Miniature 3D-Printed Centrifugal Pump with Non-Contact Electromagnetic Actuation

Abstract

:1. Introduction

2. Materials and Methods

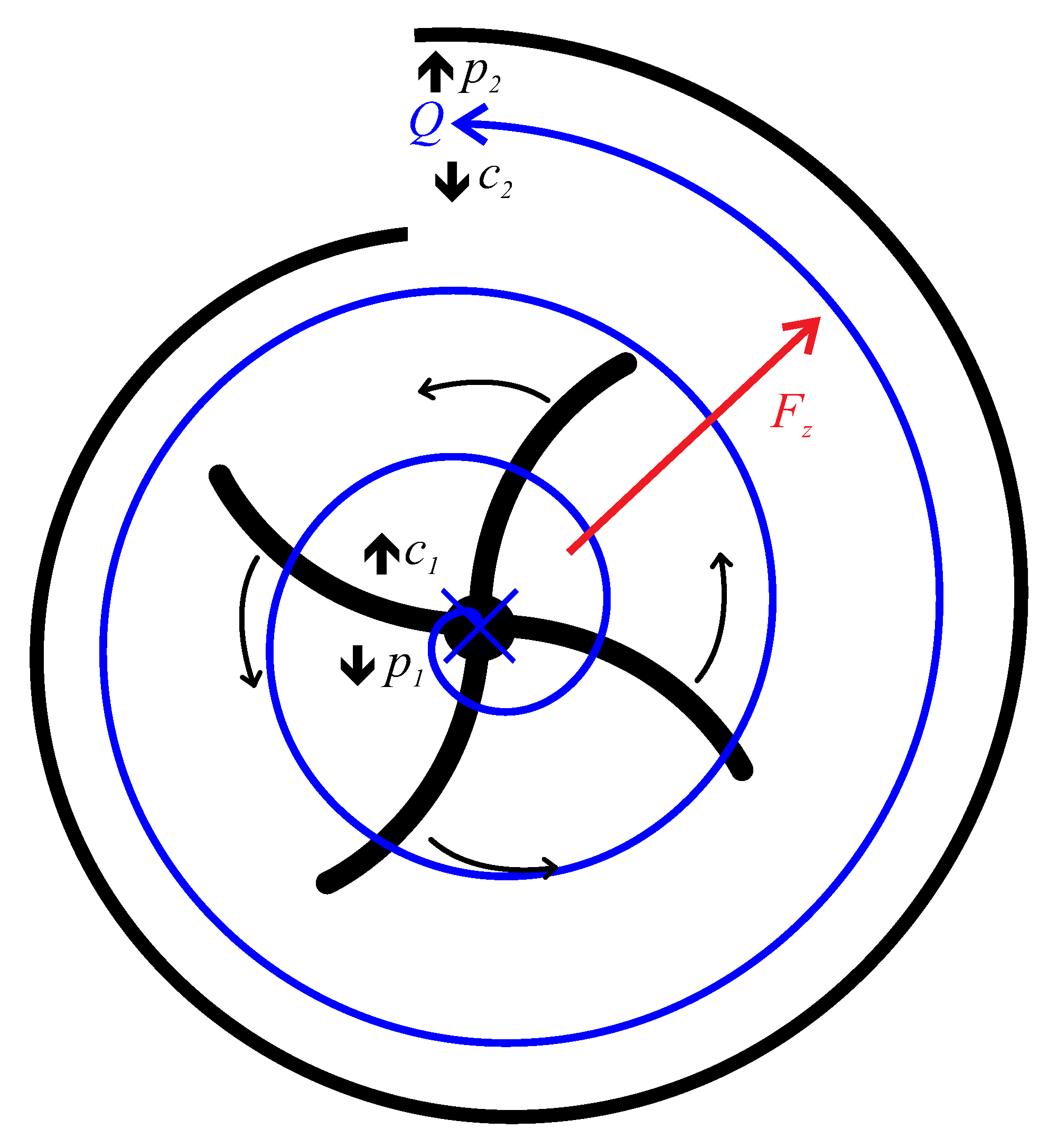

