Construction of Microclimatic Zone Based on Convection–Radiation System for Local Cooling in Deep Mines

Abstract

1. Introduction

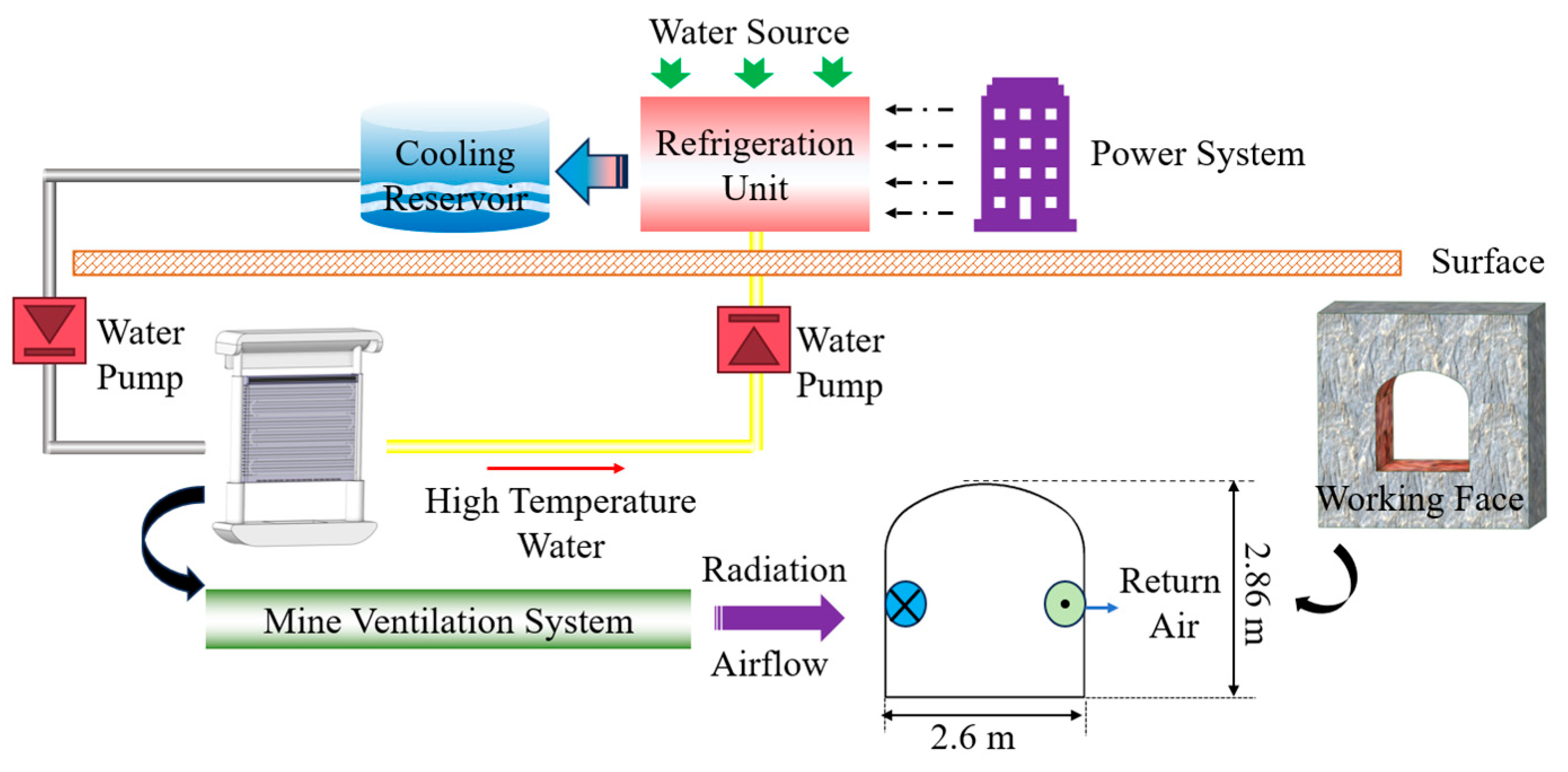

2. Design Principles of Enhanced Fan Configuration for Modular Convection–Radiation Cooling System

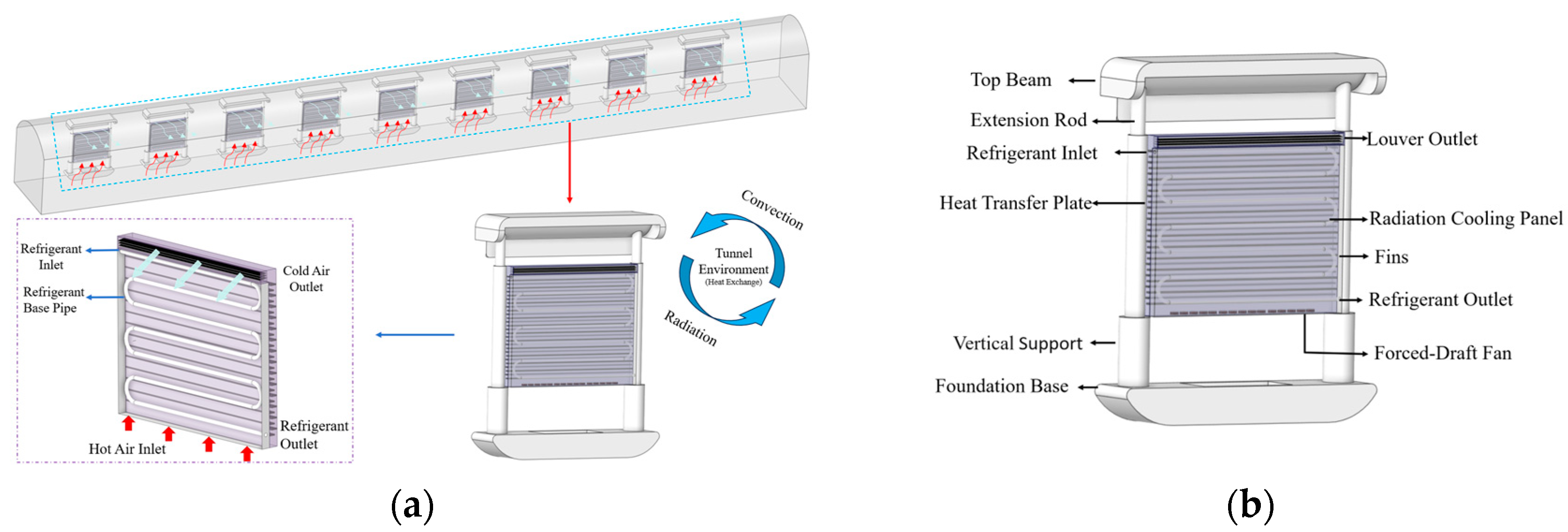

2.1. Modular Convection–Radiation Cooling System

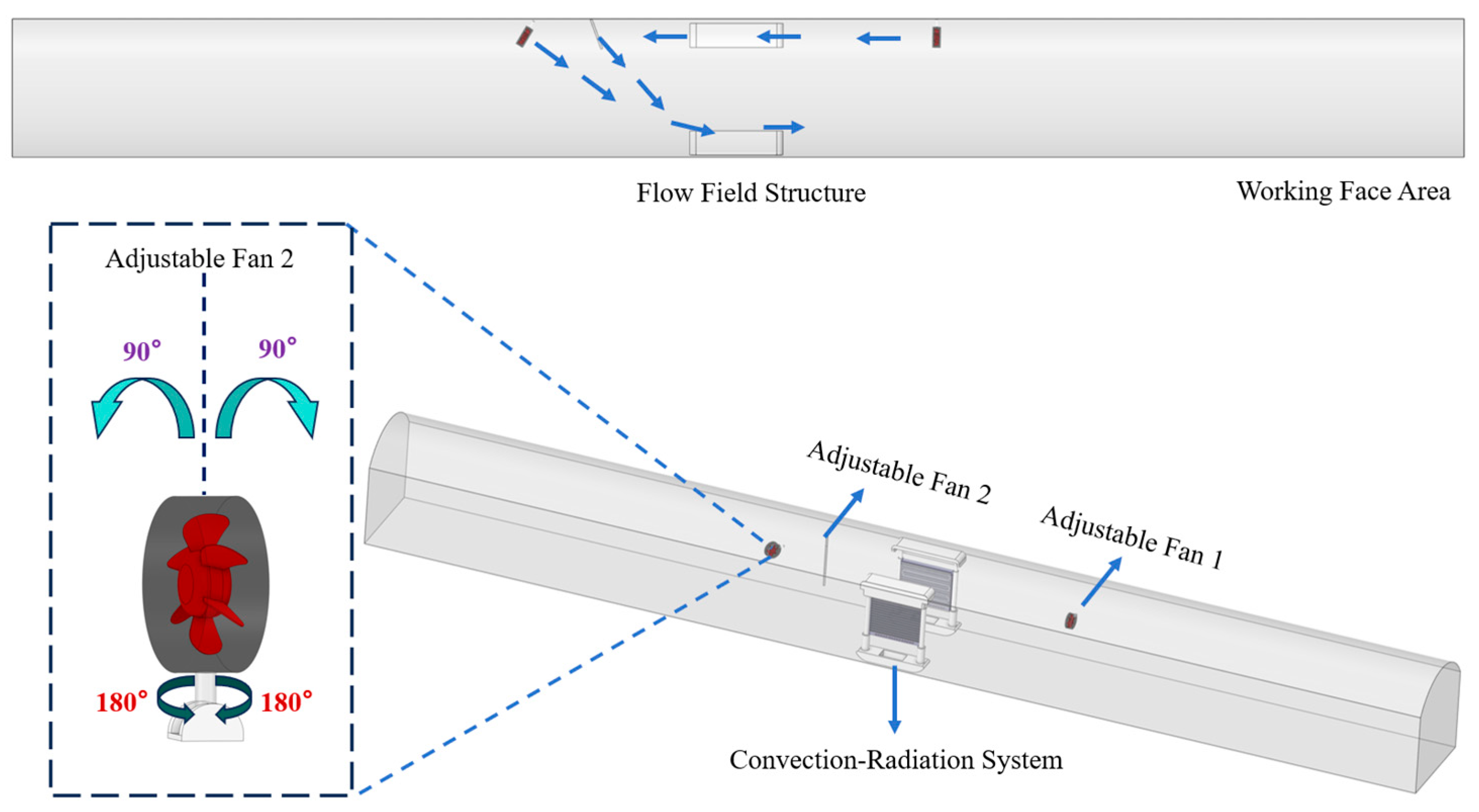

2.2. External Enhancement Design Concept and Configuration Scheme

2.3. Theoretical Model Development

- (1)

- Heat transfer processes are based on steady-state conditions.

- (2)

- The thickness of the radiation cooling panel is significantly smaller than its width; therefore, heat transfer along the thickness direction of the cooling radiation panel is negligible.

- (3)

- The influence of the semicircular tubing at the ends of the serpentine coil is disregarded.

