Structural and Electrical Analysis of Crystalline Silicon Solar Cells: The Role of Busbar Geometry in First-Generation PV Technology

Abstract

1. Introduction

1.1. Generations of Photovoltaic Solar Cells

- Monocrystalline Cells (mono-Si) are characterised by high efficiencies, often over 20%, with longer lifespans and better performance, which leads to potential savings. However, they are typically more expensive to produce and have a smooth surface. The production process involves growing crystals and slicing them into thin wafers.

- Polycrystalline Cells (multi-Si) have somewhat lower efficiency (around 15–17%, below 20%) but are cheaper to produce. Their surface typically has a slightly matte appearance and is often grey or blue. Arising from the production method, these cells often exhibit greater variations in size and shape. The production process of these solar cells involves melting silicon and cooling it in moulds, which leads to the creation of a material composed of many crystals.

- Amorphous (a-Si)—They generally have lower conversion efficiency (around 6–10%) than traditional crystalline cells but perform better in low-light conditions and are less sensitive to high temperatures, making them suitable for areas with limited sunlight. These cells are cheaper to produce, making them more affordable for specific applications (e.g., sundials). However, they may degrade more quickly over time, leading to a decline in efficiency. This type of silicon lacks a regular crystalline structure, with its atoms arranged randomly. This irregular arrangement influences the material’s electrical and optical properties.

- Copper–Indium–Gallium-Selenide (CIGS)—CIGS cells consist of a thin layer of active material on a substrate, typically glass, stainless steel, or plastic, resulting in lightweight and flexible cells. They achieve a relatively high energy conversion efficiency of up to 23% in laboratory settings, making them among the most efficient thin-film cells. Recent production advancements have further improved their efficiency, and their compatibility with flexible substrates opens up various application possibilities. Cadmium Telluride (CdTe). The materials used in CIGS cell production, such as indium and selenium, may raise environmental concerns. However, this technology can promote renewable energy development and reduce CO2 emissions compared to fossil fuel-based energy methods.

- Cadmium Telluride (CdTe)—CdTe cells achieve energy conversion efficiencies of about 15–22%, making them competitive with other photovoltaic types. They are produced through a chemical deposition method, resulting in thin-film, semi-transparent structures. These cells are commonly used in large-scale photovoltaic farms and smaller home installations. However, their disposal poses challenges due to toxic materials, necessitating the development of effective recycling processes. CdTe is a cost-effective material, and the production process for CdTe cells is more affordable than that of crystalline cells. This affordability makes them appealing for commercial applications.

- Dye-Sensitised Solar Cells (DSSC) utilise organic dyes, enabling production in various colours for architectural applications and enhancing building aesthetics. They have lower production costs than traditional silicon cells and can be applied to different substrates, including flexible materials. However, they have lower energy conversion efficiency (from 7 to 11%). However, some components, such as electrolytes, may degrade over time and are sensitive to atmospheric conditions, particularly humidity and temperature.

- Organic cells contain heavy metals and use organic compounds as electrodes or electrolytes, making them perceived as more environmentally friendly. These cells can be produced in lightweight and flexible forms for use in portable devices and modern architecture. However, challenges remain, including the degradation of organic materials, longevity, and lower conductivity compared to traditional materials, which continue to be areas of ongoing research.

- Perovskite achieves conversion efficiencies over 25% in lab tests and is relatively inexpensive to produce compared to traditional silicon solar cells. However, challenges remain regarding long-term stability and resistance to weather conditions like humidity and temperature. Their versatility allows for use on various substrates, making them suitable for flexible and lightweight photovoltaic panels.

1.2. Construction and Operating Principle of a Single-Junction Silicon Photovoltaic Cell

- The internal photoelectric effect,

- The transport of generated charge carriers within the cell structure, which occurs due to the influence of the electric field and diffusion driven by the concentration gradient of the carriers.

