Modeling Supply Chain Integration in an Integrated Project Delivery System

Abstract

:1. Introduction

2. Background

2.1. Construction Supply Chain

2.2. Supply Chain Integration

2.3. Waste in Design

2.4. Virtual Design Team

3. Methodology

- Step 1—Explanation of the VDT conceptual model: This step aimed to introduce first the VDT graphic language; that is, explaining the meaning of each shape and link that represents the project organization and project delivery process. Then, we explained the representation of the VDT conceptual model. For that purpose, we focused on explaining the structure of the project organization, links among project participants or groups, types of meetings, links between project participants and activities, the sequence of the project delivery process, and links among activities of the project delivery process.

- Step 2—Comparison between the VDT conceptual model and the actual project events: From the first step, key participants understood how to interpret the VDT conceptual model. Thus, the key participants were able to compare the actual project events relating to the project organization and project delivery process with the graphical representation of the VDT conceptual model. For the comparison process, we led an open discussion where the key participants validated the structure of the project organization, links among project participants or groups, types of meetings, links between project participants and activities, the sequence of the project delivery process and links among activities of the project delivery process. If the key participant disagreed with the graphical representation, changes were made, and Step 2 was repeated.

- Definition of the values of direct work, coordination work, and waste work: due to the lack of information that supports the values of these types of work in both building projects, these values were defined based on the experience and knowledge of the key participants that participated in these building projects. Hence, the key participants defined a relative percentage for these types of work, considering the duration of each stage, definition, and preconstruction.

- Calibration of direct work, coordination work, and waste work: we used the suggested values from the user guide of the software SimVision to determine information exchange probability and project error probability [33]. These values were calibrated in order to get the relative percentage defined in the first step. In other words, the values of these two probability values were changed based on the range suggested by the user guide until obtaining an approximation to a relative percentage for each type of work.

