On the Influence of the Sample Absorptivity when Studying the Thermal Degradation of Materials

Abstract

:1. Introduction

2. Experimental Study of the Radiative Properties

2.1. Setup

- A plywood sample, studied in a former study [9]. It was made of oak, its thickness was 18 mm, and its density was 580 kg/m.

- A carbon composite sample, made with carbon fibers and epoxy resin, used for vessel manufacturing, with a thickness of 4.5 mm.

- A clear PMMA sample with a thickness of 15 mm.

2.2. Data Analysis

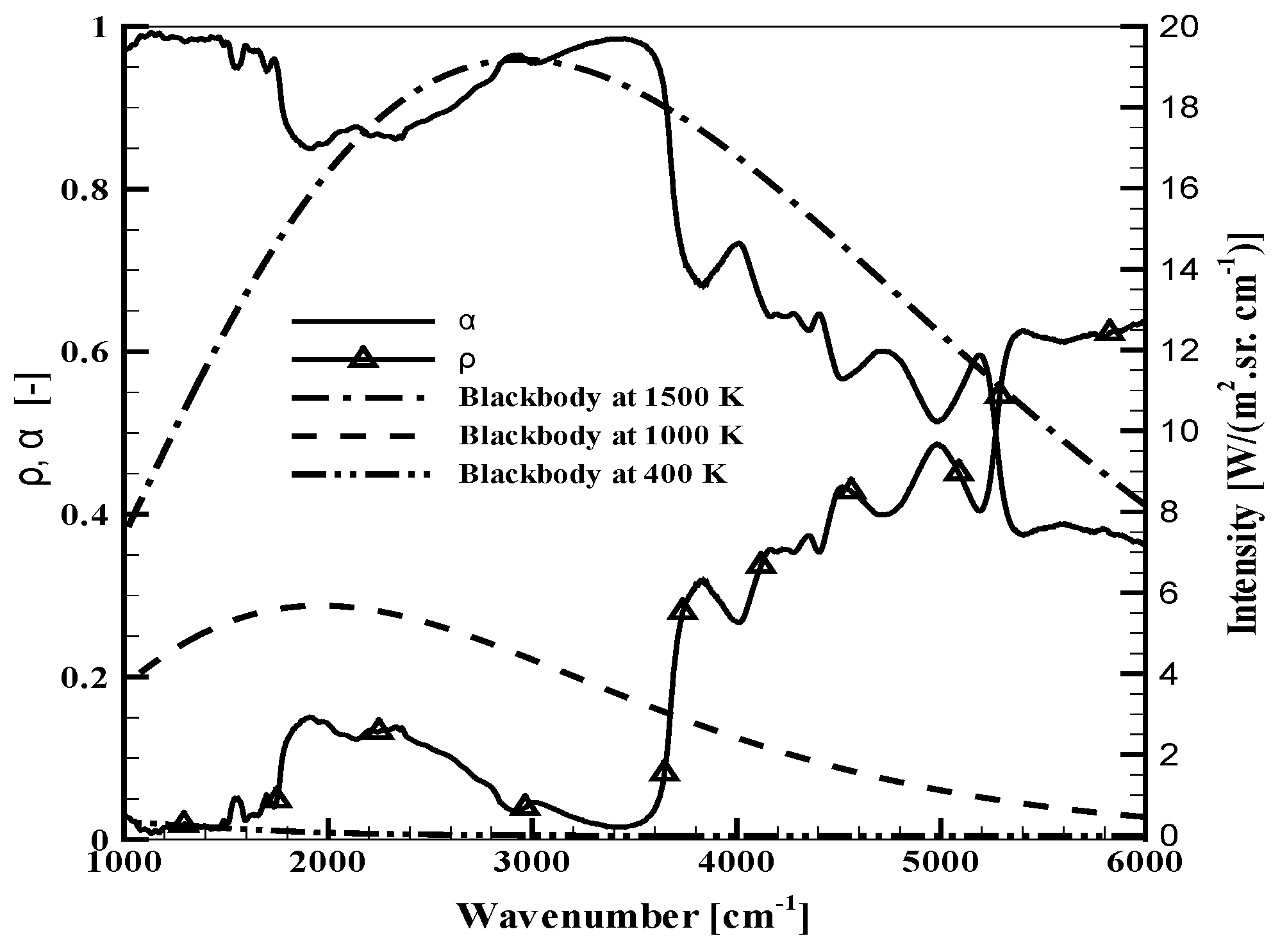

- Considering Figure 1, the plywood is obviously non-grey, as already discussed in [9]. Its absorptivity varies in a range between 0.4 and 1, being weaker in the near infrared range. It can never be considered as a black surface, and it seems that any simplification to an average absorptivity between 0.9 and 1, as it is often read in the literature, could be far from reality. Planck’s curves are also plotted in the same figure for blackbody temperatures equal to 400, 1000 and 1500 K. For a black emitter at 400 or 1000 K, the main part of the emitted radiation is below 4000 cm, in the range where the absorption variations are moderate. For a source with a 1500 K temperature, a significant emission also occurs above 4000 cm, where the non-grey behavior is obvious.