2.4. System Safety and Compliance Assessment

3. System Performance Theoretical Model and Numerical Simulation

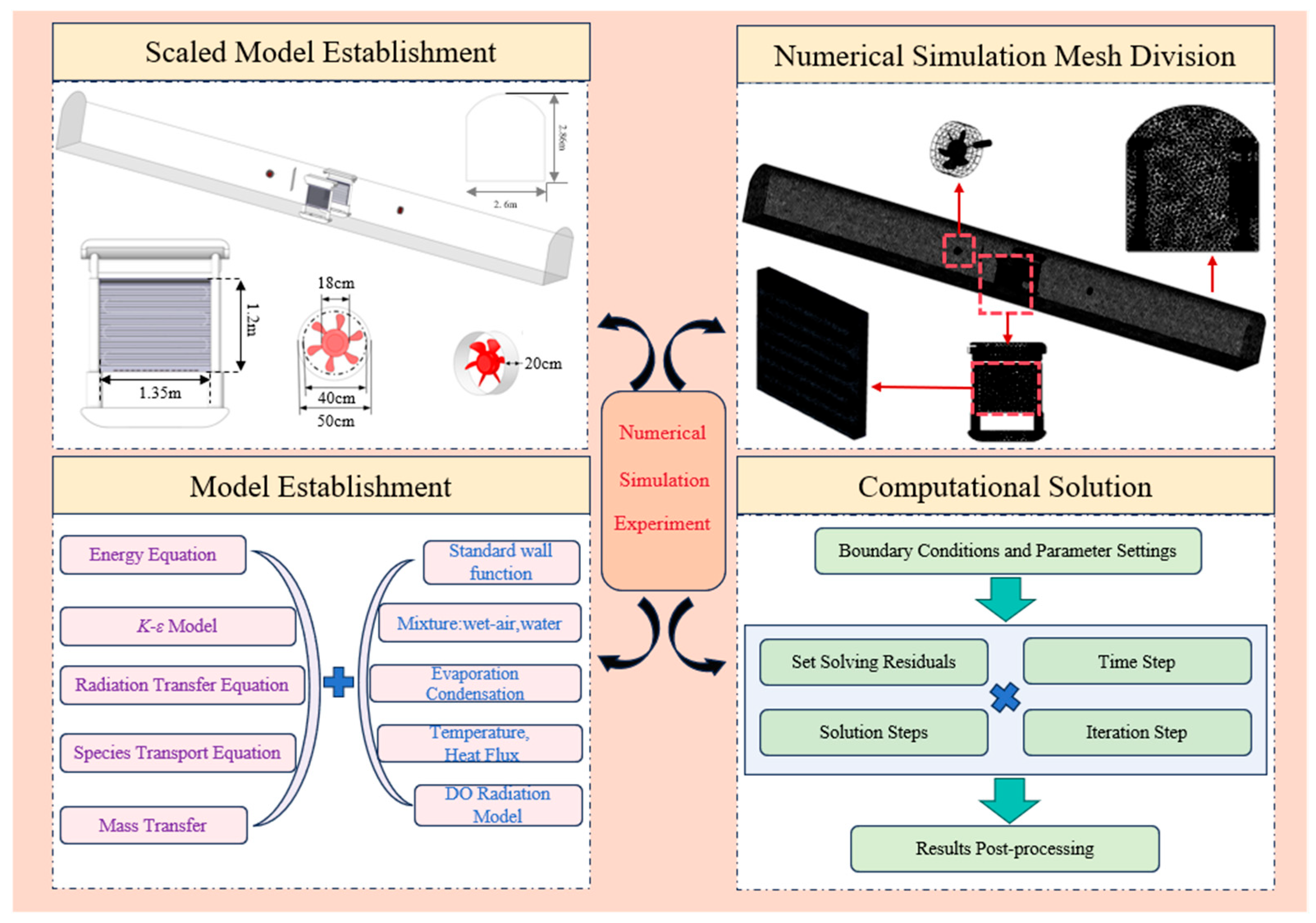

3.1. Research Approach and Numerical Simulation Workflow

3.2. Governing Equations and Model Parameters

- Airflow in the mine environment is considered as incompressible flow.

- The chilled water flow rate, temperature, and inlet airflow remain constant and uniform.

- The contact thermal resistance between the packing material and heat exchange tubes is neglected.