4. Case Illustrations

4.1. Case Study 1: Healthcare Project

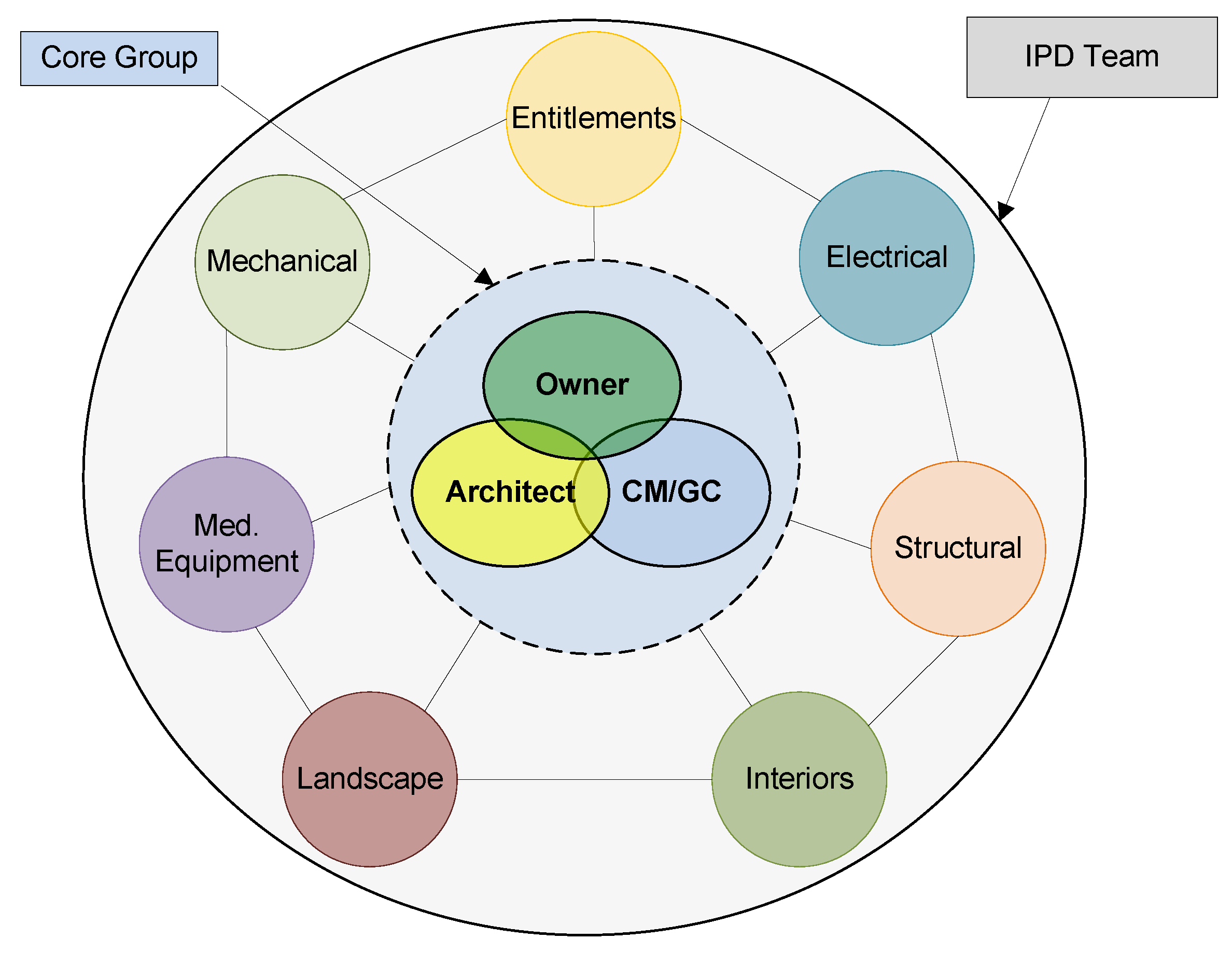

4.1.1. Project Organizational Structure

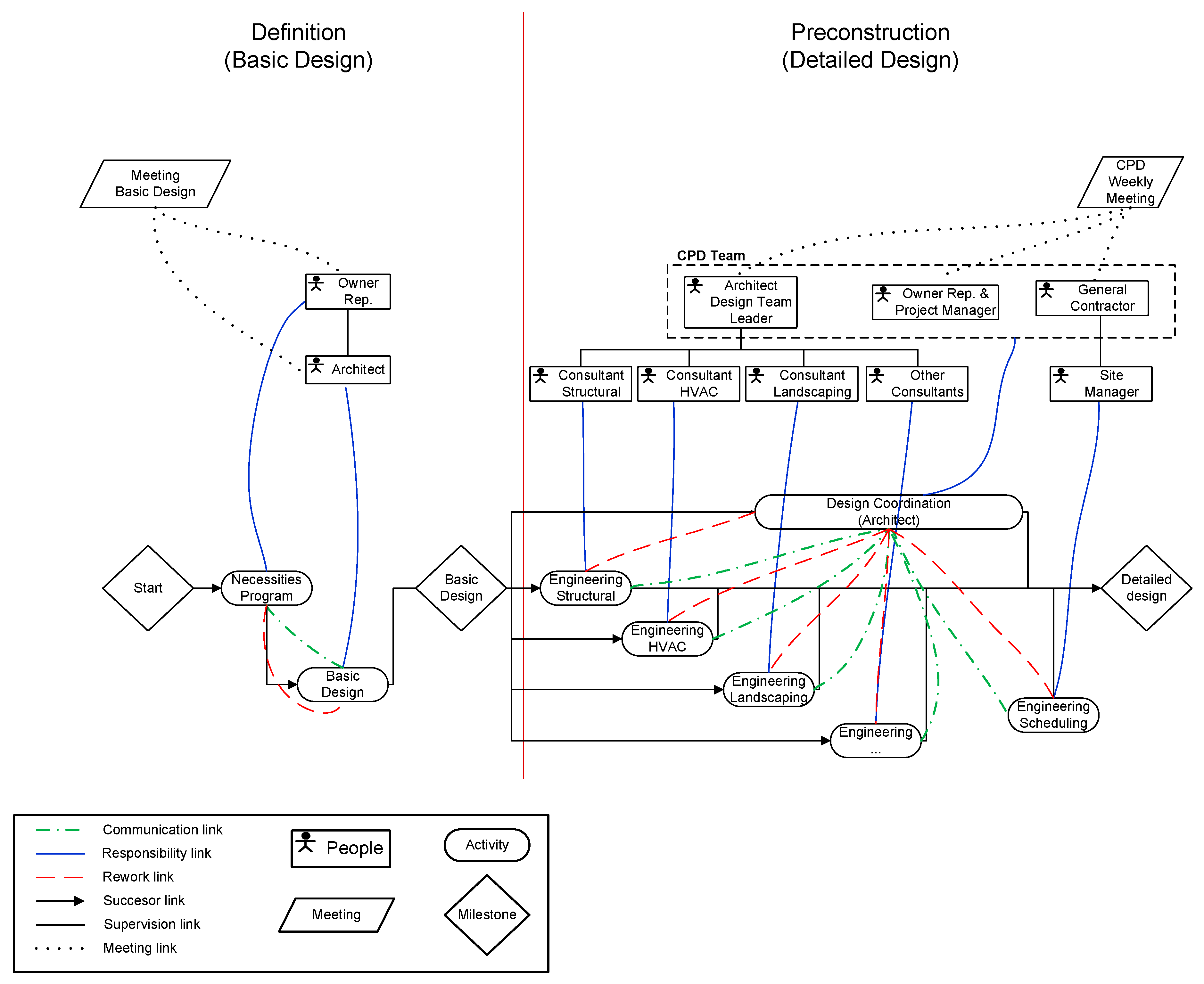

4.1.2. Project Delivery Process

4.2. Case Study 2: Conference Center Project

4.2.1. Project Organizational Structure

4.2.2. Project Delivery Process

5. VDT Model

5.1. Description of VDT Conceptual Model

5.1.1. Healthcare Project

5.1.2. Conference Center Project

5.2. Conceptual Analysis of VDT Models

6. VDT Simulation Model

- Team experience: defines the relative degree to which the project team has successfully performed the related project. The team experience can be set up in the range of low, medium, or high for different levels of team experience.

- Centralization: defines the qualitative degree to which decision-making and exception-handling responsibilities are decentralized to the individual responsible (low), or centralized to senior project managers (high).

- Formalization: defines the relative degree to which communication among project participants takes place informally (low), or through formal meetings and memos (high).

- Matrix strength: defines the extent to which project participants are located in skill-based functional departments or areas and supervised directly by functional managers (low), or co-located with other skilled specialists in dedicated project teams and with project supervision from a project manager (high).

- Information exchange probability: measures the level of communication in the project among project participants that are responsible for activities linked by communications (green) links. The information exchange probability can be set up in the range of 0.2 (low) to 0.9 (high) for different levels of communication.

- Project error probability: defines the probability that an activity will fail and generate rework for all dependent activities connected to it by rework links. Project error probability can be set up in the range of 0.05 (low) to 0.10 (significant but common) for different probabilities.

