Drivability-Related Discrete-Time Model Predictive Control of Mode Transition in Pre-Transmission Parallel Hybrid Powertrains

Abstract

:1. Introduction

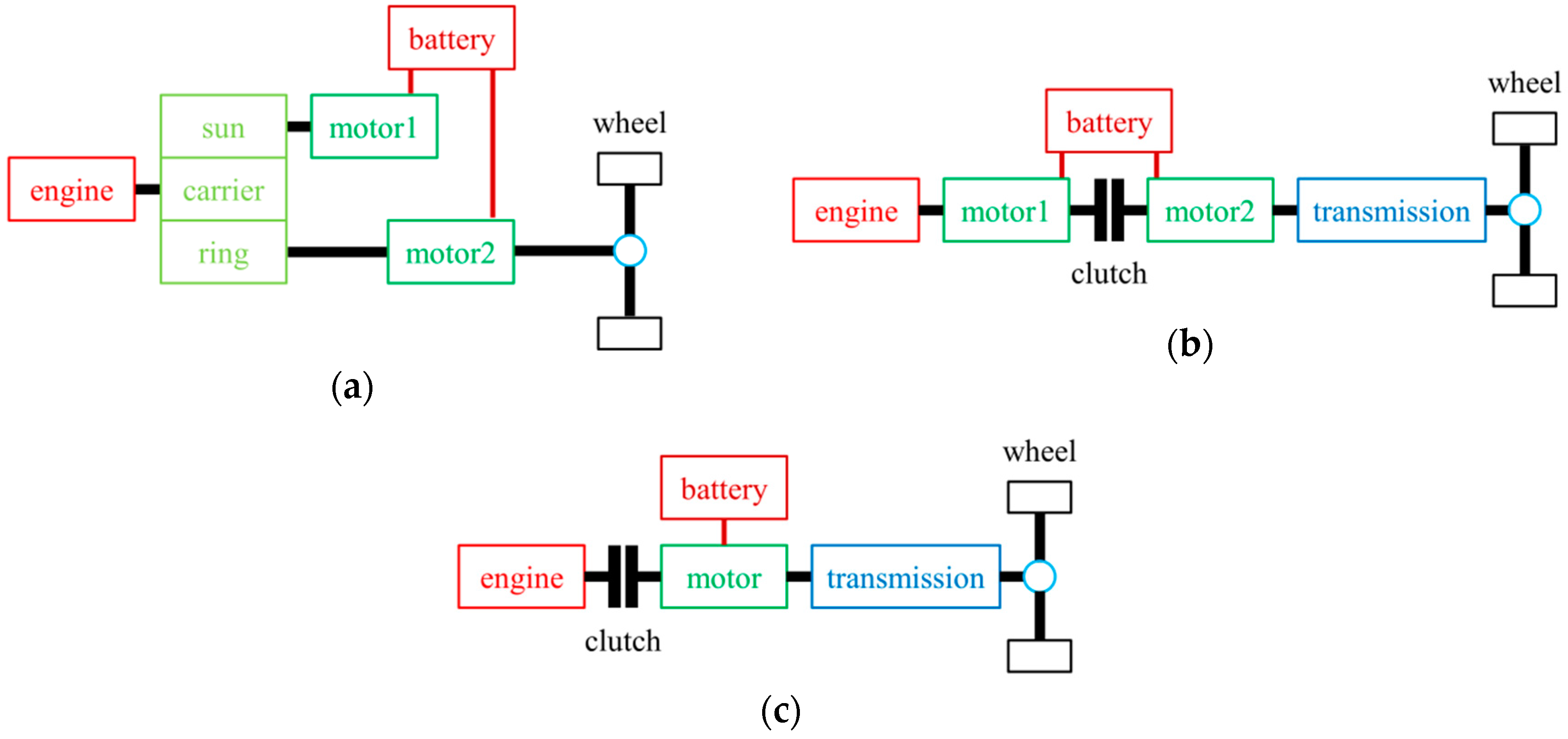

2. Powertrain Configuration

3. Powertrain Modeling

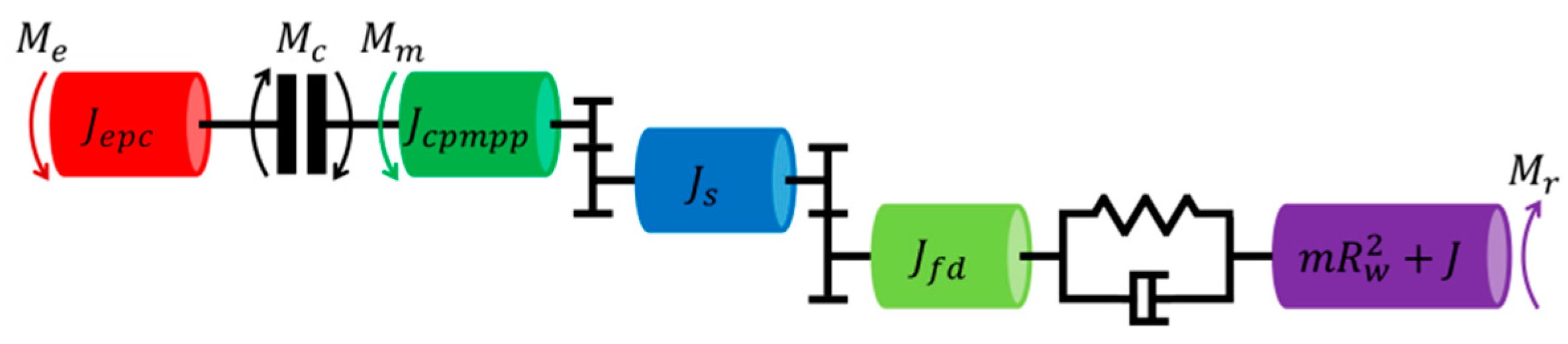

3.1. Simulation-Oriented Model

3.1.1. Engine

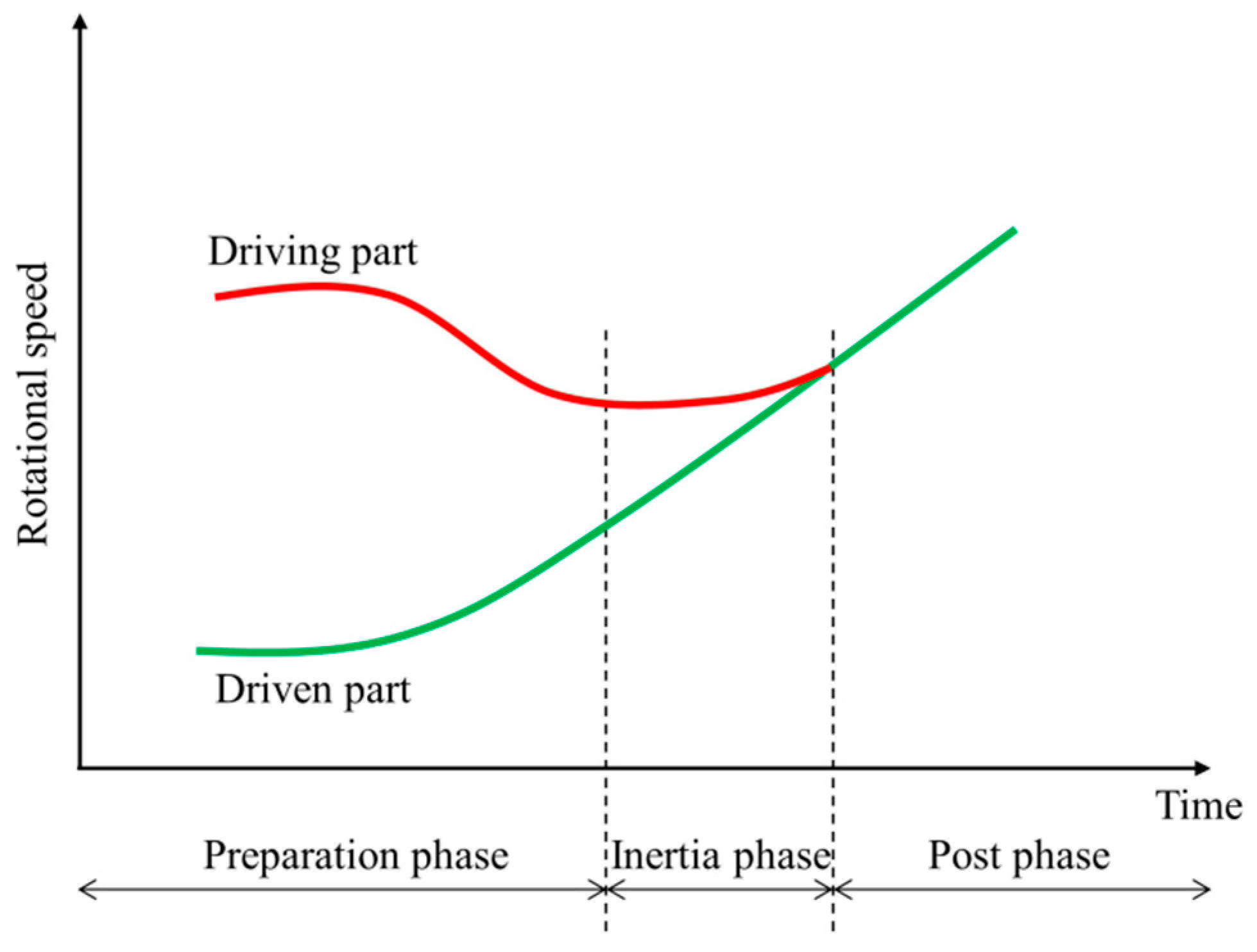

3.1.2. Clutch

3.1.3. Motor

3.1.4. Transmission

3.1.5. Final Drive

3.1.6. Driving Axle Shaft

3.1.7. Longitudinal Vehicle Dynamics

3.2. Control-Oriented Model

4. Controller Design

4.1. Optimization Objectives

4.2. Control Principle

4.3. Equilibrium State

4.4. Control-Oriented Discrete-Time State Space Model

4.5. Optimization Problem Formulation

4.6. Optimization Solution

- Solve the optimization problem without inequality constraints:

- Check whether obtained in Step 1 satisfies the inequality constraint (46). If not, by introducing a Lagrange multiplier, compute , the clutch torque command and the motor output torque command :

- Check whether or not obtained in Step 2 satisfies the inequality constraints (47) and (48). If not, calculate the clutch torque command and the motor output torque command :

