Spray Deposition of Ag Nanowire–Graphene Oxide Hybrid Electrodes for Flexible Polymer–Dispersed Liquid Crystal Displays

Abstract

:1. Introduction

2. Materials and Methods

2.1. Ag NW–GO Hybrid Electrode Fabrication

2.2. PDLC Fabrication

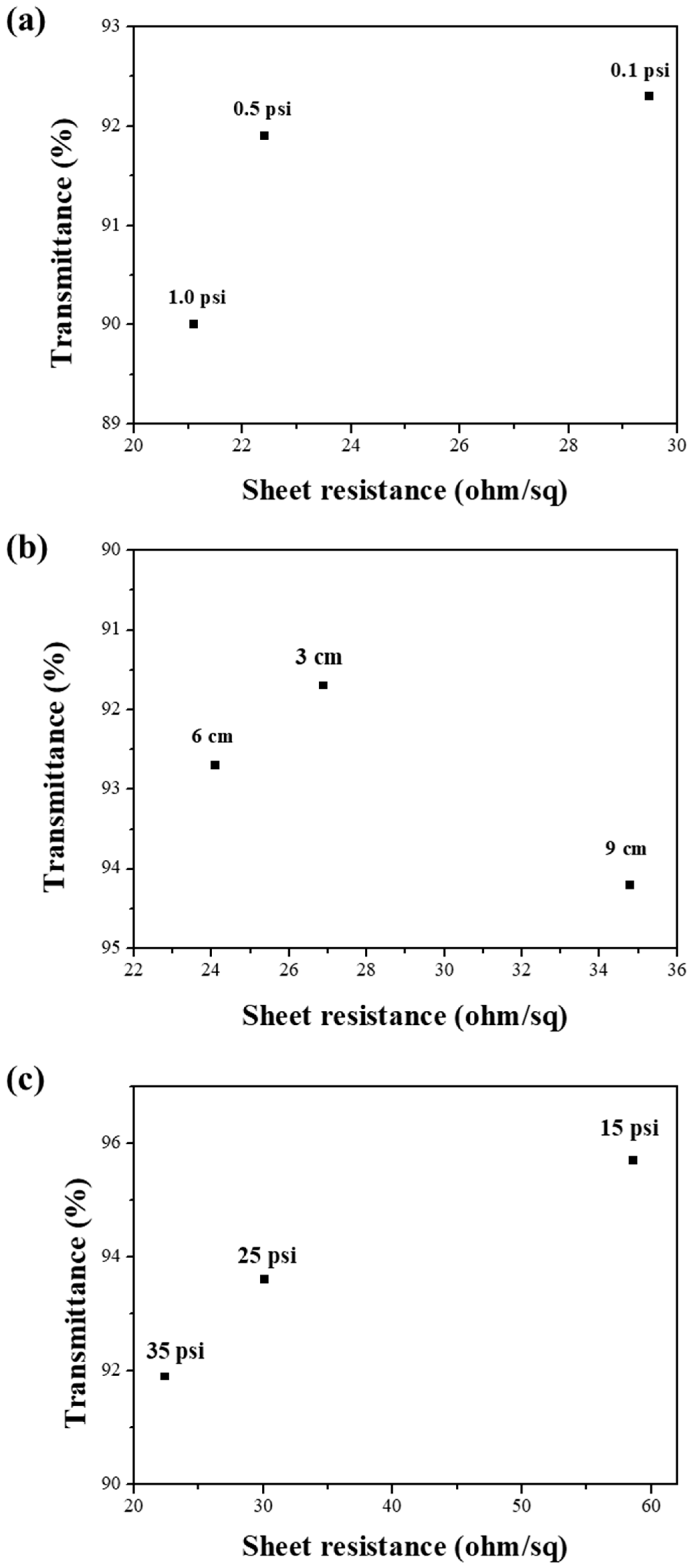

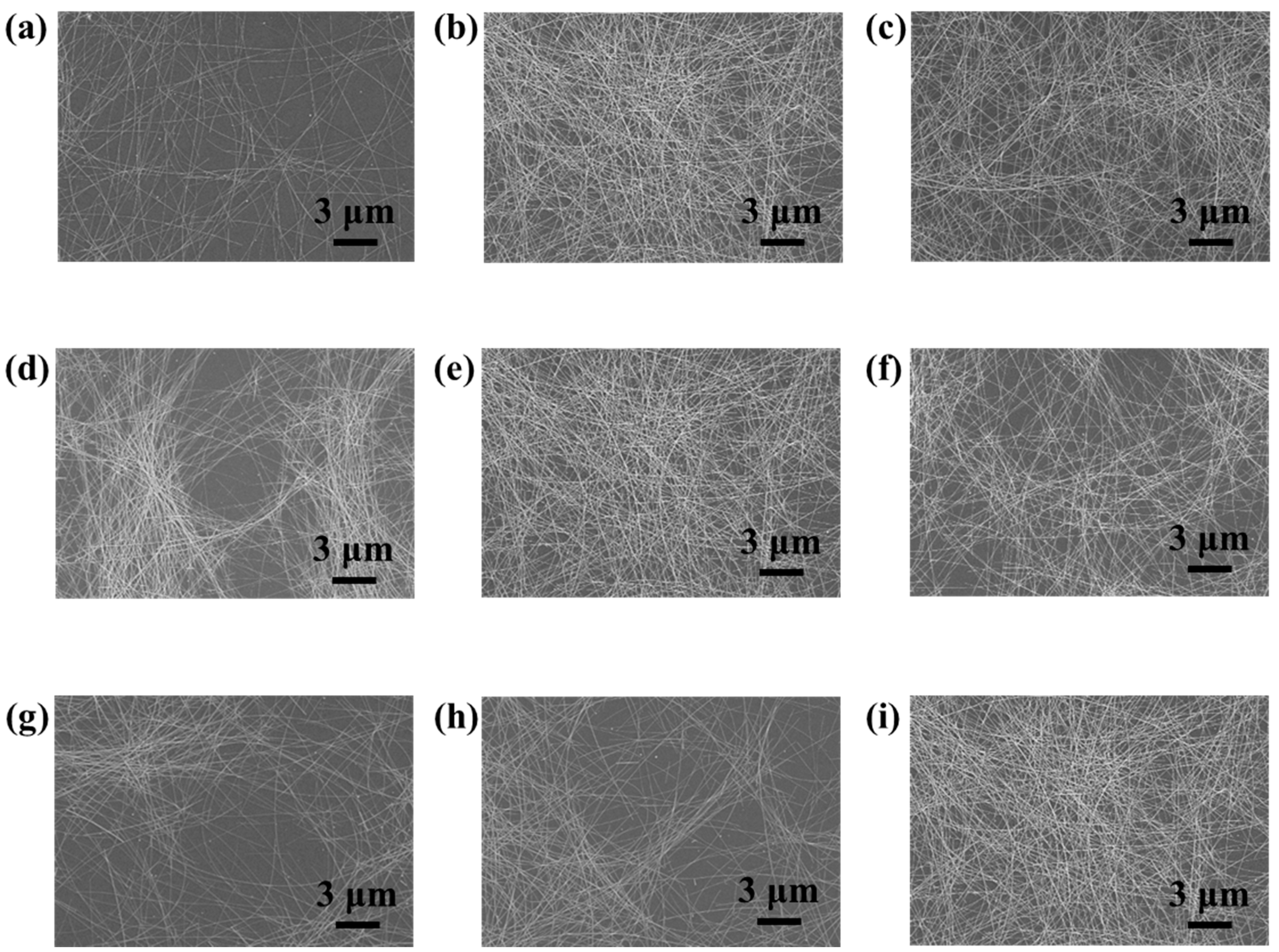