- Project complexity: defines the degree of complexity and uncertainty of activities of the project delivery process. Activity complexity defines the number of internal project requirements that the activity must satisfy and the amount of communication across communications links that are required to perform a task. Project complexity can be set up in the range of low, medium, or high for different levels of complexity.

6.1. Analysis of the VDT Simulation Results

6.2. Discussion of the VDT Simulation Results

6.3. Sensitivity Analysis

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mesa, H.A.; Molenaar, K.R.; Alarcón, L.F. Exploring performance of the integrated project delivery process on complex building projects. Int. J. Proj. Manag. 2016, 34, 1089–1101. [Google Scholar] [CrossRef]

- El Asmar, M.; Hanna, A.S.; Loh, W.Y. Quantifying performance for the integrated project delivery system as compared to established delivery systems. J. Constr. Eng. Manag. 2013, 139, 04013012. [Google Scholar] [CrossRef] [Green Version]

- American Institute of Architects. AIA Minnesota. School of Architecture—University of Minnesota IPD Case Studies; American Institute of Architects: Minneapolis, MN, USA, 2012; pp. 1–114. [Google Scholar]

- American Institute of Architects. AIA California Council Integrated Project Delivery: Case Studies; McGraw Hill Construction: Sacramento, CA, USA, 2010; pp. 1–62. [Google Scholar]

- Sødal, A.H.; Lædre, O.; Svalestuen, F.; Lohne, J. Early Contractor Involvement: Advantages and Disadvantages for the Design Team. In Proceedings of the IGLC 2014-22th Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 519–531. [Google Scholar]

- Ashcraft, H.W. IPD Teams: Creation, Organization and Management. Available online: https://www.hansonbridgett.com/-/media/Files/Publications/IPD-Teams.pdf (accessed on 1 May 2013).

