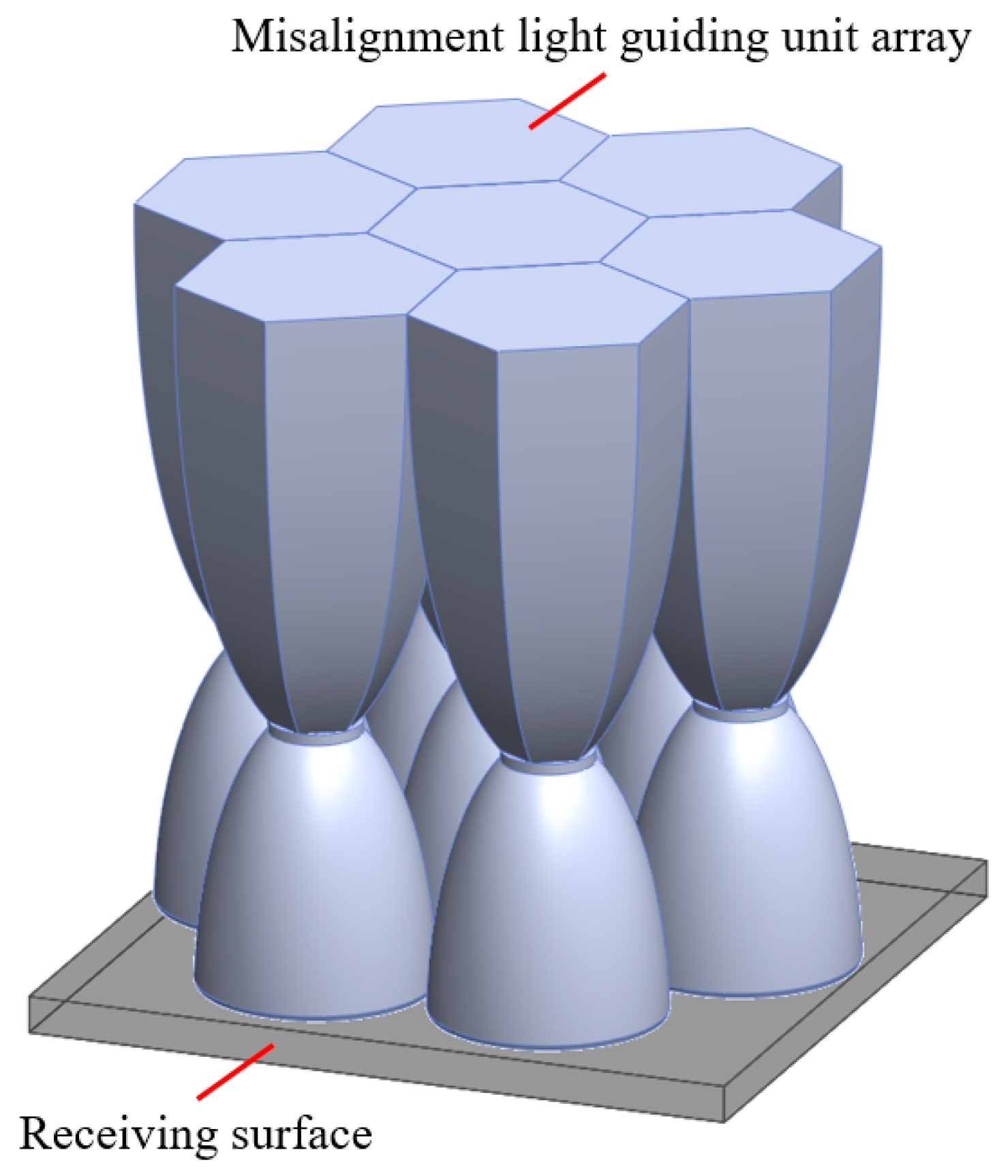

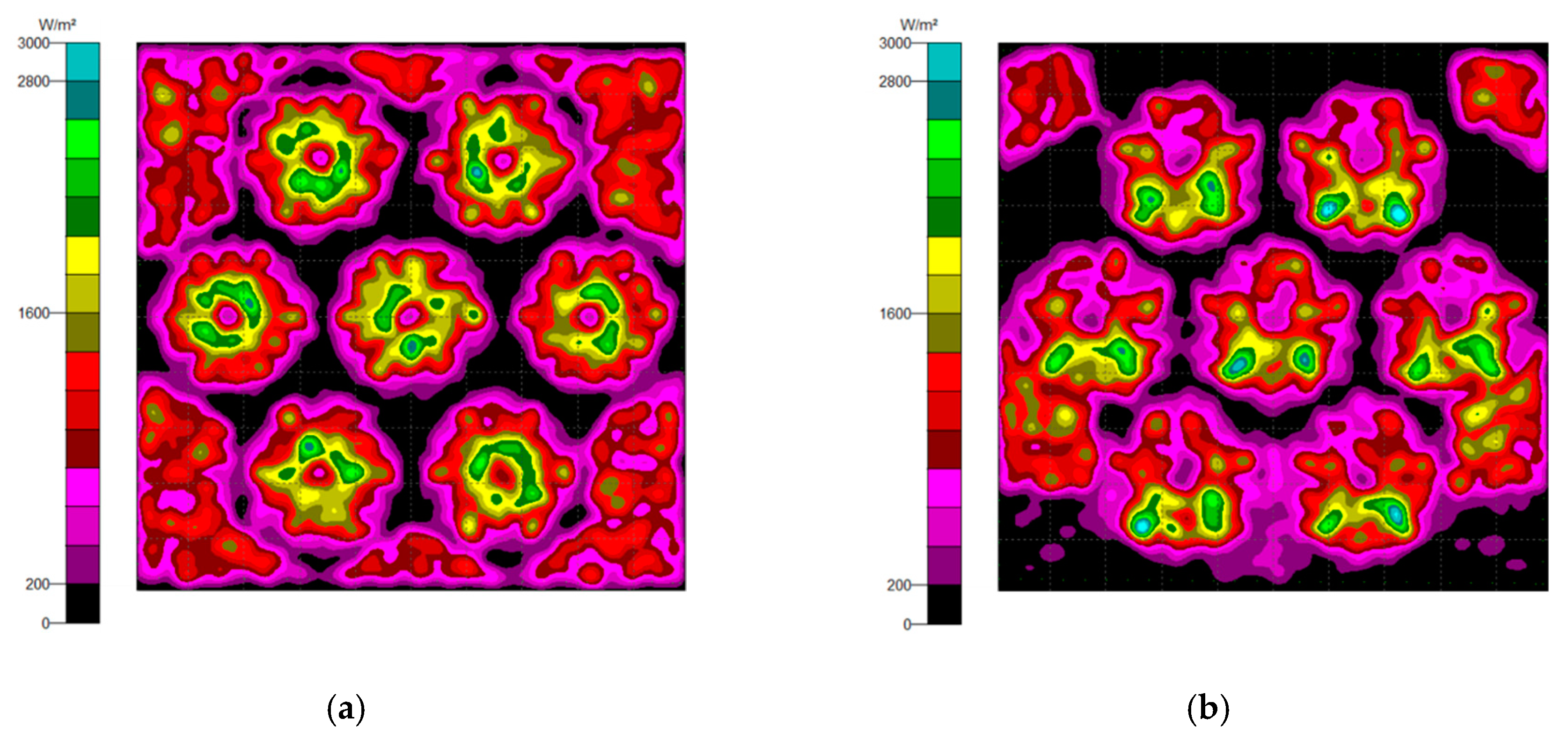

3.4. The Misalignment Light-Guiding Unit Array

3.5. The Misalignment Light-Guiding Unit Array

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Winston, R.; Miñano, J.C.; Benitez, P.G. Nonimaging Optics; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Abbott, D. Keeping the energy debate clean: How do we supply the world’s energy needs? Proc. IEEE 2010, 98, 42–66. [Google Scholar] [CrossRef]

- Mallick, T.; Eames, P. Design and fabrication of low concentrating second generation PRIDE concentrator. Sol. Energy Mater. Sol. Cells 2007, 91, 597–608. [Google Scholar] [CrossRef]

- Rosell, J.; Vallverdú, X.; Lechón, M.; Ibáñez, M. Design and simulation of a low concentrating photovoltaic/thermal system. Energy Convers. Manag. 2005, 46, 3034–3046. [Google Scholar] [CrossRef]

- Muhammad-Sukki, F.; Ramirez-Iniguez, R.; McMeekin, S.G.; Stewart, B.G.; Clive, B. Solar concentrators. Int. J. Appl. Sci. 2010, 1, 1–15. [Google Scholar]

- Luque, A.; Araújo, G.L. Solar Cells and Optics for Photovoltaic Concentration; Hilger, A., Ed.; CRC Press: Boca Raton, FL, USA, 1989. [Google Scholar]

- Welford, W.T. High Collection Nonimaging Optics; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Winston, R. Dielectric compound parabolic concentrators. Appl. Opt. 1976, 15, 291–292. [Google Scholar] [CrossRef] [PubMed]

