Assessment of Field Compaction of Aggregate Base Materials for Permeable Pavements Based on Plate Load Tests

Abstract

:1. Introduction

2. Permeable Base and Compaction Quality Control

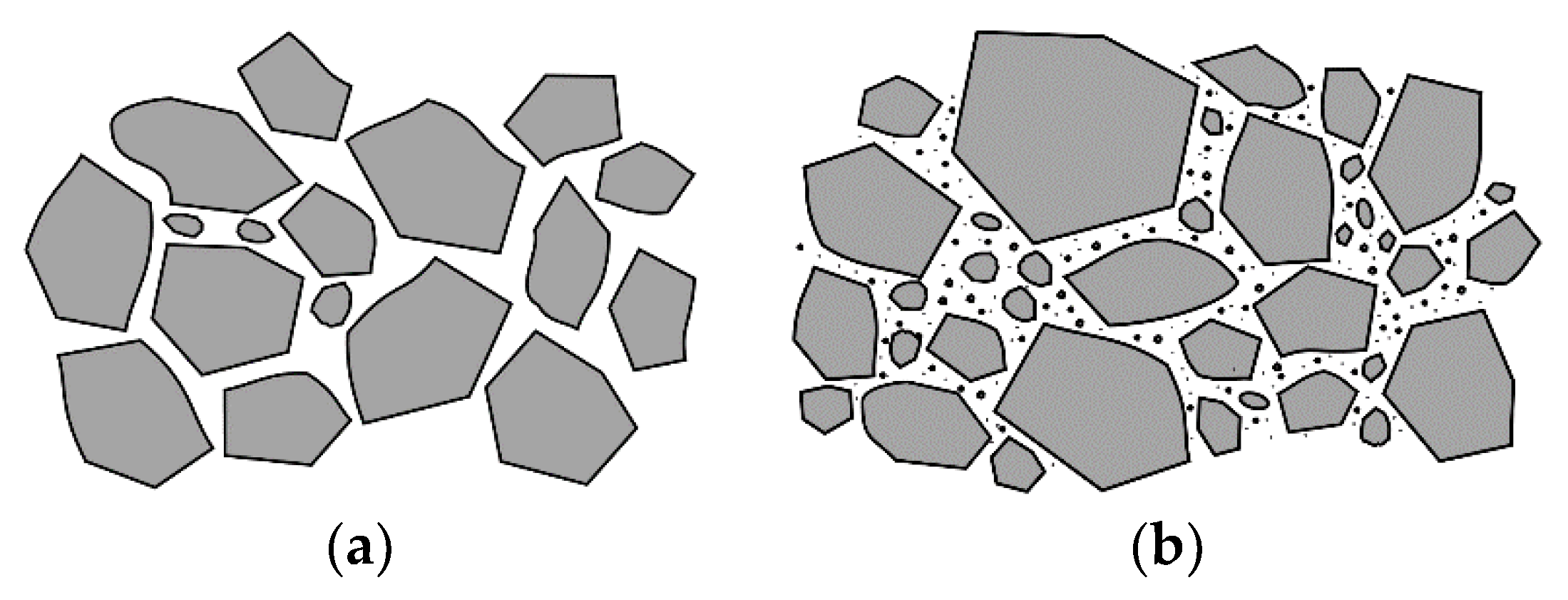

2.1. Permeable Base and Open-Graded Aggregates

2.2. Compaction Quality Control and Permeable Base

3. Field Test

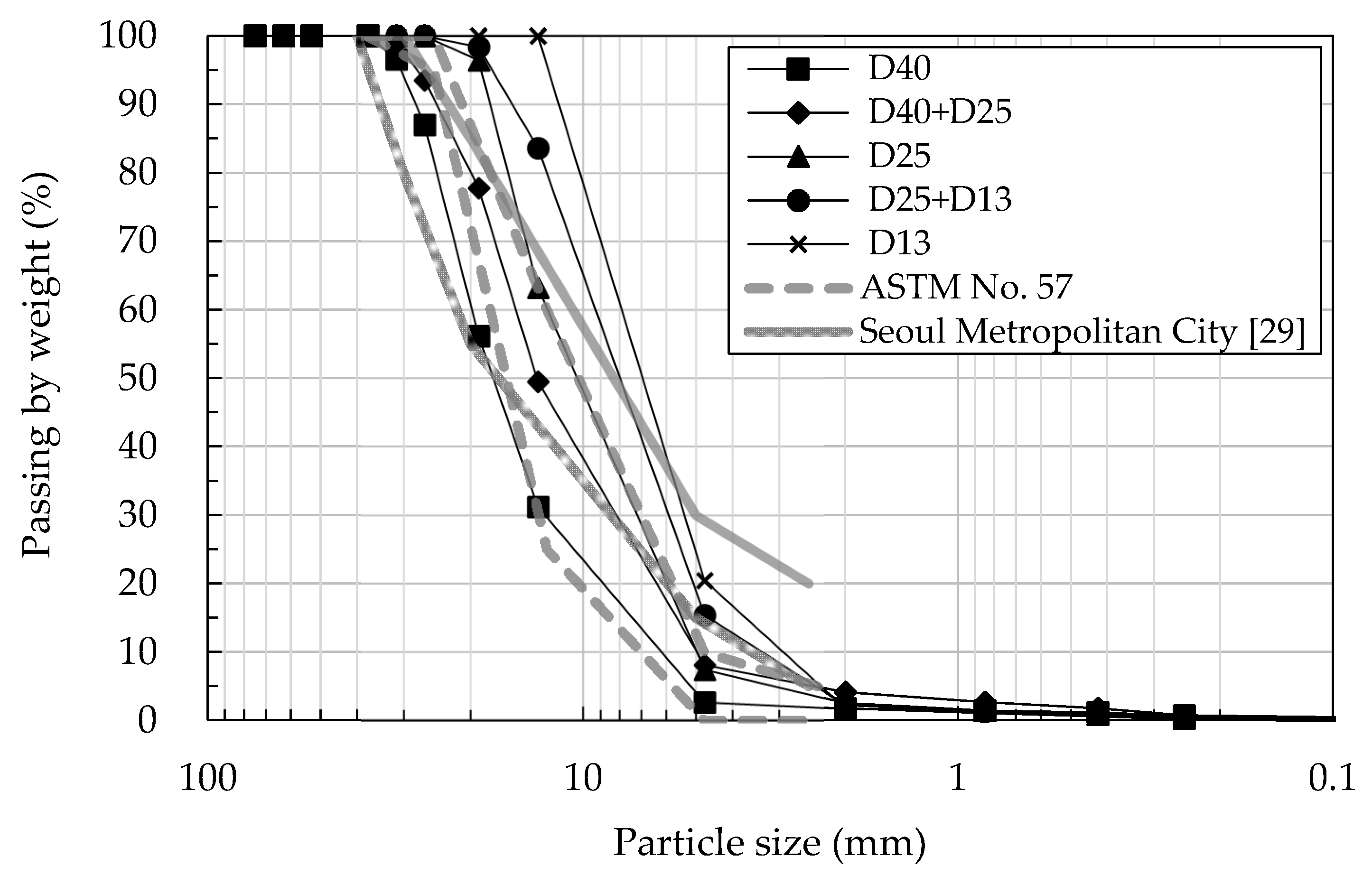

3.1. Test Materials

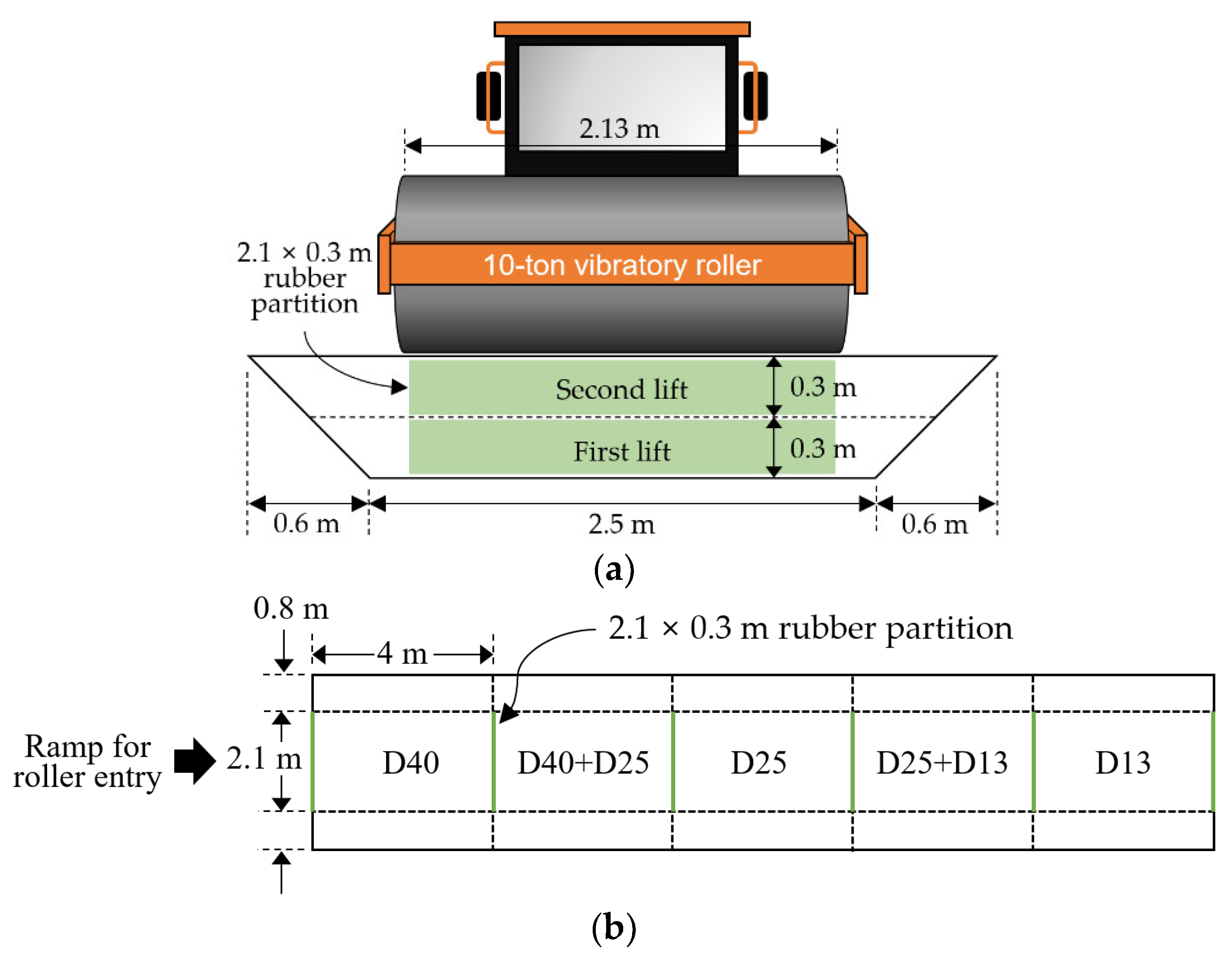

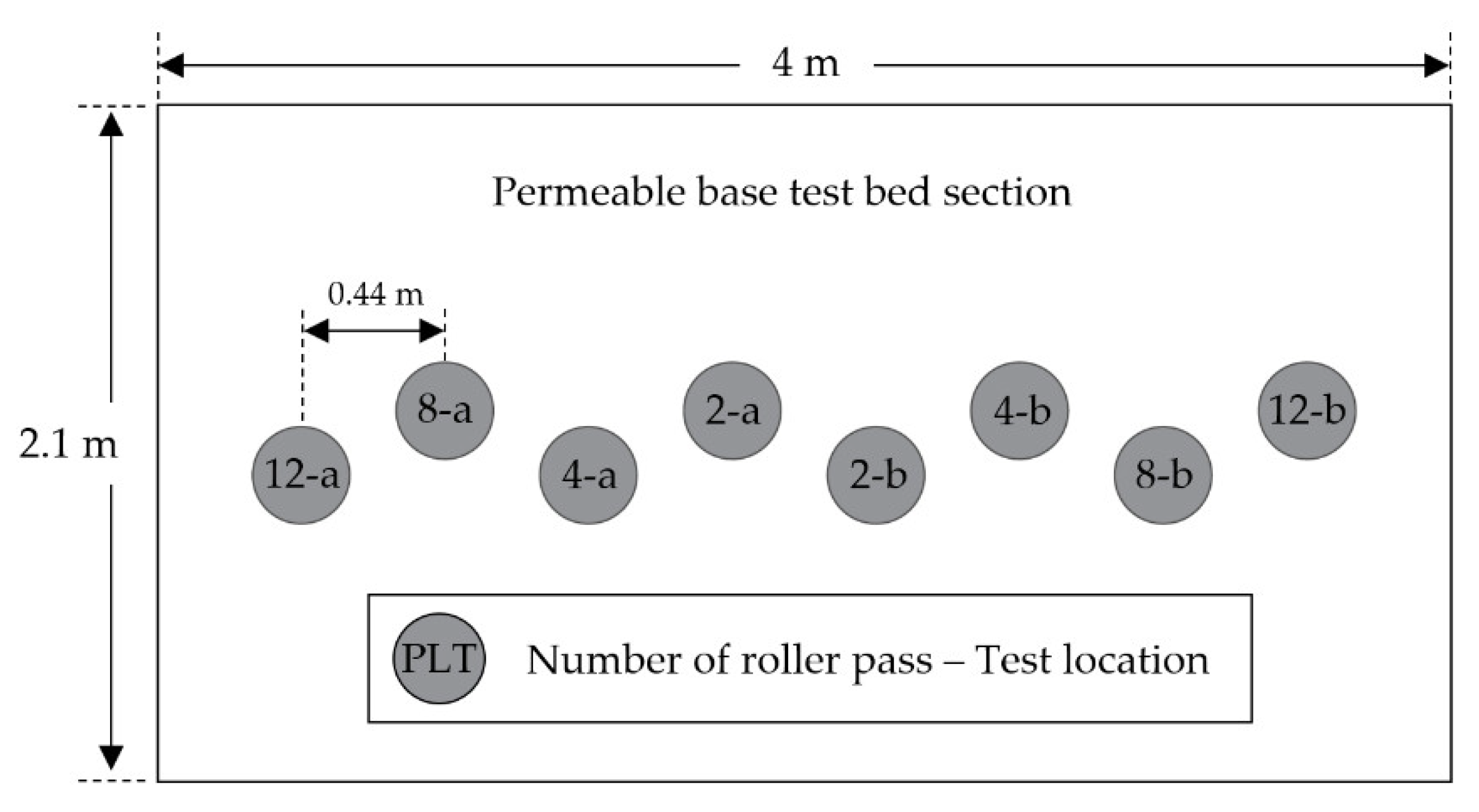

3.2. Test Program

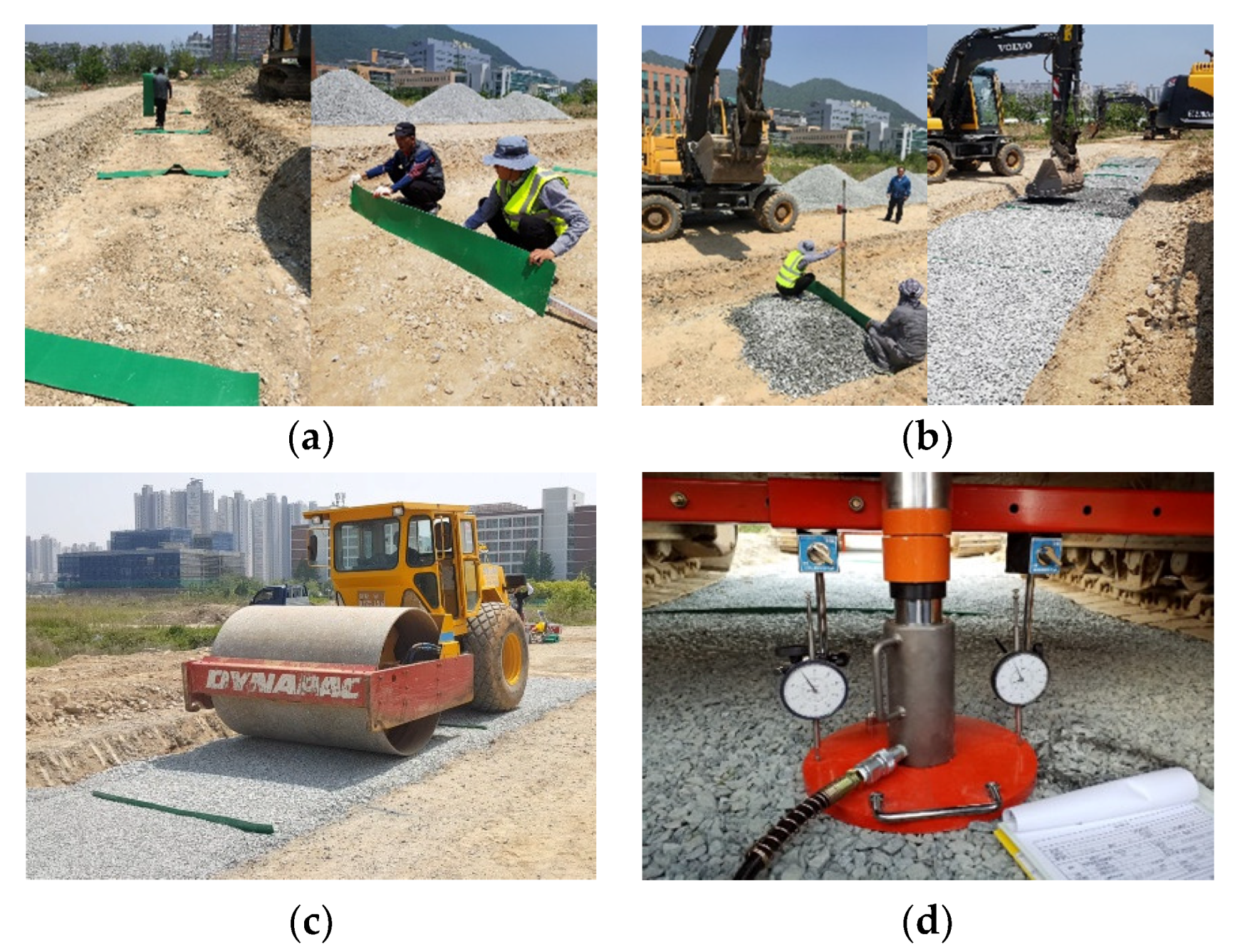

3.3. Test Bed Construction and Test Procedure

4. Results and Discussion

4.1. Modulus Calculation

4.2. Relationship Between Roller Pass and Modulus

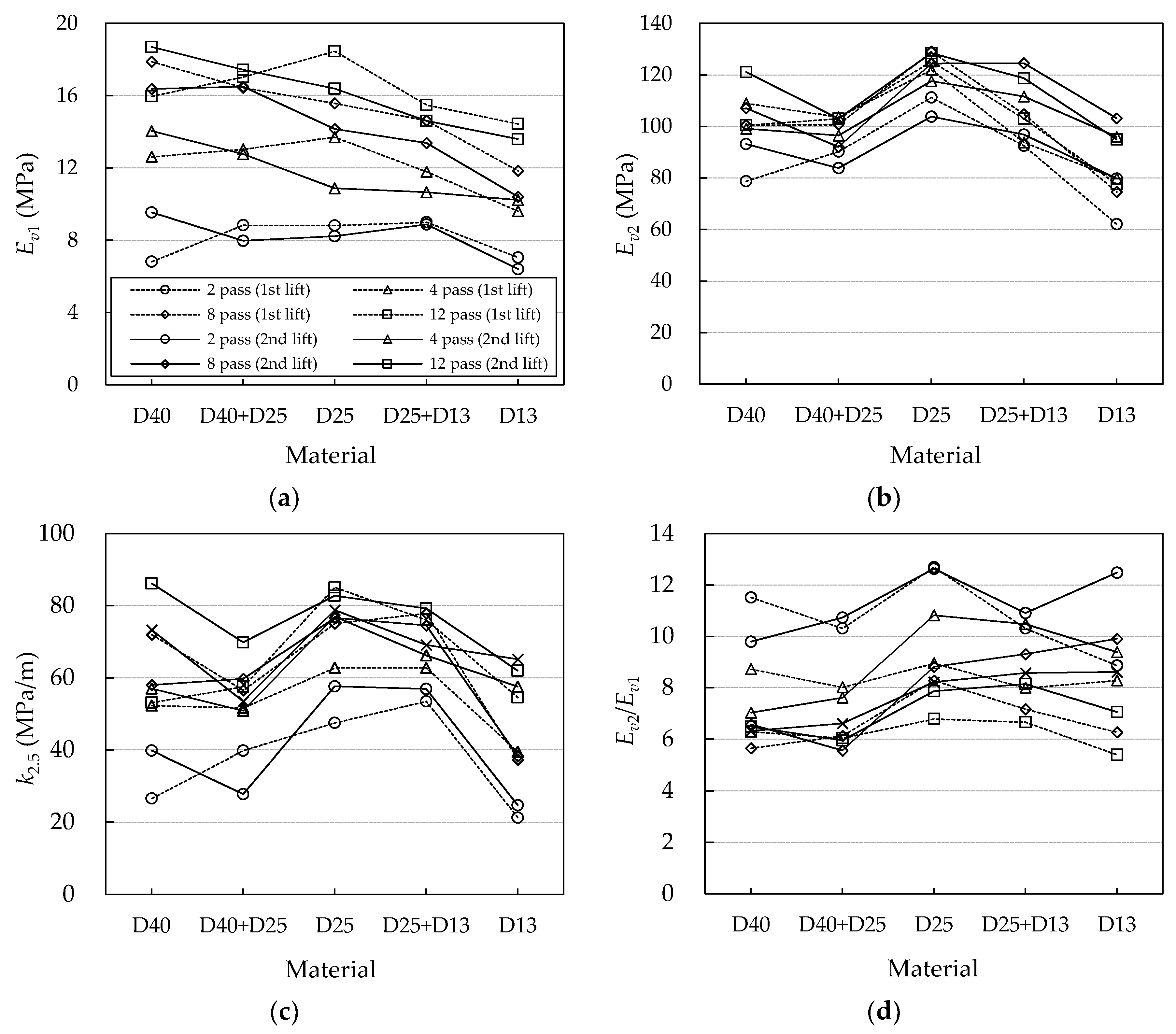