2.1. Centrifugal Pumping Principle

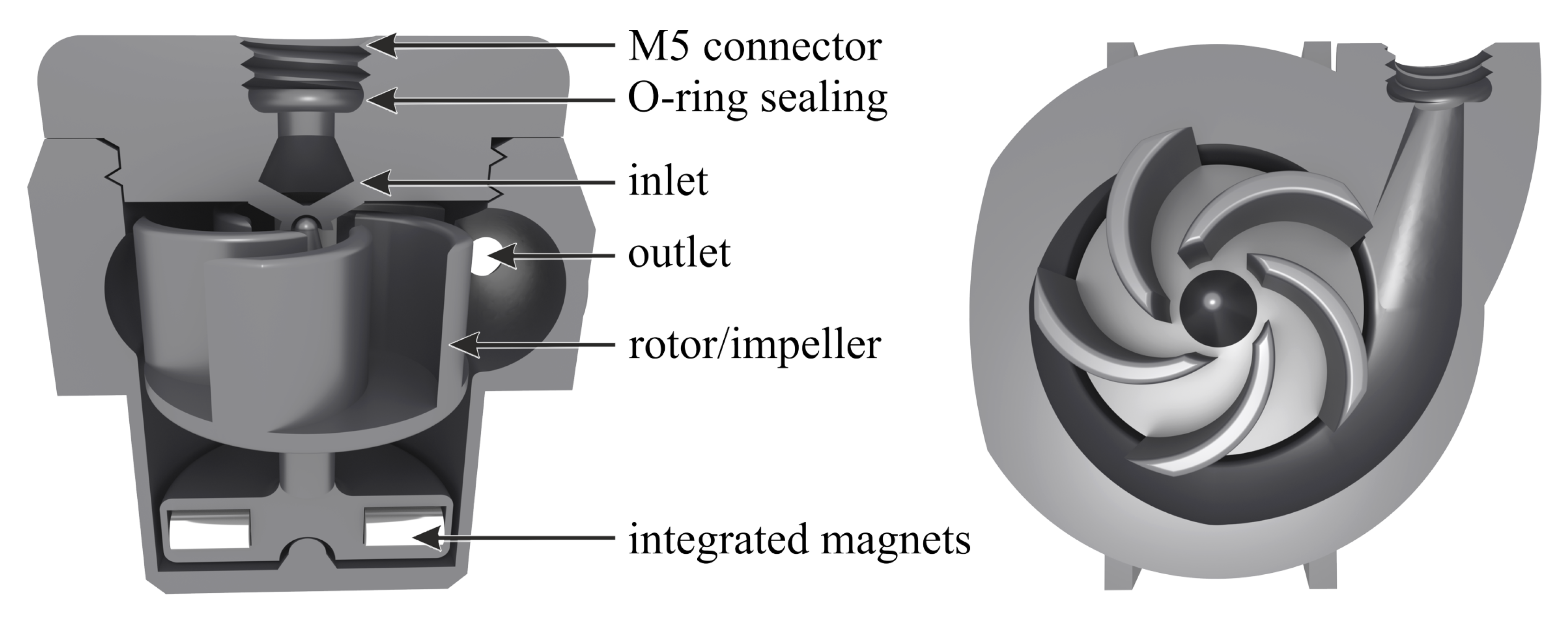

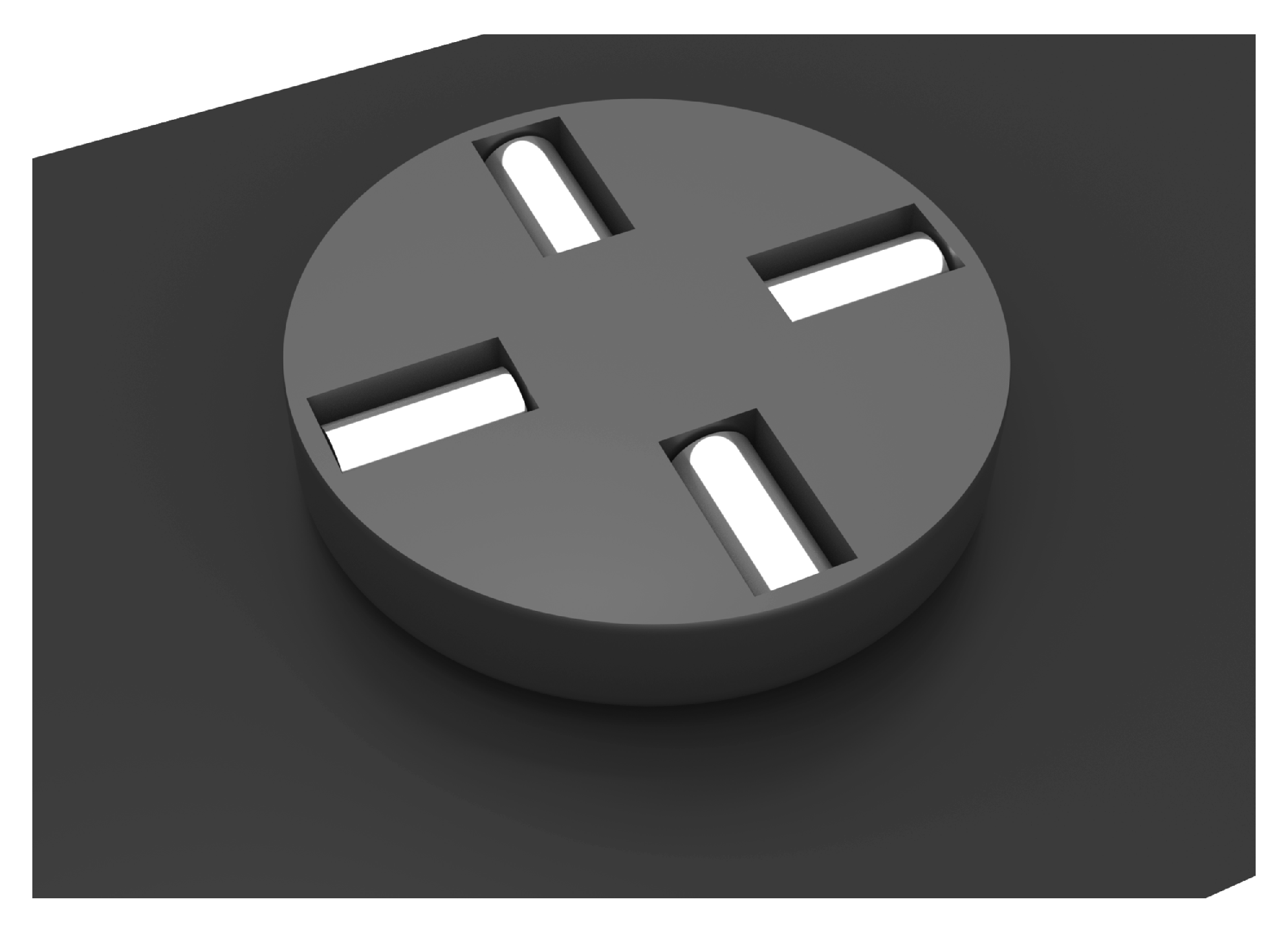

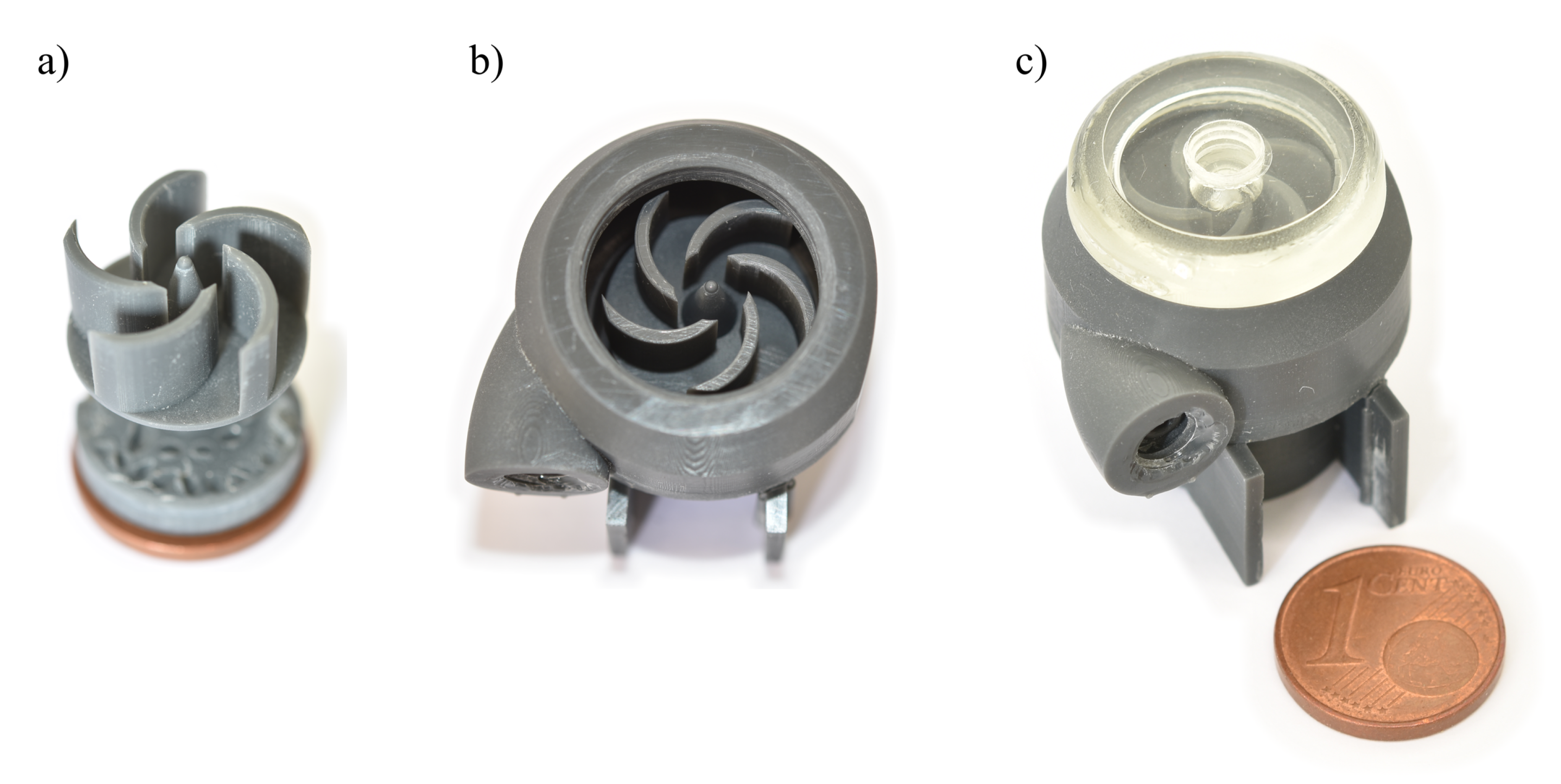

