Valorization of Tomato Processing by-Products: Fatty Acid Extraction and Production of Bio-Based Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

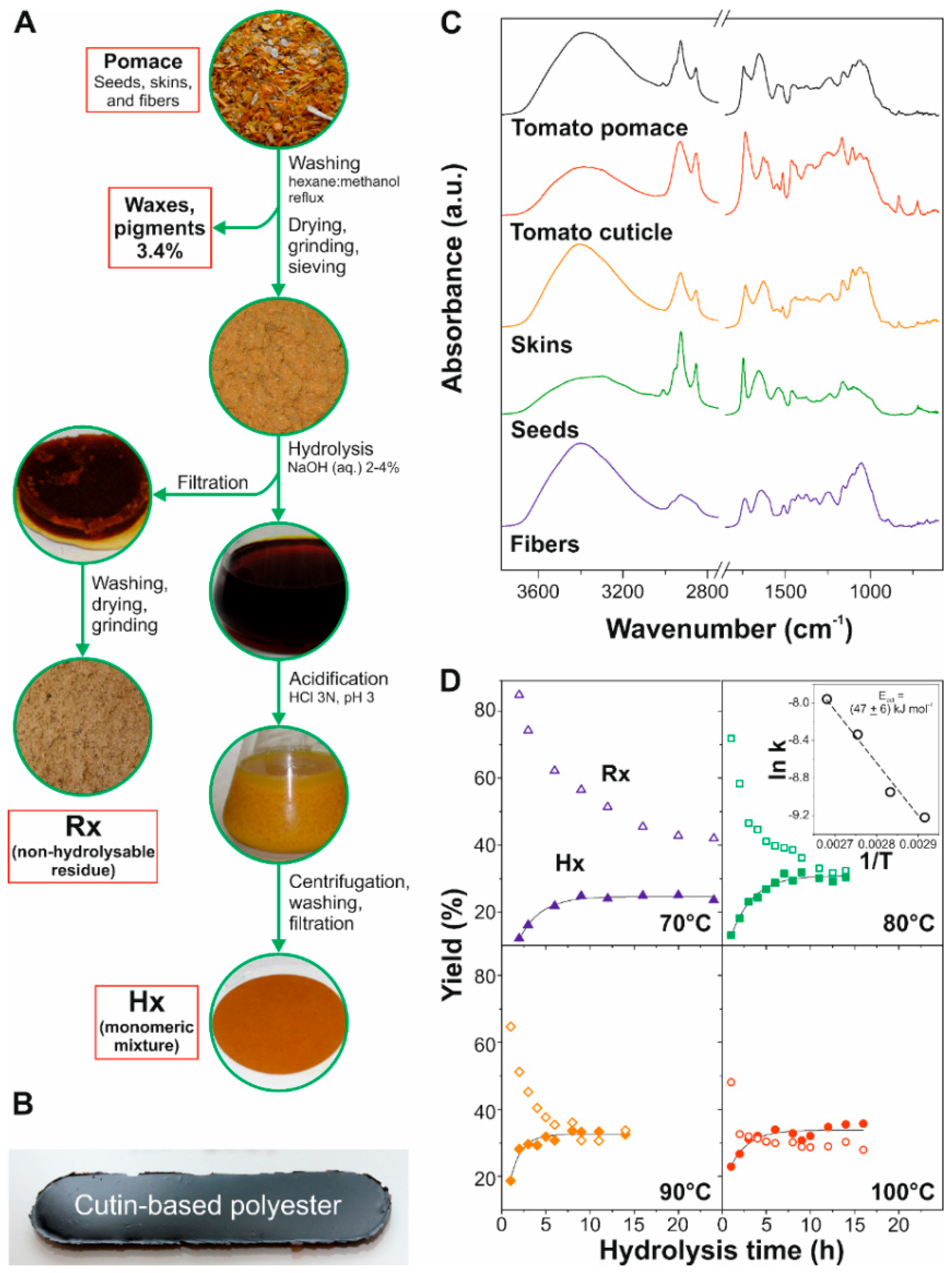

2.2. Tomato Pomace Conditioning

2.3. Hydrolysis and Recovery of Fractions

2.4. Chemical Characterization of Tomato Pomace and its Components and Fractions

2.4.1. Infrared Spectroscopy

2.4.2. Fatty Acid Composition

2.5. Polymer Synthesis

2.6. Polymer Characterization

2.6.1. Chemical Characterization

2.6.2. Thermal Characterization

2.6.3. Mechanical Characterization

2.6.4. Surface Hydrophobicity

3. Results and Discussion

3.1. Characterization of Tomato Pomace Fractions

3.2. Kinetics and Activation Energy of the Alkaline Hydrolysis

