Influence of Fiber Orientation on the Water and Ions Transportation of Engineered Cementitious Composite (ECC)

Abstract

1. Introduction

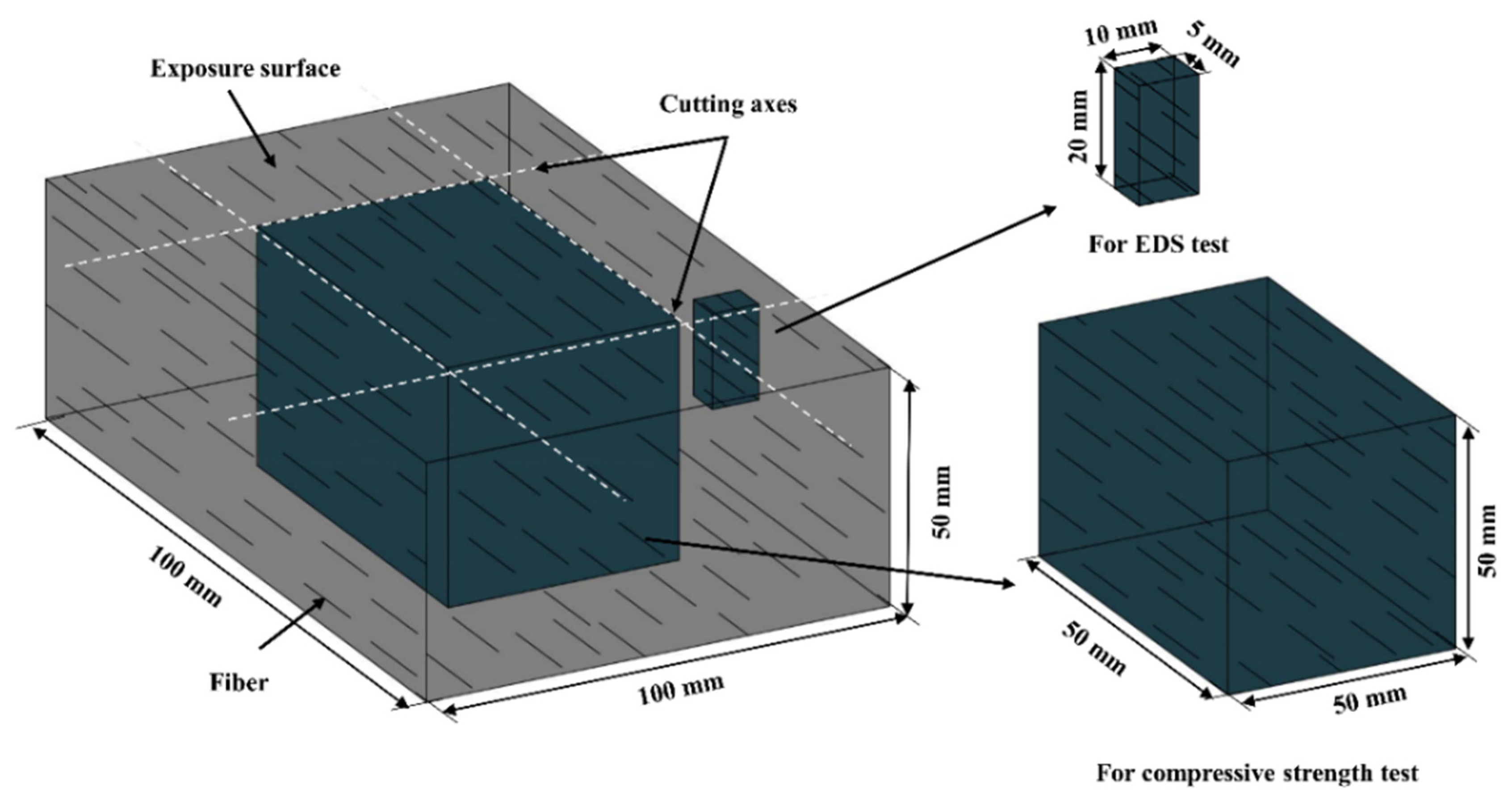

2. Experimental Procedure

2.1. Raw Materials and Mixture Proportion

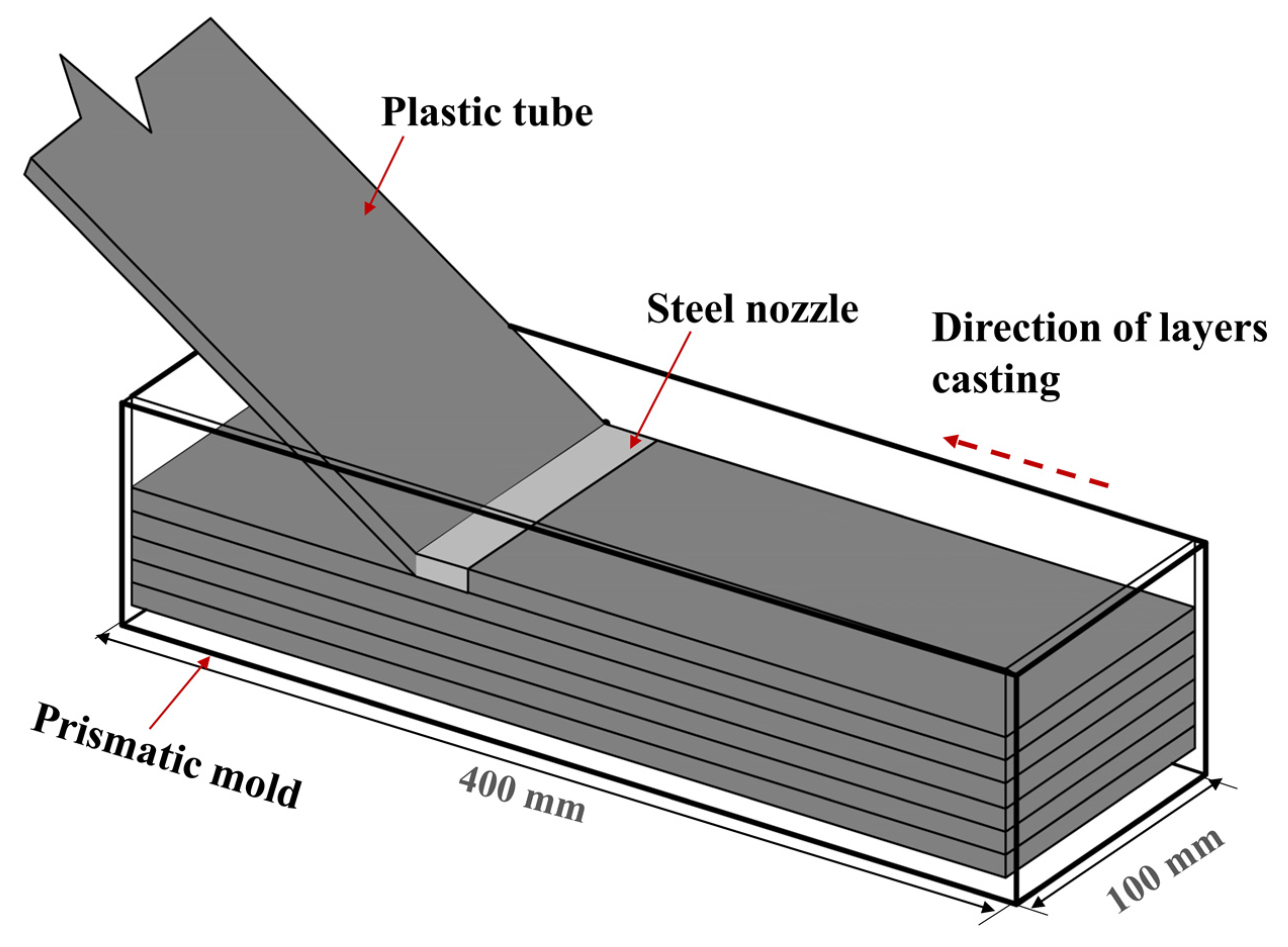

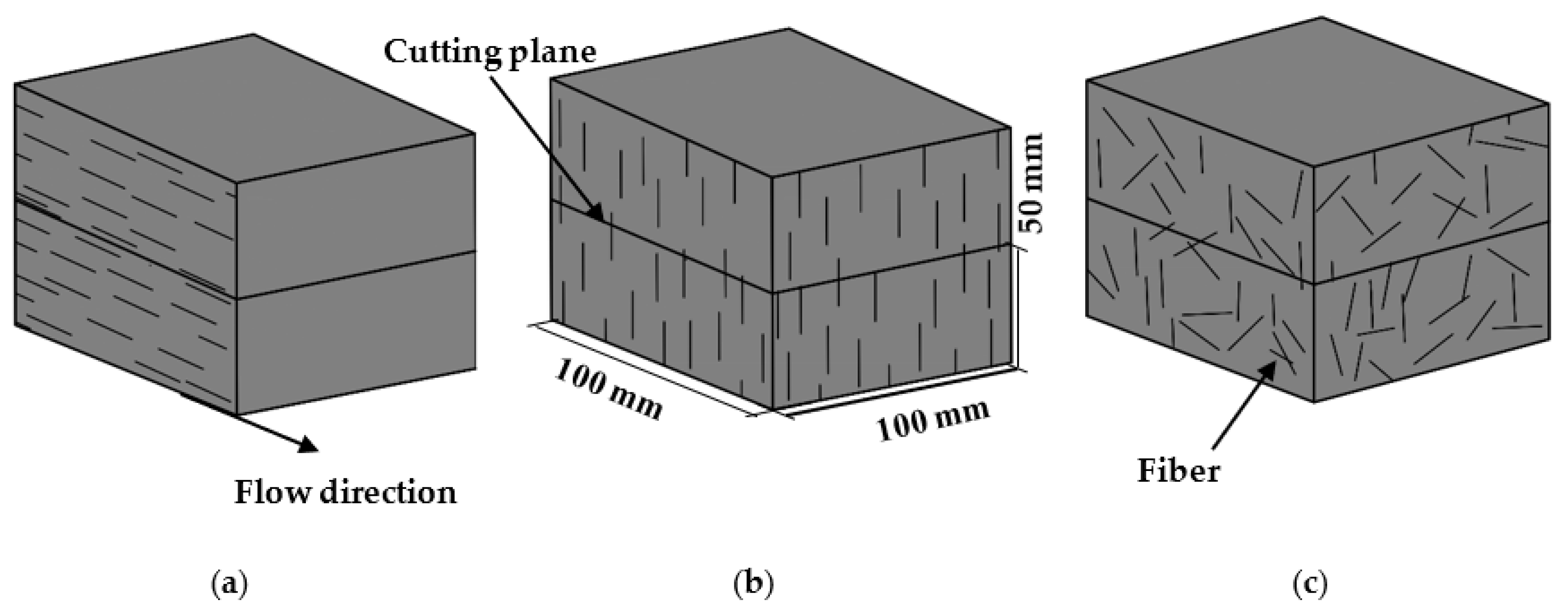

2.2. Mixing and Casting

3. Test Program

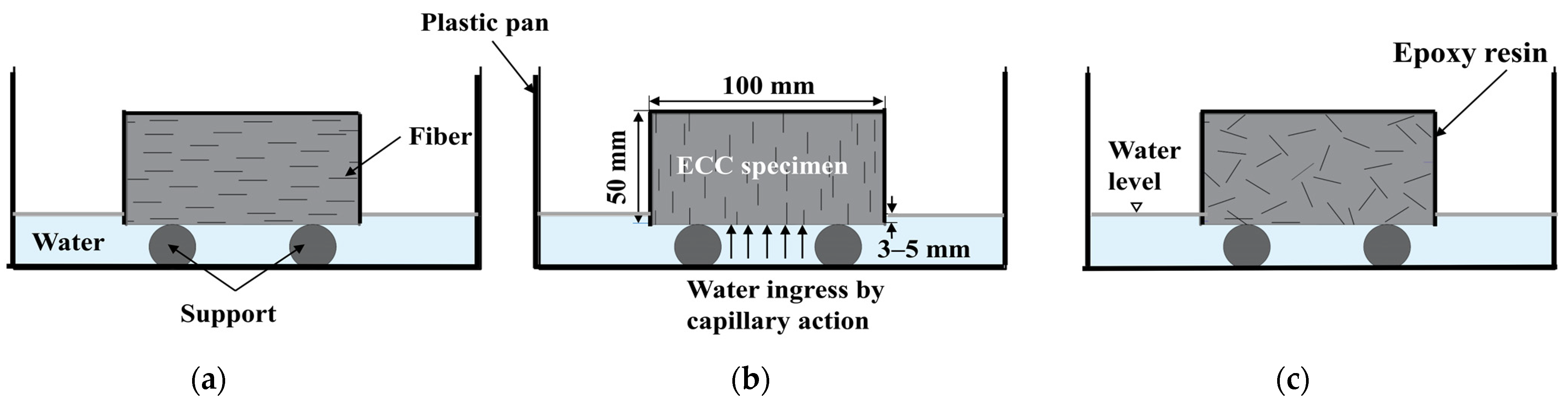

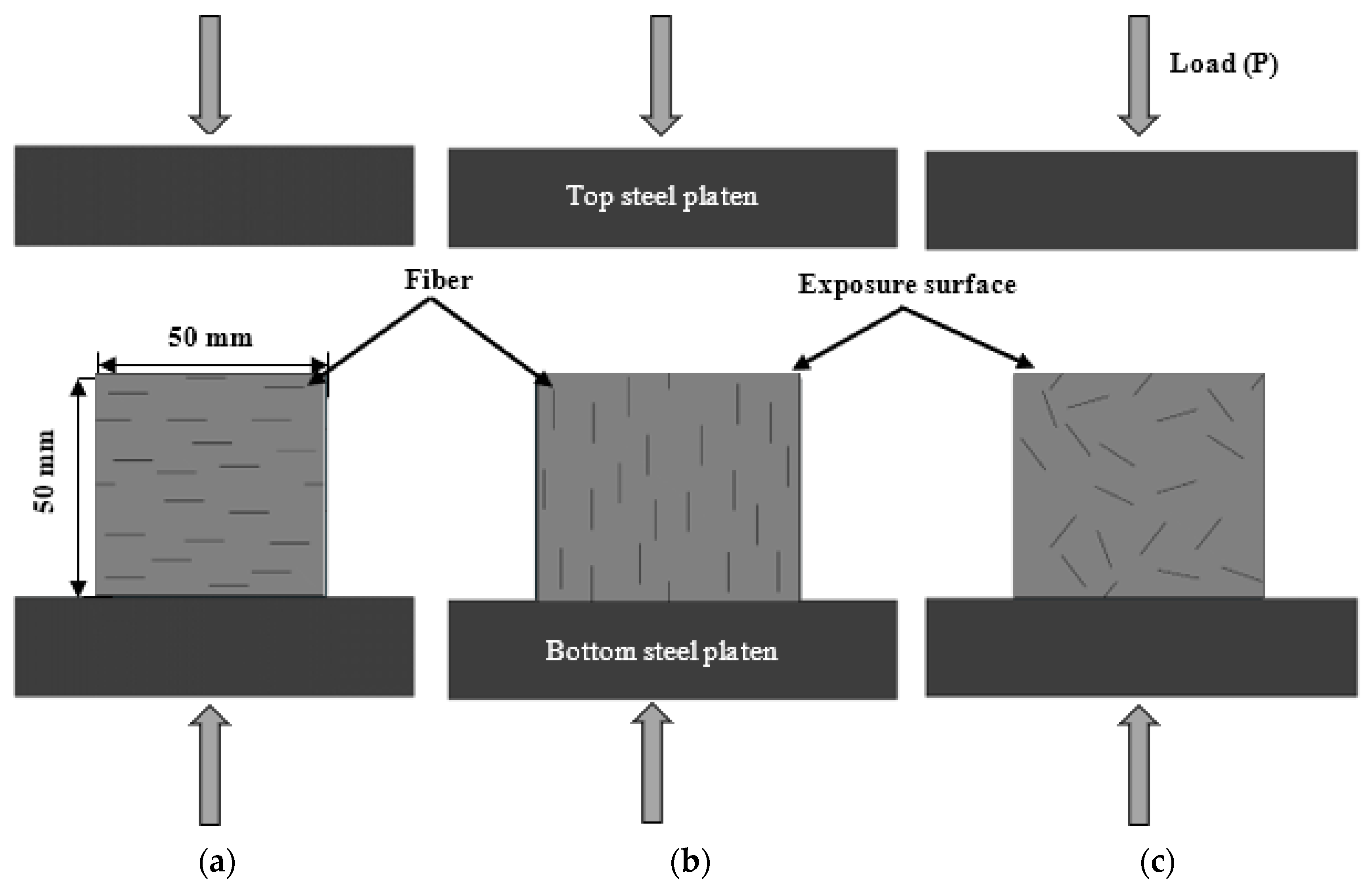

3.1. Water Absorption

3.2. Water Sorptivity

3.3. Chloride Penetration

3.4. Sulfate Attack

3.5. Freeze–Thaw Resistance

4. Results and Discussion

4.1. Water Absorption

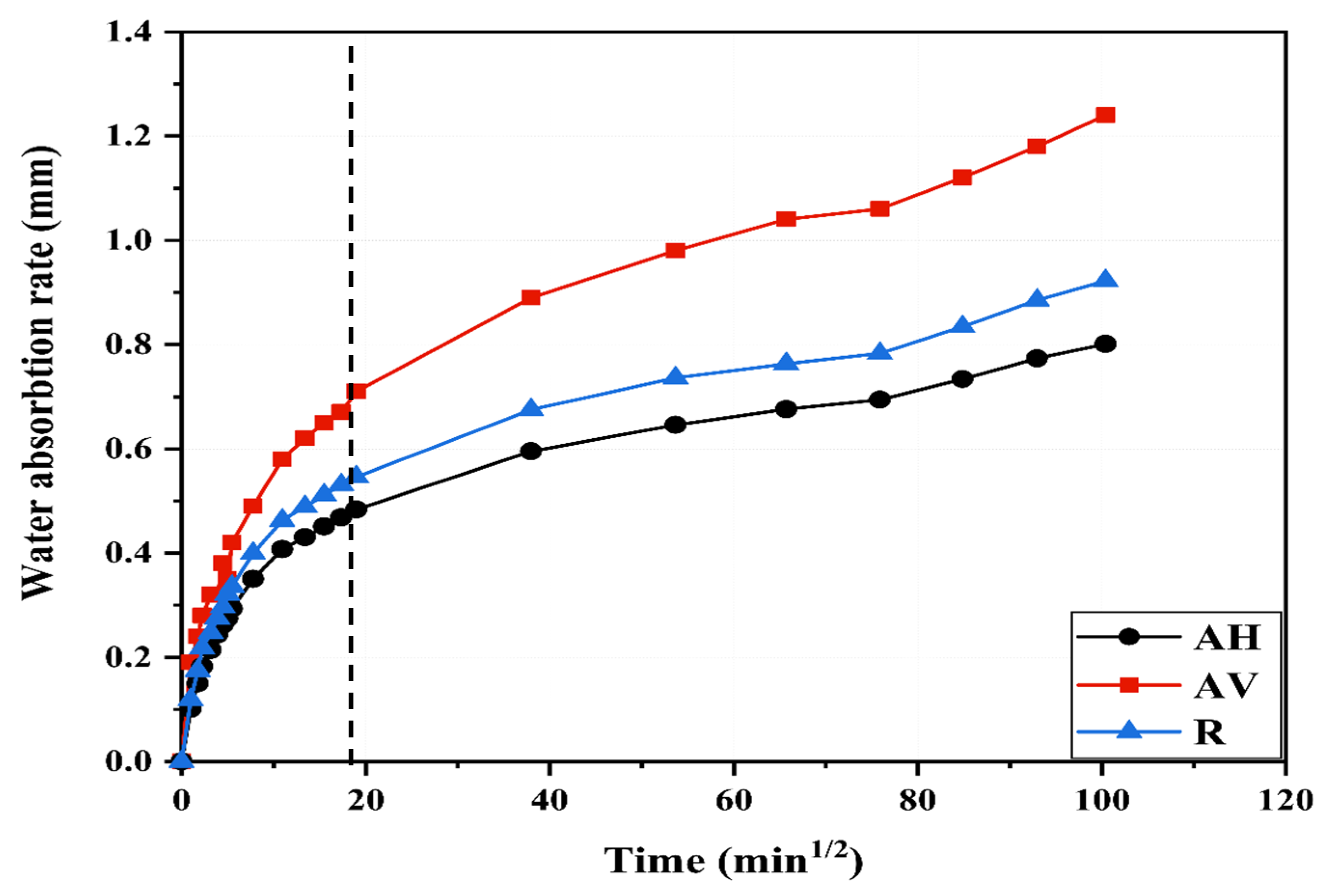

4.2. Water Sorptivity

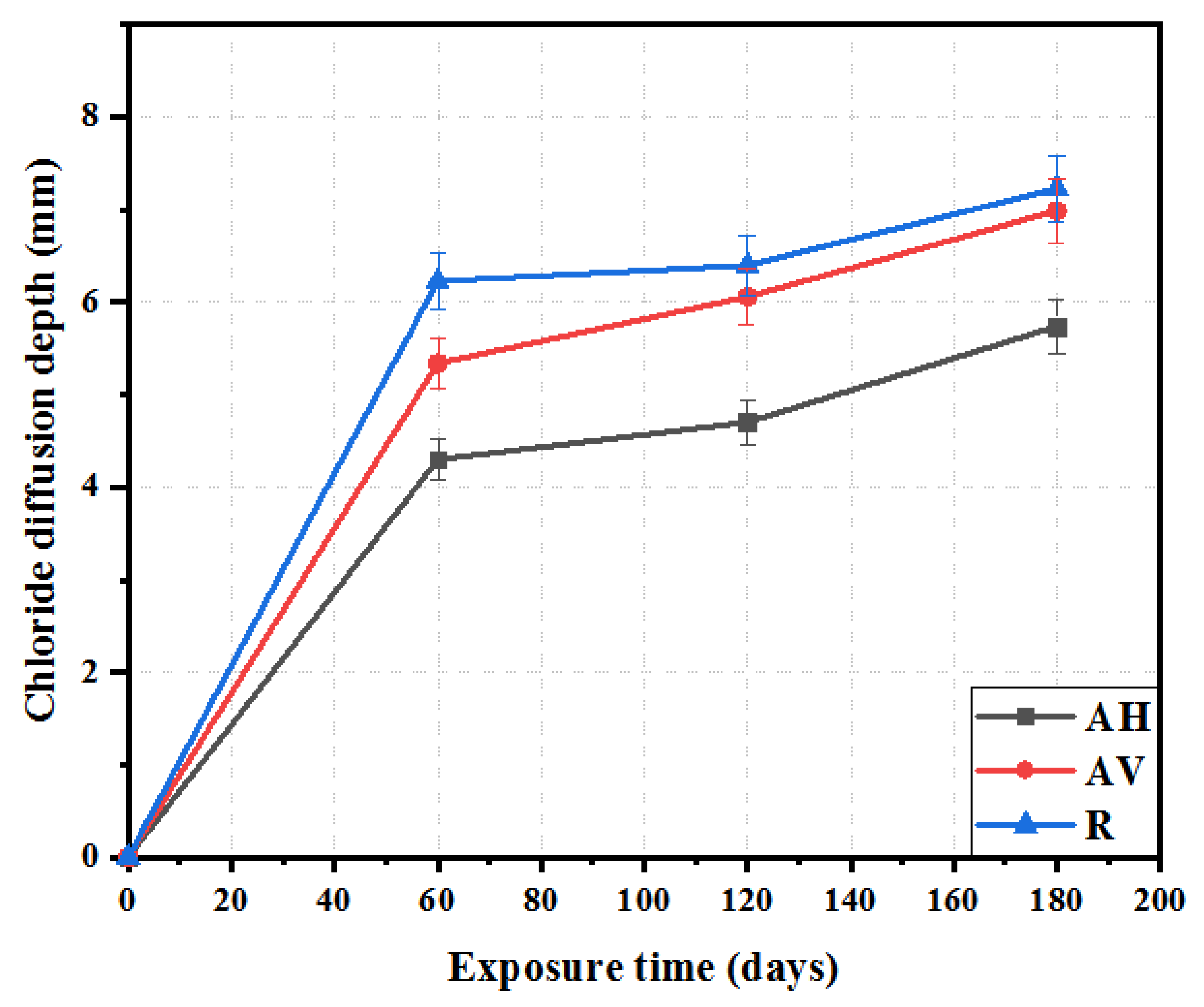

4.3. Chloride Penetration