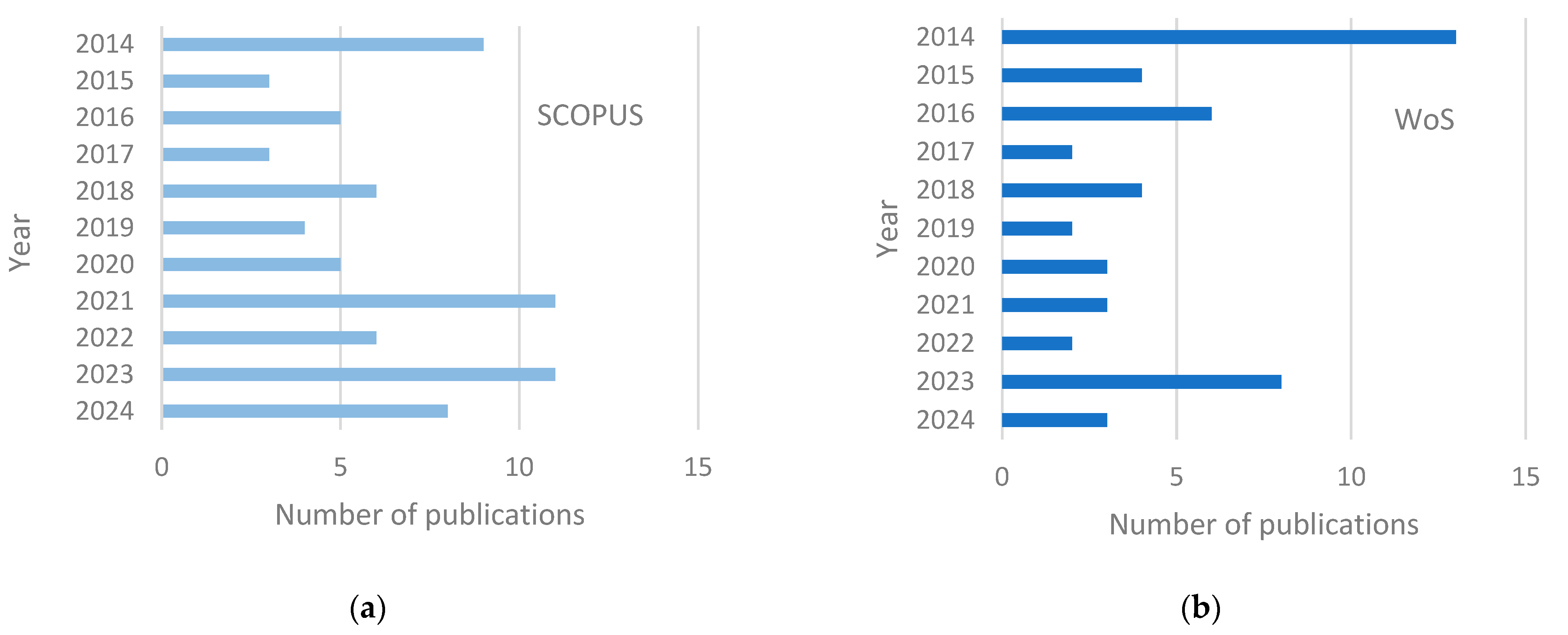

1.3. Publication Trends in Monocrystalline and Polycrystalline Silicon Solar Cells (Supplementary Information)

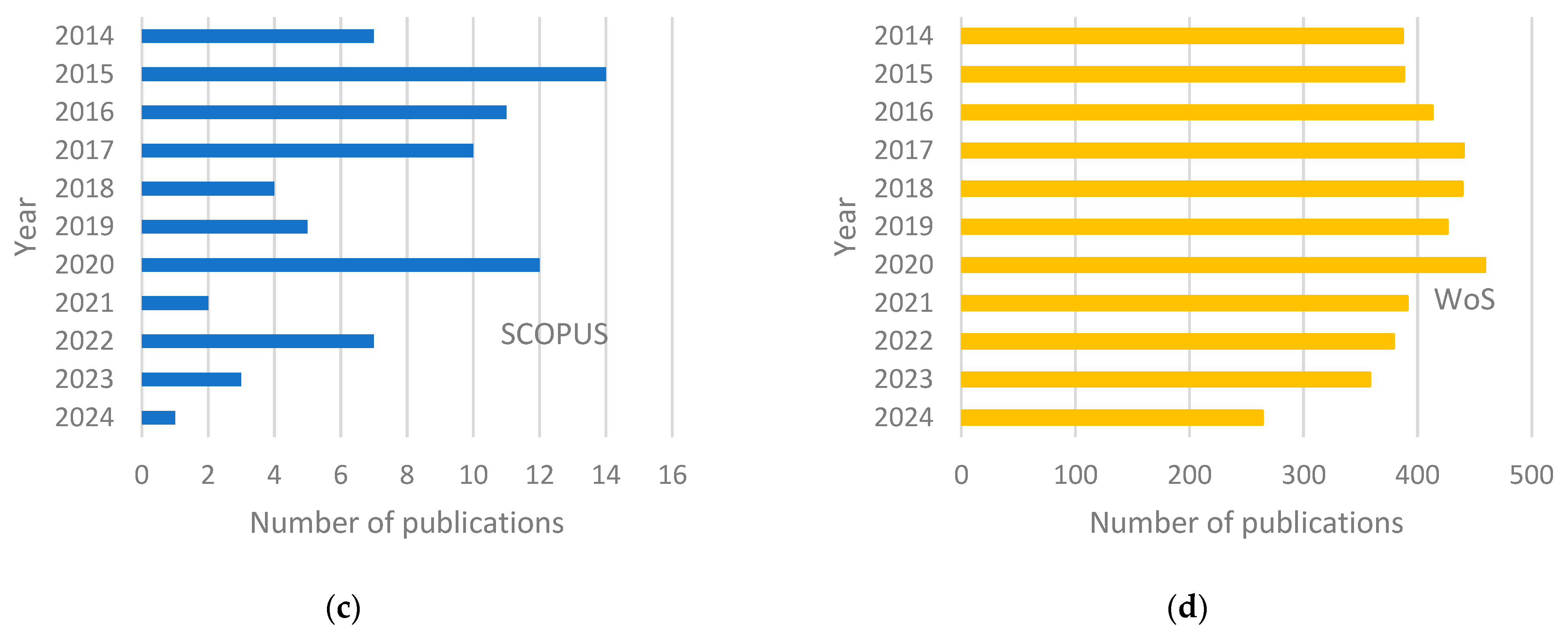

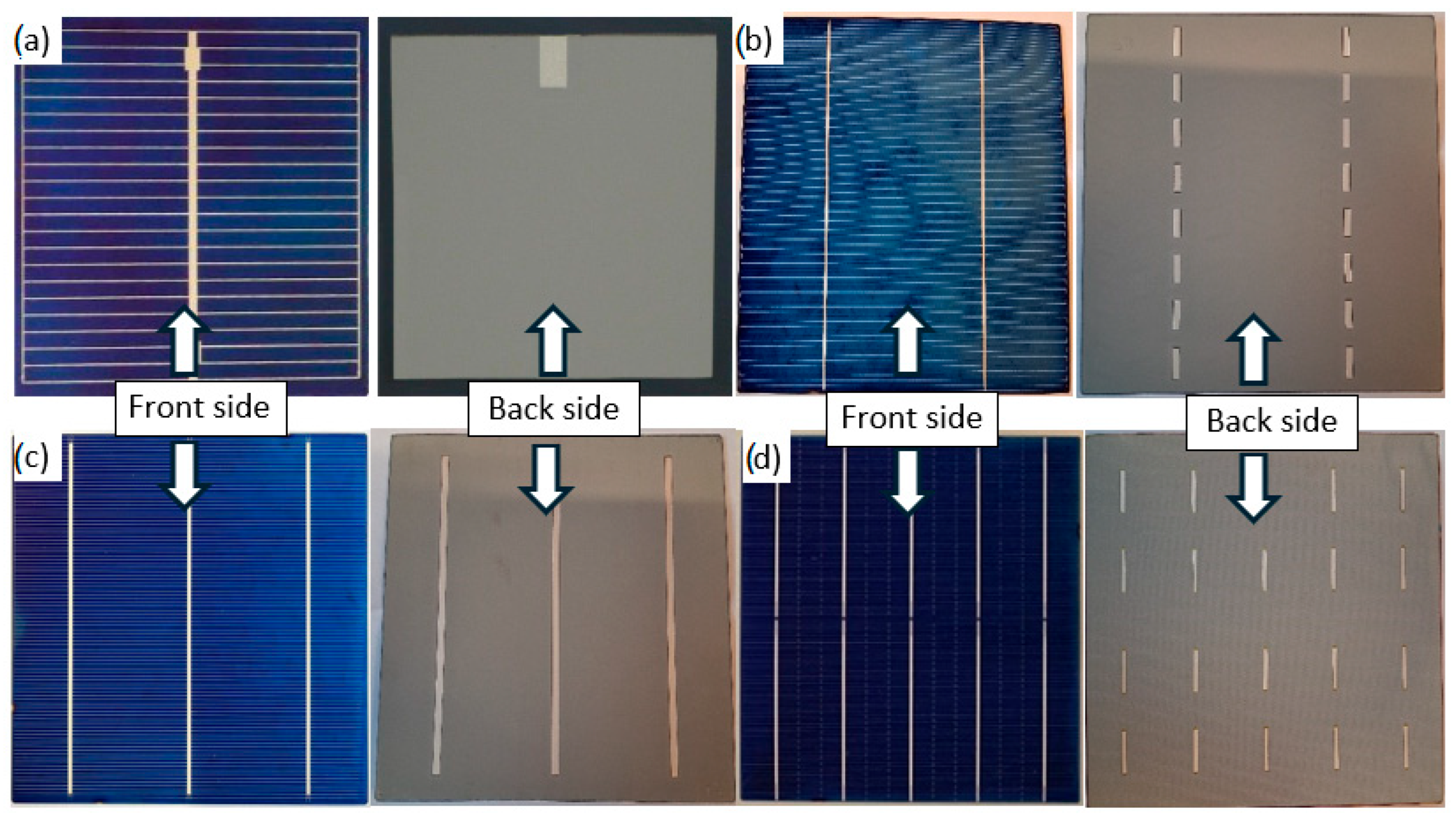

