Effect of Annealing Holding Time on Microstructure, Interface Diffusion Behavior, and Deformation Behavior of Cu/Al Composite Foil After Secondary Micro-Rolling

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

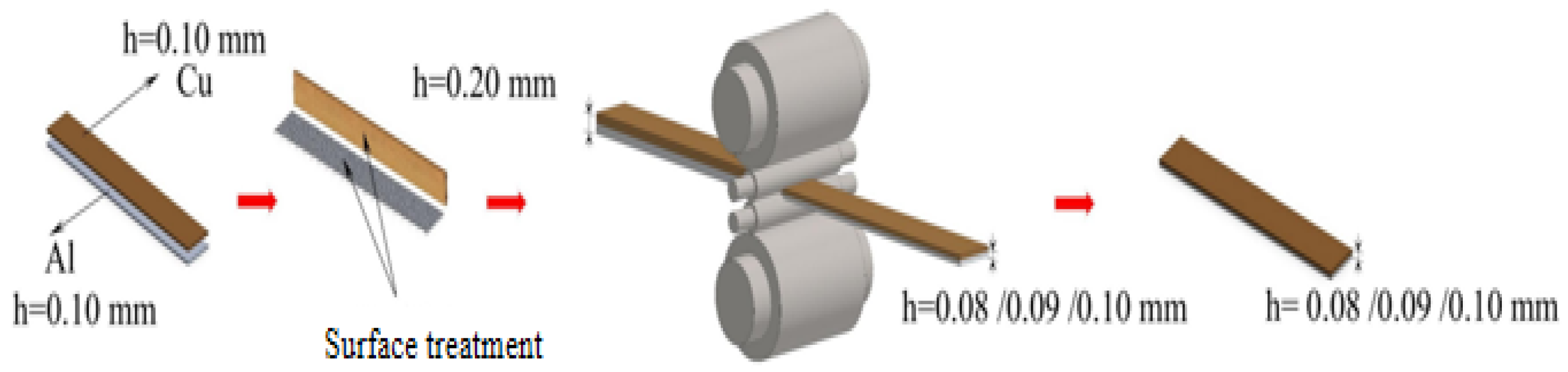

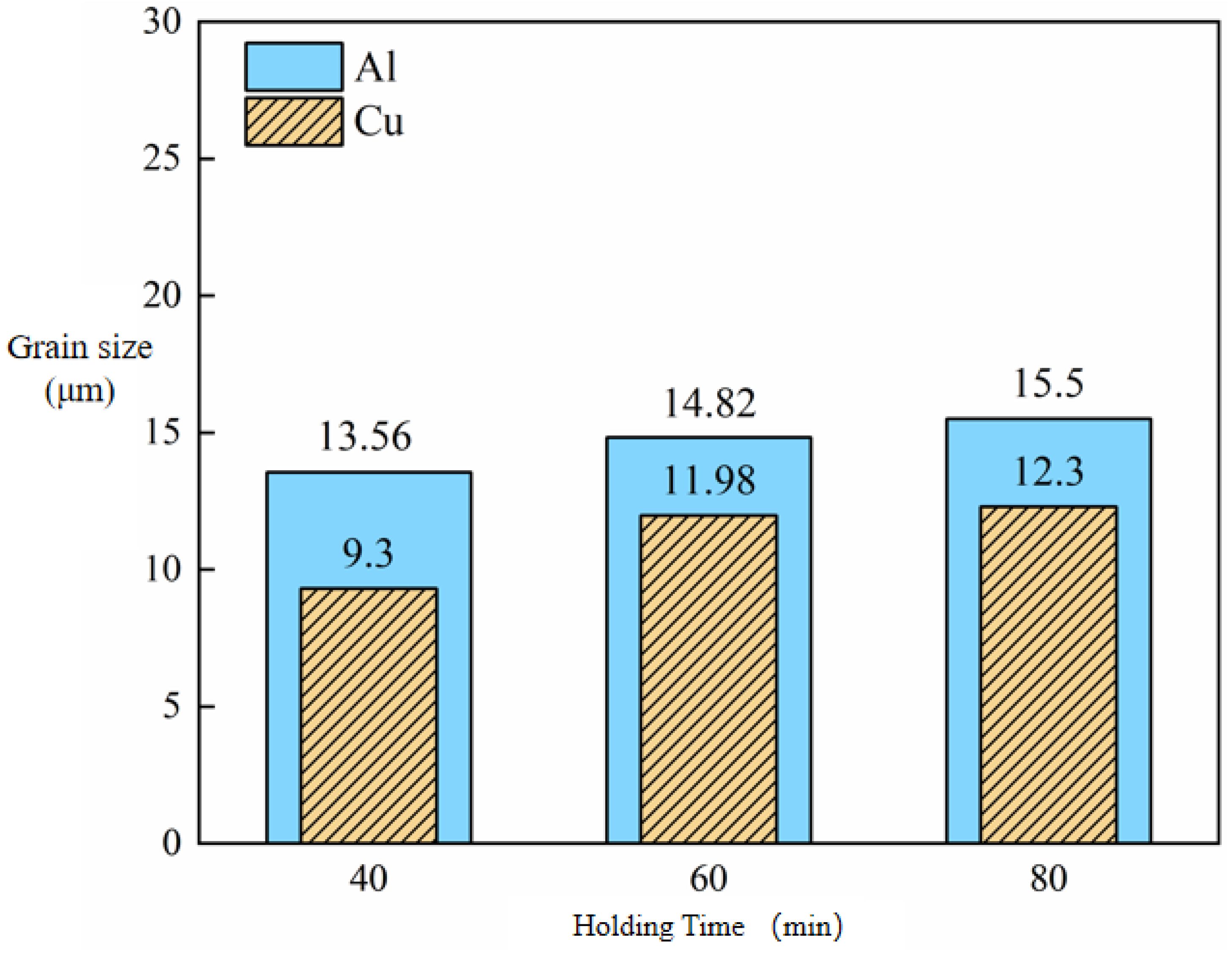

2.2. Experimental Methods

3. Experimental Results

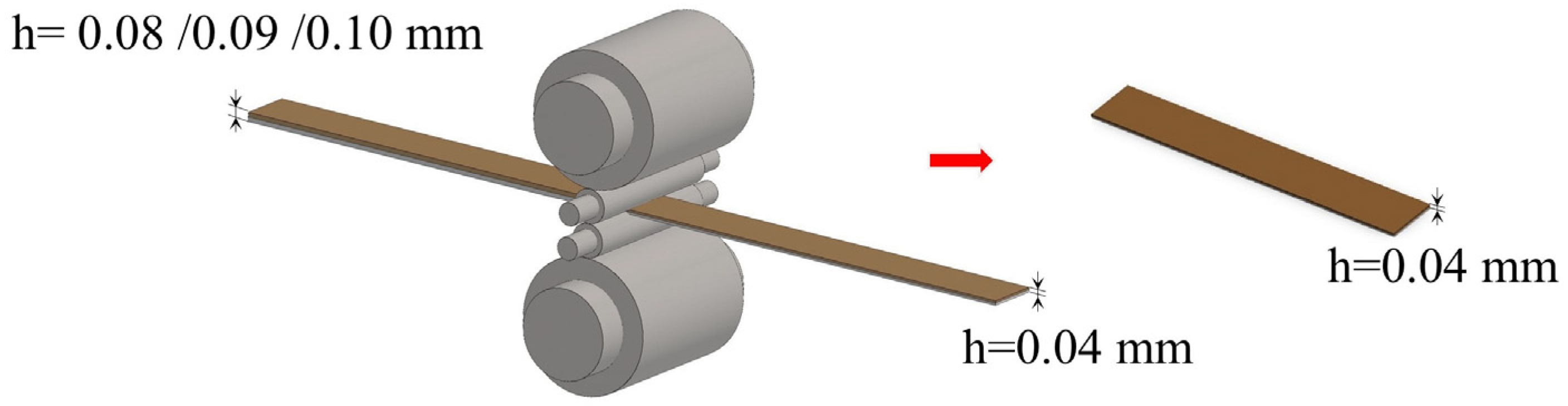

3.1. Effect of Annealing Holding Time on Microstructure of Cu/Al Composite Foil After Secondary Micro-Rolling

3.1.1. Effect of Holding Time on Microstructure of Cu/Al Composite Foil Produced by First Micro-Rolling

