Evaluating Material’s Interaction in Wire Electrical Discharge Machining of Stainless Steel (304) for Simultaneous Optimization of Conflicting Responses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Grey Relational Generating

2.2. Grey Relational Coefficient (GC)

2.3. Grey Relational Grade

3. Results

3.1. Analysis of Variance for SR, CS, and KW

3.2. Analysis of the Effect of Control Factors on Responses

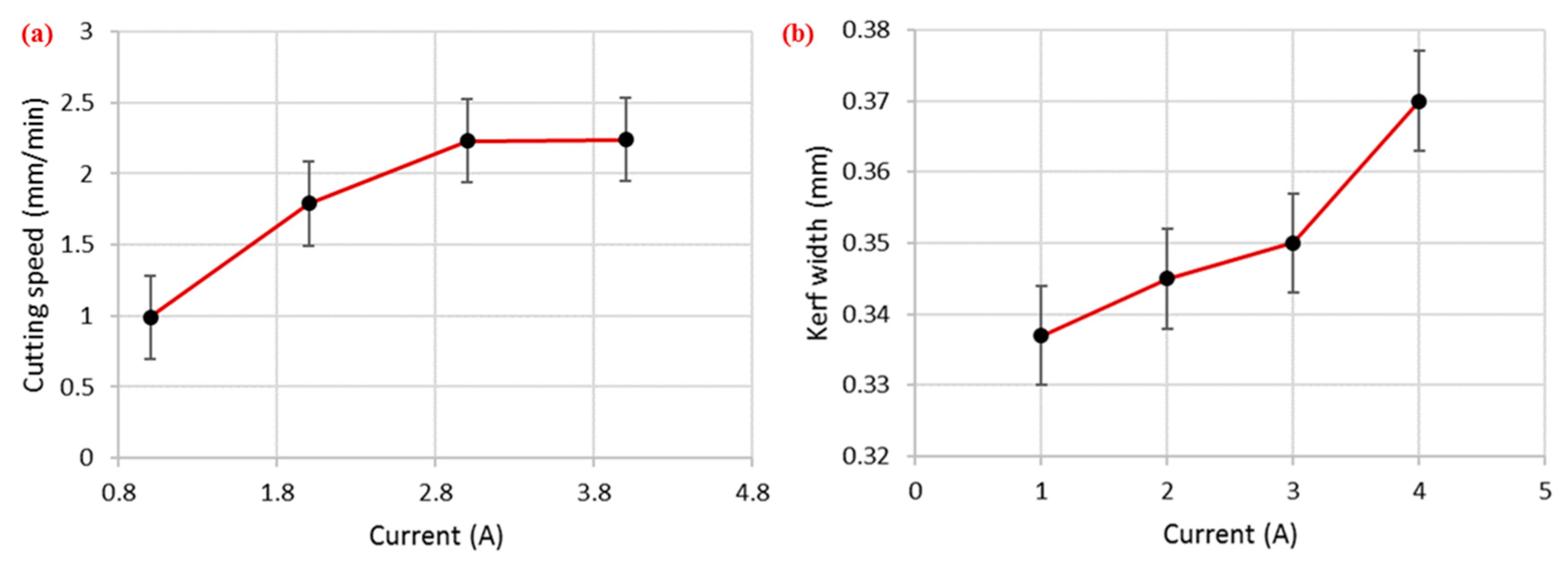

3.2.1. Effect of Current

3.2.2. Effect of Voltage

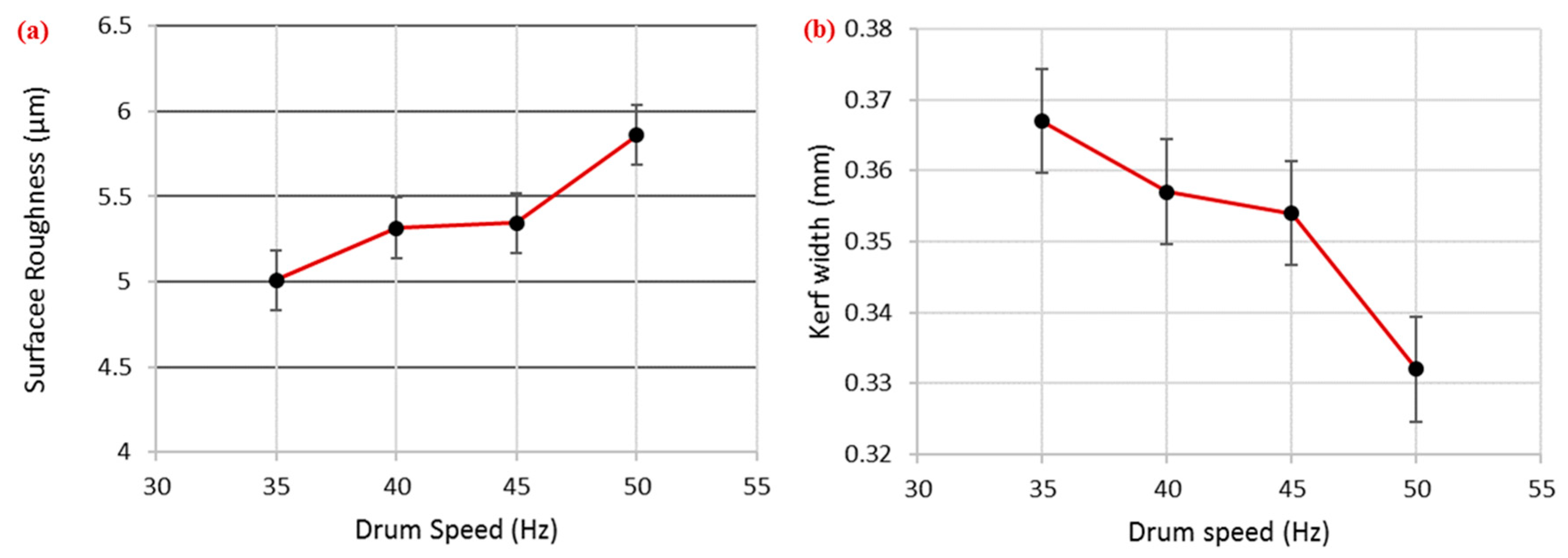

3.2.3. Effect of Drum Speed

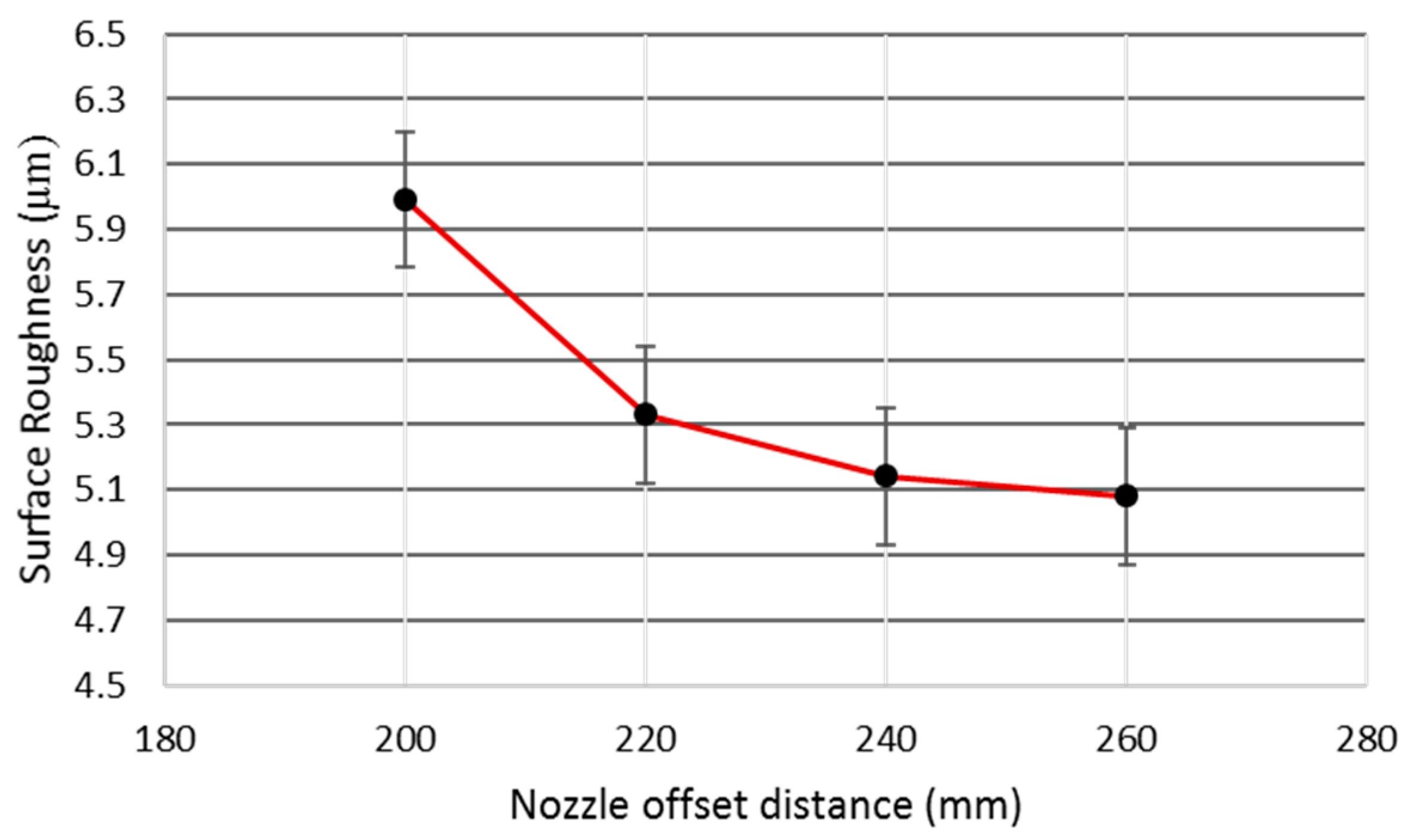

3.2.4. Effect of Nozzle Offset Distance

3.3. Multiresponse Optimization through GRA

Confirmatory Test

4. Conclusions

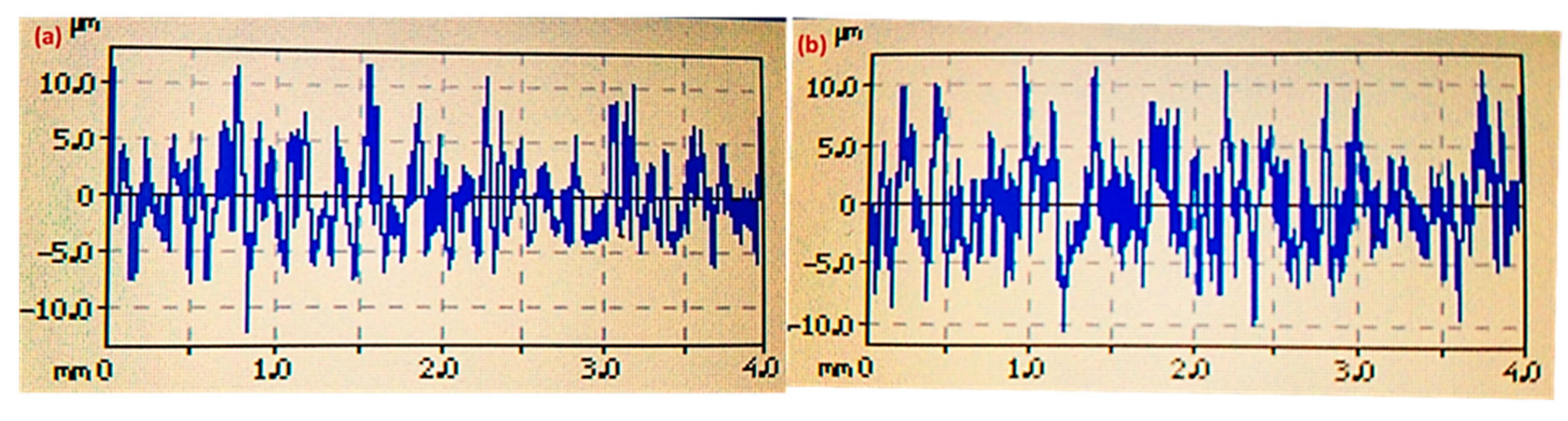

- Analysis of variance revealed that the voltage, drum speed, and nozzle offset distance were significant factors for surface roughness. However, voltage was the major contributing factor, with a percentage contribution of 45%, followed by drum speed (25.8%) and nozzle offset distance (~21%). Higher values of NOD and V at a low DS yielded a high surface finish.

- Cutting speed during WEDM of SS 304 was mainly influenced by the current, which had an exceptionally high percentage contribution of 85.5%. Moreover, an increase in the current value had a positive impact on the cutting rate. The role of drum speed and nozzle offset distance was observed to be insignificant for cutting rate; however, smaller NOD and larger DS values improved the cutting rate.