5. Results and Discussion

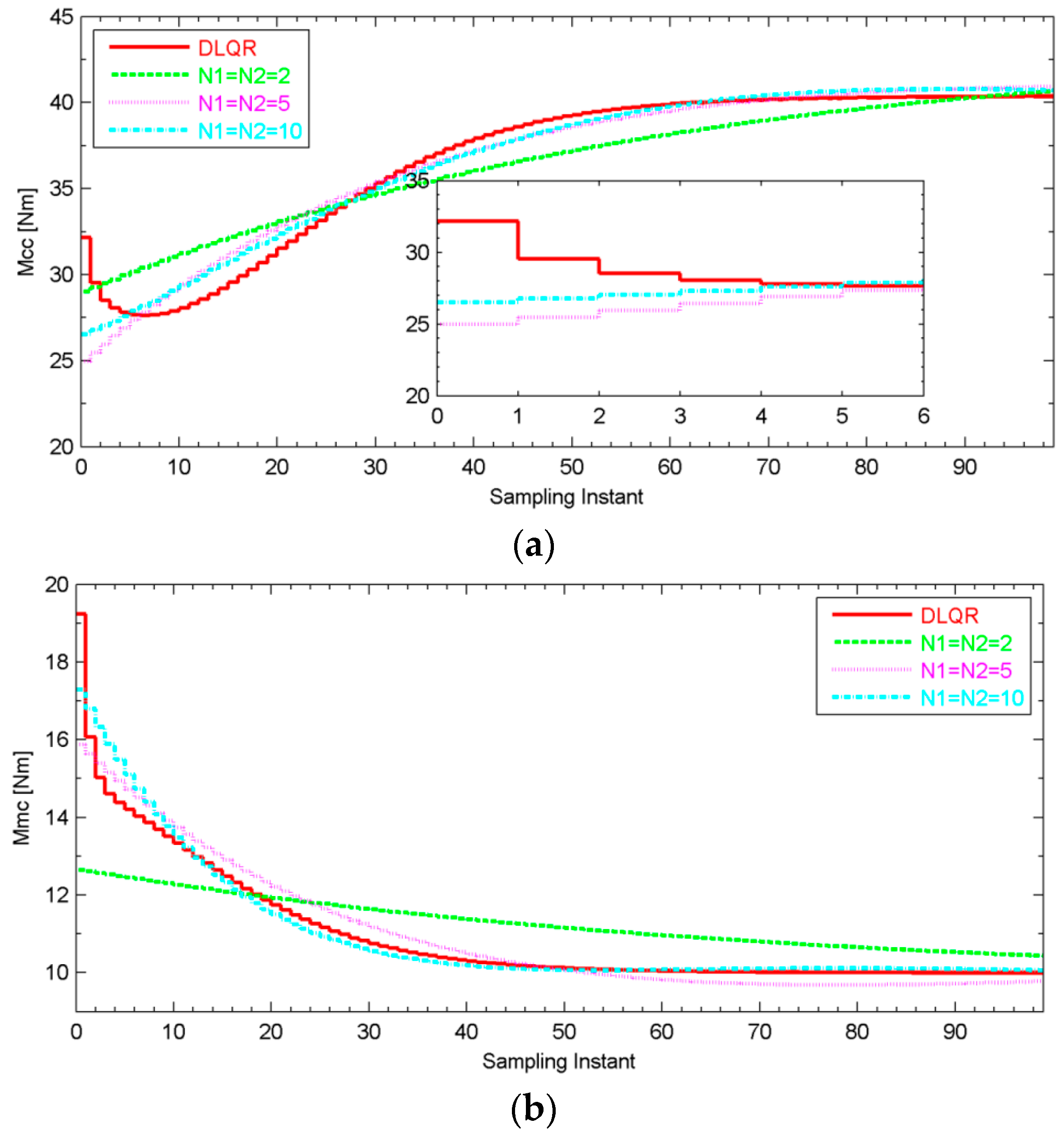

5.1. Parameter Selection

- Firstly, solve the following Riccati equation for finding the Riccati matrix :

- Secondly, compute the state feedback gain matrix :

- Thirdly, calculate the optimum input vector for the current sampling instant:

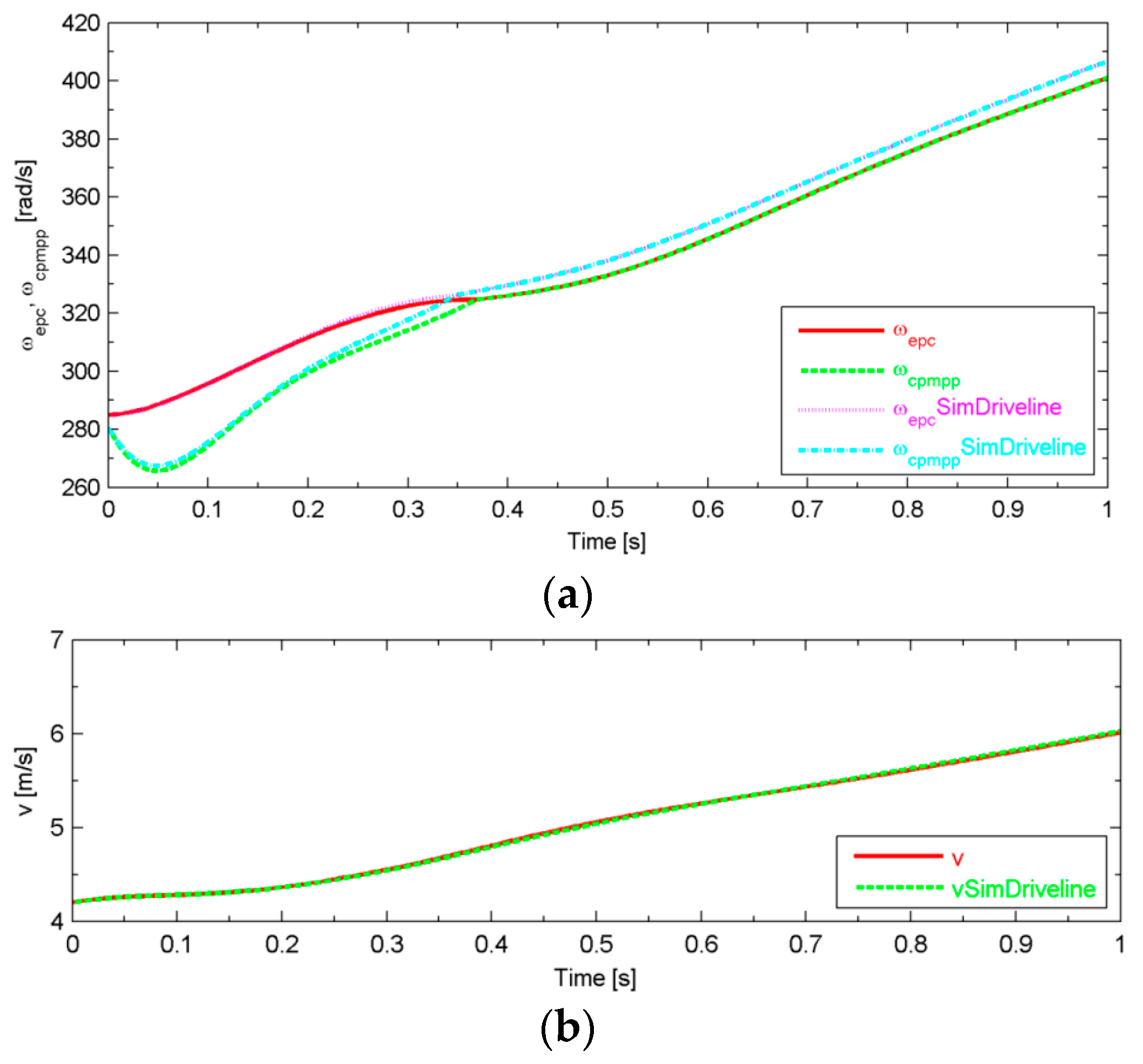

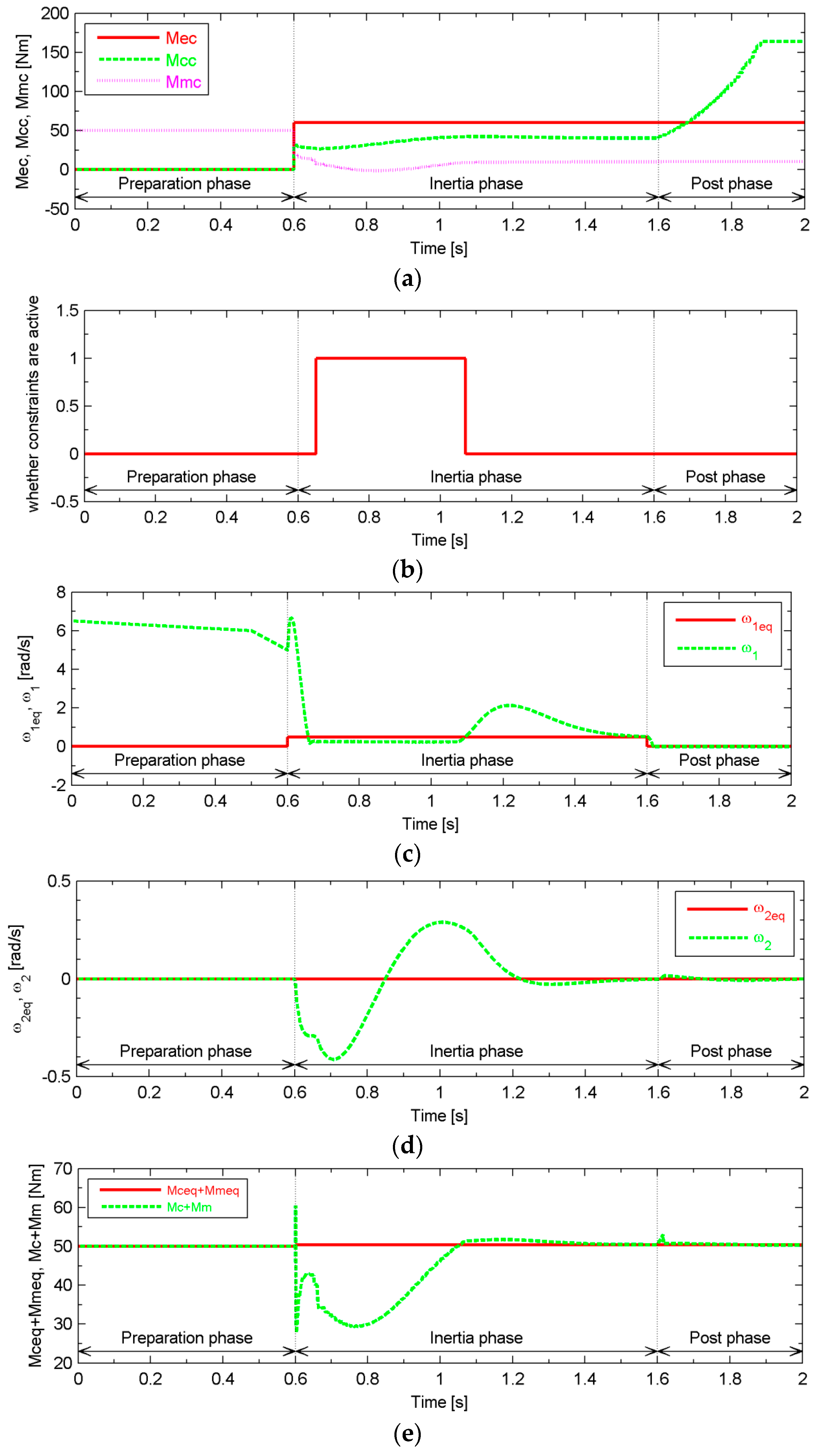

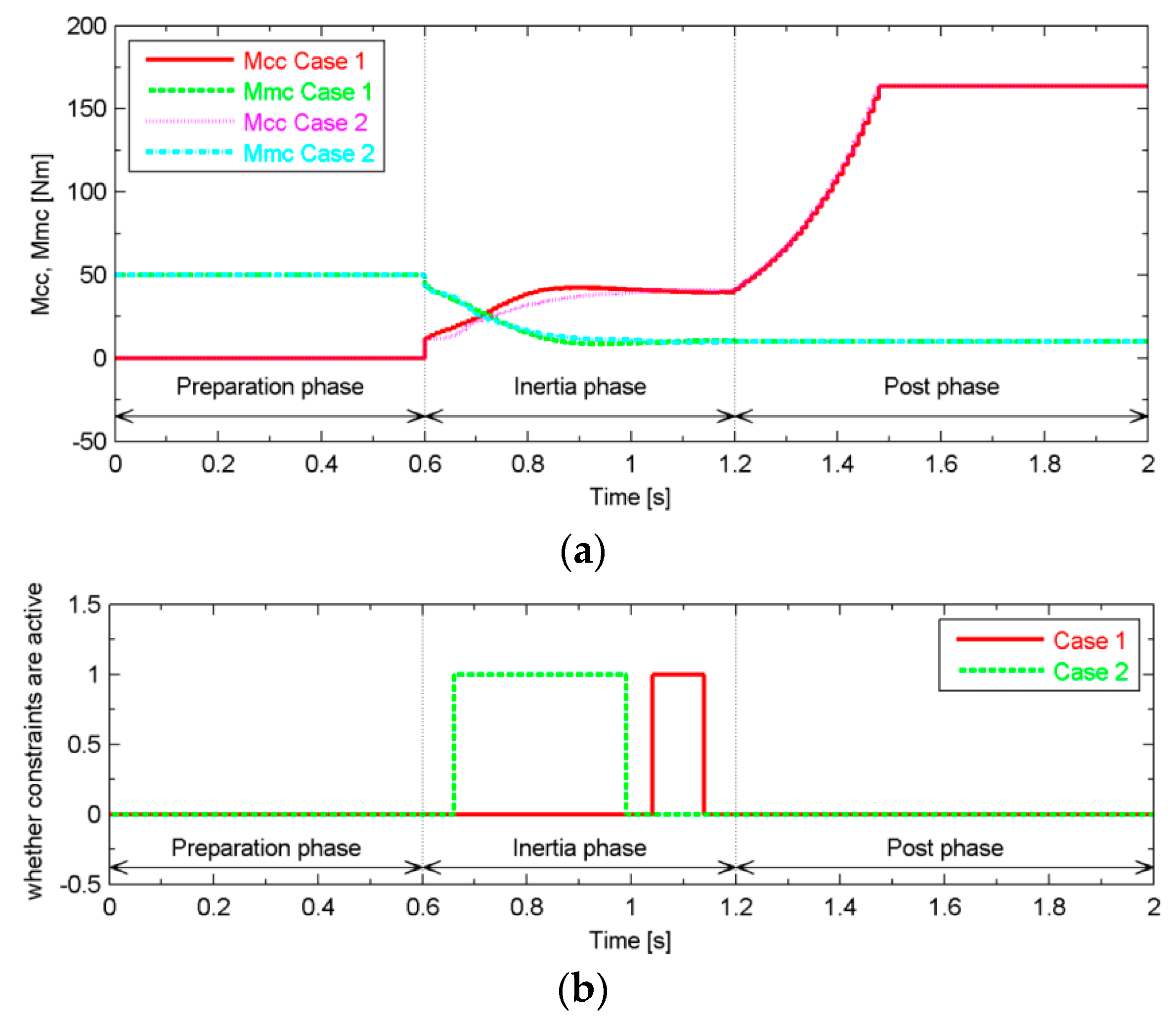

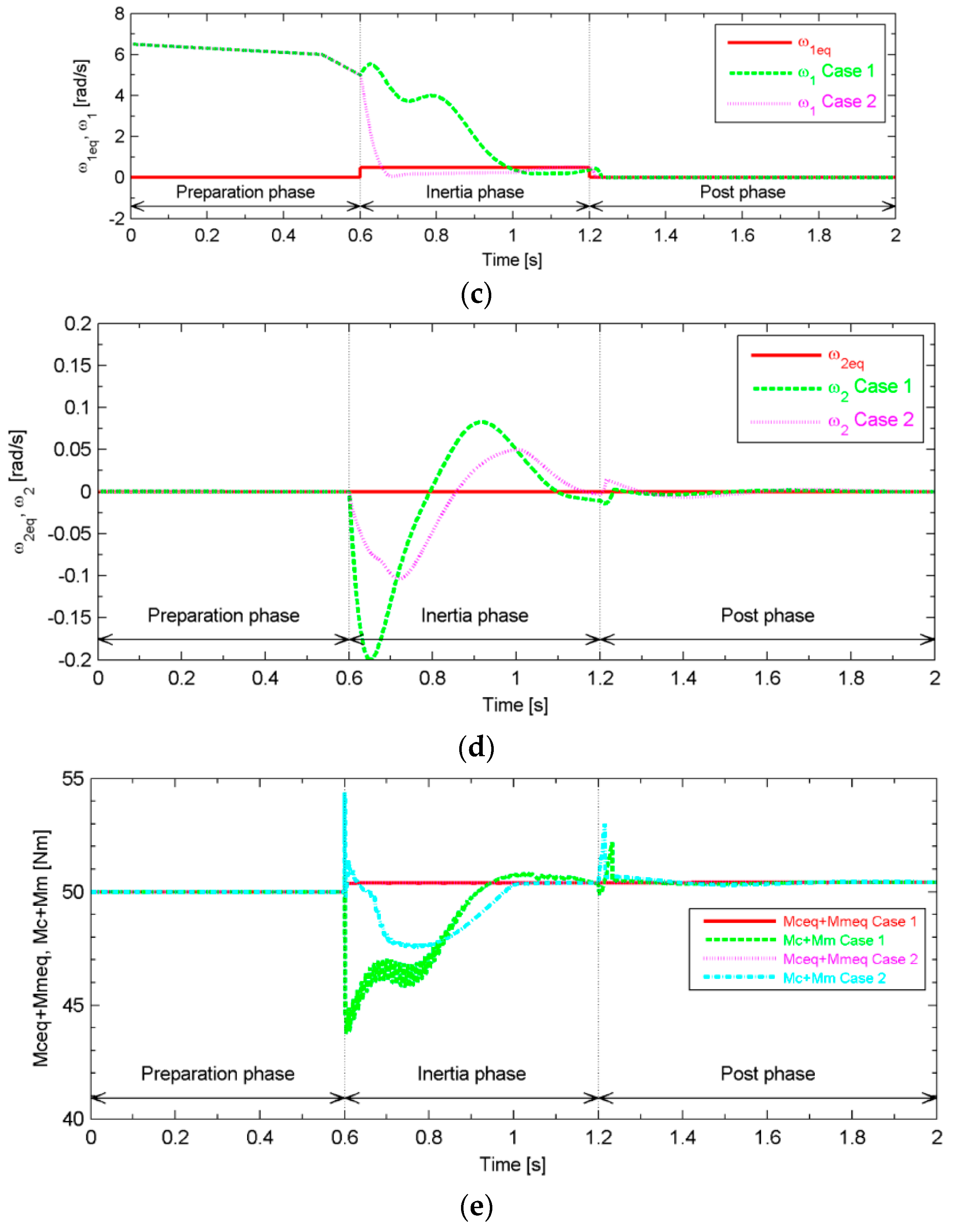

5.2. Performance in Nominal Conditions

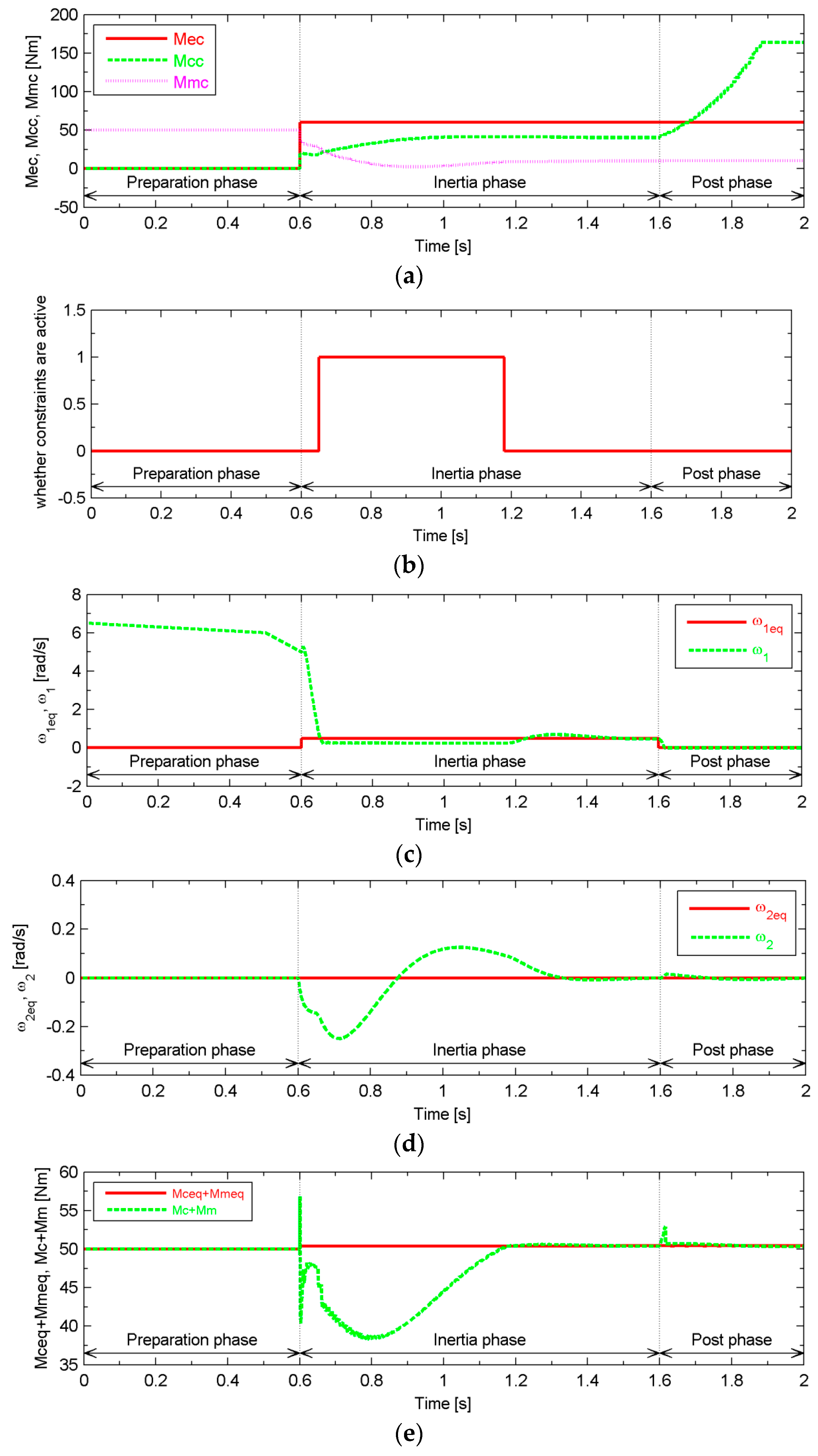

5.3. Comparison with Conditions Without DMPC

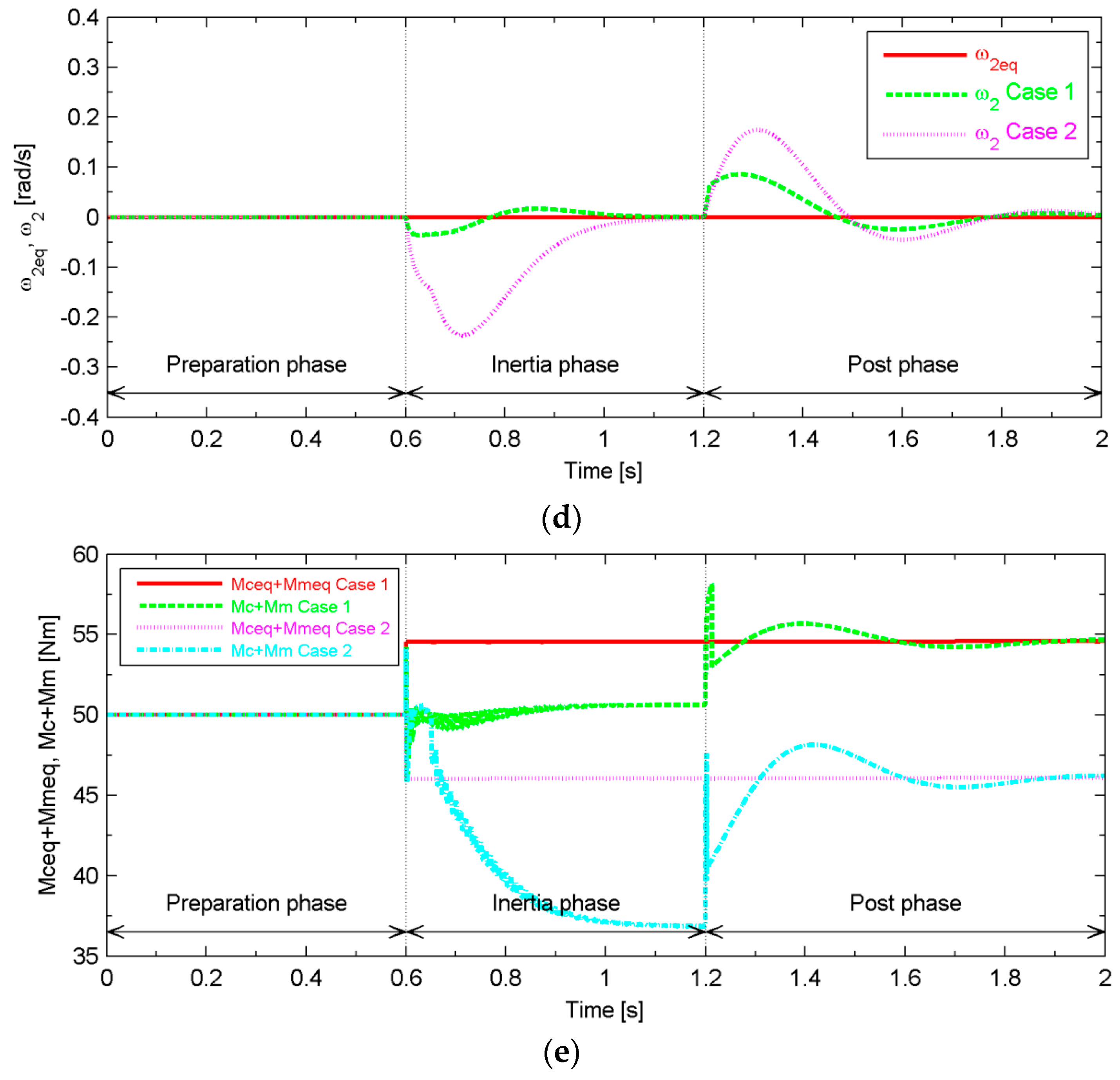

5.4. Robustness

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CPPHP | Clutch-based pre-transmission parallel hybrid powertrain |

| DMPC | Discrete-time model predictive control |

| HEV | Hybrid electric vehicle |

| DLQR | Discrete-time linear quadratic regulator |

References

- Wu, G.; Zhang, X.; Dong, Z.M. Powertrain architectures of electrified vehicles: Review, classification and comparison. J. Franklin Inst. 2015, 352, 425–448. [Google Scholar] [CrossRef]

- Qin, K.J.; Wang, E.H.; Zhao, H.; Shi, G.K.; Wang, R.G.; Kong, Z.G.; Wang, W. Development and experimental validation of a novel hybrid powertrain with dual planetary gear sets for transit bus applications. Sci. China Technol. Sci. 2015, 58, 2085–2096. [Google Scholar] [CrossRef]

