To assess the capability of the newly proposed FE-FCT method, the propagation of (longitudinal) waves in homogeneous as well as heterogeneous slender bodies (rods) is simulated. To check the accuracy of the method, results are compared to an analytical solution derived next.

4.1. Analytical solution

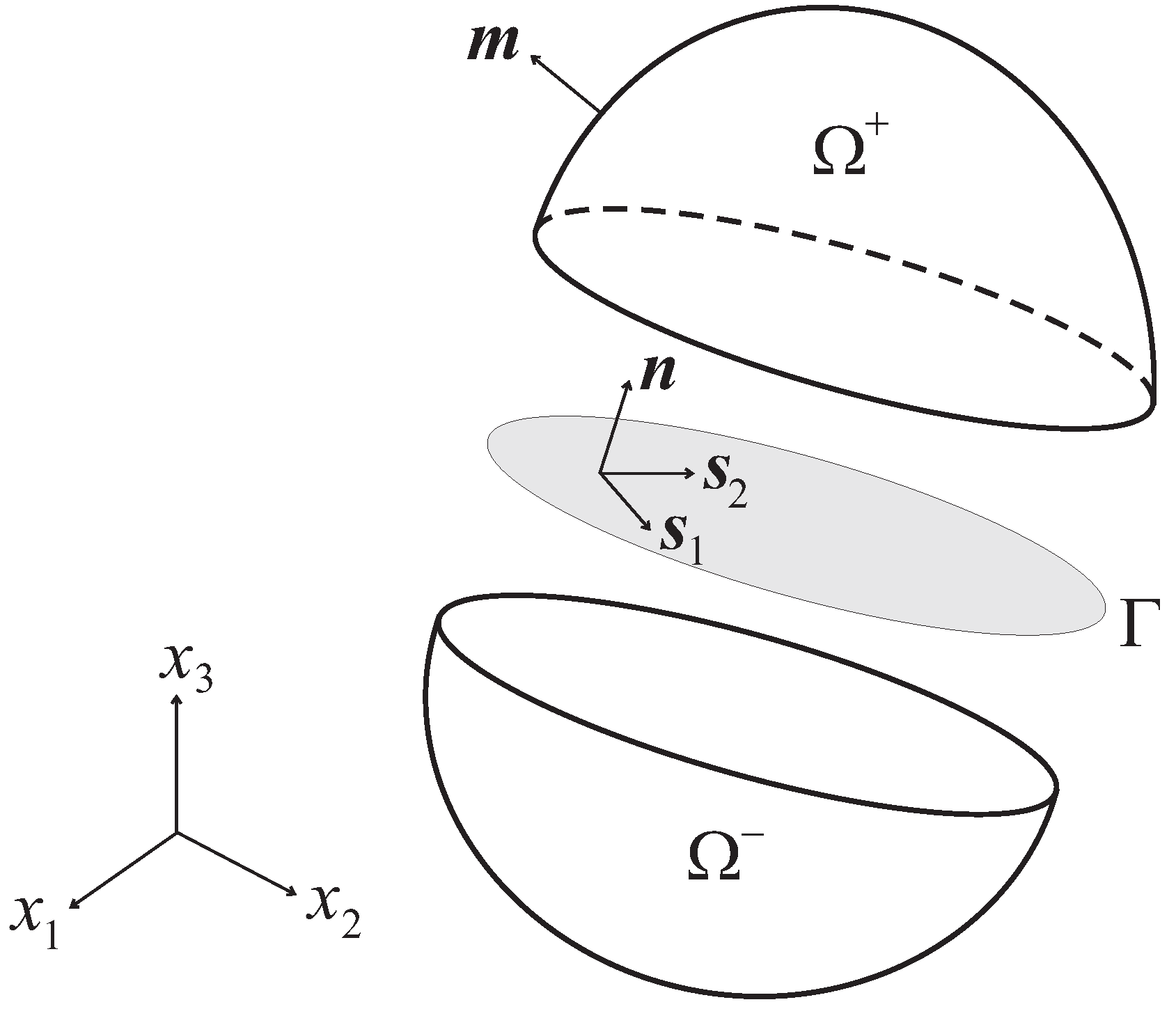

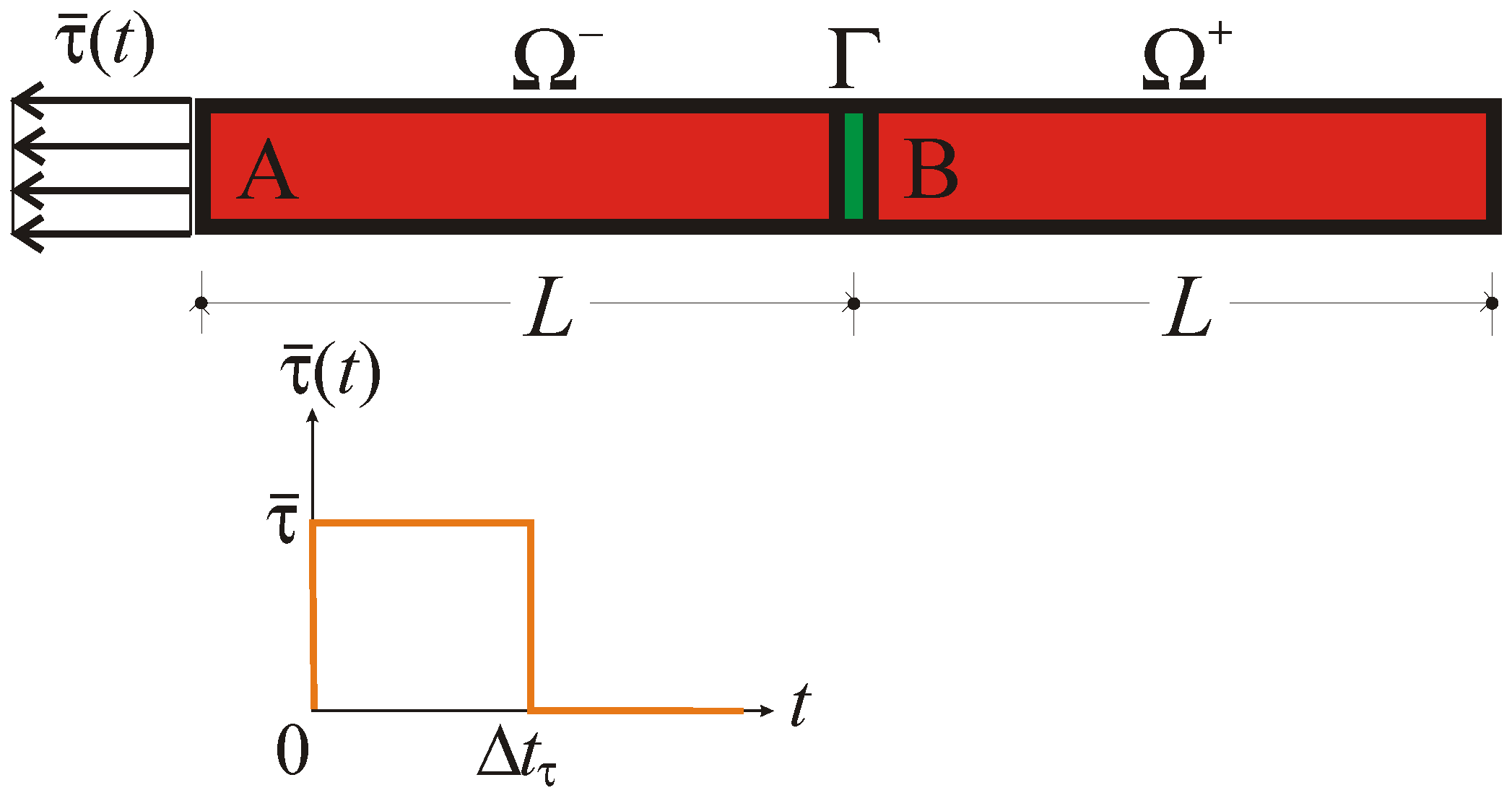

Let Ω be a slender body, such that only the propagation of longitudinal waves is of interest. According to the schematic of

Figure 4, the body is assumed to be loaded by a constant pressure

, acting over the time interval

. To get insights into the effect of inner boundaries on wave reflection and dispersion, a two-phase body in considered, with phases A and B (of length

L in the direction of wave propagation) respectively featuring Young’s moduli

and

, and mass densities

and

; the relevant longitudinal wave speeds thus are

and

.

In view of the elastic response of the bulk, a tensile wave propagating inside material A turns out to be characterized by the following relationship between the stress amplitude

and the particle velocity

:

Figure 7.