- Tillmann, P.; Berghede, K.; Ballard, G.; Tommelein, I. Developing a Production System on IPD: Considerations for a Pluralistic Environment. In Proceedings of the 22nd Annual Conference of the International Group Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 317–328. [Google Scholar]

- Vrijhoef, R.; Koskela, L. The four roles of supply chain management in construction. Eur. J. Purch. Supply Manag. 2000, 6, 169–178. [Google Scholar] [CrossRef]

- Rauniar, R.; Rawski, G. Organizational structuring and project team structuring in integrated product development project. Int. J. Prod. Econ. 2012, 135, 939–952. [Google Scholar] [CrossRef]

- Yeo, K.T.; Ning, J.H. Integrating supply chain and critical chain concepts in engineer-procure-construct (EPC) projects. Int. J. Proj. Manag. 2002, 20, 253–262. [Google Scholar] [CrossRef]

- Cho, S.; Ballard, G. Last Planner and Integrated Project Delivery. Lean Constr. J. 2011, 2, 67–78. [Google Scholar]

- Jin, Y.; Levitt, R.E. The virtual design team: A computational model of project organizations. Comput. Math. Organ. Theory 1996, 2, 171–195. [Google Scholar] [CrossRef]

- Levitt, R. Overview of the Virtual Design Team (VDT) Research Program: 1988–2010. Available online: https://gpc.stanford.edu/sites/g/files/sbiybj8226/f/wp052_0.pdf (accessed on 6 May 2020).

- Christopher, M. Logistics and Supply Chain Management: Strategies for Reducing Cost and Improving Service (Second Edition). Int. J. Logist. Res. Appl. 1999, 2, 103–104. [Google Scholar] [CrossRef]

- Meng, X. The effect of relationship management on project performance in construction. Int. J. Proj. Manag. 2012, 30, 188–198. [Google Scholar] [CrossRef]

- Behera, P.; Mohanty, R.P.; Prakash, A. Understanding Construction Supply Chain Management. Prod. Plan. Control 2015, 26, 1332–1350. [Google Scholar] [CrossRef]

- Xue, X.; Shen, Q.; Ren, Z. Critical Review of Collaborative Working in Construction Projects: Business Environment and Human Behaviors. J. Manag. Eng. 2010, 26, 196–208. [Google Scholar] [CrossRef]

- Mitropoulos, P. Management-Driven Integration; Center for Integrated Facility Engineering, Stanford: Stanford, CA, USA, 1994. [Google Scholar]

- Chan, A.P.C.; Chan, D.W.M.; Chiang, Y.H.; Tang, B.S.; Chan, E.H.W.; Ho, K.S.K. Exploring Critical Success Factors for Partnering in Construction Projects. J. Constr. Eng. Manag. 2004, 130, 188–198. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Law, K.H.; Bjornsson, H.; Jones, A.; Sriram, R. A service oriented framework for construction supply chain integration. Autom. Constr. 2009, 19, 246–260. [Google Scholar] [CrossRef]

- Le, P.L.; Elmughrabi, W.; Dao, T.M.; Chaabane, A. Present focuses and future directions of decision-Making in construction supply chain management: A systematic review. Int. J. Constr. Manag. 2018, 20, 490–590. [Google Scholar] [CrossRef]

- Isatto, E.L.; Formoso, C.T. The inter-firm coordination of the construction project supply chain. In Proceedings of the 14th Annual Conference of the International Group for Lean Construction, IGLC-14, Santiago, Chile, July 2006; pp. 293–308. [Google Scholar]

- Austin, S.A.; Baldwin, A.N.; Steele, J.L. Improving building design through integrated planning and control. Eng. Constr. Archit. Manag. 2002, 9, 249–258. [Google Scholar] [CrossRef]

- Baiden, B.K.; Price, A.D.F.; Dainty, A.R.J. Looking beyond processes: Human factors in team integration. In Proceedings of the 19th Annual ARCOM Conference, Brighton, UK, 3–5 September 2003; pp. 233–242. [Google Scholar]

- Baiden, B.K.; Price, A.D.F. The effect of integration on project delivery team effectiveness. Int. J. Proj. Manag. 2011, 29, 129–136. [Google Scholar] [CrossRef]

- Fergusson, K. Impact of Integration on Industrial Facility Quality; Center for Integrated Facility Engineering, Stanford: Stanford, CA, USA, June 1993. [Google Scholar]

- Mitropoulos, P.; Tatum, C. Management-Driven Integration. J. Manag. Eng. 2000, 16, 48–58. [Google Scholar] [CrossRef]

- Baiden, B.K.; Price, A.D.F.; Dainty, A.R.J. The extent of team integration within construction projects. Int. J. Proj. Manag. 2006, 24, 13–23. [Google Scholar] [CrossRef]

