Structural Formation of UHMWPE Film Tracked by Real-Time Retardation Measurements during Uniaxial/Biaxial Stretching

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Stretching Process

2.3. Retardation and Birefringence Measurements

2.4. Wide-Angle X-ray Diffraction(WAXD)

2.5. Light Transmittance

2.6. Thermal Analysis

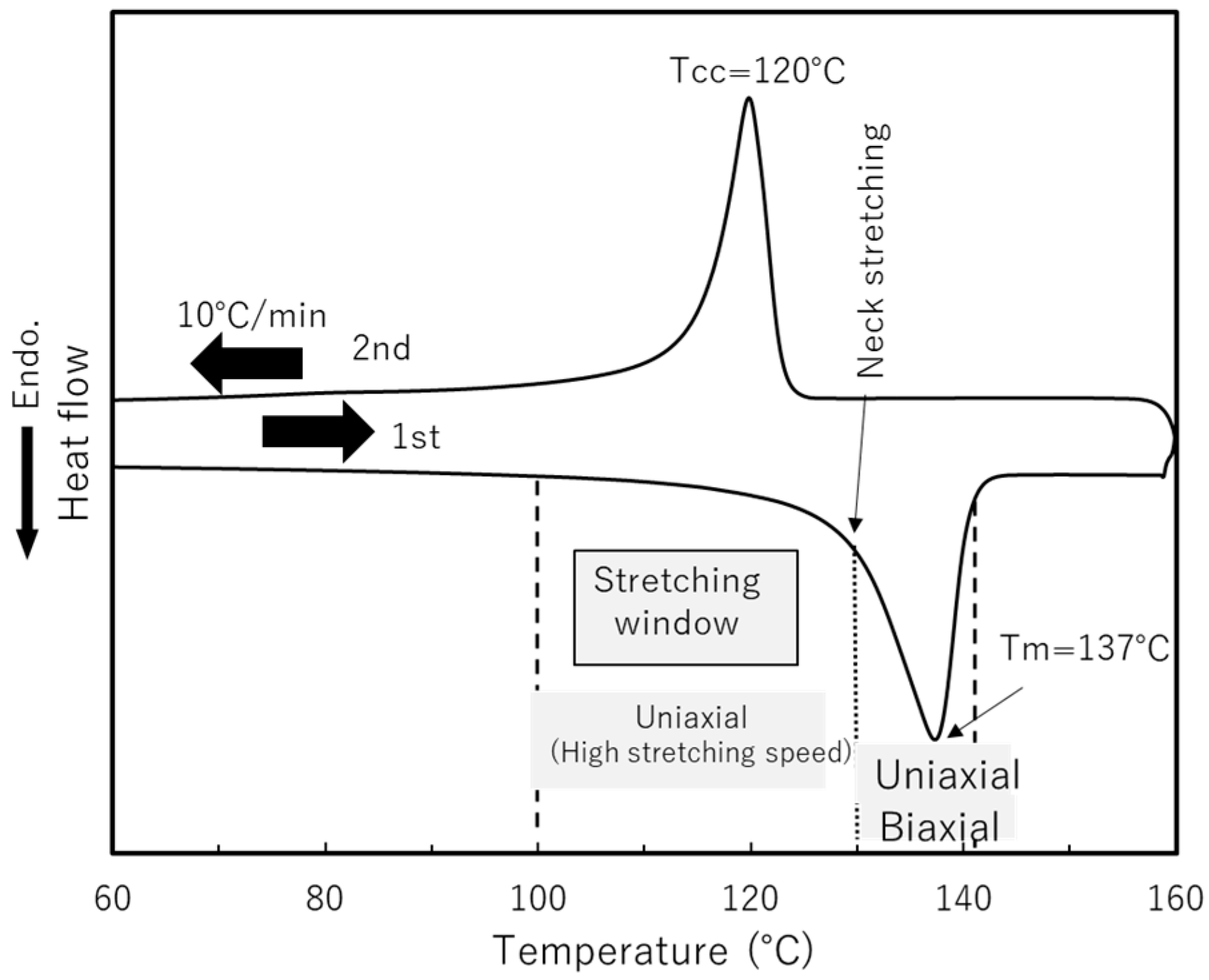

