1. Introduction

The disposal of the spent nuclear fuel is a challenging task where the careful planning and optimization of processes definitely pays dividends. The difficulty of the decision making is increased also by the fact that the disposal continues for the distant future and many parameters are still unknown. Indeed, the decisions made now have long term consequences. Thus, it is only reasonable to investigate different scenarios by utilizing multiobjective optimization from the different perspectives.

The disposal is a topical issue since many of the countries utilizing nuclear power have not yet disposed of any spent nuclear fuel. Nevertheless, all of them have to do something for it sooner or later. Long-term storage in interim storage is not considered a safe or ethical solution [

1]. At the same time, the geological disposal is stated to be widely accepted as a safe method [

1]. Finland is going to be one of the first countries to dispose of the spent nuclear fuel by starting the disposal in 2020s [

2].

The aim in the geological disposal is to isolate the spent nuclear fuel to the bedrock such that it has no more impacts on the environment than the regular background radiation. First, the fuel assemblies are removed from the reactor and stored in the water pool in the reactor hall in order to decrease the radiation and the decay heat power to the suitable level such that the assemblies can be transferred to the water pool in the interim storage facility for decades. When the assemblies are cool enough, they can be transferred to the encapsulation facility, where the assemblies are encapsulated into the copper-iron canisters. After that, the canister moves on towards the disposal facility, in depth of more than 400 m. The disposal facility consists of the central tunnel and several parallel disposal tunnels that are connected to the central tunnel. The canister is placed vertically in the hole on the floor of the disposal tunnel. Finally, the disposal tunnel is filled up and sealed. In this study, we divide the disposal process into three parts: the interim storage, the encapsulation facility, and the disposal facility.

As the entire nuclear waste management is a large task, optimization related studies about it are usually focused on some smaller entities. Some of these entities are concentrated more on political or social aspects like to determine where to put a disposal repository [

3] or how to route the transfer of the nuclear waste, or hazardous waste in general [

4,

5]. More safety-related aspects are the optimization of the nuclear safeguards [

6,

7] and the safety assessment of nuclear waste repositories [

8]. In our study, we aim to produce a disposal schedule such that several goals related to all the interim storage, the encapsulation facility, and the disposal facility are taken into account simultaneously with multiobjective optimization. Other studies aiming at a disposal schedule are, for example, [

9] where a single-objective mixed-integer linear programming (MILP) model minimizing the costs is given and [

10] trying to achieve the minimal area of the disposal facility with a linear transportation model. Another research related to the disposal facility is discussed in [

11], where the multiobjective MILP problem is given to optimize the nuclear waste placement in the disposal facility. In addition, there are attempts to optimize the loading of canisters in Finland [

9,

12], Slovenia [

13], and Switzerland [

14].

This study continues the work of [

9], where the aim was to minimize the total costs of the disposal in Finland by selecting the schedule of the disposal. Here, this work has been continued by remodeling the situation as the nonsmooth multiobjective mixed-integer nonlinear programming (MINLP) problem. As a nonsmooth optimization problem [

15,

16,

17], the objectives and the constraints are not necessarily continuously differentiable functions. This allows us to model the situation more accurately. Indeed, many practical applications have nonsmooth nature (see e.g., [

18,

19,

20]) even if they are modeled as differentiable problems in many cases in practice.

Many practical problems also involve several objectives [

21,

22,

23,

24]. As a problem of this scale, this application has several conflicting objectives to offer naturally. Besides total costs, it is reasonable to optimize, for instance, the area of the disposal facility. In our model, this is done by minimizing the lengths of both disposal and central tunnels. In total, our model contains nine objectives. In addition to the previous three objectives, we have three objectives related to the interim storage and three related to the encapsulation facility. In the interim storage, we want to minimize the maximum number of assemblies in the storage, the maximum storage time, and the average storage time. On the other hand, the operation time of the encapsulation facility is aimed to be minimized and al number of canisters, or in other words, the number of the empty assembly positions.

These objectives indeed are conflicting. For instance, we want the whole disposal process to be over as early as possible, but this raises the heat production load of the canister. This in its turn, increases the distances between the canisters in the disposal facility. However, the heat load of the canister can be decreased by leaving empty assembly positions, but then more canisters are needed. Another option is to increase the cooling time which again delays the end of the disposal, but if the disposal delays, more storage space is needed. Obviously, all of these decisions have an impact on costs. As exemplified, the minimization of only one objective may lead to an unsatisfactory solution with respect to some other objective. This leads us to a situation where compromises are certainly needed.

As a result of the multiobjective optimization, we obtain several mathematically equally good compromises, called Pareto optimal solutions. The final selection is left to the decision-maker who has more insight into the problem. In this paper, we propose an interactive procedure utilizing the achievement scalarizing function (ASF), in particular, the two-slope parameterized ASF [

25] which bases on parameterized ASF [

26] and two-slope ASF [

27] generalizing both of them by combining their advantages. Via scalarization, the original multiobjective problem is transformed into one single-objective problem. The idea in brief with ASF is that the decision-maker gives a reference point including the decision maker’s wishes towards the final solution. Then, the closest optimal solution with respect to some metric is found. If we use only one metric, as is the case in general with ASF, the selected metric defines which solution is found [

28,

29,

30]. With the parameterization, we are able to use several metrics, nine in this particular case, and thus, yield different solutions with reasonable distribution. This ability to systematically generate different solutions from the same preference information is utilized in the interactive framework.

This paper is organized as follows. In

Section 2, we begin by depicting the situation under the consideration and give a nonsmooth multiobjective MINLP model for it. In

Section 3, we first introduce some fundamental preliminaries about multiobjective optimization, and then describe the multiobjective interactive method utilizing two-slope parameterized ASFs (MITSPA). In

Section 4, one special case study of the disposal in Finland is given and the solutions are analyzed. Finally, in

Section 5 some concluding remarks are discussed.

2. Mathematical Model

In this section, we give a comprehensive description of the model for scheduling the disposal of the spent nuclear fuel. The aim is to provide general guidelines for the disposal schedule and we only plan how many canisters are disposed of rather than which assemblies are placed in which canister nor give any complex lay-out for the disposal facility. We model the situation adapting the disposal in Finland as described in the introduction with some limitations like we omit the transportation between the facilities. Furthermore, we suppose that nothing is disposed of yet and only one type of fuel is considered. Some other simplifying assumptions are that we have access to all the assemblies, assemblies are identical, and the bedrock is homogeneous such that we can build tunnels anywhere.

