The Performance of Wood Decking after Five Years of Exposure: Verification of the Combined Effect of Wetting Ability and Durability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Outdoor Exposure

2.3. Determination of Factors Describing Inherent Durability (kinh)

2.4. Determination of Factors Describing Wetting Ability (kwa)

2.5. Factor Approach for Quantifying the Resistance Dose DRd

2.6. Dose–Response Model

3. Results and Discussion

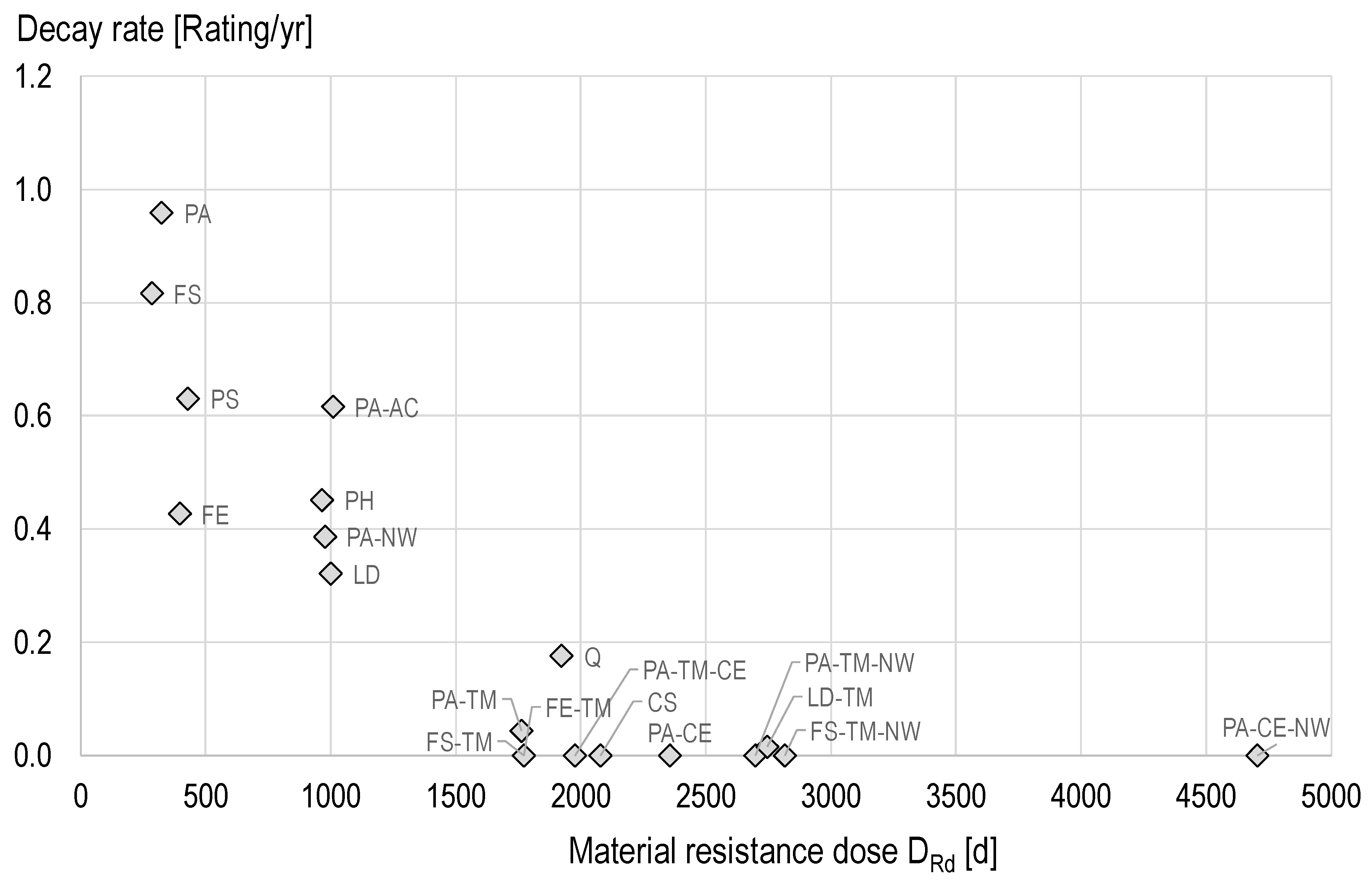

3.1. Resistance Dose Based on Inherent Durability and Wetting Ability

3.2. Moisture Performance of Decking

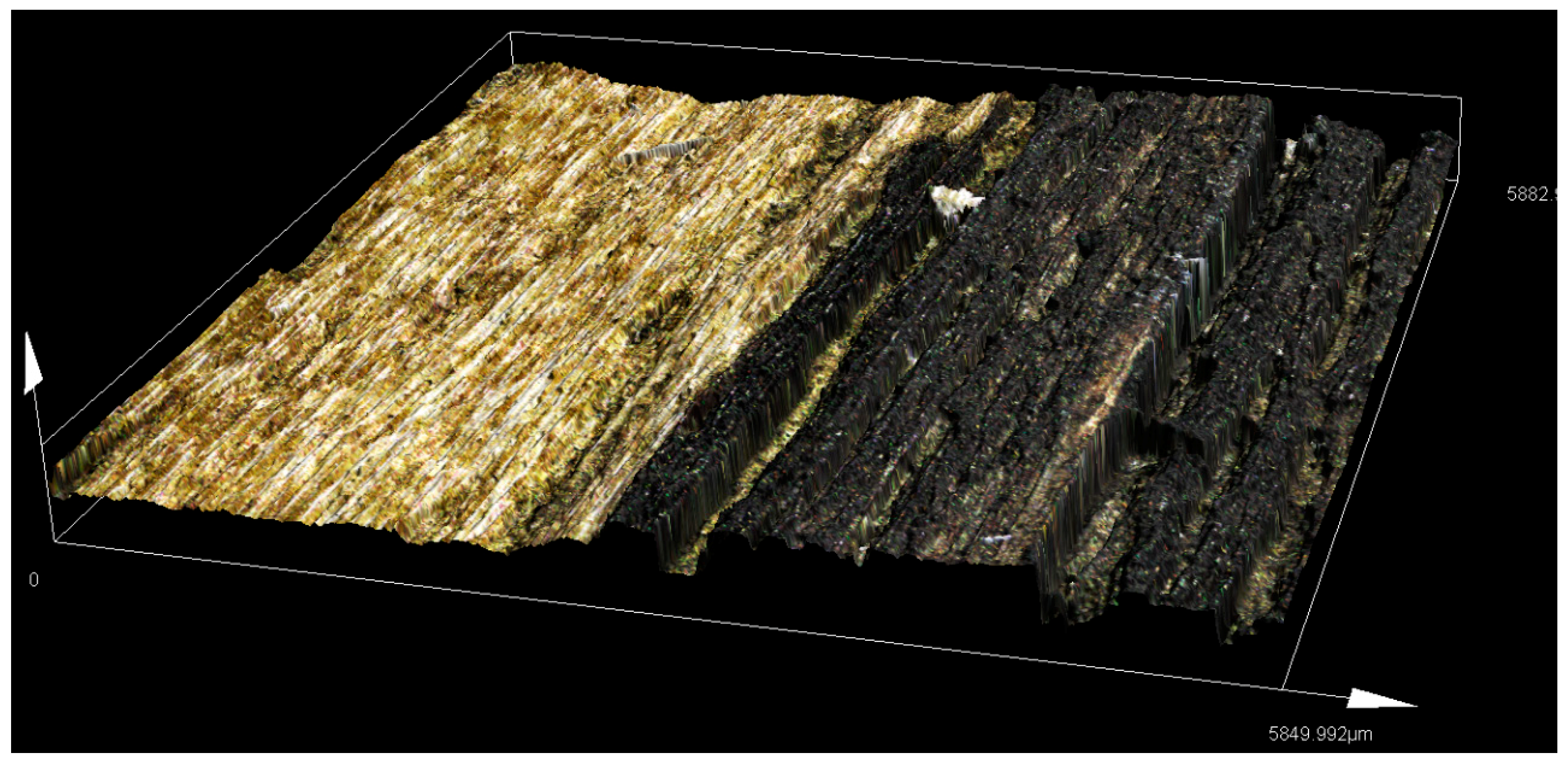

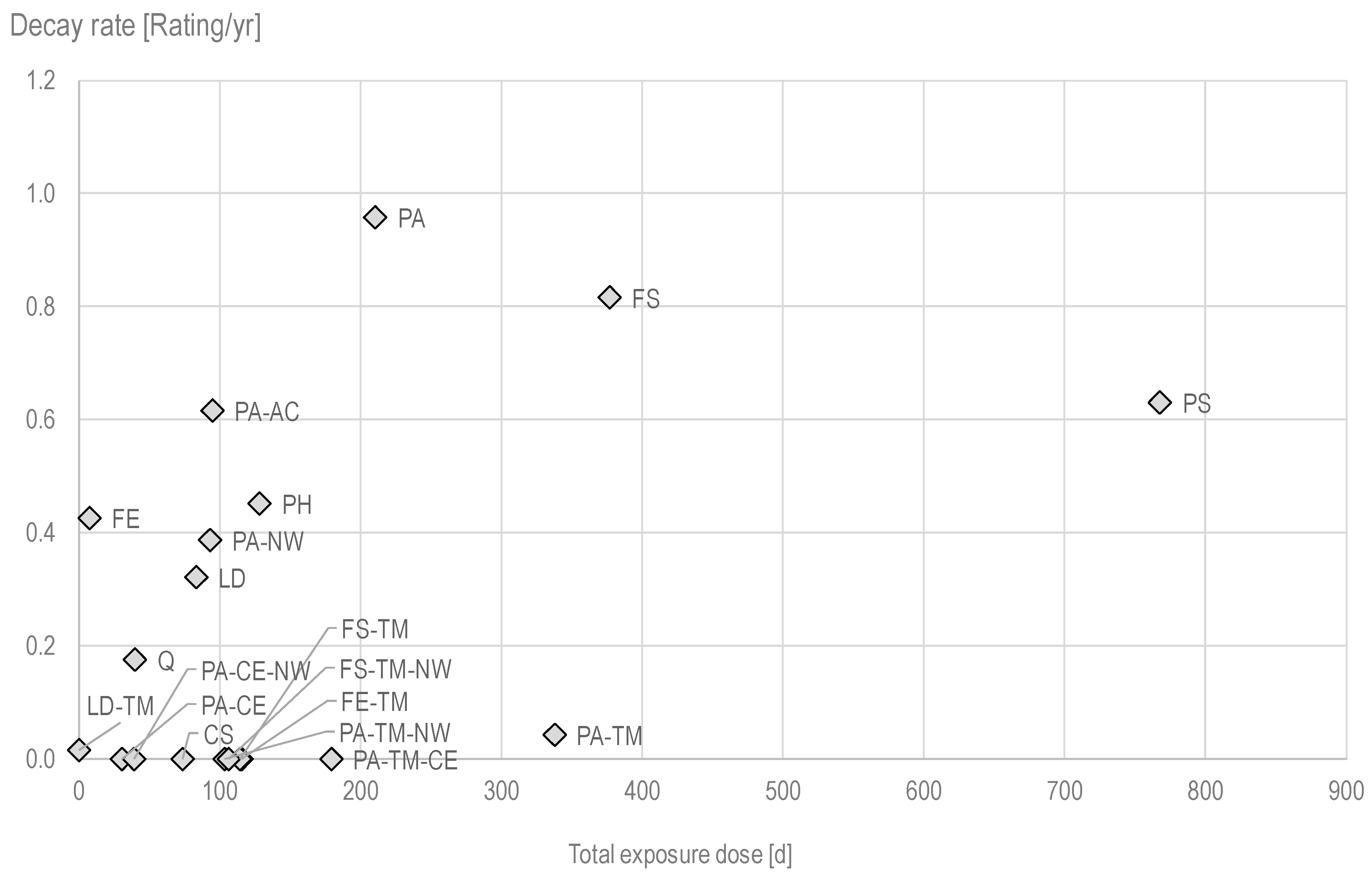

3.3. Decay Rate in the Decking of the Model House

3.4. Modelling Decay Rates of Treated and Modified Wood

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bulcke, J.V.D.; De Windt, I.; Defoirdt, N.; De Smet, J.; Van Acker, J. Moisture dynamics and fungal susceptibility of plywood. Int. Biodeterior. Biodegradation 2011, 65, 708–716. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, O. Wood and Tree Fungi: Biology, Damage, Protection, and Use; Springer: Berlin, Germany, 2006. [Google Scholar]