3.3. Chemical Analysis of Rx and Hx

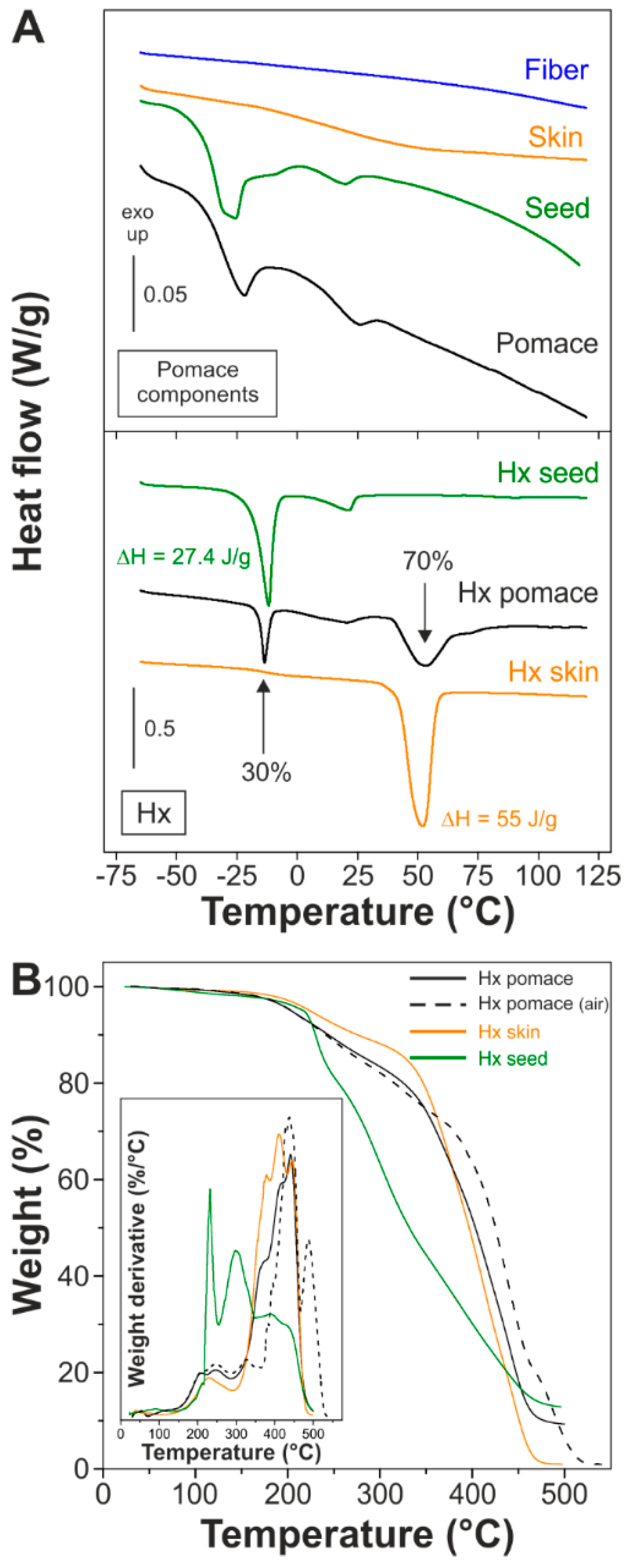

3.4. Thermal Characterization of Pomace Components and Hx Fractions

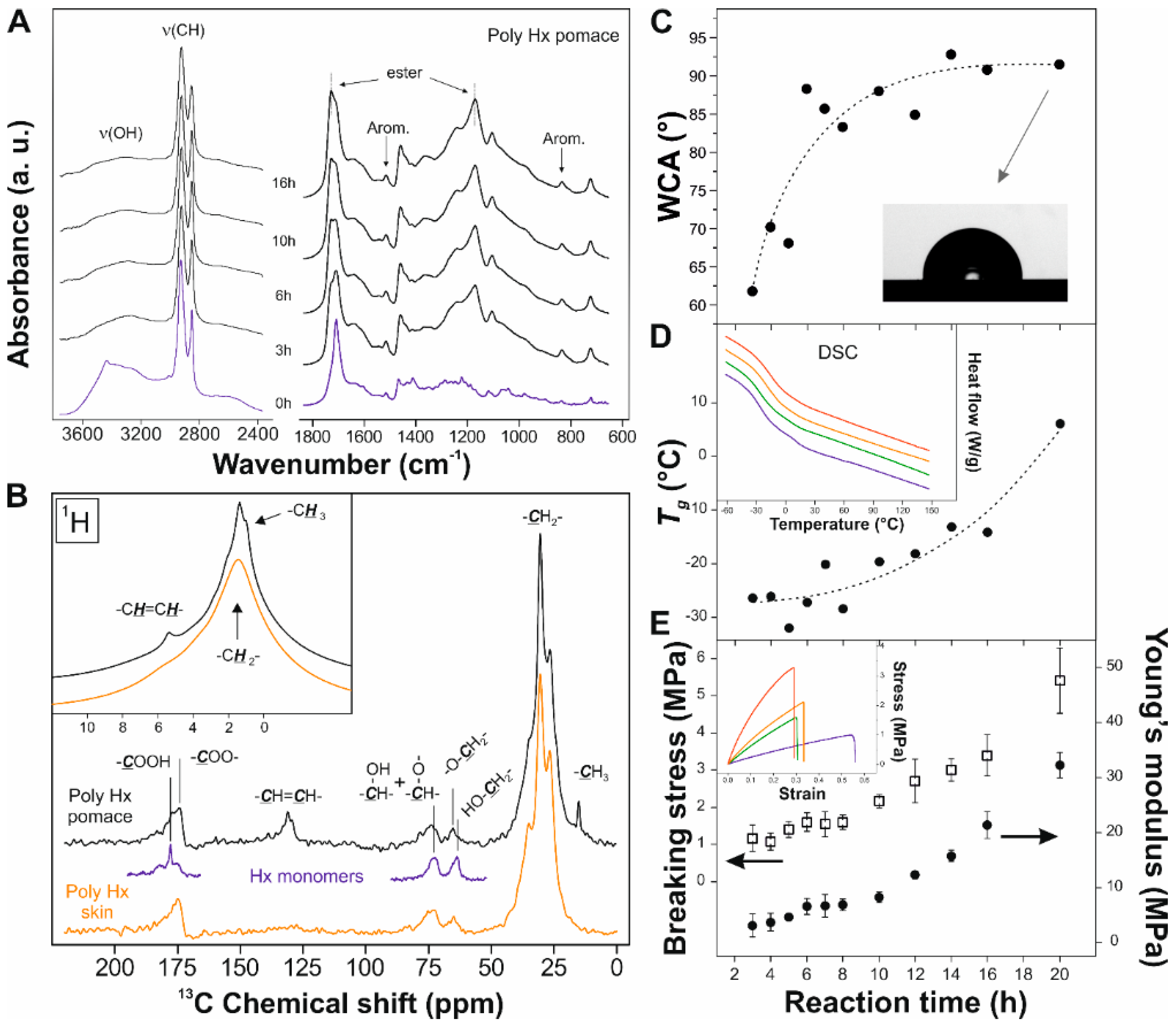

3.5. Polymerization of Hx

3.6. Physical Characterization of Poly Hx

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gustafsson, J.; Cederberg, C.; Sonesson, U.; Emanuelsson, A. The Methodology of the FAO Study: Global Food Losses and Food Waste-Extent, Causes and Prevention-FAO, 2011; SIK Institutet för Livsmedel och Bioteknik: Gothenburg, Sweden, 2013. [Google Scholar]

- Stenmarck, A.; Jensen, C.; Quested, T.; Moates, G.; Buksti, M.; Cseh, B.; Juul, S.; Parry, A.; Politano, A.; Redlingshofer, B. Estimates of European Food Waste Levels; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2016. [Google Scholar]

- Tonini, D.; Albizzati, P.F.; Astrup, T.F. Environmental impacts of food waste: Learnings and challenges from a case study on UK. Waste Manag. 2018, 76, 744–766. [Google Scholar] [CrossRef] [PubMed]

- Fritsch, C.; Staebler, A.; Happel, A.; Cubero Márquez, M.; Aguiló-Aguayo, I.; Abadias, M.; Gallur, M.; Cigognini, I.; Montanari, A.; López, M.; et al. Processing, Valorization and Application of Bio-Waste Derived Compounds from Potato, Tomato, Olive and Cereals: A Review. Sustainability 2017, 9, 1492. [Google Scholar] [CrossRef]

- FAOSTAT, Crops. 2016. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 1 November 2018).

