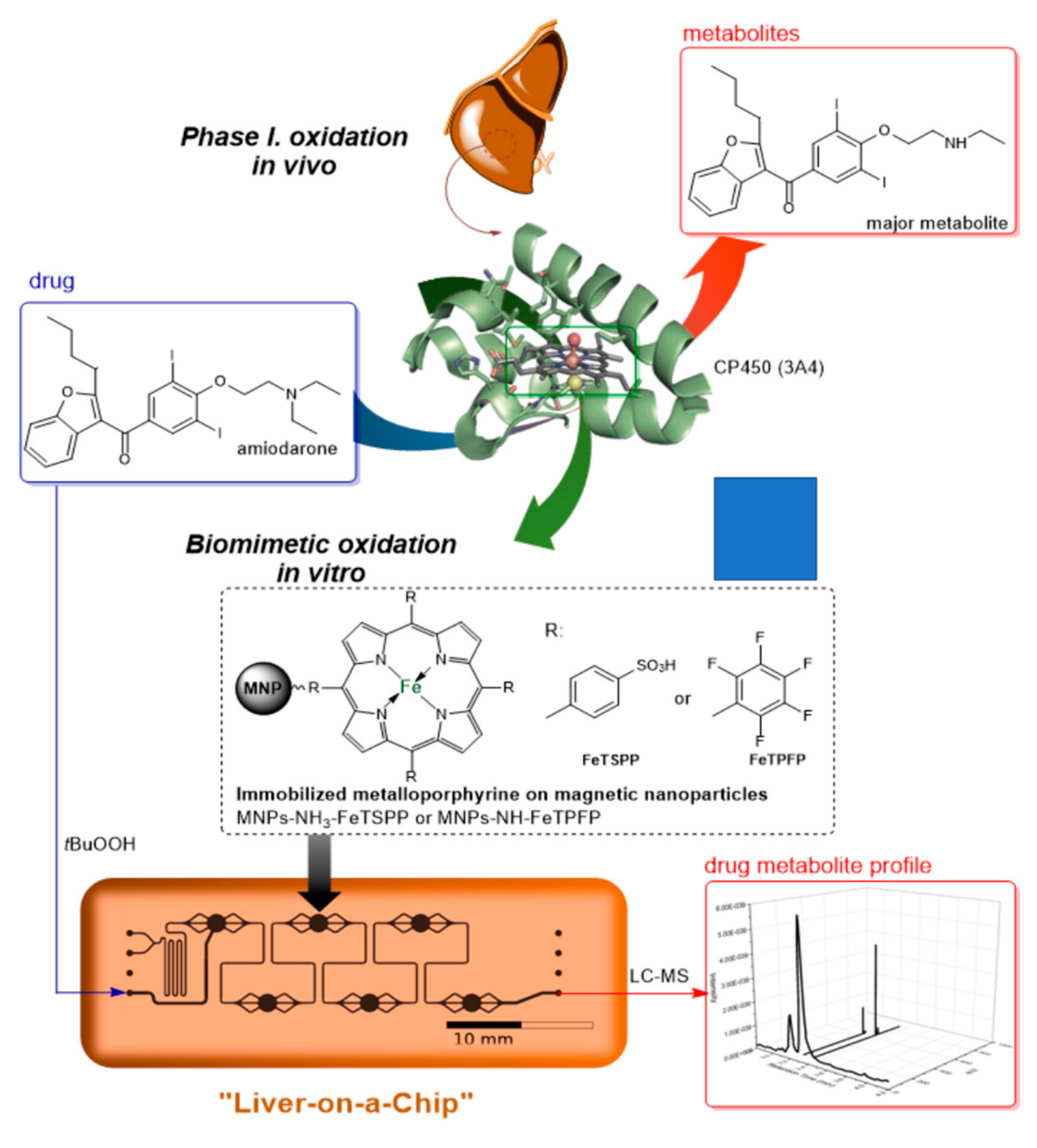

Liver-on-a-Chip‒Magnetic Nanoparticle Bound Synthetic Metalloporphyrin-Catalyzed Biomimetic Oxidation of a Drug in a Magnechip Reactor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. HPLC-DAD-MS Analysis