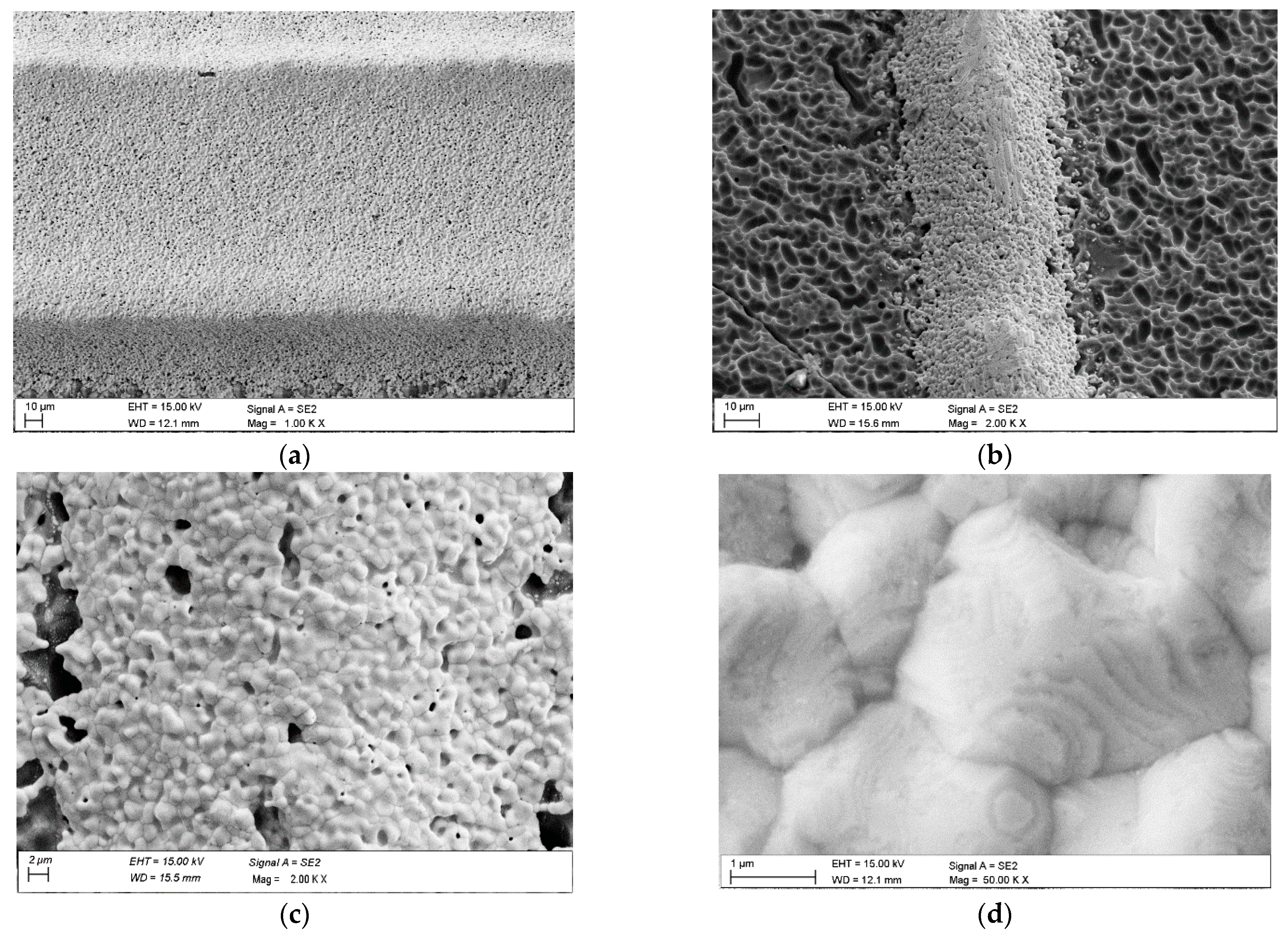

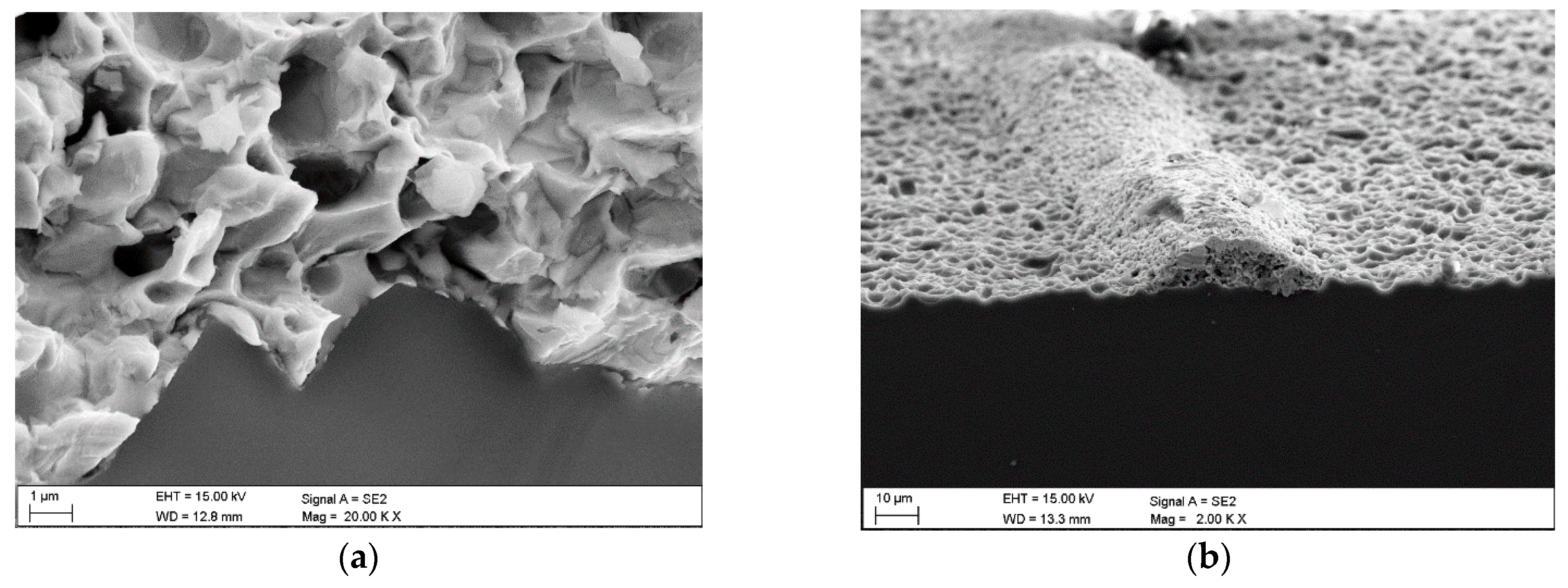

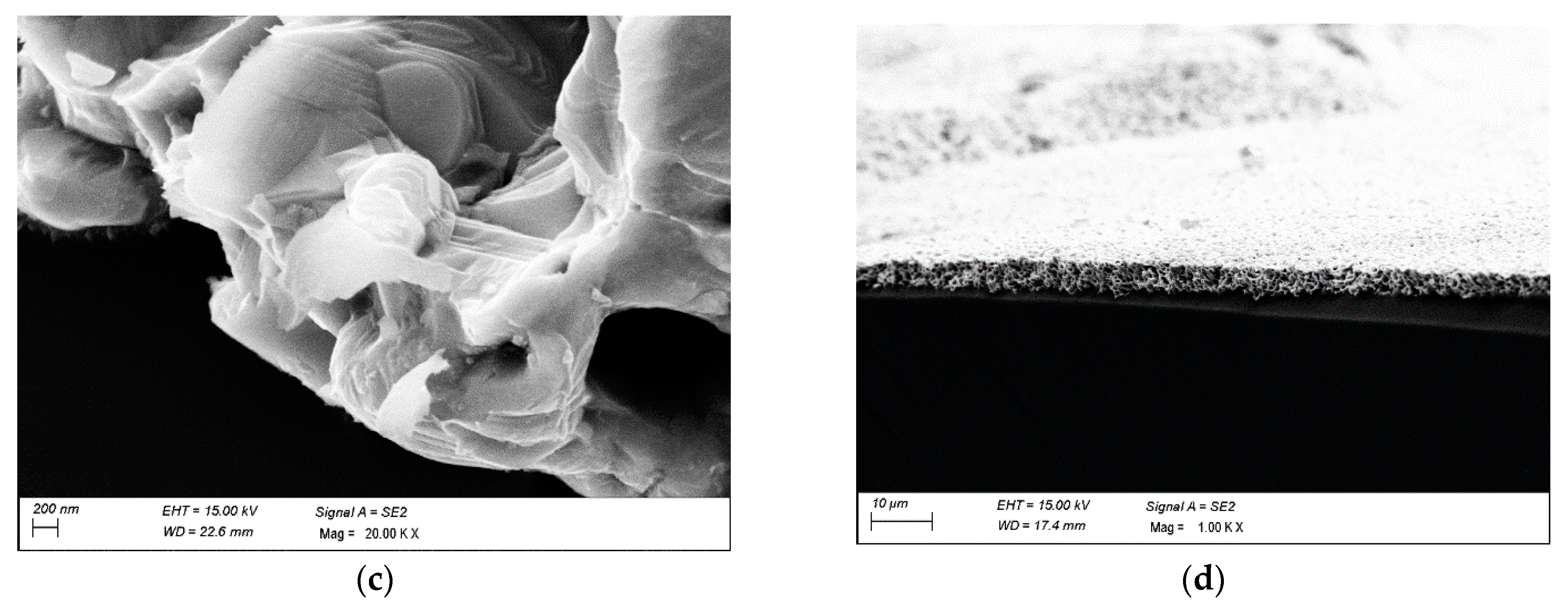

