1. Introduction

In the last decade, the circular economy (CE) concept has become an issue of heightened interest for researchers, practitioners, policymakers, companies, and industries [

1,

2,

3]. CE moves away from the conventional linear approach which utilizes a “make-use-dispose” economic model to one that is “regenerative by design” [

4,

5]. It aims to eradicate waste through careful design; reduce negative impacts; rebuild environmental, economic, and social capital; and maintain the value of products, components, and materials [

6,

7]. The value can be maintained through the implementation of various circularity strategies [

8].

Currently, some companies are taking steps to implement circularity strategies and, therefore, more circular products and services are reaching the market [

9,

10]. However, widespread adoption of circularity strategies still has not taken place [

11] and companies are struggling to implement and operationalize CE. This means that CE research is focusing on understanding the barriers and challenges that companies face (e.g., [

11,

12]) as well as developing decision-making support in the form of tools, metrics, and methods for companies to implement circularity strategies [

13].

Research focused on the evaluation of circularity strategies for products and services compared to each other or to their business-as-usual counterparts or other products in the same product group which are just starting to take off [

14]. More generally, there is a lack of evaluation methods of CE strategies of products and services at the micro level, i.e., product, company or single consumer-level [

9,

15,

16,

17] and there are few studies that have conducted and presented evaluations of such circularity strategies [

9,

18,

19]. These kinds of evaluation methods can serve different purposes, e.g., strategy selection or identification of hotspots.

One specific area where business decision-makers need indicators or methods to help them evaluate circularity strategies is to select the best strategy when a product reaches the end-of-life (EoL) stage. There is a lack of such evaluation methods of product-level circularity strategies, as indicated by Sassanelli et al. [

20] in a literature review on CE assessment methods and tools, and by Saidani et al. [

10], who created a taxonomy of CE indicators including more than 55 sets of indicators. Elia et al. [

9] supported this argument in the recent work on critical analysis of CE assessment and indicators at micro level.

The objective of this article is, therefore, to address the following research question (RQ):

Evaluating a circularity strategy cannot be done based on a single indicator or criterion, because apart from the contributing to waste reduction and negative impact mitigation, a strategy also needs to be

feasible and

financially viable and may require considerable investments [

21,

22] (see

Section 2.2 for a more in-depth discussion). Therefore, the main research question is further broken down into two sub-questions:

What are the relevant criteria and sub-criteria/indicators to be used to evaluate circularity strategies?

How to evaluate circularity strategies using a decision-making method that incorporates the criteria and sub-criteria/indicators?

The overarching aim is to propose a decision-making method to evaluate circularity strategies of products and added services. The method evaluates potential alternative circularity strategies including (but not limited to) the initial or business-as-usual strategy of the company which could be traditional product sales or includes some form of product-level circular strategy, e.g., remanufacturing (reman), compared with various forms of more advanced or transformative strategies and future circularity strategies. Transformative strategies could be advanced remanufacturing, multiple or mixed reuse strategies and added service offerings (also known as product-service systems). The method aims to help business decision-makers to select the best feasible circularity strategy. It can be implemented at EoL phase by the company providing the initial product and third-party recovery/remanufacturing companies. Apart from introducing the method, this work gives two examples of its application and subsequent verification.

The organization of this article is as follows:

Section 2 presents a literature review about CE, circularity strategies, decision-making factors, and CE assessment methods.

Section 3 exposes the research methodology employed in this study to build the circularity strategies decision-making method. The results of this paper, i.e., the multi-criteria evaluation method of product-level circularity strategies, is presented in

Section 4. Verification of the proposed method through cases is presented in

Section 5.

Section 6 discusses and summarizes the main findings of the study and points out future research opportunities.

3. Materials and Methods

The point of departure for this research is a review of literature on the main themes related to the research question and sub-questions, namely, circularity strategies for a product and/or service, and evaluation methods of circularity strategies; identification and selection of decision-making criteria as well as sub-criteria and indicators. More than fifty relevant publications related to the subject area are reviewed. The research process for developing the evaluation method of circularity strategies for products and/or services includes (i) initial evaluation method selection, (ii) selection of criteria, sub-criteria and indicators, (iii) method development, and (iv) verification of the proposed method.