2.2. Pump Design

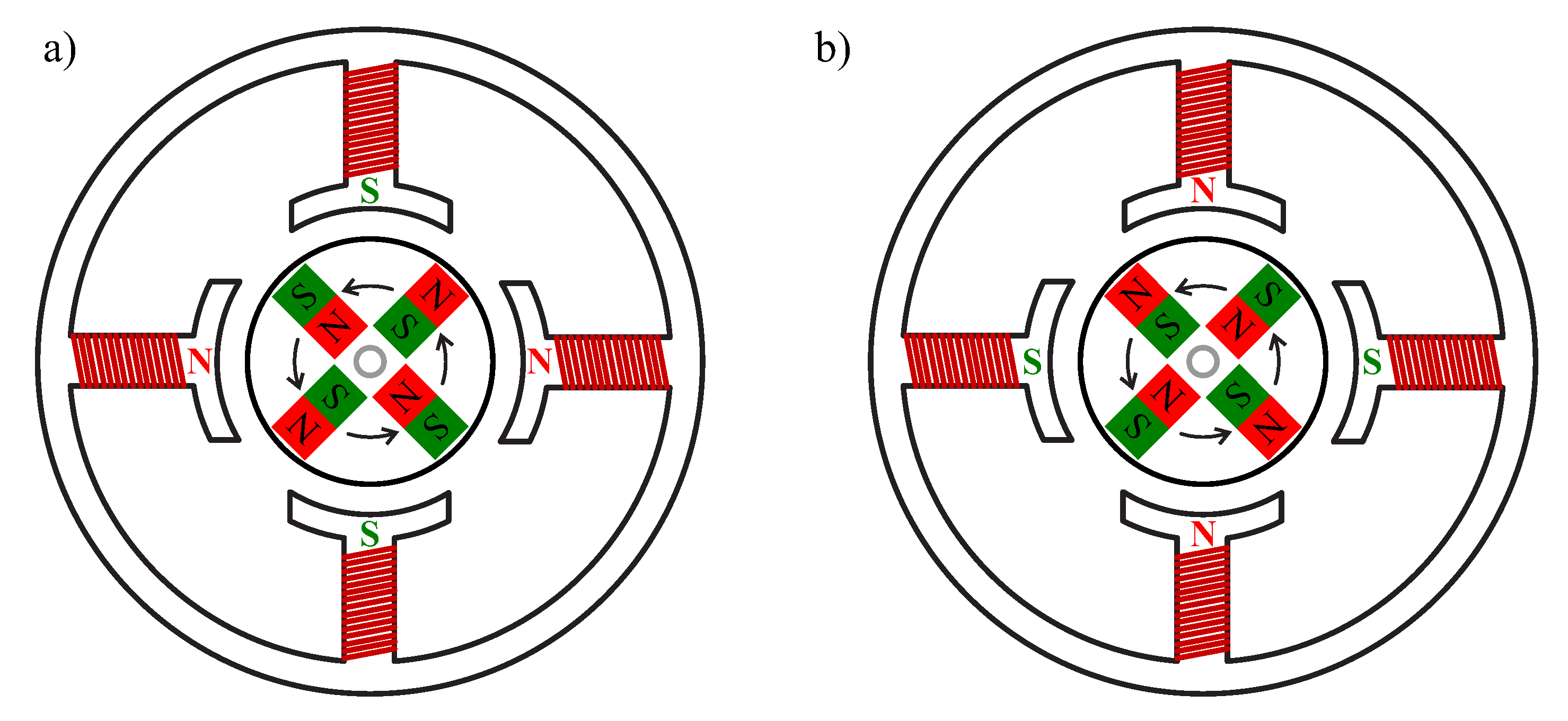

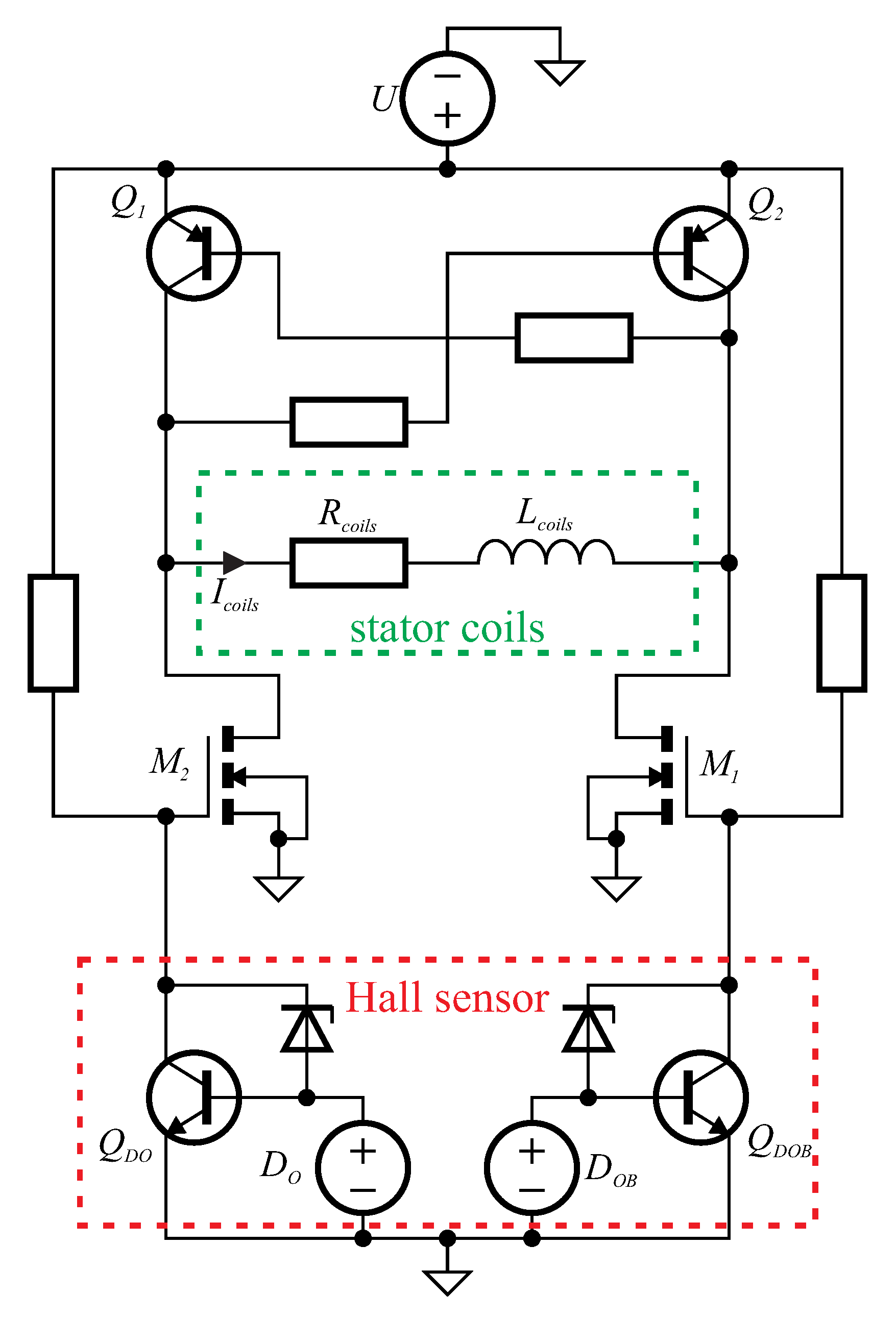

2.3. Electromagnetic Actuation

2.4. Fabrication and Assembly