2. Materials

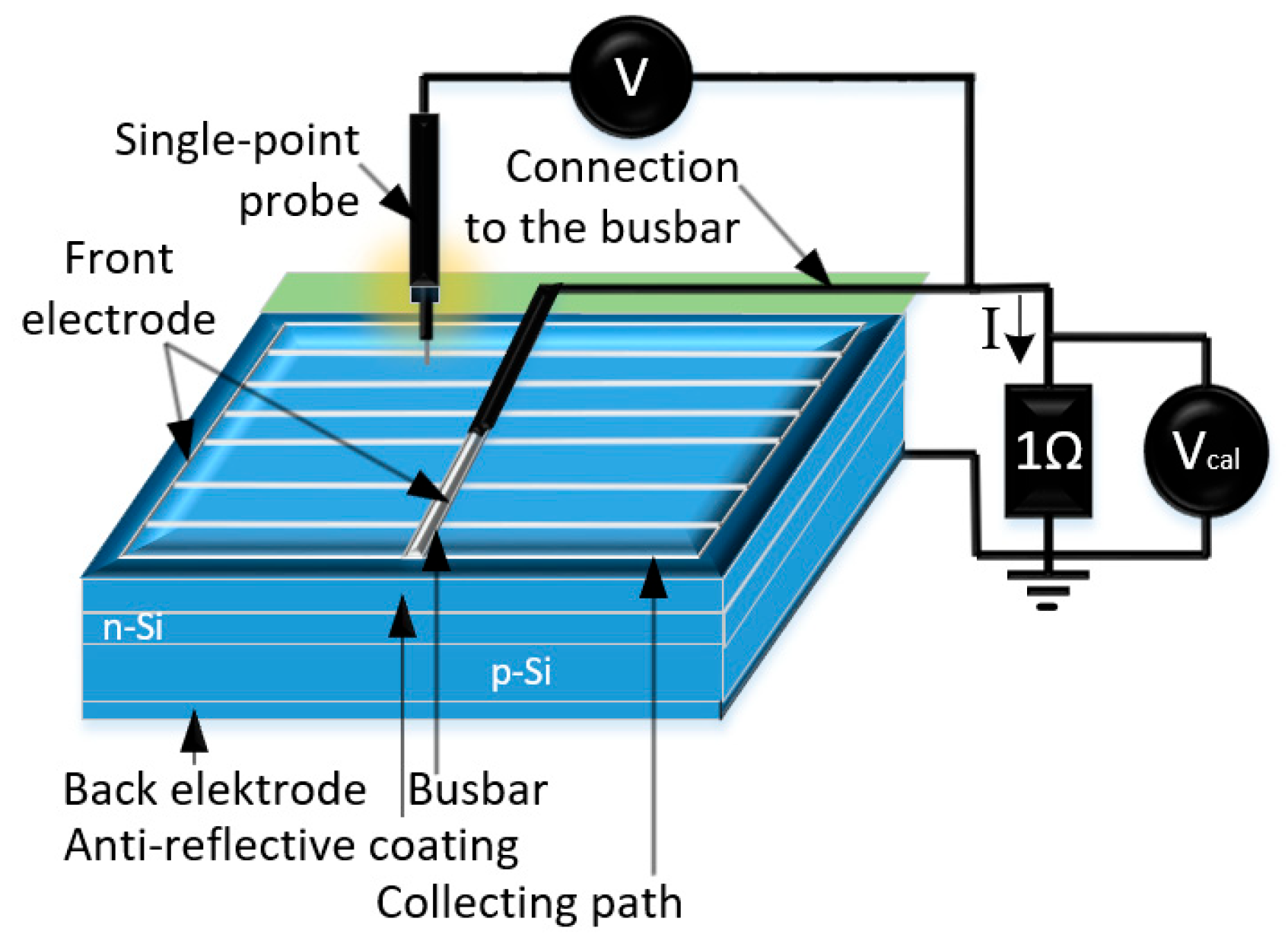

3. Methodology

- Contact resistance Rc and resistivity ρ (Core Scan);