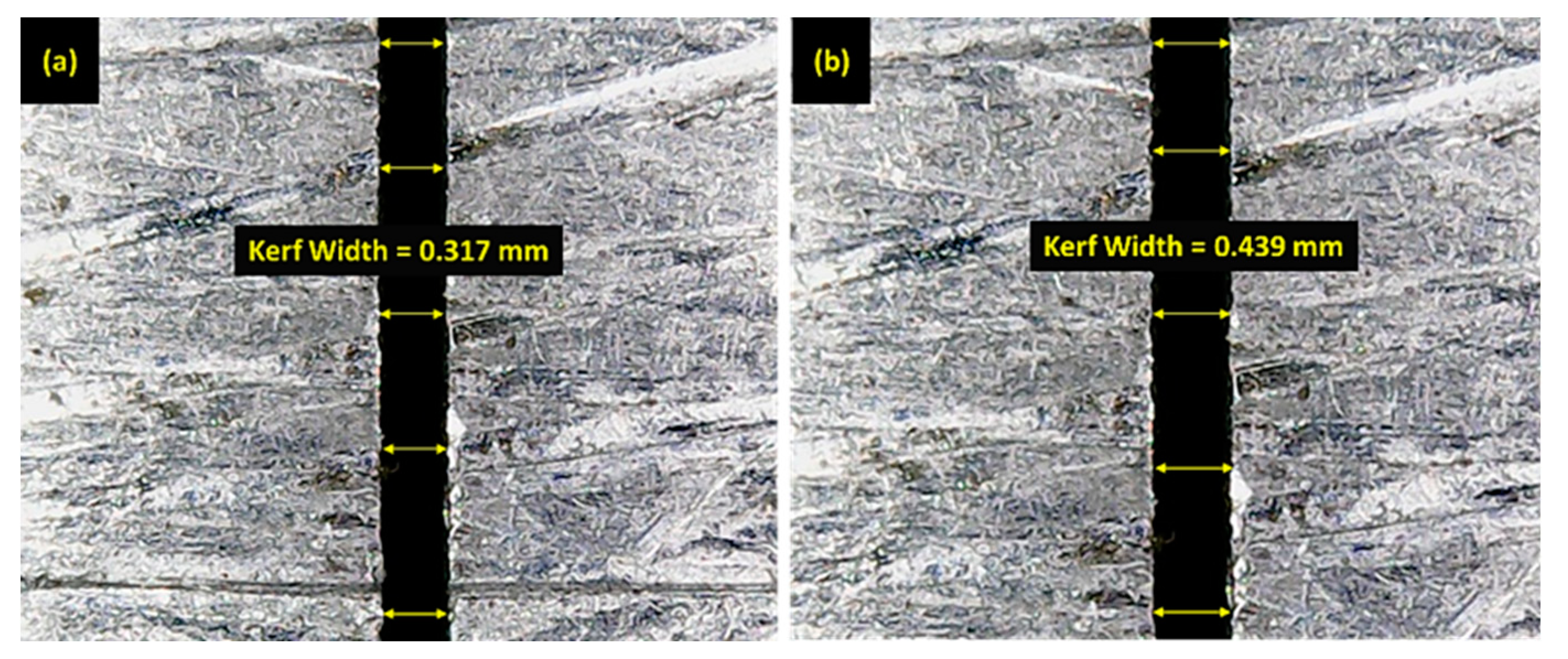

- In addition to current and voltage, drum speed was also found to be a contributing factor in reference to kerf width. The percentage contributions of current, voltage, and drum speed were 53.3%, 22.2%, and 21.2%, respectively, for kerf width. However, high values of drum speed and voltage along with a low amount of current yielded a narrower kerf.