2.6.1. Differential Scanning Calorimetry (DSC)

2.6.2. Dynamic Mechanical Analysis (DMA)

2.6.3. Thermal Mechanical Analysis (TMA)

2.7. Mechanical Property Measurements

3. Results and Discussion

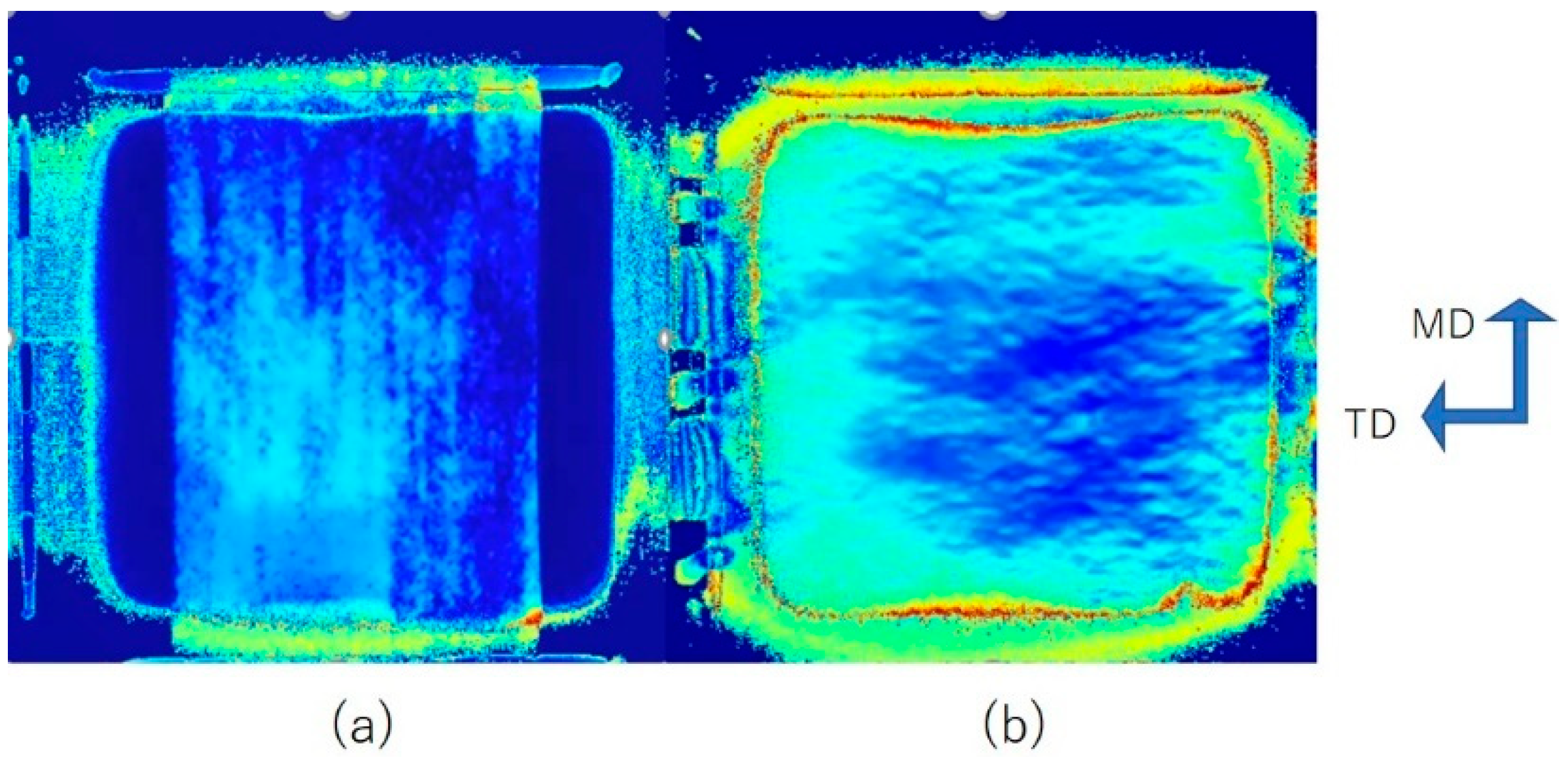

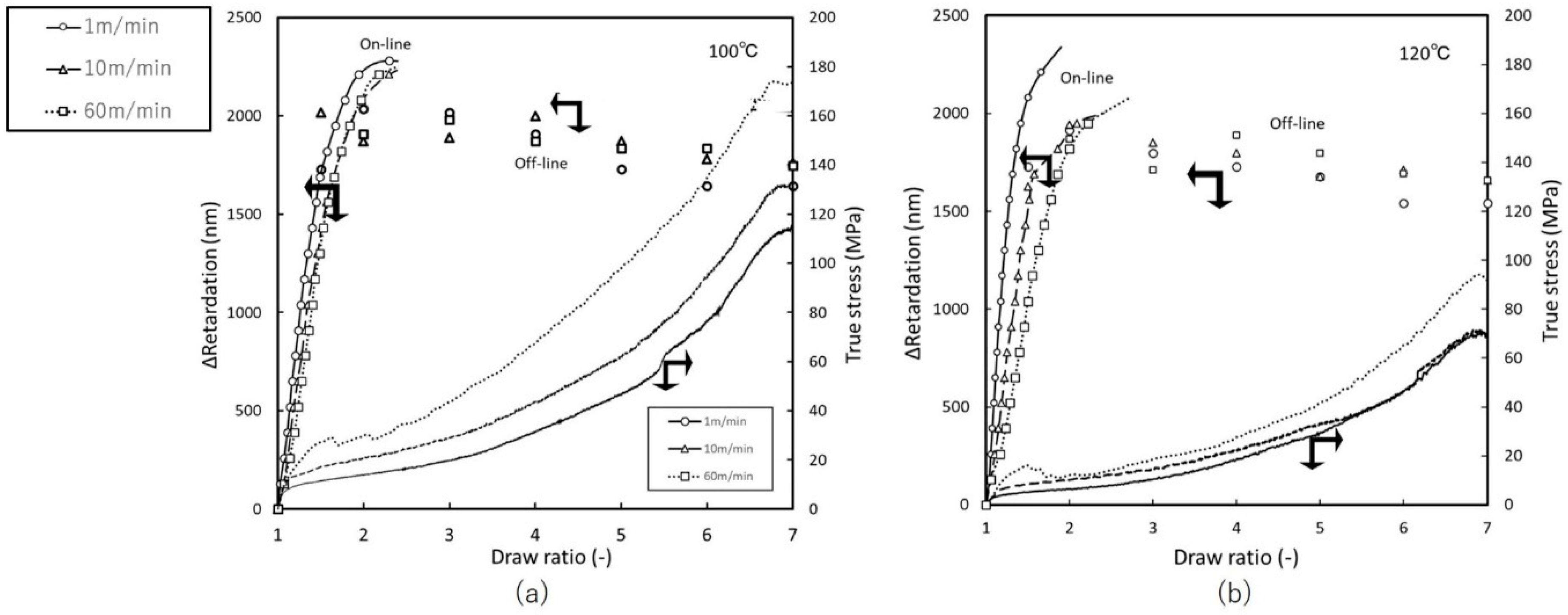

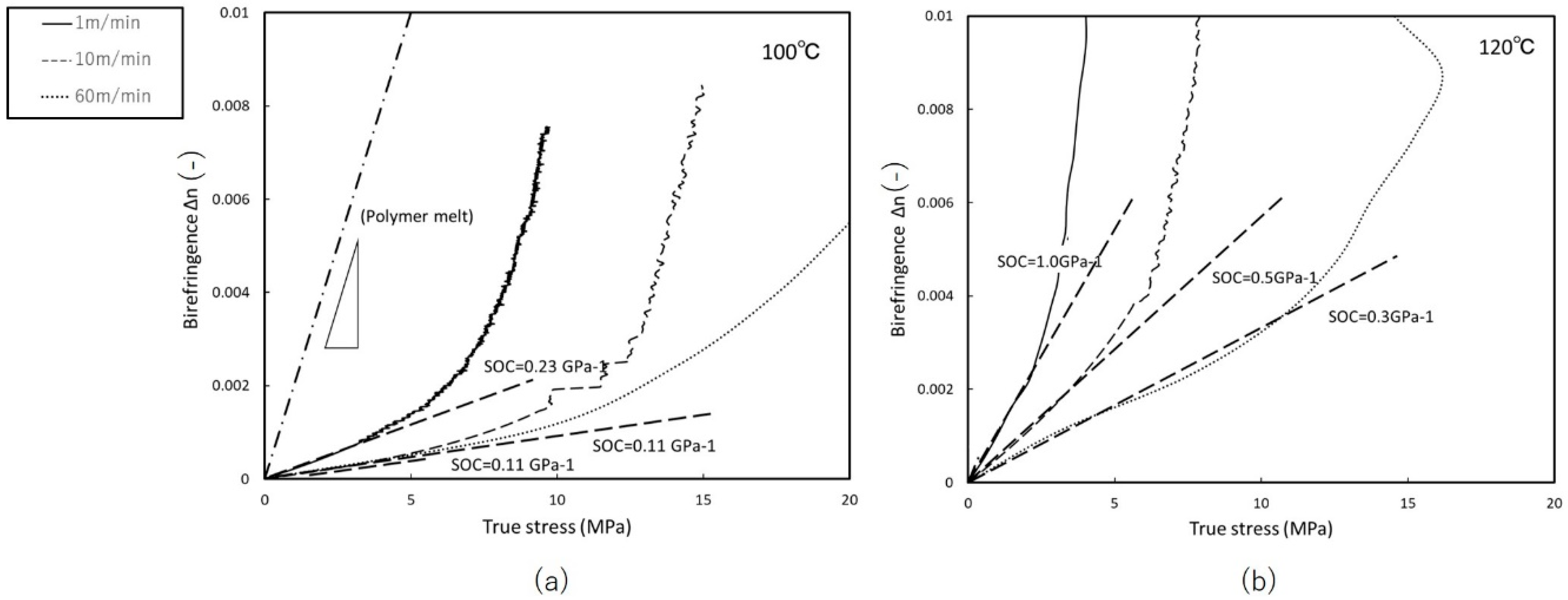

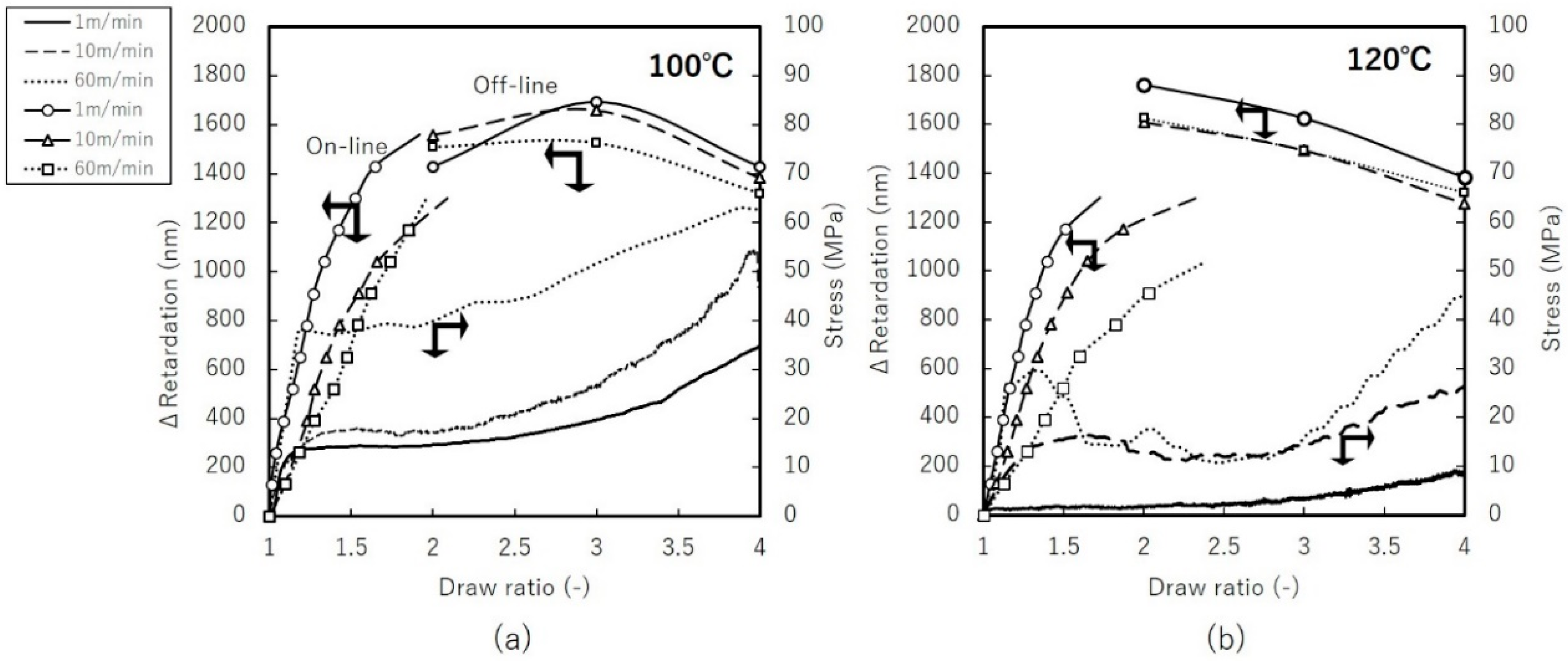

