Decreasing Mining Losses for the Room and Pillar Method by Replacing the Inter-Room Pillars by the Construction of Wooden Cribs Filled with Waste Rocks

Abstract

1. Introduction

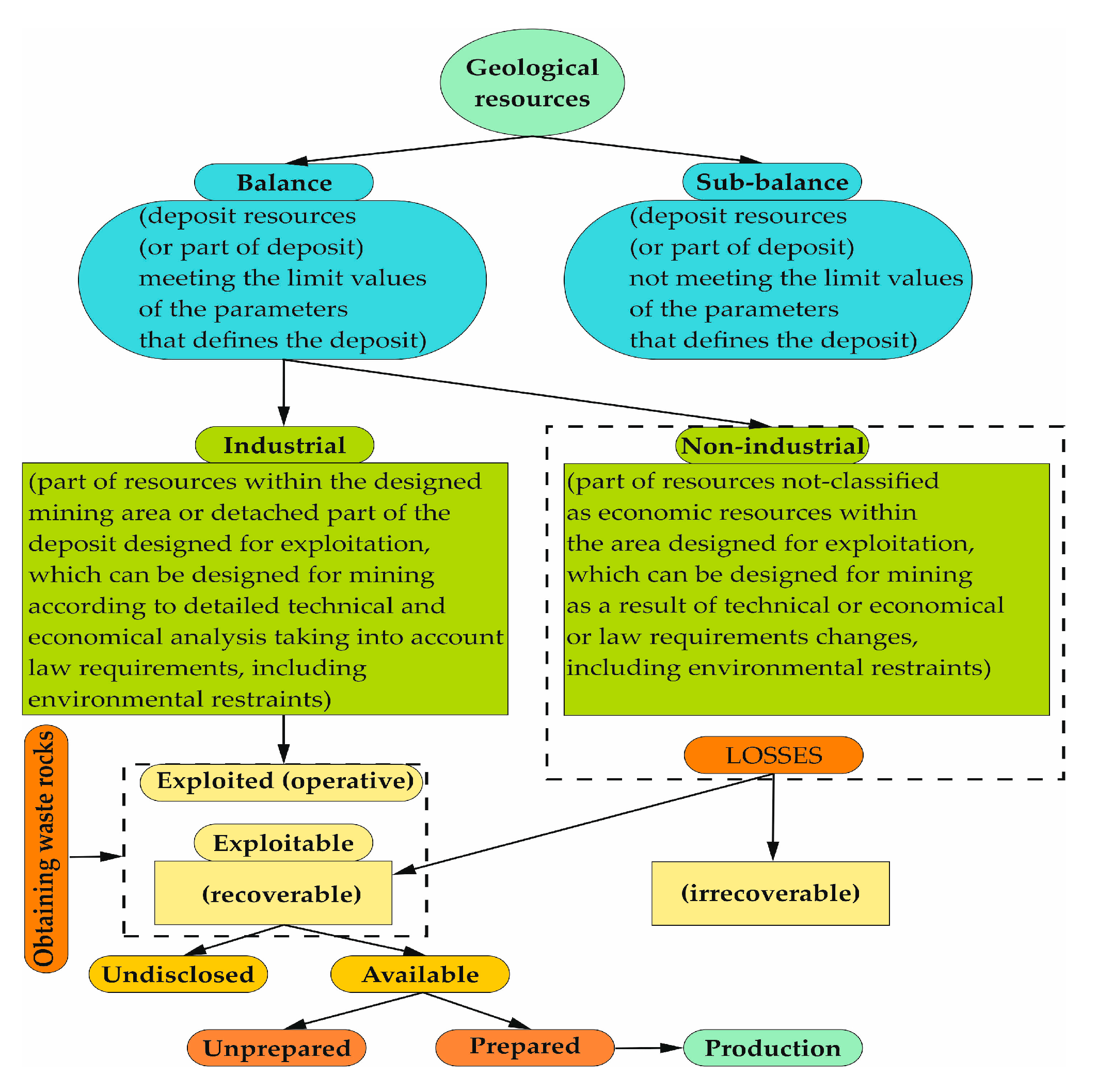

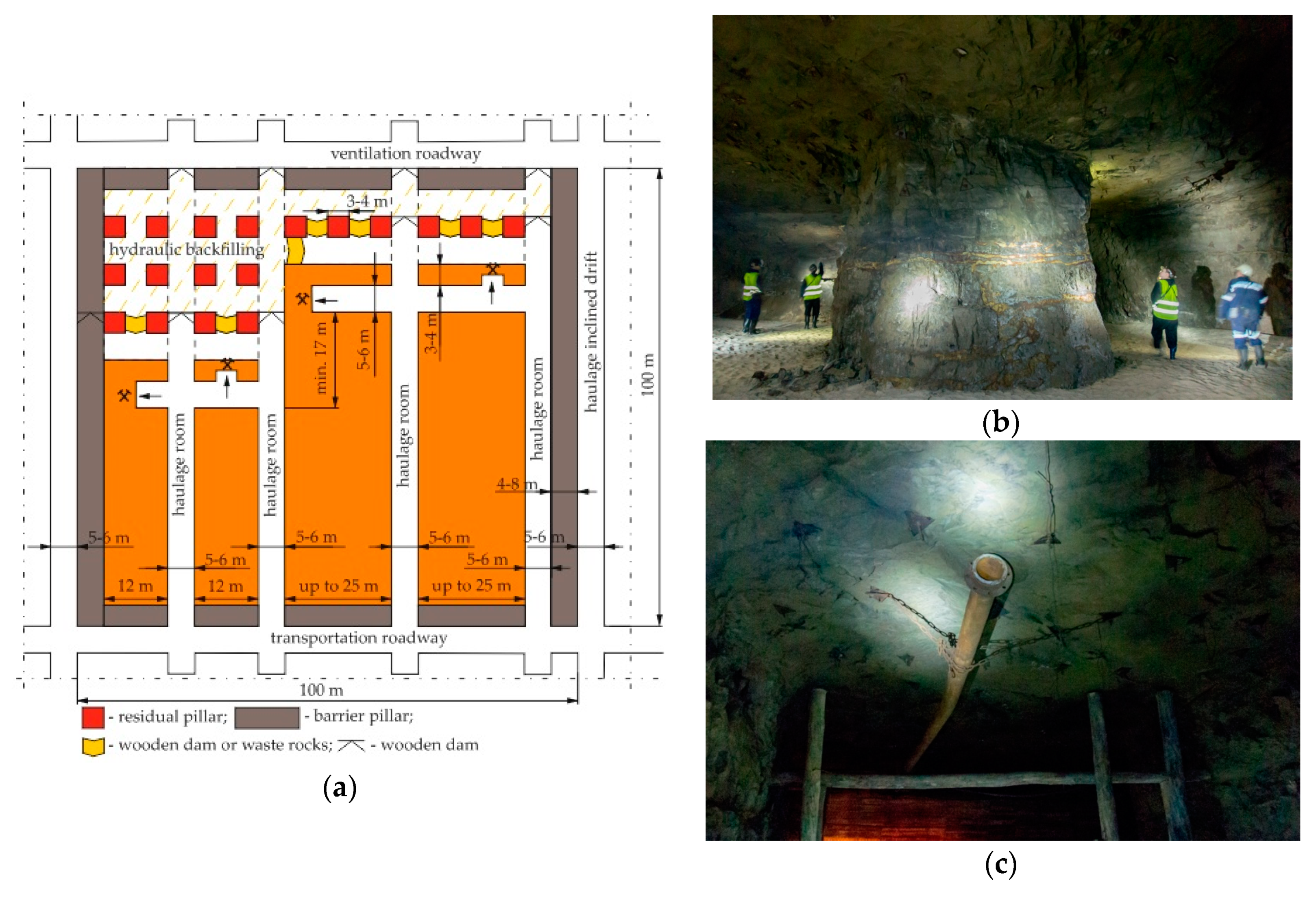

2. Sources of the Mining Losses in the Room and Pillar Method for Lead and Zinc Ore Deposit

- geological factors (arising as a result of deposit disruption by discharges, elevations, or fissures, as well as losses resulting from the complicated form of the deposit: exclusion, irregularities in a deposit occurring);

- hydrogeological factors (losses related to leaving protective pillars, preventing the ingress of water or the inability to select a deposit due to water accumulation);

- leaving the deposit in pillars to protect capital excavations, surface structures, canals, rivers, roads, and other objects that are within the impact of mining works (pillars left between exploitation fields or individual excavations, to avoid mutual interaction; losses in protective pillars, and also in pillars left to support the roof in a room methods);

- leaving part of the deposit as a result of changing deposit parameters;

- the method of transporting the excavated material underground (losses occur as a result of spilling the excavated material while loading it onto carts or conveyors);

- losses in non-industrial resources as a result of mining being removed by mining works;

- loosening of the mineral in the filling, during layer exploitation, as well as ore discharge.

