Green Supply Chain Integration, New Product Launch Speed, and Green Innovation Performance: The Moderating Role of Enterprise Intelligence Level

Abstract

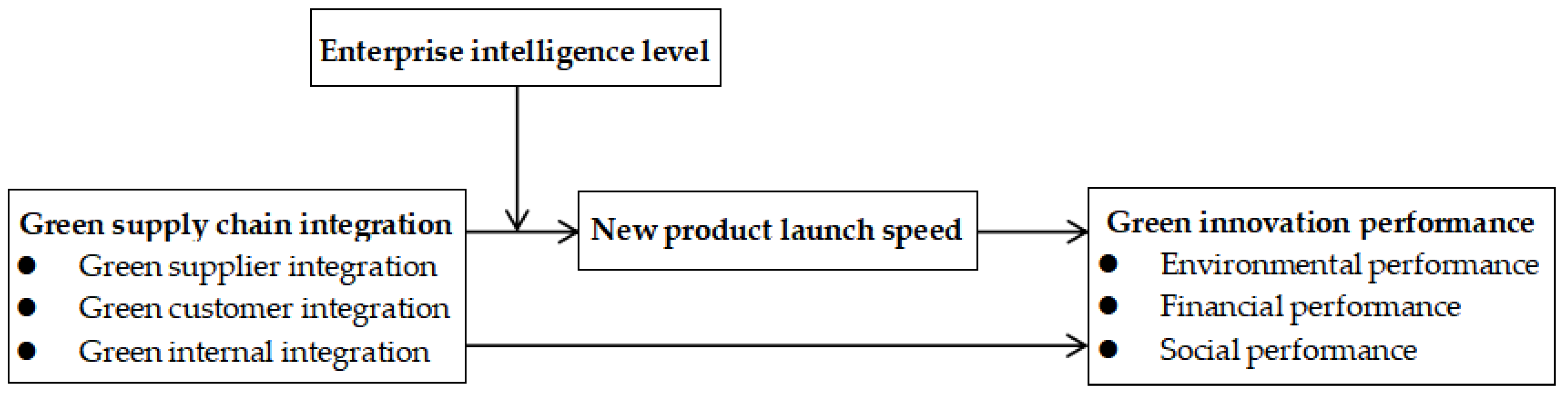

1. Introduction

2. Hypothesis Development

2.1. Green Supply Chain Integration and New Product Launch Speed

2.2. Green Supply Chain Integration and Green Innovation Performance

2.3. New Product Launch Speed and Green Innovation Performance

2.4. The Mediating Role of New Product Launch Speed

2.5. The Moderating Role of Enterprise Intelligence Level

3. Methodology

3.1. Questionnaire Design and Data Collection

3.2. Reliability and Validity Tests

3.3. Hypothesis Testing

3.3.1. Direct Effect Testing

3.3.2. Mediating Effect of New Product Launch Speed

3.3.3. Moderating Effect of Enterprise Intelligence Level

4. Discussion

4.1. The Impact of Green Supply Chain Integration on New Product Launch Speed

4.2. The Impact of New Product Launch Speed on Green Innovation Performance

4.3. The Impact of Green Supply Chain Integration on Green Innovation Performance

4.4. The Mediating Role of New Product Launch Speed

4.5. The Moderating Role of Enterprise Intelligence Level

4.6. Managerial Challenges and Implementation Risks

4.7. The Role of Organizational Change Management and Innovation Culture

5. Conclusions and Implications

5.1. Integrated Conclusions and Implications

5.2. Limitations and Future Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. The European Green Deal. COM(2019) 640 Final. Brussels. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2019%3A640%3AFIN (accessed on 28 November 2025).

- Junaid, M.; Zhang, Q.; Syed, M.W. Effects of sustainable supply chain integration on green innovation and firm performance. Sustain. Prod. Consum. 2022, 30, 145–157. [Google Scholar] [CrossRef]

- Chen, Y.; Yuan, M.; Lin, H.; Han, Y.; Yu, Y.; Sun, C. Organizational improvisation and green innovation: A dynamic capability perspective. Bus. Strategy Environ. 2023, 32, 5686–5701. [Google Scholar] [CrossRef]