2.2.2. Dynamic Light Scattering (DLS) Analysis

2.2.3. ζ-Potential Analysis

2.2.4. Covalent Immobilization of FeTPFP on Functionalized Magnetic Nanoparticles (MNPs)

2.2.5. Ionic Immobilization of FeTSPP on Functionalized MNPs

2.2.6. Immobilization Yield (YI) of MNP-Porphyrines

2.2.7. Metabolism of Amiodarone (1) by Human Liver Microsomal Reactions

2.2.8. General Method of Homogeneous Biomimetic Batch Reactions of Amiodarone (1)

2.2.9. General Method of Heterogeneous Biomimetic Batch Reactions of Amiodarone (1)

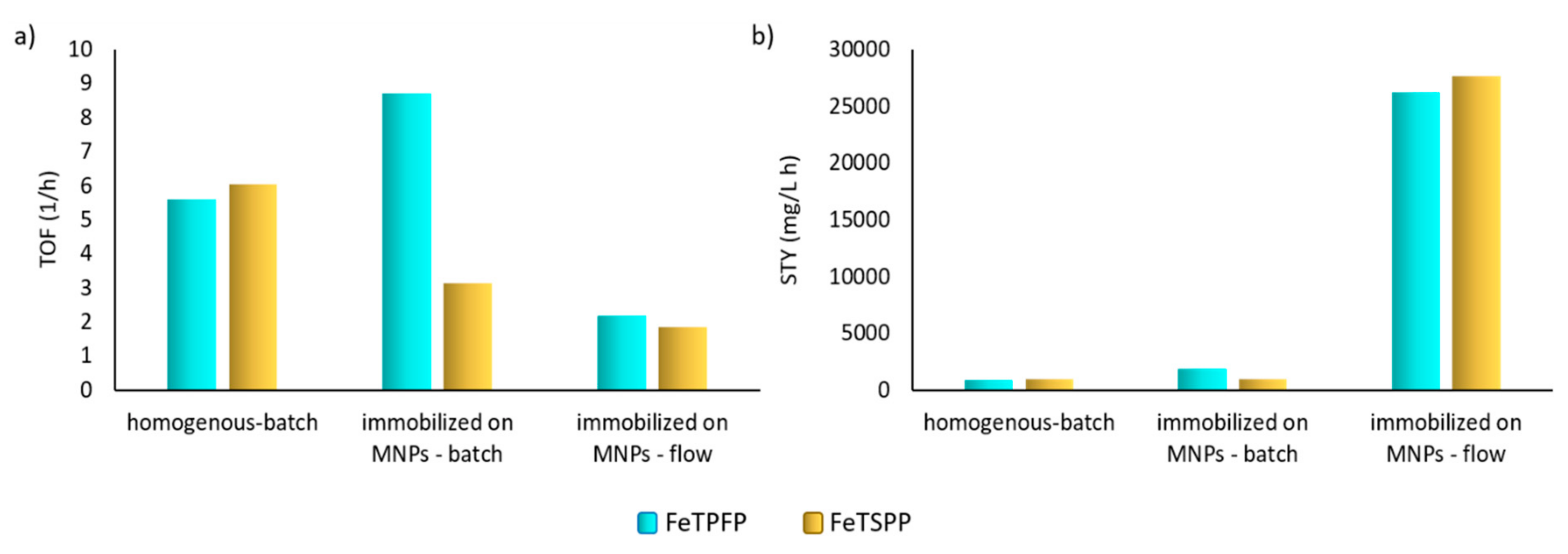

2.2.10. Calculation of the Biocatalytic Parameters

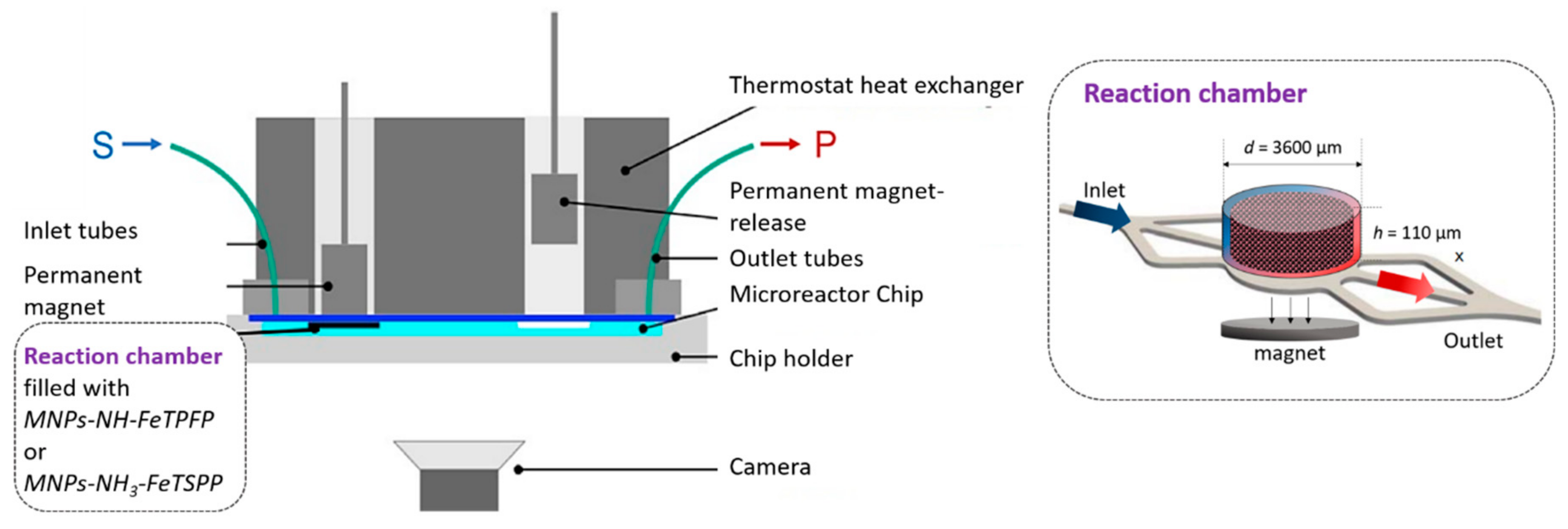

2.2.11. General method for Loading the Microfluidic Magnetic Chip Reactor with Catalyst

2.2.12. General Method of Microfluidic Biomimetic Reactions

3. Results and Discussion