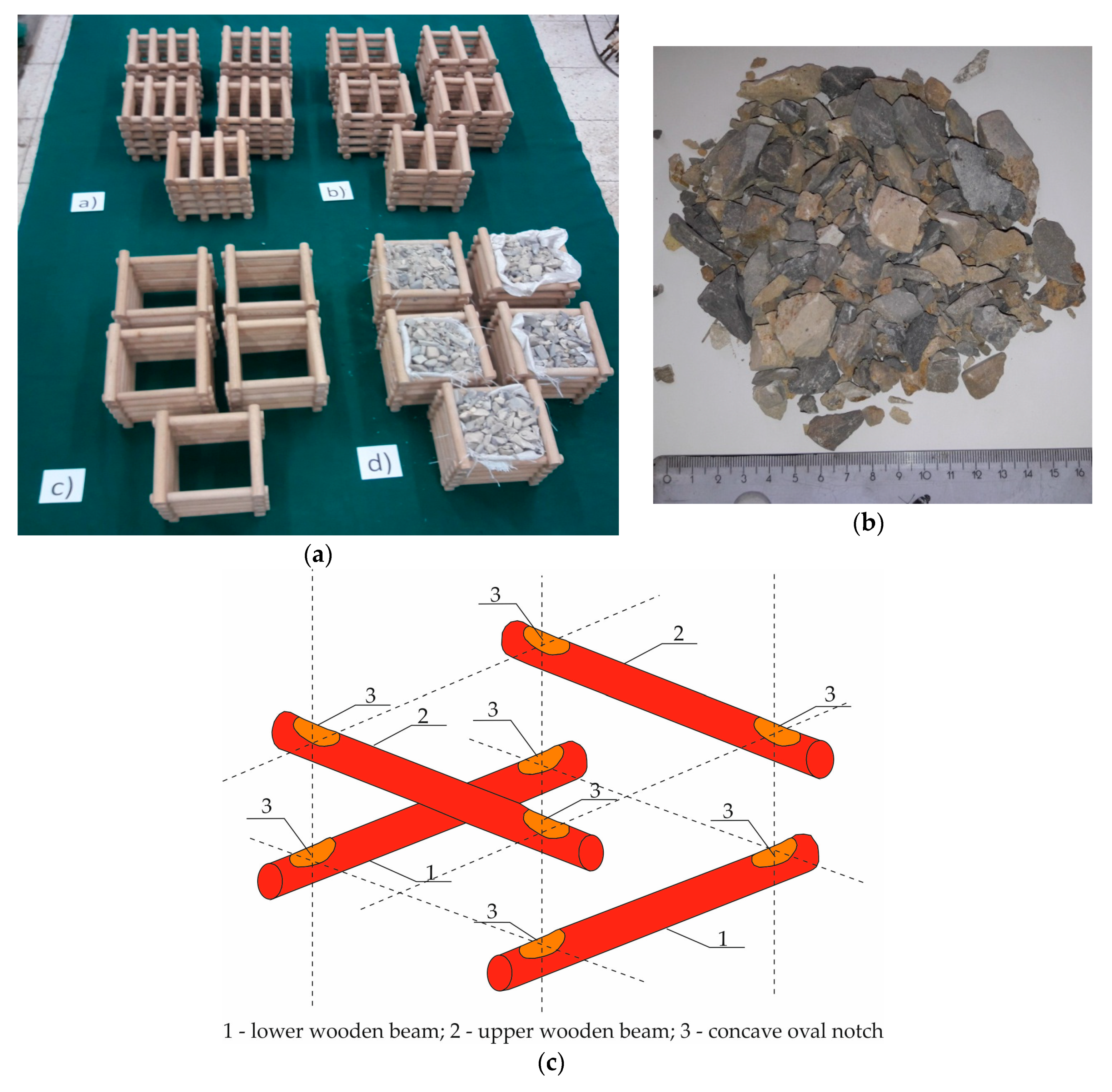

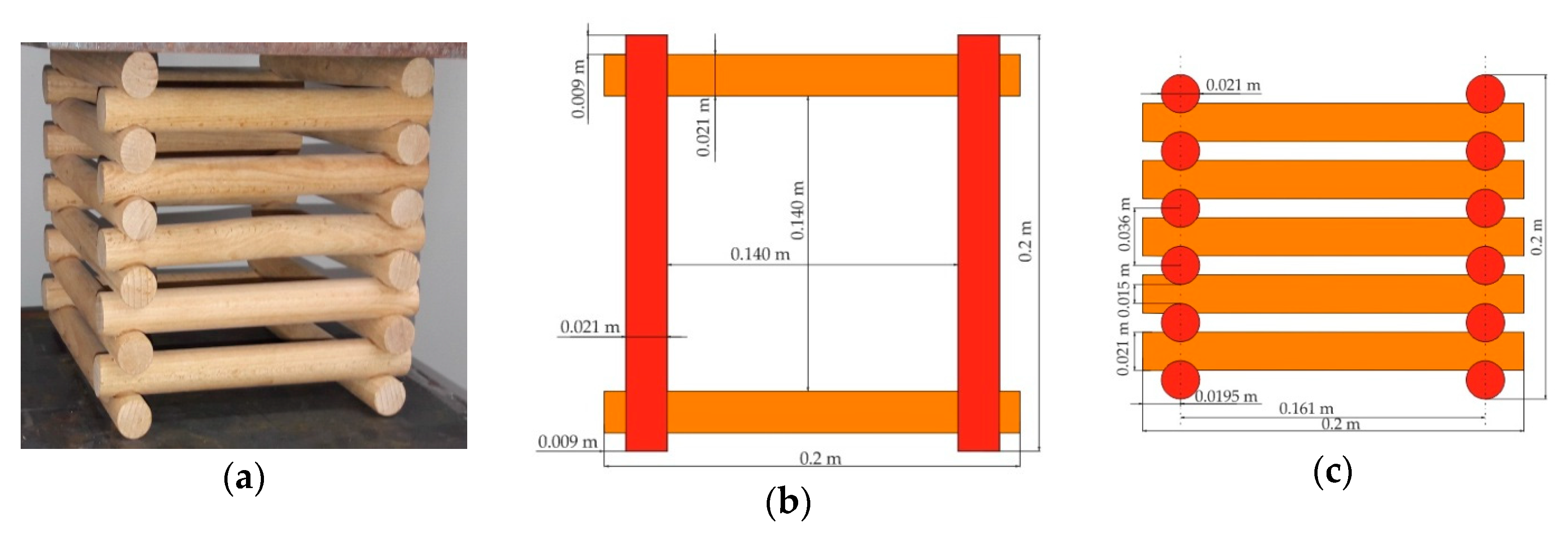

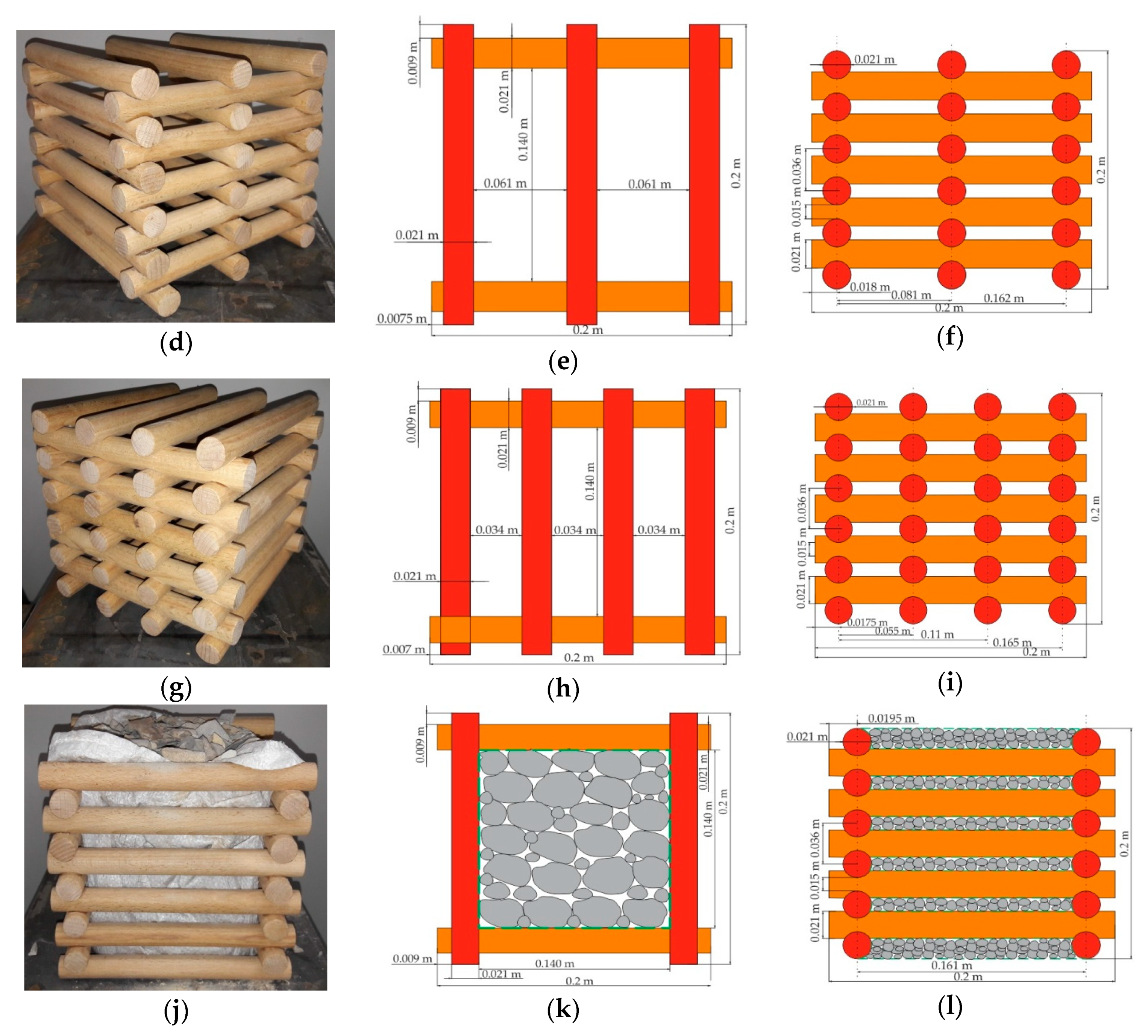