- Freire, J.; Alarcón, L.F. Achieving Lean Design Process: Improvement Methodology. J. Constr. Eng. Manag. 2002, 128, 248–256. [Google Scholar] [CrossRef] [Green Version]

- Lauri, K. An Exploration towards a Production Theory and Its Application to Construction. Doctoral Thesis, Helsinki University of Technology, Espoo, Finland, 2000. [Google Scholar]

- Ballard, G. Positive vs Negative Iteration in Design. In Proceedings of the 8th Annual Conference of the International Group for Lean Construction, Brigthon, UK, 17–19 July 2000; pp. 1–8. [Google Scholar]

- Wynn, D.C.; Eckert, C.M. Perspectives on iteration in design and development. Res. Eng. Des. 2017, 28, 153–184. [Google Scholar] [CrossRef]

- ePM. SimVision Tutorial: User Guide; ePM LLC: Austin, TX, USA, 2005; p. 444. Available online: http://www.epm.cc/downloads/UserGuide_v11.pdf (accessed on 6 May 2020).

- March, J.G.; Simon, H.A.; Guetzkow, H.S. Organizations; Blackwell: New York, NY, USA, 1993; ISBN 9780631186311. [Google Scholar]

- Galbraith, J.R. Organization Design; Addison-Wesley Pub. Co: Boston, MA, USA, 1977; ISBN 0201025582. [Google Scholar]

- Galbraith, J.R. Organization Design: An Information Processing View. Interfaces 1974, 4, 28–36. [Google Scholar] [CrossRef]

- Christiansen, T.R. The Virtual Design Team: Using Simulation of Information Processing to Predict the Performance of Project Teams; Center for Integrated Facility Engineering: Stanford, CA, USA, 1992. [Google Scholar]

- Levitt, R.E.; Nissen, M.E. The virtual design team (VDT): A multi-Agent analysis framework for designing project organizations. In Proceedings of the IEMC ‘03 Proceedings. Managing Technologically Driven Organizations: The Human Side of Innovation and Change (IEEE Cat. No.03CH37502), Albany, NY, USA, 2–4 November 2003; pp. 115–120. [Google Scholar]

- Concha, M.; Mourgues, C.; Alarcón, L.F. Reference virtual design team (vdt) probabilities to design construction project organizations. Rev. Constr. 2015, 14, 29–34. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, R.; Nissen, M. Simulating environmental contingencies using SimVision®. In Proceedings of the North American Association for Computational Social and Organizational Science, Pittsburgh, PA, USA, 27–29 June 2004. [Google Scholar]

- ePM. ePM VDT Case Study: Design-Build Biotech Plant Case; ePM LLC: Austin, TX, USA, 2002. [Google Scholar]

- Kunz, J.C.; Levitt, R.E.; Thomsen, J. Intervention studies using the virtual design team. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics, Bari, Italy, 6–9 October 2019; Volume 5, pp. 4483–4487. [Google Scholar]

- Kunz, J.; Fischer, M. Virtual Design and Construction: Themes, Case Studies and Implementation Suggestions; Center for Integrated Facility Engineering: Stanford, CA, USA, 2012. [Google Scholar]

- Levitt, R.; Kunz, J. Design Your Project Organization as Engineers Design Bridges; Center for Integrated Facility Engineering: Stanford, CA, USA, 2002. [Google Scholar]

- Phillips, L.D. A theory of requisite decision models. Acta Psychol. 1984, 56, 29–48. [Google Scholar] [CrossRef]

- Lichtig, W.A. Integrated Agreement for Lean Project Delivery between Owner, Architect & CM/GC 2008. In Improving Healthcare through Built Environment Infrastructure; Kagioglou, M., Tzortzopoulos, P., Eds.; Wiley-Blackwell: London, UK, 2012. [Google Scholar]

- Rybkowski, Z. The Application of Root Cause Analysis and Target Value Design to Evidence-Based Design in the Capital Planning of Healthcare Facilities; University of California: Berkeley, CA, USA, 2009. [Google Scholar]

- Ballard, G. The Lean Project Delivery System: An Update. Lean Constr. J. 2008, 2, 1–19. [Google Scholar]

- Thompson, J.D. Organizations in Action: Social Science Bases of Administrative Theory; Transaction Publishers: New Brunswick, NJ, USA, 1967. [Google Scholar]

- ConsensusDocs Consensusdocs 300: Standard Tri-Party Agreement for Integrated Project Delivery. Available online: https://www.consensusdocs.org/Catalog/collaborative (accessed on 13 April 2013).