3.1. Initial Method Selection

A literature review was conducted to understand the state of the art on the evaluation of circularity strategies. As discussed in

Section 2.2, circularity strategies’ evaluation methods often employ optimization, multi-criteria, or empirical methods for decision-making. Based on the review of literature concerning the challenges and complexity faced by companies implementing circularity strategies (

Section 2.2), the advantages and disadvantages of using each method for decision-making are analyzed. In this paper, a MCDM approach is used to develop a circularity strategies’ evaluation method. The reasons for choosing MCDM are: (i) that a wide range of criteria can be included, (ii) both qualitative and quantitative data can be incorporated, and (iii) flexibility and tailoring to the case requirements is allowed (see

Section 2.3 for an in-depth review).

3.2. Selection of Decision Criteria, Sub-Criteria and Indicators

Based upon a comprehensive literature review of more than 50 relevant publications and feedback from five experts in the subject domain, decision-making criteria, sub-criteria and indicators are identified. Firstly, an exhaustive list of criteria was made. Then the decision-making factors were sorted into various categories (i.e., business, technical, economic, environmental, legislative and societal) by the authors as seen in

Table 2. Afterwards, the list was updated and verified based on expertise feedback from the industry and academia. Detailed results of this research can be accessed from Alamerew and Brissaud (2018) [

49]. This list was revisited in preparation of this article and checked against literature, e.g., challenges and barriers to circular strategy adoption, published in intervening years, i.e., 2018–2020. In accordance with MCDM methodology, this list is recommended but not required since decision-makers can choose the most relevant criteria, sub-criteria and indicators for their case.

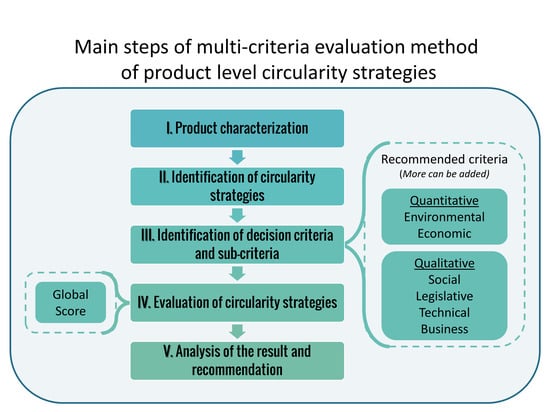

3.3. Method Development

Due to the complexity of circular systems, an integrated approach is required to incorporate all the decision-making criteria and to take into consideration both quantitative and qualitative factors. Based on the result of a comprehensive literature review, evaluation of circularity strategies can be formulated as an MCDM problem. The multi-criteria evaluation method of circularity strategies involves (i) description of the product under consideration, (ii) finding potential circularity strategies, (iii) identifying evaluation criterion and decision-making factors, (iv) evaluation of circularity strategies, and (v) analysis and ranking of circularity alternatives.

In this study, MCDM is used to build the proposed method. The proposed method is first developed based on simple multi-attribute rating technique (SMART) [

74,

75,

76]. SMART is a multi-criteria decision-making method that can comprehensively account both qualitative and quantitative criteria. Afterward, the authors reduce the complexity in order to develop a practical method that can be effectively applied to real case studies. All authors contributed to the development of the method by iteratively commenting on the method during the development period.

3.4. Verification of the Method

To verify the application of the proposed circularity strategies’ evaluation method, two illustrative examples are presented based on two case studies. Secondary data from two Swedish companies, so-called Company A and Company B, is used to exemplify the application of the method. Company A is involved in waste management whereas Company B is a storage furniture supplier. Descriptions of the case companies are presented in

Section 6.