- Shrestha, N.; Fogg, A.; Wilder, J.; Franco, D.; Komisar, S.; Gadhamshetty, V. Electricity generation from defective tomatoes. Bioelectrochemistry 2016, 112, 67–76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Del Valle, M.; Cámara, M.; Torija, M.E. Chemical characterization of tomato pomace. J. Sci. Food Agric. 2006, 86, 1232–1236. [Google Scholar] [CrossRef]

- Mangut, V.; Sabio, E.; Gañan, J.; González, J.F.; Ramiro, A.; González, C.M.; Román, S.; Al-Kassir, A. Thermogravimetric study of the pyrolysis od biomass residues from tomato processing industry. Fuel Process. Technol. 2006, 87, 109–115. [Google Scholar] [CrossRef]

- Liadakis, G.N.; Tzia, C.; Oreopoulou, V.; Thomopoulos, C.D. Protein Isolation from Tomato Seed Meal, Extraction Optimization. J. Food Sci. 1995, 60, 477–482. [Google Scholar] [CrossRef]

- Grassino, A.N.; Halambek, J.; Djaković, S.; Rimac Brnčić, S.; Dent, M.; Grabarić, Z. Utilization of tomato peel waste from canning factory as a potential source for pectin production and application as tin corrosion inhibitor. Food Hydrocoll. 2016, 52, 265–274. [Google Scholar] [CrossRef]

- Sabio, E.; Álvarez-Murillo, A.; Román, S.; Ledesma, B. Conversion of tomato-peel waste into solid fuel by hydrothermal carbonization: Influence of the processing variables. Waste Manag. 2016, 47, 122–132. [Google Scholar] [CrossRef] [PubMed]

- Rao, A.V.; Rao, L.G. Carotenoids and human health. Pharmacol. Res. 2007, 55, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, E.; Heredia-Guerrero, J.A.; Heredia, A. The biophysical design of plant cuticles: An overview. New Phytol. 2011, 189, 938–949. [Google Scholar] [CrossRef] [PubMed]

- Kershaw, P. Exploring the Potential for Adopting Alternative Materials to Reduce Marine Plastic Litter; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2018; ISBN 978-92-807-3703-5. [Google Scholar]

- Heredia-Guerrero, J.A.; Heredia, A.; Domínguez, E.; Cingolani, R.; Bayer, I.S.; Athanassiou, A.; Benítez, J.J. Cutin from agro-waste as a raw material for the production of bioplastics. J. Exp. Bot. 2017, 68, 5401–5410. [Google Scholar] [CrossRef] [PubMed]

- Montanari, A.; Bolzoni, L.; Cigognini, I.M.; Ciruelos, A.; Gómez Cardoso, M.; de la Torre, R. Tomato bio-based lacquer for sustainable metal packaging. Agro Food Ind. High. Technol. 2014, 25, 50–54. [Google Scholar] [CrossRef]

- Arrieta-Baez, D.; Cruz-Carrillo, M.; Gómez-Patiño, M.B.; Zepeda-Vallejo, L.G. Derivatives of 10,16-dihydroxyhexadecanoic acid isolated from tomato (Solanum lycopersicum) as potential materials for aliphatic polyesters. Molecules 2011, 16, 4923–4936. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Patiño, M.B.; Gutiérrez-Salgado, D.Y.; García-Hernández, E.; Mendez-Mendez, J.V.; Andraca Adame, J.A.; Campos-Terán, J.; Arrieta-Baez, D. Polymerization of 10,16-dihydroxyhexadecanoic acid, main monomero of tomato cuticle, using the Lewis acidic ionic liquid choline chloride 2ZnCl2. Front. Mater. 2015, 2, 67. [Google Scholar] [CrossRef]

- Manrich, A.; Moreira, F.K.; Otoni, C.G.; Lorevice, M.V.; Martins, M.A.; Mattoso, L.H. Hydrophobic edible films made up of tomato cutin and pectin. Carbohydr. Polym. 2017, 164, 83–91. [Google Scholar] [CrossRef] [PubMed]