The model formulated is a nonsmooth multiobjective MINLP problem having nine objectives. One obvious objective is total costs. Due to the long term time perspective of the disposal, the costs will probably change during the years so we minimize also some cost factors as their own objectives. Besides being a cost factor, these objectives have also other reasons to be selected as an objective. The interim storage-related objectives minimize storage times and amounts. The faster the assemblies get under the ground, the safer it is. Other safety issues are handled as constraints, like the cooling time of the assembly must be sufficient, the maximum decay heat power of the canister is limited, and the distances between disposal tunnels and canisters depend on the heat load of the canister. While we allow empty positions in canisters, we still try to keep the total amount of the canisters as low as possible. The other objectives related to the encapsulation facility aim to get disposal done as soon as possible. Finally, the area of the disposal facility is minimized.

2.1. Parameters

The model involves several parameters mostly dealing with lower and upper bounds and costs. First, we begin with two parameters determining the size of the model. Let

| N | be a total number of disposal periods |

| Z | be a total number of removals from the reactor. |

In addition, we define two sets of indices: the set of periods

and the set of removals from the reactor

. Note that part of the removals are done before the first disposal period begins. In order to link the removals from the reactor and periods, we introduce two parameters:

| a | the last removal before the first disposal period |

| b | the disposal period when the last removal is done. |

In the following, we specify notation and measurement units for some physical magnitudes:

| | number of assemblies belonging to the removal |

| Q | length of one disposal tunnel [m] |

| | storage time of an assembly belonging to the removal |

| | in the period [period] |

| | decay heat power of an assembly belonging to the removal |

| | in the period [W]. |

The next seven parameters describe the cost information needed as an input data for the model:

| | storage cost per one assembly per period [€] |

| | costs related to the interim storage per period [€] |

| | cost of a storage place per one assembly [€] |

| | cost of one canister [€] |

| | costs related to operating the encapsulation facility per period [€] |

| | cost of a disposal tunnel per meter [€] |

| | cost of a central tunnel per meter [€]. |

Finally, we give some parameters related to the upper and lower bounds:

| R | minimum storage time of an assembly [period] |

| K | maximum capacity of a canister |

| T | minimum number of canisters disposed in one period |

| U | maximum number of canisters disposed in one period |

| , | lower and upper bound for the maximum average power of |

| | a canister [W] |

| , | lower and upper bound for the distance between canisters [m] |

| | lower and upper bound for the distance between disposal |

| | tunnels [m]. |

2.2. Continuous Variables

The model involves

continuous variables such that they all are assumed to be non-negative. The continuous variables used are:

| | number of assemblies belonging to the removal disposed during |

| | the period |

| | number of canisters disposed during the period |

| | number of assemblies belonging to the removal being in storage |

| | at the end of the period |

| | maximum average power of a canister |

| | distance between two adjacent disposal tunnels |

| | distance between two adjacent canisters in a disposal tunnel. |

Note that the first three variables have integer nature, but in order to ease the computation, they are relaxed as continuous variables.

2.3. Binary Variables

Besides continuous variables, the model consists also

binary variables listed below:

| | encapsulation starts in the beginning of the period |

| | encapsulation ends in the beginning of the period |

| | encapsulation facility is in operation during the period |

| | assemblies belonging to the removal take off from disposal |

| | at the beginning of the period |

| | indicates that assemblies belonging to the removal |

| | can be disposed during the period . |

2.4. Objectives

The model involves nine objectives such that six of them are nonlinear and three are linear. These objectives are:

Note that from nonlinear objectives, the objectives (

1), (2), (5) and (

9) are also nonsmooth. The objectives (

1)–(3) are related to the interim storage such that (

1) minimizes the maximum number of assemblies in the storage, (2) minimizes the maximum storage time, and (3) minimizes the average storage time. In the objective (

1), with the first component we take into account the first

a removals from the reactor where all the assemblies must be stored simultaneously. The second component handles the cases when removals are accomplished during the disposal periods. Finally, with the third component the cases when all removals are done are considered.

The next three objectives (4)–(6) are related to the encapsulation facility. The objective (4) minimizes the total number of canisters, (5) aims to stop the disposal as early as possible, and (6) minimizes the time which the encapsulation facility is in operation.

The objectives (7) and (8) aim to minimize the size of the disposal facility such that (7) minimizes the total length of disposal tunnels and (8) minimizes the length of the central tunnel.

Finally, the ninth objective (

9) minimizes the total costs of the disposal process. The costs taken into account are related to the storage, cost of individual canisters, the encapsulation facility operating costs, and the building costs of the disposal and central tunnels.

2.5. Constraints—Interim Storage

The first set of constraints are related to the interim storage. All of these constraints are linear.

The constraints (

10)–(12) define the variables

depicting the amount of assemblies in storage. The constraint (13) enforces all the assemblies to be disposed once. With the constraints (14)–(16) the variables

are defined. The constraint (17) ensures that the production capacity is not exceeded and the constraint (18) ensures that the assembly disposed has been cooling long enough.

2.6. Constraints—Encapsulation Facility

In order to guarantee the acceptable encapsulation, the following linear constraints are needed.

The constraints (

19) and (20) ensures that the encapsulation facility is switched on and off exactly once meaning that all the canisters must be encapsulated at once. The constraints (21) and (22) define the variable

. The constraints (23)–(25) guide the encapsulation process: (23) guarantees that there exist enough canisters such that all the assemblies can be disposed, (24) keeps the number of canisters under the production capacity, and (25) forces the minimum production to be fulfilled.

2.7. Constraints—Disposal Facility

The number of constraints related to the disposal facility is such that of them are nonlinear, and three of the constraints are box constraints.

The constraints (

26) and (27) are the nonlinear constraints of this model. The constraint (

26) ensures that the heat power of the canisters disposed is allowable while the constraint (27) defines the dependence between the variables

,

, and

. In our case, this nonlinear function

is approximated with a piece-wise linear function (see

Appendix A). Finally, the box constraints (28)–(30) give lower and upper bounds for variables

,

, and

, respectively.