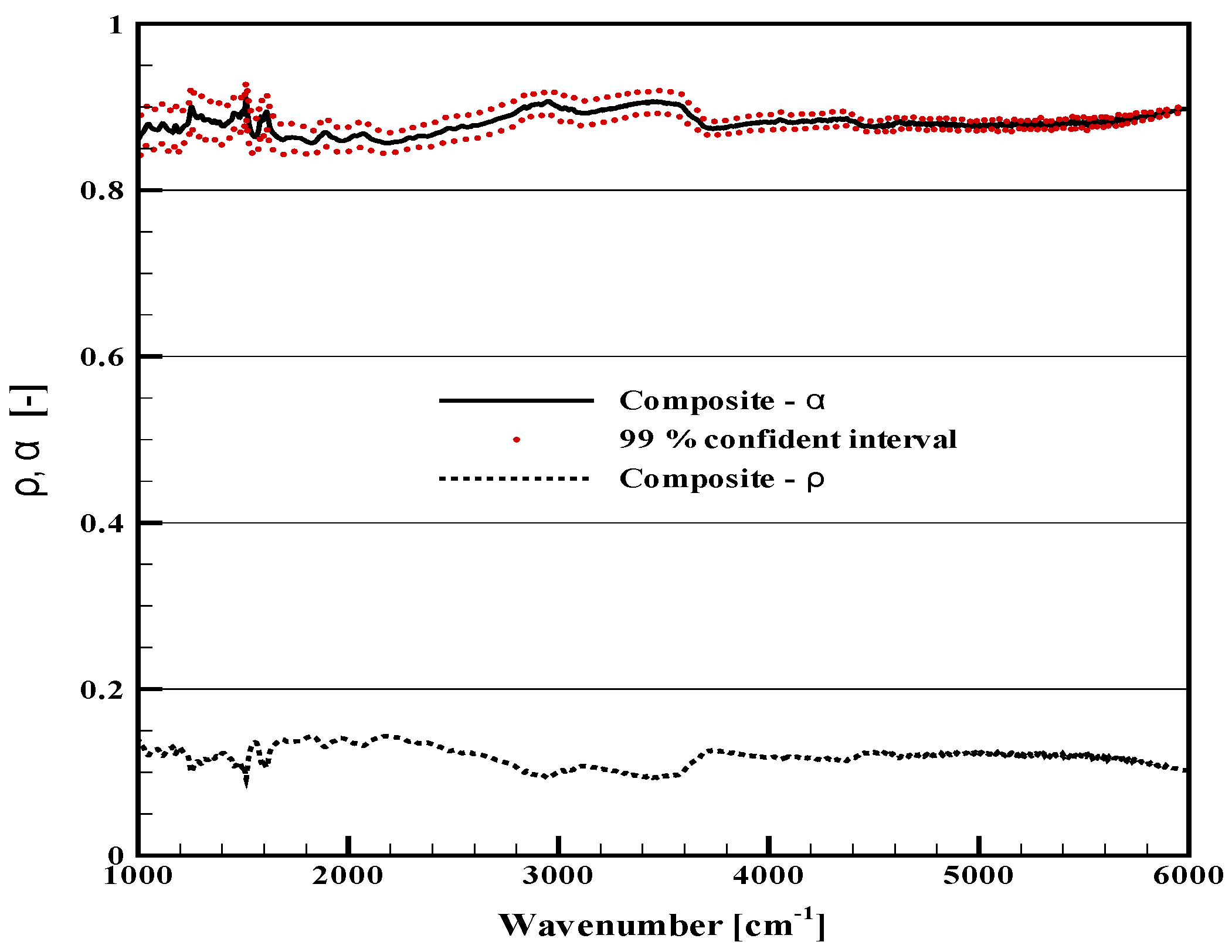

- As discussed above, the carbon composite raised some difficulties because of its heterogeneous surface, which required numerous measurements to obtain a representative average value for the reflectivity. The resulting absorptivity is presented with a confidence interval at 99% in Figure 2 (this care brought to the experimental data processing was not necessary for the two other materials with smooth and homogeneous surfaces). Considering the average properties, it can be observed that the reflectivity and the absorptivity only vary within a narrow interval. There are some spectral variations, but these are obviously limited, and in this case, the grey assumption could be considered with less inaccuracy than for the plywood. The carbon composite sample cannot be simplified as a black surface, but a representative value can be given for an average absorptivity, as will be discussed below.