Wave propagating along a homogeneous rod discretized with an unstructured mesh: stress field at s. Effect of parameters on the capability of the newly proposed FE-FCT scheme to accurately track the stress discontinuity across the wave fronts.

Figure 7.

Wave propagating along a homogeneous rod discretized with an unstructured mesh: stress field at s. Effect of parameters on the capability of the newly proposed FE-FCT scheme to accurately track the stress discontinuity across the wave fronts.

After impinging upon the interface Γ at

, the incident wave induces reflected and transmitted waves, respectively characterized by relations [

17]:

where

and

are the amplitudes of the reflected and transmitted stress waves, and

and

are the relevant particle velocities. Equilibrium across Γ requires:

while compatibility reads:

being the opening velocity on Γ. Account taken of the interface constitutive law (10), written for mode I loadings as

, one arrives at the differential equation:

where:

is the time-scale of the opening process along interface Γ (sometimes called characteristic relaxation time [

17]);

. Upon integration of (38), the solution in terms of time histories of the reflected and transmitted waves reads:

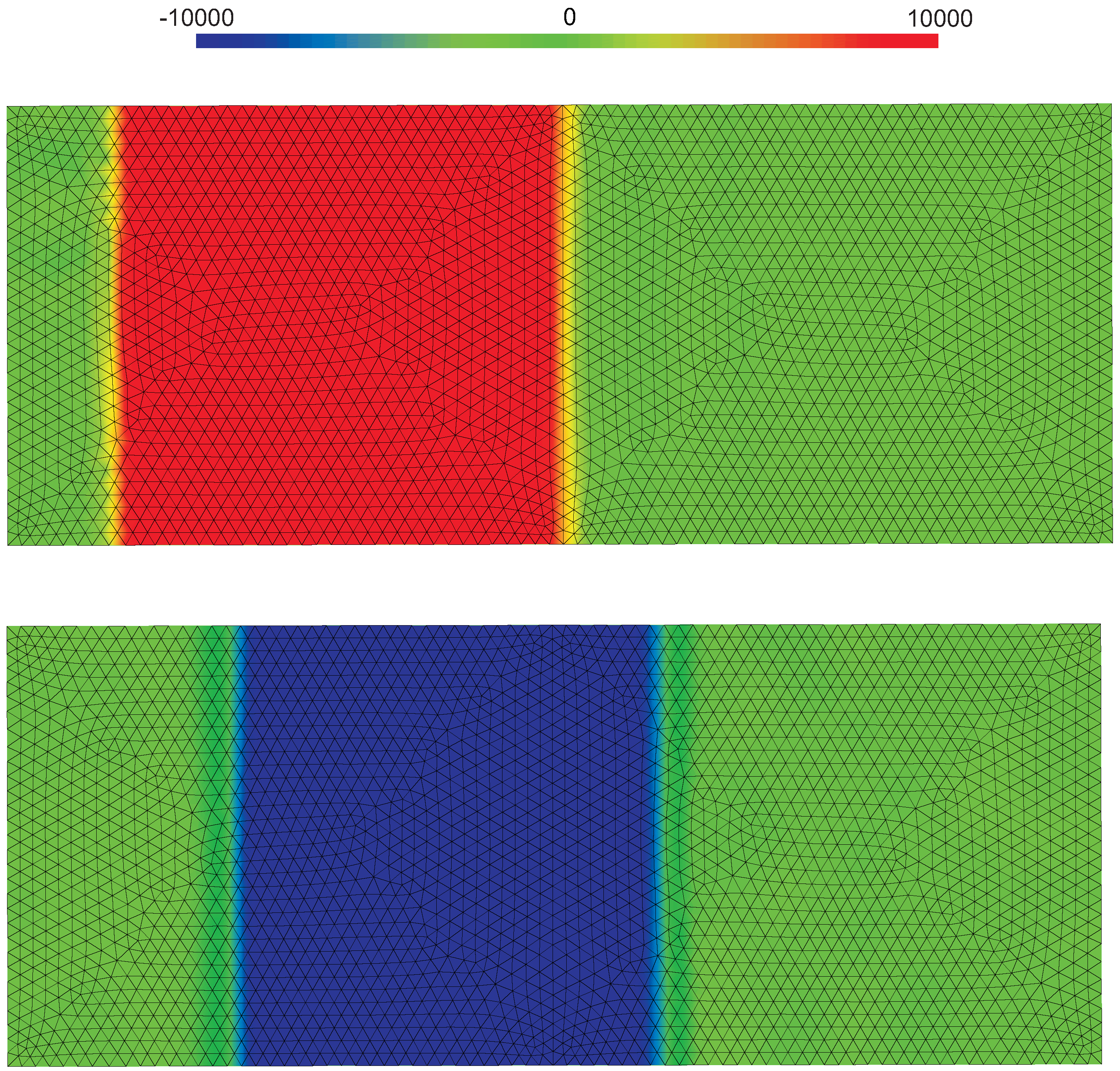

Figure 8.