3.1.2. Effect of Holding Time on Microstructure of Secondary Micro-Rolled Cu/Al Composite Foil

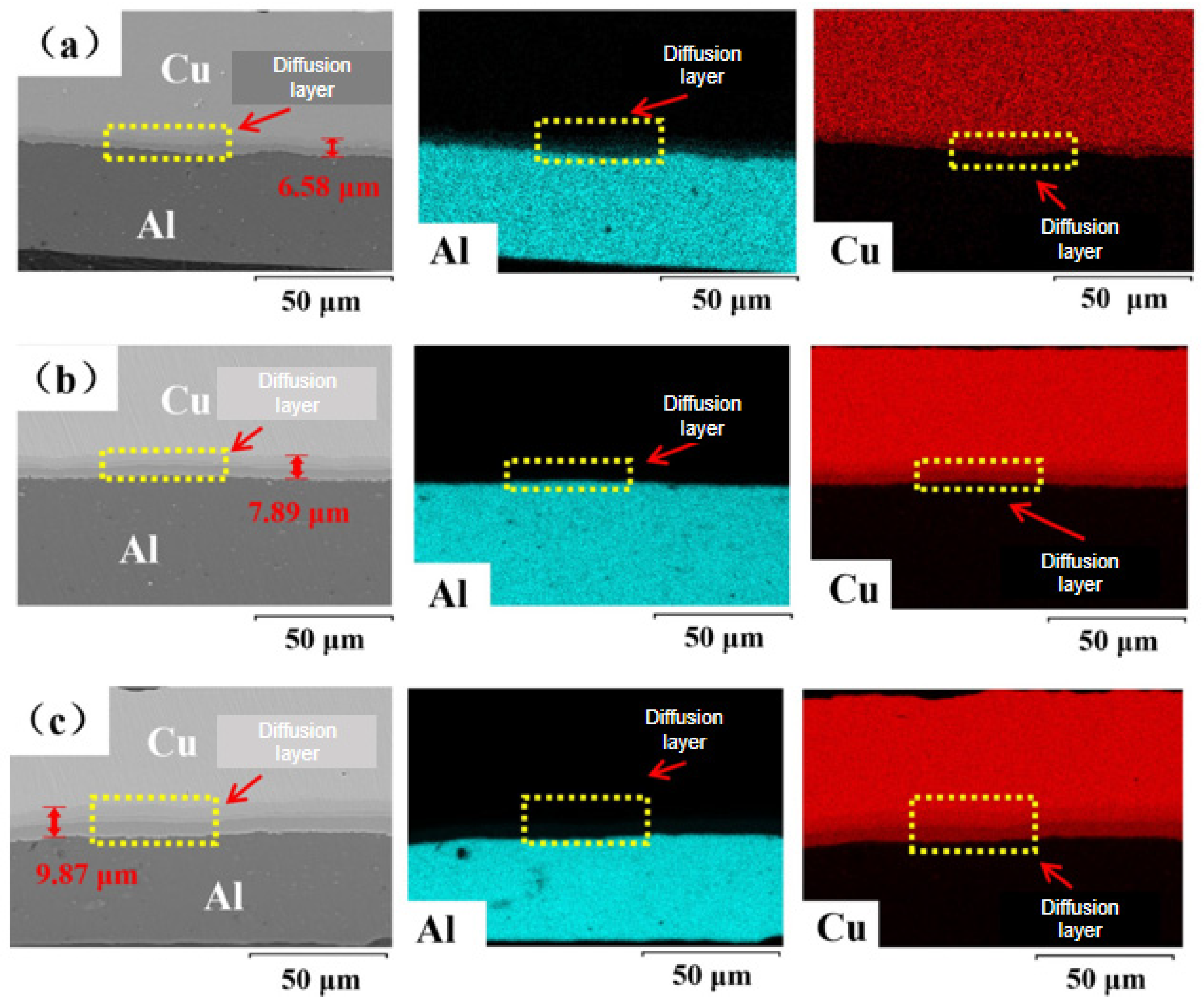

3.2. Effect of Annealing Holding Time on Diffusion Behavior at the Composite Interface of Cu/Al Composite Foil After Secondary Micro-Rolling

3.2.1. Effect of Holding Time on Interfacial Diffusion Behavior in First Micro-Rolled Cu/Al Composite Foil

3.2.2. Effect of Holding Time on Interfacial Diffusion Behavior in Secondary Micro-Rolled Cu/Al Composite Foil

3.3. Effect of Annealing Holding Time on Edge Deformation Behavior of Cu/Al Composite Foil After Secondary Micro-Rolling

3.3.1. Effect of Holding Time on Edge Profile of Secondary Micro-Rolled Cu/Al Composite Foil

3.3.2. Effect of Holding Time on Edge Cracking in Secondary Micro-Rolled Cu/Al Composite Foil

4. Conclusions

- As holding time increases, both Cu and Al grain sizes in first and second micro-rolled specimens gradually increase; holding time has a more pronounced effect on the coarsening of the first rolled Al grains. Concurrently, the reduction in the number of Cu and Al grain layers reduces the grains’ ability to undergo coordinated deformation. Meanwhile, the coarsening of Cu grains after secondary micro-rolling significantly intensifies with increasing holding time.