3.1. Immobilization of Metaloporphyrin on Functionalized Magnetic Nanoparticles

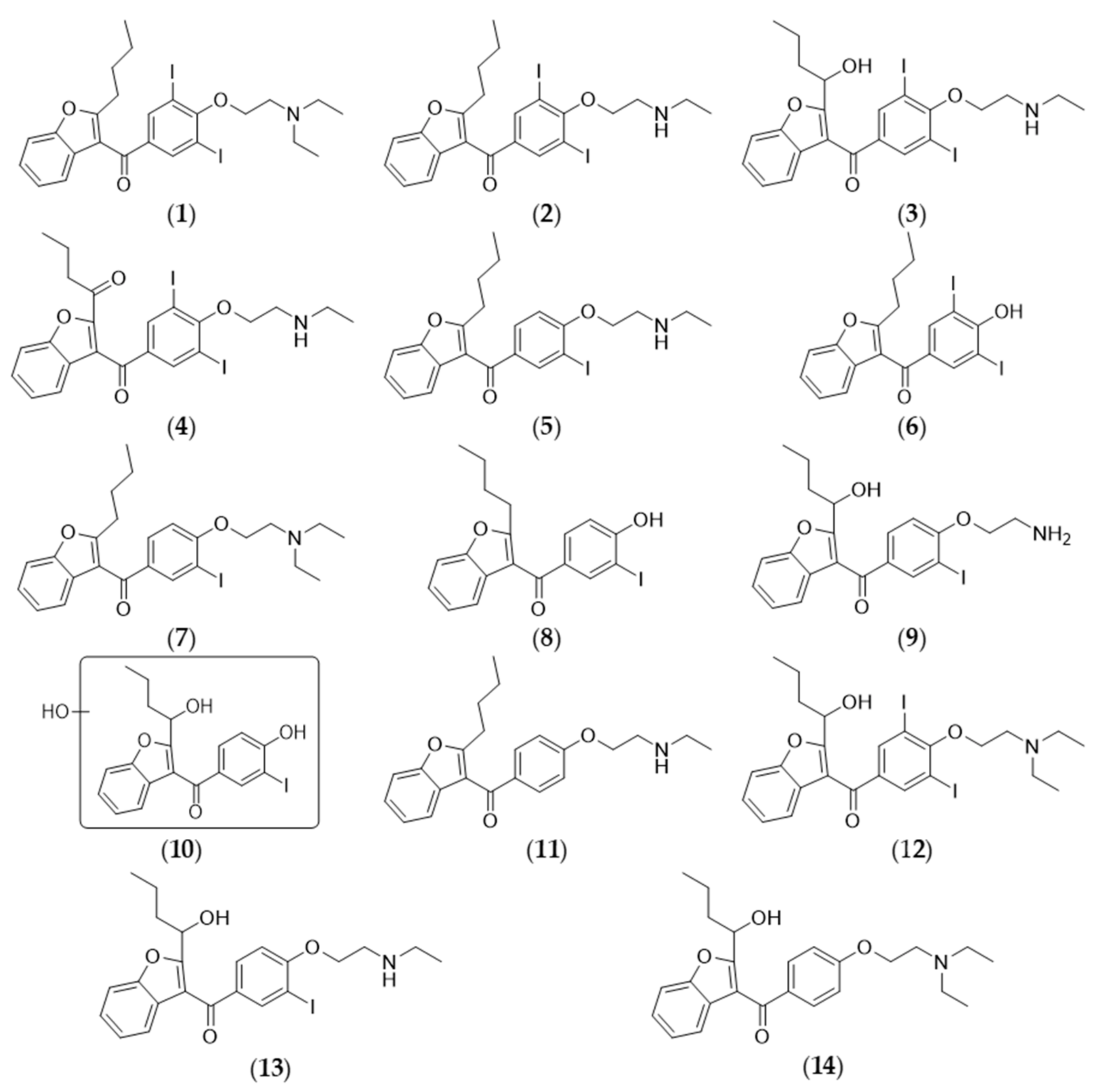

3.2. Metabolism of Amiodarone (1)

3.3. Biomimetic Oxidation of Amiodarone (1) Catalyzed by Metalloporphyrins in Batch Mode

3.4. Biomimetic Oxidation of Amiodarone (1) Catalyzed by MNP-Porphyrines in Continuous-Flow Chip Reactor—Liver-on-a-Chip

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Baumann, M.; Baxendale, I.R. The synthesis of active pharmaceutical ingredients (APIs) using continuous flow chemistry. Beilstein J. Org. Chem. 2015, 11, 1194–1219. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- May, S.A. Flow Chemistry, Continuous Processing, and Continuous Manufacturing: A Pharmaceutical Perspective. J. Flow Chem. 2017, 7, 137–145. [Google Scholar] [CrossRef]

- Calabrese, G.S.; Pissavini, S. From batch to continuous flow processing in chemicals manufacturing. AIChE J. 2011, 57, 828–834. [Google Scholar] [CrossRef]

- Fortt, R.; Wootton, R.C.R.; de Mello, A.J. Continuous-flow generation of anhydrous diazonium species: Monolithic microfluidic reactors for the chemistry of unstable intermediates. Org. Process Res. Dev. 2003, 7, 762–768. [Google Scholar] [CrossRef]

- Yoshida, J.I.; Takahashi, Y.; Nagaki, A. Flash chemistry: Flow chemistry that cannot be done in batch. Chem. Commun. 2013, 49, 9896–9904. [Google Scholar] [CrossRef]

- Kockmann, N.; Gottsponer, M.; Zimmermann, B.; Roberge, D.M. Enabling continuous-flow chemistry in microstructured devices for pharmaceutical and fine-chemical production. Chem. Eur. J. 2008, 14, 7470–7477. [Google Scholar] [CrossRef] [PubMed]