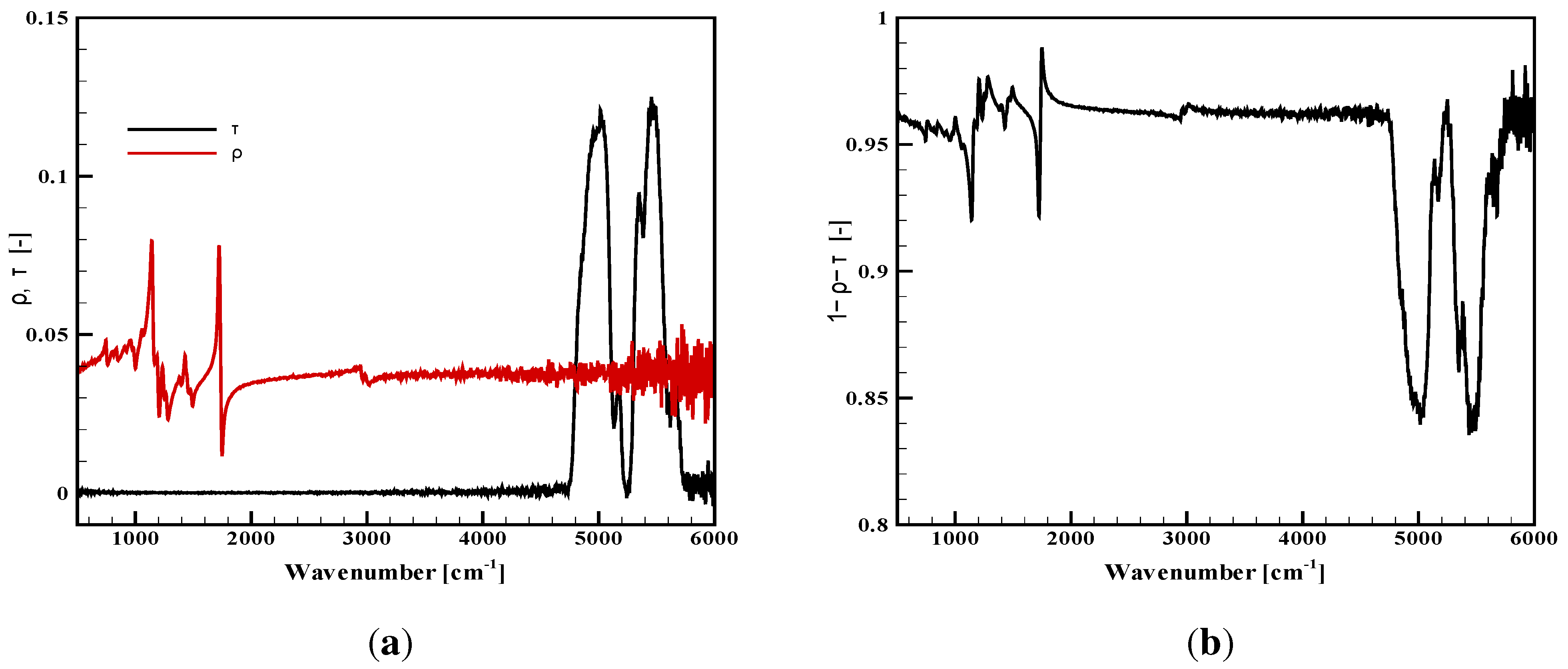

- For the virgin PMMA, in-depth radiation is observed, and the analysis rather leads to the identification of an absorptance or an absorption coefficient, which represents the volumetric absorption of radiation inside the sample, rather than an absorptivity, which would correspond to a surface property. A presentation of the absorptance was chosen here, but details on the derivation of an absorption coefficient can be found in [11]. Figure 3a presents the sample transmittance and reflectance, while Figure 3b shows the corresponding absorptance. These properties were compared to a similar work carried out on other samples of PMMA [11] (not shown here), showing the perfect agreement with the properties obtained during the present study. As for the plywood, the sample exhibits a non-grey behavior. In the case of the PMMA, it is mainly a consequence of some variations in the transmittance for high wavenumbers. The two sharp transmission peaks close to 5000 cm would be even higher for thinner samples. The absorptance of the present 15 mm-thick sample ranges between 0.84 and 0.99. The influence of this non-grey behavior will depend on the spectral distribution of the radiative source used for the sample heating. As a cone calorimeter is considered here, it will mainly depend on the coil temperature, and the same comments related to the Planck’s curves could be done as for Figure 1. PMMA would appear especially non-grey for sources with high temperatures. Note that the absorptance is the result of the global sample response to the radiation, but the in-depth radiation also changes with the wavenumber, meaning that radiation would reach different depths inside the sample depending on the wavenumbers. Hence, the sample heating occurs in the material volume at various positions.