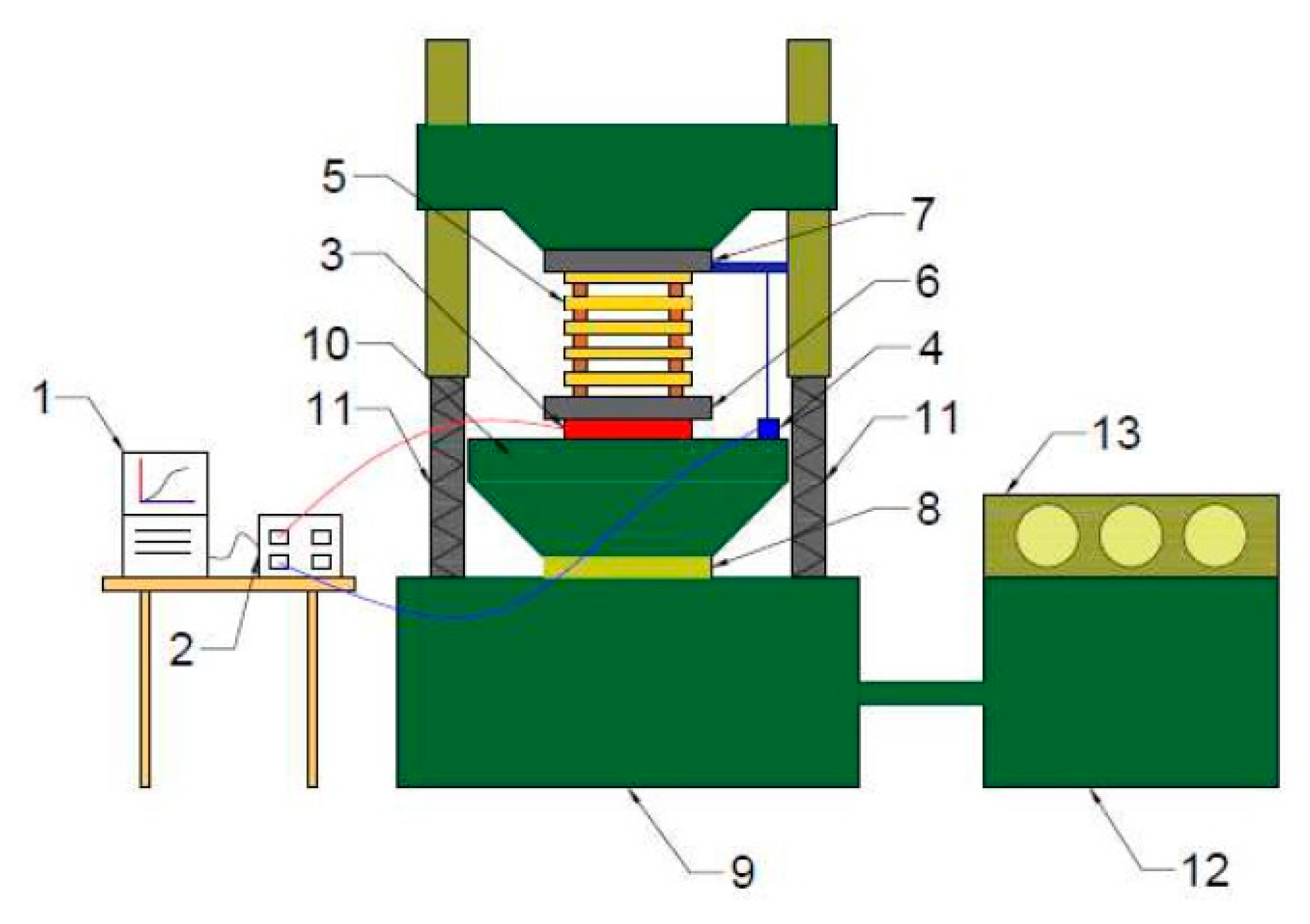

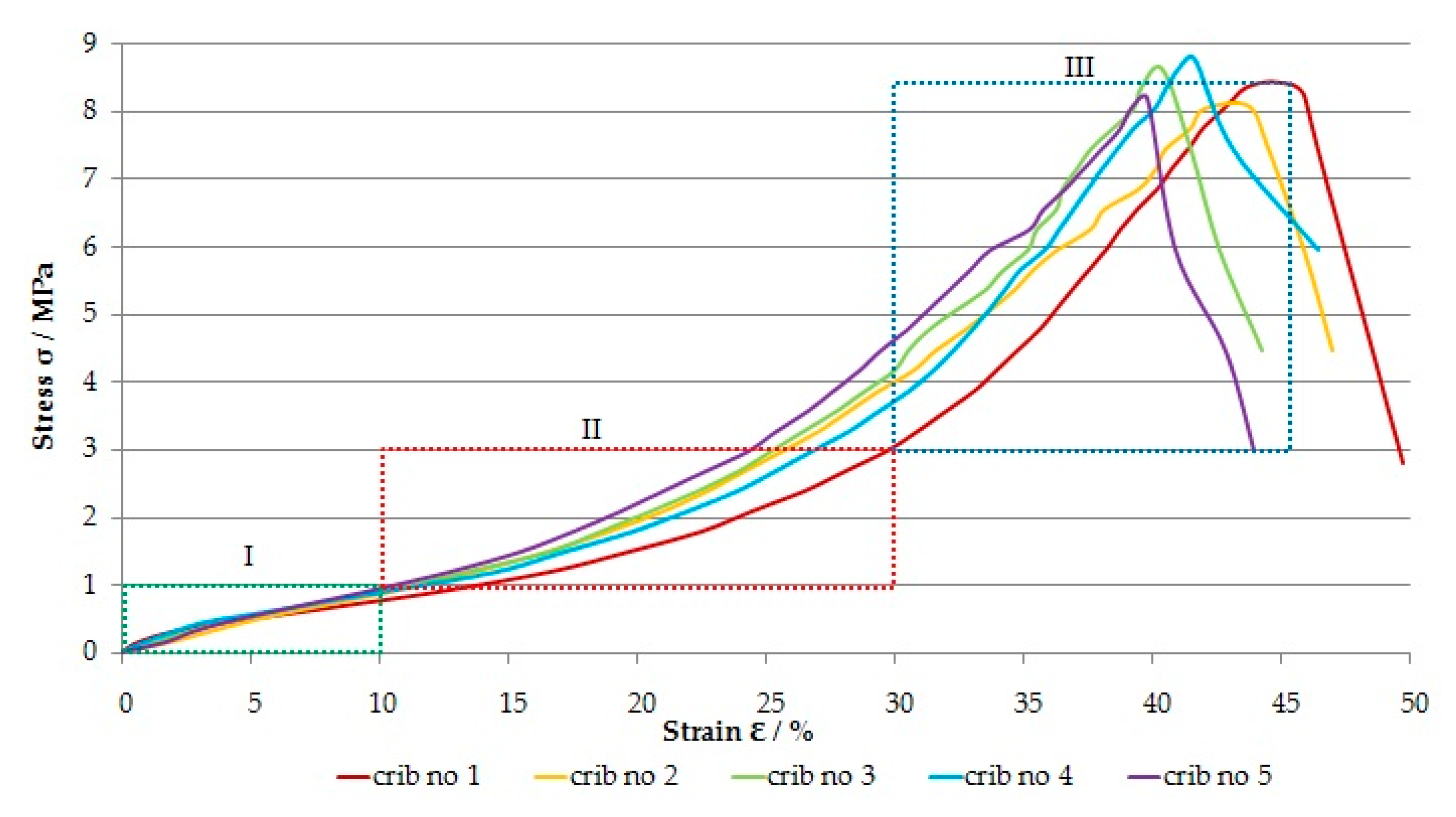

3. Laboratory Tests on the Mining Crib Models

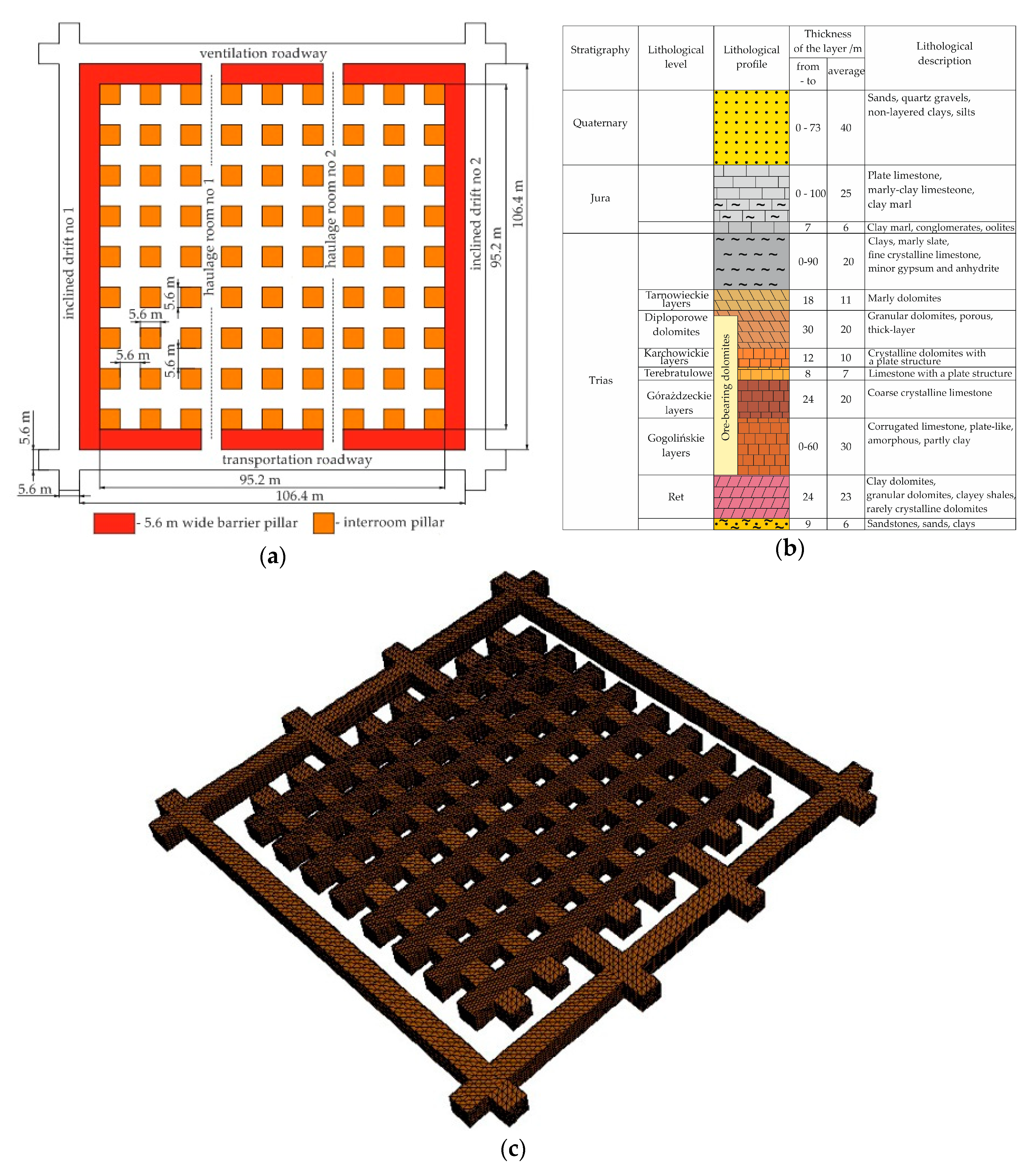