- Aguinis, H.; Glavas, A. What we know and don’t know about corporate social responsibility: A review and research agenda. J. Manag. 2012, 38, 932–968. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Initiatives and outcomes of green supply chain management implementation by Chinese manufacturers. J. Environ. Manag. 2007, 85, 179–189. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Green supply chain management: Pressures, practices and performance within the Chinese automobile industry. J. Clean. Prod. 2007, 15, 1041–1052. [Google Scholar] [CrossRef]

- Song, Y.; Cai, J.; Feng, T. The influence of green supply chain integration on firm performance: A contingency and configuration perspective. Sustainability 2017, 9, 763. [Google Scholar] [CrossRef]

- Handoyo, S. Green supply chain management: A bibliometric analysis of global research trends and future directions. Prod. Manuf. Res. 2024, 12, 2422614. [Google Scholar] [CrossRef]

- Agyapong, A.; Aidoo, S.O.; Acquaah, M.; Akomea, S. Environmental orientation and sustainability performance: The mediated moderation effects of green supply chain management practices and institutional pressure. J. Clean. Prod. 2023, 430, 139592. [Google Scholar] [CrossRef]

- Hejazi, T.M.; Habani, A.M. Impact of green supply chain integration management on business performance: A mediating role of supply chain resilience and innovation the case of Saudi Arabian manufacturing sector. Cogent Bus. Manag. 2024, 11, 2392256. [Google Scholar] [CrossRef]

- Feng, T.; Sheng, H.; Li, M. The bright and dark sides of green customer integration (GCI): Evidence from Chinese manufacturers. Bus. Process Manag. J. 2021, 27, 1610–1632. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, H.Y.; Xiao, T.; Liu, J.; Chai, C.; Zhou, P. Impacts of external involvement on new product development performance: Moderating role of organisational culture. Technol. Anal. Strateg. Manag. 2021, 33, 70–83. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Yang, F. The impact of external involvement on new product market performance: An analysis of mediation and moderation. Ind. Manag. Data Syst. 2016, 116, 1520–1539. [Google Scholar] [CrossRef]

- Fisher, G.J.; John-Mariadoss, B.; Kuzmich, D.; Qualls, W.J. The timing of diverse external stakeholder involvement during interfirm open innovation: The effects on new product speed to market and product lifespan. Ind. Mark. Manag. 2024, 117, 386–401. [Google Scholar] [CrossRef]

- Kong, T.; Feng, T. Enhancing supply chain resilience: The role of big data analytics capability and organizational ambidexterity. Ind. Manag. Data Syst. 2025, 125, 2348–2370. [Google Scholar] [CrossRef]

- Parente, R.C.; Baack, D.W.; Hahn, E.D. The effect of supply chain integration, modular production, and cultural distance on new product development: A dynamic capabilities approach. J. Int. Manag. 2011, 17, 278–290. [Google Scholar] [CrossRef]

- Han, Z.; Huo, B. The impact of green supply chain integration on sustainable performance. Ind. Manag. Data Syst. 2020, 120, 657–674. [Google Scholar] [CrossRef]

- Lee, L.K.; Wong, Y.S.; Alzoubi, M.H.; Al Kurdi, B.; Alshurideh, M.T.; El Khatib, M. Adopting smart supply chain and smart technologies to improve operational performance in manufacturing industry. Int. J. Eng. Bus. Manag. 2023, 39, 95–121. [Google Scholar] [CrossRef]

- Yang, J.; Ying, L.; Gao, M. The influence of intelligent manufacturing on financial performance and innovation performance: The case of China. Enterp. Inf. Syst. 2020, 14, 812–832. [Google Scholar] [CrossRef]

- Goncalves, L.; Patricio, L. From smart technologies to value cocreation and customer engagement with smart energy services. Energy Policy 2022, 170, 113249. [Google Scholar] [CrossRef]

- Cheng, K.; Jin, Z.; Wu, G. Unveiling the role of artificial intelligence in influencing enterprise environmental performance: Evidence from China. J. Clean. Prod. 2024, 440, 140934. [Google Scholar] [CrossRef]

- Cockburn, L.M.; Henderson, R.; Stern, S. The impact of artificial intelligence on exploratory analysis. In The Economics of Artificial Intelligence; University of Chicago Press: Chicago, IL, USA, 2018; pp. 115–146. [Google Scholar]

- Haug, A.; Wickstrom, K.A.; Stentoft, J.; Philipsen, K. The impact of information technology on product innovation in SMEs: The role of technological orientation. J. Small Bus. Manag. 2020, 7, 384–410. [Google Scholar] [CrossRef]