4.3. Relationship Between Materials and Modulus

4.4. Variations Between Modulus Measurements

5. Conclusions

- The values of Ev1, Ev2, and k2.5 steeply increased up to four roller passes for most of the test materials and lifts considered here. Ev1 clearly keeps increasing as the number of passes raises after four passes but with declined trends. The minimum of four roller passes recommended by the ICPI and ASCE [1,28] is efficient, but one can expect hardening of the open-graded materials for larger number of roller passes than four.

- The strain modulus at the second loading cycle (Ev2) showed high dependency on the material type. Large particles at the lowest compaction level, in some cases, had higher Ev2 than the smaller particles at the highest compaction level. The selection of materials is very important, and the level of compaction does not compensate the mis-selection of the materials.

- For open-graded aggregates that undergoes large deformation during PLT, the strain modulus Ev1 and Ev2 measures much wider range of stress and displacement than k2.5. As such, Ev1 and Ev2 give more consistent results. For open-graded aggregates, Ev1 and Ev2 would make a more reliable measure for QC than k2.5.

- When the results are compared to the requirements in German and Korean guides, all the materials tested meet the requirement for Ev2 but not for Ev2/Ev1 and k2.5. This would be partially because the current requirements are setup focusing on dense-graded materials. It will be necessary to develop more suitable QC requirements for the open-graded aggregate base.