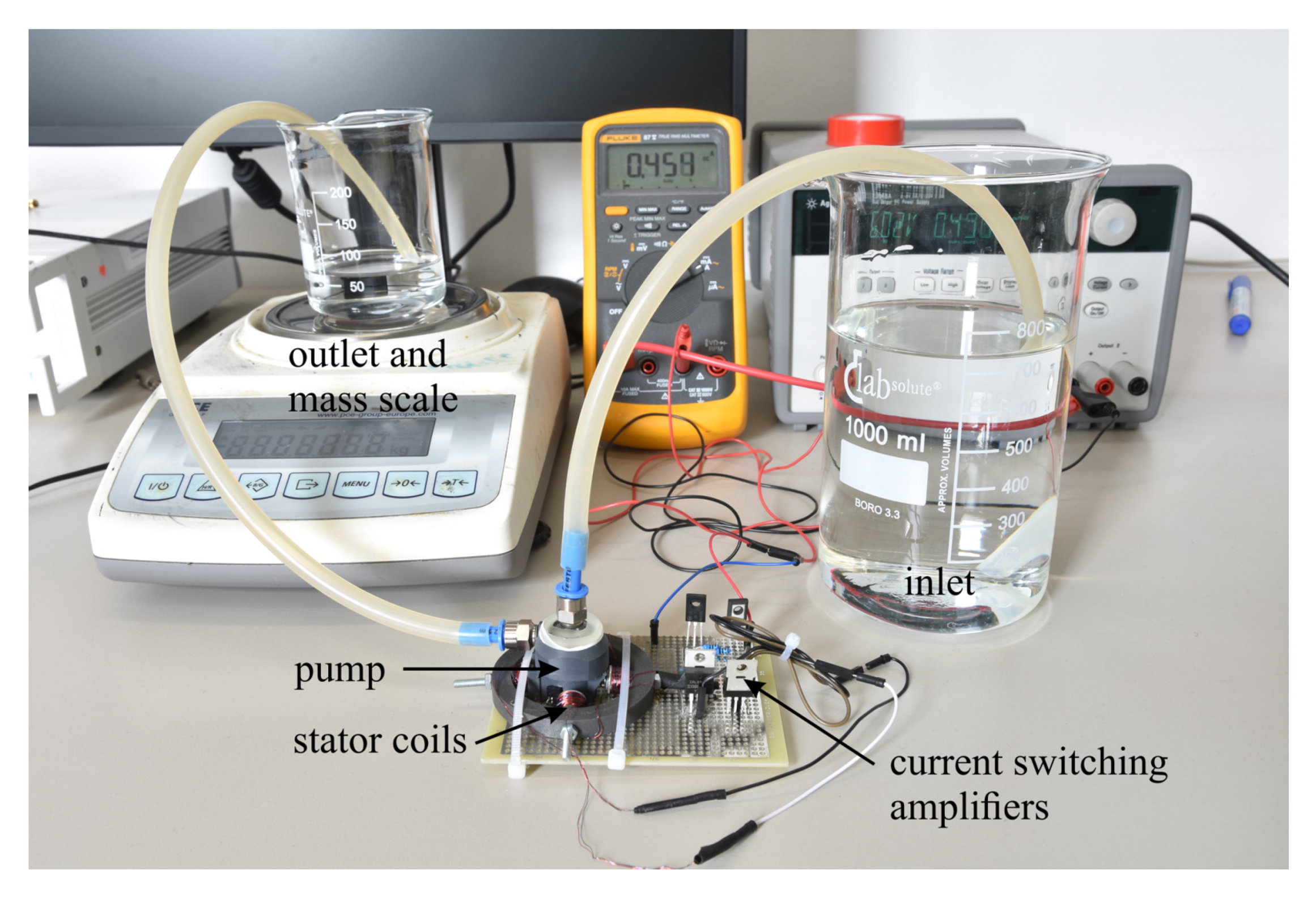

2.5. Measurement Setup

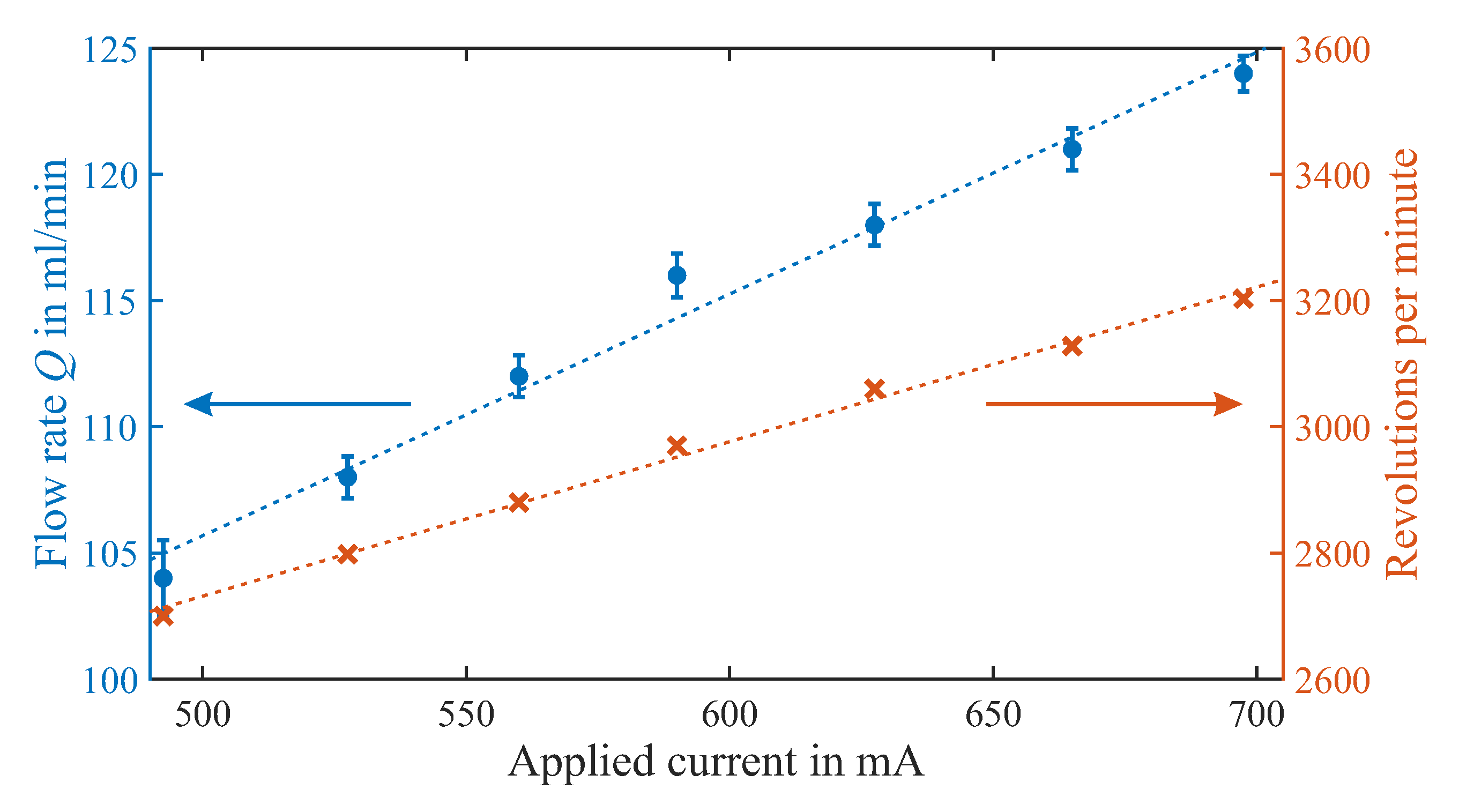

3. Results and Discussion

3.1. Volumetric Flow Rate