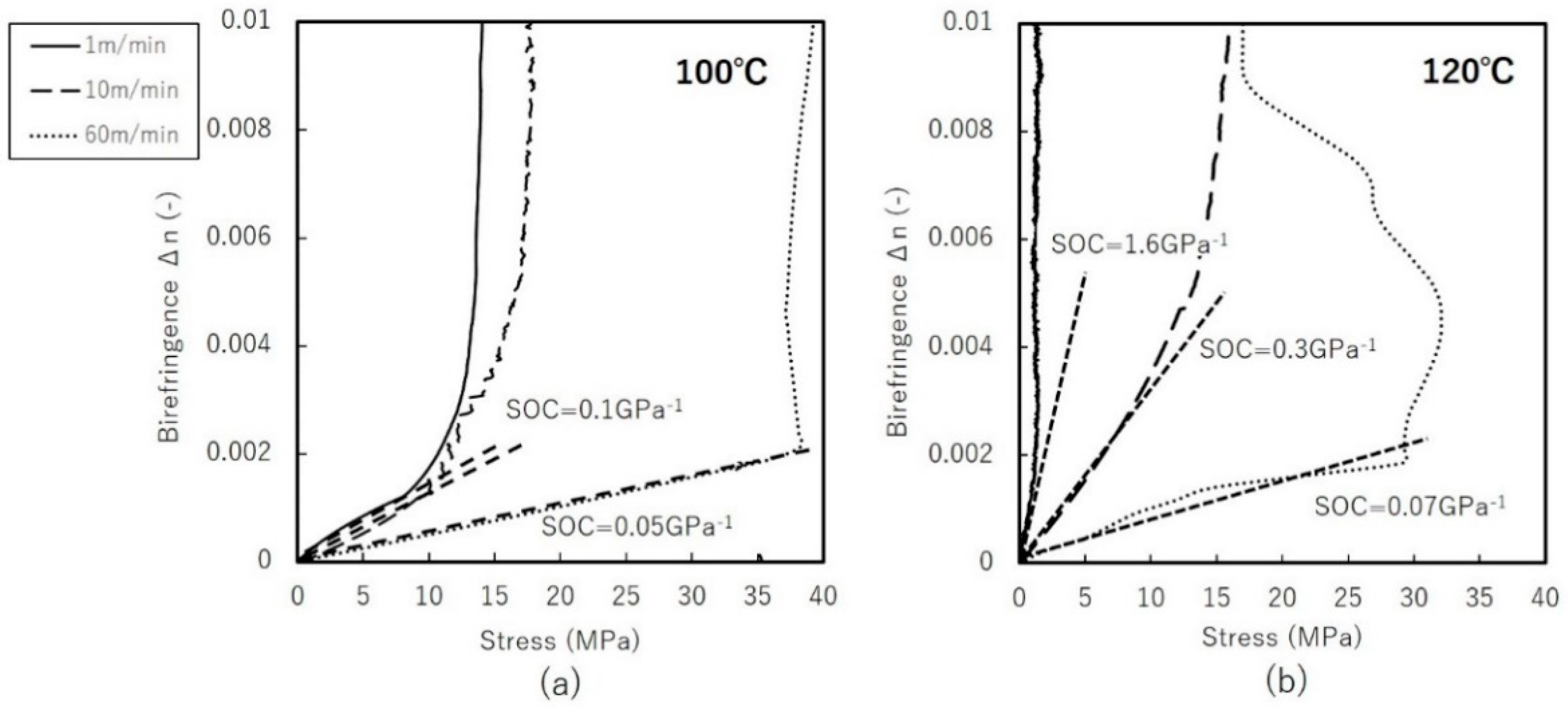

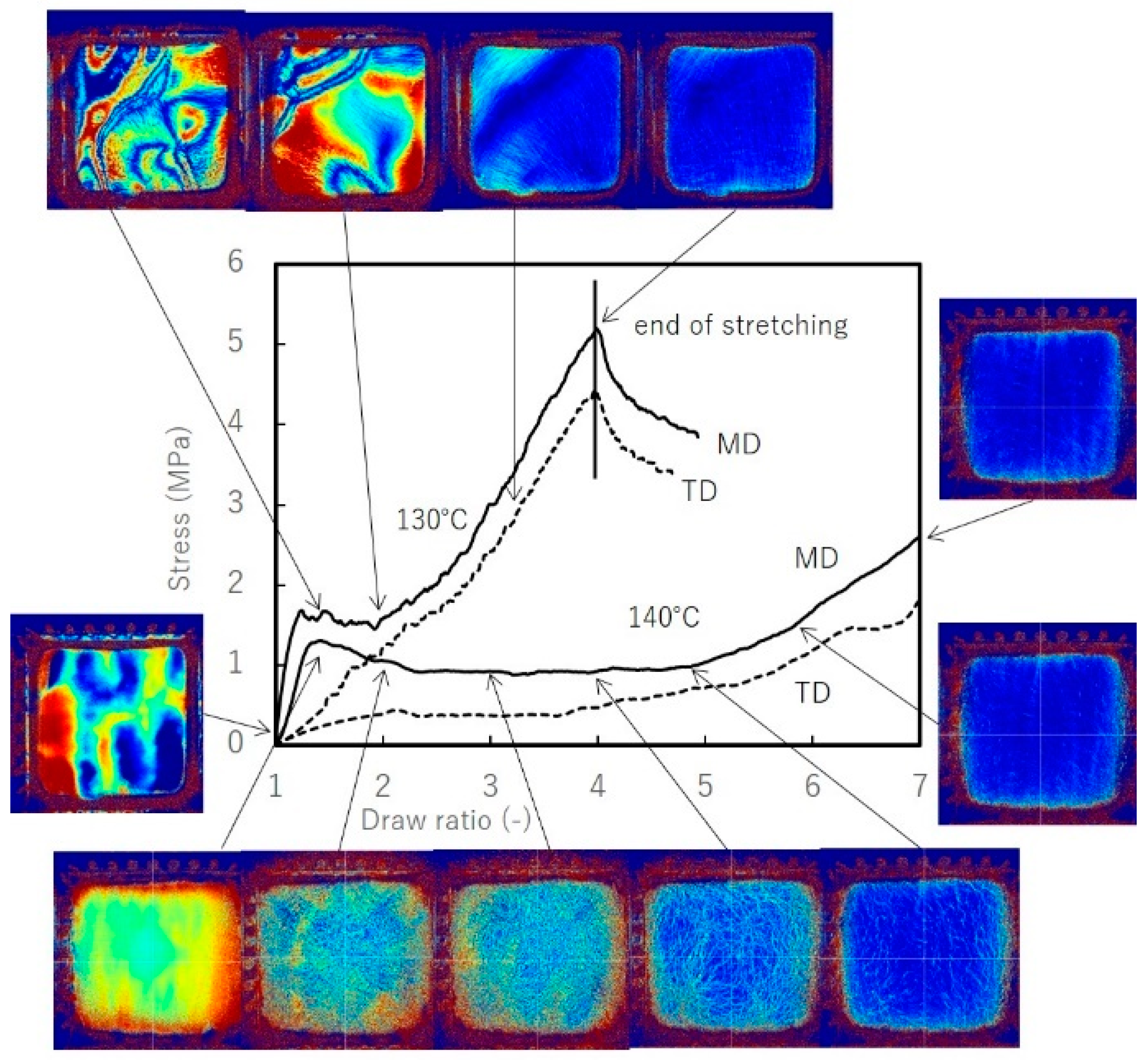

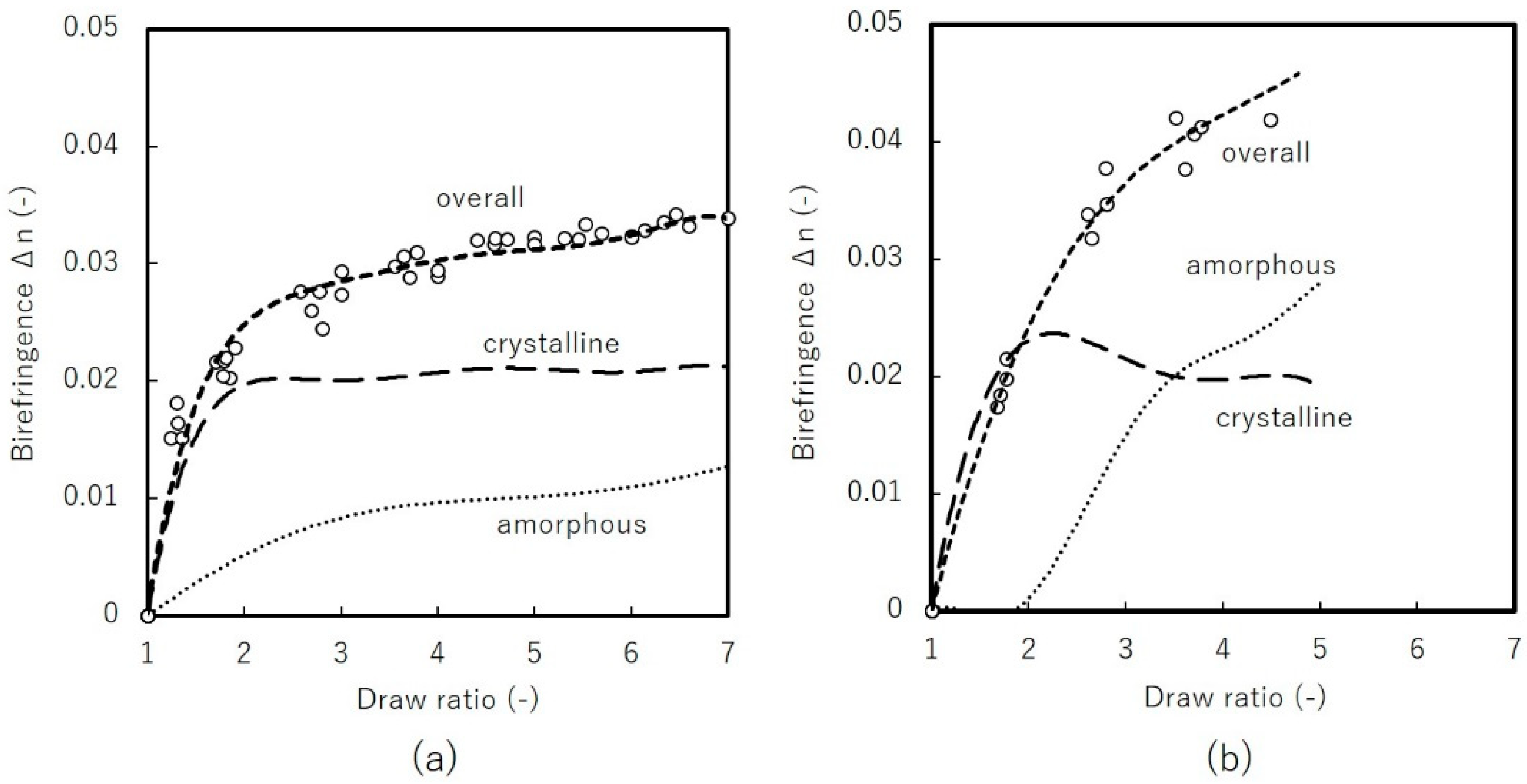

3.1. Retardation and Birefringence Measurements

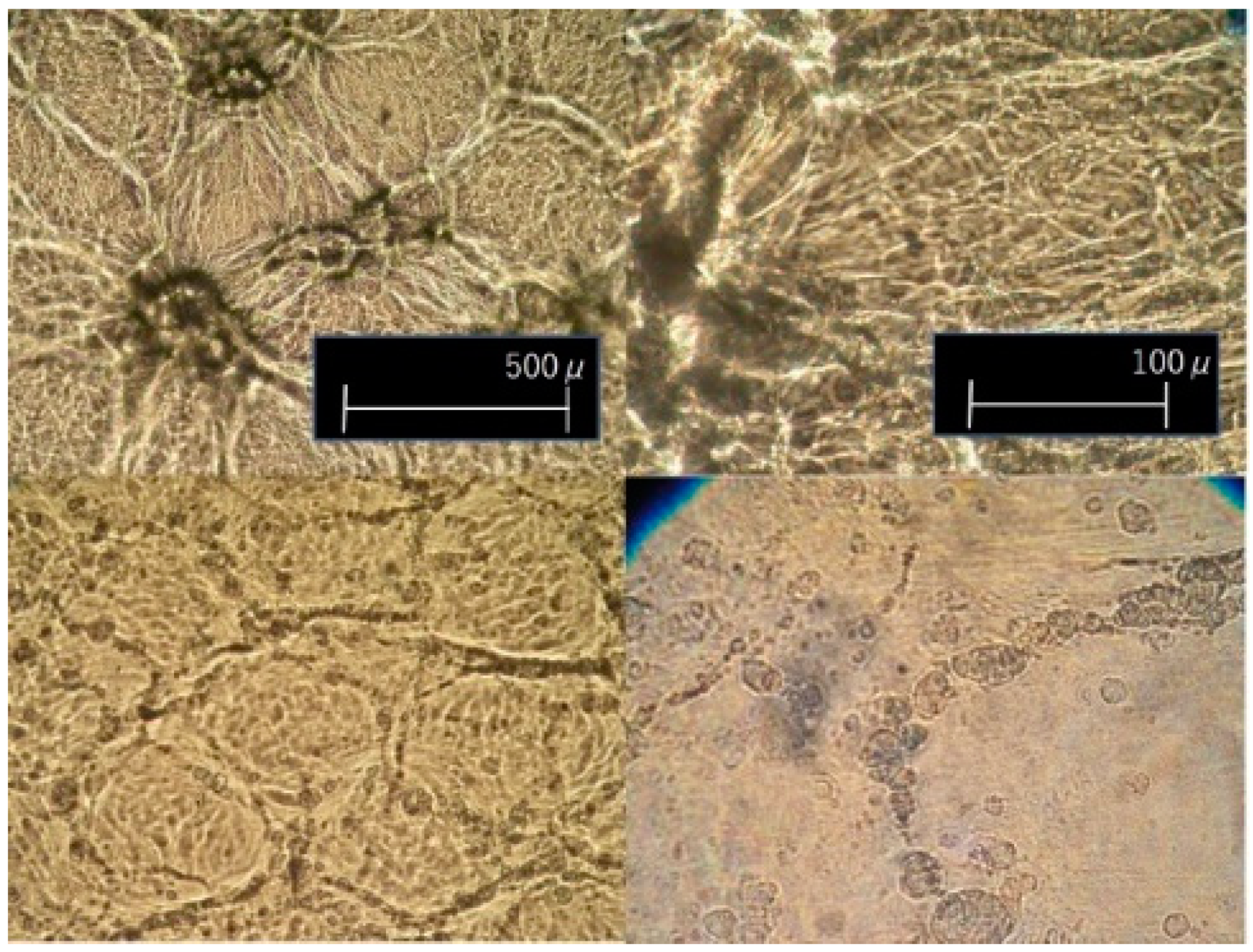

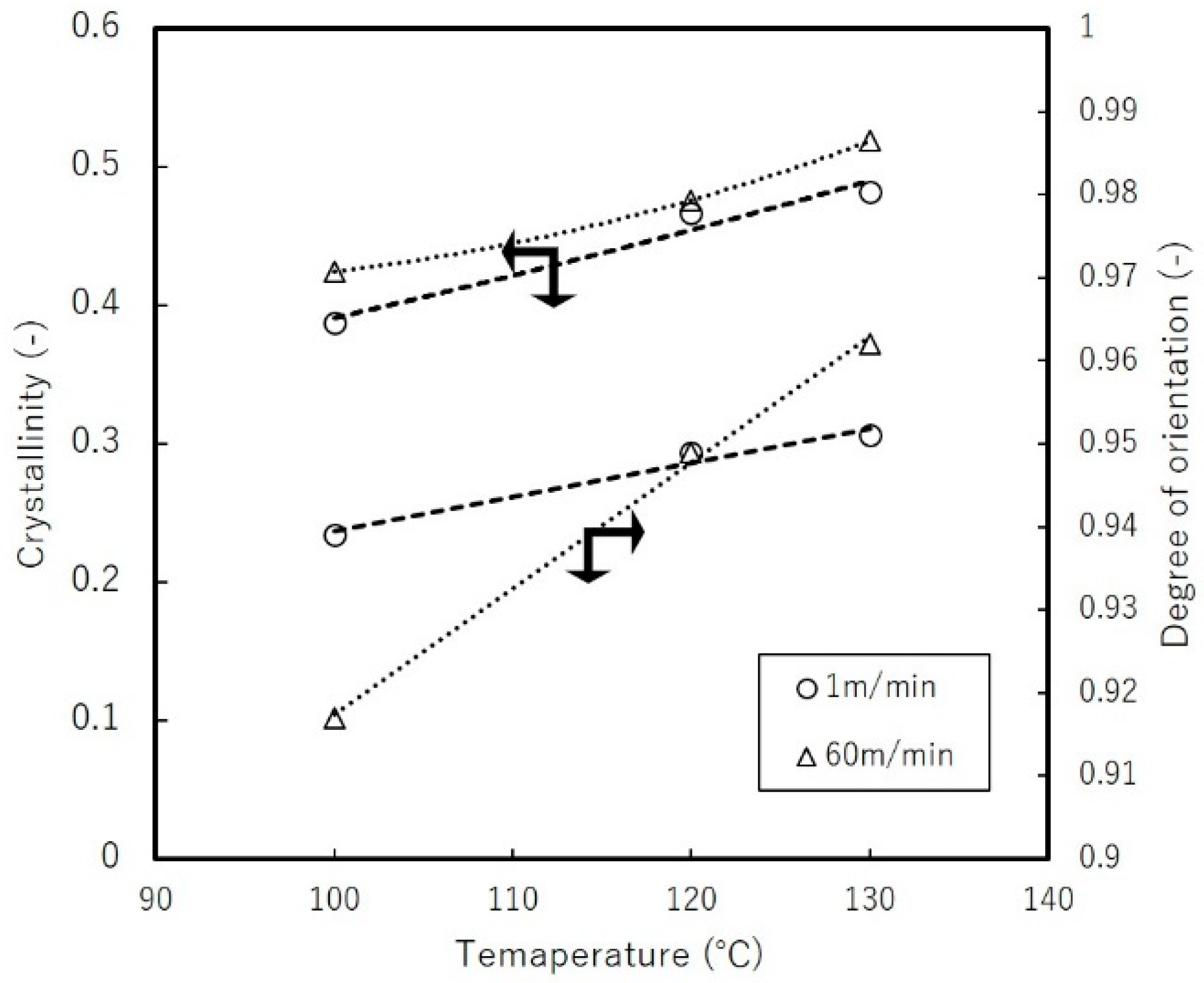

3.2. Wide-Angle X-ray Diffraction (WAXD)

3.3. Thermal Analysis

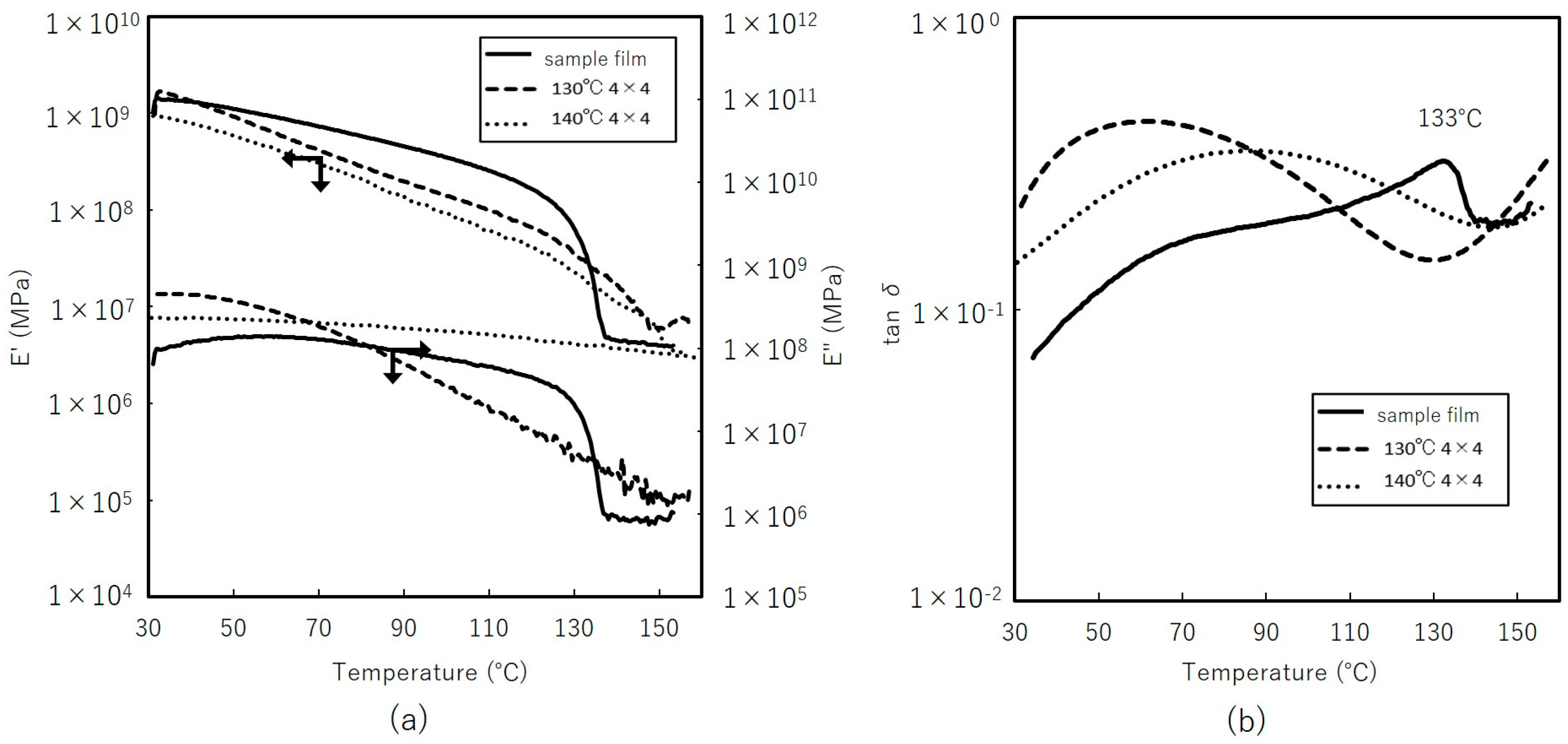

3.3.1. Dynamic Mechanical Analysis (DMA)