- Reinprecht, L. Wood Deterioration, Protection and Maintenance; Wiley: Hoboken, NJ, USA, 2016; p. 366. [Google Scholar]

- FTP. The Forest–based Sector Technology Platform Vision 2040 of the European forest–based sector. Brussels. Available online: http://www.forestplatform.org (accessed on 26 August 2019).

- Durability of Wood and Wood–based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood–based Materials; European Committee for Standardization: Brussels, Belgium, 2016.

- Isaksson, T.; Thelandersson, S. Experimental investigation on the effect of detail design on wood moisture content in outdoor above ground applications. Build. Environ. 2013, 59, 239–249. [Google Scholar] [CrossRef]

- Brischke, C.; Rapp, A.O. Dose–response relationships between wood moisture content, wood temperature and fungal decay determined for 23 European field test sites. Wood Sci. Technol. 2008, 42, 507–518. [Google Scholar] [CrossRef]

- Van Acker, J.; De Windt, I.; Li, W.; Van den Bulcke, J. Critical parameters on moisture dynamics in relation to time of wetness as factor in service life prediction. In Proceedings of the 44th Scientific Conference of the International Research Group on Wood Protection; IRG/WP 14–20555; IRG Secretariat: Stockholm, Sweden, 2014. [Google Scholar]

- Marzouk, M.; Azab, S.; Metawie, M. BIM-based approach for optimizing life cycle costs of sustainable buildings. J. Clean. Prod. 2018, 188, 217–226. [Google Scholar] [CrossRef]

- EC (2011) Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products (CPR) and repealing Council Directive 89/106/EEC. Off. J. Eur. Union L 2011, 88/5, 5–43.

- Kutnik, M.; Suttie, E.; Brischke, C. European standards on durability and performance of wood and wood-based products—Trends and challenges. Wood Mater. Sci. Eng. 2014, 9, 122–133. [Google Scholar] [CrossRef]

- Eurocode—Basis of Structural Design; European Committee for Standardization: Brussels, Belgium, 2002.

- Meyer-Veltrup, L.; Brischke, C.; Alfredsen, G.; Humar, M.; Flæte, P.O.; Isaksson, T.; Larsson-Brelid, P.; Westin, M.; Jermer, J. The combined effect of wetting ability and durability on outdoor performance of wood–Development and verification of a new prediction approach. Wood Sci. Technol. 2017, 51, 615–637. [Google Scholar] [CrossRef]

- Meyer-Veltrup, L.; Brischke, C.; Niklewski, J.; Frühwald Hansson, E. Design and performance prediction of timber bridges based on a factorization approach. Wood Mater. Sci. Eng. 2018, 13, 167–173. [Google Scholar] [CrossRef]

- De Angelis, M.; Romagnoli, M.; Vek, V.; Poljanšek, I.; Oven, P.; Thaler, N.; Lesar, B.; Kržišnik, D.; Humar, M. Chemical composition and resistance of Italian stone pine (Pinus pinea L.) wood against fungal decay and wetting. Ind. Crops Prod. 2018, 117, 187–196. [Google Scholar] [CrossRef]

- Brischke, C.; Hesse, C.; Meyer-Veltrup, L.; Humar, M. Studies on the material resistance and moisture dynamics of Common juniper, English yew, Black cherry, and Rowan. Wood Mater. Sci. Eng. 2018, 13, 222–230. [Google Scholar] [CrossRef]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Performance of Bark Beetle Damaged Norway Spruce Wood Against Water and Fungal Decay. Bioresource 2018, 13, 3473–3486. [Google Scholar] [CrossRef]