Finally, we give some boundaries for the variables:

To conclude, the model has nine objectives such that 6 are nonlinear and 3 are linear. The rest of the dimensions of the model are depending on two parameters: the number of periods N and the number of the removals from the reactor Z. Number of constraints is , where are linear, nonlinear and 3 box constraints. The total number of variables is and of them are non-negative continuous variables and are binary variables. Evidently, with any realistic values of N and Z, for example and when one period is five years, the size of the problem will come quite large.

4. Case Study: The Disposal in Finland

In practice, the scalarized problem (

32) with an augmentation term (

33) in Step 2 of MITSPA is solved with a branch-and-cut type method for single-objective MINLP problems called BARON [

44,

45] in GAMS [

46]. The CPU time of solving each problem (

32) presented here varies from 9 s to 28000 s while the average CPU time is 3475 s and the median CPU time is 142 s. The weighting vectors used are of the form

such that

and

as suggested in [

27]. The approximation of the nadir vector used is obtained with a pay-off table [

31,

32].

We investigate the disposal of the spent nuclear fuel from the European pressurized water reactor (EPR) produced by Olkiluoto 3 in Finland starting to operate in the near future. The length of one disposal period is selected to be 5 years, and the parameters

N and

Z are 19 and 11, respectively. The other parameters used are given in

Appendix A, except the cost parameters that are omitted due to their commerce-related nature. This parameter selection yields a multiobjective MINLP problem with 9 objectives, 440 continuous and 475 binary variables, 1144 linear constraints, 20 nonlinear constraints, and three box constraints. Apart from these, we need some auxiliary variables and constraints to overcome the non-smoothness of the problem. Indeed, the two-slope parameterized ASFs are nonsmooth, but due to their min-max structure, the problem (

32) can be written in the MINLP form as in [

25]. Similarly, this trick can be applied also for the nonsmooth objectives. After that, we have to solve a single-objective problem with 441 continuous and 484 binary variables, 1153 linear constraints, 21–146 nonlinear constraints and 3 box constraints.

Before we proceed to the solution process, we discuss the trade-offs of the problem. There are three parts in the final disposal of spent nuclear fuel: the interim storage, the encapsulation facility, and the disposal facility. These three parts interact with each other as is exemplified in the following.

Interim storage versus disposal facility: The interim storage-related goals all imply transferring the spent nuclear fuel from the interim storage as rapidly as possible. However, in order to minimize the disposal facility-related goals, the cooling times should be maximized.

Encapsulation facility versus interim storage: By delaying the start of disposal, it is possible to shorten the operation time of the encapsulation facility, and thus, decrease the operating costs. Again, the delay at the start of the encapsulation can cause an increase of the inventories in the interim storage.

Encapsulation facility versus disposal facility: The disposal should be started and ended as soon as possible. Both of these aims have a tendency to increase the canister heat load, and hence, affect the disposal facility goals. To minimize the operation time of the encapsulation facility, empty assembly positions can be used. However, the price to pay is the increased number of canisters. In addition, a larger number of canisters necessitates an increase in the disposal facility area.

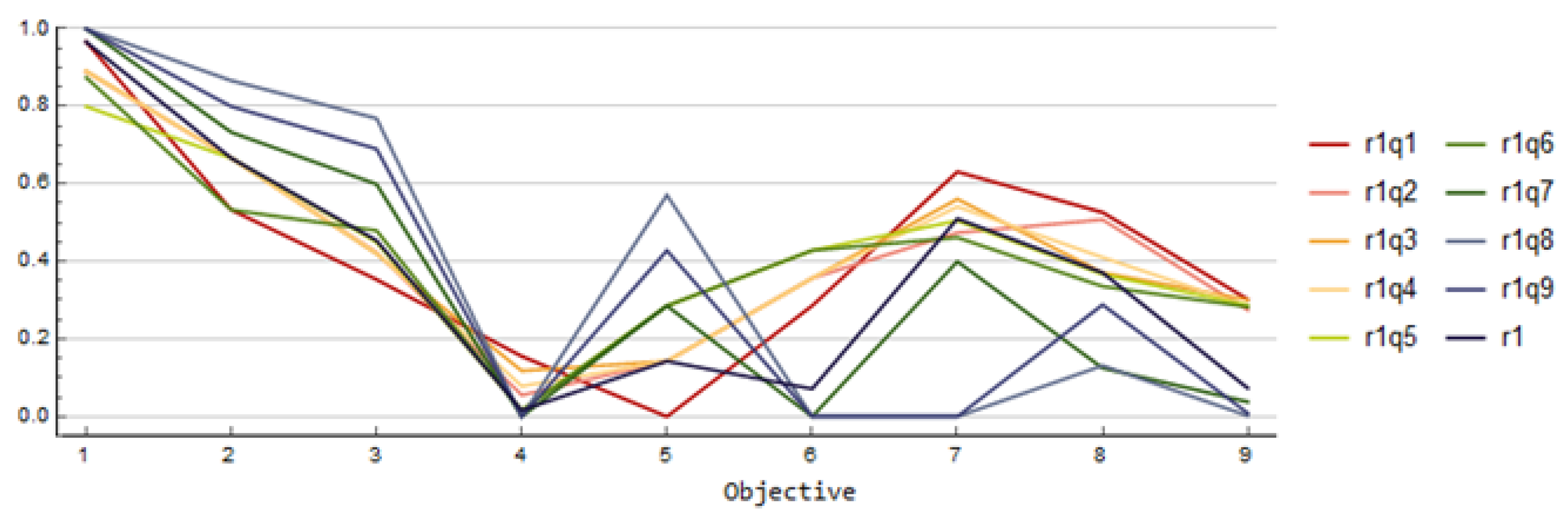

In order to investigate these, and other trade-offs, the interactive method MITSPA is employed. In each iteration of MITSPA, some new preference information is asked from the decision-maker reflecting his/her preferences. For each iteration, we compute nine solutions by using the current reference point with different metrics by varying the value of the parameter

q from 1 to 9 in Step 2. In order to exemplify this, the nine solutions computed using reference point 1 are shown in

Figure 1. These nine solutions represent different trade-offs between objective function values. The results obtained are scaled to the interval from 0 to 1 such that 0 is the value of the ideal vector and 1 is the value of the nadir vector for the objective under consideration. The different solutions are labeled based on the reference point used and the value of the parameter

q. For example, the solution r1q1 is the result obtained by using the reference point 1 and

. Moreover, the reference point 1 is labeled with r1.