4. Multi-Criteria Evaluation Method of Product-Level Circularity Strategies Description

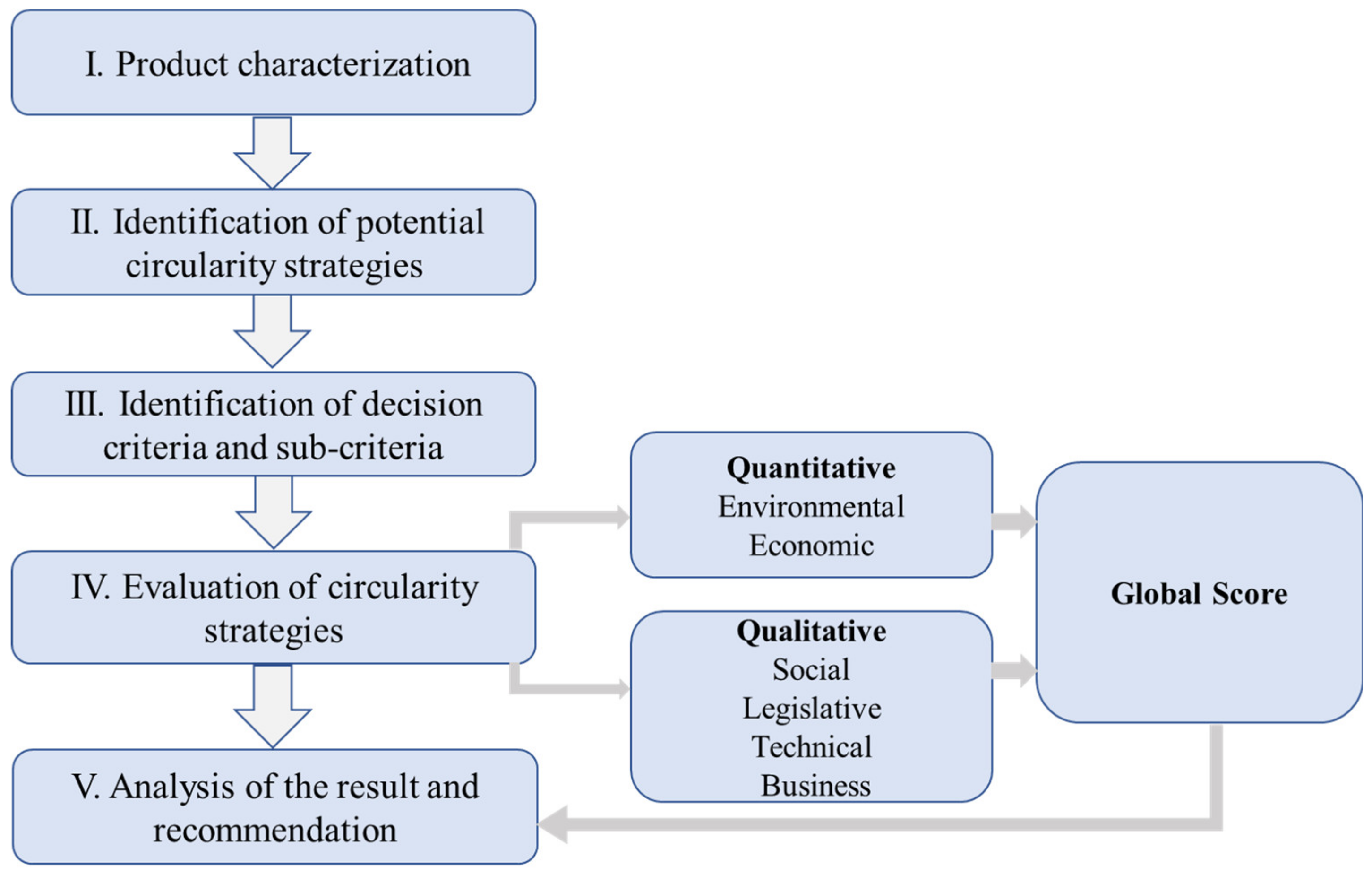

In this section, the main contribution of the research is presented. An MCDM is proposed to evaluate alternative circularity strategies for products in a specific company at the EoL stage. The proposed MCDM consists of five main steps: (I) description of the product and/or service under consideration, (II) identification of potential circularity strategies, (III) identification of evaluation criteria, sub-criteria and indicators, (IV) evaluation of circularity strategies, and (V) analysis and ranking of alternative circularity strategies. The focus of this method is on steps III and IV. The graphical representation of the method is shown in

Figure 2. In this section, each step of the evaluation method is described in detail.