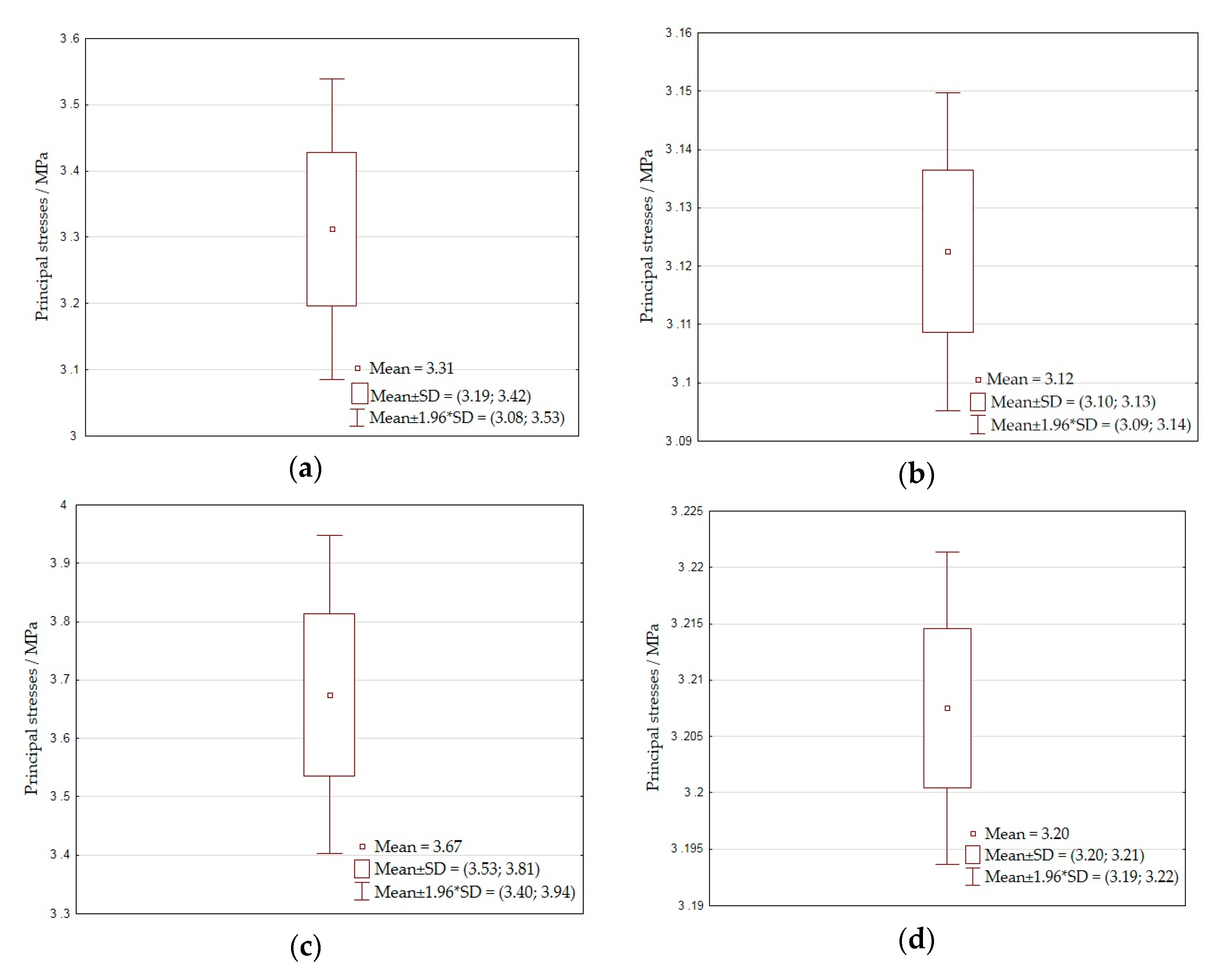

4. Numerical Modeling of Principal Stresses in the Inter-Room Pillars

- σ—total normal stress on the slip surface;

- τ—shear stress on the slip surface;

- σ1—major principal stress;

- σ3—minor principal stress;

- (σ1 + σ2)/2—horizontal coordinate of the Mohr circle center;

- (σ1−σ3)/2—Mohr circle radius;

- φ—effective angle of internal friction;

- c—effective cohesion.