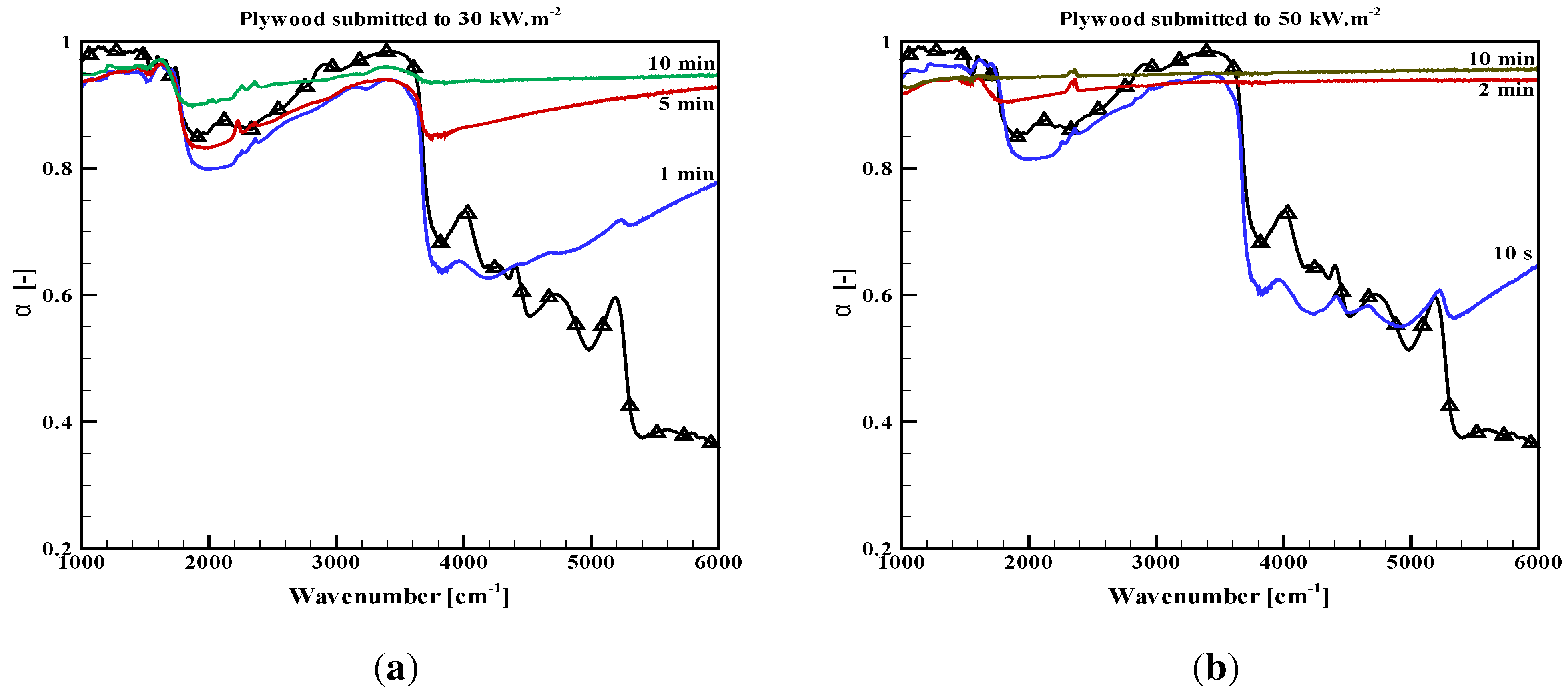

- The plywood absorptivity globally increases in the near-infrared range (Figure 4). It tends to a grey behavior with an absorptivity above 0.90, after an exposure duration, which of course depends on the incident flux, as already commented on in [9]. The higher the incident flux is, the faster the transition to grey behavior is, but it always lasted a few minutes for the present studied fluxes. There are some strange local decreases in some wavenumbers, which were explained through complex internal multiple reflections within the carbon layer developing at the sample surface in [9]. However, as a whole, the grey assumption becomes more and more valid as the degradation process occurs.