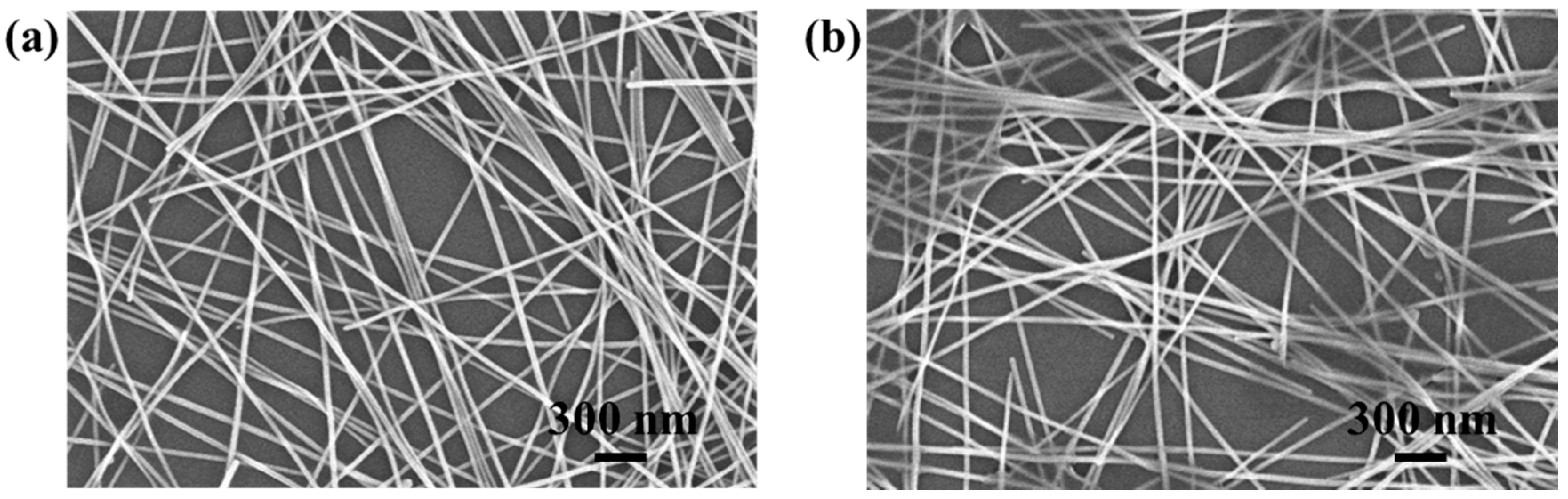

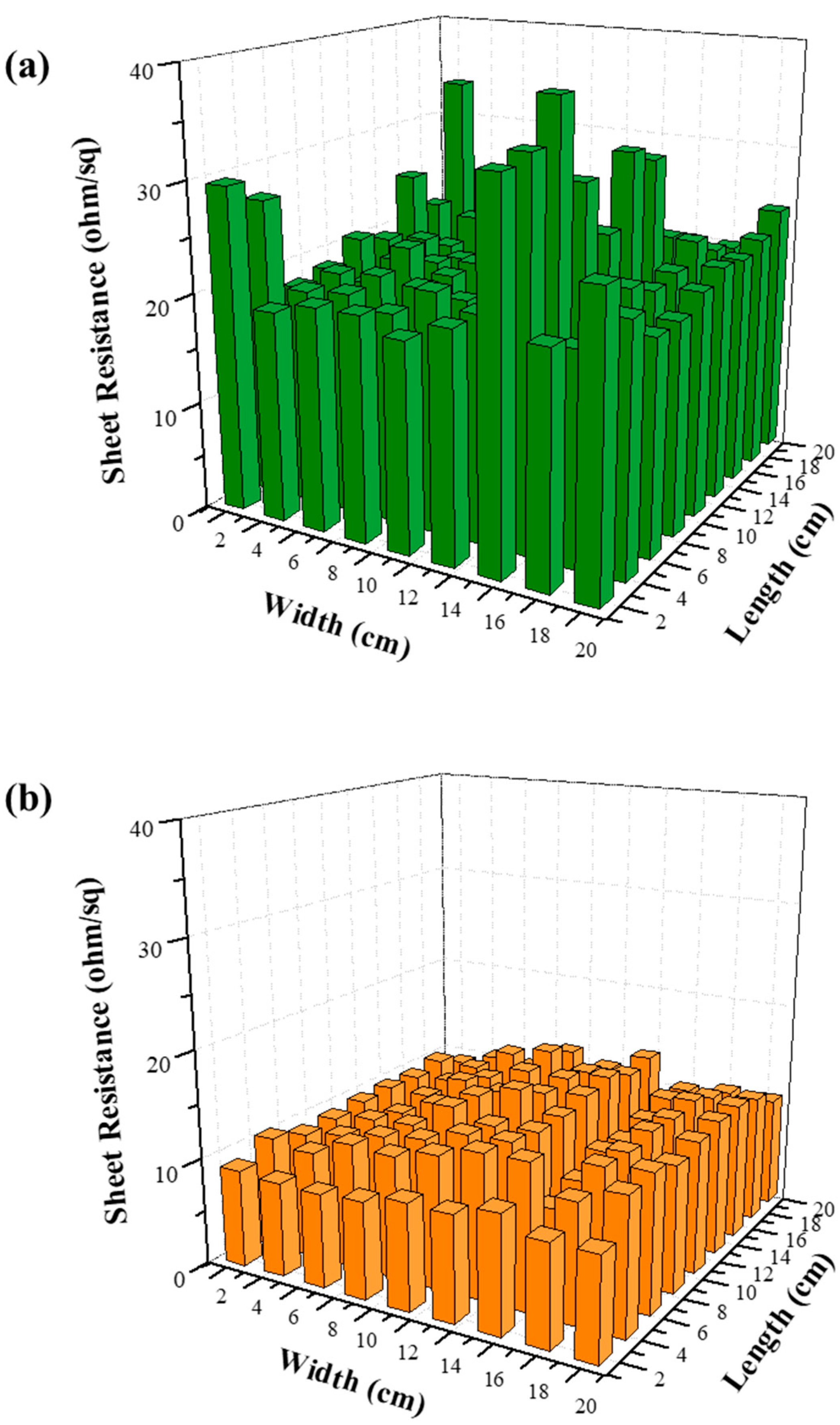

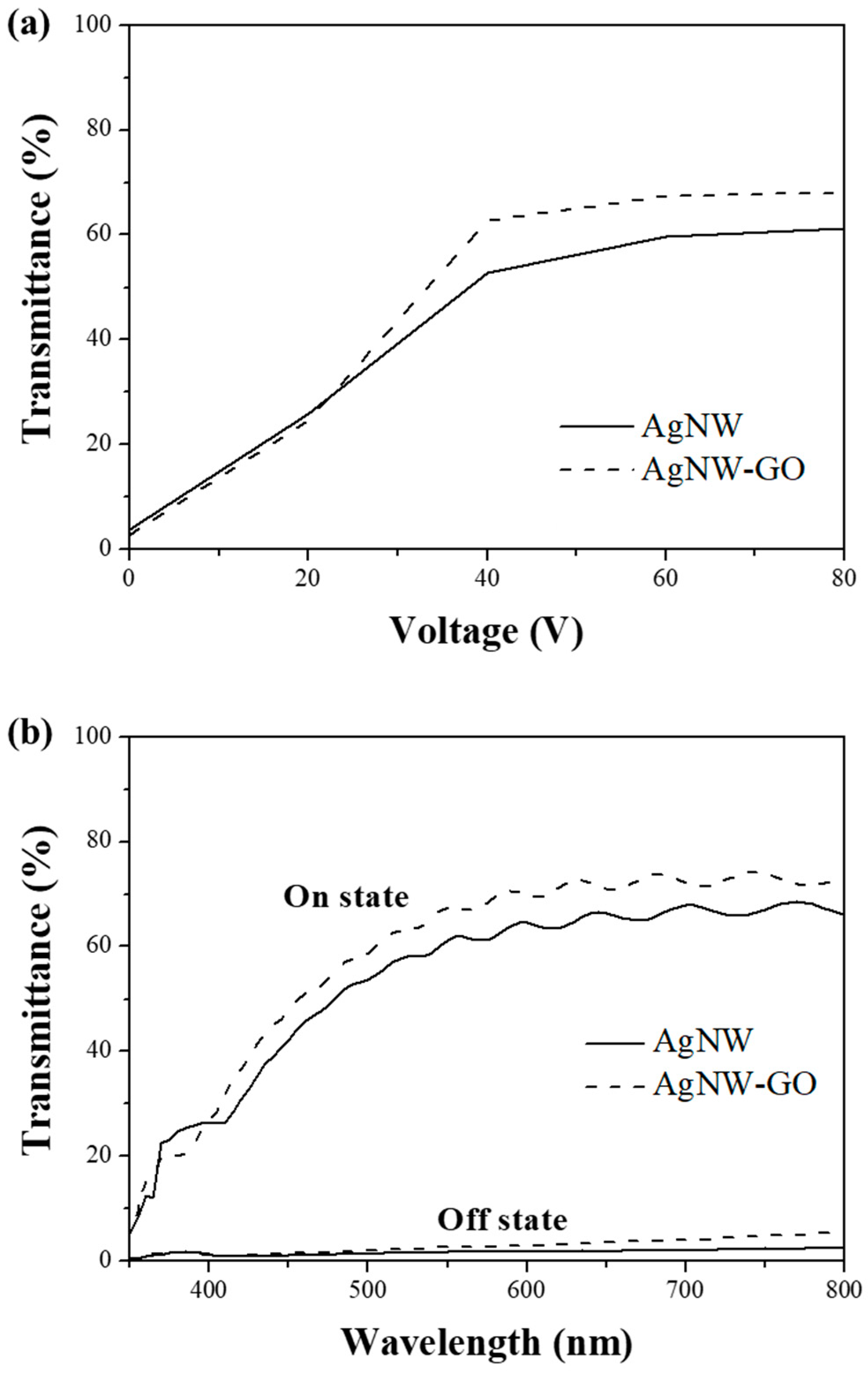