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Smith, D.R. Permeable Interlocking Concrete Pavements, 4th ed.; Interlocking Concrete Pavement Istitute: Herndon, VA, USA, 2011; ISBN 978-1-4507-8440-5. [Google Scholar]

- Brattebo, B.O.; Booth, D.B. Long-term stormwater quantity and quality performance of permeable pavement systems. Water Res. 2003, 37, 4369–4376. [Google Scholar] [CrossRef]

- Kumar, K.; Kozak, J.; Hundal, L.; Cox, A.; Zhang, H.; Granato, T. In-Situ infiltration performance of different permeable pavements in a employee used parking lot—A four-year study. J. Environ. Manag. 2016, 167, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Abu-Farsakh, M.; Alshibli, K.A.; Nazzal, M.; Seyman, E. Assessment of In-Situ Test Technology for Construction Control of Base Courses and Embankments; FHWA/LA.041389; Louisiana Transportation Research Center: Boton Rouge, LA, USA, 2004. [Google Scholar]

- Berney, E.S., IV; Mejias-Santiago, M.; Kyzar, J.D. Non-Nuclear Alternatives to Monitoring Moisture-Density Response in Soils; ERDC/GSL TR-13-6; U.S. Army Engineer Research and Development Center Geotechnical and Structures Laboratory: Vicksburg, MS, USA, 2013. [Google Scholar]

- ASTM International. Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2700 kN-m/m3)); ASTM D1557; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM International. Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)); ASTM D698; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM International. Standard Test Method for Density and Unit Weight of Soil in Place by Sand-Cone Method; ASTM D1556/D1556M; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM International. Standard Test Method for Density and Unit Weight of Soil in Place by the Rubber Balloon Method; ASTM D2167; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM International. Standard Test Methods for In-Place Density and Water Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow depth); ASTM D6938 REV A; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Nazzal, M. Non-Nuclear Methods for Compaction Control of Unbound Materials; National Cooperative Highway Research Program Synthesis 456; Transportation Research Board: Washington, DC, USA, 2014. [Google Scholar]