- Wegner, J.; Ceylan, S.; Kirschning, A. Ten key issues in modern flow chemistry. Chem. Commun. 2011, 47, 4583–4592. [Google Scholar] [CrossRef] [Green Version]

- Manz, A.; Graber, N.; Widmer, H.M. Miniaturized total chemical analysis systems: A novel concept for chemical sensing. Sens. Actuators B Chem. 1990, 1, 244–248. [Google Scholar] [CrossRef]

- Nguyen, N.-T.; Wereley, S.T. Fundamentals and Applications of Microfluidics, 2nd ed.; Artech House Books: Norwood, MA, USA, 2006; pp. 1–9. ISBN 9781580539722. [Google Scholar]

- Wang, J.; Escarpa, A.; Pumera, M.; Feldman, J. Capillary electrophoresis-electrochemistry microfluidic system for the determination of organic peroxides. J. Chromatogr. A 2002, 952, 249–254. [Google Scholar] [CrossRef]

- Breadmore, M.C.; Wolfe, K.A.; Arcibal, I.G.; Leung, W.K.; Dickson, D.; Giordano, B.C.; Power, M.E.; Ferrance, J.P.; Feldman, S.H.; Norris, P.M.; et al. Microchip-based purification of DNA from biological samples. Anal. Chem. 2003, 75, 1880–1886. [Google Scholar] [CrossRef]

- Greenway, G.M.; Haswell, S.J.; Morgan, D.O.; Skelton, V.; Styring, P. Use of a novel microreactor for high throughput continuous flow organic synthesis. Sens. Actuators B Chem. 2000, 63, 153–158. [Google Scholar] [CrossRef]

- Burns, M.A.; Johnson, B.N.; Brahmasandra, S.N.; Handique, K.; Webster, J.R.; Krishnan, M.; Sammarco, T.S.; Man, P.M.; Jones, D.; Heldsinger, D.; et al. An Integrated Nanoliter DNA Analysis Device. Science 1998, 282, 484–487. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ender, F.; Weiser, D.; Nagy, B.; Bencze, C.L.; Paizs, C.; Pálovics, P.; Poppe, L. Microfluidic multiple cell chip reactor filled with enzyme-coated magnetic nanoparticles—An efficient and flexible novel tool for enzyme catalyzed biotransformations. J. Flow Chem. 2016, 6, 43–52. [Google Scholar] [CrossRef]

- Zheng, F.; Fu, F.; Cheng, Y.; Wang, C.; Zhao, Y.; Gu, Z. Organ-on-a-Chip Systems: Microengineering to Biomimic Living Systems. Small 2016, 12, 2253–2282. [Google Scholar] [CrossRef] [PubMed]

- Fasinu, P.; Patrick, J.B.; Rosenkranz, B. Liver-based in vitro technologies for drug biotransformation studies—A review. Curr. Drug Metab. 2012, 13, 215–224. [Google Scholar] [CrossRef] [PubMed]

- Kremers, P. Liver microsomes: A convenient tool for metabolism studies but. In European Symposium on the Prediction of Drug Metabolism in Man: Progress and Problems; Boobis, A.R., Kremers, P., Pelkonen, O., Pithan, K., Eds.; Office for Official Publications of the European Communities: Luxembourg, 1999; pp. 38–52. [Google Scholar]

- Lohmann, W.; Karst, U. Biomimetic modeling of oxidative drug metabolism: Strategies, advantages and limitations. Anal. Bioanal. Chem. 2008, 391, 79–96. [Google Scholar] [CrossRef]

- Mansuy, D. A brief history of the contribution of metalloporphyrin models to cytochrome P450 chemistry and oxidation catalysis. C. R. Chim. 2007, 10, 392–413. [Google Scholar] [CrossRef]

- Wolak, M.; van Eldik, R. Mechanistic studies on peroxide activation by a water-soluble iron (III)-porphyrin: Implications for O-O bond activation in aqueous and nonaqueous solvents. Chem. Eur. J. 2007, 13, 4873–4883. [Google Scholar] [CrossRef]

- Cooke, P.R.; Lindsay Smith, J.R. Alkene epoxidation catalysed by ligand-bound supported metalloporphyrins. Tetrahedron Lett. 1992, 33, 2737–2740. [Google Scholar] [CrossRef]