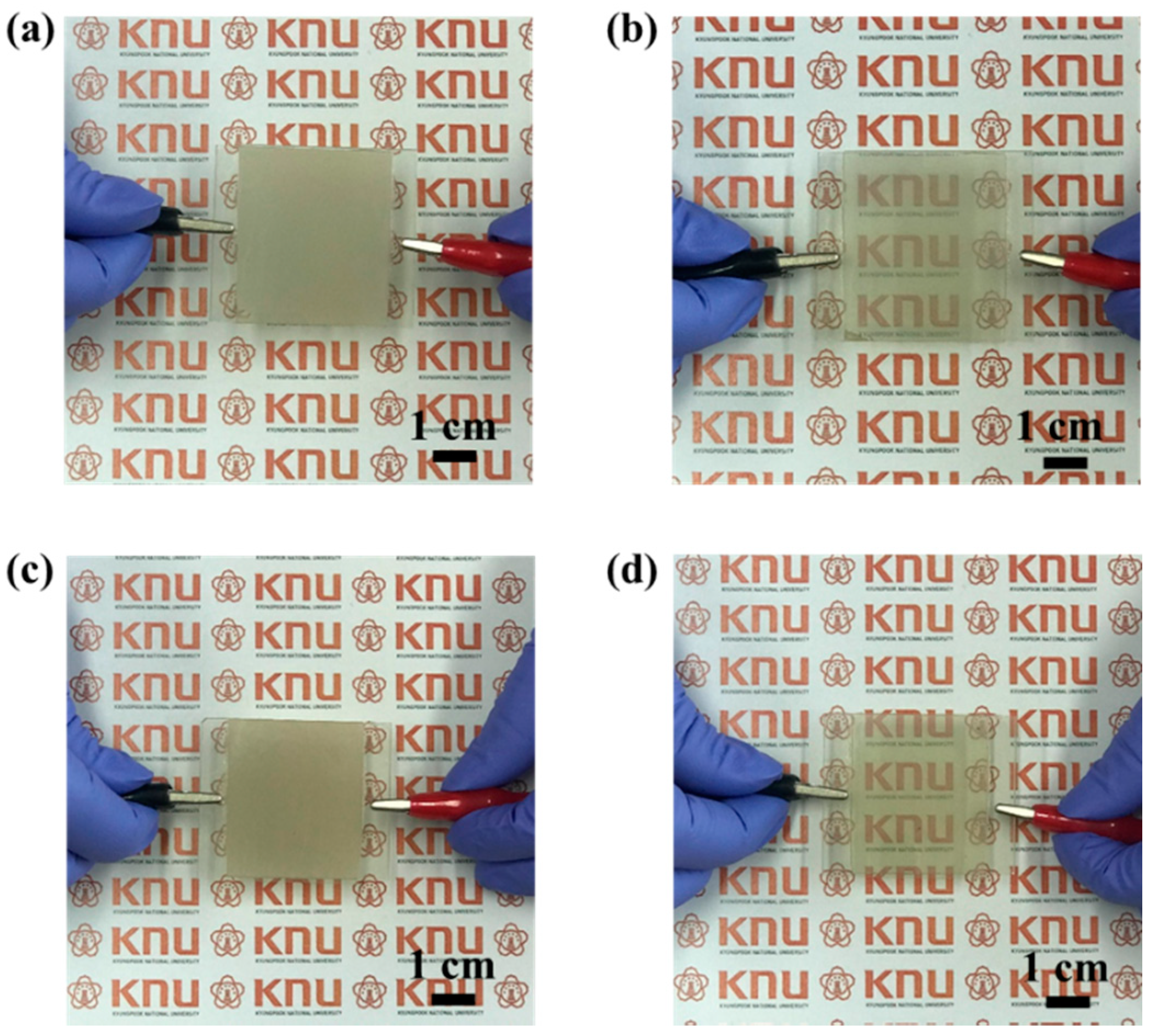

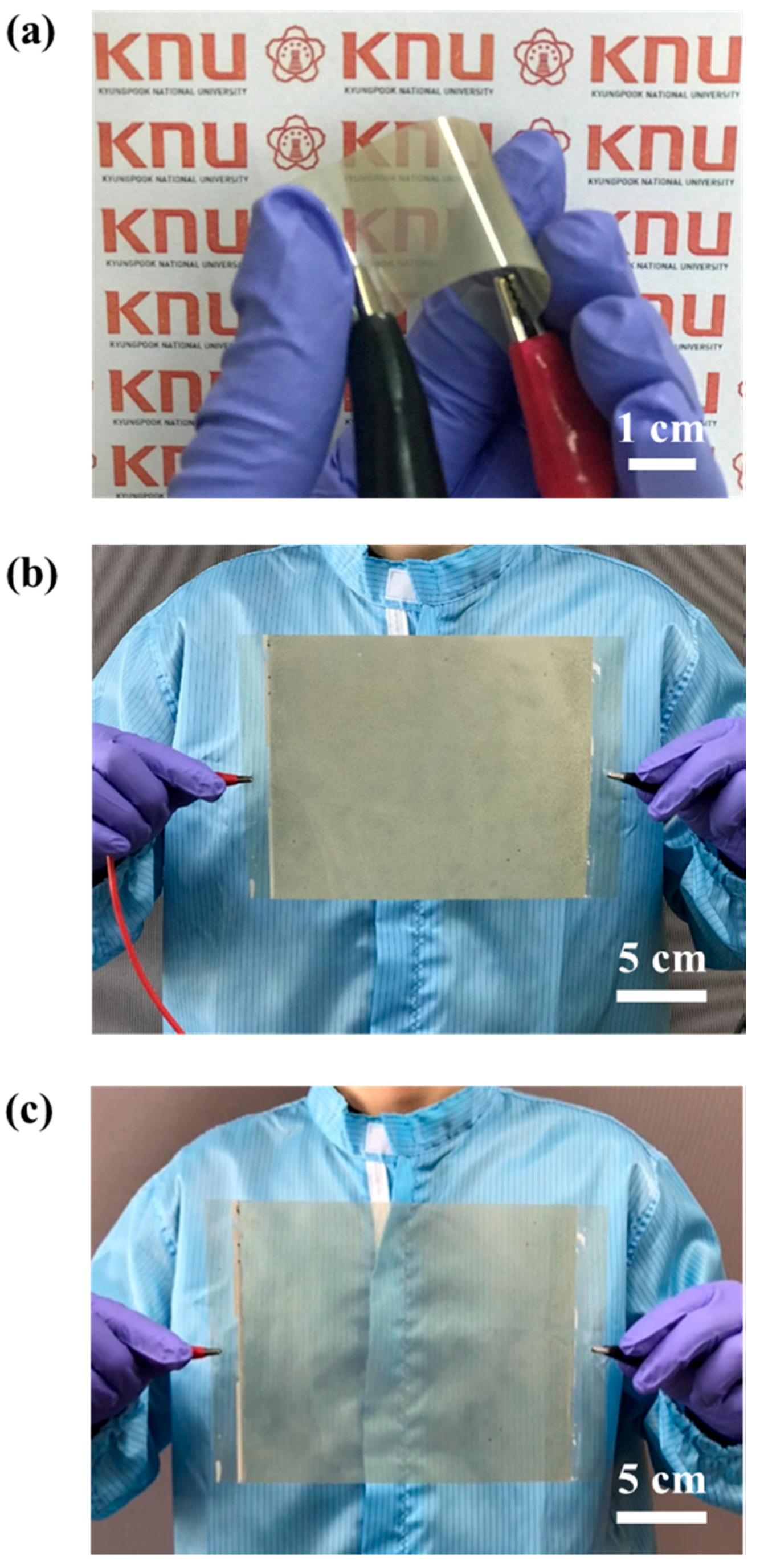

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Lampert, C.M. Large-area smart glass and integrated photovoltaics. Sol. Energ. Mater. Sol. Cells 2003, 76, 489–499. [Google Scholar] [CrossRef]

- Sol, J.A.; Timmermans, G.H.; van Breugel, A.J.; Schenning, A.P.; Debije, M.G. Multistate Luminescent Solar Concentrator “Smart” Windows. Adv. Energy Mater. 2018, 8, 1702922. [Google Scholar] [CrossRef]