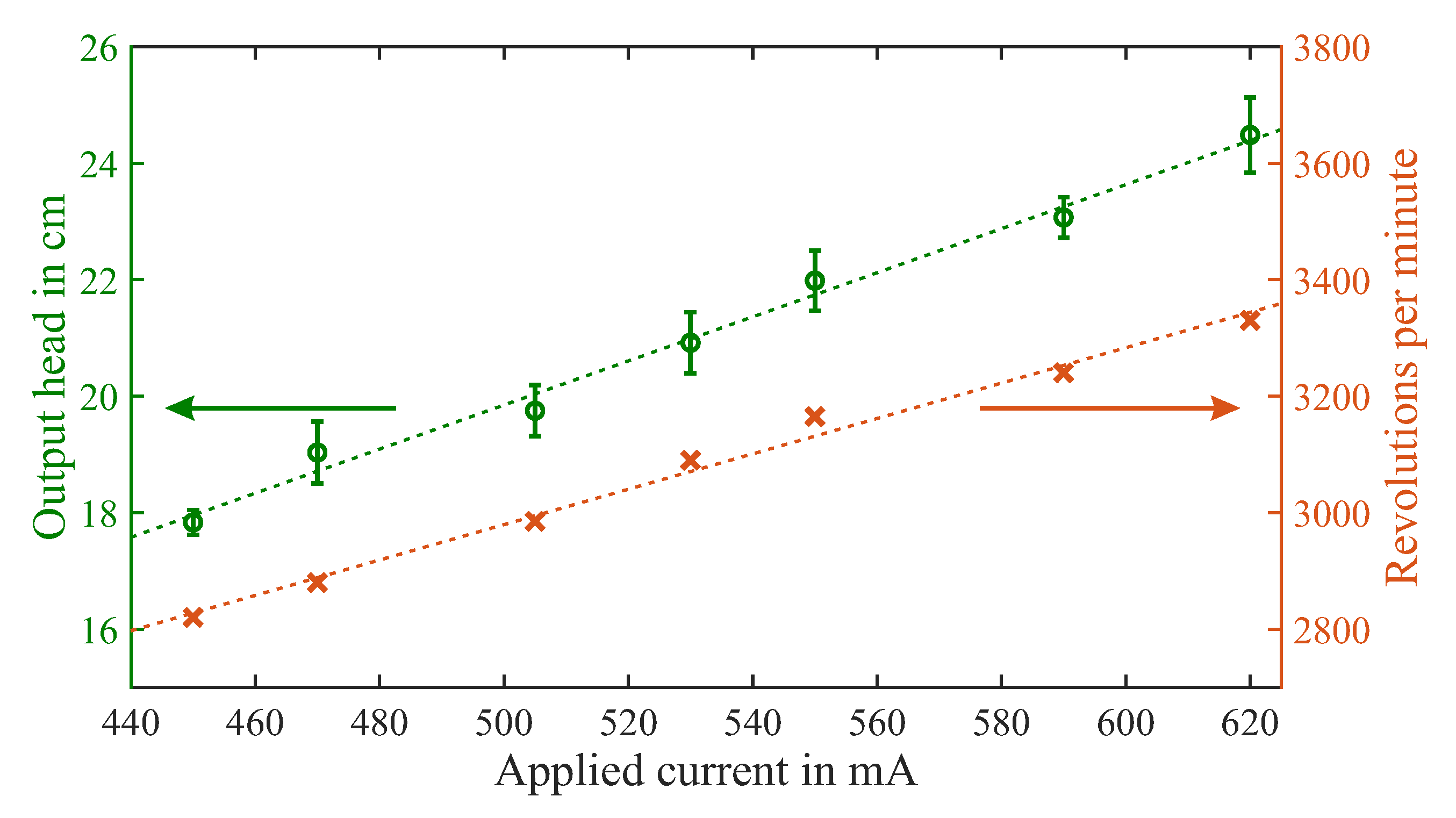

3.2. Output Pressure

3.3. Comparison with other 3D-Printed Pumps

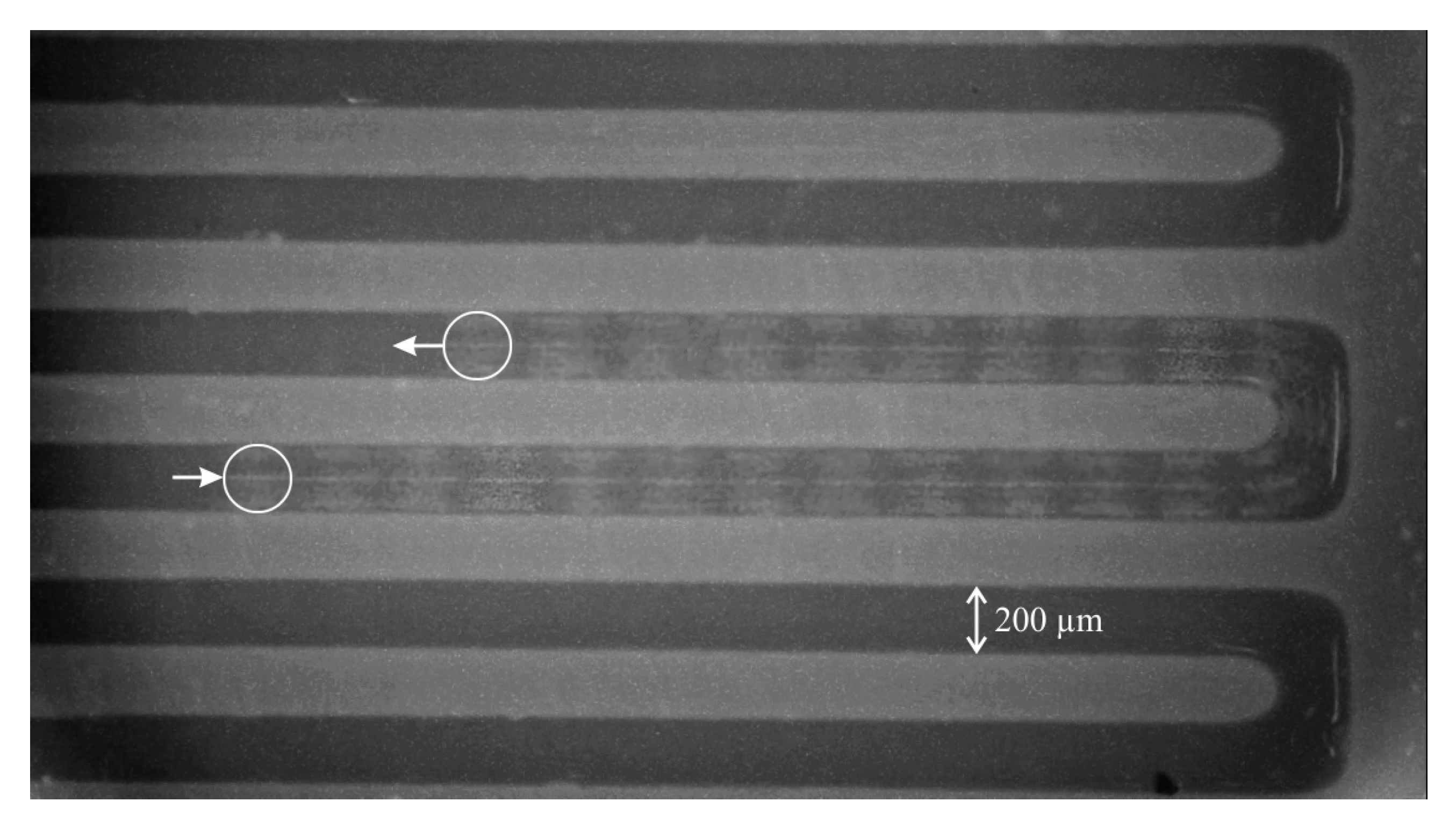

3.4. Pumping in a Microfluidic Channel and Outlook

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Nguyen, N.T.; Huang, X.; Chuan, T.K. MEMS-Micropumps: A Review. J. Fluids Eng. 2002, 124, 384–392. [Google Scholar] [CrossRef]

- Laser, D.J.; Santiago, J.G. A review of micropumps. J. Micromech. Microeng. 2004, 14, R35–R64. [Google Scholar] [CrossRef]