In Step 3, two solutions are selected to be presented for the decision-maker for the closer inspection. The number of presented solutions s is restricted to two in order to aid the decision maker’s task to select best out of only two options and in order to keep the presentation clear. At each iteration, one solution with a smaller value of q and one with a larger value of q are presented and different values of q are demonstrated in order to exemplify the variety of solutions. Next, we present four iterations of MITSPA.

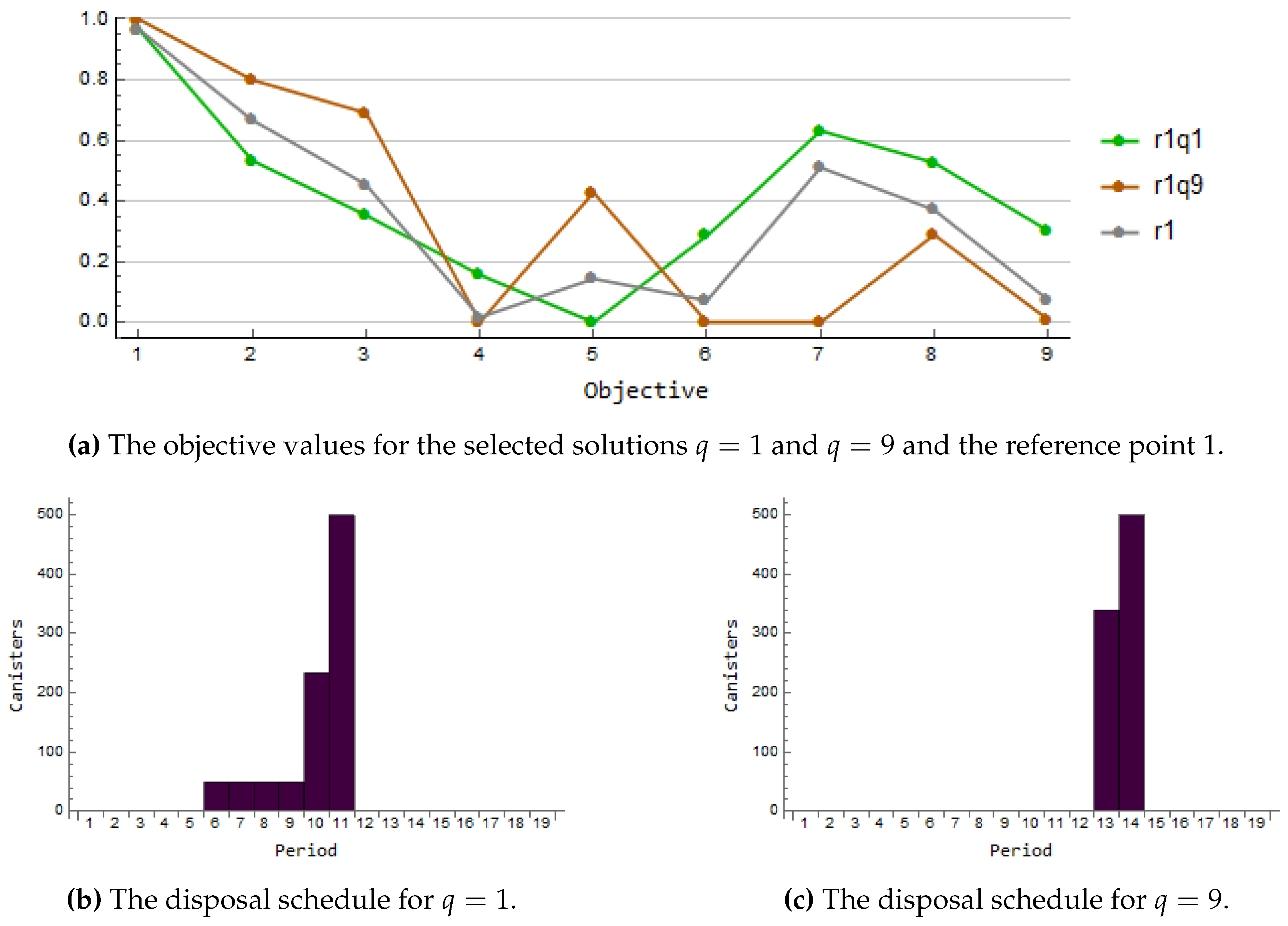

Iteration 1. At the first iteration, the decision maker begins by investigating the trade-off between operation time of the encapsulation facility and the cooling times of assemblies by deciding to start with the unachievable reference point such that the operation time is short and the cooling time is long. The two solutions chosen for reference point 1 are shown in

Figure 2a together with reference point 1. The solution obtained by using value

(r1q1) shown in the green line corresponds to the early starting time of disposal. The solution obtained by using value

(r1q9) shown in the orange line corresponds to the late starting time of the disposal. In

Figure 2b,c, the corresponding disposal schedules are given. The solution r1q9, has the shortest possible encapsulation time but the maximum cooling time is long. The solution r1q9, like r1q1, has a high maximum number of assemblies in the storage (see the objective (

1)), but the maximum and average storage times (the objectives (2) and (3)) are slightly shorter. The solution r1q9 does not allow any empty positions in canisters while the solution r1q1 does (see (4)), but the encapsulation ends much later (see (5)) in the solution r1q9 than in r1q1. However, the operation time of the encapsulation facility (see (6)) is shorter in the solution r1q9 than in r1q1. When the disposal facility-related objectives (see (7) and (8)) are compared, the solution r1q9 needs a smaller area than the solution r1q1. Moreover, the solution r1q9 is cheaper than the reference, while the solution r1q1 is more expensive than the reference (see (

9)). Mainly due to the significant difference in the costs, the decision maker selects the solution r1q9 as the current solution

.