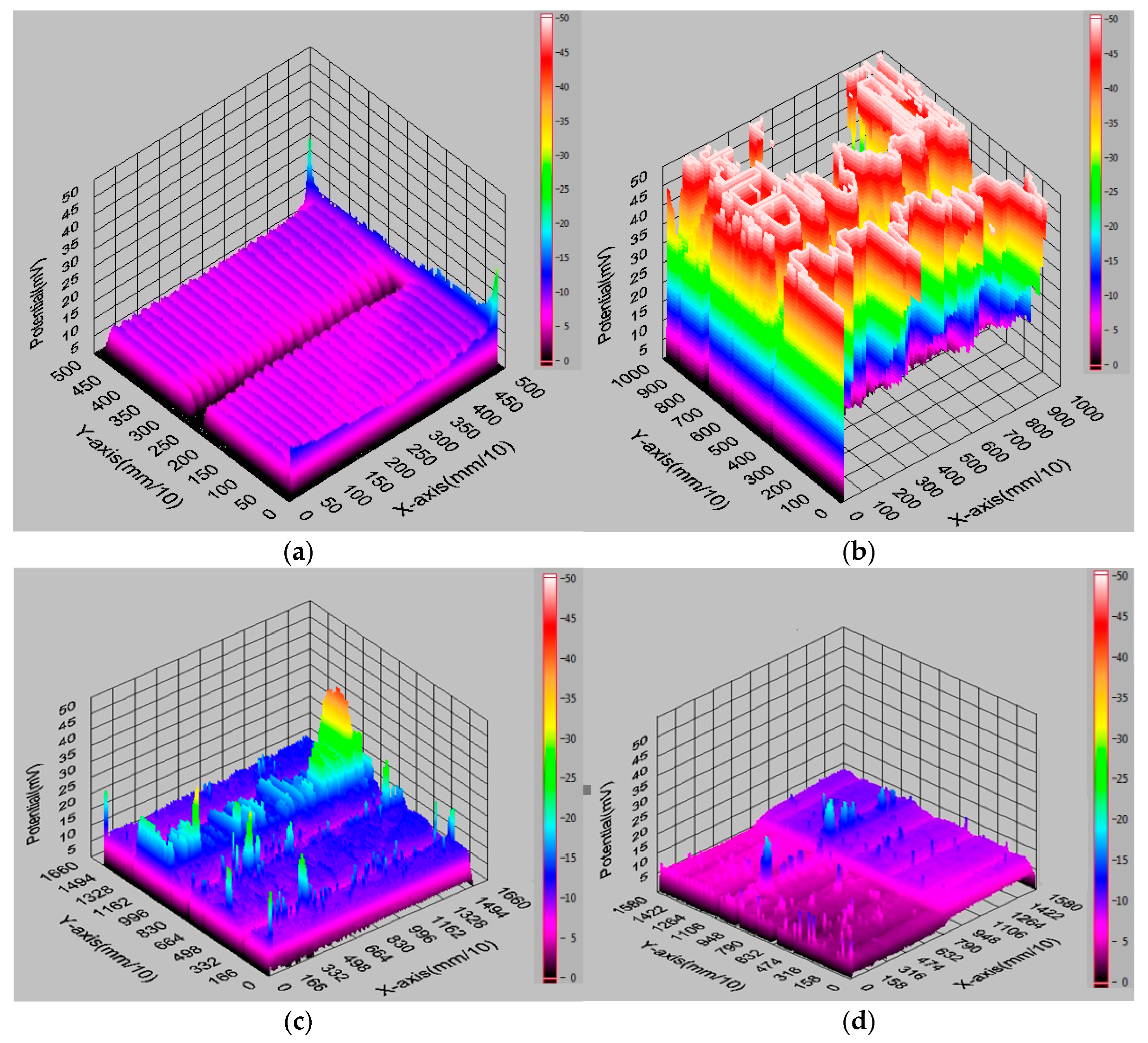

- Open-circuit voltage Uoc (Uoc Scan);

- Voltage UR (Shunt Scan);

- Photogenerated current density (LBIC Scan).

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cheng, D.; Gao, Y.; Yang, C. A Comprehensive Review on Wafering of Silicon Substrate for Photovoltaic Solar Cell. Sol. Energy 2025, 301, 113977. [Google Scholar] [CrossRef]

- Stefani, B.V.; Kim, M.; Zhang, Y.; Hallam, B.; Green, M.A.; Bonilla, R.S.; Fell, C.; Wilson, G.J.; Wright, M. Historical Market Projections and the Future of Silicon Solar Cells. Joule 2023, 7, 2684–2699. [Google Scholar] [CrossRef]

- Al-Ali, S.; Olabi, A.G.; Mahmoud, M. A Review of Solar Photovoltaic Technologies: Developments, Challenges, and Future Perspectives. Energy Convers. Manag. X 2025, 27, 101057. [Google Scholar] [CrossRef]

- Reddy, P.J. Science & Technology of Photovoltaics, 2nd ed.; BS Publications: Hyderabad, India, 2010; ISBN 978-81-7800-210-1. [Google Scholar]

- Bordun, I.; Sowiński, J.; Kornatka, M.; Gawlak, A.; Panowski, M.; Kacprzak, A.; Ìvaŝišin, F.O.; Kogut, Z.O.; Wichliński, M.; Rajczyk, R. (Eds.) Directions and Perspectives for the Development of Renewable Energy Sources: Selected Aspects: A Monograph; University of Technology Publishing House: Częstochowa, Poland, 2022; ISBN 978-83-7193-875-7. [Google Scholar]

- Lewandowski, W.M. Pro-Ecological Renewable Energy Sources; WNT: Warsaw, Poland, 2012. [Google Scholar]

- Best Research-Cell Efficiency Chart|Photovoltaic Research|NREL. Available online: https://www.nrel.gov/pv/cell-efficiency (accessed on 3 February 2025).

- Musztyfaga-Staszuk, M. Application of the Transmission Line Method (TLM) to Measure the Resistivity of Contacts; Monography; Silesian University of Technology Publishing House: Gliwice, Poland, 2022; ISBN 978-83-7880-861-9. [Google Scholar]

- Sharma, P.; Mishra, R.K. Comprehensive study on photovoltaic cells’ generation and factors affecting its performance: A review. Mater. Renew. Sustain. Energy 2025, 14, 21. [Google Scholar] [CrossRef]

- Fraunhofer Institute. Photovoltaics Report; 2023. Available online: https://www.ise.fraunhofer.de/en/publications/studies/photovoltaics-report.html (accessed on 14 October 2025).

- Frydrychowicz-Jastrzębska, G. Solar Cells: Construction, Technology, and Applications, 2nd ed.; Communication and Connectivity Publishing House: Sulejówek, Poland, 2024; ISBN 978-83-206-2071-9. [Google Scholar]

- Sibiński, M.; Znajdek, K. (Eds.) Advances in Photovoltaics: Structure and Manufacturing of PV Cells, Design and Applications of Photovoltaic Systems, Conventional and Innovative Solar Cells in Practice; PWN: Warsow, Poland, 2021; ISBN 978-83-01-21666-5. [Google Scholar]

- Arifuku, N.; Dhamrin, M.; Suda, M.; Saitoh, T.; Kamisako, K. 21st European Photovoltaic Solar Energy Conference: Proceedings of the International Conference, Dresden, Germany, 4–8 September 2006; WIP Renewable Energies: München, Germany, 2006; ISBN 978-3-936338-20-1. [Google Scholar]

- Yang, W.S.; Noh, J.H.; Jeon, N.J.; Kim, Y.C.; Ryu, S.; Seo, J.; Seok, S.I. High-Performance Photovoltaic Perovskite Layers Fabricated through Intramolecular Exchange. Science 2015, 348, 1234–1237. [Google Scholar] [CrossRef]

- Bartusik, M. Rekord Wydajności dla Panelu Perowskitowego. Naukowcy z Hong Kongu z Wyjątkowym Odkryciem; ŚwiatOZE.pl: Kraków, Poland, 2023. [Google Scholar]

- Ogniwa HJT—Hanplast EnergyTM. Available online: https://hanplast.energy/technologia/ogniwa-hjt (accessed on 3 March 2025).

- Musztyfaga-Staszuk, M.M. Laser Micromachining of Silicon Photovoltaic Cell Components. Ph.D. Thesis, Silesian University of Technology, Gliwice, Poland, 2011. [Google Scholar]

- Panek, P. Photovoltaics Poland 2011: Solar cells: Basic operation, construction, applications: National research and development and commercial centers of the PV sector. Electron. Constr. Technol. Appl. 2011, 52, 69–117. Available online: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-BWA1-0045-0021 (accessed on 6 September 2025).