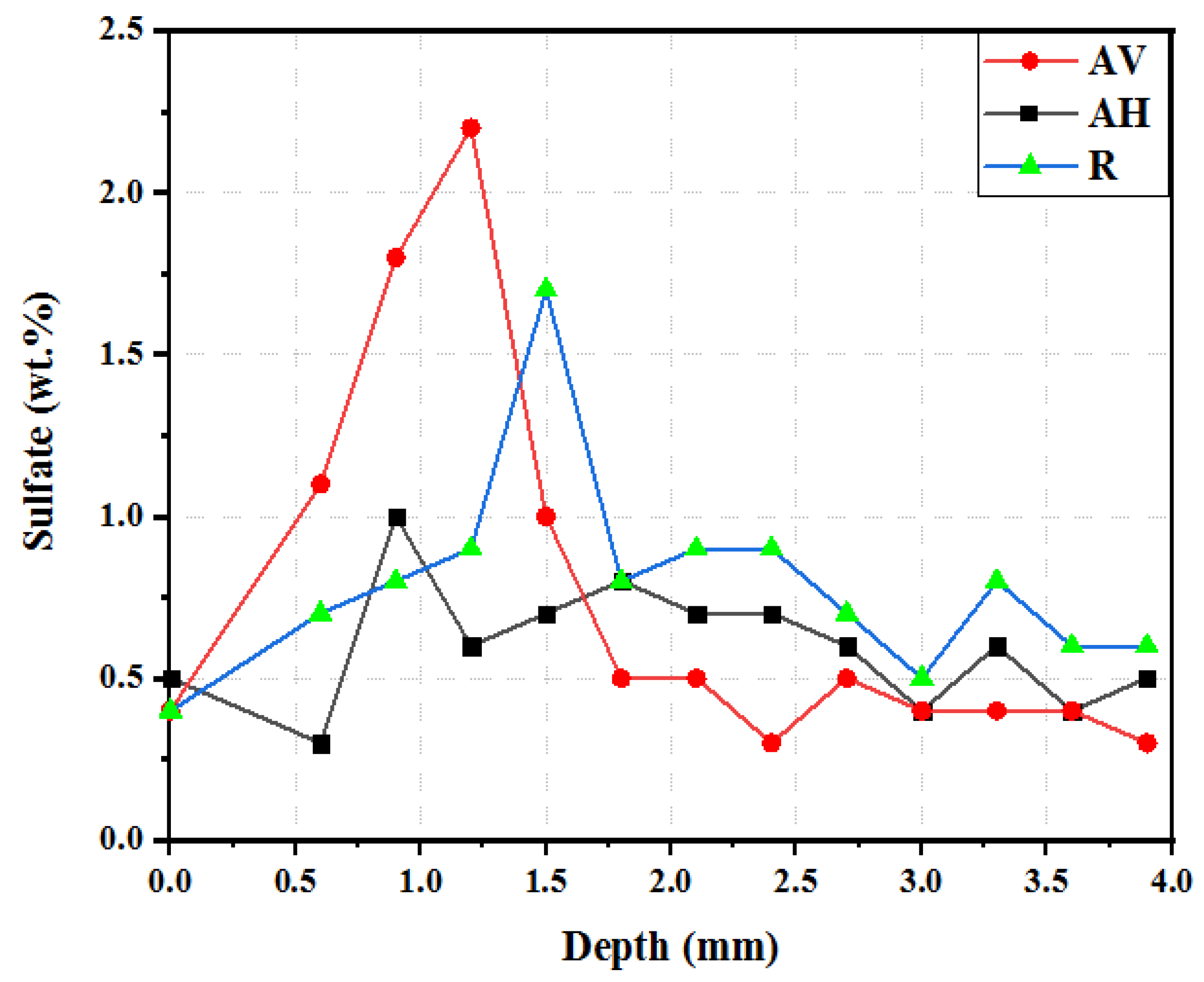

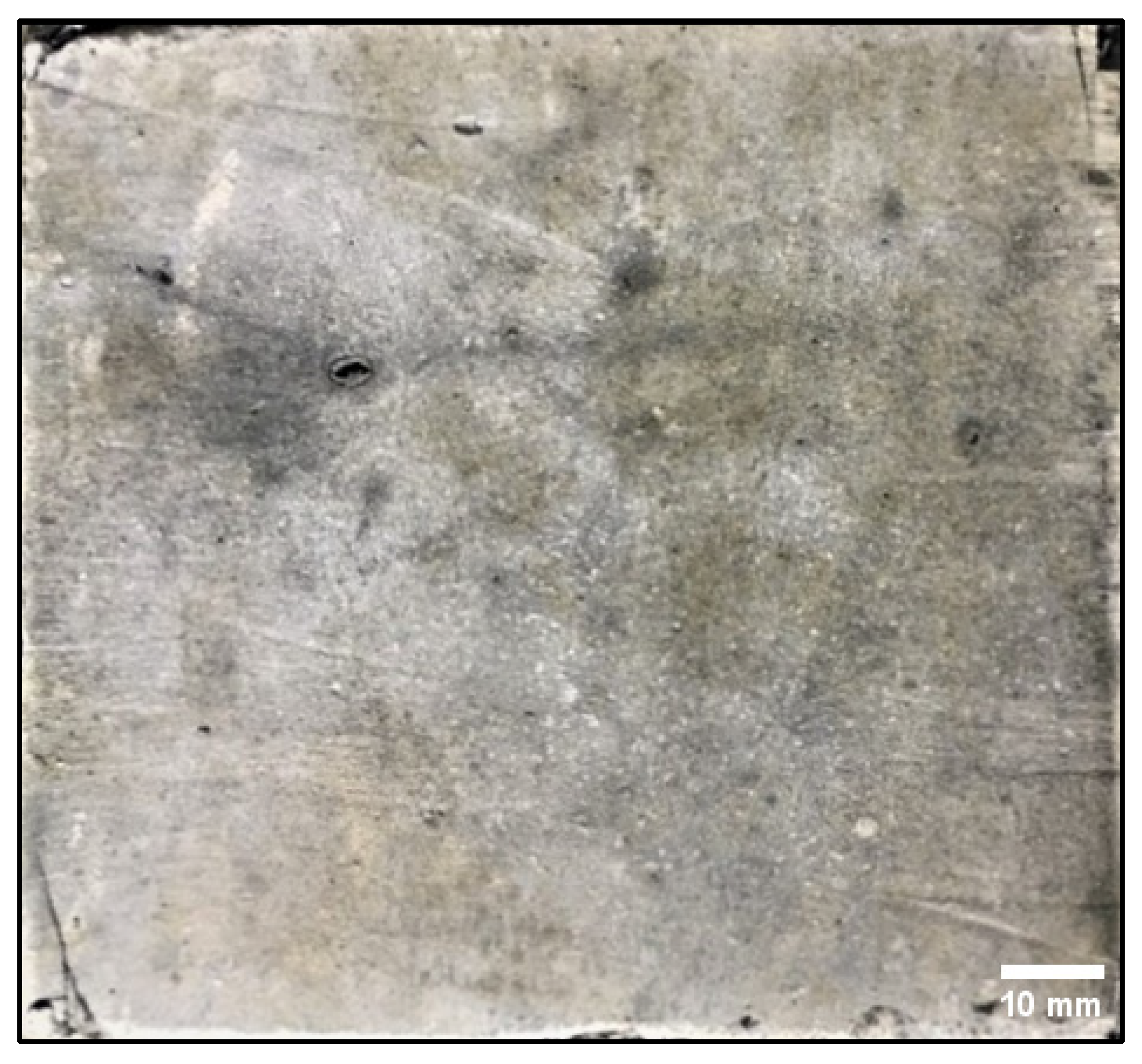

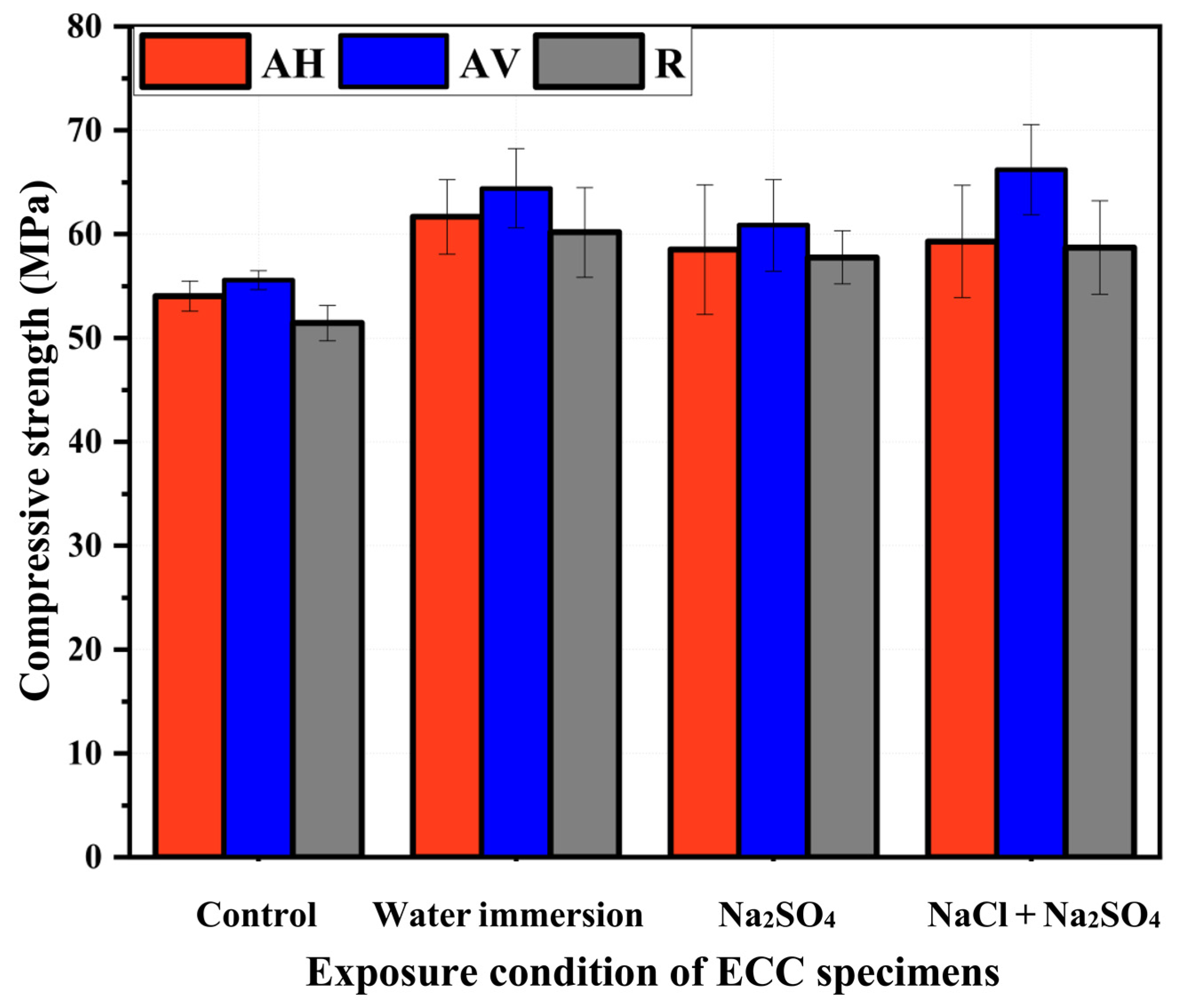

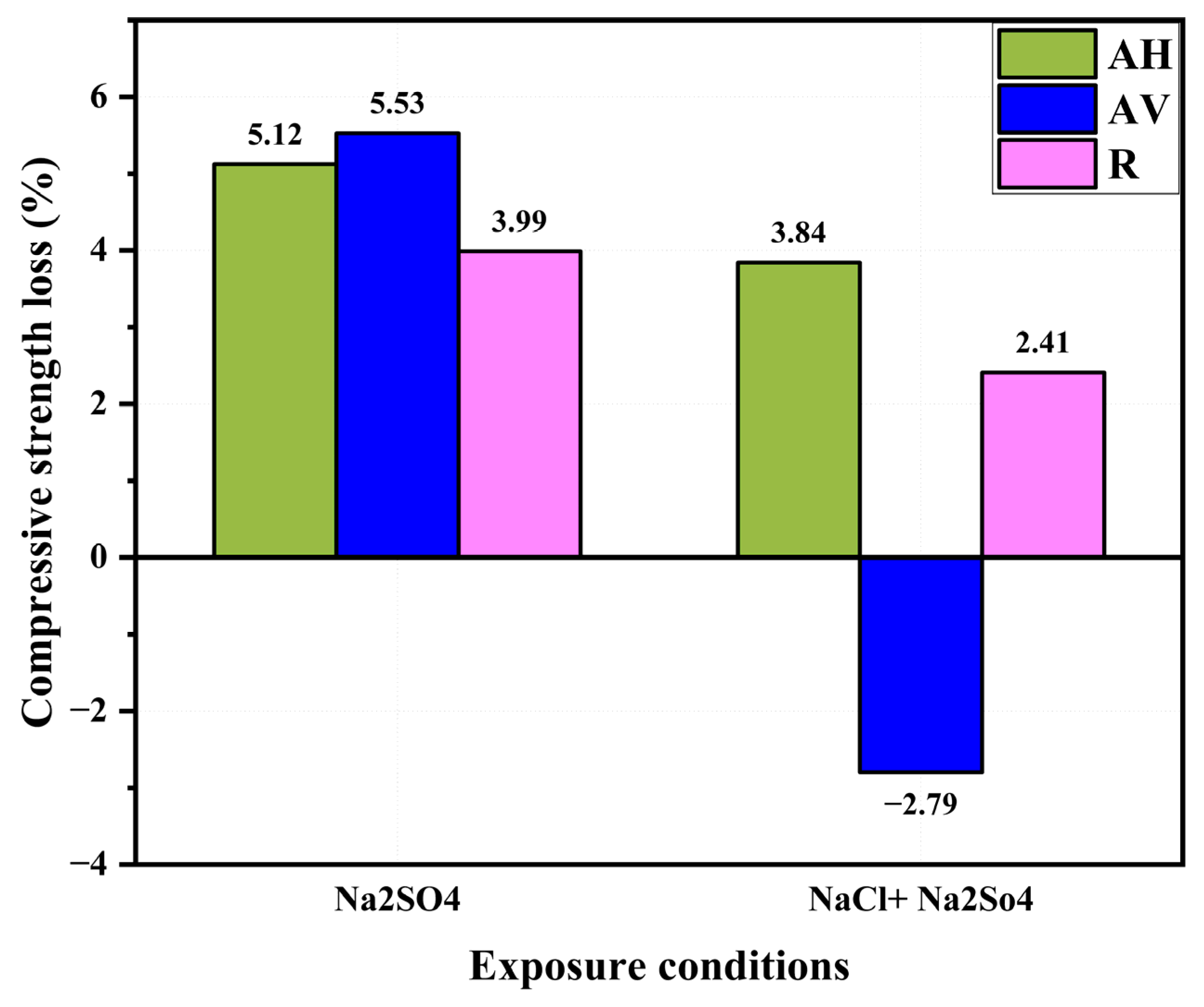

4.4. Sulfate Attack

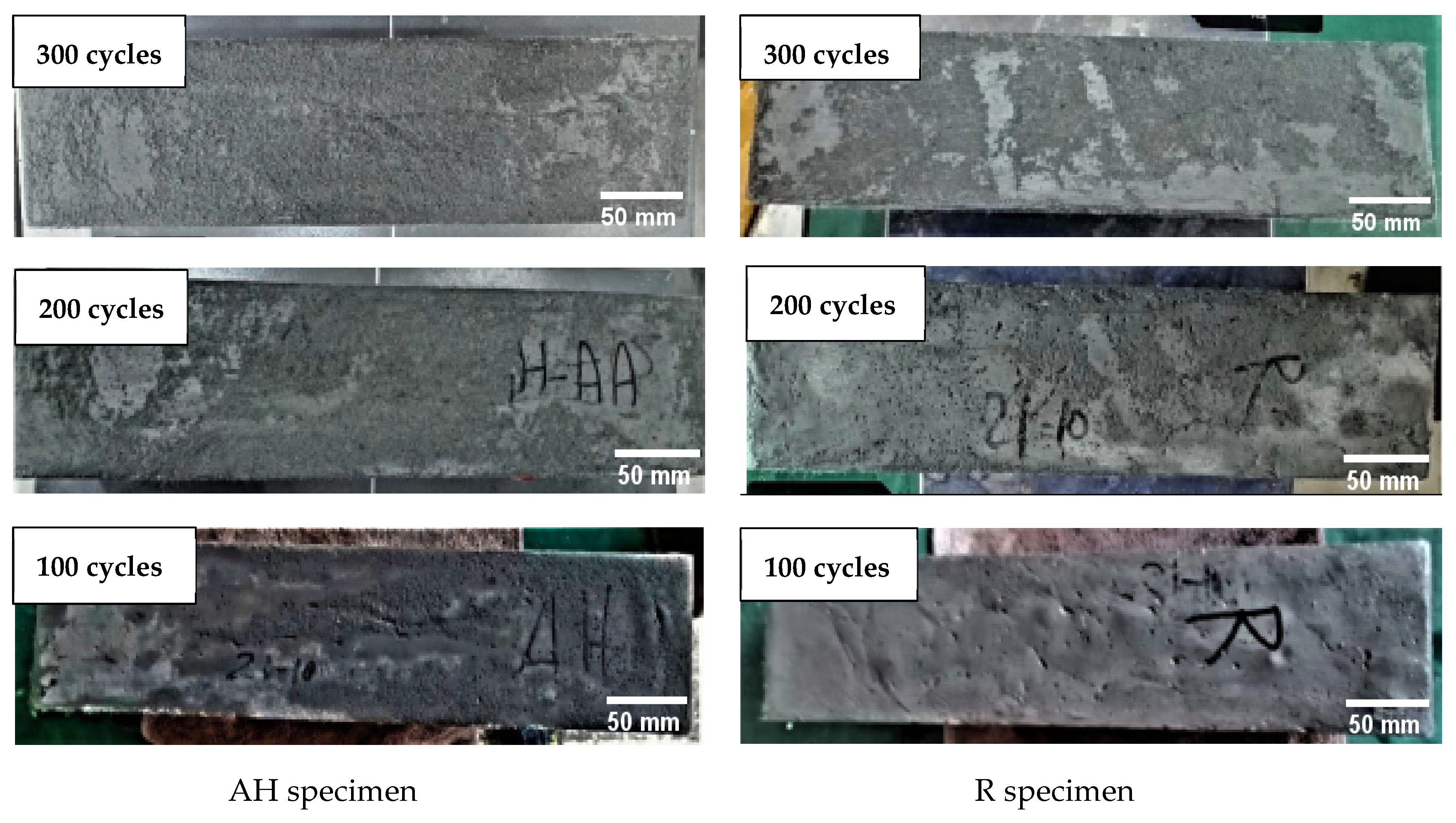

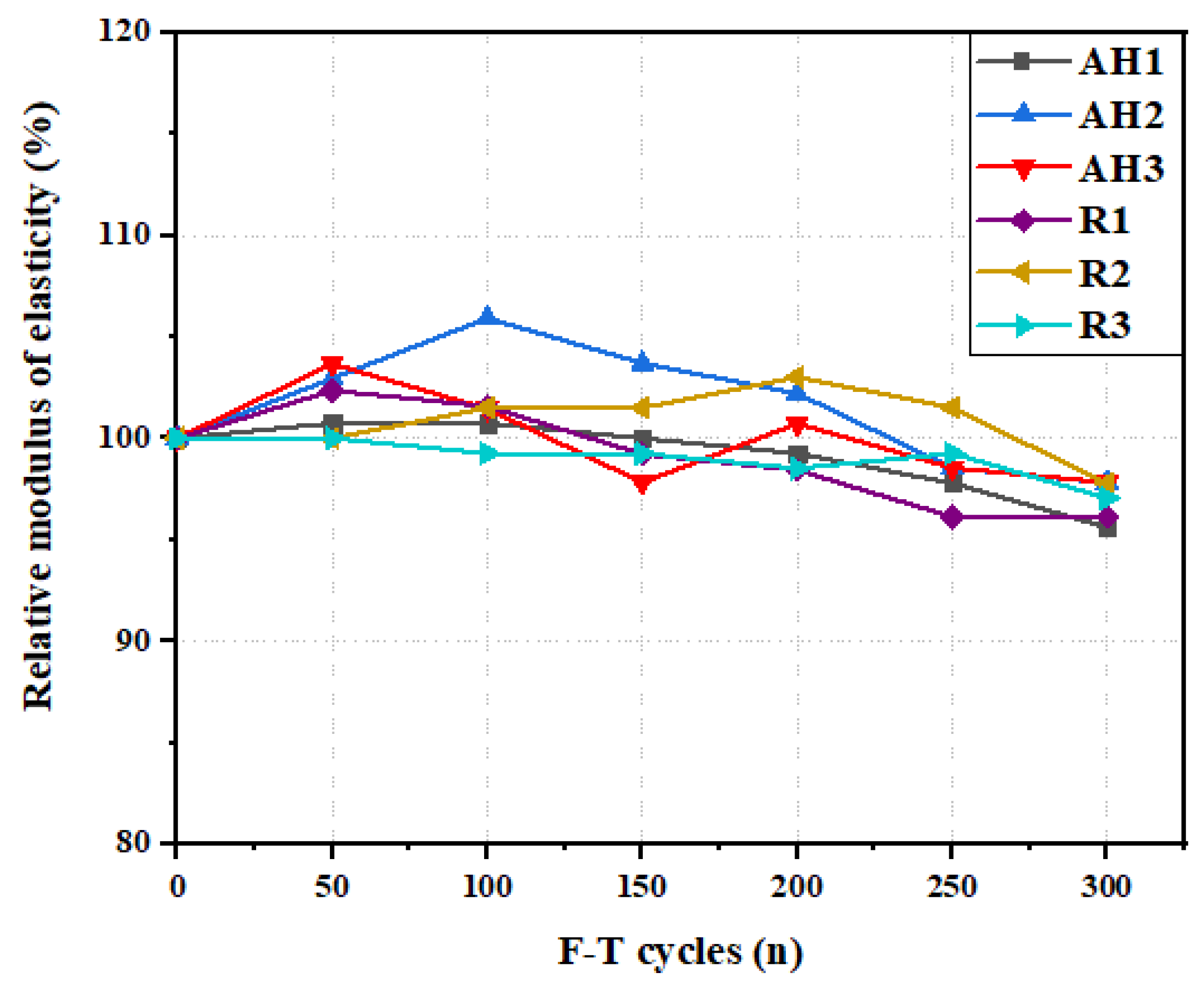

4.5. Freeze–Thaw Resistance

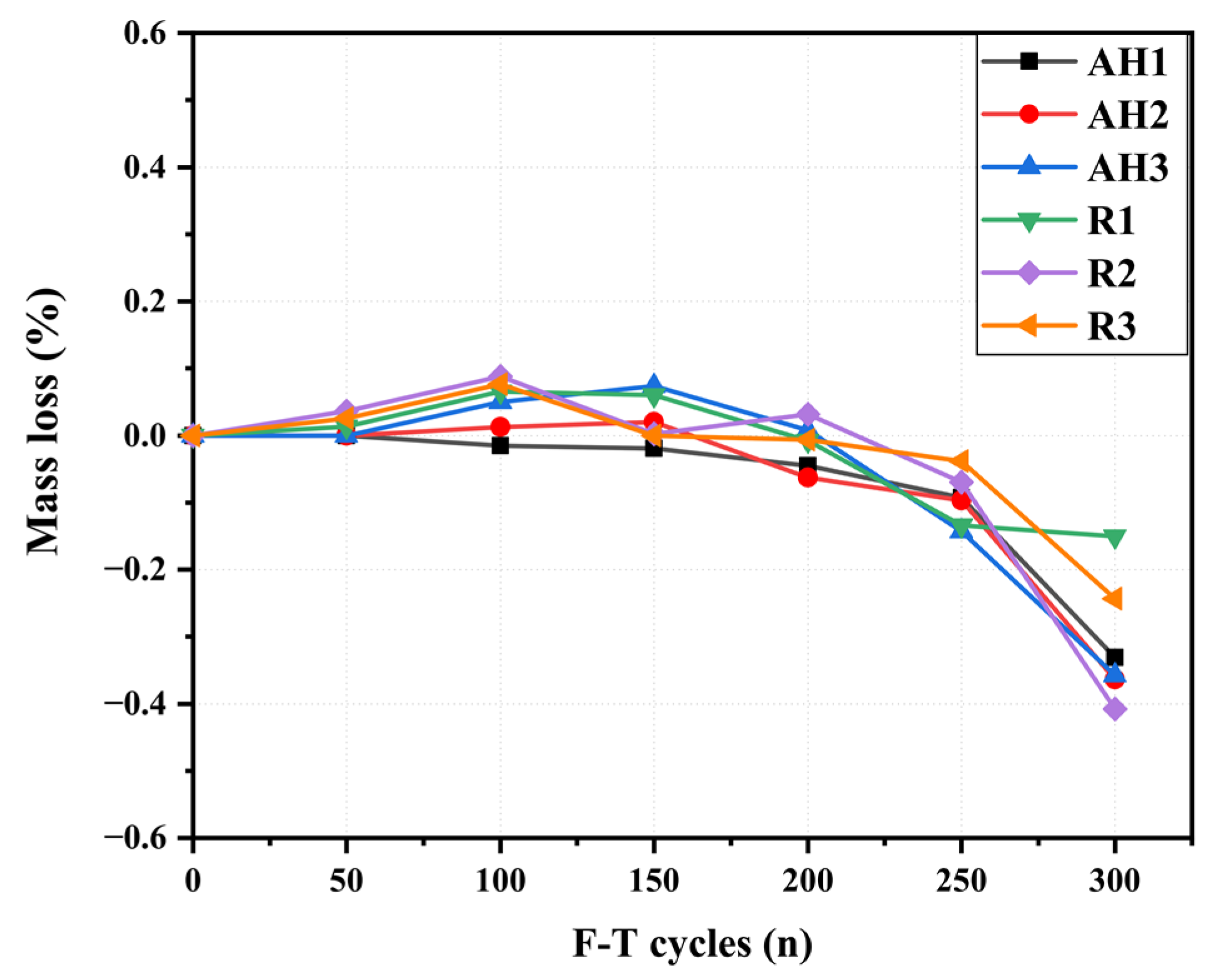

4.5.1. Mass Loss

4.5.2. Relative Dynamic Elastic Modulus

5. Conclusions

- Orienting fibers perpendicular to the water path in the ECC delays water migration into the matrix. After 28 days of immersion, the water absorption capacity of the AH specimens is 5.04%, which is 7.01% and 8.53% lower than that of the AV and R specimens, respectively.