- Meehan, C.L.; Tehrani, F.S.; Vahedifard, F. A comparison of density-based and modulus-based in situ test measurements for compaction control. Geotech. Test. J. 2012, 35, 387–399. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Repetitive Static Plate Load Tests of Soils and Flexible Pavement Components, for Use in Evaluation and Design of Airport and Highway Pavements; ASTM D1195/D1195M; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Deutsches Institut fur Normung E.V. Soil—Testing Procedures and Testing Equipment—Plate Load Test; DIN 18134; Deutsches Institut fur Normung E.V.: Berlin, Germany, 2012. [Google Scholar]

- ASTM International. Standard Test Method for Measuring Deflections Using a Portable Impulse Plate Load Test Device; ASTM E2835; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM International. Standard Test Method for Measuring Stiffness and Apparent Modulus of Soil and Soil-Aggregate In-Place by Electro-Mechanical Method; ASTM D6758; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM International. Standard Test Method for Use of the Dynamic Cone Penetrometer in Shallow Pavement Applications; ASTM D6951/D6951M; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Kim, D.; Park, S. Relationship between the subgrade reaction modulus and the strain modulus obtained using a plate loading test. In Proceedings of the 9th World Congress on Railway Research, Lille, France, 22–26 May 2011. [Google Scholar]

- Alshibli, K.A.; Abu-Farsakh, M.; Seyman, E. Laboratory evaluation of the geogauge and light falling weight deflectometer as construction control tools. J. Mater. Civ. Eng. 2005, 17, 560–569. [Google Scholar] [CrossRef]

- Hufenus, R.; Rueegger, R.; Banjac, R.; Mayor, P.; Springman, S.M.; Bronnimann, R. Full-scale field tests on geosynthetic reinforced unpaved roads on soft subgrade. Geotext. Geomembr. 2006, 24, 21–37. [Google Scholar] [CrossRef]

- Jimenez, J.R.; Ayuso, J.; Agrela, F.; Lopez, M.; Galvin, A.P. Utilisation of unbound recycled aggregates from selected CDW in unpaved rural roads. Resour. Conserv. Recycl. 2012, 58, 88–97. [Google Scholar] [CrossRef]

- Sulewska, M.J. The control of soil compaction degree by means of LFWD. Balt. J. Road Bridge Eng. 2012, 7, 36–41. [Google Scholar] [CrossRef]

- Umashankar, B.; Hariprasad, C.; Kumar, G.T. Compaction quality control of pavement layers using LWD. J. Mater. Civ. Eng. 2016, 28. [Google Scholar] [CrossRef]

- Wersall, C.; Nordfelt, I.; Larsson, S. Resonant roller compaction of gravel in full-scale tests. Transp. Geotech. 2018, 14, 93–97. [Google Scholar] [CrossRef]

- Lenke, L.R.; McKeen, R.G.; Grush, M. Evaluation of a Mechanical Stiffness Gauge for Compaction Control of Granular Media; NM99MSC-07.2; New Mexico State Highway & Transportation Department: Albuquerque, NM, USA, 2001. [Google Scholar]

- Maher, A.; Bennert, T.; Gucunski, N. Evaluation of the Humboldt Stiffness Gauge; FHWA-NJ-2002-002; New Jersey Department of Transportation: Trenton, NJ, USA, 2002. [Google Scholar]

- Wiman, L.G. Accelerated Load Testing of Pavements: HVS-NORDIC Tests at VTI Sweden 2003–2004; VTI rapport 544A; Swedish National Road and Transport Research Institute: Linköping, Sweden, 2006. [Google Scholar]

- Eisenberg, B.E.; Lindow, K.C.; Smith, D.R. Permeable Pavements, 1st ed.; American Society of Civil Engineers: Reston, VA, USA, 2015; ISBN 978-0-7844-7867-7. [Google Scholar]

- Seoul Metropolitan City. Design, Construction and Maintenance Standards of Permeable Block Pavement; Ver. 2.0; Seoul Metropolitan City: Seoul, Korea, 2013. [Google Scholar]

- AASHTO. AASHTO Guide for Design of Pavement Structures; AASHTO: Washington, DC, USA, 1993; Volume 1, ISBN 1-56051-055-2. [Google Scholar]

- Cetin, A.; Kaya, Z.; Cetin, B.; Aydilek, A.H. Influence of laboratory compaction method on mechanical and hydraulic characteristics of unbound granular base materials. Road Mater. Pavement Des. 2014, 15, 220–235. [Google Scholar] [CrossRef]

- Kim, D.; Choi, C.; Kim, S.J.; Yu, J.Y.; Yang, S.C. Study on the subgrade reaction modulus (K30) and strain modulus (Ev). J. Korean Soc. Railw. 2007, 10, 264–270. [Google Scholar]

- Research Society of Road and Traffic. Additional Technical Contractual Conditions and Guidelines for Earthwork in Road Construction and Technical Testing Instructions for Soil and Rock in Road Construction; ZTVE-StB 94; Research Society of Road and Traffic: Koln, Germnay, 1994. [Google Scholar]

- Ministry of Land, Infrastructure and Transport. Standard Specification for Road Construction; Ministry of Land, Infrastructure and Transport: Sejong, Korea, 2015.