- Adamczewska, J. (Ed.) Technological Processes in Semiconductor Electronics: Collective Work; Scientific and Technical Publishing House: Warsaw, Poland, 1980; ISBN 978-83-204-0298-8. [Google Scholar]

- IMIM PAN. Structuring of Porous Silicon in Terms of Electrical and Optical Properties of a Solar Cell; Project 4 T 08A 04623 (Promoter’s Grant); IMIM PAN: Kraków, Poland, 2005. [Google Scholar]

- Aberle, A.G. Surface Passivation of Crystalline Silicon Solar Cells: A Review. Prog. Photovolt. Res. Appl. 2000, 8, 473–487. [Google Scholar] [CrossRef]

- Goetzberger, A.; Knobloch, J.; Voss, B. Crystalline Silicon Solar Cell; John Wiley & Sons: Chichester, UK, 1998. [Google Scholar]

- Hamer, D. Thick-Film Integrated Circuit Technology; Scientific and Technical Publishing Houses: Amsterdam, The Netherlands, 1976. [Google Scholar]

- Schuler, S.; Luck, I. Cell metallization by screen printing, Cost, limits and alternatives. Photovolt. Int. 2014, 23, 46–52. [Google Scholar]

- Klugmann-Radziemska, E. Alternative Energy Sources: Photovoltaic Energy; Economics and Environment Publishing House: Srodowisko, Poland, 1999. [Google Scholar]

- Co to Jest Efekt Fotowoltaiczny? Available online: https://www.pelsun.pl/akademia-wiedzy/fotowoltaika/co-to-jest-efekt-fotowoltaiczny (accessed on 10 February 2025).

- SUNDEK Energia. Historia Fotowoltaiki. Kto Wynalazł Panele Fotowoltaiczne? SUNDEK Energia: Mikołów, Poland, 2023. [Google Scholar]

- Rodacki, T.; Kandyba, A. Energy Conversion in Solar Power Plants; Monograph; Silesian University of Technology: Gliwice, Poland, 2000; ISBN 978-83-88000-96-6. [Google Scholar]

- Jarzębski, J. Solar Energy Photovoltaic Conversion; PWN Scientific Publishing House: Warsaw, Poland, 1990. [Google Scholar]

- Drabek, A. Indexing Journals in Reference Databases; Adam Mickiewicz University: Poznań, Poland, 2018. [Google Scholar] [CrossRef]

- Corescan. Corescan User Manual Master MRN, Software Version 10.00 MRN-061-EN; Registration Number: MRN-061-EN 2025; Corescan. Available online: https://www.corescan.com.au/ (accessed on 1 January 2025).

| Number of Busbars in a Solar Cell | Area | Thickness |

|---|---|---|

| One | 5 cm × 5 cm ± 0.25 mm | 200 ± 30 μm |

| Two | 10 cm × 10 cm ± 0.25 mm | 150 ± 30 μm |

| Three | 16.6 cm × 16.6 cm ± 0.25 mm | 175 ± 30 μm |

| Five | 15.8 cm × 15.8 cm ± 0.25 mm | 180 ± 30 μm |

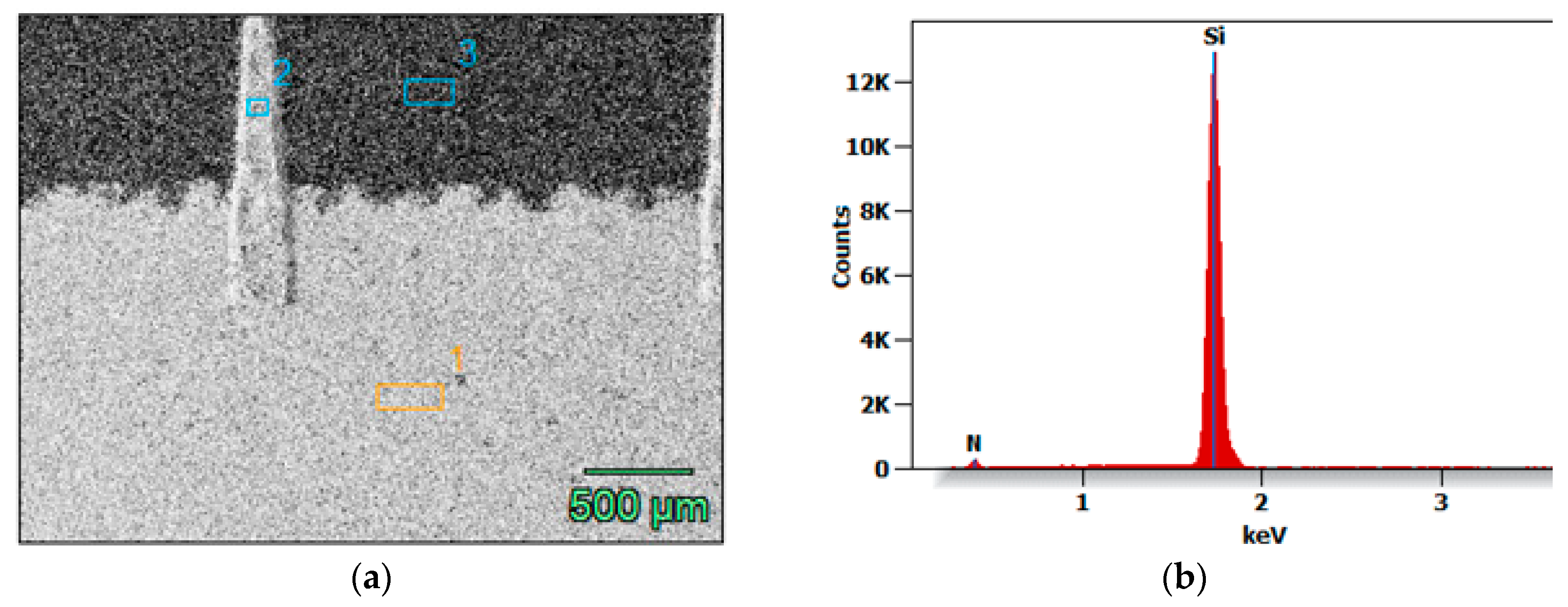

| The Area | Weight Fraction of Elements,% | ||

|---|---|---|---|

| N | Si | Ag | |

| 1 | 100.0 | ||

| 2 | 0.8 | 99.2 | |

| 3 | 16.8 | 83.2 | |

| Number of Busbars in a Solar Cell | Jsc, mA/cm2 | Uce, mV | Rcont, mΩcm2 | ρ, Ωcm |