- Xi, M.J.; Liu, Y.; Fang, W.; Feng, T. Intelligent manufacturing for strengthening operational resilience during the COVID-19 pandemic: A dynamic capability theory perspective. J. Clean. Prod. 2024, 267, 109078. [Google Scholar] [CrossRef]

- Li, H.; Thurasamy, R. Green supply chain integration and sustainable performance in pharmaceutical industry of China: A moderated mediation model. System 2025, 13, 388. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, H.Y. The impact of customer orientation on new product development performance: The role of top management support. Int. J. Prod. Perform. Manag. 2018, 67, 590–607. [Google Scholar] [CrossRef]

- Chavez, R.; Yu, W.; Feng, M.; Wiengarten, F. The effect of customer-centric green supply chain management on operational performance and customer satisfaction. Bus. Strategy Environ. 2016, 25, 205–220. [Google Scholar] [CrossRef]

- Feng, T.; Wang, D. Supply chain involvement for better product development performance. Ind. Manag. Data Syst. 2013, 113, 190–206. [Google Scholar] [CrossRef]

- Zhao, X.; Huo, B.; Flynn, B.B.; Yeung, J.H.Y. The impact of power and relationship commitment on the integration between manufacturers and customers in a supply chain. J. Oper. Manag. 2008, 26, 368–388. [Google Scholar] [CrossRef]

- Foumani, M.; Smith-Miles, K. The impact of various carbon reduction policies on green flowshop scheduling. Appl. Energy 2019, 249, 300–315. [Google Scholar] [CrossRef]

- Petersen, K.J.; Handfield, R.B.; Ragatz, G.L. Supplier integration into new product development: Coordinating product, process and supply chain design. J. Oper. Manag. 2005, 23, 371–388. [Google Scholar] [CrossRef]

- Rajaguru, R.; Matanda, M.J. Effects of inter-organizational compatibility on supply chain capabilities: Exploring the mediating role of inter organizational information systems (IOIS) integration. Ind. Mark. Manag. 2013, 42, 620–632. [Google Scholar] [CrossRef]

- Giovanni, P.D. Do internal and external environmental management contribute to the triple bottom line? Int. J. Oper. Prod. Manag. 2012, 32, 265–290. [Google Scholar] [CrossRef]

- Elkington, J. Accounting for the triple bottom line. Meas. Bus. Excell. 1998, 2, 18–22. [Google Scholar] [CrossRef]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Svensson, G.; Hogevold, N.; Ferro, C.; Varela, J.C.S.; Padin, C. A triple bottom line dominant logic for business sustainability: Framework and empirical findings. J. Bus. Bus. Mark. 2016, 23, 153–188. [Google Scholar] [CrossRef]

- Sun, Y.; Sun, H. Green innovation strategy and ambidextrous green innovation: The mediating effects of green supply chain integration. Sustainability 2021, 13, 4876. [Google Scholar] [CrossRef]

- Liu, X.; Tse, Y.; Yu, Y.; Huang, H.; Zhao, X. Managing quality risk in supply chain to drive firm’s quality performance: The mediating role of supply chain quality integration. Ind. Manag. Data Syst. 2025, 125, 797–821. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. J. Purch. Supply Manag. 2013, 19, 106–117. [Google Scholar] [CrossRef]

- Feng, T.; Sun, L.; Sohal, A.S.; Wang, D. External involvement and firm performance: Is time-to-market of new products a missing link? Int. J. Prod. Res. 2014, 52, 727–742. [Google Scholar] [CrossRef]

- Asamoah, D.; Acquah, I.N.; Nuertey, D.; Agyei-Owusu, B.; Kumi, C.A. Unpacking the role of green absorptive capacity in the relationship between green supply chain management practices and firm performance. Benchmarking Int. J. 2024, 31, 2793–2818. [Google Scholar] [CrossRef]

- Visamitanan, K.; Assarut, N. Impact of Green Supply Chain Management Practices on Employee Engagement and Organizational Commitment: Mediating Role of Firm Performance. Glob. Bus. Rev. 2024, 25, 1336–1355. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J.; Meng, L. Toward new-generation intelligent manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Lu, Y.Q.; Xu, X.; Wang, L.H. Smart manufacturing process and system automation-A critical review of the standard sand envisioned scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, C.; Chen, C.; Huang, G.Q. Big data analytics for physical Internet-based Intelligent manufacturing shop floors. Int. J. Prod. Res. 2015, 55, 2610–2621. [Google Scholar] [CrossRef]