Wave propagating along a homogeneous rod discretized with a two-dimensional unstructured mesh: longitudinal stress field at (top) s and (bottom) s.

Figure 8.

Wave propagating along a homogeneous rod discretized with a two-dimensional unstructured mesh: longitudinal stress field at (top) s and (bottom) s.

In case of perfect adhesion between the two phases, i.e. in case of , the exponential terms in (39) and (40) drop to zero. The time-dependent feature of the solution is thus lost in view of the non-evolving microstructure along the interface.

4.2. FE-FCT results

Similarly to what done in [

9], all the results to follow have been obtained by adopting:

m;

kg/m

;

Pa, so as to initially cause the propagation of a tensile wave inside material A of magnitude

Pa;

s. As for the FCT parameters, if not otherwise stated we have adopted:

[

9], and

.

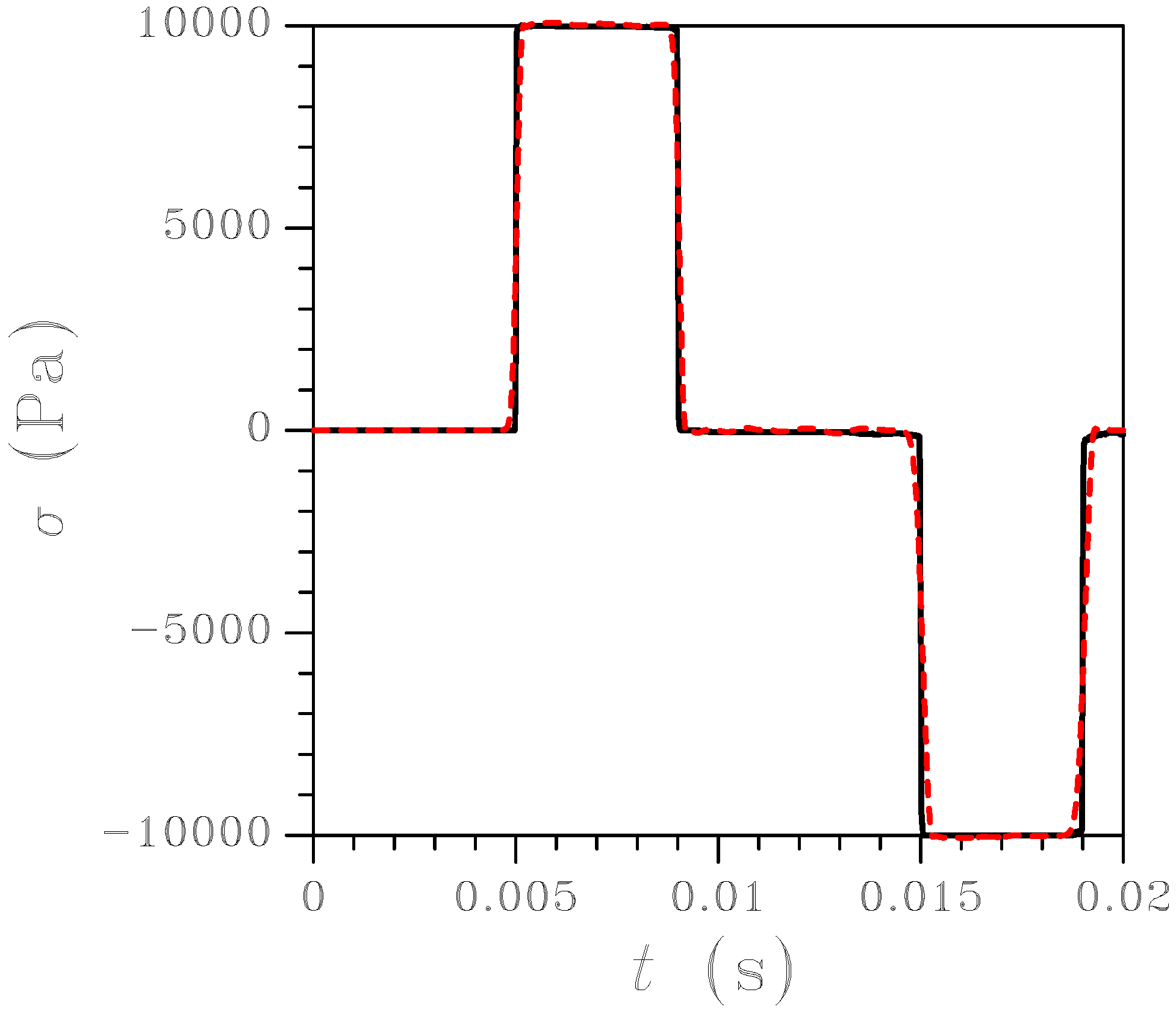

Figure 9.

Wave propagating along a homogeneous rod discretized with unstructured meshes: comparison between the evolutions of the longitudinal stress at m, as obtained through one-dimensional (black solid line) and two-dimensional (red dashed line) simulations.

Figure 9.

Wave propagating along a homogeneous rod discretized with unstructured meshes: comparison between the evolutions of the longitudinal stress at m, as obtained through one-dimensional (black solid line) and two-dimensional (red dashed line) simulations.