- Ouyang, M.G.; Zhang, W.L.; Wang, E.H.; Yang, F.Y.; Li, J.Q.; Li, Z.Y.; Yu, P.; Ye, X. Performance analysis of a novel coaxial power-split hybrid powertrain using a CNG engine and supercapacitors. Appl. Energy 2015, 157, 595–606. [Google Scholar] [CrossRef]

- Fan, J.X.; Zhang, J.Y.; Shen, T.L. Map-Based power-split strategy design with predictive performance optimization for parallel hybrid electric vehicles. Energies 2015, 8, 9946–9968. [Google Scholar] [CrossRef]

- Bishop, J.D.K.; Martin, N.P.D.; Boies, A.M. Cost-Effectiveness of alternative powertrains for reduced energy use and CO2 emissions in passenger vehicles. Appl. Energy 2014, 124, 44–61. [Google Scholar] [CrossRef]

- Zou, Y.; Liu, T.; Sun, F.C.; Peng, H. Comparative Study of Dynamic Programming and Pontryagin’s Minimum Principle on Energy Management for a Parallel Hybrid Electric Vehicle. Energies 2013, 6, 2305–2318. [Google Scholar]

- Nüesch, T.; Cerofolini, A.; Mancini, G.; Cavina, N.; Onder, C.; Guzzella, L. Equivalent Consumption Minimization Strategy for the Control of Real Driving NOx Emissions of a Diesel Hybrid Electric Vehicle. Energies 2014, 7, 3148–3178. [Google Scholar] [CrossRef]

- Lakshmanan, S.; Palaniappan, A.; Chekuri, V. Methodology for Evaluation of Drivability Attributes in Commercial Vehicle; SAE Tech. Paper 2015-01-2767; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Jayaraman, H.; Rao, N.; Muthiah, S.; Mohan, S. Optimization of Tip-In Response Character of Sports Utility Vehicle and Verification with Objective Methodology; SAE Tech. Paper 2015-01-1354; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Khodabakhshian, M.; Feng, L.; Wikander, J. Optimization of Gear Shifting and Torque Split for Improved Fuel Efficiency and Drivability of HEVs; SAE Tech. Paper 2013-01-1461; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Opila, D.F.; Aswani, D.; McGee, R.; Cook, J.A.; Grizzle, J.W. Incorporating drivability metrics into optimal energy management strategies for hybrid vehicles. In Proceedings of the 47th IEEE Conference on Decision and Control, Cancun, Mexico, 9–11 December 2008; pp. 4382–4389.