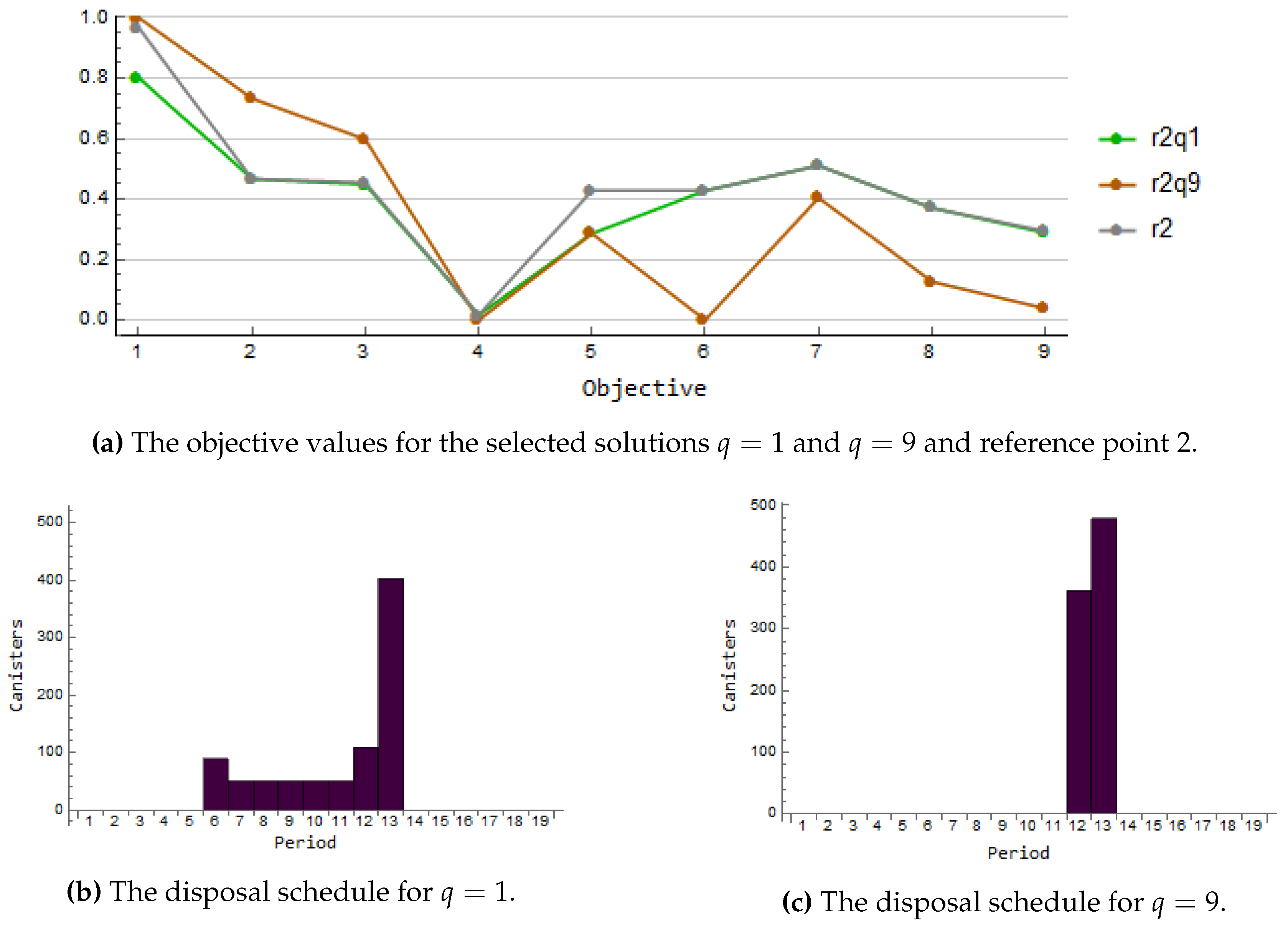

Iteration 2. In order to learn more about the trade-off between the operation time of the encapsulation facility and the cooling time, another reference point (reference point 2) is selected. In this case, the reference point is achievable. Now we try to find solutions such that the operation time is longer and cooling time shorter. The two solutions chosen for reference point 2 are shown in

Figure 3a and the corresponding disposal schedules in

Figure 3b,c. Again, the solution obtained with the small value

(r2q1) represents the early starting time of the disposal. This is depicted with the green line in

Figure 3a while the orange line depicts the solution obtained using value

(r2q9) corresponding to the late starting time of the disposal.

If we compare the disposal schedules in

Figure 3b,c to the schedules for reference point 1 given in

Figure 2b,c, we notice some similarity. Even though the starting and ending times differ as well as the total number of canisters, the solutions with the parameter

q value 1 and value 9 have the same shape. The smaller

q suggests the schedule such that first, we encapsulate a small number of canisters per period and the number of canisters is growing while the time goes by, whereas the larger

q recommends the schedule where all the canisters are encapsulated within two periods. The solution r2q1 captures the reference point well since they coincide with respect to other objectives than the objectives (

1) and (5) which are better than the reference values. Thus, the decision maker is willing to continue with the solution r2q1 as the current solution

.