- Benitez, J.J.; Heredia-Guerrero, J.A.; Bayer, I.S.; Athanassiou, A. A Polyester from Tomato Fruit Processing Residues Obtained by Non-Catalyzed Melt-Polycondensation in Air. ES201630194, February 2016. [Google Scholar]

- Heredia-Guerrero, J.A.; Benitez, J.J.; Cataldi, P.; Paul, U.C.; Contardi, M.; Cingolani, R.; Bayer, I.S.; Heredia, A.; Athanassiou, A. All-Natural Sustainable Packaging Materials Inspired by Plant Cuticles. Adv. Sustain. Syst. 2017, 1, 1600024. [Google Scholar] [CrossRef]

- Heredia-Guerrero, J.A.; Goldoni, L.; Benitez, J.J.; Davis, A.; Ceseracciu, L.; Cingolani, R.; Bayer, I.S.; Heinze, T.; Koschella, A.; Heredia, A.; et al. Cellulose-polyhydroxylated fatty acid ester-based bioplastics with tuning properties: Acylation via a mixed anhydride system. Carbohydr. Polym. 2017, 173, 312–320. [Google Scholar] [CrossRef] [PubMed]

- Cigognini, I.; Montanari, A.; De la Torre Carreras, R.; Cardoso, G. Extraction Method of a Polyester Polymer or Cutin from the Wasted Tomato Peels and Polyester Polimer so Extracted. Patent WO2015028299A1, March 2015. [Google Scholar]

- Al-Wandawi, H.; Abdul-Rahman, M.; Al-Shaikhly, K. Tomato processing wastes as essential raw materials source. J. Agric. Food Chem. 1985, 33, 804–807. [Google Scholar] [CrossRef]

- Domínguez, E.; López-Casado, G.; Cuartero, J.; Heredia, A. Development of fruit cuticle in cherry tomato (Solanum lycopersicum). Funct. Plant Biol. 2008, 35, 403–411. [Google Scholar] [CrossRef]

- Latlief, S.J.; Knorr, D. Tomato Seed Protein Concentrates: Effects of Methods of Recovery Upon Yield and Compositional Characteristics. J. Food Sci. 1983, 48, 1583–1586. [Google Scholar] [CrossRef]

- López-Casado, G.; Matas, A.J.; Domínguez, E.; Cuartero, J.; Heredia, A. Biomechanics of isolated tomato (Solanum lycopersicum L.) fruit cuticles: The role of the cutin matrix and polysaccharides. J. Exp. Bot. 2007, 58, 3875–3883. [Google Scholar] [CrossRef] [PubMed]

- Higgins, H.G.; Stewart, C.M.; Harrington, K.J. Infrared spectra of cellulose and related polysaccharides. J. Polym. Sci. 1961, 51, 59–84. [Google Scholar] [CrossRef]

- Kačuráková, M.; Belton, P.S.; Wilson, R.H.; Hirsch, J.; Ebringerová, A. Hydration properties of xylan-type structures: An FTIR study of xylooligosaccharides. J. Sci. Food Agric. 1999, 77, 38–44. [Google Scholar] [CrossRef]

- Boeriu, C.G.; Bravo, D.; Gosselink, R.J.A.; van Dam, J.E.G. Characterisation of structure-dependent functional properties of lignin with infrared spectroscopy. Ind. Crops Prod. 2004, 20, 205–218. [Google Scholar] [CrossRef]

- Xiao, B.; Sun, X.F.; Sun, R. Chemical, structural, and thermal characterizations of alkali-soluble lignins and hemicelluloses, and cellulose from maize stems, rye straw, and rice straw. Polym. Degrad. Stab. 2001, 74, 307–319. [Google Scholar] [CrossRef]

- Sene, C.; McCann, M.C.; Wilson, R.H.; Grinter, R. Fourier-Transform Raman and Fourier-Transform Infrared Spectroscopy (An Investigation of Five Higher Plant Cell Walls and Their Components). Plant Physiol. 1994, 106, 1623–1631. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdel-Rahman, Y. The chemical constituents of tomato seeds. Food Chem. 1982, 9, 315–318. [Google Scholar] [CrossRef]

- Heredia-Guerrero, J.A.; Benítez, J.J.; Domínguez, E.; Bayer, I.S.; Cingolani, R.; Athanassiou, A.; Heredia, A. Infrared and Raman spectroscopic features of plant cuticles: A review. Front. Plant Sci. 2014, 5, 305. [Google Scholar] [CrossRef] [PubMed]