3.3.2. Thermal Mechanical Analysis (TMA)

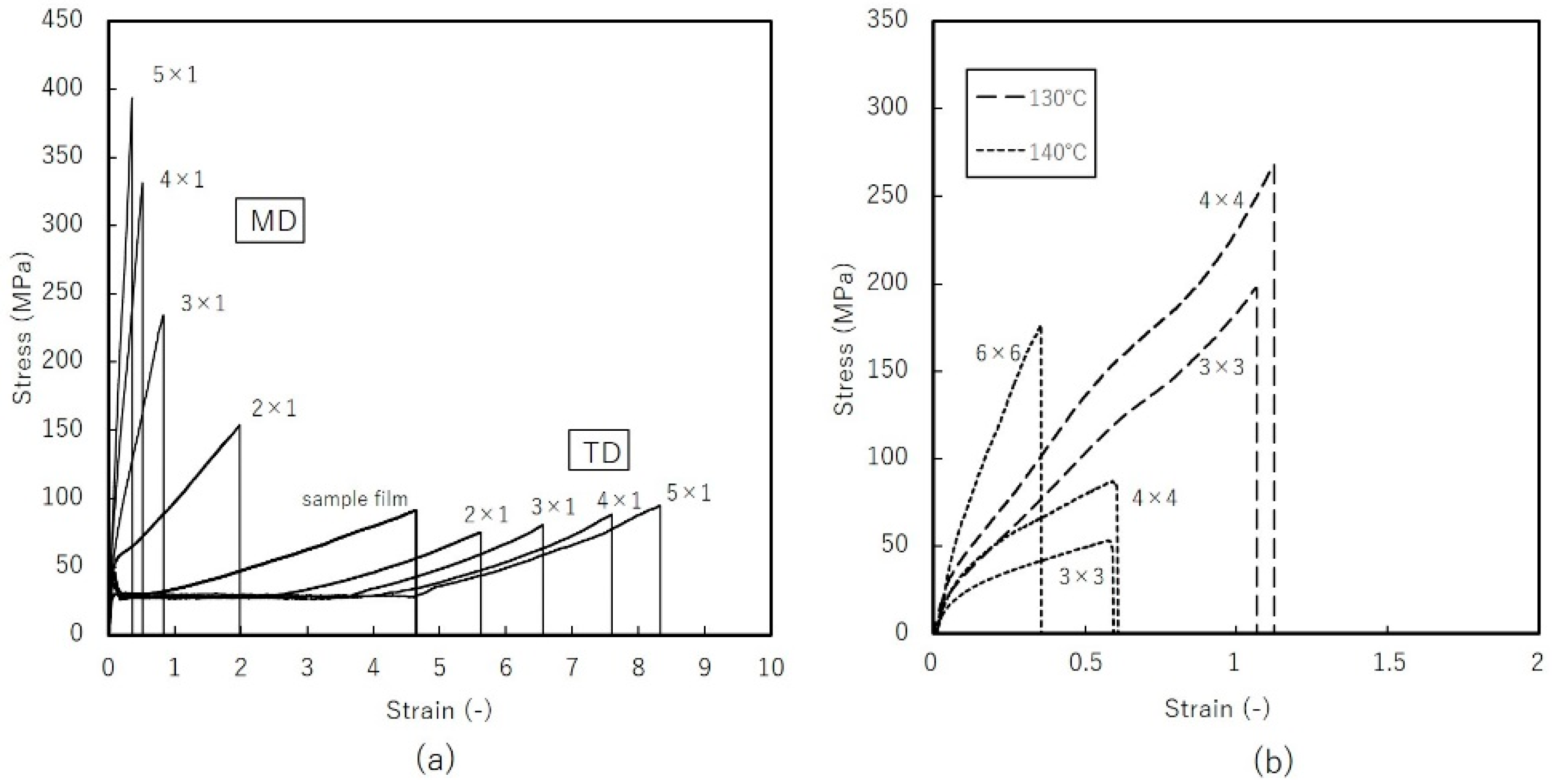

3.4. Tensile Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Deimede, V.; Elmasides, C. Separators for Lithium-Ion Batteriese: A Review on the Production Processes and Recent Developments. Energy Technol. 2015, 3, 453–468. [Google Scholar] [CrossRef]