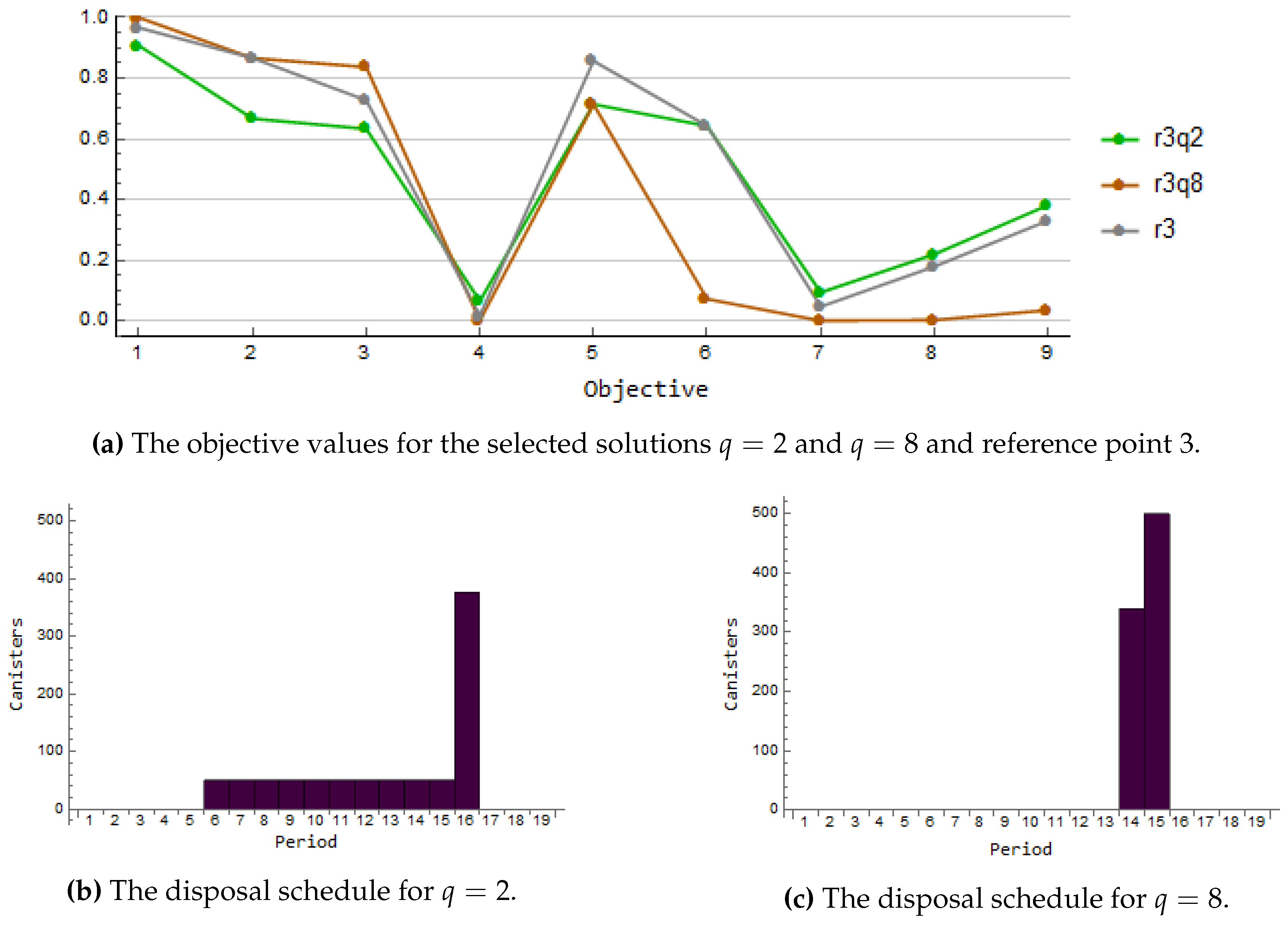

Iteration 3. The long operation time of the encapsulation facility (the objective (6)) is still under the microscope at the third iteration but the decision-maker is tempted by the short central tunnel appeared in the previous iteration and combines the long operation time with small disposal facility area. Like the first reference point, also this is unachievable. The solution obtained by using

(r3q2) is shown in green and the solution obtained with

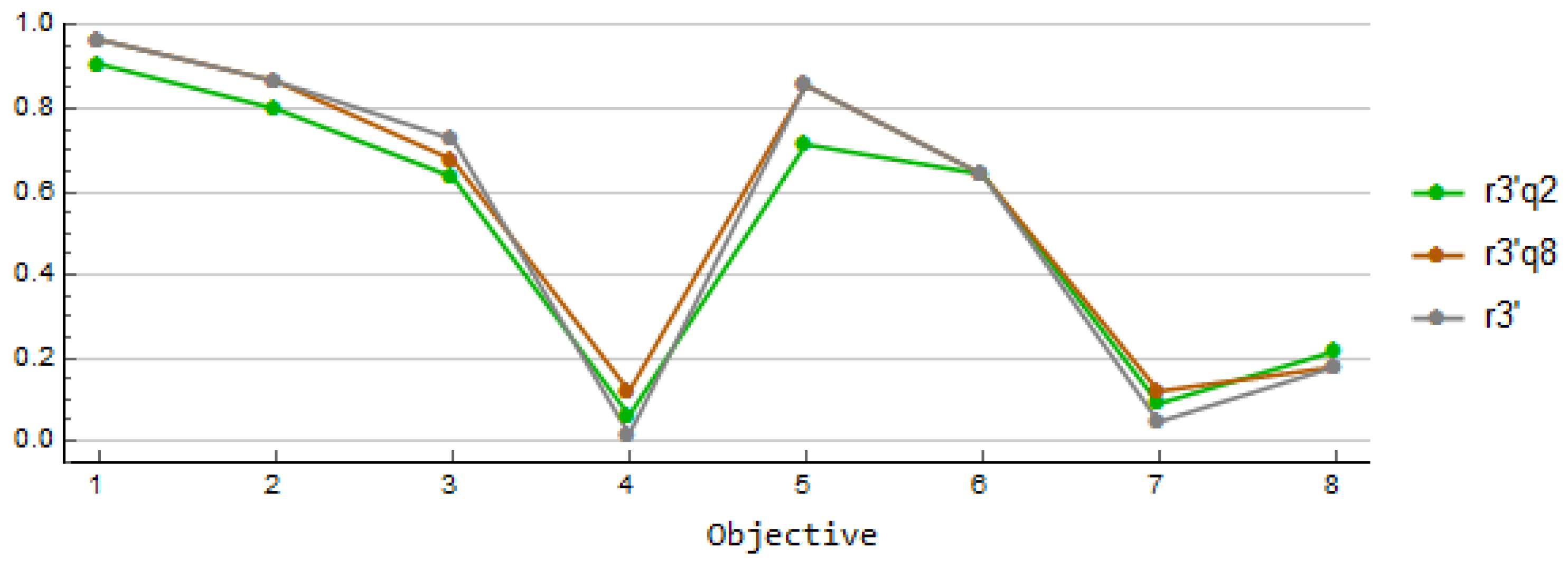

(r3q8) is shown in orange in

Figure 4a.