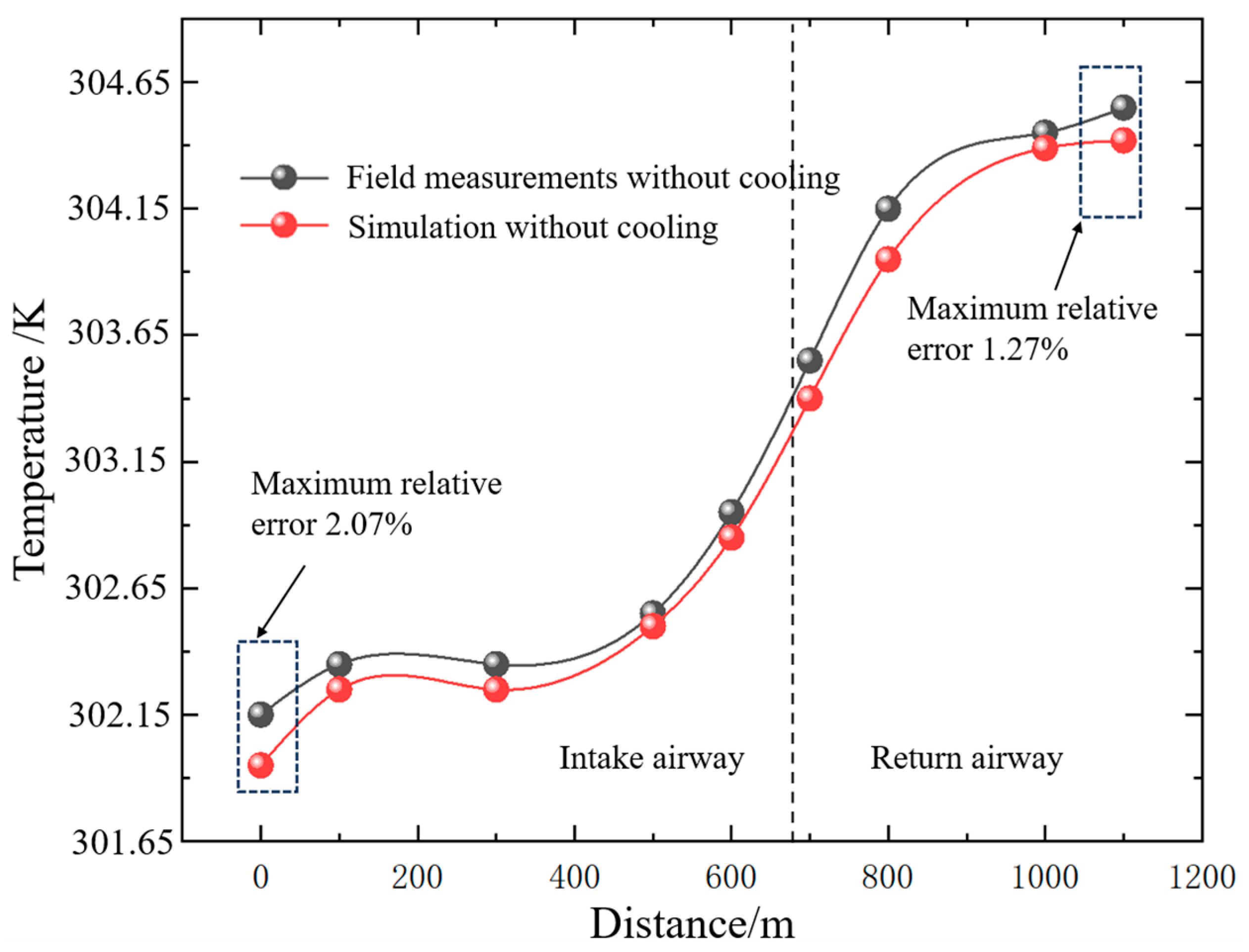

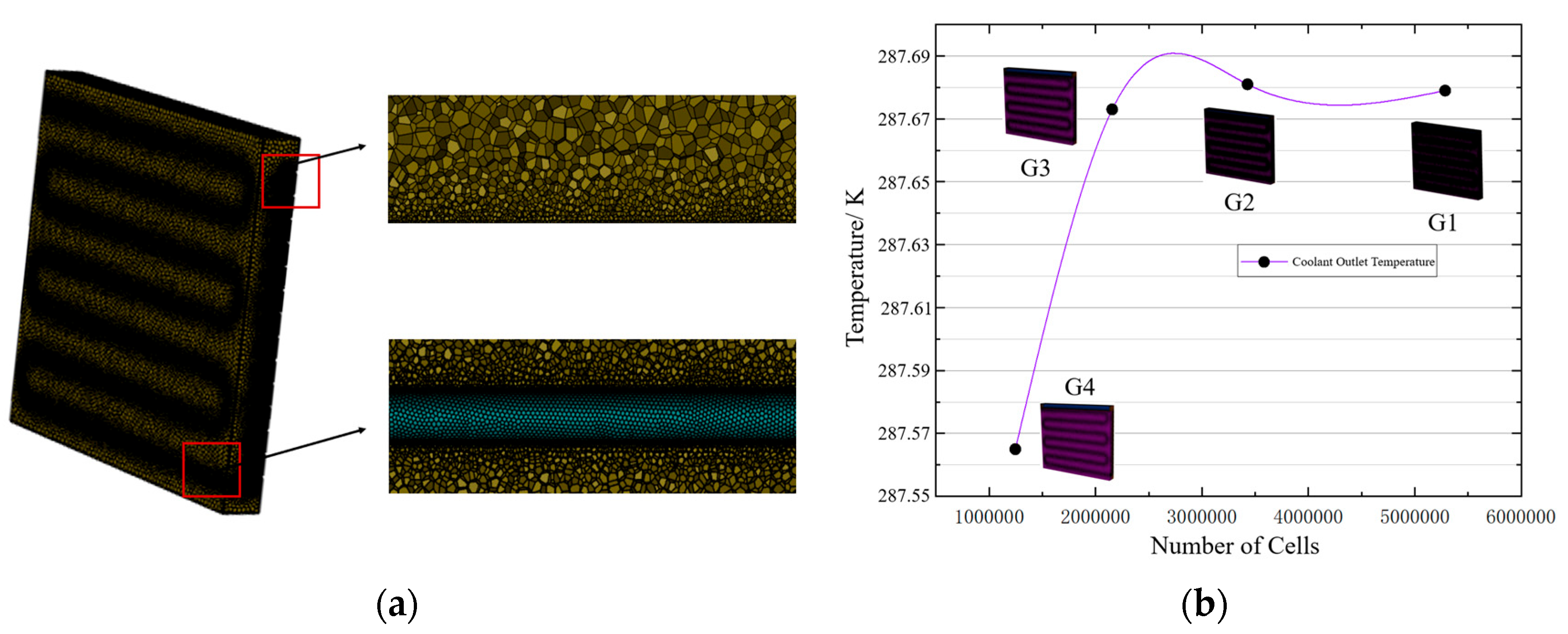

3.3. Grid Independence Verification

4. System Cooling Performance and Energy Consumption Analysis

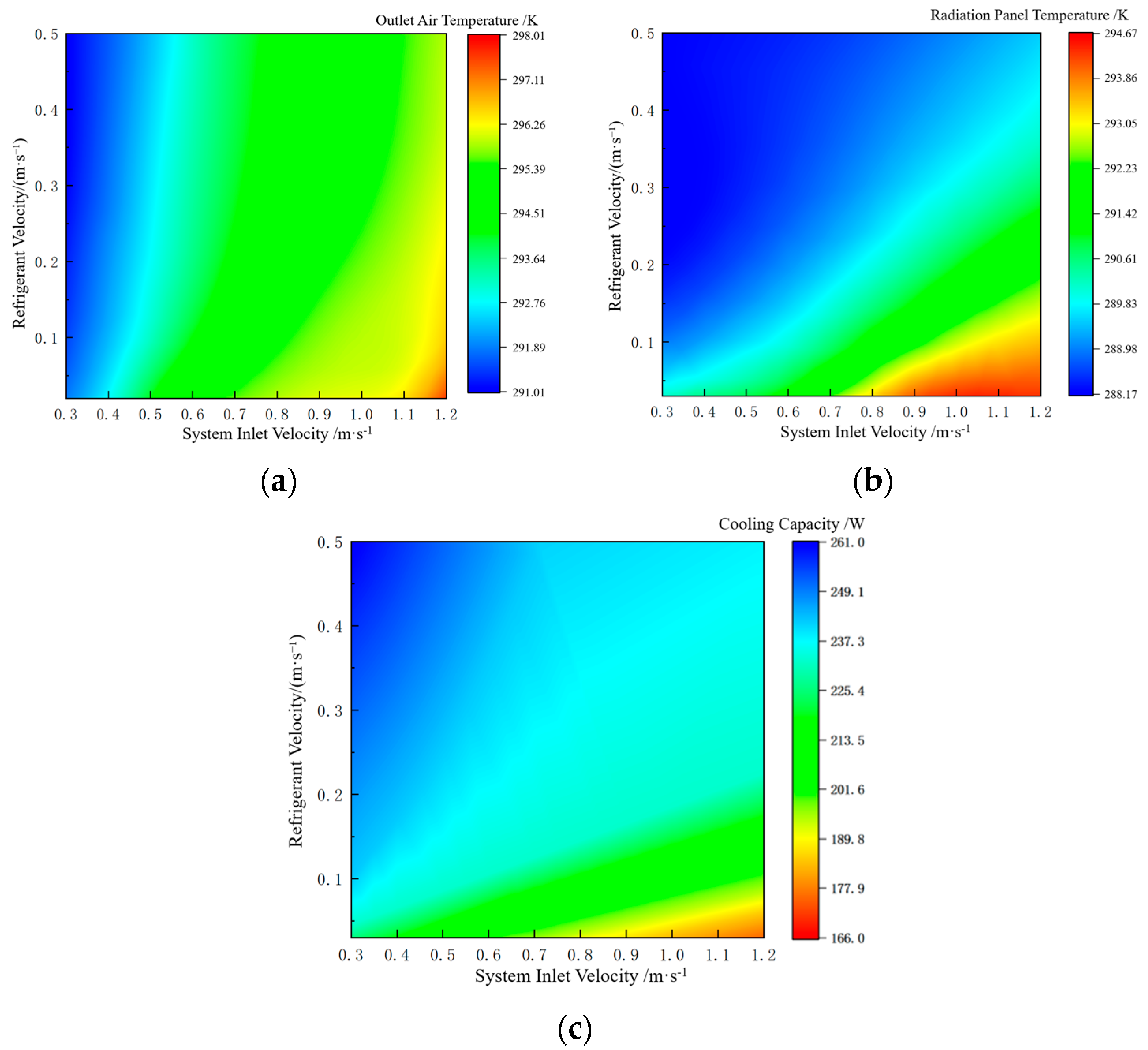

4.1. System Cooling Capacity and Determination of Optimal Operating Condition

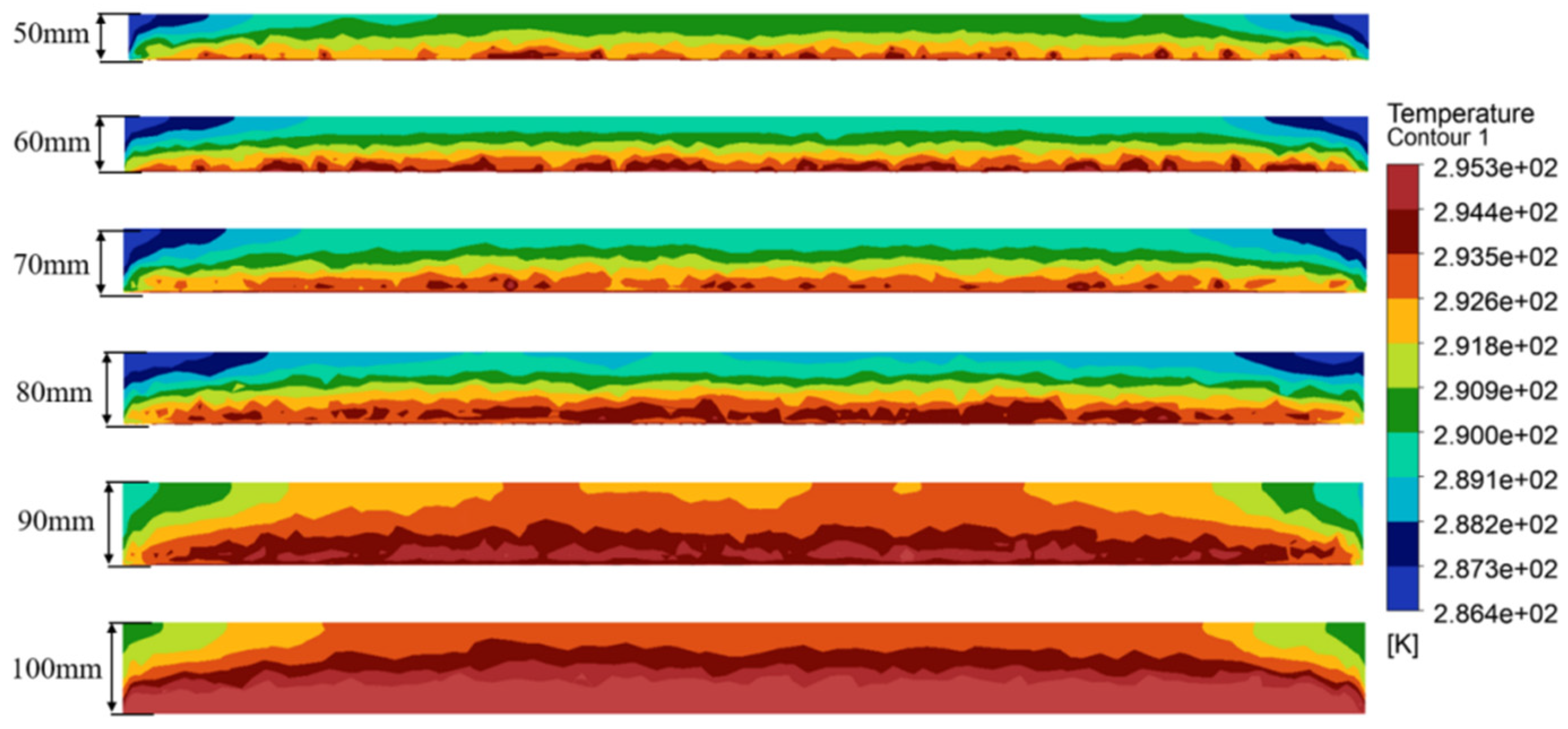

4.2. Impact of Outlet Height on System Cooling Capacity

4.3. Cooling Effect Analysis of Deep Mine Excavation Working Face

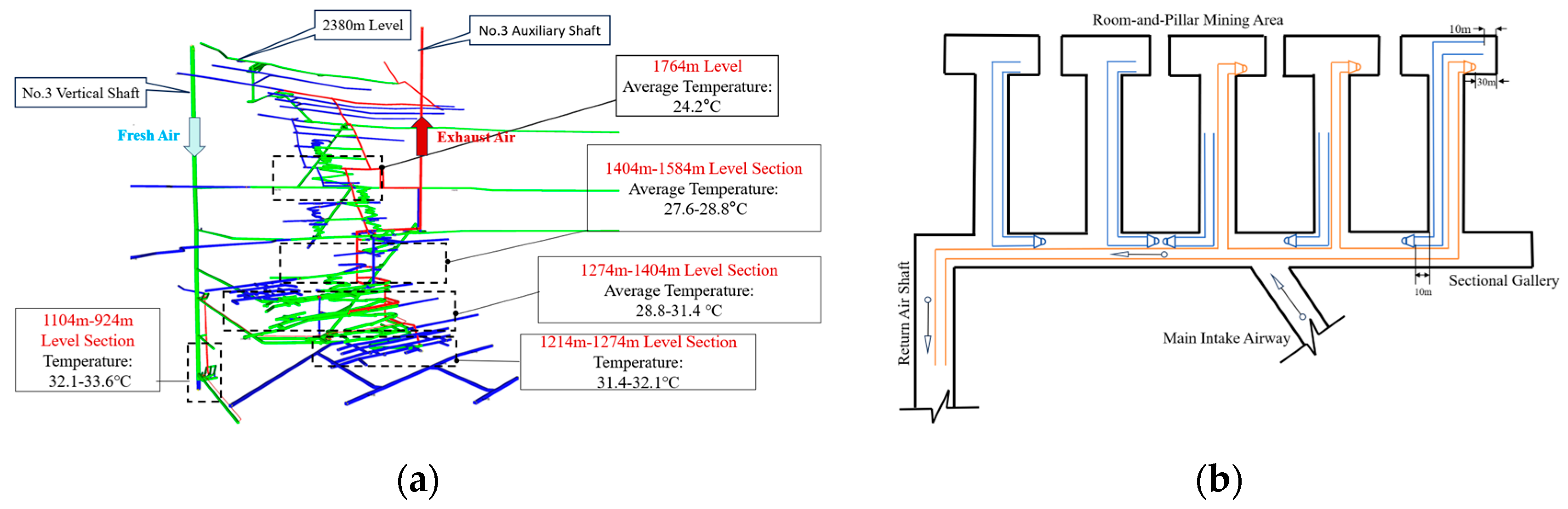

4.3.1. Research Background and Engineering Overview

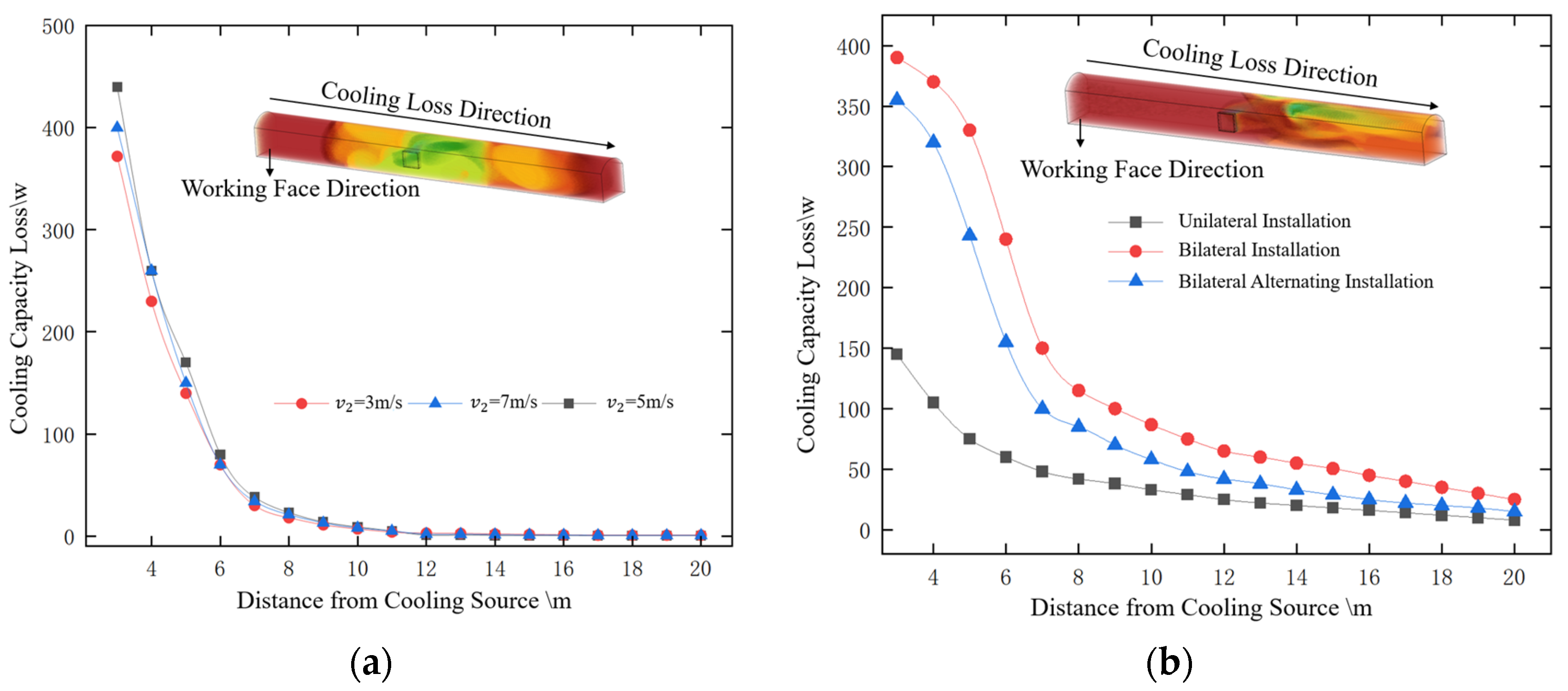

4.3.2. System Cooling Effect and Energy Loss Analysis

4.3.3. Fan-Enhanced System Comfort Improvement and Energy Consumption Analysis in Mine Tunnels

5. Conclusions

- (1)

- The optimal operating parameters for the modular convection–radiation system were determined through numerical simulation: refrigerant velocity of 0.2 m/s, inlet air velocity of 0.45 m/s, and outlet