- Fiber direction plays a crucial role in sorptivity. When the fibers are aligned perpendicular to the water path, the sorptivity index of the ECC is clearly reduced, indicating that the oriented-fiber AH specimens can significantly delay sorptivity. After 7 days, the sorptivity of the AH specimens is 0.008 mm/t0.5, which is 13% and 35% lower than that of the R and AV specimens, respectively.

- Controlling the fiber orientation improves the chloride resistance of the ECC. The chloride penetration depth of the AH specimens is 5.7 mm, which is 13.6% and 20.8% lower than that of the AV and R specimens, respectively.

- The fibers aligned perpendicular to the penetration path can delay sulfate migration. After 180 days of exposure, the AV specimens show the highest peak in the sulfate profile compared to the AH and R specimens. In addition, all the ECC specimens exposed to the Na2SO4 solution do not show any surface cracking.

- The AV specimens under the Na2SO4 + NaCl condition gain more compressive strength than the other specimens, which is 2.8% and 9.5% greater than the specimens under water and the Na2SO4 solution, respectively.

- The fiber direction has no significant effect on the freezing–thawing resistance of the ECC. A slight difference in the mass loss between the AH and R specimens, 0.07%, is observed.

- The ECC with a controlled fiber alignment could be utilized in applications where moisture resistance is crucial, such as in hydraulic structures, foundations, or coastal environments where chloride exposure is a concern. In future