4.1. Product Characterization

This first step of the method aims to identify the main characteristics of the product and/or service under consideration. This information will help to identify decision-making criteria and potential circularity strategies that are relevant to the product at hand, in the next steps of the methodology [

77]. A potential circularity strategy is a possible candidate for evaluation and comparison during the decision-making process [

78]. A description of the product is decisive for a company to be able to efficiently choose potential circularity strategies for a typical product. Description of the product covers relevant information regarding its characteristics, e.g., type of components and materials as well as functional use by the consumer. The main output of this step is to identify characteristics that influence the selection of circularity strategies.

4.2. Identification of Circularity Strategies

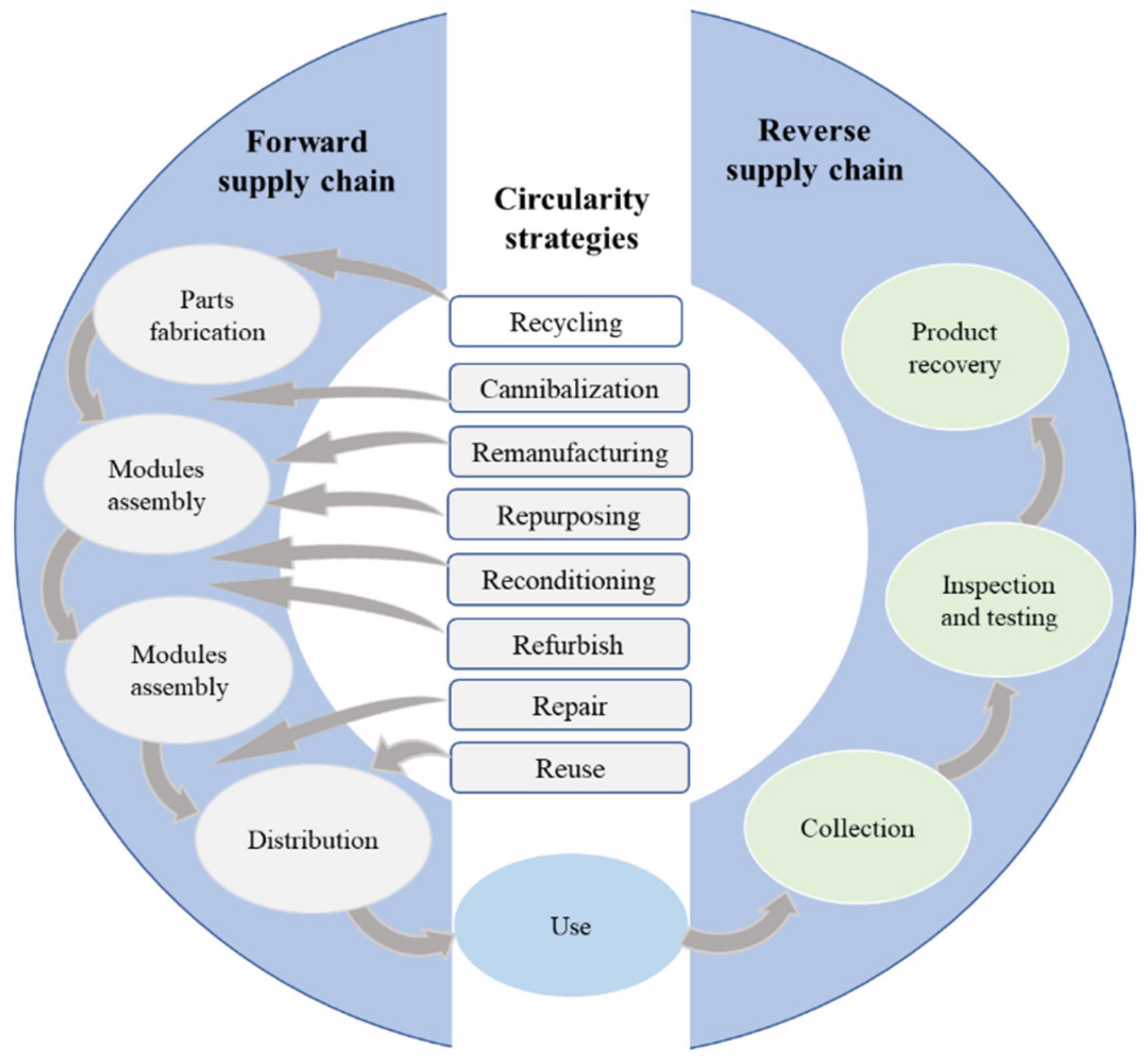

Based on the outputs of step 1, i.e., description of characteristics of the product, in this step, potential circularity strategies are identified. First, the current business strategy of the company (business-as-usual or traditional business strategy) is identified from a set of circularity strategies defined in