- Opila, D.F.; Wang, X.Y.; McGee, R.; Gillespie, R.B.; Cook, J.A.; Grizzle, J.W. An energy management controller to optimally trade off fuel economy and drivability for hybrid vehicles. IEEE Trans. Control Syst. Technol. 2012, 20, 1490–1505. [Google Scholar] [CrossRef]

- Koprubasi, K.; Westervelt, E.R.; Rizzoni, G. Toward the systematic design of controllers for smooth hybrid electric vehicle mode changes. In Proceedings of the 2007 American Control Conference, New York, NY, USA, 11–13 July 2007; pp. 2985–2990.

- Kim, H.; Kim, J.; Lee, H. Mode transition control using disturbance compensation for a parallel hybrid electric vehicle. Proc. Inst. Mech. Eng. Part D J. Autom. Eng. 2010, 225, 150–166. [Google Scholar] [CrossRef]

- Chen, L.; Xi, G.; Sun, J. Torque coordination control during mode transition for a series–parallel hybrid electric vehicle. IEEE Trans. Veh. Technol. 2012, 61, 2936–2949. [Google Scholar] [CrossRef]

- Kum, D.; Peng, H.; Bucknor, N.K. Control of engine-starts for optimal drivability of parallel hybrid electric vehicles. J. Dyn. Syst. Meas. Control 2013, 135. [Google Scholar] [CrossRef]

- Dolcini, P.; Canudas de Wit, C.; Béchart, H. Lurch avoidance strategy and its implementation in AMT vehicles. Mechatronics 2008, 18, 289–300. [Google Scholar] [CrossRef]

- Walker, P.D.; Zhang, N. Active damping of transient vibration in dual clutch transmission equipped powertrains: A comparison of conventional and hybrid electric vehicles. Mech. Mach. Theory 2014, 77, 1–12. [Google Scholar] [CrossRef]

- Lu, X.H.; Chen, H.; Gao, B.Z.; Zhang, Z.W.; Jin, W.W. Data-Driven predictive gearshift control for dual-clutch transmissions and FPGA implementation. IEEE Trans. Ind. Electron. 2015, 62, 599–610. [Google Scholar] [CrossRef]

- Beck, R.; Saenger, S.; Richert, F.; Bolling, A.; Neiß, K.; Scholt, T.; Noreikat, K.E.; Abel, D. Model predictive control of a parallel hybrid vehicle drivetrain. In Proceedings of the 44th IEEE Conference on Decision and Control, and the European Control Conference, Seville, Spain, 12–15 December 2005; pp. 2670–2675.