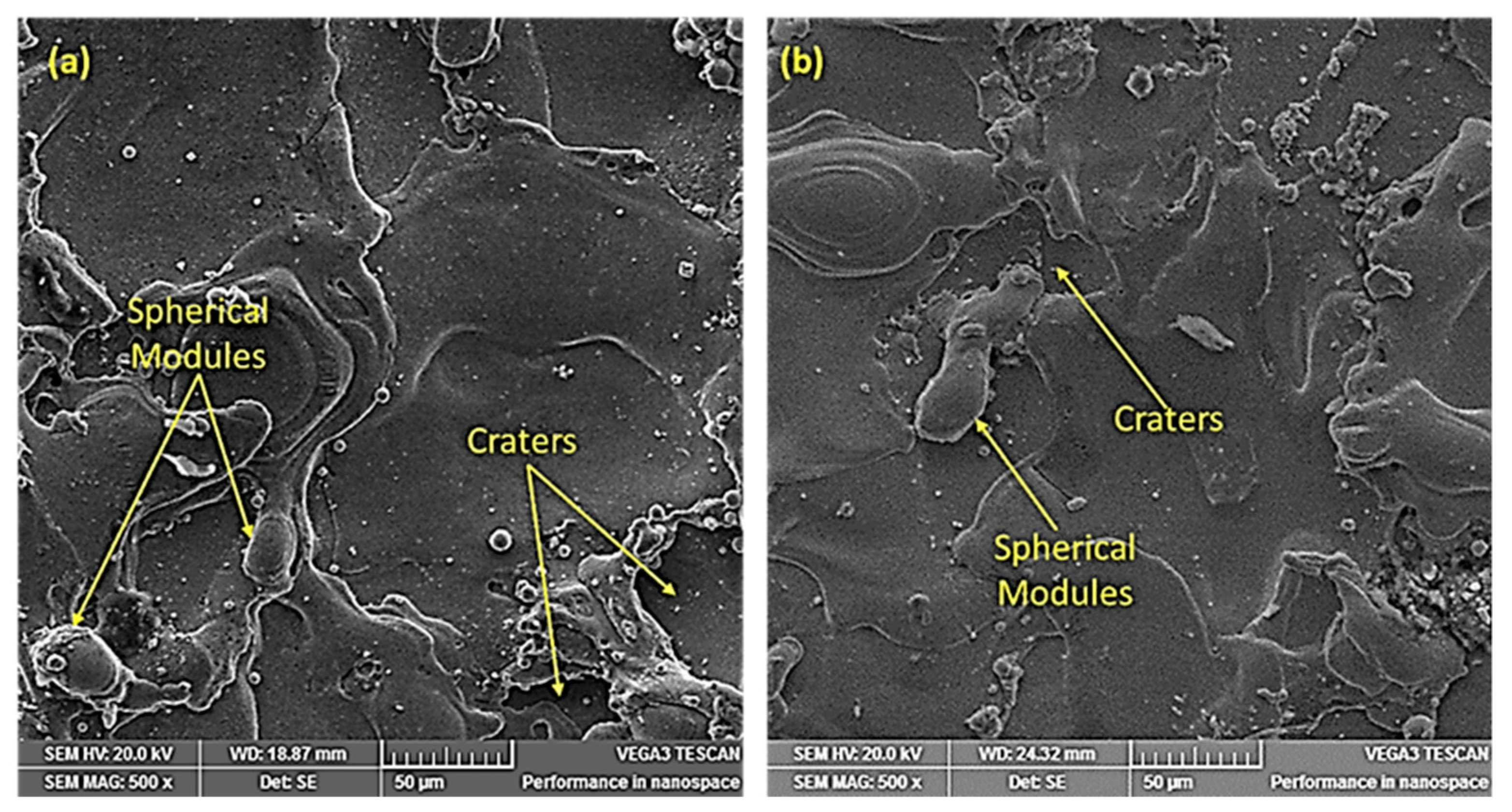

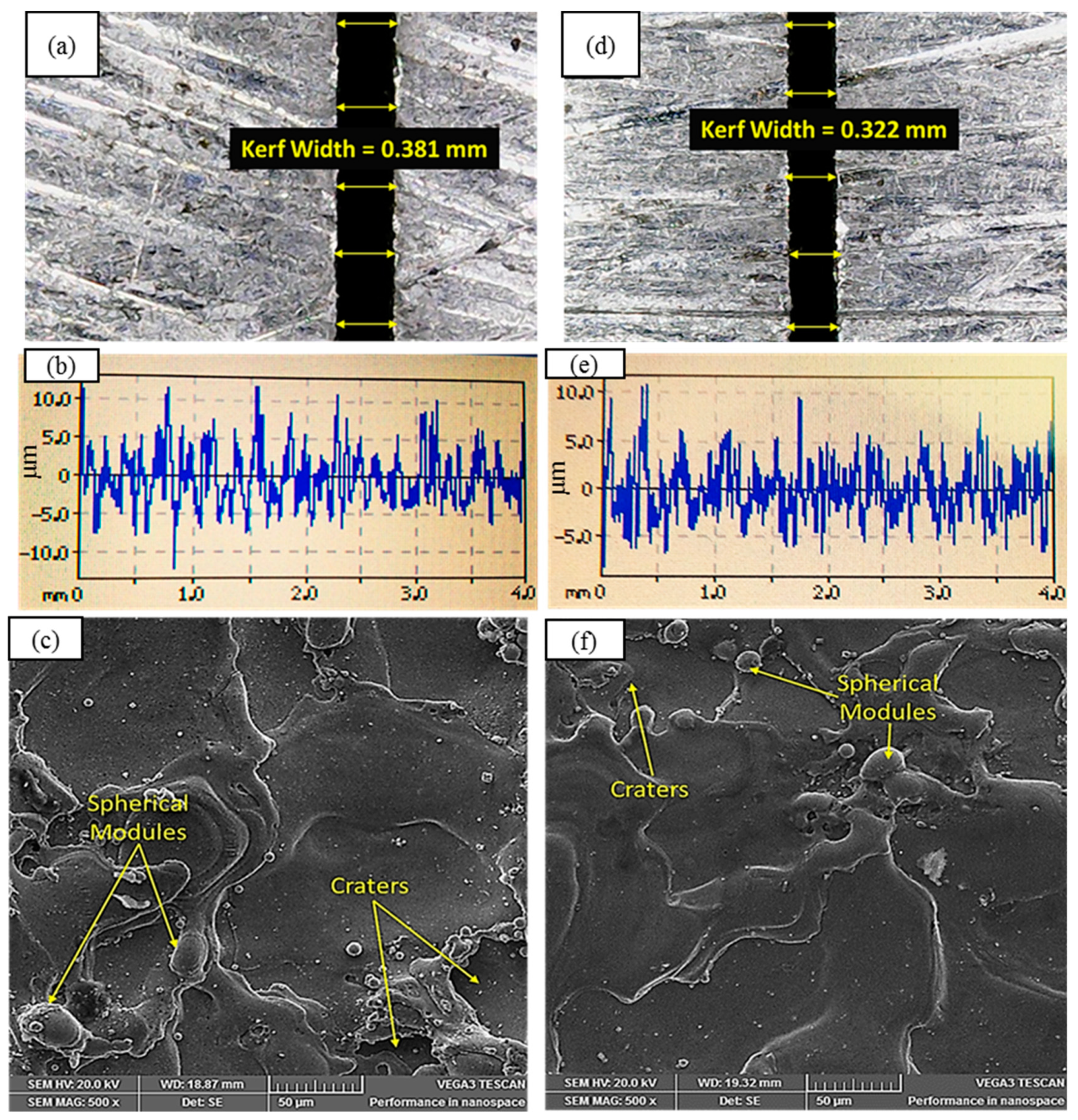

- SEM analysis revealed that the cut surface was crowded with spherical modules at a larger nozzle offset distance because the flushing capability of the dielectric had been reduced. A low offset distance value ensured appropriate flushing because of the higher dielectric pressure, which ultimately minimized spherical module formation on the machined surface.

- Against conflicting response attributes such as surface roughness, cutting speed, and kerf width, the optimal combination of WEDM parameters achieved though grey relational analysis was voltage of 50 V, drum speed of 35 Hz, current of 3 A, and nozzle offset distance of 220 mm. This combination provided the maximum cutting speed (2.62 mm/min) along with the minimum amount of surface roughness (4.47 µm) and kerf width (0.32 mm). The results were validated by a confirmatory test, as presented in Table 5 and Figure 11.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, J.T.; Liao, Y.S. Optimization of machining parameters of Wire-EDM based on Grey relational and statistical analyses. Int. J. Prod. Res. 2003, 41, 1707–1720. [Google Scholar] [CrossRef]

- Abu Qudeiri, J.E.; Saleh, A.; Ziout, A.; Mourad, A.-H.I.; Abidi, M.H.; Elkaseer, A. Advanced electric discharge machining of stainless steels: Assessment of the state of the art, gaps and future prospect. Materials 2019, 12, 907. [Google Scholar] [CrossRef] [PubMed]

- Murti, V.S.; Philip, P.K. A comparative analysis of machining characteristics in ultrasonic assisted EDM by the response surface methodology. Int. J. Prod. Res. 1987, 25, 259–272. [Google Scholar] [CrossRef]

- Scott, D.; Boyina, S.; Rajurkar, K.P. Analysis and optimization of parameter combinations in wire electrical discharge machining. Int. J. Prod. Res. 1991, 29, 2189–2207. [Google Scholar] [CrossRef]

- Świercz, R.; Oniszczuk-Świercz, D. Investigation of the influence of reduced graphene oxide flakes in the dielectric on surface characteristics and material removal rate in EDM. Materials 2019, 12, 943. [Google Scholar] [CrossRef] [PubMed]