- As holding time increases, the atomic diffusion at the Cu/Al interface of the first and second micro-rolled specimens is promoted, resulting in a continuous increase in the thickness of the interfacial diffusion layer. XRD analysis indicated that the intermetallic compounds formed at different holding times contained CuAl2, Cu4Al, and Cu9Al4. When the holding time reaches 80 min, CuAl is generated in the secondary micro-rolled sample.

- As holding time increases, the coordinated deformation ability of grains decreases, the content of brittle compounds between metals increases, and the plastic flow of the material in the edge area is uneven; the protruding height of the edge contour of the Cu/Al composite foil gradually increases after secondary micro-rolling, the degree of edge cracking slightly intensifies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, M.W.; Wang, J.L.; Korsunsky, A.M. A Review of Geometrical and Microstructural Size Effects in Micro-Scale Deformation Processing of Metallic Alloy Components. Int. J. Mach. Tools Manuf. 2016, 109, 94–125. [Google Scholar] [CrossRef]

- Hossain, N.; Mahmud, M.Z.A.; Hossain, A.; Rahman, M.K.; Islam, M.S.; Tasnim, R.; Mobarak, M.H. Advances of Materials Science in MEMS Applications: A Review. Results Eng. 2024, 22, 102115. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, J.; Li, F.; Liu, S.; Ye, Y.; Shen, R. A review on solid propellant micro-thruster array based on MEMS technology. FirePhysChem 2024, 4, 95–106. [Google Scholar] [CrossRef]

- Liu, G.; Wang, Q.; Shang, Z.; Luo, L.; Ye, B.; Jiang, H.; Ding, W. An Investigation on Microstructures and Mechanical Properties of Ultra-Low Cu Layer Thickness Ratio Cu/8011/1060 Clads. Met. Mater. Trans. A 2019, 50, 5866–5876. [Google Scholar] [CrossRef]

- Li, L.; Nagai, K.; Yin, F. Progress in Cold Roll Bonding of Metals. Sci. Technol. Adv. Mater. 2008, 9, 023001. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.M.; Chen, R.; Jing, V.; Li, N.; Jiang, Z.Y. Size effect on deformation behavior and fracture in a pure copper microtensile test. Strength Mater. 2021, 53, 539–549. [Google Scholar] [CrossRef]

- Wang, C.; Ma, X.; Ma, L.; Jiang, Z.; Hasan, M.; Islam, A.; Kasi, A.K.; Zhao, J. A study on the microstructural evolution of copper/aluminum composite strips fabricated by micro flexible rolling. Mater. Charact. 2023, 205, 113315. [Google Scholar] [CrossRef]

- Wang, J.; Gao, K.; Xiong, X.; Zhang, Y.; Ding, Y.; Wang, J.; Wu, X.; Wen, S.; Huang, H.; Wei, W.; et al. The Influence of Precipitated Particles on the Grain Size in Cold-Rolled Al–Mn Alloy Foils upon Annealing at 100–550 °C. Materials 2024, 17, 1671. [Google Scholar] [PubMed]

- Zhang, P.; Zhang, H.; Yu, G.; Jiang, Z. Size Effect on Tensile Properties and Fracture Mechanism of Micro-Rolled Ultra-Thin Cu/Al Composite Sheet. Metals 2025, 15, 907. [Google Scholar]

- Yu, G.; Zhang, H.; Yu, Z.; Li, H.; Jiang, Z. Effect of annealing temperature on interface diffusion behavior of ultra-thin Cu/Al composite sheet by secondary micro-rolling. Mater. Lett. 2024, 377, 137308. [Google Scholar]

- Chen, D.; Zhang, H.; Zhao, D.; Liu, Y.; Jiang, Z. Effects of annealing temperature on interface microstructure and element diffusion of ultra-thin Cu/Al composite foil. Mater. Lett. 2022, 322, 132491. [Google Scholar] [CrossRef]

- Jing, Y.; Zhang, H.; Wu, H.; Li, L.; Jia, H.; Jiang, Z. Effects of microrolling parameters on the microstructure and deformation behavior of pure copper. Int. J. Miner. Metall. Mater. 2018, 25, 45–52. [Google Scholar] [CrossRef]

- Xu, Z.T.; Peng, L.F.; Lai, X.M.; Fu, M. Geometry and grain size effects on the forming limit of sheet metals in micro-scaled plastic deformation. Mater. Sci. Eng. A 2014, 611, 345–353. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, H.; Li, H.; Zhu, R.; Zhu, Y.; Jiang, Z. Study on microstructure and properties of ultra-thin Cu/Al composite foil using the cold-rolled composite method at the microscale. Metals 2023, 13, 780. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, F.; Wang, R.; Liu, X. Preparation and properties of copper-aluminum composite strips and foils by horizontal continuous composite casting and rolling. J. Mater. Process. Technol. 2023, 322, 118168. [Google Scholar] [CrossRef]