Section 2.1. Then potential transformative strategies are selected based on the characteristics of the product outlined in

Section 4.1 and a set of circularity strategies defined in

Section 2.1. The transformative strategy can be identified from the current business model of the company in case if the company is implementing circular strategies. Transformative circularity strategies may include strategies such as advanced remanufacturing, multiple/mixed reuse strategies and product service offerings. Afterwards, a possible future strategy is identified that may have considerable business potential for the company in the near future. The main output of this step is a list of potential circularity strategies.

Depending on the specifics of the case, e.g., company size and complexity of the supply chain, it can be relevant to include a variety of stakeholders in this step and, as well, as employ tools that support innovation for a circular economy. Bocken et al. (2019) [

79] have reviewed such available tools and new ones are being developed, e.g., Bloosma et al. (2020) [

59].

4.3. Identification of Decision Criteria, Sub-Criteria and Indicators

There are various factors that influence the choice of a circularity strategy of products at EoL stage [

12,

14,

61] (see

Section 2.2). Based on a systematic literature review, Alamerew and Brissaud (2018) [

49], developed a list of CE evaluation criteria as well as sub-criteria, and evaluation indicators that are presented in

Table 2.

The list consists of both quantitative and qualitative criteria. These criteria cover, as discussed in

Section 2.2 and

Section 2.3, the circular strategies’ potential contributions to CE, i.e., environmental, economic, and social, as well as their feasibility, i.e., legislative, technical, and business. The latter three criteria also coincide with three of the four major challenges faced by companies when implementing circular strategies, which were identified more recently by Kirchherr et al. (2018) [

11] as cultural, regulatory, market, and technological. Therefore, the criteria in

Table 2 are the recommended criteria for evaluating circularity strategies.

Alamerew and Brissaud (2018) [

49] also suggest sub-criteria and indicators that can be used when setting values to the criteria (

Table 2). Not all the sub-criteria need to be used, e.g., only Life Cycle Assessment (LCA) could be used to evaluate the environmental criterion. Moreover, the list is not exhaustive, as new indicators targeting the circular economy are constantly being introduced. For example, Pauliuk (2018) [

58] makes a strong case for using Material Flows Analysis (MFA) as an indicator of circularity.

Concerning the three criteria for assessing contributions towards a circular economy, i.e., environmental, economic, and social, there is a strong recommendation to use life cycle approaches because circularity strategies that influence one life cycle stage can shift burdens to other life cycle stages [

77,

80]. Therefore, Life Cycle Assessment (LCA) and LCC are recommended as the indicators for evaluating environmental and economic criteria respectively and care should be made when making methodological choices so that they can be used in parallel [

81]. Since Social Life Cycle Assessment (SLCA) is not robust and widely used [

82], other types of qualitative indicators are recommended as sub-criteria or indicators for the criterion “social”.

Concerning the three feasibility criteria, i.e., legislative, technical, and business, there is a strong recommendation that decision-makers use qualitative indicators. For example, a scoring table including three: 3—High; 2—Average; 1—Low; or five scales: 5—Very high; 4—High; 3—Average; 2—Low; 1—Very Low can be used. Additionally, more than one type of indicator can be used so that multiple areas within a criterion are covered, e.g., volatility of the price of recovered materials and expected demand.

It must be clarified that criteria, sub-criteria, and indicators can be changed depending on the specifics of the case, such as the complexity of the supply chain, the decision-makers’ normative values, the availability of data, and the type of the product under consideration. For example, some companies might add a criterion about “company culture”. Learnings from the research on challenges companies face when implementing circularity strategies, e.g., Kirchherr et al. (2018) [

11], Mont et al. (2017) [

56], Rizos et al. (2016) [

12] indicate that challenges are case-specific although there are some similarities. Therefore, it is especially important that the sub-criteria and indicators for legislative, technical, and business criteria are chosen carefully by decision-makers to suit the context.