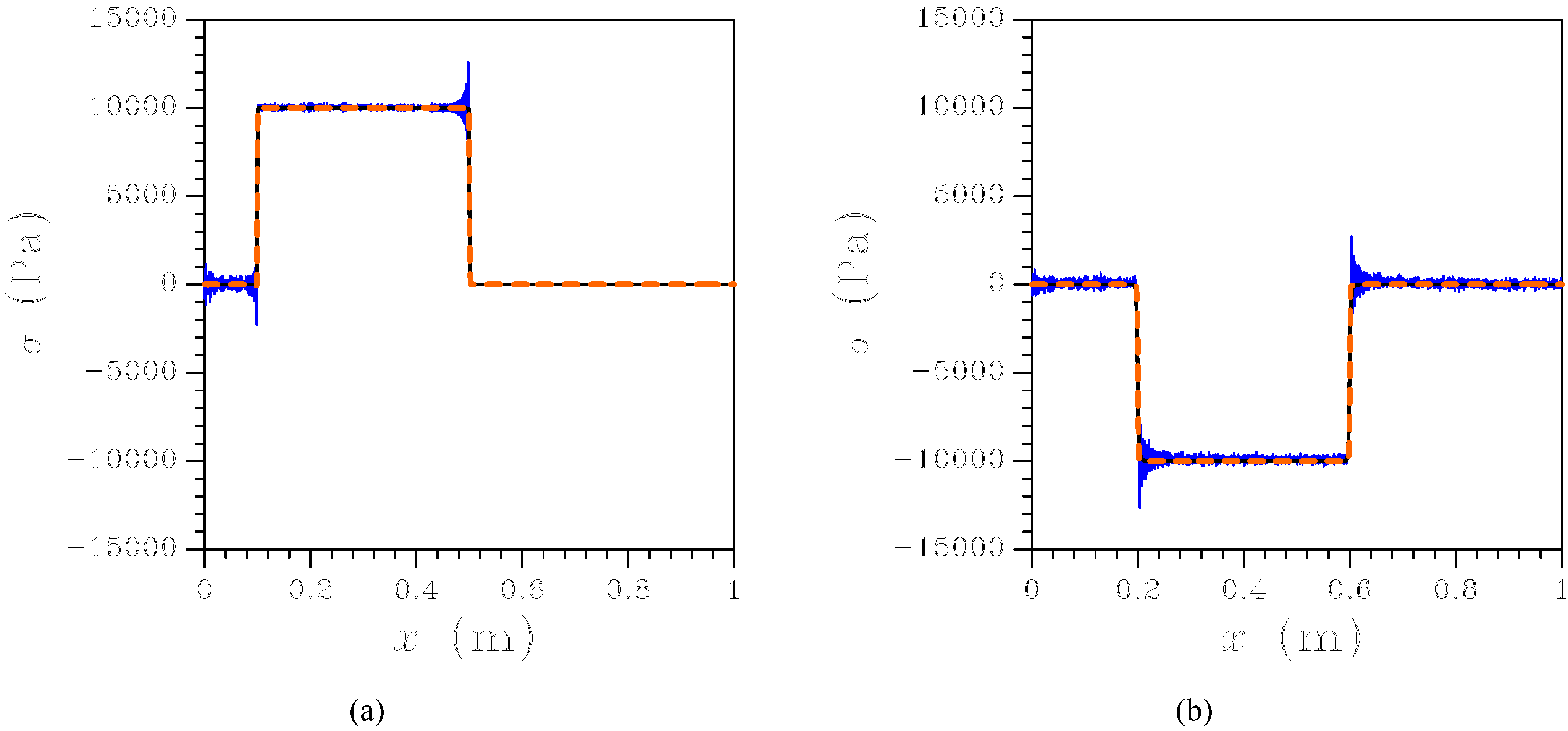

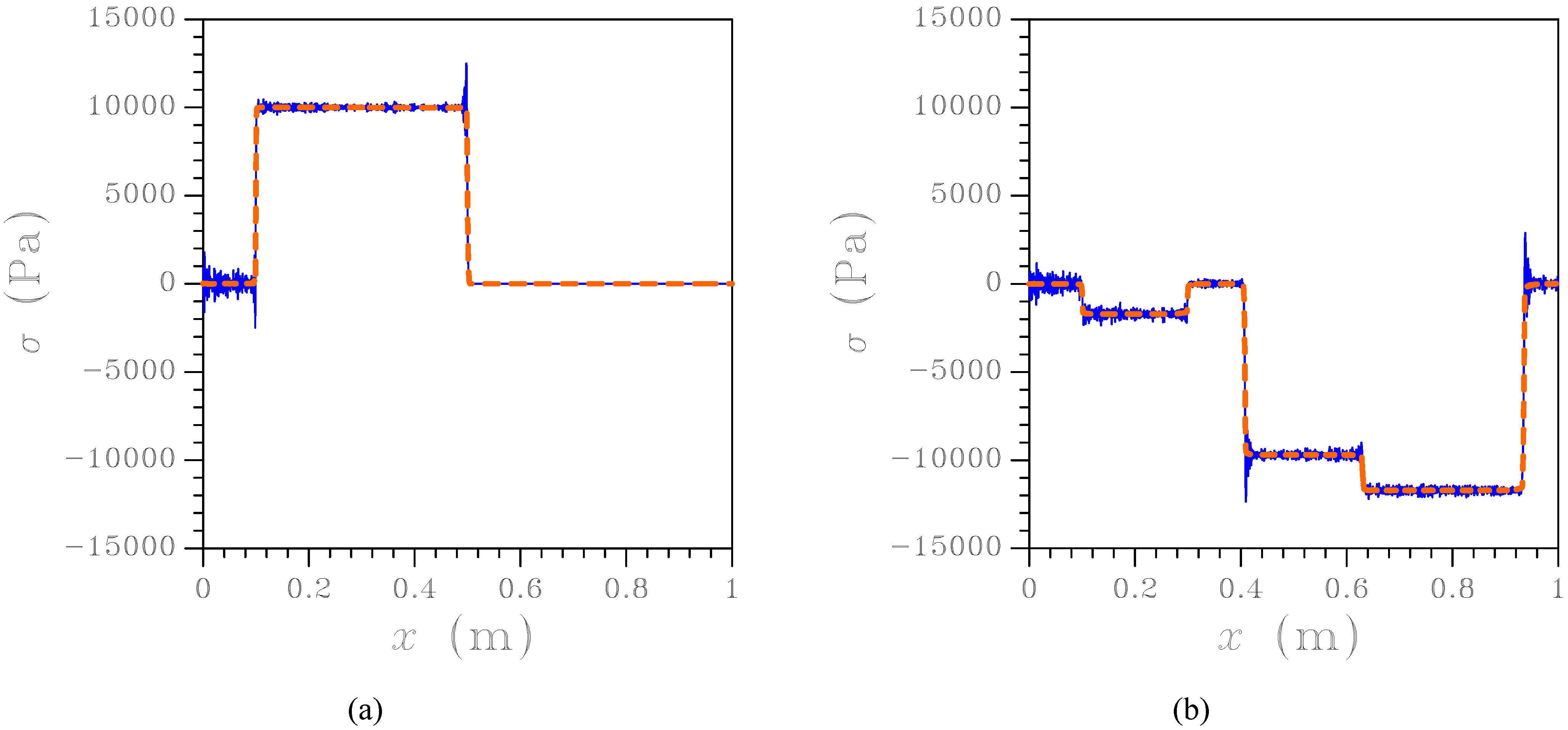

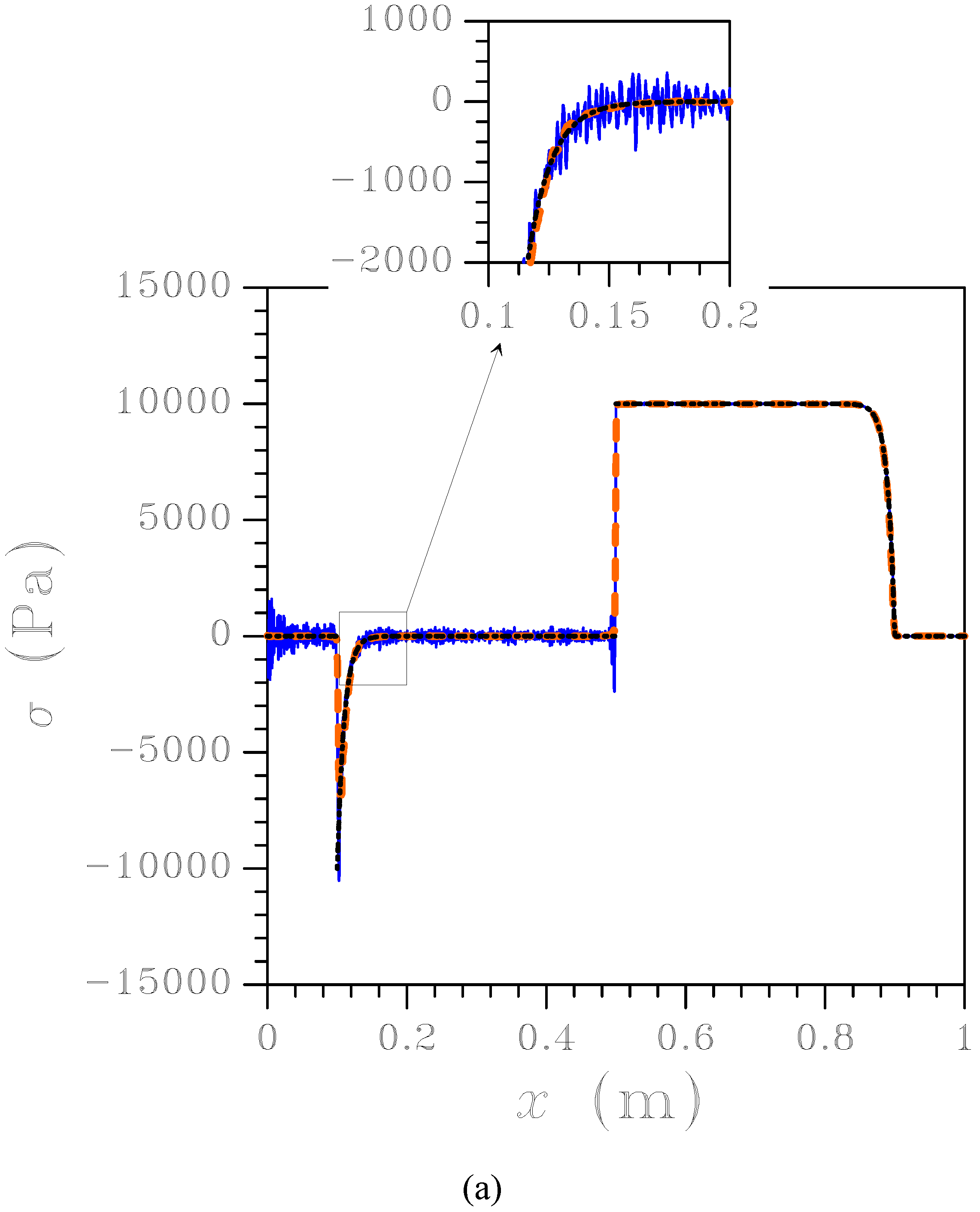

Figure 10.

Wave propagating along a heterogeneous rod with perfect bonding between phases, discretized with an unstructured mesh: stress field at (a) s and at (b) s. Blue solid line: FE solution; orange dashed line: newly proposed FE-FCT solution.

Figure 10.

Wave propagating along a heterogeneous rod with perfect bonding between phases, discretized with an unstructured mesh: stress field at (a) s and at (b) s. Blue solid line: FE solution; orange dashed line: newly proposed FE-FCT solution.

Figure 11.