- Rep, G.; Pohleven, F. Wood modification––A promising method for wood preservation. Wood Ind. 2001, 52, 71–76. [Google Scholar]

- Rep, G.; Pohleven, F.; Bučar, B. Characteristics of thermally modified wood in vacuum. In Proceedings of the 34th scientific conference of the International Research Group on Wood Protection, Stockholm, Sweden, 6–10 June 2004. [Google Scholar]

- Humar, M.; Pohleven, F. Solution for wood preservation. EP 1791682 (B1). 3 September 2018. [Google Scholar]

- Durability of Wood and Wood-based Products—Use Classes: Definitions, Application to Solid Wood and Wood-based Products; European Committee for Standardization: Brussels, Belgium, 2013.

- Humar, M.; Kržišnik, D.; Lesar, B.; Thaler, N.; Ugovšek, A.; Zupančič, K.; Žlahtič, M. Thermal modification of wax-impregnated wood to enhance its physical, mechanical, and biological properties. Holzforsch 2017, 71, 57–64. [Google Scholar] [CrossRef]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials. Forests 2018, 9, 488. [Google Scholar]

- Field Test Method for Determining the Relative Protective Effectiveness of a Wood Preservative in Ground Contact; European Committee for Standardization: Brussels, Belgium, 2015.

- Kržišnik, D.; Lesar, B.; Thaler, N.; Planinšič, J.; Humar, M.A. Study of moisture performance of wood determined in laboratory and field trials. Eur. J. Wood Wood Prod. Submitted manuscript.

- Brischke, C.; Lampen, S. Resistance based moisture content measurements on native, modified and preservative treated wood. Eur. J. Wood Wood Prod. 2014, 72, 289–292. [Google Scholar] [CrossRef]

- Otten, K.A.; Brischke, C.; Meyer, C. Material moisture content of wood and cement mortars—Electrical resistance-based measurements in the high ohmic range. Constr. Build. Mater. 2017, 153, 640–646. [Google Scholar] [CrossRef]

- Durability of Wood and Wood–based Products—Determination of the Natural Durability of Solid Wood against Wood–destroying Fungi, Test Methods—Part 1: Basidiomycetes; European Committee for Standardization: Brussels, Belgium, 2005.

- Raspor, P.; Smole Možina, S.; Podjavoršek, J.; Pohleven, F.; Gogala, N.; Nekrep, F.V.; Hacin, J. Collection of industrial microorganisms. In Catalogue of Cultures; Biotechnical Faculty, University of Ljubljana: Ljubljana, Slovenia, 1995; p. 98. [Google Scholar]

- Thermal Insulating Products for Building Applications—Determination of Short Term Water Absorption by Partial Immersion; European Committee for Standardization: Brussels, Belgium, 1997.

- Wood Preservatives—Methods for Measuring Losses of Active Ingredients and Other Preservative Ingredients From Treated Timber—Part 2: Laboratory Method for Obtaining Samples for Analysis to Measure Losses by Leaching into Water or Synthetic Sea Water; European Committee for Standardization: Brussels, Belgium, 1994.

- Isaksson, T.; Thelandersson, S.; Jermer, J.; Brischke, C. Beständighet för utomhusträ ovan mark. In Guide för Utformning och Materialval (Rapport TVBK–3066); Lund University, Division of Structural Engineering: Lund, Sweden, 2014. [Google Scholar]

- Isaksson, T.; Brischke, C.; Thelandersson, S. Development of decay performance models for outdoor timber structures. Mater. Struct. 2013, 46, 1209–1225. [Google Scholar] [CrossRef]

- Brischke, C.; Meyer Veltrup, L. Modelling timber decay caused by brown rot fungi. Mater. Struct. 2016, 49, 3281–3291. [Google Scholar] [CrossRef]

- Freeman, M.H.; McIntyre, C.R. A comprehensive review of copper–based wood preservatives with a focus on new micronized or dispersed copper systems. For. Prod. J. 2008, 58, 6–27. [Google Scholar]