- Deutsches Institut fur Normung E.V. Earthworks and Foundations—Soil Classification for Civil Engineering Purposes; DIN 18196; Deutsches Institut fur Normung E.V.: Berlin, Germany, 2011. [Google Scholar]

| Literature | Soil Type | MDD 2 (g/cm3) | OMC 3 (%) | RC 4 (%) | MC 5 (%) | Ev16 (MPa) | Ev27 (MPa) |

|---|---|---|---|---|---|---|---|

| Wiman [27] | Fine sand subgrade | 1.72 3 | 14.4 3 | 99–101 | 5.3–9.9 | 35–36 | 97–107 |

| Natural gravel | 2.18 3 | 3.7 3 | 99.7 | 2.4 | 65 | 190 | |

| Crushed rock aggregate | 2.17 3 | 4.7 3 | 99.8 | 2.7 | 61 | 185 | |

| Granular base | 2.35 3 | 4.5 3 | 95.8 | 2.2 | 77.6 | 191 | |

| Kim and Park [18] | Poorly graded gravel | 2.27 | - | - | 5.9 | 23–53 | 48–137 |

| Kim et al. [32] | Silty sand | - | - | - | - | 11~15 | 21~28 |

| Lean clay | - | - | - | - | 12~23 | 18~37 |

| Literature | Country | Material | Requirement | Corresponding RC (%) | ||

|---|---|---|---|---|---|---|

| Ev2 (MPa) | Ev2/Ev1 | k2.5 (MPa/m) | ||||

| ZTVE-StB 94 [33] | Germany | GW, GI, GU, GT 1 | ≥70 | - | - | ≥98 |

| - | - | ≤2.5 | - | - | ||

| Standard specification for road construction [34] | Korea | Subbase | - | - | ≥294 2 | ≥95 |

| Test Material | Lithology | Material Composition by Volume | Cu 1 | Cc 2 | Specific Gravity | Abrasion Rate (%) | ||

|---|---|---|---|---|---|---|---|---|

| D40 | D25 | D13 | ||||||

| D40 | Rhyolite | 100% | - | - | 2.88 | 1.19 | 2.67–2.75 | 12.8 |

| D40 + D25 | 50% | 50% | - | 2.99 | 1.08 | 9.8 | ||

| D25 | - | 100% | - | 2.48 | 1.02 | 10.3 | ||

| D25 + D13 | - | 50% | 50% | 2.84 | 1.16 | 11.2 | ||

| D13 | - | - | 100% | 2.79 | 1.16 | 12.3 | ||

| Test Materials | Lift | Number of Roller Passes |

|---|---|---|

| D40 | First (30 cm) Second (30 cm) | 2 4 8 12 |

| D40 + D25 | ||

| D25 | ||

| D25 + D13 | ||

| D13 |

| Modulus | Coefficient of Variation (CV) | |

|---|---|---|

| Maximum (%) | Mean (%) | |

| Ev1 | 16.1 | 5.3 |

| Ev2 | 22.4 | 4.5 |

| k2.5 | 40.6 | 10.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, Y.-J.; Ahn, D.; Nguyen, T.H.; Ahn, J. Assessment of Field Compaction of Aggregate Base Materials for Permeable Pavements Based on Plate Load Tests. Sustainability 2018, 10, 3817. https://doi.org/10.3390/su10103817

Choi Y-J, Ahn D, Nguyen TH, Ahn J. Assessment of Field Compaction of Aggregate Base Materials for Permeable Pavements Based on Plate Load Tests. Sustainability. 2018; 10(10):3817. https://doi.org/10.3390/su10103817

Chicago/Turabian StyleChoi, Yong-Jin, Donghyun Ahn, Tan Hung Nguyen, and Jaehun Ahn. 2018. "Assessment of Field Compaction of Aggregate Base Materials for Permeable Pavements Based on Plate Load Tests" Sustainability 10, no. 10: 3817. https://doi.org/10.3390/su10103817