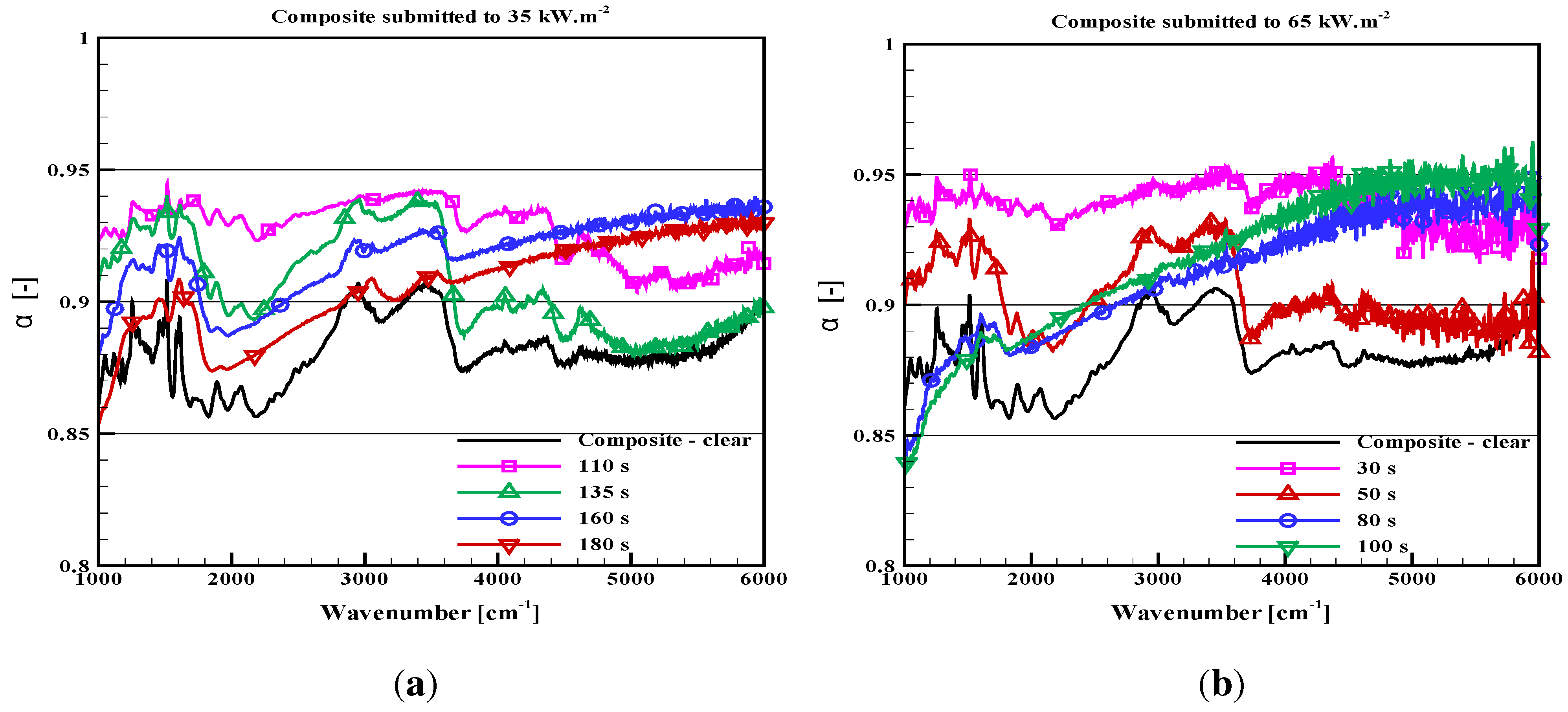

- The carbon composite absorptivity also slightly varies, but the scale in Figure 5 is modified, such that the variations are actually not so important. Recalling that the repeatability for this sample is not as good as for the other samples, the variations are in fact within a narrow range between 0.85 and 0.95. The first increase is observed up to 0.95, followed by a slight decrease, but still at high values close to 0.90. The complex degradation process probably involving the resin decomposition first and the carbon fibers aggression in the second step, could explain these variations. In any case, the grey assumption seems to be acceptable during the whole degradation test.