- Chen, W.; Tao, W.; Jian, G.Z. Effect of annealing temperature on microstructure and tensile properties of copper/aluminum composite thin strip. Trans. Nonferrous Met. Soc. China 2023, 33, 701–713. [Google Scholar] [CrossRef]

- Li, X.B.; Yang, Y.; Xu, Y.S.; Zu, G. Deformation behavior and crack propagation on interface of Al/Cu laminated composites in uniaxial tensile test. Rare Met. 2020, 39, 296–303. [Google Scholar] [CrossRef]

- Kim, Y.K.; Hong, S.I. Effect of intermetallic compound layer on peel strength and crack propagation behavior in Cu/Al/Cu clad composites. Metals 2019, 9, 1155. [Google Scholar] [CrossRef]

- Fu, X.; Wang, R.; Zhu, Q.; Wang, P.; Zuo, Y. Effect of annealing on the interface and mechanical properties of Cu-Al-Cu laminated composite prepared with cold rolling. Materials 2020, 13, 369. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Wang, Z.Y.; Gong, X.Y.; Miao, L.; Wang, P. Copper-Aluminum Asynchronous Rolling Composite process and its Microstructure and Properties. Weld. J. 2016, 37, 71–74. (In Chinese) [Google Scholar]

- Ye, L.Y.; Zhai, Y.W.; Zhou, L.Y.; He, X.M. esearch on Static Grain Growth Behavior of 25Cr2Ni4MoV Steel for Super-Large Nuclear Power Rotors. J. Plast. Eng. 2021, 28, 146–151. (In Chinese) [Google Scholar]

| Al | Zn | V | Mn | Mg | Ti | Si | Cu | Fe |

|---|---|---|---|---|---|---|---|---|

| 99.60 | 0.05 | 0.05 | 0.03 | 0.03 | 0.03 | 0.25 | 0.05 | 0.35 |

| Cu | Sb | Bi | As | Ni | Fe | Pb | P | S | Sn | Zn |

|---|---|---|---|---|---|---|---|---|---|---|

| 99.90 | <0.0010 | <0.0004 | <0.0010 | 0.0013 | 0.0074 | 0.0037 | 0.0017 | 0.0015 | 0.0023 | 0.0099 |

| Annealing Temperature °C | Heating Rate, °C/min | Holding Time, min | Annealing Condition Number |

|---|---|---|---|

| 400 | 5 | 40 | T1 |

| 400 | 60 | T2 | |

| 400 | 80 | T3 |

| Equipment Model | Equipment Parameters | Technical Indicators |

|---|---|---|

| GR.TF60-18 | Rated voltage, V | 380 |

| Rated Power, KW | 7 | |

| Maximum temperature, °C | 1800 | |

| Furnace chamber dimensions, mm | Φ 60~1000 | |

| Common temperature, °C | 1700 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zhang, H.; Wang, J.; Yu, G.; Jiang, Z. Effect of Annealing Holding Time on Microstructure, Interface Diffusion Behavior, and Deformation Behavior of Cu/Al Composite Foil After Secondary Micro-Rolling. Materials 2025, 18, 5418. https://doi.org/10.3390/ma18235418

Li X, Zhang H, Wang J, Yu G, Jiang Z. Effect of Annealing Holding Time on Microstructure, Interface Diffusion Behavior, and Deformation Behavior of Cu/Al Composite Foil After Secondary Micro-Rolling. Materials. 2025; 18(23):5418. https://doi.org/10.3390/ma18235418

Chicago/Turabian StyleLi, Xu, Hongmei Zhang, Jianling Wang, Guoao Yu, and Zhengyi Jiang. 2025. "Effect of Annealing Holding Time on Microstructure, Interface Diffusion Behavior, and Deformation Behavior of Cu/Al Composite Foil After Secondary Micro-Rolling" Materials 18, no. 23: 5418. https://doi.org/10.3390/ma18235418

APA StyleLi, X., Zhang, H., Wang, J., Yu, G., & Jiang, Z. (2025). Effect of Annealing Holding Time on Microstructure, Interface Diffusion Behavior, and Deformation Behavior of Cu/Al Composite Foil After Secondary Micro-Rolling. Materials, 18(23), 5418. https://doi.org/10.3390/ma18235418