height of 70 mm. Under this parameter combination, the system achieves optimal heat transfer performance and energy consumption balance, with a cooling power of 261 W.

- (2)

- WBGT index evaluation demonstrates that optimal performance is achieved when employing 25 m bilateral alternating installation at the 1404 m working face, with adapted personnel comfort coverage reaching 100%. As mining depth increases, system performance shows a declining trend. At the 924 m level, the adapted comfort zone decreases to 60%, while the safe thermal tolerance zone remains above 85%, indicating that this technology maintains application potential under various depth conditions.

- (3)

- The dual-fan and flow-guiding baffle collaborative design successfully achieves the construction of a “microclimatic circulation zone”. The improved system exhibits a cooling capacity loss rate of only 3% at a 7 m distance, compared to 19.23% for the unimproved system, while simultaneously enhancing refrigeration power by approximately 19.83%.

- (4)

- Field application verification was conducted to analyze the compatibility of this system with the overall mine ventilation system. Results indicate that the system’s impact on the ventilation system is equivalent to a local obstruction, occupying only 15.6–19.8% of the tunnel cross-section. The main ventilation airflow normally divides after passing through the working face, flows to the sectional galleries, and finally converges into the return airways, maintaining a complete ventilation circuit. Airflow monitoring results from sectional galleries and main return airways show that system operation only reduces ventilation volume by 0.1–0.3%. Field verification demonstrates that system operation does not cause ventilation short-circuiting or airflow disturbance, ensuring the stability and safety of the mine ventilation system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Heat Transfer Variables | ||