- Gao, P.; Li, R. Nanoporous UHMWPE Membrane Separators for Safer and High-Power-Den sity Rechargeable Batteries. Glob. Chall. 2017, 1, 1700020. [Google Scholar] [CrossRef]

- Uehara, H.; Tamura, T.; Hashidume, K.; Tanaka, H.; Yamanobe, T. Non-solvent processing for robust but thin membranes of ultra-high molecular weight polyethylene. J. Mater. Chem. A 2014, 2, 5252–5257. [Google Scholar] [CrossRef]

- Uehara, H.; Kakiage, M.; Yamanobe, T.; Komoto, T.; Murakami, S. Transient crystallization during drawing from ultra-high molecular weight polyethylene melts having different entanglement characteristics. Polymer 2006, 47, 8053–8060. [Google Scholar] [CrossRef]

- Uehara, H.; Kakiage, M.; Sekiya, M.; Yamanobe, T.; Komoto, T.; Sasaki, S.; Murakami, S. In situ SAXS analysis of extended-chain crystallization during melt-drawing of ultra-high molecular weight polyethylene. Polymer 2007, 48, 7385–7392. [Google Scholar] [CrossRef]

- Uehara, H.; Tamura, T.; Kakiage, M.; Yamanobe, T. Nanowrinkled and nanoporous Polyethylene Membranes via Entanglement Arrangement Control. Adv. Funct. Mater. 2012, 22, 2048–2057. [Google Scholar] [CrossRef]