- Lebow, S.T.; Lebow, P.; Woodward, B.; Kirker, G.; Arango, R. Fifty-Year Durability Evaluation of Posts Treated with Industrial Wood Preservatives. For. Prod. J. 2015, 65, 307–313. [Google Scholar] [CrossRef]

- Obanda, D.N.; Shupe, T.F.; Barnes, H.M. Reducing leaching of boron-based wood preservatives—A review of research. Bioresour. Technol. 2008, 99, 7312–7322. [Google Scholar] [CrossRef] [PubMed]

- Lesar, B.; Kralj, P.; Humar, M. Montan wax improves performance of boron-based wood preservatives. Int. Biodeterior. Biodegradation 2009, 63, 306–310. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. Bioresources 2009, 4, 370–404. [Google Scholar]

- Spear, M.; Binding, T.; Jenkins, D.; Nicholls, J.; Ormondroyd, G. Mild thermal modification to enhance the machinability of larch. In Proceedings of the European Conference on Wood Modification, Lisbon, Portugal, 15–19 May 2014. [Google Scholar]

- Höpken, M. Investigations on the Growth and Moisture Transport of Indoor Wood Decay Fungi in Piled Wood Specimens. Master’s Thesis, Department Biology, University Hamburg, Hamburg, Germany, June 2015. [Google Scholar]

- Meyer, L.; Brischke, C. Fungal decay at different moisture levels of selected European-grown wood species. Int. Biodeterior. Biodegradation 2015, 103, 23–29. [Google Scholar] [CrossRef]

- Popper, R.; Niemz, P. Wasserdampfsorptionsverhalten ausgewählter heimischer und überseeischer Holzarten. Bauphysik 2009, 31, 117–121. [Google Scholar] [CrossRef]

- Žlahtič-Zupanc, M.; Lesar, B.; Humar, M. Changes in moisture performance of wood after weathering. Constr. Build. Mater. 2018, 193, 529–538. [Google Scholar] [CrossRef]

- Humar, M.; Kržišnik, D.; Lesar, B.; Ugovšek, A.; Rep, G.; Šubic, B.; Thaler, N.; Žlahtič, M. Monitoring of window, door, decking and façade elements made of thermally modified spruce wood in use. In Proceedings of the 8th European Conference on Wood Modification (ECWM8), Helsinki, Finland, 26 October 2015; pp. 419–428. [Google Scholar]

- Van Acker, J.; Van den Bulcke, J.; De Windt, I.; Colpaert, S.; Li, W. Moisture dynamics of modified Wood and the Relevance Towards Decay Resistance. In Proceedings of the 8th European Conference on Wood Modification (ECWM8), Helsinki, Finland, 26 October 2015; pp. 44–55. [Google Scholar]

- Schwarze, F.W.; Landmesser, H.; Zgraggen, B.; Heeb, M. Permeability changes in heartwood of Picea abies and Abies alba induced by incubation with Physisporinus vitreus. Holzforschung 2006, 60, 450–454. [Google Scholar] [CrossRef]

- Žlahtič, M.; Humar, M. Influence of artificial and natural weathering on the moisture dynamic of wood. BioResources 2017, 12, 117–142. [Google Scholar] [CrossRef]

- Brischke, C.; Stricker, S.; Meyer-Veltrup, L.; Emmerich, L. Changes in sorption and electrical properties of wood caused by fungal decay. Holzforschung 2018, 73, 445–455. [Google Scholar] [CrossRef]

- Meyer, L.; Brischke, C.; Treu, A.; Larsson Brelid, P. Critical moisture conditions for fungal decay of modified wood by basidiomycetes as detected by pile tests. Holzforschung 2016, 70, 331–339. [Google Scholar] [CrossRef]

- Brischke, C.; Meyer, L.; Gry, A.; Humar, M.; Francis, L.; Flæte, P.O.; Larsson Brelid, P. Natural durability of timber exposed above ground: A survey. Wood Ind. 2013, 64, 113–129. [Google Scholar] [CrossRef]

- Augusta, U. Untersuchung der Natürlichen Dauerhaftigkeit Wirtschaftlich Bedeutender Holzarten Bei Verschiedener Beanspruchung im Außenbereich. Ph.D. Thesis, University of Hamburg, Hamburg, Germany, June 2007. [Google Scholar]

- Isaksson, T.; Thelandersson, S.; Jermer, J.; Brischke, C. Service life of wood in outdoor above ground applications: Engineering design guideline—Background document. Report TVBK–3067. Div. of Structural Engineering, Lund University, Sweden. 2015. Available online: http://www.kstr.lth.se (accessed on 1 August 2018).