- σ1—major principal stress;

- σ2—intermediate principal stress;

- σ3—minor principal stress.

- R0—compressive strength of the crib model filled with waste rocks;

- R1—compressive strength of the crib filled with waste rocks on a geometric scale 1:1;

- V0—volume of the crib model filled with waste rocks;

- V1—volume of the crib filled with waste rocks on a geometric scale 1:1;

- m—Weibull modulus; this can be estimated from the formula [26]:

5. Results

- FoS—factor of safety;

- Ps—pillar strength/MPa;

- S—applied pillar stress/MPa.

- K—strength of 0.3 m cubic sample = 0.7 × uniaxial compressive strength (UCS, 30MPa) (50 mm diameter sample)/MPa;

- K = 0.7 × 30 = 21 MPa;

- w—pillar width/m;

- h—pillar height/m.

6. Conclusions

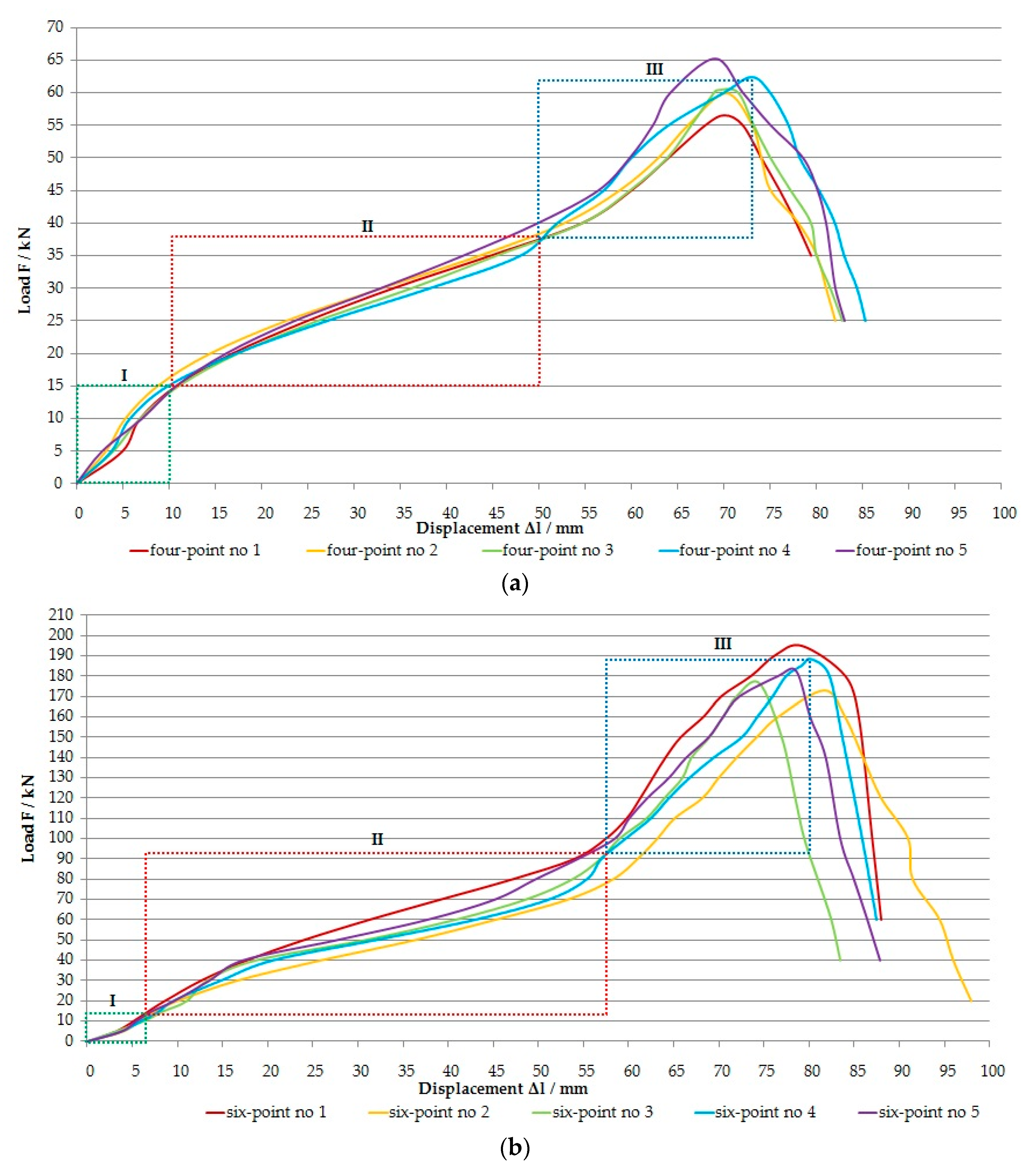

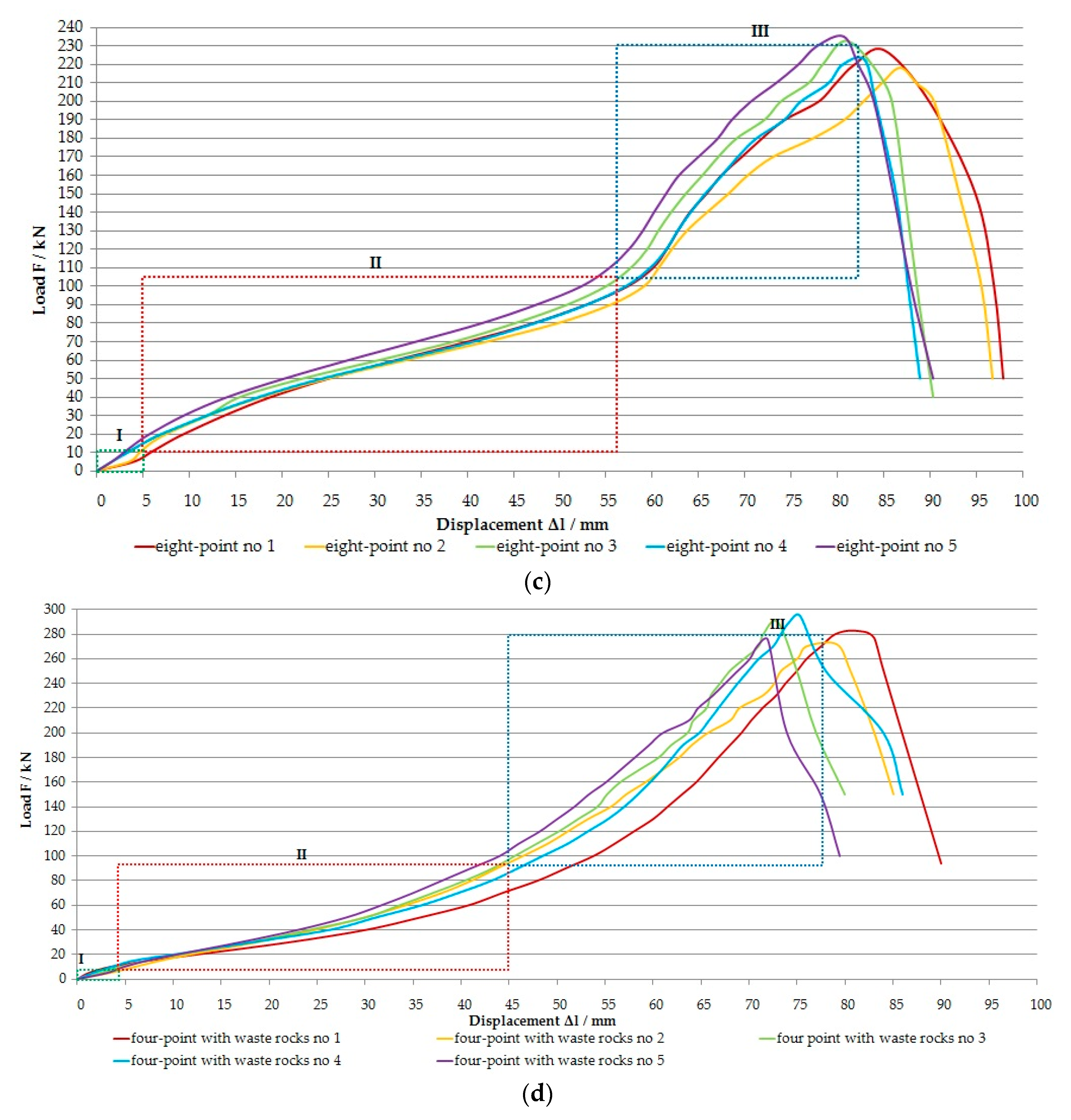

- the four-point empty crib, built of 22 beams, showed an average capacity of 60.9 kN and an average specific deformation of 35.5%;

- increasing the number of connections in the crib increased its load;

- the six-point empty crib was characterized by a load capacity of more than three times greater and an average specific deformation greater by 4.25% compared to the four-point crib;

- the eight-point empty crib was characterized by a load capacity of more than three and a half times greater and an average specific deformation greater by 6.5% compared to the four-point crib;

- filling the four-point crib with waste rocks (crushed dolomite with a diameter of 10–25 mm) meant that its capacity was more than four and a half times greater and that the average specific deformation increased by 2.9% compared to the four-point empty crib;