- Straka, Ľ.; Čorný, I.; Piteľ, J. Properties evaluation of thin microhardened surface layer of tool steel after wire EDM. Metals 2016, 6, 95. [Google Scholar] [CrossRef]

- Sanchez, J.A.; Plaza, S.; Ortega, N.; Marcos, M.; Albizuri, J. Experimental and numerical study of angular error in wire-EDM taper-cutting. Int. J. Mach. Tools Manuf. 2008, 48, 1420–1428. [Google Scholar] [CrossRef]

- Tosun, N.; Çoğun, C.; Tosun, G. A study on kerf and material removal rate in wire electrical discharge machining based on Taguchi method. J. Mater. Process. Technol. 2004, 152, 316–322. [Google Scholar] [CrossRef]

- Ding, X.M.; Fuh, J.Y.H.; Lee, K.S.; Zhang, Y.F.; Nee, A.Y.C. A computer-aided EDM electrode design system for mold manufacturing. Int. J. Prod. Res. 2000, 38, 3079–3092. [Google Scholar] [CrossRef]

- Salcedo, A.; Arbizu, I.; Pérez, C. Analytical modelling of energy density and optimization of the EDM machining parameters of Inconel 600. Metals 2017, 7, 166. [Google Scholar] [CrossRef]

- Durairaj, M.; Sudharsun, D.; Swamynathan, N. Analysis of process parameters in wire EDM with stainless steel using single objective Taguchi method and multi objective Grey relational grade. Proc. Eng. 2013, 64, 868–877. [Google Scholar] [CrossRef]

- Abdulkareem, S.; Khan, A.A.; Zain, Z.M. Effect of machining parameters on surface roughness during wet and drywire-EDM of stainless steel. J. Appl. Sci. 2011, 11, 1867–1871. [Google Scholar]

- Sun, Y.; Gong, Y.; Liu, Y.; Li, Q.; Zhou, Y. Experimental study on surface characteristics and improvement of microelectrode machined by low speed wire electrical discharge turning. Arch. Civ. Mech. Eng. 2017, 17, 964–977. [Google Scholar] [CrossRef]

- Ishfaq, K.; Mufti, N.A.; Mughal, M.P.; Saleem, M.Q.; Ahmed, N. Investigation of wire electric discharge machining of stainless-clad steel for optimization of cutting speed. Int. J. Adv. Manuf. Technol. 2018, 96, 1429–1443. [Google Scholar] [CrossRef]

- Mandal, A.; Dixit, A.R.; Das, A.K.; Mandal, N. Modeling and optimization of machining nimonic C-263 superalloy using multicut strategy in WEDM. Mater. Manuf. Process. 2016, 31, 860–868. [Google Scholar] [CrossRef]

- Yang, R.T.; Tzeng, C.J.; Yang, Y.K.; Hsieh, M.H. Optimization of wire electrical discharge machining process parameters for cutting tungsten. Int. J. Adv. Manuf. Technol. 2012, 60, 135–147. [Google Scholar] [CrossRef]

- Azam, M.; Jahanzaib, M.; Abbasi, J.A.; Wasim, A. Modeling of cutting speed (CS) for HSLA steel in wire electrical discharge machining (WEDM) using moly wire. J. Chin. Inst. Eng. Trans. Chin. Inst. Eng. AChung-Kuo K. Cheng Hsuch Kan 2016, 39, 802–808. [Google Scholar] [CrossRef]

- Ikram, A.; Mufti, N.A.; Saleem, M.Q.; Khan, A.R. Parametric optimization for surface roughness, kerf and MRR in wire electrical discharge machining (WEDM) using Taguchi design of experiment. J. Mech. Sci. Technol. 2013, 27, 2133–2141. [Google Scholar] [CrossRef]

- Shah, A.; Mufti, N.A.; Rakwal, D.; Bamberg, E. Material removal rate, kerf, and surface roughness of tungsten carbide machined with wire electrical discharge machining. J. Mater. Eng. Perform. 2011, 20, 71–76. [Google Scholar] [CrossRef]

- Kumar, K.; Agarwal, S. Multi-objective parametric optimization on machining with wire electric discharge machining. Int. J. Adv. Manuf. Technol. 2012, 62, 617–633. [Google Scholar] [CrossRef]

- Dhobe, M.M.; Chopde, I.K.; Gogte, C.L. Optimization of wire electro discharge machining parameters for improving surface finish of cryo-treated tool steel using DOE. Mater. Manuf. Process. 2014, 29, 1381–1386. [Google Scholar] [CrossRef]

- Bhatia, A.; Kumar, S.; Kumar, P. A study to achieve minimum surface roughness in wire EDM. Procedia Mater. Sci. 2014, 5, 2560–2566. [Google Scholar] [CrossRef]

- Rajendran, S.; Sakthivel, M.; Dharamalingam, S. An investigation of the effect of surface integrity and layer thickness using T90Mn2W50Cr45 tool steel. Mater. Manuf. Process. 2015, 30, 199–203. [Google Scholar] [CrossRef]