studies, mechanical properties such as ductility, tensile strain capacity, and toughness as a function of fiber orientation under different environmental conditions will be performed for worthwhile applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wen, Z.; Was, M.; He, Z.; Suleyman Goke, L.V. Time-Dependent Fresh Properties Characterization of 3D Printing Engineered Cementitious Composites (3DP-ECC): On the Evaluation of Buildability. Cem. Concr. Compos. 2022, 133, 104704. [Google Scholar]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital Concrete: A Review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Yu, K.; Mcgee, W.; Yan, T.; Zhu, H.; Li, V.C. 3D-Printable Engineered Cementitious Composites (3DP-ECC): Fresh and Hardened Properties. Cem. Concr. Res. 2021, 143, 106388. [Google Scholar] [CrossRef]

- Asprone, D.; Menna, C.; Bos, F.P.; Salet, T.A.M.; Mata-Falcón, J.; Kaufmann, W. Rethinking Reinforcement for Digital Fabrication with Concrete. Cem. Concr. Res. 2018, 112, 111–121. [Google Scholar] [CrossRef]

- Niu, H.M.; Xing, Y.M.; Zhao, Y. Effects of Processing on Fiber Distribution and Mechanical Performance of Engineered Cementitious Composites(ECC). Adv. Mater. Res. 2013, 709, 122–126. [Google Scholar] [CrossRef]

- Zhou, J.; Qian, S.; Ye, G.; Copuroglu, O.; Van Breugel, K.; Li, V.C. Improved Fiber Distribution and Mechanical Properties of Engineered Cementitious Composites by Adjusting the Mixing Sequence. Cem. Concr. Compos. 2012, 34, 342–348. [Google Scholar] [CrossRef]