Finally, as proposed by Lindfors et al. (2019), every effort should be made so that criteria, sub-criteria, and indicators are comprehensive but do not overlap, and that relevant stakeholders are included in the process of identifying them [

22].

4.4. Evaluation of Circularity Strategies

After identifying the list of circularity strategies and evaluation criteria, sub-criteria, and indicators, the next phase of the method is to evaluate each alternative circularity strategy against the decision criteria. The main output of this step is an assessment value for each circularity strategy. The graphical representation of the main steps of the proposed evaluation method is shown below in

Figure 2.

A typical problem consists of a set of available circularity strategies Ai (i = 1,2, …, n). Circularity strategies are evaluated against a set of criteria Cj (j = 1,2, …, m). Each criteria Cj may be broken down into Pj sub-criteria (decision factors) or indicators, Cjk (K = 1,2, …, Pj). The decision-maker is expected to evaluate circularity strategies with respect to each decision criteria denoted as Xij (i = 1,2, …, n; j = 1,2, …, m).

The general model applied for the proposed method is:

where:

Wj is the weighted value of j of m criteria

Xi(j) is the value of i of criterion j

M(Ai) is total evaluation result for each strategy.

The weighting value (Wj) is assigned based on the relative importance of each criterion/sub-criterion for the evaluation decision. It depends on the type of product, the type of industry, and the perception of the decision-maker. In this step, the decision-maker assigns the value based on experience with the business-as-usual product and strategy. Often, many decision-makers may be involved in assigning weighting values and a discursive approach is recommended.

Then, the evaluation score for each of the circularity strategies against each sub-criteria/decision factor and indicator both for the qualitative and quantitative factors is calculated. In this step, a scale-based parameter value (5—Very high; 4—High; 3—Average; 2—Low; 1—Very low) can be assigned for the qualitative decision factors such as business, technical, societal, and legislative. LCA and LCC can, for example, be performed to evaluate the environmental and economic performance for the quantitative indicators respectively. As discussed in

Section 4.3, these criteria, sub-criteria and indicators can be changed depending on the preferences of the decision-maker(s) as well as the availability of data and related factors.

Afterward, relative weighting (normalization) is conducted to allow a comparable scale for all circular strategies using Equations (2) and (3). Depending on the typical problem, Equation (2) is used when the objective of the problem is to maximize the result and Equation (3) is used when the objective is to minimize the result.

The normalization for maximization problem:

The normalization for minimization problem:

where:

Finally, the overall score of each circularity strategy is computed based on Equation (4) and ranked the result in descending order.

where:

Wj is the weighted value of j of m criteria

Xi(j) is the value of i of criterion j

M(Ai) is total evaluation result for each strategy.