- Bobbili, R.; Madhu, V.; Gogia, A.K. Modelling and analysis of material removal rate and surface roughness in wire-cut EDM of armour materials. Eng. Sci. Technol. Int. J. 2015, 18, 1–5. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Z.; Guo, J.; Ming, W.; Li, M.; Huang, Y. Modeling and optimization of medium-speed WEDM process parameters for machining SKD11. Mater. Manuf. Process. 2013, 28, 1124–1132. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A.K.; Islam, M.N.; Littlefair, G. Electrical discharge machining of 6061 aluminium alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 2866–2874. [Google Scholar] [CrossRef]

- Tilekar, S.; Das, S.S.; Patowari, P.K. Process parameter optimization of wire EDM on Aluminum and mild steel by using Taguchi method. Procedia Mater. Sci. 2014, 5, 2577–2584. [Google Scholar] [CrossRef]

- Gadakh, V.S. Parametric optimization of wire electrical discharge machining using topsis method. Adv. Prod. Eng. Manag. 2012, 7, 157. [Google Scholar] [CrossRef]

- Weng, W.; Yang, F.; Elsherbeni, A.Z. Linear antenna array synthesis using Taguchi’s method: A novel optimization technique in electromagnetics. IEEE Trans. Antennas Propag. 2007, 55, 723–730. [Google Scholar] [CrossRef]

- Ishfaq, K.; Mufti, N.A.; Ahmed, N.; Mughal, M.P.; Saleem, M.Q. An investigation of surface roughness and parametric optimization during wire electric discharge machining of cladded material. Int. J. Adv. Manuf. Technol. 2018, 97, 4065–4079. [Google Scholar] [CrossRef]

- Khan, Z.A.; Siddiquee, A.N.; Khan, N.Z.; Khan, U.; Quadir, G.A. Multi response optimization of wire electrical discharge machining process parameters using Taguchi based Grey relational analysis. Procedia Mater. Sci. 2014, 6, 1683–1695. [Google Scholar] [CrossRef]

- Sun, P. Effect of the vibration on machining gap of WEDM. Appl. Mech. Mater. 2013, 395, 1053–1056. [Google Scholar] [CrossRef]

- Chang, C.-L.; Tsai, C.-H.; Chen, L. Applying Grey relational analysis to the decathlon evaluation model. Int. J. Comput. Internet Manag. 2003, 11, 54–62. [Google Scholar]

- Abidi, M.; Al-Ahmari, A.; Siddiquee, A.; Mian, S.; Mohammed, M.; Rasheed, M. An investigation of the micro-electrical discharge machining of nickel-titanium shape memory alloy using Grey relations coupled with principal component analysis. Metals 2017, 7, 486. [Google Scholar] [CrossRef]

- Pradhan, M.K. Estimating the effect of process parameters on MRR, TWR and radial overcut of EDMed AISI D2 tool steel by RSM and GRA coupled with PCA. Int. J. Adv. Manuf. Technol. 2013, 68, 591–605. [Google Scholar] [CrossRef]

- Azhiri, B.; Teimouri, R.; Ghasemi Baboly, M.; Leseman, Z. Application of Taguchi, ANFIS and Grey relational analysis for studying, modeling and optimization of wire EDM process while using gaseous media. Int. J. Adv. Manuf. Technol. 2014, 71, 279–295. [Google Scholar] [CrossRef]

- Julong, D. Introduction to Grey system theory. J. Grey Syst. 1989, 1, 1–24. [Google Scholar]

| Elements | C | Cr | Si | Ni | S | P | Fe |

|---|---|---|---|---|---|---|---|

| Weight (%) | 0.075 | 18.4 | 1.03 | 9.76 | 0.03 | 0.048 | Balance |

| Input Parameters | Units | Levels | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| Voltage (V) | V | 50 | 60 | 70 | 80 |