- Granqvist, C.G. Electrochromics for smart windows: Oxide-based thin films and devices. Thin Solid Films 2014, 564, 1–38. [Google Scholar] [CrossRef]

- Cupelli, D.; Nicoletta, F.P.; Manfredi, S.; Vivacqua, M.; Formoso, P.; De Filpo, G.; Chidichimo, G. Self-adjusting smart windows based on polymer-dispersed liquid crystals. Sol. Energ. Mater. Sol. Cells 2009, 93, 2008–2012. [Google Scholar] [CrossRef]

- Kim, Y.; Jung, D.; Jeong, S.; Kim, K.; Choi, W.; Seo, Y. Optical properties and optimized conditions for polymer dispersed liquid crystal containing UV curable polymer and nematic liquid crystal. Curr. Appl. Phys. 2015, 15, 292–297. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, K.; Kim, K.B.; Park, J.; Lee, N.; Seo, Y. Flexible polymer dispersed liquid crystal film with graphene transparent electrodes. Curr. Appl. Phys. 2016, 16, 409–414. [Google Scholar] [CrossRef]

- Khaligh, H.H.; Liew, K.; Han, Y.; Abukhdeir, N.M.; Goldthorpe, I.A. Silver nanowire transparent electrodes for liquid crystal-based smart windows. Sol. Energ. Mater. Sol. Cells 2015, 132, 337–341. [Google Scholar] [CrossRef]

- Chou, T.; Chen, S.; Chiang, Y.; Chang, T.; Lin, C.; Chao, C. Highly conductive PEDOT: PSS film by doping p-toluenesulfonic acid and post-treatment with dimethyl sulfoxide for ITO-free polymer dispersed liquid crystal device. Org. Electron. 2017, 48, 223–229. [Google Scholar] [CrossRef]

- Lim, J.; Lee, S.; Kim, S.; Kim, T.; Koo, H.; Kim, H. Brush-paintable and highly stretchable Ag nanowire and PEDOT: PSS hybrid electrodes. Sci. Rep. 2017, 7, 14685. [Google Scholar] [CrossRef] [PubMed]

- Ricciardulli, A.G.; Yang, S.; Wetzelaer, G.A.; Feng, X.; Blom, P.W. Hybrid Silver Nanowire and Graphene-Based Solution-Processed Transparent Electrode for Organic Optoelectronics. Adv. Funct. Mater. 2018, 28, 1706010. [Google Scholar] [CrossRef]

- Chen, D.; Liang, J.; Liu, C.; Saldanha, G.; Zhao, F.; Tong, K.; Liu, J.; Pei, Q. Thermally stable silver nanowire–polyimide transparent electrode based on atomic layer deposition of zinc oxide on silver nanowires. Adv. Funct. Mater. 2015, 25, 7512–7520. [Google Scholar] [CrossRef]

- Kim, C.; Jung, C.; Oh, Y.; Kim, D. A highly flexible transparent conductive electrode based on nanomaterials. NPG Asia Mater. 2017, 9, e438. [Google Scholar] [CrossRef] [Green Version]

- Jang, J.; Im, H.; Jin, J.; Lee, J.; Lee, J.; Bae, B. A Flexible and Robust Transparent Conducting Electrode Platform Using an Electroplated Silver Grid/Surface-Embedded Silver Nanowire Hybrid Structure. ACS Appl. Mater. Interfaces 2016, 8, 27035–27043. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Di, Y.; Huard, C.M.; Guo, L.J.; Wei, J.; Guo, J. Highly stable and stretchable graphene–polymer processed silver nanowires hybrid electrodes for flexible displays. J. Mater. Chem. C 2015, 3, 1528–1536. [Google Scholar] [CrossRef]

- Lee, J.; Lee, P.; Lee, H.B.; Hong, S.; Lee, I.; Yeo, J.; Lee, S.S.; Kim, T.; Lee, D.; Ko, S.H. Room-temperature nanosoldering of a very long metal nanowire network by conducting-polymer-assisted joining for a flexible touch-panel application. Adv. Funct. Mater. 2013, 23, 4171–4176. [Google Scholar] [CrossRef]