- Tian, H.; Li, Y.; Zhang, Y. Digital and intelligent empowerment: Can big data capability drive green process innovation of manufacturing enterprises? J. Clean. Prod. 2022, 377, 134261. [Google Scholar] [CrossRef]

- Zhao, X.; Huo, B.; Selen, W.; Yeung, J.H.Y. The impact of internal integration and relationship commitment on external integration. J. Oper. Manag. 2011, 29, 17–32. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Green supply chain management in China: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Extending green practices across the supply chain: The impact of upstream and downstream integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- Chen, I.J.; Paulraj, A. Towards a theory of supply chain management: The constructs and measurements. J. Oper. Manag. 2004, 22, 119–150. [Google Scholar] [CrossRef]

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Darnell, N.; Corley, C.A.; Handfield, R. Environmental management systems and green supply chain management: Complementary or redundant? Bus. Strategy Environ. 2010, 17, 30–45. [Google Scholar] [CrossRef]

- Wu, G.C. The influence of green supply chain integration and environmental uncertainty on green innovation in Taiwan’s IT industry. Supply Chain Manag. 2013, 18, 539–552. [Google Scholar] [CrossRef]

- Boyer, K.K.; Verma, R. Multiple raters in survey-based operations management research: A review and tutorial. Prod. Oper. Manag. 2010, 9, 128–140. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Chin, W.W. Commentary: Issues and opinion on structural equation modeling. MIS Q. 1998, 22, 7–16. [Google Scholar]

- European Commission. ‘Fit for 55’: Delivering the EU’s 2030 Climate Target on the way to climate neutrality. COM(2021) 550 final. Brussels. 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52021DC0550 (accessed on 28 November 2025).

- Appelbaum, E. Improving the efficacy of carbon tax policies. J. Gov. Econ. 2021, 4, 100027. [Google Scholar] [CrossRef]

| Dimension | Previous Seminal Studies (e.g., Zhu et al., 2007 [6,7]; Han & Huo, 2020 [20]) | Current Study’s Novel Contribution |

|---|---|---|

| Theoretical Foundation | Primarily Resource-Based View; Natural Resource-Based View | Extends to Dynamic Capabilities Theory; Triple Bottom Line integration |

| Core Variables | Focus on direct GSCI-Performance relationships | Introduces NPLS mediation and EIL moderation mechanisms |

| Research Context | Single-country focus (mainly China); Single industry | Multi-country (10 nations); Three technology-intensive industries |

| Methodological Approach | Cross-sectional surveys; Standard regression analysis | Advanced SEM with bootstrapping; Moderated mediation analysis |

| Main Findings | GSCI directly improves environmental performance | Reveals dual pathways: direct effects AND mediated through NPLS |

| Innovation Mechanism | Static resource acquisition perspective | Dynamic capability perspective: speed-to-market as crucial mechanism |

| Construct | Measurement Items | References |

|---|---|---|

| Green supplier integration | GSI1. Our enterprise maintains an open and honest communication attitude when collaborating with suppliers to advance green management and energy conservation and emissions reduction. | [51,52] |

| GSI2. Our enterprise and its suppliers have reached a highly consistent understanding of green management information across all supply chain segments. | ||

| GSI3. Our enterprise consistently engages in the exchange of green management information with suppliers in an honest manner. | ||

| Green customer integration | GCI1. Our enterprise believes it is very important to share information on green products and sustainable development with customers. | [53,54] |

| GCI2.Our enterprise will openly inform customers about its own problems in environmental practices and sustainable development. | ||

| GCI3.Our enterprise believes it is very important to establish sustainable development partnerships with customers. | ||

| GCI4.Our enterprise trusts that customers will treat us fairly when making important decisions related to the environment or sustainable development. | ||

| GCI5.Our enterprise emphasizes the importance of frank communication regarding green products and environmental issues in its cooperation with customers. | ||

| Green internal integration | GII1. Our enterprise continuously implements environmental upgrades and transformations to production equipment. | [51,53] |

| GII2. Our enterprise implements effective pollution prevention measures in its production and operational processes. | ||