| Symbol | Description | Units |

| Cooling capacity input to the system | W | |

| Heat transferred by the refrigerant water | W | |

| Heat transferred through the pipe walls | W | |

| Heat transferred through the radiation panel | W | |

| Heat transferred through the fins | W | |

| External heat transfer | W | |

| Radiative heat exchange between radiation panel and environment | W | |

| Convective heat transfer at radiation panel surface | W | |

| Convective heat transfer at louver outlet | W | |

| Cooling loss | W | |

| Total system cooling power | W | |

| Temperature Variables | ||

| Symbol | Description | Units |

| Temperature variation of refrigerant water | K | |

| Average temperature of refrigerant water | K | |

| Inner wall temperature of the pipe | K | |

| Average surface temperature of radiation cooling panel | K | |

| Average outlet air temperature | K | |

| Average air temperature inside the tunnel | K | |

| the tunnel wall temperature | K | |

| Wet bulb temperature | K | |

| Coil outer wall temperature | K | |

| Coil inner wall temperature | K | |

| Average temperature | K | |

| Excess temperature of the fin | K | |

| Globe temperature | K | |

| Ambient temperature | K | |

| Average temperature at specified cross-section | K | |

| Flow and Velocity Variables | ||

| Symbol | Description | Units |

| Mass flow rate of refrigerant water | kg/s | |

| Magnitude of velocity for the i-th fan | m/s | |

| Velocity component along x-axis | m/s | |

| Velocity component along y-axis | m/s | |

| System’s resultant velocity vector | m/s | |

| Velocity vector of the i-th fan | m/s | |

| Magnitude of resultant airflow velocity | m/s | |

| Velocity component in x-direction | m/s | |

| Velocity component in y-direction | m/s | |

| , | Velocity components | m/s |

| Geometric Parameters | ||

| Symbol | Description | Units |

| Pipe internal diameter | m | |

| Pipe external diameter | m | |

| Pipe length | m | |

| Thickness of radiation panel | m | |

| Fin center distance | m | |

| Louver outlet area | m2 | |

| Effective cross-sectional area | m2 | |

| , | Spatial coordinate components | m |

| Angular Variables | ||

| Symbol | Description | Units |

| Outlet angle of the i-th fan | ° | |

| Outlet angle after reflection | ° | |

| Incident angle of airflow | ° | |

| Exit angle of airflow; Direction angle of resultant airflow | ° | |

| Angle between baffle and side wall | ° | |

| Heat Transfer Coefficients | ||

| Symbol | Description | Units |

| Convective heat transfer coefficient inside pipe | W/(m2·K) | |

| Convective heat transfer coefficient of fin surface to air | W/(m2·K) | |

| Convective heat transfer coefficient of air in tunnel | W/(m2·K) | |

| Effective thermal conductivity | W/(m2·K) | |

| Material Properties | ||

| Symbol | Description | Units |

| Thermal conductivity of pipe wall material | W/(m·K) | |

| Thermal conductivity of radiation panel material | W/(m·K) | |

| Fluid density; Air density | kg/m3 | |

| Specific heat capacity of water | kJ/(kg·K) | |

| Turbulent dynamic viscosity | Pa·s | |

| Efficiency and Performance Variables | ||

| Symbol | Description | Units |

| Fin efficiency | ||

| Cooling loss percentage | % | |

| Surface emissivity | ||

| Local resistance coefficient for airflow | ||

| Direction recovery coefficient | ||

| Pressure Variables | ||

| Symbol | Description | Units |

| Local pressure loss | Pa | |

| Pressure | Pa | |

| Comfort Zone Variables | ||

| Symbol | Description | Units |

| Wet Bulb Globe Temperature | °C | |

| Adapted worker comfort zone ratio | % | |

| Non-adapted worker comfort zone ratio | % | |

| Extreme thermal tolerance comfort zone ratio | % | |

| Distance satisfying WBGT < 28 °C | m | |

| Distance satisfying WBGT < 26 °C | m | |

| Distance satisfying WBGT < 29.11 °C | m | |

| Total length of working face | m | |

| Fluid Mechanics Variables | ||

| Symbol | Description | Units |

| Stress tensor component | Pa | |

| Gravitational acceleration component | m/s2 | |

| External body force component | N/m3 | |

| Total specific enthalpy | J/kg | |

| Species specific enthalpy | J/kg | |

| Species diffusive flux component | kg/(m2·s) | |

| Water vapor mass fraction | ||

| Diffusion coefficient of water vapor in air | m2/s | |

| Turbulent Prandtl number | ||

| Thermal diffusion coefficient | kg/(m·s·K) | |

| Source Terms | ||

| Symbol | Description | Units |

| Mass source term | kg/(m3·s) | |

| Energy source term | W/m3 | |

| Water vapor source term | kg/(m3·s) | |

| Constants | ||

| Symbol | Description | Units |

| Stefan–Boltzmann constant | W/(m2·K4) | |

| Unit vectors in x and y directions | ||

References

- Cai, M.; Li, P.; Tan, W.; De Silva, R.V.; Wu, H.; Xu, S.; Feng, X. Key engineering technologies to achieve green, intelligent, and sustainable development of deep metal mines in China. Engineering 2021, 7, 1513–1517. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Zhao, J.; Ju, M.; De Silva, R.V.K.; Rathnaweera, T.D.; Bandara, A.K.M.S. Opportunities and challenges in deep mining: A brief review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Cai, M.; Ma, M.; Pan, J.; Gao, F.; Zhao, J.; Yu, S.; Wang, K.; Ding, W. Current status and prospects of co-exploitation models for mineral and geothermal resources. Chin. J. Eng. Sci. 2022, 44, 1669–1681. [Google Scholar]

- Aizawa, K.; Uyeshima, M.; Kitada, K.; Koyama, T.; Utsugi, M.; Hase, H.; Hashimoto, T.; Inoue, H.; Suzuki, A.; Koike, K.; et al. Magmatic fluid pathways in the upper crust: Insights from dense magnetotelluric observations around the Kuju volcanoes, Japan. Geophys. J. Int. 2022, 228, 755–772. [Google Scholar] [CrossRef]

- Krawczyk, J.; Ligęza, P.; Poleszczyk, E.; Skotniczny, P. Advanced hot-wire anemometric measurement systems in investigation of the air flow velocity fields in mine headings. Arch. Min. Sci. 2011, 56, 683–699. [Google Scholar]

- Xu, Y.; Li, Z.; Chen, Y.; Wu, Z.; Yang, G.; Feng, L.; Kong, Z.; Jiang, Q.; Liu, J. Synergetic mining of geothermal energy in deep mines: An innovative method for heat hazard control. Appl. Therm. Eng. 2022, 210, 118398. [Google Scholar] [CrossRef]

- Liu, H.F.; Zhang, J.X.; Rodriguez-Dono, A. Utilization of mine waste heat in phase change rechargeable battery. Appl. Therm. Eng. 2023, 233, 121136. [Google Scholar] [CrossRef]

- Xin, S.; Han, X.; Li, S.; Xiao, Y.; Yang, W. Application of Data Envelopment Analysis in the Ventilation and Cooling Efficiency Evaluation of Hot Development Headings. Processes 2022, 10, 1375. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S.; Xin, S. Performance Test and Thermal Insulation Effect Analysis of Basalt-Fiber Concrete. Materials 2022, 15, 8236. [Google Scholar] [CrossRef]

- Wang, Y. An analytical study of unsteady heat transfer in the rock surrounding a deep airway. Int. J. Min. Sci. Technol. 2012, 22, 411–415. [Google Scholar] [CrossRef]

- Yuan, L. Research and practice on mine cooling in Huainan mining area. J. Min. Saf. Eng. 2007, 24, 298–301. (In Chinese) [Google Scholar]

- Wu, X.; Chen, F.; Wang, Y.; Liu, M.; Zhang, G. Cold loss of supply chilled air for level roadway drifting during mine construction. J. China Coal Soc. 2021, 46, 2593–2599. [Google Scholar]

- Li, X. Analysis and treatment technology of heat sources in the coal mining face of Bultai Coal Mine. Coal Technol. 2021, 40, 112–115. [Google Scholar]

- Miao, D.; Zhang, Y.; Sui, X. Optimization study on air cooler arrangement and cooling parameters of coal mining working face. Energy 2024, 291, 130175. [Google Scholar] [CrossRef]

- You, S.; Mi, L.; Wang, Y.; Shen, C.; Tang, W.; Hu, J.; Zeng, Z.; Zheng, W.; He, F. Unsteady hydraulic modeling and dynamic response analysis of a district heating network. J. Tianjin Univ. (Sci. Technol.) 2019, 52, 849–856. [Google Scholar]

- Hong, S.P.; Kim, T.; Lee, S. A precision pump schedule optimization for the water supply networks with small buffers. Omega 2019, 82, 24–37. [Google Scholar] [CrossRef]

- Gao, T.; Zhao, M.; Mao, Y. Analysis of valve closing schemes and key valves in water distribution networks. J. Harbin Inst. Technol. 2018, 50, 94–99. [Google Scholar]

- Zhou, X.; Liu, G.; Wang, X.; Li, M.; Song, J. Study on optimal adjustment method of second pipe network in central heating system based on dynamic hydraulic balance. J. Cent. South Univ. (Sci. Technol.) 2019, 50, 220–233. [Google Scholar]

- Rathod, M.K.; Banerjee, J. Thermal performance enhancement of shell and tube latent heat storage unit using longitudinal fins. Appl. Therm. Eng. 2015, 75, 1084–1092. [Google Scholar] [CrossRef]