- Zilberberg, K.; Gasse, F.; Pagui, R.; Polywka, A.; Behrendt, A.; Trost, S.; Heiderhoff, R.; Görrn, P.; Riedl, T. Highly Robust Indium-Free Transparent Conductive Electrodes Based on Composites of Silver Nanowires and Conductive Metal Oxides. Adv. Funct. Mater. 2014, 24, 1671–1678. [Google Scholar] [CrossRef]

- Kim, D.; Zhu, L.; Jeong, D.; Chun, K.; Bang, Y.; Kim, S.; Kim, J.; Oh, S. Transparent flexible heater based on hybrid of carbon nanotubes and silver nanowires. Carbon 2013, 63, 530–536. [Google Scholar] [CrossRef]

- Fan, Z.; Liu, B.; Liu, X.; Li, Z.; Wang, H.; Yang, S.; Wang, J. A flexible and disposable hybrid electrode based on Cu nanowires modified graphene transparent electrode for non-enzymatic glucose sensor. Electrochim. Acta 2013, 109, 602–608. [Google Scholar] [CrossRef]

- Lee, J.; Shin, D.; Park, J. Fabrication of silver nanowire-based stretchable electrodes using spray coating. Thin Solid Films 2016, 608, 34–43. [Google Scholar] [CrossRef]

- Scardaci, V.; Coull, R.; Lyons, P.E.; Rickard, D.; Coleman, J.N. Spray deposition of highly transparent, low-resistance networks of silver nanowires over large areas. Small 2011, 7, 2621–2628. [Google Scholar] [CrossRef] [PubMed]

- Deegan, R.D.; Bakajin, O.; Dupont, T.F.; Huber, G.; Nagel, S.R.; Witten, T.A. Contact line deposits in an evaporating drop. Phys. Rev. E 2000, 62, 756. [Google Scholar] [CrossRef]

- Ha, B.; Jo, S. Hybrid Ag nanowire transparent conductive electrodes with randomly oriented and grid-patterned Ag nanowire networks. Sci. Rep. 2017, 7, 11614. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Li, L.; Tong, K.; Ren, Z.; Hu, W.; Niu, X.; Chen, Y.; Pei, Q. Silver nanowire percolation network soldered with graphene oxide at room temperature and its application for fully stretchable polymer light-emitting diodes. ACS Nano 2014, 8, 1590–1600. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Salmi, Z.; Joshi, N.; Jha, P.; Decorse, P.; Lecoq, H.; Lau-Truong, S.; Jouini, M.; Aswal, D.; Chehimi, M. Electrochemical investigation of free-standing polypyrrole–silver nanocomposite films: A substrate free electrode material for supercapacitors. RCS Adv. 2013, 3, 24567–24575. [Google Scholar] [CrossRef]

- Kim, Y.; Hong, J.; Lee, S. Fabrication of a highly bendable LCD with an elastomer substrate by using a replica-molding method. J. Soc. Inf. Disp. 2006, 14, 1091–1095. [Google Scholar] [CrossRef]

- Kim, I.; Kim, T.; Lee, S.; Kim, B. Extremely Foldable and Highly Transparent Nanofiber-Based Electrodes for Liquid Crystal Smart Device. Sci. Rep. 2018, 8, 11517. [Google Scholar] [CrossRef] [PubMed]

| Electrode | Sheet Resistance (Ω/sq) | Transmittance (%) (at 550 nm) | FoM (10−3 Ω−1) |

|---|---|---|---|

| Ag NW | 22.8 | 92.0 | 19.1 |

| Ag NW–GO | 15.6 | 90.7 | 24.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, Y.; Kim, C.S.; Jo, S. Spray Deposition of Ag Nanowire–Graphene Oxide Hybrid Electrodes for Flexible Polymer–Dispersed Liquid Crystal Displays. Materials 2018, 11, 2231. https://doi.org/10.3390/ma11112231

Choi Y, Kim CS, Jo S. Spray Deposition of Ag Nanowire–Graphene Oxide Hybrid Electrodes for Flexible Polymer–Dispersed Liquid Crystal Displays. Materials. 2018; 11(11):2231. https://doi.org/10.3390/ma11112231

Chicago/Turabian StyleChoi, Yumi, Chang Su Kim, and Sungjin Jo. 2018. "Spray Deposition of Ag Nanowire–Graphene Oxide Hybrid Electrodes for Flexible Polymer–Dispersed Liquid Crystal Displays" Materials 11, no. 11: 2231. https://doi.org/10.3390/ma11112231