- Meng, D.; Huang, T.; Zhang, Y.X.; Lee, C.K. Mechanical Behaviour of a Polyvinyl Alcohol Fibre Reinforced Engineered Cementitious Composite (PVA-ECC) Using Local Ingredients. Constr. Build. Mater. 2017, 141, 259–270. [Google Scholar] [CrossRef]

- Fischer, G.; Li, V.C. Deformation Behavior of Fiber-Reinforced Polymer Reinforced Engineered Cementitious Composite (ECC) Flexural Members under Reversed Cyclic Loading Conditions. ACI Struct. J. 2003, 100, 25–35. [Google Scholar]

- Sidiq, A.; Gravina, R.J.; Setunge, S.; Giustozzi, F. High-Efficiency Techniques and Micro-Structural Parameters to Evaluate Concrete Self-Healing Using X-Ray Tomography and Mercury Intrusion Porosimetry: A Review. Constr. Build. Mater. 2020, 252, 119030. [Google Scholar] [CrossRef]

- Tosun-Felekoǧlu, K.; Felekoǧlu, B.; Ranade, R.; Lee, B.Y.; Li, V.C. The Role of Flaw Size and Fiber Distribution on Tensile Ductility of PVA-ECC. Compos. Part B Eng. 2014, 56, 536–545. [Google Scholar] [CrossRef]

- Nateghi-A, F.; Ahmadi, M.H.; Dehghani, A. Experimental Study on Improved Engineered Cementitious Composite Using Local Material. Mater. Sci. Appl. 2018, 9, 315–329. [Google Scholar] [CrossRef]

- Sidiq, A.; Gravina, R.; Giustozzi, F. Is Concrete Healing Really Efficient? A Review. Constr. Build. Mater. 2019, 205, 257–273. [Google Scholar] [CrossRef]

- Linde, A.; Overmeir, V.; Figueiredo, S.C.; Šavija, B.; Bos, F.P.; Schlangen, E. Design and Analyses of Printable Strain Hardening Cementitious Composites with Optimized Particle Size Distribution. Constr. Build. Mater. 2022, 324, 126411. [Google Scholar] [CrossRef]

- Li, V.C.; Bos, F.P.; Yu, K.; Mcgee, W.; Yan, T.; Chaves, S.; Nefs, K.; Mechtcherine, V.; Naidu, V.; Pan, J.; et al. On the Emergence of 3D Printable Engineered, Strain Hardening Cementitious Composites (ECC/SHCC). Cem. Concr. Res. 2020, 132, 106038. [Google Scholar] [CrossRef]

- Ogura, H.; Nerella, V.N.; Mechtcherine, V. Developing and Testing of Strain-Hardening Cement-Based Composites (SHCC) in the Context of 3D-Printing. Materials 2018, 11, 1375. [Google Scholar] [CrossRef]

- Zhu, B.; Pan, J.; Nematollahi, B.; Zhou, Z.; Zhang, Y.; Sanjayan, J. Development of 3D Printable Engineered Cementitious Composites with Ultra-High Tensile Ductility for Digital Construction. Mater. Des. 2019, 181, 108088. [Google Scholar] [CrossRef]

- Bao, Y.; Xu, M.; Soltan, D.; Xia, T.; Shih, A.; Clack, H.L.; Li, V.C. Three-Dimensional Printing Multifunctional Engineered Cementitious Composites (ECC) for Structural Elements. In Proceedings of the RILEM International Conference on Concrete and Digital Fabrication, Zurich, Switzerland, 10–12 September 2019; pp. 115–128. [Google Scholar]

- Pang, Z.; Lu, C.; Li, B.; Wang, J. A Multiscale Model for Quantifying Fiber Orientation Effects on the Tensile Properties of 3D Printed Engineered Cementitious Composites (3DP-ECC). J. Build. Eng. 2023, 68, 106090. [Google Scholar] [CrossRef]

- Lu, C.; Leung, C.K.Y. Cement and Concrete Research Theoretical Evaluation of Fi Ber Orientation and Its Effects on Mechanical Properties in Engineered Cementitious Composites (ECC) with Various Thicknesses. Cem. Concr. Res. 2017, 95, 240–246. [Google Scholar] [CrossRef]

- Soltan, D.G.; Li, V.C. A Self-Reinforced Cementitious Composite for Building-Scale 3D Printing. Cem. Concr. Compos. 2018, 90, 1–13. [Google Scholar] [CrossRef]

- Kanarska, Y.; Duoss, E.B.; Lewicki, J.P.; Rodriguez, J.N.; Wu, A. Fiber Motion in Highly Confined Flows of Carbon Fiber and Non-Newtonian Polymer. J. Nonnewton. Fluid Mech. 2019, 265, 41–52. [Google Scholar] [CrossRef]

- Tawfek, A.M.; Ge, Z.; Yuan, H.; Zhang, N. Influence of Fiber Orientation on the Mechanical Responses of Engineering Cementitious Composite (ECC) under Various Loading Conditions. J. Build. Eng. J. 2023, 63, 105518. [Google Scholar] [CrossRef]

- De Koker, D.; van Zijl, G. Extrusion of Engineered Cement-Based Composite Material. Proc. BEFIB 2004, 20, 1301–1310. [Google Scholar]

- Ge, Z.; Tawfek, A.M.; Zhang, H.; Yang, Y.; Yuan, H.; Sun, R.; Wang, Z. Influence of an Extrusion Approach on the Fiber Orientation and Mechanical Properties of Engineering Cementitious Composite. Constr. Build. Mater. 2021, 306, 124876. [Google Scholar] [CrossRef]

- Soroushian, P. Evaluation of Normal-Weight and Light-Weight Fillers in Extruded Cellulose Fiber Cement Products. Cem. Concr. Compos. 2006, 28, 69–76. [Google Scholar] [CrossRef]

- Lei, D.Y.; Guo, L.P.; Chen, B.; Curosu, I.; Mechtcherine, V. The Connection between Microscopic and Macroscopic Properties of Ultra-High Strength and Ultra-High Ductility Cementitious Composites (UHS-UHDCC). Compos. Part B Eng. 2019, 164, 144–157. [Google Scholar] [CrossRef]

- Deshpande, A.A.; Kumar, D.; Mourougassamy, A.; Ranade, R. Development of a Steel-PVA Hybrid Fiber SHCC; University at Buffalo: Buffalo, NY, USA, 2018; Volume 15, pp. 195–201. Available online: https://alokdeshpande.info/Development%20of%20a%20Steel-PVA%20Hybrid%20Fiber%20SHCC%20v1.pdf (accessed on 1 January 2018).

- Ramezanianpour, A.A.; Esmaeili, M.; Ghahari, S.A.; Najafi, M.H. Laboratory Study on the Effect of Polypropylene Fiber on Durability, and Physical and Mechanical Characteristic of Concrete for Application in Sleepers. Constr. Build. Mater. 2013, 44, 411–418. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.; Alaskar, A. Enhancement of Strength and Transport Properties of a Novel Preplaced Aggregate Fiber Reinforced Concrete by Adding Waste Polypropylene Carpet Fibers. J. Build. Eng. 2020, 27, 101003. [Google Scholar] [CrossRef]

- Akid, A.S.M.; Hossain, S.; Munshi, M.I.U.; Elahi, M.M.A.; Sobuz, M.H.R.; Tam, V.W.Y.; Islam, M.S. Assessing the Influence of Fly Ash and Polypropylene Fiber on Fresh, Mechanical and Durability Properties of Concrete. J. King Saud Univ. Eng. Sci. 2021, 1018–3639. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Qian, R.; Liu, G.; Du, H. Influence of Steel Fiber on the Water Absorption of 3D Printed Concrete. Mater. Lett. 2023, 330, 133252. [Google Scholar] [CrossRef]

- ASTM Standard C 642-06; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 1997; pp. 1–3.

- Test, C.C.; Drilled, T.; Ag, C.; Test, C.C.; Concrete, H.; Mass, D. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic. ASTM Stand. 2013, 41, 1–6. [Google Scholar] [CrossRef]

- Fu, C. Chloride Resistance and Binding Capacity of Cementitious Materials Containing High Volumes of Fly Ash and Slag. Mag. Concr. Res. 2019, 73, 55–68. [Google Scholar] [CrossRef]

- NT BUILD. Concrete, Hardened: Accelerated Chloride Penetration; Nordtest: Esbo, Finland, 1995; Volume 443. [Google Scholar]

- Liu, H.; Zhang, Q.; Li, V.; Su, H.; Gu, C. Durability Study on Engineered Cementitious Composites (ECC) under Sulfate and Chloride Environment. Constr. Build. Mater. 2017, 133, 171–181. [Google Scholar] [CrossRef]

- Nasrazadani, S.; Hassani, S. Modern Analytical Techniques in Failure Analysis of Aerospace, Chemical, and Oil and Gas Industries; Elsevier: Oxford, UK, 2016; Available online: https://www.sciencedirect.com/science/article/abs/pii/B9780081001172000108 (accessed on 4 July 2023). [CrossRef]

- Rokugo, K.; Kanda, T.; Yokota, H.; Sakata, N. Applications and Recommendations of High Performance Fiber Reinforced Cement Composites with Multiple Fine Cracking (HPFRCC) in Japan. Mater. Struct. 2009, 42, 1197–1208. [Google Scholar] [CrossRef]

- Freezing, R.; Mortar, H.; Speci, C.C.T.; Statements, B. Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing 1. ASTM Standard 97AD, 04.02. Available online: https://assets.master-builders-solutions.com/en-us/mbs-astm-c666_06_24_2020.pdf (accessed on 1 June 1997).