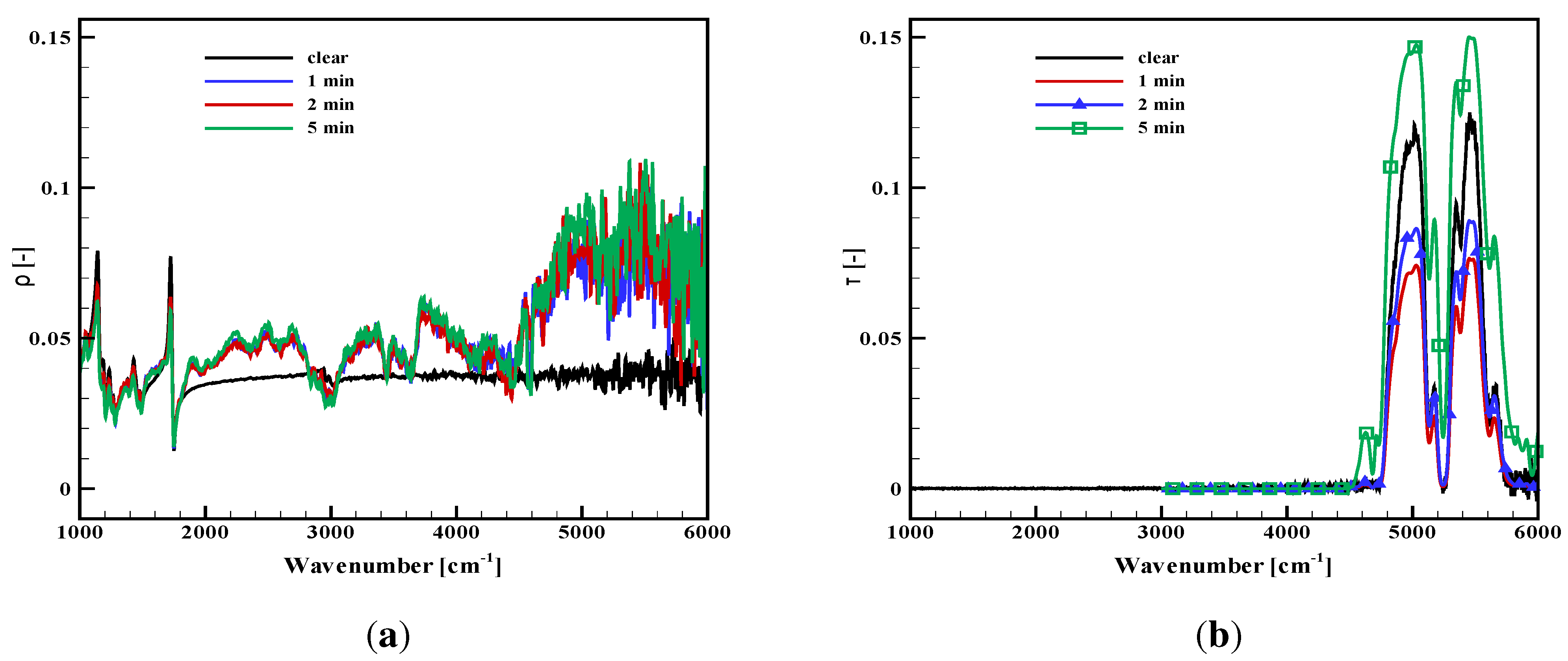

- The measurements for PMMA are still presented through the slab reflectance and transmittance (Figure 6). The reflectance seems to quickly evolve to a slightly higher value in the near-infrared range, especially around 5000 cm and with no more change below 1800 cm. The changes are weak, since the spectral variations are limited between 0.03 and 0.10, but at the same time, the sample aspect is clearly affected and the sample less translucent. Similarly, the transmittance is varying in the near-infrared, in the range corresponding to the peaks observed on the virgin material close to 5000 cm. The first decrease in the transmittance is observed for an irradiation during one minute as a consequence of an opacification, which is obvious through visible observation. Then, the transmittance strangely re-increases, but this can be explained by the sample thickness regression, since in-depth absorption occurs in a slab with decreasing thickness. The transmittance is still lower than the one measured on virgin samples with similar thicknesses [11]. This is due to an opacification of the degraded sample as compared to a virgin sample, which is obvious in the visible range and also appears here in the infrared. For a longer time exposure, the sample alteration is so important that the sample shape itself is altered and the measurements cannot be done anymore. As a whole, increases in the reflectance and transmittance values modify the absorptance toward stronger spectral variations (Figure 6c). For a short time exposure, the decrease in transmittance first compensates the increase in reflectance. However, for a longer time exposure, the absorption decreases, in particular in the high wavenumbers, down to 0.75. Note that the modification is moderate below 4000 cm. This leads us to the conclusion that the consequences on the absorbed flux will not be important when the sample will be submitted to a cone calorimeter or any source with a temperature below 1000 K (the main part of the emission below this 4000 cm threshold), but it could be dramatic for high wavenumber sources, like tungsten lamps used in an FPA.