- Kržišnik, D.; Brischke, C.; Lesar, B.; Thaler, N.; Humar, M. Performance of wood in the Franja partisan hospital. Wood Mater. Sci. Eng. 2019, 14, 24–32. [Google Scholar] [CrossRef]

| Wood Species | Treatment | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Norway Spruce (Picea abies) | Scots Pine – Sapwood (Pinus sylvestris) | Scots Pine – Heartwood (Pinus sylvestris) | European Larch (Larix decidua) | European Ash (Fraxinus excelsior) | European Beech (Fagus sylvatica) | Sweet Chestnut (Castanea sativa) | English Oak (Quercus sp.) | Thermal Modification | Impregnation with Natural Wax | Copper–Ethanolamine Impregnation | Water Borne Acrylic Surface Coating | |

| Abbreviation | PA | PS | PH | LD | FE | FS | CS | Q | TM | NW | CE | AC |

| PA | PA | |||||||||||

| PA–NW | PA | NW | ||||||||||

| PA–AC | PA | AC | ||||||||||

| PA–CE | PA | CE | ||||||||||

| PA–CE–NW | PA | NW | CE | |||||||||

| PA–TM | PA | TM | ||||||||||

| PA–TM–NW | PA | TM | NW | |||||||||

| PA–TM–CE | PA | TM | CE | |||||||||

| PS | PS | |||||||||||

| PH | PH | |||||||||||

| LD | LD | |||||||||||

| LD–TM | LD | TM | ||||||||||

| FE | FE | |||||||||||

| FE–TM | FE | TM | ||||||||||

| FS | FS | |||||||||||

| FS–TM | FS | TM | ||||||||||

| FS–TM–NW | FS | TM | NW | |||||||||

| CS | CS | |||||||||||

| Q | Q | |||||||||||

| Term | Description |

|---|---|

| kwa | Factor describing the wetting ability of wood-based materials. Factor is expressed in relative values, relative to the wetting ability of the spruce. |

| kinh | Factor describing the inherent durability of wood-based materials. Factor is expressed in relative values, relative to the inherent durability of the spruce. |

| DRd | Resistance dose reflects the material property and is expressed in days (d), with optimum wood MC and wood temperature conditions for fungal decay, before the first evidence of decay. |

| Rel. DRd | Relative resistance dose. Usually spruce is used as the normalisation factor. |

| Material | kinh | kwa | DRd | rel. DRd |

|---|---|---|---|---|

| PA | 1.0 | 1.0 | 325 | 1.00 |

| PA–NW | 1.3 | 2.4 | 977 | 3.01 |

| PA–AC | 1.1 | 2.9 | 1009 | 3.10 |

| PA–CE | 5.0 | 1.5 | 2356 | 7.25 |

| PA–CE–NW | 5.0 | 2.9 | 4705 | 14.48 |

| PA–TM | 3.1 | 1.8 | 1763 | 5.43 |

| PA–TM–NW | 3.4 | 2.5 | 2698 | 8.30 |

| PA–TM–CE | 5.0 | 1.2 | 1978 | 6.09 |

| PS | 1.1 | 1.2 | 430 | 1.32 |

| PH | 2.5 | 1.2 | 966 | 2.97 |

| LD | 1.6 | 1.9 | 1002 | 3.08 |

| LD–TM | 2.7 | 3.2 | 2746 | 8.45 |

| FE | 1.2 | 1.0 | 396 | 1.22 |

| FE–TM | 2.9 | 1.9 | 1771 | 5.45 |

| FS | 0.9 | 1.0 | 284 | 0.88 |

| FS–TM | 2.6 | 2.1 | 1773 | 5.46 |

| FS–TM–NW | 3.3 | 2.6 | 2815 | 8.66 |

| CS | 5.0 | 1.3 | 2080 | 6.40 |

| Q | 3.9 | 1.5 | 1923 | 5.92 |

| Material | Average MC (%) | Median MC (%) | No. of meas. MC > 25% | % of meas. MC > 25% |