- Zacharopoulos, A.; Eames, P.; McLarnon, D.; Norton, B. Linear Dielectric Non-Imaging Concentrating Covers For PV Integrated Building Facades. Sol. Energy 2000, 68, 439–452. [Google Scholar] [CrossRef]

- Yoshioka, K.; Suzuki, A.; Saitoh, T. Performance evaluation of two-dimensional compound elliptic lens concentrators using a yearly distributed insolation model. Sol. Energy Mater. Sol. Cells 1999, 57, 9–19. [Google Scholar] [CrossRef]

- Uematsu, T.; Warabisako, T.; Yazawa, Y.; Muramatsu, S. Static micro-concentrator photovoltaic module with an acorn shape reflector. In Proceedings of the 2nd World Conference and Exhibition on Photovoltaic Solar Energy Conversion, Vienna, Austria, 6–10 July 1998; pp. 1570–1573. [Google Scholar]

- Moehlecke, A.; Krenzinger, A.; Santos, G. Modules Assembled with Diffuse Reflectors for Photovoltaic Bifacial Cells. In Proceedings of the Tenth E.C. Photovoltaic Solar Energy Conference, Lisbon, Portugal, 8–12 April 1991; Springer Science and Business Media LLC: Berlin, Germany, 1991; pp. 967–970. [Google Scholar]

- Antonini, A.; Stefancich, M.; Coventry, J.; Parretta, A. Modelling of Compound Parabolic Concentrators for Photovoltaic Applications. Int. J. Opt. Appl. 2013, 3, 40–52. [Google Scholar] [CrossRef] [Green Version]

- Shaw, N.; Wenham, S. Design of a novel static concentrator lens utilising total internal reflection surfaces. In Proceedings of the 16th European Photovoltaic Solar Energy Conference, Glasgow, UK, 1–5 May 2000; pp. 2342–2345. [Google Scholar]

- Parretta, A.; Martinelli, G.; Stefancich, M.; Vincenzi, D.; Winston, R. Modelling of CPC-based photovoltaic concentrator. In Proceedings of the 19th Congress of the International Commission for Optics: Optics for the Quality of Life, Florence, Italy, 25–30 August 2003; pp. 1045–1047. [Google Scholar]

- Su, Y.; Pei, G.; Riffat, S.B.; Huang, H. A Novel Lens-Walled Compound Parabolic Concentrator for Photovoltaic Applications. J. Sol. Energy Eng. 2012, 134, 021010. [Google Scholar] [CrossRef]

- Abu-Bakar, S.H.; Muhammad-Sukki, F.; Ramirez-Iniguez, R.; Mallick, T.K.; Munir, A.B.; Yasin, S.H.M.; Rahim, R.A. Rotationally asymmetrical compound parabolic concentrator for concentrating photovoltaic applications. Appl. Energy 2014, 136, 363–372. [Google Scholar] [CrossRef]

- Hsu, F.-T. The Design and Fabrication for the Controllable Optical Field of Multi-Curvature Lens with Thin Film Metallic Glasses. Master’s Thesis, National Sun Yat-Sen University, Kaohsiung, Taiwan, 2013. [Google Scholar]

- Chen, J.-J.; Wang, T.-Y.; Huang, K.-L.; Liu, T.-S.; Tsai, M.-D.; Lin, C.-T. Freeform lens design for LED collimating illumination. Opt. Express 2012, 20, 10984–10995. [Google Scholar] [CrossRef] [PubMed] [Green Version]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, C.-T.; Yen, C.-K.; Wang, S.-Y.; Sun, P.-Y.; Huang, S.-Y.; Hwang, Y.-M.; Liu, Z.-H.; Chu, L.-M.; Hoe, Z.-Y. A Misalignment Optical Guiding Module for Power Generation Enhancement of Fixed-Type Photovoltaic Systems. Micromachines 2019, 10, 687. https://doi.org/10.3390/mi10100687

Pan C-T, Yen C-K, Wang S-Y, Sun P-Y, Huang S-Y, Hwang Y-M, Liu Z-H, Chu L-M, Hoe Z-Y. A Misalignment Optical Guiding Module for Power Generation Enhancement of Fixed-Type Photovoltaic Systems. Micromachines. 2019; 10(10):687. https://doi.org/10.3390/mi10100687

Chicago/Turabian StylePan, Cheng-Tang, Chung-Kun Yen, Shao-Yu Wang, Pei-Yuan Sun, Sin-Yu Huang, Yeong-Maw Hwang, Zong-Hsin Liu, Li-Ming Chu, and Zheng-Yu Hoe. 2019. "A Misalignment Optical Guiding Module for Power Generation Enhancement of Fixed-Type Photovoltaic Systems" Micromachines 10, no. 10: 687. https://doi.org/10.3390/mi10100687