| Material | α at T = 1000 K | α at T = 1500 K | ϵ at T = 400 K |

|---|---|---|---|

| Plywood - virgin | 0.86 | 0.78 | 0.95 |

| Plywood - 30 kW/m, 1 min | 0.85 | 0.80 | 0.92 |

| Plywood - 30 kW/m, 5 min | 0.90 | 0.90 | 0.93 |

| Plywood - 30 kW/m, 10 min | 0.94 | 0.94 | 0.95 |

| Plywood - 50 kW/m, 10 s | 0.84 | 0.77 | 0.93 |

| Plywood - 50 kW/m, 2 min | 0.93 | 0.93 | 0.93 |

| Plywood - 50 kW/m, 10 min | 0.95 | 0.95 | 0.94 |

| Carbon composite - virgin | 0.88 | 0.88 | 0.86 |

| Carbon composite - 35 kW/m, 110 s | 0.93 | 0.93 | 0.93 |

| Carbon composite - 35 kW/m, 135 s | 0.91 | 0.91 | 0.91 |

| Carbon composite - 35 kW/m, 160 s | 0.91 | 0.91 | 0.89 |

| Carbon composite - 35 kW/m, 180 s | 0.89 | 0.89 | 0.86 |

| Carbon composite - 65 kW/m, 30 s | 0.94 | 0.94 | 0.94 |

| Carbon composite - 65 kW/m, 50 s | 0.91 | 0.91 | 0.91 |

| Carbon composite - 65 kW/m, 80 s | 0.89 | 0.91 | 0.85 |

| Carbon composite - 65 kW/m, 100 s | 0.90 | 091 | 0.84 |

| PMMA - virgin | 0.96 | 0.95 | 0.96 |

| PMMA - 30 kW/m, 1 min | 0.92 | 0.95 | 0.96 |

| PMMA - 30 kW/m, 2 min | 0.93 | 0.95 | 0.96 |

| PMMA - 30 kW/m, 5 min | 0.92 | 0.95 | 0.96 |

| PMMA - 50 kW/m, 1 min | 0.92 | 0.94 | 0.96 |

| PMMA - 50 kW/m, 2 min | 0.92 | 0.94 | 0.96 |

| PMMA - 50 kW/m, 5 min | 0.87 | 0.93 | 0.96 |

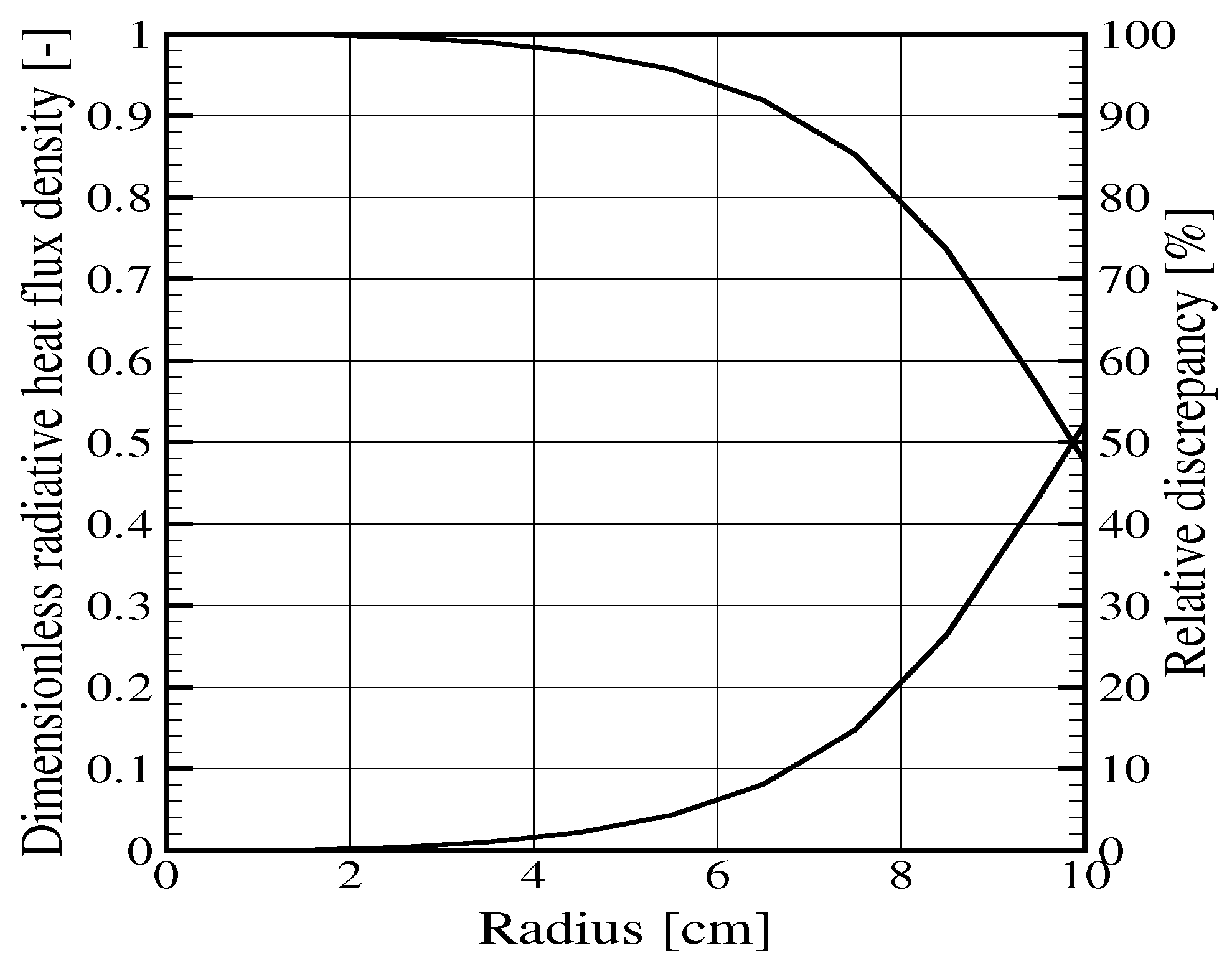

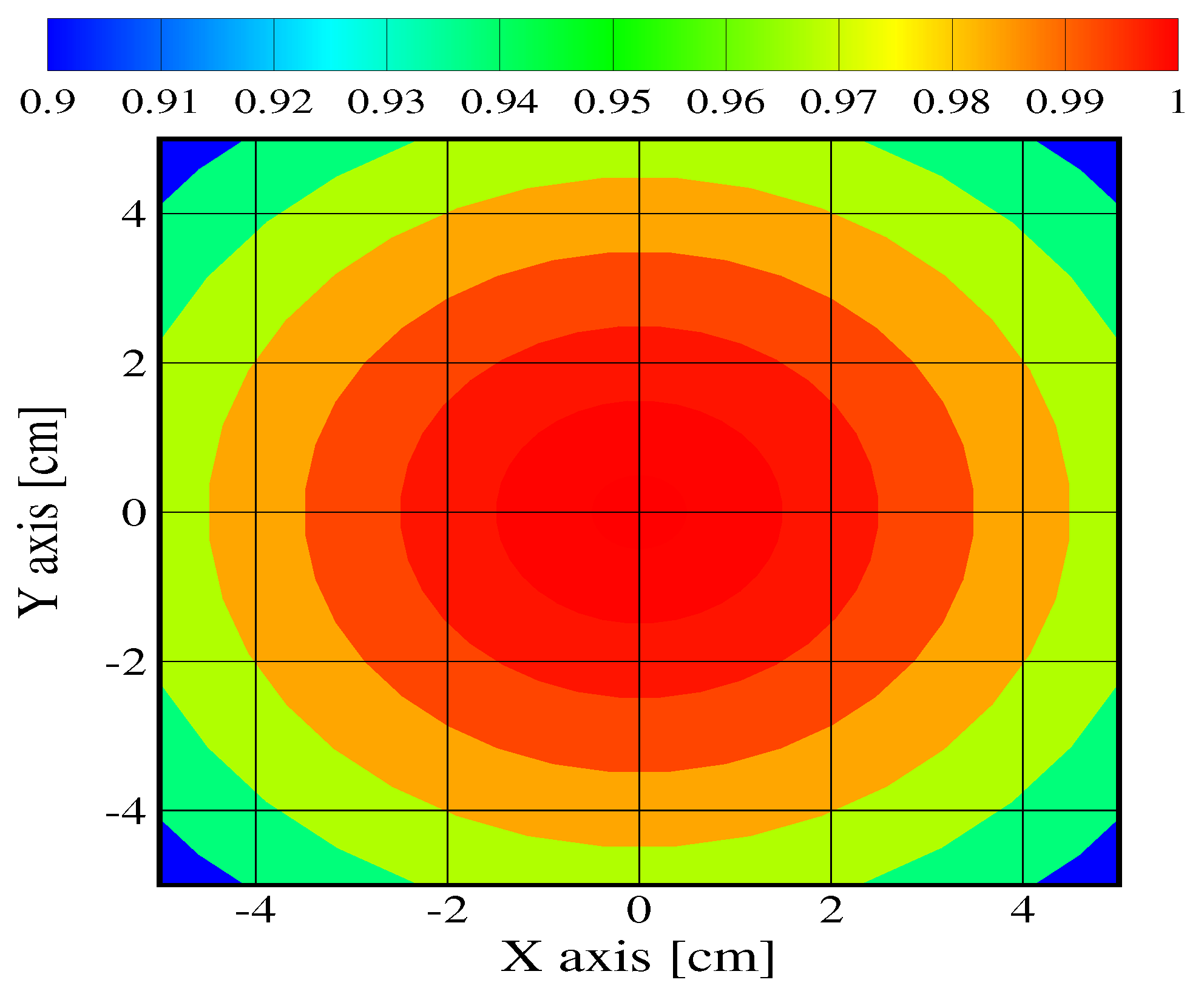

3. Radiative Flux Simulation

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Organization for Standardization (ISO). Reaction to Fire Tests—Heat Release, Smoke Production and Mass Loss rate—Part 1: Heat release Rate (Cone Calorimeter Method); ISO 5660-1; ISO: Geneva, Switzerland, 2002. [Google Scholar]

- Boulet, P.; Parent, G.; Acem, Z.; Collin, A.; Forsth, M.; Bal, N.; Rein, G.; Torero, J. Radiation emission from a heating coil or a halogen lamp on a semitransparent sample. Int. J. Therm. Sci. 2014, 77, 223–232. [Google Scholar] [CrossRef]

- Bal, N.; Rein, G. Relevant model complexity for non-charring polymer pyrolysis. Fire Saf. J. 2013, 61, 36–44. [Google Scholar] [CrossRef]

- Lautenberger, C.; Fernandez-Pello, C. Generalized pyrolysis model for combustible solids. Fire Saf. J. 2009, 44, 819–839. [Google Scholar] [CrossRef]

- Stoliarov, S.I.; Crowley, S.; Lyon, R.E.; Linteris, G.T. Prediction of the burning rates of non-charring polymers. Combust. Flame 2009, 156, 1068–1083. [Google Scholar] [CrossRef]