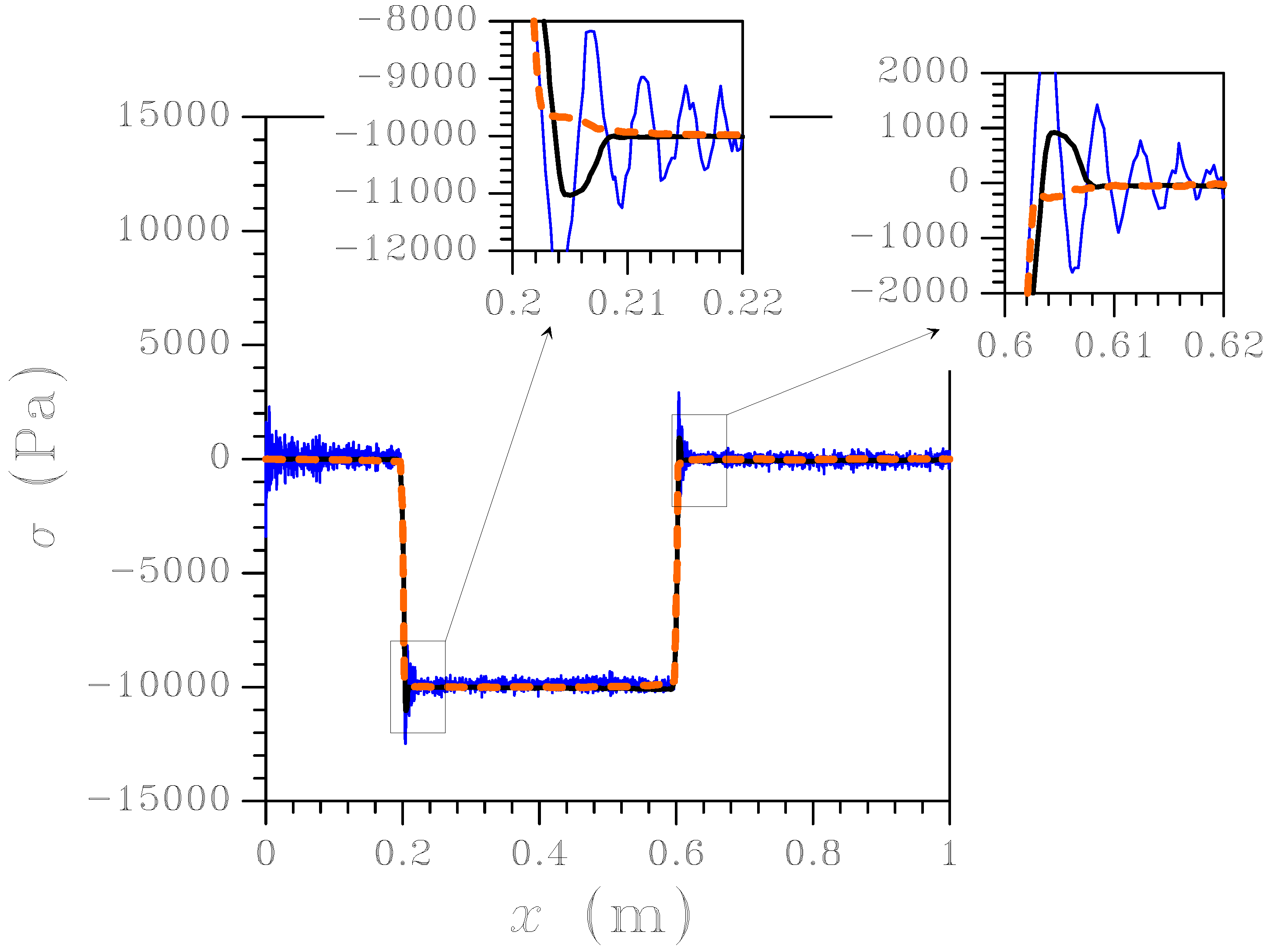

Wave propagating along an interface-containing homogeneous rod ( N/m) discretized with an unstructured mesh: stress field at s. Black dotted line: analytical solution; blue solid line: FE solution; orange dashed line: newly proposed FE-FCT solution.

Figure 11.

Wave propagating along an interface-containing homogeneous rod ( N/m) discretized with an unstructured mesh: stress field at s. Black dotted line: analytical solution; blue solid line: FE solution; orange dashed line: newly proposed FE-FCT solution.

In a first example the rod has been assumed homogeneous, i.e. made of two phases featuring the same Young’s modulus

Pa and perfectly bonded together. In the absence of wave reflection along inner surfaces, the present outcomes are meant to assess the robustness of the new FE-FCT scheme when either structured or unstructured space discretizations are adopted. In our analysis, unstructured one-dimensional meshes have been obtained from the relevant structured ones as follows. Starting with a nodal spacing

(here

m, meaning that 1000 quadratic elements, with characteristic size

, have been adopted to discretize the whole specimen), a random sequence

is generated so as:

where:

and

are the longitudinal coordinates of the

th node in the structured and unstructured meshes, respectively;

is a scaling factor, introduced to ensure positivity of the length of each element in the unstructured mesh.

Figure 5 shows the stress distribution in the rod at time instants

s and

s; it can be seen that the tensile wave, after reflection at the rear free surface of the specimen, becomes a compressive wave of same amplitude. These results have been obtained with a structured mesh, hence the standard [

8] and the newly proposed FE-FCT schemes furnish the same outcomes. Moreover, the analytical solution can not be distinguished from the FE-FCT ones; on the other hand, ripples show up in the FE solution, initially just behind the wave fronts (see

Figure 5(a), where the discontinuities are propagating from left to right) and eventually spoiling the accuracy of the solution along the whole specimen (see

Figure 5(b)).

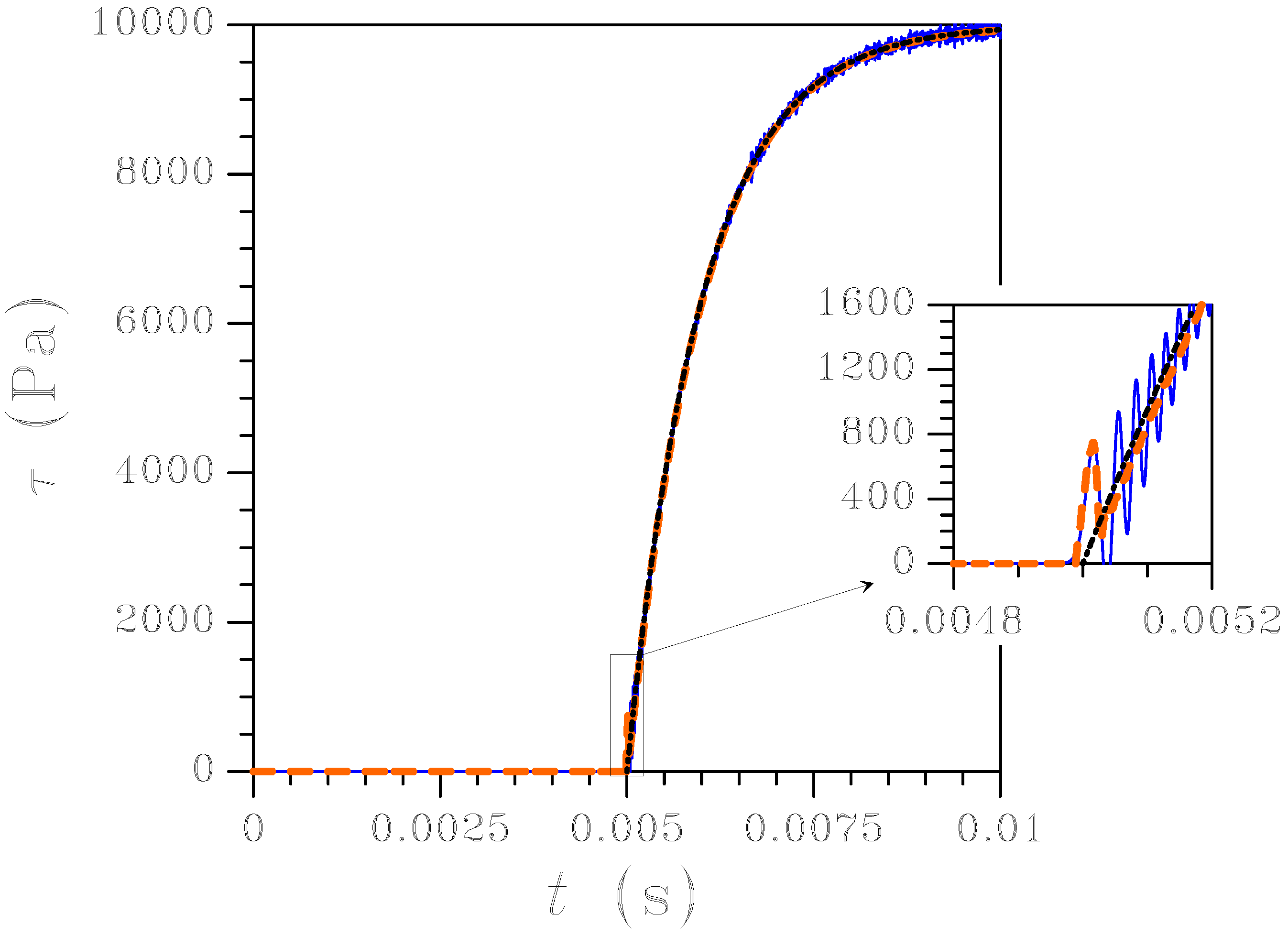

Figure 12.