- Fődi, T.; Ignácz, G.; Decsi, B.; Béni, Z.; Túrós, G.I.; Kupai, J.; Weiser, D.B.; Greiner, I.; Huszthy, P.; Balogh, G.T. Biomimetic Synthesis of Drug Metabolites in Batch and Continuous-Flow Reactors. Chem. Eur. J. 2018, 24, 9385–9392. [Google Scholar] [CrossRef]

- Liu, R.; Guo, Y.; Odusote, G.; Qu, F.; Priestley, R.D. Core-shell Fe3O4 polydopamine nanoparticles serve multipurpose as drug carrier, catalyst support and carbon adsorbent. ACS Appl. Mater. Interfaces 2013, 5, 9167–9171. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Mei, Y.; Drechsler, M.; Ballauff, M. Thermosensitive core-shell particles as carriers for Ag nanoparticles: Modulating the catalytic activity by a phase transition in networks. Angew. Chem. Int. Ed. 2006, 45, 813–816. [Google Scholar] [CrossRef] [PubMed]

- Vaghari, H.; Jafarizadeh-Malmiri, H.; Mohammadlou, M.; Berenjian, A.; Anarjan, N.; Jafari, N.; Nasiri, S. Application of magnetic nanoparticles in smart enzyme immobilization. Biotechnol. Lett. 2016, 38, 223–233. [Google Scholar] [CrossRef] [PubMed]

- Weiser, D.; Bencze, L.C.; Bánóczi, G.; Ender, F.; Kiss, R.; Kókai, E.; Szilágyi, A.; Vértessy, B.G.; Farkas, Ö.; Paizs, C.; et al. Phenylalanine ammonia-lyase-catalyzed deamination of an acyclic amino acid: Enzyme mechanistic studies aided by a novel microreactor filled with magnetic nanoparticles. ChemBioChem 2015, 16, 2283–2288. [Google Scholar] [CrossRef] [PubMed]

- Stoytcheva, M.; Zlatev, R. Lab-on-a-Chip Fabrication and Application; InTech: London, UK, 2016; pp. 157–178. ISBN 978-953-51-2457-3. [Google Scholar]

- Ender, F.; Weiser, D.; Vitéz, A.; Sallai, G.; Németh, M.; Poppe, L. In-situ measurement of magnetic nanoparticle quantity in a microfluidic device. Microsyst. Technol. 2017, 23, 3979–3990. [Google Scholar] [CrossRef]

- Kirby, B.J. Micro-and Nanoscale Fluid Mechanics: Transport in Microfluidic Devices; Cambridge University Press: Cambridge, MA, USA, 2010. [Google Scholar]

- Trivier, J.M.; Libersa, C.; Belloc, C.; Lhermitte, M. Amiodarone N-deethylation in human liver microsomes: Involvement of cytochrome P450 3A enzymes (first report). Life Sci. 1993, 52, 91–96. [Google Scholar] [CrossRef]

- Freedman, M.D.; Somberg, J.C. Pharmacology and pharmacokinetics of amiodarone. J. Clin. Pharmacol. 1991, 31, 1061–1069. [Google Scholar] [CrossRef]

- Berger, Y.; Harris, L. Amiodarone, Pharmacology–Pharmacokinetics–Toxicology–Clinical Effects; Médicine Sciences Internationales: Paris, France, 1986; Volume 59, pp. 45–98. [Google Scholar]

| Type of MNPs | dP (nm) | ζ-Potential (mV) |

|---|---|---|

| MNPs-NH2 | 429 ± 46 | −22.9 ± 0.8 |

| MNPs-NH-FeTPFP | 336 ± 25 | −16.0 ± 0.8 |

| MNPs-NH3-FeTSPP | 296 ± 4 | −5.3 ± 1.2 |

| Metabolite a | In Vitro Human Liver Microsomal Investigation | Homogenous Biomimetic Reaction “Free Metalloporphyrin” | Heterogeneous Biomimetic Reaction “Immobilized Metallo-porphyrin on MNPs” | ||