Figure 4b illustrates that the solution r3q2 yields a schedule with an early starting date and the disposal takes the longest time while the solution r3q8 starts the disposal later but it is performed faster as seen in

Figure 4c. The solution r3q8 yields almost ideal value for the costs, and we can deduce that in order to achieve lower costs we have to give up in the objectives related to the storage capacity and times. Moreover, the disposal ends rather late. For the current solution

the decision-maker selects the solution r3q8 due to the low costs and small disposal facility area.

Since one motivation for this research was to take into account more goals than just the costs, we are eager to see what happens if we omit the costs and solve the problem with only the first eight objectives (

1)–(8). The reference point 3’ is similar to the reference point 3 without the value for the costs. The results with

(r3’q2) and

(r3’q8) are given in

Figure 5. Note that since there are now only eight objectives, the scalarized function is different than in the case of nine objectives. The solutions in

Figure 5 are quite similar and there is less variation than in the solutions in

Figure 4a.

Iteration 4. The current solution

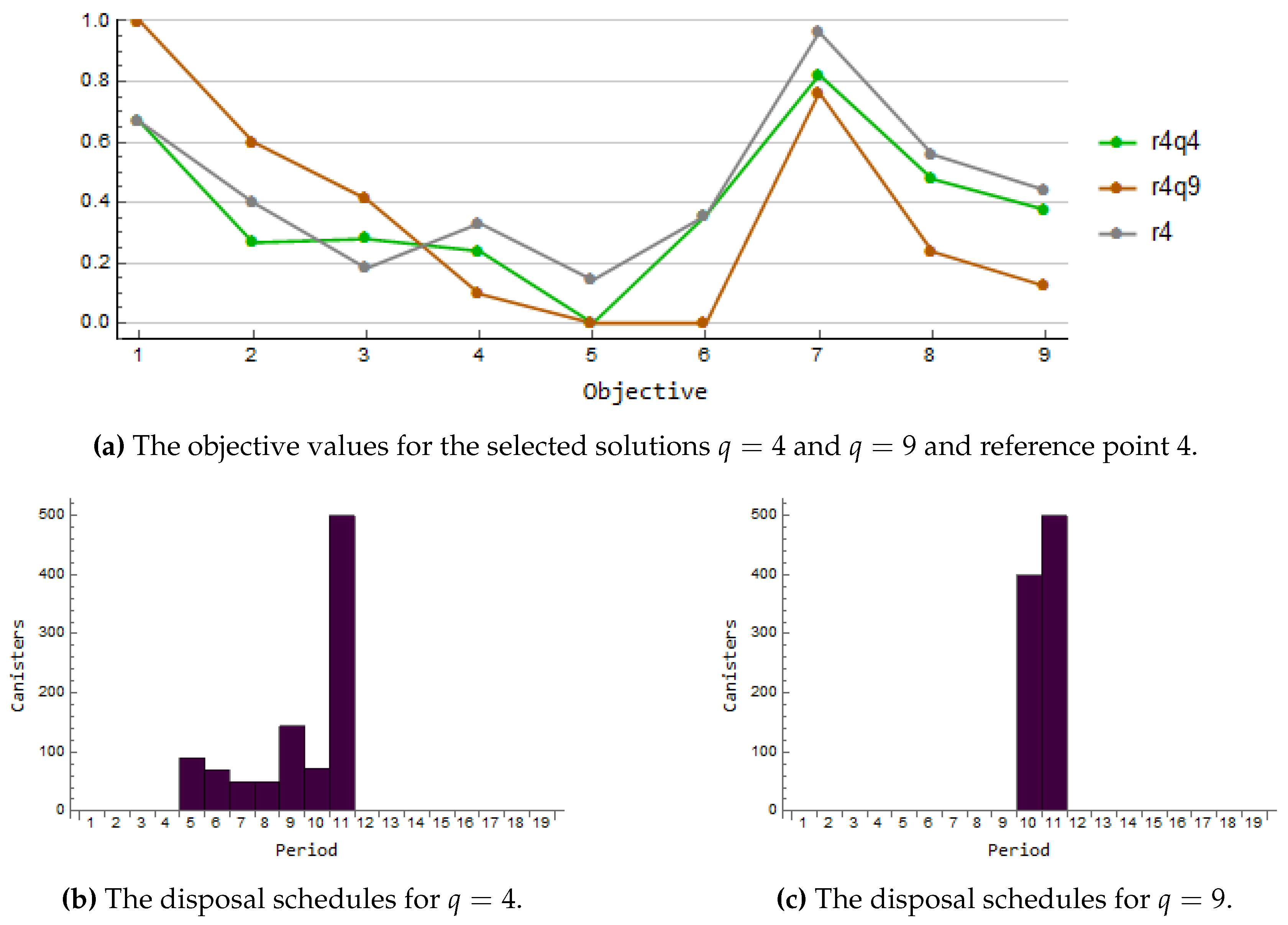

has high interim storage capacity and a small amount of canisters. At the fourth iteration, the decision maker is interested in to see if the opposite is possible, namely a solution with small interim storage capacity with allowing the higher number of canisters. Again, the reference point is unachievable. In

Figure 6a, the reference point 4 and the solutions with

(r4q4) and

(r4q9) are illustrated. The solutions are shown in green and orange, respectively. Again, the corresponding disposal schedules are given in

Figure 6b,c. As we see, the solution r4q4 satisfies the wishes towards the interim storage capacity as well as the utilization of the empty canister positions quite well. Additionally, the better values than the reference are obtained in the repository area related goals and the costs. The solution r4q9 express this as well, but the original wishes towards the interim storage capacity are not satisfied. Since the solution r4q4 captures better the ideas of the decision-maker, it is selected for the current solution

.

Eventually, the decision maker is ready to make the final choice. During the solution process, we have learned that the solutions obtained from 4 different reference points can be split broadly into two main groups. The first group includes solutions where the disposal starts early while the other group includes the solutions with late starting. The most striking fact is that the solutions of the first group are obtained with smaller values of

q and the solutions of the second group with the larger values of

q. This phenomenon is repeated with all of four reference points. Interestingly, with the modified reference point 3 where only eight objectives were considered, mainly solutions with earlier starting time were obtained. In general, the earlier starting time of the disposal improves the objectives (

1)–(3) and impairs others compared with the case where the disposal starts later. In general, we notice that the solutions obtained adapt the reference points quite well.