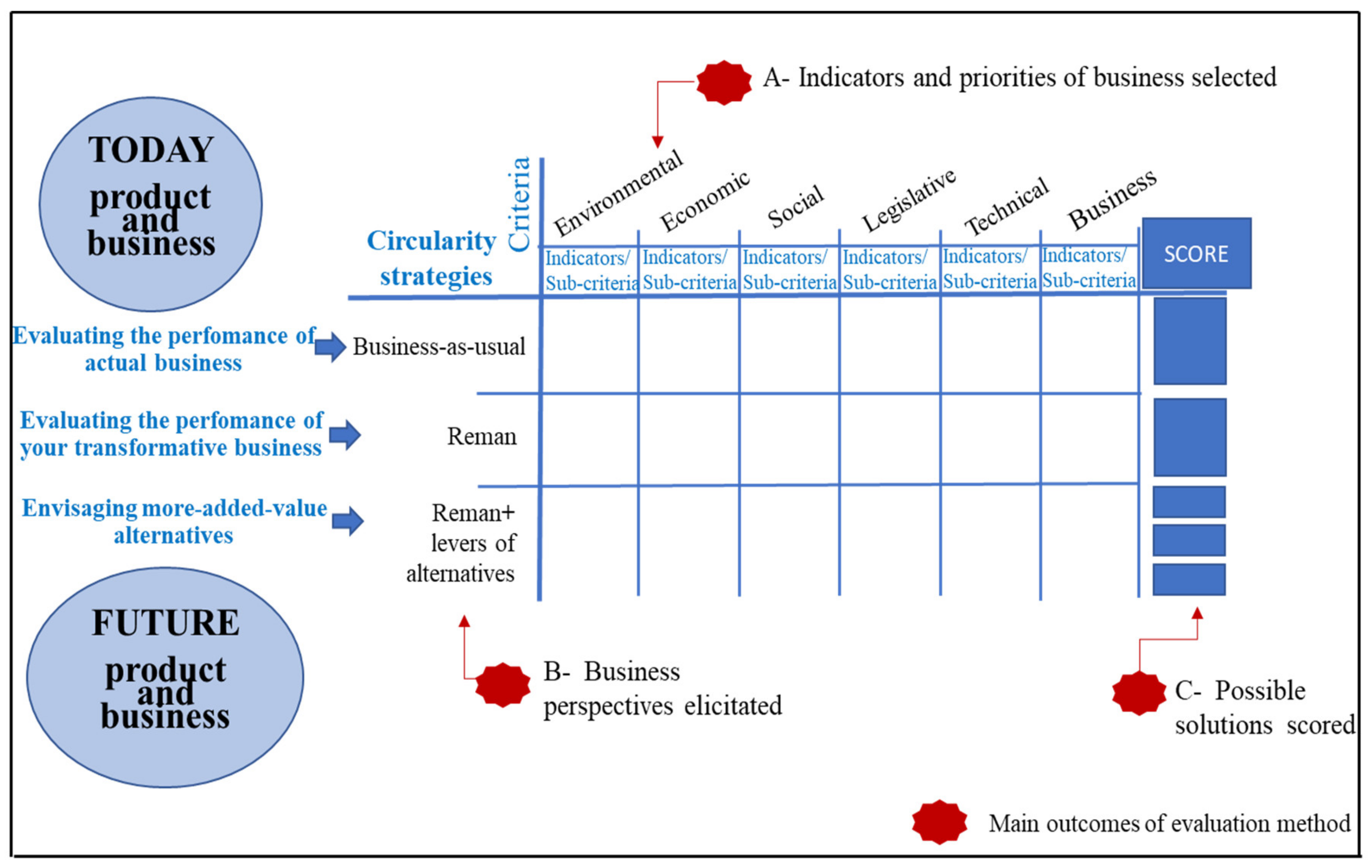

4.5. Analysis of the Result and Recommendation

This step involves analyzing the overall score of each of the circularity strategies and providing recommendations concerning the circularity strategies from the available list of alternatives. The main elements and outcomes of the evaluation method for the user (decision-maker) are depicted in

Figure 3.

6. Discussion and Conclusions

6.1. Discussion

One of the challenges that impede companies from transforming their business towards a CE model is the lack of methods, tools, and indicators to be able to evaluate different circularity strategies. In this article, a multi-criteria evaluation method of circularity strategies for products and/or services has been developed and verified. This method can be implemented at EoL phase by the company providing the initial product and third-party recovery/remanufacturing companies.

One of the limitations of this MCDM method is a lack of linkages between the criteria. MCDM is characterized by criteria independence without correlation [

83]. Due to the complexity of CE, it is imperative to understand the interaction (direct or indirect dependency) among decision factors in the decision-making process.

There is also a risk with MCDM, that sub-criteria and indicators present overlaps so the effect of a decision gets double-counted or that they do not comprehensively cover a criterion so some effects are not taken into account when making a decision [

22]. Moreover, MCDM uses qualitative indicators. The assignment of verbal grading to these indicators and its conversion into a parameter value based on a qualitative scale is subject to ambiguity. When assigning weighing values to criteria, it may be difficult for the decision-maker to decide which of the criteria have more influence and to quantify this influence for the circularity alternatives. To minimize but not eliminate these risks, it is recommended that relevant stakeholders and decision-makers deliberate over and jointly discuss various choices, e.g., indicator choice, grading, and weighting.

In order to transform the qualitative criteria into quantitative numbers, a rating scale is used. In this study, a semantic scale, Likert, is recommended as it is commonly used in business decision-making [

84,

85]. A scoring scale from 1 to 5 is used to quantify the qualitative factors. Theoretically, the numerical scale/verbal grading cannot be restricted, and other scales can be used following investigation.