- Linteris, G.T. Numerical simulations of polymer pyrolysis rate: Effect of property variations. Fire Mater. 2011, 35, 463–480. [Google Scholar] [CrossRef]

- Linteris, G.T.; Zammarano, M.; Wilthan, B.; Hanssen, L. Absorption and reflection of infrared radiation by polymers in fire-like environments. Fire Mater. 2012, 36, 537–553. [Google Scholar] [CrossRef]

- Forsth, M.; Roos, T. Absorptivity and its dependence on heat source temperature and degree of thermal breakdown. Fire Mater. 2010, 1053, 1–17. [Google Scholar] [CrossRef]

- Boulet, P.; Parent, G.; Acem, Z.; Rogaume, T.; Fateh, T.; Zaida, J.; Richard, F. Characterization of the radiative exchanges when using a cone calorimeter for the study of the plywood pyrolysis. Fire Saf. J. 2012, 51, 53–60. [Google Scholar] [CrossRef]

- Bal, N.; Raynard, J.; Rein, G.; Torero, J.; Forsth, M.; Boulet, P.; Parent, G.; Acem, Z.; Linteris, G. Experimental study of radiative heat transfer in a translucent fuel sample exposed to different spectral sources. Int. J. Heat Mass Transf. 2013, 61, 742–748. [Google Scholar] [CrossRef]

- Boulet, P.; Gerardin, J.; Acem, Z.; Parent, G.; Collin, A.; Pizzo, Y.; Porterie, B. Optical and radiative properties of clear PMMA samples exposed to a radiant heat flux. Int. J. Therm. Sci. 2014, 82, 1–8. [Google Scholar] [CrossRef]

- Pizzo, Y.; Lallemand, C.; Kacem, A.; Kaiss, A.; Gerardin, J.; Acem, Z.; Boulet, P.; Porterie, B. Steady and transient pyrolysis of thick clear PMMA slabs. Combust. Flame 2015, 162, 226–236. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boulet, P.; Brissinger, D.; Collin, A.; Acem, Z.; Parent, G. On the Influence of the Sample Absorptivity when Studying the Thermal Degradation of Materials. Materials 2015, 8, 5398-5413. https://doi.org/10.3390/ma8085251

Boulet P, Brissinger D, Collin A, Acem Z, Parent G. On the Influence of the Sample Absorptivity when Studying the Thermal Degradation of Materials. Materials. 2015; 8(8):5398-5413. https://doi.org/10.3390/ma8085251

Chicago/Turabian StyleBoulet, Pascal, Damien Brissinger, Anthony Collin, Zoubir Acem, and Gilles Parent. 2015. "On the Influence of the Sample Absorptivity when Studying the Thermal Degradation of Materials" Materials 8, no. 8: 5398-5413. https://doi.org/10.3390/ma8085251