| GII3. Our enterprise takes measures to reduce the probability and potential harm of environmental accidents. | ||

| New product launch speed | NPLS1. The time interval from product concept formation to the initiation of formal development is very short. | [3,16] |

| NPLS2. The coordination efficiency between various stages of the product development process is high, with minimal time consumption. | ||

| NPLS3. The pre-launch processes are advanced efficiently without significant delays. | ||

| NPLS4. The entire cycle time from concept design to the formal market launch of a new product is significantly shorter than the industry average. | ||

| Enterprise intelligence level | EIL1. The maturity level of utilizing big data analytics technologies to support strategic decision-making. | [21,23] |

| EIL2. The degree of integration of intelligent systems such as ERP/MES within core business processes including production, supply chain, and finance. | ||

| EIL3. The practical impact of intelligent platforms in facilitating knowledge sharing and collaborative innovation both internally and externally. | ||

| EIL4. The extent of real-time optimization and automation of supply chain and production processes achieved by intelligent systems. | ||

| EIL5. The breadth and depth of application of intelligent technologies in enabling personalized product/service innovation. | ||

| Environmental performance | EP1. Assesses the environmental impact throughout the entire lifecycle from raw materials to finished products. | [3,55,56] |

| EP2. Incorporates environmental factors into supplier evaluation and selection criteria. | ||

| EP3. Prioritizes the procurement of raw materials certified by third-party environmental certifications (e.g., green-certified products). | ||

| Financial performance | FP1. Improved overall profitability | [3,55,56] |

| FP2. Increased overall market success. | ||

| FP3. Improved the return on investment | ||

| Social performance | SP1. Prioritizes sourcing raw materials from economically underdeveloped regions. | [3,55,56] |

| SP2. Conducts on-site inspections of suppliers’ production bases and supervises their protection of labor rights. | ||

| SP3. Promotes the enhancement of environmentally friendly production processes among supply chain partners. |

| Country | Industry | Total | ||

|---|---|---|---|---|

| Electronics | Machinery | Transportation Components | ||

| Brazil | 2 | 5 | 6 | 13 |

| Germany | 6 | 11 | 7 | 24 |

| China | 94 | 79 | 31 | 204 |

| Spain | 6 | 5 | 10 | 21 |

| Israel | 5 | 1 | 0 | 6 |

| Sweden | 4 | 3 | 1 | 8 |

| Italy | 5 | 17 | 4 | 26 |

| Japan | 5 | 6 | 9 | 20 |

| Republic of Korea | 8 | 5 | 13 | 26 |

| Finland | 6 | 6 | 4 | 16 |

| Total | 141 | 138 | 85 | 364 |

| Firm Age | Frequency | Percentage |

|---|---|---|

| ≤20 | 67 | 18.40% |

| 21~40 | 150 | 41.20% |

| 41~60 | 73 | 20.10% |

| 61~80 | 52 | 14.30% |

| 81~100 | 12 | 3.30% |

| >100 | 10 | 2.70% |

| Respondents | Number of Respondents per Firm |

|---|---|

| Plant accounting manager | 1 |

| Direct labor | 10 |

| Human resources manager | 1 |

| Information systems manager | 1 |

| Production control manager | 1 |

| Inventory manager | 1 |

| Member of product development team | 1 |

| Process engineer | 1 |

| Plant manager | 1 |

| Quality manager | 1 |

| Supervisor | 3 |

| Plant superintendent | 1 |

| Total respondents per firm | 23 |

| Construct | Dimension | Item Code | CITC | Cronbach’s α If Item Deleted | Cronbach’ α |

|---|---|---|---|---|---|

| Green supply chain integration | Green supplier integration | GSI1 | 0.640 | 0.609 | 0.754 |