The proposed method uses an integrated approach to evaluate the environmental and economic benefits of circularity strategies together with social, legislative, business and technical aspects. An illustrative example through the two case studies is presented which shows that the proposed method is simple and effective in dealing with circularity strategy evaluation problems. The case studies demonstrate the process of evaluating CE strategies at the EoL phase of the product. However, the case examples lack in demonstrating the broader impact of each strategy due to the implementation of circular practices across the product life cycle such as the continuous flow of products, components, materials and information, as well as the application of service offering. This can be analyzed by studying the environmental, economic and social benefit for the company and the resulting outcome due to the implementation of circularity strategies.

The results from the cases demonstrate that the method can identify not only differences between business-as-usual and circularity strategies, but also between different types of circularity strategies. Compared to Alamerew and Brissaud (2018) [

49], this method evaluates and compares the initial business of the company, a transformative strategy that transforms a product through the implementation of advanced circularity strategies and future circular strategies.

Some of the main benefits of the proposed method are:

It guides the decision-makers through the whole process of identifying and evaluating various potential circularity strategies against each other and business-as-usual.

It helps companies identify potential circular offerings and strategies.

It suggests a list of criteria and sub-criteria/indicators which are relevant for evaluating circular strategies, but also allows for flexibility so that the decision-maker can modify these criteria and provides insights on how to approach such modifications.

It can be used to evaluate and compare a large number of circular strategies.

It is a flexible method that can easily be scaled up or down to meet the needs of the decision-makers.

Finally, by using this method, more companies may be encouraged to implement circularity strategies. This can reduce the environmental impacts associated with their products and/or services, and thereby potentially contribute to relative resource decoupling [

86]. Of course, there is always a risk of rebound effects so it might not necessarily lead to absolute resource decoupling (ibid.). Therefore, a limitation of this evaluation method is that it does not take into consideration rebound effects.

This evaluation method, however, can even help companies who are, as Matschewsky (2019) [

87] describes it, unintentionally contributing to relative resource decoupling to evaluate their contributions. These are companies that have pursued circular strategies as good business without having considered their environmental and other benefits.

6.2. Conclusions and Future Research

Evaluation of circularity strategies is crucial to select appropriate strategies and move towards a CE. Even though various methods and indicators have been developed by academics to measure the progress towards CE, there is a lack of circularity strategies’ evaluation methods at the product level [

13,

21]. Therefore, in this article, a multi-criteria evaluation method of product-level circularity strategies is developed. Its contribution lies in the multi-criteria approach that can address the complexity of such an evaluation, and support decision-making by taking into account both how a circularity strategy performs with respect to the CE principles and how feasible the strategy is. This is done by providing a list of recommended criteria, sub-criteria and indicators while still allowing companies to modify them based on their specific case. The application and usefulness of the proposed evaluation method are demonstrated by applying it on two cases: a vacuum waste collection system and office furniture.

Although this research has contributed to filling some of the research gaps presented in

Section 1, further investigations are required. One future research path is to use the proposed method for various types of products, services, and industrial sectors together with practitioners. This helps to generalize the application of the proposed method to various industrial sectors. Moreover, it could be interesting to compare and analyze the results across various industrial sectors. This helps to learn from successful experiences so that one industrial sector can learn from other sectors in an effort to transform to a CE. In addition, more research could be conducted to test the proposed method on first-hand company data.

Another important research opportunity could be to extend the proposed evaluation method to include pre-use/use phase of the product/service, e.g., production energy efficiency measures. This method evaluates a post-use product/service at the EoL phase. Furthermore, the environmental, economic and social benefit of the strategies for the company and the resulting outcome could be studied due to the implementation of circularity strategies. Along this line, apart from zooming out to include more types of circular strategies, further research could zoom in to identify sub-criteria and indicators that target specific circular strategies or product groups, e.g., reuse. Moreover, the interaction between criteria and sub-criteria and their influence on the overall result from a system perspective should be studied in the future. One approach to address this gap would be to use Analytical Network Process (ANP) to understand the inter-dependency among decision factors.