|---|---|---|---|---|

| PA | 27.9 | 21.7 | 1.075 | 31.8% |

| PA–NW | 20.1 | 17.8 | 838 | 24.8% |

| PA–AC | 18.5 | 16.9 | 672 | 19.9% |

| PA–CE | 16.9 | 15.9 | 247 | 7.3% |

| PA–CE–NW | 20.1 | 18.9 | 242 | 7.2% |

| PA–TM | 25.4 | 25.5 | 1.764 | 52.2% |

| PA–TM–NW | 16.1 | 12.4 | 643 | 19.0% |

| PA–TM–CE | 19.1 | 14.0 | 927 | 27.4% |

| PS | 49.4 | 55.3 | 2.841 | 84.0% |

| PH | 19.5 | 15.9 | 844 | 25.0% |

| LD | 19.3 | 17.8 | 723 | 21.4% |

| LD–TM | 13.3 | 12.0 | 6 | 0.2% |

| FE | 14.6 | 14.0 | 94 | 2.8% |

| FE–TM | 17.5 | 16.8 | 779 | 23.0% |

| FS | 27.3 | 25.7 | 1.747 | 51.7% |

| FS–TM | 18.9 | 19.5 | 811 | 24.0% |

| FS–TM–NW | 17.7 | 14.0 | 771 | 22.8% |

| CS | 17.3 | 15.6 | 608 | 18.0% |

| Q | 16.6 | 15.8 | 370 | 10.9% |

| Material | Average Decay Rating of the Decking Elements | ||||

|---|---|---|---|---|---|

| 2014 | 2015 | 2016 | 2017 | 2018 | |

| PA | 0.0 | 1.0 | 2.4 | 3.7 | 4.0 |

| PA–NW | 0.0 | 0.0 | 0.2 | 1.1 | 1.9 |

| PA–AC | 0.0 | 0.0 | 0.8 | 1.6 | 2.8 |

| PA–CE | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| PA–CE–NW | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| PA–TM | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| PA–TM–NW | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| PA–TM–CE | 0.0 | 0.0 | 0.0 | 0.0 | 0.2 |

| PS | 0.0 | 0.6 | 1.2 | 2.2 | 3.1 |

| PH | 0.0 | 0.0 | 0.6 | 1.5 | 2.3 |

| LD | 0.0 | 0.0 | 0.6 | 1.3 | 1.6 |

| LD–TM | 0.0 | 0.0 | 0.0 | 0.0 | 0.1 |

| FE | 0.0 | 0.0 | 1.0 | 1.4 | 2.1 |

| FE–TM | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| FS | 0.0 | 1.0 | 2.2 | 3.1 | 3.7 |

| FS–TM | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| FS–TM–NW | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| CS | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Q | 0.0 | 0.0 | 0.0 | 0.5 | 0.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Humar, M.; Kržišnik, D.; Lesar, B.; Brischke, C. The Performance of Wood Decking after Five Years of Exposure: Verification of the Combined Effect of Wetting Ability and Durability. Forests 2019, 10, 903. https://doi.org/10.3390/f10100903

Humar M, Kržišnik D, Lesar B, Brischke C. The Performance of Wood Decking after Five Years of Exposure: Verification of the Combined Effect of Wetting Ability and Durability. Forests. 2019; 10(10):903. https://doi.org/10.3390/f10100903

Chicago/Turabian StyleHumar, Miha, Davor Kržišnik, Boštjan Lesar, and Christian Brischke. 2019. "The Performance of Wood Decking after Five Years of Exposure: Verification of the Combined Effect of Wetting Ability and Durability" Forests 10, no. 10: 903. https://doi.org/10.3390/f10100903