| GSI2 | 0.592 | 0.661 | |||

| GSI3 | 0.522 | 0.742 | |||

| Green customer integration | GCI1 | 0.621 | 0.721 | 0.783 | |

| GCI2 | 0.6 | 0.734 | |||

| GCI3 | 0.592 | 0.733 | |||

| GCI4 | 0.549 | 0.747 | |||

| GCI5 | 0.453 | 0.775 | |||

| Green internal integration | GII1 | 0.746 | 0.717 | 0.834 | |

| GII2 | 0.629 | 0.833 | |||

| GII3 | 0.711 | 0.754 | |||

| New product launch speed | NPLS1 | 0.498 | 0.657 | 0.716 | |

| NPLS2 | 0.516 | 0.654 | |||

| NPLS3 | 0.532 | 0.637 | |||

| NPLS4 | 0.484 | 0.666 | |||

| Enterprise intelligence level | EIL1 | 0.758 | 0.918 | 0.926 | |

| EIL2 | 0.734 | 0.923 | |||

| EIL3 | 0.856 | 0.899 | |||

| EIL4 | 0.846 | 0.901 | |||

| EIL5 | 0.840 | 0.902 | |||

| Green innovation performance | Environmental performance | EP1 | 0.668 | 0.662 | 0.786 |

| EP2 | 0.661 | 0.677 | |||

| EP3 | 0.555 | 0.787 | |||

| Financial performance | FP1 | 0.741 | 0.666 | 0.815 | |

| FP2 | 0.534 | 0.807 | |||

| FP3 | 0.739 | 0.668 | |||

| Social performance | SP1 | 0.577 | 0.749 | 0.782 | |

| SP2 | 0.653 | 0.667 | |||

| SP3 | 0.632 | 0.691 |

| KMO-Value | 0.838 | |

| Bartlett’s sphericity test | Approximate chi-square (χ2) | 5270.090 |

| df | 406 | |

| p-value | 0.000 | |

| Construct | Dimension | Item Code | Factor Loading | CR | AVE |

|---|---|---|---|---|---|

| Green supply chain integration | Green supplier integration | GSI1 | 0.852 | 0.840 | 0.650 |

| GSI2 | 0.787 | ||||

| GSI3 | 0.767 | ||||

| Green customer integration | GCI1 | 0.788 | 0.840 | 0.520 | |

| GCI2 | 0.756 | ||||

| GCI3 | 0.742 | ||||

| GCI4 | 0.699 | ||||

| GCI5 | 0.606 | ||||

| Green internal integration | GII1 | 0.703 | 0.780 | 0.540 | |

| GII2 | 0.712 | ||||

| GII3 | 0.794 | ||||

| New product launch speed | NPLS1 | 0.700 | 0.810 | 0.510 | |

| NPLS2 | 0.692 | ||||

| NPLS3 | 0.764 | ||||

| NPLS4 | 0.710 | ||||

| Enterprise intelligence level | EIL1 | 0.820 | 0.940 | 0.750 | |

| EIL2 | 0.817 | ||||

| EIL3 | 0.895 | ||||

| EIL4 | 0.899 | ||||

| EIL5 | 0.886 | ||||

| Green innovation performance | Environmental performance | EP1 | 0.780 | 0.820 | 0.610 |

| EP2 | 0.803 | ||||

| EP3 | 0.749 | ||||

| Financial performance | FP1 | 0.880 | 0.870 | 0.690 | |

| FP2 | 0.728 | ||||

| FP3 | 0.882 | ||||

| Social performance | SP1 | 0.701 | 0.790 | 0.560 | |

| SP2 | 0.742 | ||||

| SP3 | 0.796 |

| Y | ← | X | Unstandardized Path Coefficient | S.E. | C.R. | p | Standardized Path Coefficient | Significant/ Non-Significant |

|---|---|---|---|---|---|---|---|---|

| New product launch speed | ← | Green customer integration | 0.316 | 0.120 | 2.628 | 0.009 | 0.192 | Significant |

| New product launch speed | ← | Green internal integration | 0.096 | 0.067 | 1.441 | 0.150 | 0.093 | Non-significant |

| New product launch speed | ← | Green supplier integration | 0.283 | 0.094 | 3.022 | 0.003 | 0.225 | Significant |

| Environmental performance | ← | New product launch speed | 0.501 | 0.121 | 4.139 | *** | 0.303 | Significant |

| Financial performance | ← | New product launch speed | 0.344 | 0.087 | 3.971 | *** | 0.276 | Significant |

| Social performance | ← | New product launch speed | 0.393 | 0.094 | 4.177 | *** | 0.318 | Significant |

| Environmental performance | ← | Green supplier integration | 0.137 | 0.079 | 1.744 | 0.081 | 0.079 | Non-significant |

| Financial performance | ← | Green supplier integration | 0.006 | 0.061 | 0.094 | 0.925 | 0.011 | Non-significant |