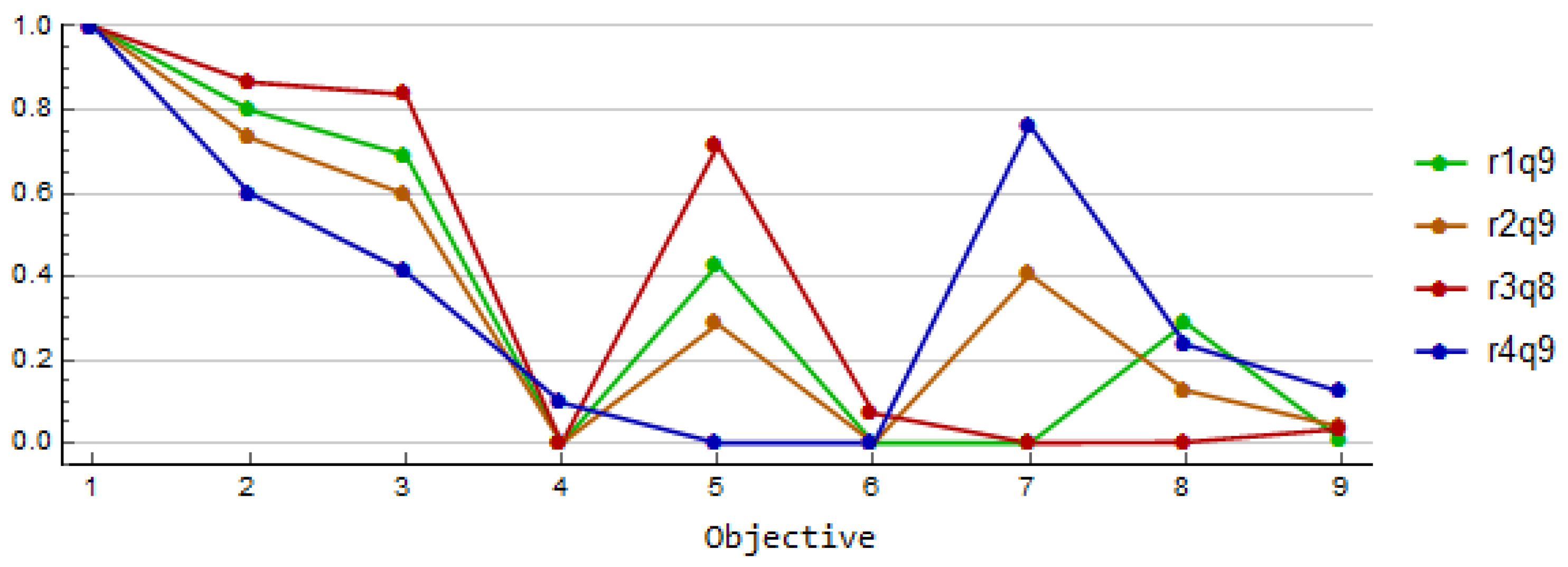

In

Figure 7, the solutions related to the first group with an early starting time are illustrated. It can be seen that even if all these solutions suggest the early start of the disposal, they still have some differences. One can improve goals (7) and (8) by disposing of spent fuel with a small volume at the beginning. However, this declines goals (

1)–(3), (5), (6) and (

9) which can be seen from the solution r3q2. It is possible to improve the goals (

1)–(3), (5) and (6) by allowing some canister positions to be empty. However, this in its turn declines goals (4) and (7)–(

9) which can be seen from the solution r4q4. As the final solution, the decision maker likes to return to the reference point 2 and the solution r2q1 looks like a good compromise when disposal begins early.

A similar examination is done for the solutions of the second group with the late starting time. The solutions in terms of the objective function values and the disposal schedules are given in

Figure 8. Again, we can observe some differences. The differences depend on the number of years the start of disposal operations is prolonged. It can be seen from

Figure 8, that the disposal volume is large in every solution where disposal starts late. On the one hand, one can improve goals (7)–(

9) by delaying the start of disposal but on the other hand, this declines goals (2), (3) and (5), as illustrated in the solution r3q8. When the disposal starts late, empty canister positions have only a minor impact on the solution. One can improve goals (2), (3), and (5) by allowing empty canister positions. This yields to the impairing of the goals (4), and (7)–(

9) which can be seen from the solution r4q9. Again, the decision maker is willing to return to the reference point 2 and consider the solution r2q9 as a satisfactory solution when the disposal starts late. Additionally, the decision maker selects this solution also for the final solution

, since it yields a rather good solution for other objectives than the maximum storage. However, we learned that this is the price of the lower costs and smaller disposal facility area. Moreover, compared with the solution r2q1 also presented from the reference point 2, the later starting does not delay the ending of the disposal.

5. Conclusions

In this paper, we have proposed the nonsmooth multiobjective MINLP model to optimize the spent nuclear fuel disposal in order to obtain a disposal schedule. The modeled process is described and the model is presented in detail. Then, the two-slope parameterized ASF is briefly stated and validated the use of it. Additionally, we proposed an interactive solution method utilizing these ASFs. Finally, some numerical results from the case study are given. The solutions obtained are exemplified and analyzed in terms of objective function values and disposal schedules.

With slight modifications, the model presented is applicable to other countries than Finland as well, if the spent nuclear fuel is decided to dispose of the disposal facility. It is possible to change the objectives or leave some of them out. Indeed, this model has quite many objectives, and in some cases it may be advantageous to have fewer goals either to ease the decision maker’s task or reduce the computations needed.

The schedules obtained are realistic and viable. One conspicuous feature for the solutions is that they are segmented in two groups based on the value of the parameter q enabling the parameterization when the two-slope parameterized ASF is used. With the lower values of q (i.e., closer to metric), the disposal starts early and with the larger values of q (i.e., closer to metric) the later start of the disposal is suggested. If only one metric, for instance metric, was used, no solutions with late starting would have been obtained in these iterations. For further studies, it would be interesting to investigate, is this kind of phenomenon observable in other applications as well, if the two-slope parameterized ASF is used. The role of q is also fascinating in terms of which value of q yields the most desirable solution for the decision maker.

As future research, it would also be interesting to include all of the three different fuel types used in Finland. Another interesting topic would be including the possible hiatus for the operation of the encapsulation facility in the model.