- Martys, N.S.; Ferraris, C.E. Capillary Transport in Mortars and Concrete. Cem. Concr. Res. 1997, 27, 747–760. [Google Scholar] [CrossRef]

- He, S.; Li, Z.; Yang, E. Quantitative Characterization of Anisotropic Properties of the Interfacial Transition Zone (ITZ) between Micro Fi Ber and Cement Paste. Cem. Concr. Res. 2019, 122, 136–146. [Google Scholar] [CrossRef]

- Muñoz, E. Water Absorption Behaviour and Its Effect on the Mechanical Properties of Flax Fibre Reinforced Bioepoxy Composites. Int. J. Polym. Sci. 2015, 2015, 16–18. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Science and Effect of Water Absorption on the Mechanical Properties of Hemp Fibre Reinforced Unsaturated Polyester Composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Mohammadi, B. Development of Concrete Water Absorption Testing for Quality Control School of Graduate Studies. Master’s Thesis, Concordia University, Montreal, QC, Canada, 2013. [Google Scholar]

- Mohamad, F.; Evans, R. Assessment of Sorptivity Coefficient in Concrete Cubes. Discov. Publ. 2018, 54, 377–386. [Google Scholar]

- Liu, J.; Song, Z.; Li, B.; Ren, J.; Chen, F.; Xiao, M. Experimental Study on the Microstructure of Coal with Different Particle Sizes. Energies 2022, 15, 4043. [Google Scholar] [CrossRef]

- Hall, C. Anomalous Diffusion in Unsaturated Flow: Fact or Fiction? Cem. Concr. Res. 2007, 37, 378–385. [Google Scholar] [CrossRef]

- Alderete, N.M.; Zaccardi, Y.A.V.; Belie, N. Mechanism of Long-Term Capillary Water Uptake in Cementitious Materials. Cem. Concr. Compos. 2019, 106, 103448. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Zhang, P.; Ma, Y.; Zhao, T.; Wang, H.; Zhang, Z. Water Absorption and Chloride Diffusivity of Concrete under the Coupling Effect of Uniaxial Compressive Load and Freeze–Thaw Cycles. Constr. Build. Mater. 2019, 209, 566–576. [Google Scholar] [CrossRef]

- Ghasemzadeh, F.; Rashetnia, R.; Smyl, D.; Pour-ghaz, M. A Comparison of Methods to Evaluate Mass Transport in Damaged Mortar. Cem. Concr. Compos. 2016, 70, 119–129. [Google Scholar] [CrossRef]

- Yu, Z.; Ye, G. New Perspective of Service Life Prediction of Fly Ash Concrete. Constr. Build. Mater. 2013, 48, 764–771. [Google Scholar] [CrossRef]

- Stanish, K.D.; Hooton, R.D. Testing the Chloride Penetration Resistance of Concrete: A Literature Review. 2001. Available online: https://rosap.ntl.bts.gov/view/dot/35971 (accessed on 28 August 2001).

- Šavija, B.; Schlangen, E.; Pacheco, J.; Millar, S.; Eichler, T.; Wilsch, G. Chloride Ingress in Cracked Concrete: A Laser Induced Breakdown Spectroscopy (LIBS) Study. J. Adv. Concr. Technol. 2014, 12, 135–144. [Google Scholar] [CrossRef]

- Yu, C.; Sun, W.; Scrivener, K. Mechanism of Expansion of Mortars Immersed in Sodium Sulfate Solutions. Cem. Concr. Res. 2013, 43, 105–111. [Google Scholar] [CrossRef]

- Song, M.; Zhang, C.; Mi, H.; Wang, K.; Wang, S. Diffusion Concentration Distribution and Numerical Simulation of Sulfate Ions in Polypropylene Fiber Concrete. Vibroeng. Procedia 2022, 42, 95–101. [Google Scholar] [CrossRef]

- Shi, C.; Hu, X.; Wang, X.; Wu, Z.; Schutter, G. Effects of Chloride Ion Binding on Microstructure of Cement Pastes. J. Mater. Civ. Eng. 2014, 29, 04016183. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Chandrasekar, M.; Aisyah, H.A.; Rafiqah, S.A.; Ilyas, R.A. Effect of Fiber Orientation and Fiber Loading on the Mechanical and Thermal Properties of Sugar Palm Yarn Fiber Reinforced Unsaturated Polyester Resin Composites. Polimery 2020, 65, 115–124. [Google Scholar] [CrossRef]

- Sadeghian, P.; Rahai, A.R.; Ehsani, M.R. Effect of Fiber Orientation on Compressive Behavior of CFRP-Confined Concrete Columns. J. Reinf. Plast. Compos. 2010, 29, 1335–1346. [Google Scholar] [CrossRef]

- Al-amoudi, O.S.B. Role of Chloride Ions on Expansion and Strength Reduction in Plain and Blended Cements in Sulfate Environments. Constr. Build. Mater. 1995, 9, 25–33. [Google Scholar] [CrossRef]

- Tian, W.; Han, N. Experiment Analysis of Concrete’s Mechanical Property Deterioration Suffered Sulfate Attack and Drying-Wetting Cycles. Adv. Mater. Sci. Eng. 2017, 5673985. [Google Scholar] [CrossRef]

- Sherir, M.A.A.; Hossain, K.M.A.; Lachemi, M. Fresh State, Mechanical & Durability Properties of Strain Hardening Cementitious Composite Produced with Locally Available Aggregates and High Volume of Fly Ash. Constr. Build. Mater. 2018, 189, 253–264. [Google Scholar] [CrossRef]

- Karahan, O.; Lachemi, M.; Hossain, K.M.A.; Duran, C. Dual Effectiveness of Freezing—Thawing and Sulfate Attack on High-Volume. Compos. Part B 2013, 45, 1384–1390. [Google Scholar] [CrossRef]

- Rong, H.; Wang, C. Micro-Structural Improvement-Based Experimental Study on Durability of Cement Concrete Material. Water Resour. Hydropower Eng. 2019, 50, 155–159. [Google Scholar]

- Wang, Y.; Yu, M.A.Z. Durability of Reactive Powder Concrete under Chloride-Salt Freeze—Thaw Cycling. Mater. Struct. 2017, 50, 1–9. [Google Scholar] [CrossRef]

- Şahmaran, M.; Lachemi, M.; Li, V.C. Assessing the Durability of Engineered Cementitious Composites under Freezing and Thawing Cycles. J. ASTM Int. 2009, 6, 1–13. [Google Scholar] [CrossRef]

- Zhong, J.; Shi, J.; Shen, J.; Zhou, G.; Wang, Z. Investigation on the Failure Behavior of Engineered Cementitious Composites under Freeze-Thaw Cycles. Mater. Artic. 2019, 12, 1808. [Google Scholar] [CrossRef]

| Compositions | SiO2 | Al2O3 | Fe2O3 | CaO | SO3 | MgO | TiO2 | MnO | P2O5 | K2O |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 22.66 | 6.53 | 3.05 | 58.26 | 4.51 | 3.00 | 0.55 | 0.33 | 0.13 | 0.76 |

| Fly Ash | 54.59 | 25.8 | 6.96 | 5.49 | 1.83 | 0.99 | 1.26 | 0.11 | 0.27 | 1.76 |

| Cement | Fly Ash | Sand | Fiber Content | Water | Superplasticizer | VMA | w/b |

|---|---|---|---|---|---|---|---|

| 568 | 682 | 455 | 26 | 325 | 6.25 | 0.57 | 0.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tawfek, A.M.; Ge, Z.; Li, J.; Zhang, K.; Jiang, N.; Shao, Y.; Ling, Y.; Šavija, B. Influence of Fiber Orientation on the Water and Ions Transportation of Engineered Cementitious Composite (ECC). Materials 2023, 16, 4877. https://doi.org/10.3390/ma16134877

Tawfek AM, Ge Z, Li J, Zhang K, Jiang N, Shao Y, Ling Y, Šavija B. Influence of Fiber Orientation on the Water and Ions Transportation of Engineered Cementitious Composite (ECC). Materials. 2023; 16(13):4877. https://doi.org/10.3390/ma16134877

Chicago/Turabian StyleTawfek, Abdullah M., Zhi Ge, Jian Li, Kangkang Zhang, Nengdong Jiang, Yingxuan Shao, Yifeng Ling, and Branko Šavija. 2023. "Influence of Fiber Orientation on the Water and Ions Transportation of Engineered Cementitious Composite (ECC)" Materials 16, no. 13: 4877. https://doi.org/10.3390/ma16134877

APA StyleTawfek, A. M., Ge, Z., Li, J., Zhang, K., Jiang, N., Shao, Y., Ling, Y., & Šavija, B. (2023). Influence of Fiber Orientation on the Water and Ions Transportation of Engineered Cementitious Composite (ECC). Materials, 16(13), 4877. https://doi.org/10.3390/ma16134877