| Social performance | ← | Green supplier integration | 0.168 | 0.066 | 2.568 | 0.010 | 0.127 | Significant |

| Environmental performance | ← | Green customer integration | 0.281 | 0.109 | 2.571 | 0.010 | 0.118 | Significant |

| Financial performance | ← | Green customer integration | 0.409 | 0.129 | 3.738 | *** | 0.667 | Significant |

| Social performance | ← | Green customer integration | 0.265 | 0.091 | 2.899 | 0.004 | 0.145 | Significant |

| Environmental performance | ← | Green internal integration | 0.925 | 0.079 | 9.418 | *** | 0.679 | Significant |

| Financial performance | ← | Green internal integration | 0.175 | 0.045 | 3.892 | *** | 0.475 | Significant |

| Social performance | ← | Green internal integration | 0.619 | 0.074 | 9.352 | *** | 0.664 | Significant |

| Hypothesis | c | a | b | a × b | a × b | a × b | a × b | a × b | c’ | Test Conclusion |

|---|---|---|---|---|---|---|---|---|---|---|

| Total Effect | Mediation Effect Value | Boot SE | z-Value | p-Value | 95% Boot CI | Direct Effect | ||||

| H7a | 0.068 | 0.177 ** | 0.219 ** | 0.039 | 0.016 | 2.377 | 0.017 | 0.012~0.075 | 0.029 | Full Mediation |

| H8a | 0.178 * | 0.177 ** | 0.139 * | 0.024 | 0.011 | 2.195 | 0.028 | 0.000~0.044 | 0.154 * | Partial Mediation |

| H6a | 0.139 * | 0.177 ** | 0.164 * | 0.029 | 0.012 | 2.493 | 0.013 | 0.003~0.048 | 0.110 | Full Mediation |

| H6b | 0.113 | 0.212 ** | 0.171 * | 0.036 | 0.012 | 3.055 | 0.002 | 0.004~0.051 | 0.077 | Full Mediation |

| H7b | 0.191 ** | 0.212 ** | 0.200 ** | 0.042 | 0.013 | 3.146 | 0.002 | 0.015~0.067 | 0.149 ** | Partial Mediation |

| H8b | 0.132 | 0.212 ** | 0.149 * | 0.032 | 0.012 | 2.741 | 0.006 | 0.002~0.047 | 0.100 | Partial Mediation |

| H6c | 0.886 ** | 0.092 | 0.082 | 0.008 | 0.005 | 1.515 | 0.130 | −0.001~0.018 | 0.878 ** | Non-significant |

| H7c | 0.097 * | 0.092 | 0.215 ** | 0.020 | 0.013 | 1.503 | 0.133 | 0.001~0.052 | 0.077 | Full Mediation |

| H8c | 0.750 ** | 0.092 | 0.079 | 0.007 | 0.005 | 1.335 | 0.182 | −0.002~0.019 | 0.742 ** | Non-significant |

| Dependent Variable | Independent Variable | R2 | Adjusted R2 | F-Value |

|---|---|---|---|---|

| Environmental performance | Green supplier integration | 0.011 | 0.099 | F (5358) = 8.935, p = 0.000 |

| Green customer integration | 0.107 | 0.095 | F (5358) = 8.594, p = 0.000 | |

| Green internal integration | 0.616 | 0.610 | F (5358) = 114.757, p = 0.000 | |

| Financial performance | Green supplier integration | 0.087 | 0.075 | F (5358) = 6.849, p = 0.000 |

| Green customer integration | 0.104 | 0.091 | F (5358) = 8.282, p = 0.000 | |

| Green internal integration | 0.094 | 0.082 | F (5358) = 7.455, p = 0.000 | |

| Social performance | Green supplier integration | 0.107 | 0.095 | F (5358) = 8.607, p = 0.000 |

| Green customer integration | 0.099 | 0.087 | F (5358) = 7.884, p = 0.000 | |

| Green internal integration | 0.464 | 0.456 | F (5358) = 61.985, p = 0.000 |

| New Product Launch Speed | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | Model 6 | Model 7 | Model 8 | Model 9 | |

| Country | −0.013 | −0.012 | −0.010 | −0.012 | −0.011 | −0.008 | −0.015 | −0.014 | −0.011 |

| (−0.879) | (−0.819) | (−0.693) | (−0.870) | (−0.803) | (−0.595) | (−1.070) | (−1.001) | (−0.751) | |