Wave propagating along an interface-containing homogeneous rod ( N/m) discretized with an unstructured mesh: evolution in time of the normal traction τ at the interface. Black dotted line: analytical solution; blue solid line: FE solution; orange dashed line: newly proposed FE-FCT solution.

Figure 12.

Wave propagating along an interface-containing homogeneous rod ( N/m) discretized with an unstructured mesh: evolution in time of the normal traction τ at the interface. Black dotted line: analytical solution; blue solid line: FE solution; orange dashed line: newly proposed FE-FCT solution.

In case of unstructured meshing, the methods here compared furnish the results summarized in

Figure 6 in terms of stress field at

s. As expected, the FE solution wildly oscillates, with ripples of increased amplitude as compared to the structured mesh case; the standard FE-FCT scheme is no more able to fully damp oscillations, whereas the new one works properly and prevents the birth of spurious maxima/minima. It must be noticed that the small delay of the new FE-FCT method in the attainment of the analytical solution (characterized by sharp discontinuities), as shown in the two insets of

Figure 6, may be avoided or reduced in duration by a fine tuning of Newmark parameters

β,

γ and FCT parameters

,

. To prove it,

Figure 7 shown the effect of

on the aforementioned delay; as far as this feature of the solution is concerned, it can be seen that smaller parameter values strongly reduce the delay, even if the value of the longitudinal stress may get affected. Only results relevant to

are here reported; on the one hand, if

the solution is characterized by an excessive diffusion around the discontinuities, with fronts smeared over too many FEs; on the other hand, if

the solution has a tendency to instability, characterized by ripple amplitudes continuously increasing in time.

For comparison purposes, outcomes of a two-dimensional simulation are depicted in

Figure 8 in terms of contour plots of the longitudinal stress before (

Figure 8(a)) and after (

Figure 8(b)) reflection at the rear free surface. In this two-dimensional case a much coarser space discretization has been adopted, with 6-node triangular elements featuring a characteristic size

. It can be seen that the stress wave maintain sharp fronts, always perpendicular to the propagation direction independently of local mesh features. Because of the coarse discretization, it is expected that spurious oscillations are here characterized by an increased amplitude when compared to the one-dimensional case.

Figure 9, where the time history of the longitudinal stress at

m is reported, testifies the performance of the proposed FE-FCT scheme: even though the ratio between the characteristic sizes of FEs is

, the discrepancy between the two solutions amounts at most to 2%.

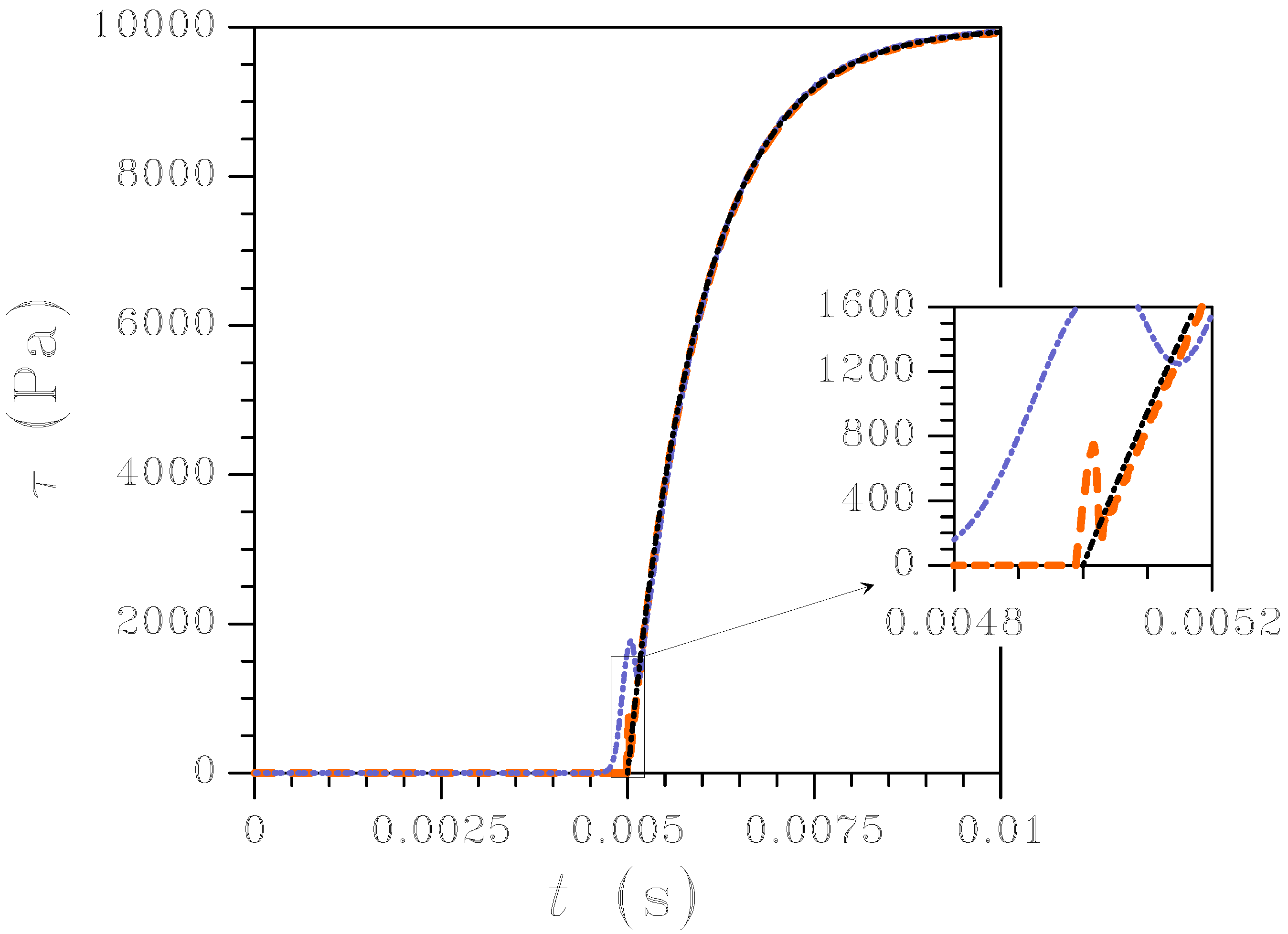

Figure 13.

Wave propagating along an interface-containing homogeneous rod ( N/m) discretized with one-dimensional and two-dimensional unstructured meshes: evolution in time of the normal traction τ at the interface. Black dotted line: analytical solution; orange dashed line: one-dimensional FCT-FE solution; blue dotted line: two-dimensional FCT-FE solution.