|---|---|---|---|---|

| 1BB | 30 | 8.8 | 26 | 2.6 |

| 9.3 | 28 | 2.8 | ||

| 18.6 | 56 | 5.6 | ||

| 2BB | 11.7 | 84 | 7.0 | |

| 18.6 | 134 | 11.1 | ||

| 30.8 | 221 | 18.5 | ||

| 3BB | 7.3 | 13 | 1.1 | |

| 14.2 | 25 | 2.1 | ||

| 45.9 | 83 | 6.9 | ||

| 5BB | 22.5 | 162 | 13.5 | |

| 36.1 | 260 | 21.7 | ||

| 55.7 | 401 | 33.4 |

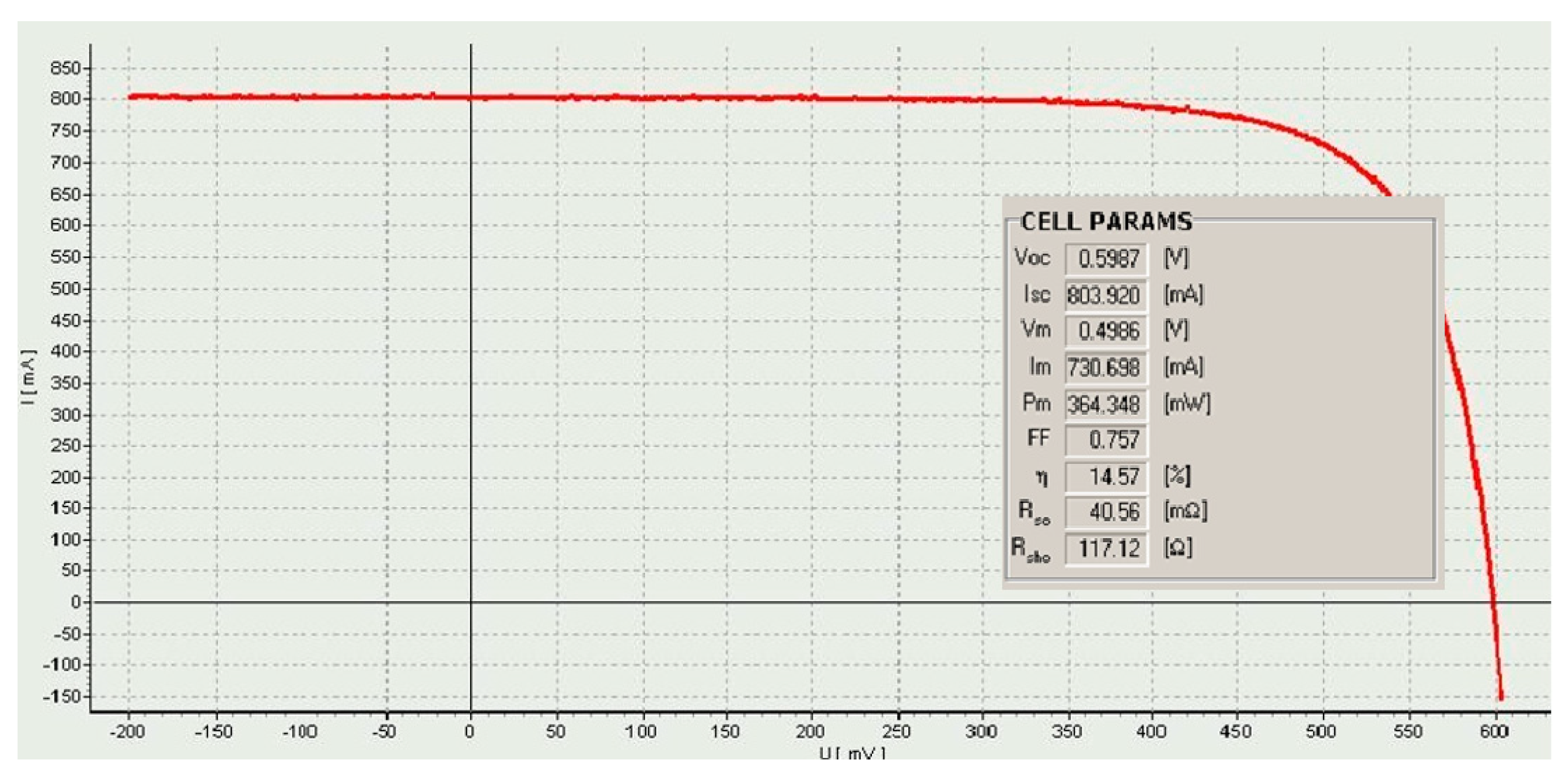

| Number of Busbars in a Solar Cell | Parameters | |||||

|---|---|---|---|---|---|---|

| Isc, mA | Uoc, mV | Pm, mW | FF | Eff, % | Rso@Uoc, mΩ | |

| 1BB | 804.9 | 598.7 | 364.3 | 0.76 | 14.57 | 40.56 |

| 2BB | 7969.0 | 672.1 | 3133.2 | 0.59 | 15.54 | 18.3 |

| 3BB | 8207.4 | 668.9 | 3315.9 | 0.60 | 16.09 | 15.6 |

| 5BB | 8076.2 | 670.9 | 3665.6 | 0.68 | 17.91 | 10.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musztyfaga-Staszuk, M.M.; Mele, C. Structural and Electrical Analysis of Crystalline Silicon Solar Cells: The Role of Busbar Geometry in First-Generation PV Technology. Materials 2025, 18, 4979. https://doi.org/10.3390/ma18214979

Musztyfaga-Staszuk MM, Mele C. Structural and Electrical Analysis of Crystalline Silicon Solar Cells: The Role of Busbar Geometry in First-Generation PV Technology. Materials. 2025; 18(21):4979. https://doi.org/10.3390/ma18214979

Chicago/Turabian StyleMusztyfaga-Staszuk, Małgorzata Monika, and Claudio Mele. 2025. "Structural and Electrical Analysis of Crystalline Silicon Solar Cells: The Role of Busbar Geometry in First-Generation PV Technology" Materials 18, no. 21: 4979. https://doi.org/10.3390/ma18214979

APA StyleMusztyfaga-Staszuk, M. M., & Mele, C. (2025). Structural and Electrical Analysis of Crystalline Silicon Solar Cells: The Role of Busbar Geometry in First-Generation PV Technology. Materials, 18(21), 4979. https://doi.org/10.3390/ma18214979