| Industry | −0.086 | −0.085 | −0.084 | −0.084 | −0.083 | −0.092 * | −0.083 | −0.082 | −0.095 * |

| (−1.918) | (−1.917) | (−1.924) | (−1.879) | (−1.885) | (−2.133) | (−1.834) | (−1.850) | (−2.149) | |

| Firm age | 0.003 * | 0.003 * | 0.003 * | 0.004 * | 0.004 ** | 0.003 * | 0.003 | 0.003 * | 0.004 * |

| (1.996) | (2.213) | (2.241) | (2.496) | (2.653) | (2.417) | (1.957) | (2.213) | (2.437) | |

| GSI | 0.177 *** | 0.150 ** | 0.185 *** | ||||||

| (3.368) | (2.845) | (3.470) | |||||||

| GCI | 0.212 *** | 0.184 ** | 0.238 *** | ||||||

| (3.560) | (3.097) | (4.017) | |||||||

| GII | 0.092 | 0.059 | 0.102 * | ||||||

| (1.959) | (1.258) | (2.103) | |||||||

| EIL | 0.102 ** | 0.103 ** | 0.103 ** | 0.096 ** | 0.109 *** | 0.112 *** | |||

| (3.160) | (3.208) | (3.189) | (3.049) | (3.304) | (3.457) | ||||

| GSI × EIL | 0.143 ** | ||||||||

| (2.927) | |||||||||

| GCI × EIL | 0.221 *** | ||||||||

| (4.344) | |||||||||

| GII × EIL | 0.132 ** | ||||||||

| (3.192) | |||||||||

| R2 | 0.052 | 0.078 | 0.099 | 0.055 | 0.081 | 0.128 | 0.032 | 0.061 | 0.087 |

| Adjusted R2 | 0.041 | 0.065 | 0.084 | 0.045 | 0.069 | 0.113 | 0.022 | 0.048 | 0.072 |

| F | F (4359) = 4.922, p = 0.001 | F (5358) = 6.033, p = 0.000 | F (6357) = 6.562, p = 0.000 | F (4359) = 5.262, p = 0.000 | F (5358) = 6.351, p = 0.000 | F (6357) = 8.702, p = 0.000 | F (4359) = 3.004, p = 0.018 | F (5358) = 4.652, p = 0.000 | F (6357) = 5.675, p = 0.000 |

| ΔR2 | 0.052 | 0.026 | 0.022 | 0.055 | 0.026 | 0.046 | 0.032 | 0.029 | 0.026 |

| ΔF | F (4359) = 4.922, p = 0.001 | F (1358) = 9.986, p = 0.002 | F (1357) = 8.569, p = 0.004 | F (4359) = 5.262, p = 0.000 | F (1358) = 10.170, p = 0.002 | F (1357) = 18.870, p = 0.000 | F (4359) = 3.004, p = 0.018 | F (1358) = 10.916, p = 0.001 | F (1357) = 10.189, p = 0.002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Chen, J.; Song, Y.; Hu, J.; Zhang, H.; Shao, Y. Green Supply Chain Integration, New Product Launch Speed, and Green Innovation Performance: The Moderating Role of Enterprise Intelligence Level. Sustainability 2025, 17, 10967. https://doi.org/10.3390/su172410967

Yang F, Chen J, Song Y, Hu J, Zhang H, Shao Y. Green Supply Chain Integration, New Product Launch Speed, and Green Innovation Performance: The Moderating Role of Enterprise Intelligence Level. Sustainability. 2025; 17(24):10967. https://doi.org/10.3390/su172410967

Chicago/Turabian StyleYang, Fan, Jingyi Chen, Yuting Song, Jinyi Hu, Huiying Zhang, and Yiting Shao. 2025. "Green Supply Chain Integration, New Product Launch Speed, and Green Innovation Performance: The Moderating Role of Enterprise Intelligence Level" Sustainability 17, no. 24: 10967. https://doi.org/10.3390/su172410967

APA StyleYang, F., Chen, J., Song, Y., Hu, J., Zhang, H., & Shao, Y. (2025). Green Supply Chain Integration, New Product Launch Speed, and Green Innovation Performance: The Moderating Role of Enterprise Intelligence Level. Sustainability, 17(24), 10967. https://doi.org/10.3390/su172410967