- Bhattacharjee, N.; Urrios, A.; Kang, S.; Folch, A. The upcoming 3D-printing revolution in microfluidics. Lab Chip 2016, 16, 1720. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Mehl, B.T.; Munshi, A.S.; Townsend, A.D.; Spence, D.M.; Martin, R.S. 3D-printed microfluidic devices: fabrication, advantages and limitations—A mini review. Anal. Methods 2016, 8, 6005–6012. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Macdonald, N.P.; Guijt, R.M.; Breadmore, M.C. Increasing the functionalities of 3D printed microchemical devices by single material, multimaterial, and print-pause-print 3D printing. Lab Chip 2019, 19, 35–49. [Google Scholar] [CrossRef] [PubMed]

- Van den Driesche, S.; Lucklum, F.; Bunge, F.; Vellekoop, M.J. 3D Printing Solutions for Microfluidic Chip-To-World Connections. Micromachines 2018, 9, 71. [Google Scholar] [CrossRef] [PubMed]

- Au, A.K.; Bhattacharjee, N.; Horowitz, L.F.; Chang, T.C.; Folch, A. 3D-printed microfluidic automation. Lab Chip 2015, 15, 1934–1941. [Google Scholar] [CrossRef] [PubMed]

- Gong, H.; Woolley, A.T.; Nordin, G.P. High density 3D printed microfluidic valves, pumps, and multiplexers. Lab Chip 2016, 16, 2450–2458. [Google Scholar] [CrossRef] [PubMed]

- Habhab, M.B.; Ismail, T.; Lo, J.F. A Laminar Flow-Based Microfluidic Tesla Pump via Lithography Enabled 3D Printing. Sensors 2016, 16, 1970. [Google Scholar] [CrossRef] [PubMed]

- Leigh, S.; Purssell, C.; Bowen, J.; Hutchins, D.; Covington, J.; Billson, D. A miniature flow sensor fabricated by micro-stereolithography employing a magnetite/acrylic nanocomposite resin. Sensors Actuators Phys. 2011, 168, 66–71. [Google Scholar] [CrossRef]

- Krishnan, R. Permanent Magnet Synchronous and Brushless DC Motor Drives; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar] [CrossRef]

- Lobanoff, V.S.; Ross, R.R. (Eds.) Centrifugal Pumps: Design and Application; Gulf Professional Publishing: Boston, MA, USA, 1992. [Google Scholar] [CrossRef]

- Meng, E.; Wang, X.-Q.; Mak, H.; Tai, Y.-H. A check-valved silicone diaphragm pump. In Proceedings of the IEEE Thirteenth Annual International Conference on Micro Electro Mechanical Systems, Miyazaki, Japan, 23–27 January 2000; pp. 62–67. [Google Scholar] [CrossRef]

- Döpper, J.; Clemens, M.; Ehrfeld, W.; Jung, S.; Kämper, K.P.; Lehr, H. Micro gear pumps for dosing of viscous fluids. J. Micromech. Microeng. 1997, 7, 230–232. [Google Scholar] [CrossRef]

- Wang, J.; McMullen, C.; Yao, P.; Jiao, N.; Kim, M.; Kim, J.W.; Liu, L.; Tung, S. 3D-printed peristaltic microfluidic systems fabricated from thermoplastic elastomer. Microfluid. Nanofluidics 2017, 21, 105. [Google Scholar] [CrossRef]

- Richter, A.; Plettner, A.; Hofmann, K.; Sandmaier, H. A micromachined electrohydrodynamic (EHD) pump. Sensors Actuators Phys. 1991, 29, 159–168. [Google Scholar] [CrossRef]

- Homsy, A.; Linder, V.; Lucklum, F.; de Rooij, N. Magnetohydrodynamic pumping in nuclear magnetic resonance environments. Sensors Actuators Chem. 2007, 123, 636–646. [Google Scholar] [CrossRef] [Green Version]

- Tang, Z.; Shao, X.; Huang, J.; Ding, G.; Yao, J. 3D printed pump based on vibrating blades to actively manipulate fluid. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 042168. [Google Scholar] [CrossRef]

| Pump Type | Volume/µL | Max. Q/mL·min−1 | Max. Pressure/Pa | Ref. |

|---|---|---|---|---|

| Pneumatic check-valve | ≈15.4 | 13 | 5900 | [13] |

| Rotary micro-gear | ≈0.14 | 0.055 | 12,500 | [14] |

| Electrohydrodynamic | ≈3.42 | 14 | 2480 | [16] |

| Magnetohydrodynamic | 0.19 | 0.0015 | 180.5 | [17] |

| Peristaltic (3D-printed) | 74.8 | 0.68 | – | [7] |

| Membrane (3D-printed) | 0.495 | 0.02 | 24,130 | [8] |

| Tesla (3D-printed) | ≈3380 | 12 | 253 | [9] |

| Peristaltic (3D-printed) | 120 | 0.71 | ≈56 | [15] |

| Vibrating blades (3D-printed) | ≈9000 | 107.8 | – | [18] |

| Centrifugal (3D-printed) | ≈4120 | 124 | 2400 | this work |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joswig, L.; Vellekoop, M.J.; Lucklum, F. Miniature 3D-Printed Centrifugal Pump with Non-Contact Electromagnetic Actuation. Micromachines 2019, 10, 631. https://doi.org/10.3390/mi10100631

Joswig L, Vellekoop MJ, Lucklum F. Miniature 3D-Printed Centrifugal Pump with Non-Contact Electromagnetic Actuation. Micromachines. 2019; 10(10):631. https://doi.org/10.3390/mi10100631

Chicago/Turabian StyleJoswig, Luca, Michael J. Vellekoop, and Frieder Lucklum. 2019. "Miniature 3D-Printed Centrifugal Pump with Non-Contact Electromagnetic Actuation" Micromachines 10, no. 10: 631. https://doi.org/10.3390/mi10100631