- Pikas, E.; Koskela, L.; Seppänen, O. Improving Building Design Processes and Design Management Practices: A Case Study. Sustainability 2020, 12, 911. [Google Scholar] [CrossRef] [Green Version]

- Silveira, S.; Alves, T. Target Value Design Inspired Practices to Deliver Sustainable Buildings. Buildings 2018, 8, 116. [Google Scholar] [CrossRef] [Green Version]

- Robinson, W.; Chan, P.; Lau, T. Finding New Ways of Creating Value: A Case Study of Servitization in Construction. Res. Technol. Manag. 2016, 59, 37–49. [Google Scholar] [CrossRef]

- Galera-Zarco, C.; Morales-Gallego, M.; Pérez-Aróstegui, M.N. Servitization in Project-Based Firms. Strateg. Chang. 2014, 23, 329–340. [Google Scholar] [CrossRef]

- Zarco, C.G.; Bustinza, O.; Perez, V.F. Adding value: How to develop a servitisation strategy in civil engineering. Proc. Inst. Civ. Eng. Civ. Eng. 2016, 169, 35–40. [Google Scholar] [CrossRef]

|

| Healthcare | Conference Center | |

|---|---|---|

| Project organization | Integrated Governance—Core Group | Integrated Governance—CPD Team |

| Cluster Groups—interdisciplinary and cross-functional groups | Functional or specialized areas | |

| Early participation of CM/GC and key subcontractors from definition stage | Early participation of CM/GC on engineering phase | |

| Coordination mechanisms | Co-location | No co-location |

| TVD, LPS, cluster and subcommittee meetings | CPD and design coordination meetings | |

| Level of integration | Integration at inter-organizational level | Integration at inter-organizational level |

| Integration at project level | No integration at project level | |

| Contractual relationship | Relational contract (IFOA) with lean principles | Relational contract (Consensus 300) without lean principles |

| Project delivery process | Process of TVD with Validation phase | Process of TVD without Validation phase |

| Operational system | Lean Project Management | Traditional Project Management |

| Tools: Target Value Design, Last Planner System, Set-based design, A3 reports, BIM | - |

| Inputs | Healthcare | Conference Center |

|---|---|---|

| Team experience | Medium | Medium |

| Centralization | Medium | High |

| Formalization | Medium | Medium |

| Matrix strength | High | Low |

| Information exchange probability | High | High |

| Project error probability | Medium | Medium |

| Project complexity | Medium | Medium |

| Project Org. Characteristics | Baseline | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 5 | Scenario 6 | |

|---|---|---|---|---|---|---|---|---|

| Inputs | Team experience | Medium | Medium | Medium | Medium | Medium | Medium | Medium |

| Centralization | High | Low | High | High | Low | High | Low | |

| Formalization | Medium | Medium | Medium | Medium | Medium | Medium | Medium | |

| Matrix Strength | Low | Low | High | Low | High | Low | High | |

| Info. exchange prob. | High | High | High | High | High | High | High | |

| Project error prob. | Medium | Medium | Medium | Low | Low | Medium | Low | |

| Project complexity | Medium | Medium | Medium | Medium | Medium | High | High | |

| Outputs | Duration (months) | 24 | 23 | 24 | 22 | 21.5 | 25 | 22 |

| Direct work | 52% | 54% | 53% | 57% | 57% | 50% | 57% | |

| Design coord. work | 35% | 35% | 36% | 36% | 37% | 35% | 37% | |

| Waste work | 13% | 10% | 11% | 7% | 6% | 15% | 6% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mesa, H.A.; Molenaar, K.R.; Alarcón, L.F. Modeling Supply Chain Integration in an Integrated Project Delivery System. Sustainability 2020, 12, 5092. https://doi.org/10.3390/su12125092

Mesa HA, Molenaar KR, Alarcón LF. Modeling Supply Chain Integration in an Integrated Project Delivery System. Sustainability. 2020; 12(12):5092. https://doi.org/10.3390/su12125092

Chicago/Turabian StyleMesa, Harrison A., Keith R. Molenaar, and Luis F. Alarcón. 2020. "Modeling Supply Chain Integration in an Integrated Project Delivery System" Sustainability 12, no. 12: 5092. https://doi.org/10.3390/su12125092