- Pisaturo, M.; Cirrincione, M.; Senatore, A. Multiple constrained MPC design for automotive dry clutch engagement. IEEE ASME Trans Mechatron 2015, 20, 469–480. [Google Scholar] [CrossRef]

- Canudas de Wit, C.; Olsson, H.; Astrom, K.J.; Lischinsky, P. A new model for control of systems with friction. IEEE Trans. Autom. Control 1995, 40, 419–425. [Google Scholar] [CrossRef]

- Gillespie, T.D. Fundamentals of Vehicle Dynamics; Society of Automotive Engineers (SAE) International: Warrendale, PA, USA, 1992. [Google Scholar]

- Oh, J.J.; Choi, S.B.; Kim, J. Driveline modeling and estimation of individual clutch torque during gear shifts for dual clutch transmission. Mechatronics 2014, 24, 449–463. [Google Scholar] [CrossRef]

- Van Berkel, K.; Hofman, T.; Serrarens, A.; Steinbuch, M. Fast and smooth clutch engagement control for dual-clutch transmissions. Control Eng. Pract. 2014, 22, 57–68. [Google Scholar] [CrossRef]

- Wang, L.P. Model Predictive Control System Design and Implementation Using MATLAB; Springer-Verlag: London, UK, 2009. [Google Scholar]

- Dolcini, P.J.; Canudas de Wit, C.; Béchart, H. Dry Clutch Control for Automotive Applications; Springer-Verlag: London, UK, 2010. [Google Scholar]

| Description | Symbol | Value |

|---|---|---|

| Engine time constant | 0.1 s | |

| Lumped moment of inertia of the engine and the driving parts of the clutch | 0.15 kg·m2 | |

| Equivalent radius of the clutch | 0.1 m | |

| Coulomb force | 348.4 N | |

| Stiction force | 1636.1 N | |

| Stribeck velocity | 22 m/s | |

| Macroscopic damping coefficient | 0.001 Ns/m | |

| Clutch actuator time constant | 0.01 s | |

| Stiffness coefficient | 108 N/m | |

| Microscopic damping coefficient | 106 Ns/m | |

| Motor time constant | 0.001 s | |

| Lumped moment of inertia of the driven parts of the clutch, the rotor of the motor and the primary shaft of the transmission | 0.05 kg·m2 | |

| Gear ratio | 4 | |

| Transmission efficiency | 0.98 | |

| Lumped moment of inertia of the secondary shaft of the transmission | 0.01 kg·m2 | |

| Final drive ratio | 5 | |

| Final drive efficiency | 0.98 | |

| Lumped moment of inertia of the final drive and the differential | 0.01 kg·m2 | |

| Equivalent stiffness coefficient of the axle shafts | 6000 Nm/rad | |

| Equivalent damping coefficient of the axle shafts | 400 Nms/rad | |

| Vehicle mass | 1250 kg | |

| Entire moment of inertia of the vehicle body and the tires | 10 kg·m2 | |

| Wheel radius | 0.3 m | |

| Rolling resistance coefficient | 0.01 | |

| Gravitational acceleration | 9.8 m/s2 | |

| Road slope | 0 | |

| Drag coefficient | 0.3 | |

| Frontal area | 2 m2 | |

| Air density | 1.25 kg/m3 |

| Test | Proposed Solver | Quadprog (Interior-Point-Convex) | Quadprog (Active-Set) |

|---|---|---|---|

| 1 | 0.030 ms | 3.985 ms | 1.221 ms |

| 2 | 0.032 ms | 3.989 ms | 1.271 ms |

| 3 | 0.031 ms | 3.891 ms | 1.228 ms |

| 4 | 0.032 ms | 3.913 ms | 1.262 ms |

| 5 | 0.033 ms | 3.960 ms | 1.251 ms |

| Test | Proposed Solver | Quadprog (Interior-Point-Convex) | Quadprog (Active-Set) |

|---|---|---|---|

| 1 | |||

| 2 | |||

| 3 | |||

| 4 | |||

| 5 |

| Description | Symbol | Value |

|---|---|---|

| Initial engine output torque | 0 Nm | |

| Initial rotational speed of | 285 rad/s | |

| Initial normalized normal force | 0 | |

| Initial value of the average deflection of the bristles | 0 m | |

| Initial motor output torque | 50 Nm | |

| Initial rotational speed of | 280 rad/s | |

| Initial wheel rotational speed | 14 rad/s | |

| Initial torsion of the axle shaft | 0.148 rad | |

| Engine output torque required by the energy management system | 60 Nm | |

| Motor output torque required by the energy management system | 10 Nm |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, D.; Du, C.; Yan, F. Drivability-Related Discrete-Time Model Predictive Control of Mode Transition in Pre-Transmission Parallel Hybrid Powertrains. Energies 2016, 9, 740. https://doi.org/10.3390/en9090740

Guo D, Du C, Yan F. Drivability-Related Discrete-Time Model Predictive Control of Mode Transition in Pre-Transmission Parallel Hybrid Powertrains. Energies. 2016; 9(9):740. https://doi.org/10.3390/en9090740

Chicago/Turabian StyleGuo, Di, Changqing Du, and Fuwu Yan. 2016. "Drivability-Related Discrete-Time Model Predictive Control of Mode Transition in Pre-Transmission Parallel Hybrid Powertrains" Energies 9, no. 9: 740. https://doi.org/10.3390/en9090740