|---|---|---|---|---|---|

| FeTPFP | FeTSPP | MNPs-NH-FeTPFP | MNPs-NH3-FeTSPP | ||

| amiodarone (1) | 86.4 | 8.1 | 4.3 | 6.3 | 53.0 |

| (2) | 13.3 | 66.7 | 66.5 | 62.6 | 38.0 |

| (3) | - | - | 1.0 | - | - |

| (4) | - | - | 7.6 | - | - |

| (5) | - | - | 10.5 | 1.4 | 1.4 |

| (6) | - | 24.3 | - | 25.7 | 5.9 |

| (7) | - | 0.9 | - | - | - |

| (8) | - | - | - | - | 1.3 |

| (9) | - | - | - | - | 0.4 |

| (10) | - | - | - | - | 0.1 |

| (11) | - | - | - | - | - |

| (12) | 0.3 | - | - | - | - |

| (13) | - | - | - | - | - |

| (14) | - | - | - | - | - |

| other b | - | - | 10.0 | 4.0 | - |

| Activity | Homogenous Catalytic Reaction | Heterogenous Catalytic Reaction | |||

|---|---|---|---|---|---|

| HLM | FeTPFP | FeTSPP | MNPs-NH-FeTPFP | MNPs-NH3-FeTSPP | |

| UB (U/g) | 0.5 | 132.7 | 153.6 | 12.1 | 6.1 |

| UP (U/g) | - | 132.7 | 153.6 | 223.8 | 80.8 |

| Metabolites a | Flow Rate (μL/min) | |||||||

|---|---|---|---|---|---|---|---|---|

| 15 | 30 | 45 | 60 | |||||

| FeTPFP | FeTSPP | FeTPFP | FeTSPP | FeTPFP | FeTSPP | FeTPFP | FeTSPP | |

| amiodarone (1) | 61.0 | 58.8 | 75.7 | 77.0 | 84.5 | 84.4 | 88.4 | 87.9 |

| (2) | 0.5 | - | 0.5 | 0.3 | 0.6 | 0.4 | 0.8 | 0.6 |

| (11) | 10.8 | 11.5 | 5.6 | 5.6 | 2.7 | 2.7 | 1.1 | 2.2 |

| (13) | 21.5 | 23.2 | 13.4 | 12.9 | 8.2 | 8.5 | 6.3 | 6.9 |

| (14) | 3.9 | 4.4 | 3.3 | 3.0 | 2.6 | 2.9 | 2.3 | 1.8 |

| other b | 2.3 | 2.2 | 1.5 | 1.4 | 1.3 | 1.2 | 1.2 | 0.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Decsi, B.; Krammer, R.; Hegedűs, K.; Ender, F.; Gyarmati, B.; Szilágyi, A.; Tőtős, R.; Katona, G.; Paizs, C.; Balogh, G.T.; et al. Liver-on-a-Chip‒Magnetic Nanoparticle Bound Synthetic Metalloporphyrin-Catalyzed Biomimetic Oxidation of a Drug in a Magnechip Reactor. Micromachines 2019, 10, 668. https://doi.org/10.3390/mi10100668

Decsi B, Krammer R, Hegedűs K, Ender F, Gyarmati B, Szilágyi A, Tőtős R, Katona G, Paizs C, Balogh GT, et al. Liver-on-a-Chip‒Magnetic Nanoparticle Bound Synthetic Metalloporphyrin-Catalyzed Biomimetic Oxidation of a Drug in a Magnechip Reactor. Micromachines. 2019; 10(10):668. https://doi.org/10.3390/mi10100668

Chicago/Turabian StyleDecsi, Balázs, Réka Krammer, Kristóf Hegedűs, Ferenc Ender, Benjámin Gyarmati, András Szilágyi, Róbert Tőtős, Gabriel Katona, Csaba Paizs, György T. Balogh, and et al. 2019. "Liver-on-a-Chip‒Magnetic Nanoparticle Bound Synthetic Metalloporphyrin-Catalyzed Biomimetic Oxidation of a Drug in a Magnechip Reactor" Micromachines 10, no. 10: 668. https://doi.org/10.3390/mi10100668