- Szymanska-Chargot, M.; Zdunek, A. Use of FT-IR Spectra and PCA to the Bulk Characterization of Cell Wall Residues of Fruits and Vegetables along a Fraction Process. Food Biophys. 2013, 8, 29–42. [Google Scholar] [CrossRef] [PubMed]

- Aksnes, G.; Olav Libnau, F.; Kobberøe Skov, L.; Kofod, P.; Elding, L.; Trabjerg, I. Temperature Dependence of Ester Hydrolysis in Water. Acta Chem. Scand. 1991, 45, 463–468. [Google Scholar] [CrossRef]

- Wan, B.-Z.; Kao, C.-Y.; Cheng, W.-H. Kinetics of Depolymerization of Poly(ethylene terephthalate) in a Potassium Hydroxide Solution. Ind. Eng. Chem. Res. 2001, 40, 509–514. [Google Scholar] [CrossRef]

- Von Soest, P.; Wine, R. Use of detergents in the analysis of fibrous feed. Iv. Determination of plant cell-wall constituent’s. J. Assoc. Anal. Chem. 1967, 50, 50–55. [Google Scholar]

- Cámara, M.; Del Valle, M.; Torija, M.E.; Castilho, C. Fatty Acid Composition of Tomato Pomace. Acta Hortic. 2001, 542, 175–180. [Google Scholar] [CrossRef]

- Kosma, D.K.; Parsons, E.P.; Isaacson, T.; Lü, S.; Rose, J.K.C.; Jenks, M.A. Fruit cuticle lipid composition during development in tomato ripening mutants. Physiol. Plant. 2010, 139, 107–117. [Google Scholar] [CrossRef] [PubMed]

- Ishiguro, T.; Adachi, S.; Matsuno, R. Thermogravimetric Analysis of Cyclodextrin-Fatty Acid Complex Formation and Its Use for Predicting Suppressed Autoxidation of Fatty Acids. Biosci. Biotechnol. Biochem. 1995, 59, 51–54. [Google Scholar] [CrossRef] [Green Version]

- Benítez, J.J.; Heredia-Guerrero, J.A.; Guzmán-Puyol, S.; Barthel, M.J.; Domínguez, E.; Heredia, A. Polyhydroxyester Films Obtained by Non-Catalyzed Melt-Polycondensation of Natural Occurring Fatty Polyhydroxyacids. Front. Mater. 2015, 2, 59. [Google Scholar] [CrossRef]

- Garbow, J.R.; Stark, R.E. Nuclear magnetic resonance relaxation studies of plant polyester dynamics. 1. Cutin from limes. Macromolecules 1990, 23, 2814–2819. [Google Scholar] [CrossRef]

- Deshmukh, A.P.; Simpson, A.J.; Hadad, C.M.; Hatcher, P.G. Insights into the structure of cutin and cutan from Agave americana leaf cuticle using HRMAS NMR spectroscopy. Org. Geochem. 2005, 36, 1072–1085. [Google Scholar] [CrossRef]

- Benítez, J.J.; Heredia-Guerrero, J.A.; de Vargas-Parody, M.I.; Cruz-Carrillo, M.A.; Morales-Flórez, V.; De la Rosa-Fox, N.; Heredia, A. Biodegradable polyester films from renewable aleuritic acid: Surface modifications induced by melt-polycondensation in air. J. Phys. D Appl. Phys. 2016, 49, 175601. [Google Scholar] [CrossRef]

- Benítez, J.J.; Heredia-Guerrero, J.A.; Cruz-Carrillo, M.A.; Barthel, M.J.; Knicker, H.E.; Heredia, A. Insolubilization and thermal stabilization of a long-chain polyester by noncatalyzed melt-polycondensation synthesis in air. J. Appl. Polym. Sci. 2016, 134, 44350. [Google Scholar] [CrossRef]