Figure 13.

Wave propagating along an interface-containing homogeneous rod ( N/m) discretized with one-dimensional and two-dimensional unstructured meshes: evolution in time of the normal traction τ at the interface. Black dotted line: analytical solution; orange dashed line: one-dimensional FCT-FE solution; blue dotted line: two-dimensional FCT-FE solution.

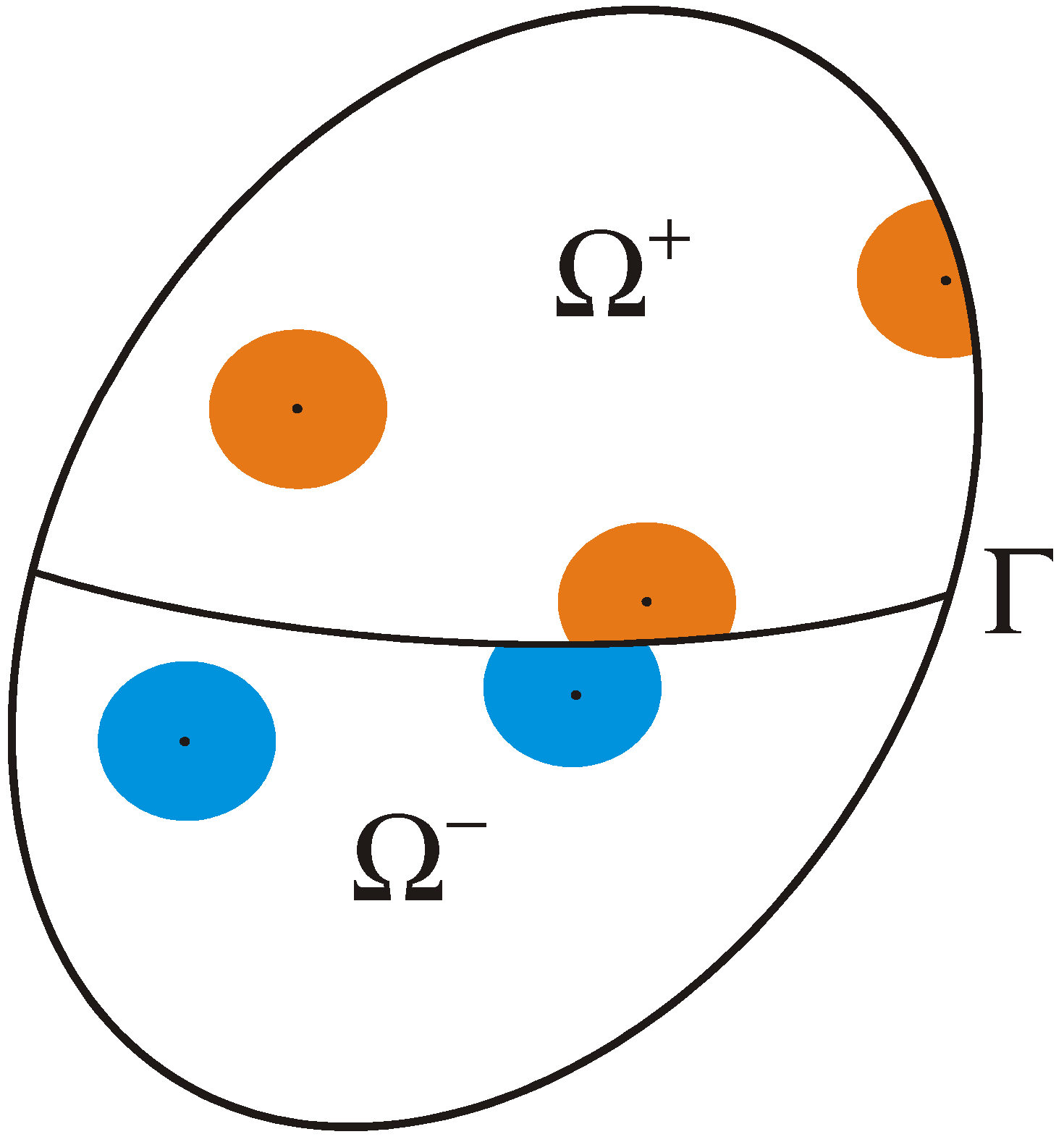

In a second example, to start assessing the efficiency of the FE-FCT scheme in the presence of inner boundaries, it has been assumed that

Pa at fixed values of all the other material parameters; perfect adherence between the two phases was also assigned. FE and FE-FCT results are shown in

Figure 10 in terms of stress field at

s and

s. At

s (

Figure 10(a)), since the leading front of the stress wave has not impinged yet upon the interface (placed at

m) the results are similar to those of

Figure 5(a), showing again that the FCT scheme properly damps oscillations (as before, the analytical solution is not reported here since it can not be distinguished from the FE-FCT one). Moreover, when waves are partially reflected by the inner surface the solution still proves accurate, even without explicitly accounting for the acoustic impedance of each phase as done in [

9].

In a third example, the behavior of a homogeneous two-phase specimen (

Pa) containing a compliant interface has been studied. In the case

N/m

, results in terms of the stress field at

s are depicted in

Figure 11; even in the presence of a compliant interface, it can be seen that the new FE-FCT method correctly reproduces the response of the body without spurious oscillations. To further assess the accuracy of the method, the time history of the normal traction

τ across Γ is shown in

Figure 12. To increase the duration of the transitory stage and to get insights into the performance of the FE-FCT method, the interface stiffness has been decreased to

N/m

, and the loading interval

has been slightly increased accordingly, so as to ensure completion of interface opening till

. Once again, the FE solution looks oscillatory; this behavior becomes a serious issue in case of nonlinear, irreversible interface modes, since spurious unloadings and overshoots may cause a drift of the computed solution away from the exact one. The FE-FCT solution instead presents only an oscillation just after the leading front of the stress wave has impinged upon the interface; afterwards, the FCT scheme filters out possible subsequent ripples. This is also shown in

Figure 13, where results of one-dimensional and two-dimensional simulations are compared; in the two-dimensional case, the same space discretization depicted in

Figure 8 has been adopted. According to previous results, the higher oscillation amplitude around

s in the two-dimensional simulation is caused by the coarser mesh; subsequently, the FCT scheme completely damps ripples.

The small time discrepancy (amounting to s in the one-dimensional case) between FE-FCT and exact solutions is due to the dispersive properties of the FE solution and can be explained as follows. While the analytical solution is characterized by sharp wave fronts, in the FE-FCT one discontinuities are smeared over the resolved length-scale, which is typically one element wide; is about the time interval required by the stress wave to travel across (or the corresponding node spacing in the unstructured mesh case) at speed .