- Cakmak, M.; Hassan, M.; Unsal, E.; Martins, C. A fast real time measurement system to track in and out of plane optical retardation/birefringence, true stress, and true strain during biaxial stretching of polymer films. Rev. Sci. Instrum. 2012, 83, 123901. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.K.; Cakmak, M. Mechano optical behavior of polyethylene terephthalate films during simultaneous biaxial stretching: Real time measurements with an instrumented system. Polymer 2013, 54, 6463–6470. [Google Scholar] [CrossRef]

- Hassan, M.K.; Cakmak, M. Mechanisms of structural organizational processes as revealed by real time mechano optical behavior of PET film during sequential biaxial stretching. Polymer 2014, 55, 5245–5254. [Google Scholar] [CrossRef]

- Kotaka, T.; Kojima, A.; Okamoto, M. Elongational flow and birefringence of low density polyethylene and its blends with ultrahigh molecular weight polyethylene. Polymer 1998, 39, 2149–2153. [Google Scholar] [CrossRef]

- Koyama, K.; Ishizuka, O. Birefringence of Polyethylene Melt in Transient Elongational Flow at Constant Strain Rate. J. Polym. Sci. Part B Polym. Phys. 1989, 27, 297–306. [Google Scholar] [CrossRef]

- Janeschitz-Kriegl, H. Polymer Melt Rheology and Flow Birefringence, 1st ed.; Springer: Berlin, Germany, 1983; p. 113, ISBN-13 978-3-642-68824-9. [Google Scholar]

- Ryu, D.S.; Inoue, T.; Osaki, K. A birefringence study of polymer crystallization in the process of elongation of films. Polymer 1998, 39, 2515–2520. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Ito, H. Structural Formation of Cyclic Olefin Copolymer (COC) Films as Revealed by Real Time Retardation Measurements during Fast Stretching Process. Technologies 2018, 6, 60. [Google Scholar] [CrossRef]

- Mackley, M.R.; Gao, P.; Nicholson, T.M. Development of anisotropy in ultra-high molecular weight polyethylene. Polymer 1990, 31, 237–242. [Google Scholar] [CrossRef]

- Bandeira, B.; Lewis, E.L.V.; Barton, D.C.; Ward, I.M. The degree of crystalline orientation as a function of draw ratio in semicrystalline polymers: A new model based on the geometry of the crystalline chain slip mechanism. J. Mater. Sci. 2016, 51, 228–235. [Google Scholar] [CrossRef]

- Li, D.; Meng, L.; Xu, J.; Chen, X.; Tian, N.; Lin, Y.; Cui, K. Constrained and free uniaxial stretching induced crystallization of polyethylene film: A comparative study. Polym. Test. 2014, 36, 110–118. [Google Scholar] [CrossRef]

- Ward, I.M.; Gordon, D.H.; Duckett, R.A. A study of uniaxial and constant-width drawing of poly(ethylene terephthalate). Polymer 1994, 35, 2554–2559. [Google Scholar] [CrossRef]

- DeMeuse, M.T. Biaxial Stretching of Film, 1st ed.; Woodhead Publishing: Cambridge, UK, 2011; ISBN-13 978-1845696757. [Google Scholar]

- Heffelfinger, C.J.; Burton, R.L. X-Ray Determination of the Crystallite Orientation Distributions of Polyethylene Terephthalate Films. J. Polym. Sci. 1960, 47, 289–306. [Google Scholar] [CrossRef]

- Ajji, A.; Zhang, X.; Elkoun, S. Biaxial orientation in HDPE films: Comparison of infrared spectroscopy, X-ray pole figures and birefringence techniques. Polymer 2005, 46, 3838–3846. [Google Scholar] [CrossRef]

- Cakmak, M.; Ou, X. Influence of biaxial stretching mode on the crystalline texture in polylactic acid films. Polymer 2008, 49, 5344–5352. [Google Scholar] [CrossRef]

- Kojima, M.; Magil, J.H.; Lin, J.S.; Magonov, S.N. Structure and Morphology of Biaxially Oriented Films of Polyethylenes. Chem. Mater. 1997, 9, 1145–1153. [Google Scholar] [CrossRef]

- Available online: https://www.saxin.jp/product/about-newlight/ (accessed on 9 November 2018).

- Norris, F.H.; Stein, R.S. The X-Ray Diffraction, Birefringence, and Infrared Dichroism of Stretched Polyethylene. J. Polym. Sci. 1956, 21, 381–396. [Google Scholar] [CrossRef]

- Hoff, M.; Pelzbauer, Z. Birefringence and orientation of polyethylene zone-drawn under various thermomechanical conditions. Polymer 1992, 33, 4158–4163. [Google Scholar] [CrossRef]

- Rossignol, J.M.; Seguela, R.; Rietsch, F. Intrinsic Amorphous Birefringence of Semi-Crystalline Polyethylene from Combined Birefringence and Infrared Dichroism Measurements. J. Polym. Sci. Part C Polym. Lett. 1989, 27, 527–532. [Google Scholar] [CrossRef]

- Takayanagi, M.; Imada, K.; Kajiyama, T. Mechanical Properties and Fine Structure of Drawn Polymers. J. Polym. Sci. Part C Polym. Synposia 1967, 15, 263–281. [Google Scholar] [CrossRef]

| Stretching Mode | Temperature (°C) | |||

|---|---|---|---|---|

| 100 | 120 | 130 | 140 | |

| Uniaxial free-width | 7 × 1 | 7 × 1 | 7 × 1 | 6 × 1 |

| Uniaxial constrained-width | 4 × 1 | 4 × 1 | 4 × 1 | 6 × 1 |

| Simultaneous biaxial | - | Break | 4 × 4 | 6 × 6 |

| Sequential biaxial | - | Break | Break | 6 × 6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashimoto, Y.; Nishitsuji, S.; Kurose, T.; Ito, H. Structural Formation of UHMWPE Film Tracked by Real-Time Retardation Measurements during Uniaxial/Biaxial Stretching. Materials 2018, 11, 2292. https://doi.org/10.3390/ma11112292

Hashimoto Y, Nishitsuji S, Kurose T, Ito H. Structural Formation of UHMWPE Film Tracked by Real-Time Retardation Measurements during Uniaxial/Biaxial Stretching. Materials. 2018; 11(11):2292. https://doi.org/10.3390/ma11112292

Chicago/Turabian StyleHashimoto, Yoshinori, Shotaro Nishitsuji, Takashi Kurose, and Hiroshi Ito. 2018. "Structural Formation of UHMWPE Film Tracked by Real-Time Retardation Measurements during Uniaxial/Biaxial Stretching" Materials 11, no. 11: 2292. https://doi.org/10.3390/ma11112292