- Benítez, J.J.; Heredia-Guerrero, J.A.; Guzmán-Puyol, S.; Domínguez, E.; Heredia, A. Long-Chain Polyhydroxyesters from Natural Occurring Aleuritic Acid as Potential Material for Food Packaging. Soft Mater. 2015, 13, 5–11. [Google Scholar] [CrossRef] [Green Version]

| Pomace Fraction | Content (%, w/w) | Components (*) | Calculated Content in Pomace (%, w/w) |

|---|---|---|---|

| Fiber | 15 | Polysaccharides (cellulose, hemicelluloses) and lignin (100%) | 15 |

| Seed | 55 | Polysaccharides (cellulose) (19%) | 10 |

| Proteins (29%) | 16 | ||

| Lipids (unsaturated:saturated ~80:20) (26%) | 14 | ||

| Others (26%) | 14 | ||

| Skin | 30 | Cutin (fatty acids, including minor contributions of flavonoids and phenolic compounds) (65%) | 20 |

| Polysaccharides (cellulose, hemicelluloses, pectin) (32%) | 9 | ||

| Waxes (3%) | 1 |

| Monomer | Abundance (Molecular %) | |||

|---|---|---|---|---|

| Hx Pomace | Hx Seed | |||

| Acids | saturated | C14 C16 C18 p-coumaric | 1.2 4.3 0.9 2.6 | 0.2 17.1 1.2 - |

| Total | 9.0 | 18.5 | ||

| unsaturated | 9(en)-C18 (oleic) 9,12(dien)-C18 (linoleic) | 11.9 16.1 | 28.4 52.9 | |

| Total | 28.0 | 81.3 | ||

| Hydroxy acids | mono-OH | 16-C16 | 2.8 | - |

| di-OH | 9,16-C16 10,16-C16 8(9),18-C18 10(11),18-C18 | 2.0 43.3 0.6 1.0 | 0.2 - - - | |

| tri-OH | 9,10,18-C18 | 1.7 | - | |

| Total | 51.4 | 0.2 | ||

| Diacids | saturated | C16 C18 | 1.8 0.2 | - - |

| Total | 2.0 | 0.0 | ||

| Hydroxy diacids | mono-OH | 7-C16 8-C16 | 2.1 4.8 | - - |

| di-OH | 6,7-C18 7(9),8-C18 9,10-C18 | 0.5 1.3 0.9 | - - - | |

| Total | 9.6 | 0.0 | ||

| Polymer | Young’s Modulus (MPa) | Breaking Stress (MPa) | Breaking Strain (%) | Rupture Energy (N mm/mm3) | Td 5% (°C) | Td max (°C) | WCA (°) |

|---|---|---|---|---|---|---|---|

| Poly Hx pomace (air) | 21 ± 4 | 3.4 ± 0.6 | 33 ± 8 | 0.5 + 0.1 | 298 | 441 | 91 ± 4 |

| Poly Hx pomace (N2) | 8.8 ± 0.6 | 1.3 ± 0.4 | 19 ± 7 | 0.15 + 0.08 | 313 | 445 | 102 ± 6 |

| Poly Hx skin (air) | 8.9 ± 0.4 | 1.9 ± 0.2 | 24 ± 4 | 0.24 + 0.08 | 330 | 448 | 103 ± 3 |

| Poly Hx skin (N2) | 9.0 ± 0.6 | 1.9 ± 0.3 | 25 ± 3 | 0.26 + 0.07 | 335 | 446 | 105 ± 3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benítez, J.J.; Castillo, P.M.; Del Río, J.C.; León-Camacho, M.; Domínguez, E.; Heredia, A.; Guzmán-Puyol, S.; Athanassiou, A.; Heredia-Guerrero, J.A. Valorization of Tomato Processing by-Products: Fatty Acid Extraction and Production of Bio-Based Materials. Materials 2018, 11, 2211. https://doi.org/10.3390/ma11112211

Benítez JJ, Castillo PM, Del Río JC, León-Camacho M, Domínguez E, Heredia A, Guzmán-Puyol S, Athanassiou A, Heredia-Guerrero JA. Valorization of Tomato Processing by-Products: Fatty Acid Extraction and Production of Bio-Based Materials. Materials. 2018; 11(11):2211. https://doi.org/10.3390/ma11112211

Chicago/Turabian StyleBenítez, José J., Paula M. Castillo, José C. Del Río, Manuel León-Camacho, Eva Domínguez, Antonio Heredia, Susana Guzmán-Puyol, Athanassia Athanassiou, and José A. Heredia-Guerrero. 2018. "Valorization of Tomato Processing by-Products: Fatty Acid Extraction and Production of Bio-Based Materials" Materials 11, no. 11: 2211. https://doi.org/10.3390/ma11112211