| Drum Speed (DS) | Hz | 35 | 40 | 45 | 50 |

| Current (I) | amp | 1 | 2 | 3 | 4 |

| Nozzle Offset Distance (NOD) | mm | 200 | 220 | 240 | 260 |

| ANOVA for SR | |||||||

| Source | DF | Seq SS | Adj SS | Adj MS | F | P | % Contribution |

| V | 3 | 2.22887 | 2.22887 | 0.74296 | 25.69 | 0.012 | 45 |

| DS | 3 | 1.27454 | 1.27454 | 0.42485 | 14.69 | 0.024 | 26 |

| I | 3 | 0.32664 | 0.32664 | 0.10888 | 3.77 | 0.153 | 7 |

| NOD | 3 | 1.02303 | 1.02303 | 0.34104 | 11.79 | 0.036 | 20 |

| Error | 3 | 0.08675 | 0.08675 | 0.02892 | 2 | ||

| Total | 15 | 4.93983 | |||||

| S = 0.170050 | R − Sq = 98.24% | R − Sq (adj) = 91.22% | |||||

| ANOVA for CS | |||||||

| Source | DF | Seq SS | Adj SS | Adj MS | F | P | % Contribution |

| V | 3 | 0.28033 | 0.28033 | 0.09344 | 3.56 | 0.163 | 6 |

| DS | 3 | 0.27686 | 0.27686 | 0.09229 | 3.51 | 0.165 | 6 |

| I | 3 | 4.10536 | 4.10536 | 1.36845 | 52.08 | 0.004 | 85 |

| NOD | 3 | 0.05902 | 0.05902 | 0.01967 | 0.75 | 0.591 | 2 |

| Error | 3 | 0.07883 | 0.07883 | 0.02628 | 1 | ||

| Total | 15 | 4.80039 | |||||

| S = 0.162098 | R − Sq = 98.36% | R − Sq (adj) = 91.79% | |||||

| ANOVA for KW | |||||||

| Source | DF | Seq SS | Adj SS | Adj MS | F | P | % Contribution |

| I | 3 | 0.01624 | 0.01624 | 0.00541 | 108.19 | 0.001 | 53 |

| NOD | 3 | 0.00090 | 0.00090 | 0.00030 | 6.06 | 0.087 | 3 |

| V | 3 | 0.00671 | 0.00671 | 0.00224 | 44.71 | 0.004 | 22 |

| DS | 3 | 0.00647 | 0.00647 | 0.00216 | 43.14 | 0.006 | 21 |

| Error | 3 | 0.00015 | 0.00015 | 0.00005 | 1 | ||

| Total | 15 | 0.03047 | |||||

| S = 0.007073 | R − Sq = 99.51% | R − Sq (adj) = 86.00% | |||||

| Exp No. | Grey Relational Generating | Grey Relational Coefficient | GRA Grade | Ranking | ||||

|---|---|---|---|---|---|---|---|---|

| SR | KW | CS | SR | KW | CS | |||

| 1 | 0.0000 | 0.7980 | 0.1965 | 0.3300 | 0.7120 | 0.3835 | 0.4751 | 14 |

| 2 | 0.2940 | 0.5710 | 0.5648 | 0.4140 | 0.5380 | 0.4696 | 0.4738 | 15 |

| 3 | 0.3880 | 0.4280 | 0.6796 | 0.4490 | 0.4660 | 0.6095 | 0.5081 | 11 |

| 4 | 0.6700 | 1.0000 | 0.7536 | 0.6020 | 1.0000 | 0.6699 | 0.7572 | 2 |

| 5 | 0.6260 | 0.3700 | 0.6250 | 0.5720 | 0.4270 | 0.4820 | 0.4936 | 12 |

| 6 | 1.0000 | 0.0840 | 0.0194 | 1.0000 | 0.3530 | 0.3377 | 0.5635 | 8 |

| 7 | 0.6090 | 0.4410 | 0.7702 | 0.5610 | 0.4720 | 0.6851 | 0.5726 | 7 |

| 8 | 0.5180 | 0.4610 | 0.6140 | 0.5090 | 0.4810 | 0.7799 | 0.5899 | 6 |

| 9 | 0.4170 | 0.6880 | 0.8640 | 0.4610 | 0.6000 | 0.7862 | 0.6157 | 3 |

| 10 | 0.4710 | 0.3830 | 0.8113 | 0.4850 | 0.4490 | 0.7260 | 0.5533 | 10 |

| 11 | 0.4700 | 0.4740 | 0.2552 | 0.4850 | 0.4870 | 0.4017 | 0.4579 | 16 |

| 12 | 0.3820 | 0.7920 | 0.7400 | 0.4470 | 0.7060 | 0.6579 | 0.6036 | 4 |

| 13 | 0.1530 | 0.0000 | 0.8477 | 0.3710 | 0.3300 | 0.7665 | 0.4891 | 13 |

| 14 | 0.7530 | 0.7660 | 1.0000 | 0.6690 | 0.6810 | 1.0000 | 0.7833 | 1 |

| 15 | 0.7410 | 0.7460 | 0.4271 | 0.6580 | 0.6630 | 0.4859 | 0.6022 | 5 |

| 16 | 0.7150 | 0.7920 | 0.0000 | 0.6360 | 0.7060 | 0.3330 | 0.5583 | 9 |

| Sr. No. | Input Parameter’s Setting | Parameter’s Level | Level Values | Cutting Speed (mm/min) | Kerf Width (mm) | Surface Roughness (µm) |

|---|---|---|---|---|---|---|

| 1 | Optimal Settings | V 1, DS 1, I 3, NOD 2 | V = 50 V, DS = 35 Hz, I = 3 A, NOD = 220 mm | 2.62 | 0.322 | 4.47 |

| 2 | Nonoptimal Settings | V 3, DS 1, I 3, NOD 3 | V = 70 V, DS = 35 Hz, I = 3 A, NOD = 240 mm | 2.02 | 0.374 | 5.69 |

| Percentage Improvement | 29% | 16% | 27.3% | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ishfaq, K.; Ahmad, N.; Jawad, M.; Ali, M.A.; M. Al-Ahmari, A. Evaluating Material’s Interaction in Wire Electrical Discharge Machining of Stainless Steel (304) for Simultaneous Optimization of Conflicting Responses. Materials 2019, 12, 1940. https://doi.org/10.3390/ma12121940

Ishfaq K, Ahmad N, Jawad M, Ali MA, M. Al-Ahmari A. Evaluating Material’s Interaction in Wire Electrical Discharge Machining of Stainless Steel (304) for Simultaneous Optimization of Conflicting Responses. Materials. 2019; 12(12):1940. https://doi.org/10.3390/ma12121940

Chicago/Turabian StyleIshfaq, Kashif, Naveed Ahmad, Muhammad Jawad, Muhammad Asad Ali, and Abdulrahman M. Al-Ahmari. 2019. "Evaluating Material’s Interaction in Wire Electrical Discharge Machining of Stainless Steel (304) for Simultaneous Optimization of Conflicting Responses" Materials 12, no. 12: 1940. https://doi.org/10.3390/ma12121940