- Jannesari, H.; Abdollahi, N. Experimental and numerical study of thin ring and annular fin effects on improving the ice formation in ice-on-coil thermal storage systems. Appl. Energy 2017, 189, 369–384. [Google Scholar] [CrossRef]

- William, S.J.; Gerald, S.J. Parametric study of heat transfer to an ice cylinder melting in air. Appl. Energy 1990, 36, 233–250. [Google Scholar]

- William, S.J.; Gerald, S.J. Natural convection heat transfer to ice spheres melting in air. In Proceedings of the ASME Heat Transfer Division 1997, Dallas, TX, USA, 16–21 November 1997; pp. 149–155. [Google Scholar]

- Han, Q.; Zhang, Y.; Li, K.; Li, Z.; Liu, M.; Peng, M. Computational evaluation of cooling system under deep hot and humid coal mine in China: A thermal comfort study. Tunn. Undergr. Space Technol. 2019, 90, 394–403. [Google Scholar]

- Engineers, R. ASHRAE Handbook: Refrigeration; American Society of Heating, Refrigerating and Air Conditioning Engineers: Atlanta, GA, USA, 1998. [Google Scholar]

- GB 16423-2020; Safety Regulation for Metal and Nonmetal Mines. State Administration for Market Regulation: Beijing, China, 2021.

- AQ 1028-2006; Coal Mine Ventilation Technical Condition. State Administration of Work Safety: Beijing, China, 2006.

- Wang, Y.; He, M.; Wang, Q.; Gao, Z.; Kang, Z.; Ren, W. Design of equipment system and surrounding rock control for N00 mining method without coal pillar left and roadway excavation. J. China Coal Soc. 2022, 47, 4011–4022. [Google Scholar]

- Corgnati, S.P.; Perino, M.; Fracastoro, G.V.; Nielsen, P.V. Experimental and numerical analysis of air and radiant cooling systems in offices. Build. Environ. 2009, 44, 801–806. [Google Scholar] [CrossRef]

- Zhao, M.; Kang, W.; Luo, X.; Zhang, Y.; Wang, J.; Yang, T. Performance comparison of capillary mat radiant and floor radiant heating systems assisted by an air source heat pump in a residential building. Indoor Built Environ. 2017, 26, 1292–1304. [Google Scholar] [CrossRef]

- Li, Z.; Wang, T.; Zhang, M. Construction of air flow heat transfer coefficient and calculation of airflow temperature in mine wet roadway. J. China Coal Soc. 2017, 42, 3176–3181. [Google Scholar]

| Hazardous Gas Name | Limit Value/% | ||

|---|---|---|---|

| Carbon Monoxide CO | 0.0024 | ||

| Nitrogen Oxides (calculated as NO2) | 0.00025 | ||

| Sulfur Dioxide SO2 | 0.0005 | ||

| Hydrogen Sulfide H2S | 0.00066 | ||

| NH3 | 0.004 | ||

| Dust Type | Free Silica Content (%) | Time-Weighted Average Concentration Limits (mg/m3) | |

| Total Dust | Respirable Dust | ||

| Silica Dust | 10–50 | 1 | 0.7 |

| 50–80 | 0.7 | 0.3 | |

| 280 | 0.5 | 0.2 | |

| Cement Dust | <10 | 4 | 1.5 |

| Item | Parameter Setting |

|---|---|

| Solver | Pressure-based |

| Velocity Formulation | Absolute velocity |

| Time Type | Steady/Transient |

| Turbulence Model | Standard k-ε model |

| Wall Function | Standard wall function |

| Species Model | Species transport |

| Radiation Model | DO |

| Wall Temperature | 306.75 K |

| Inlet Temperature | 305.55 K |

| Heat Flux | 11 |

| Outlet Boundary Type | Pressure outlet |

| Spatial Discretization Scheme (Pressure) | PRESTO |

| Material Name | Physical Parameter | Parameter Value |

|---|---|---|

| Chilled Water | Density/ρ | 998.2 kg/m3 |

| Specific Heat Capacity/cp | 4219.9 J/(kg·K) | |

| Thermal Conductivity/k | 0.561 W/(m·K) | |

| Dynamic Viscosity/μ | 0.001792 kg/(m·s) | |

| Packing Material | Density/ρ | 1750 kg/m3 |

| Specific Heat Capacity/cp: | 837 J/(kg·K) | |

| Thermal Conductivity/k: | 4.16 W/(m·K) | |

| Radiation Panel (Air/vapor) | Density/ρ | 2719 kg/m3 |

| Specific Heat Capacity/cp | 871 J/(kg·K) | |

| Thermal Conductivity/k | 202.4 W/(m·K) |

| Grid Scheme | Grid Cell Number | Background Mesh (m) | Foreground Mesh (m) | First Boundary Layer y+ Value | Number of Boundary Layers |

|---|---|---|---|---|---|

| (G4) | 1,245,632 | 0.25 | 0.03 | 58.7 | 3 |

| (G3) | 2,156,847 | 0.2 | 0.02 | 49.2 | 4 |

| (G2) | 3,427,536 | 0.1 | 0.018 | 33.4 | 5 |

| (G1) | 5,284,719 | 0.9 | 0.018 | 31.1 | 7 |

| Cooling Performance of Modular Convection–Radiation System | |||||||

|---|---|---|---|---|---|---|---|

| Equipment Installation Method | 25 m Unilateral Installation | 25 m Bilateral Alternating Installation | 40 m Alternating Installation | 25 m Bilateral Alternating Installation | |||

| Working Face | 1404 m Level | 1404 m Level | 1404 m Level | 1404 m Level | 1274 m Level | 1104 m Level | 924 m Level |

| 100 | 100 | 98% | 99 | 85 | 75 | 60 | |

| 72 | 75 | 67% | 67 | 60 | 40 | 25 | |

| 100 | 100 | 100 | 100 | 95 | 90 | 85 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Wang, X.; Wang, H. Construction of Microclimatic Zone Based on Convection–Radiation System for Local Cooling in Deep Mines. Energies 2025, 18, 3029. https://doi.org/10.3390/en18123029

Chen X, Wang X, Wang H. Construction of Microclimatic Zone Based on Convection–Radiation System for Local Cooling in Deep Mines. Energies. 2025; 18(12):3029. https://doi.org/10.3390/en18123029

Chicago/Turabian StyleChen, Xiangru, Xiaodong Wang, and Hui Wang. 2025. "Construction of Microclimatic Zone Based on Convection–Radiation System for Local Cooling in Deep Mines" Energies 18, no. 12: 3029. https://doi.org/10.3390/en18123029

APA StyleChen, X., Wang, X., & Wang, H. (2025). Construction of Microclimatic Zone Based on Convection–Radiation System for Local Cooling in Deep Mines. Energies, 18(12), 3029. https://doi.org/10.3390/en18123029