- the rigidity of empty four-point, six-point, and eight-point cribs decreases with increasing compressibility (up to 30%); above 30% compressibility, the stiffness of the cribs increases;

- the stiffness of four-point cribs filled with waste rocks increases with increasing compressibility.

- the maximal value of principal stresses in the inter-room rock pillars is 3.50 MPa;

- the replacement of rock pillars by means of wooden cribs filled with waste rocks causes an increase in principal stresses in the inter-room pillars by 0.4 MPa in comparison with rock pillars;

- the value of the factor of safety for the inter-room rock pillars ranges from 3.9 to 4.25 and ranges from 1.75 to 2.19 when rock pillars are replaced by wooden cribs filled with waste rocks.

Funding

Conflicts of Interest

References

- Barczak, T.; Tastillo, C. Evaulation of Multitimber Wood Crib Support; Report of Investigations 9341; United States Department of the Interior. Bureau of Mines: Washington, DC, USA, 1991.

- Korzeniowski, W.; Skrzypkowski, K. Comparative investigations of the load capacity and load-strain characteristics of chocks with different filling. Min. Rev. 2012, 68, 36–40. [Google Scholar]

- Korzeniowski, W.; Skrzypkowski, K.; Szumiński, A. Characteristics of a model of mining wooden chock with increased load capacity. Min. Rev. 2014, 70, 26–33. [Google Scholar]

- Daehnke, A.; Taggart, P.N.; Roberts, M.K.C. Evaluation of the influence of grout prestressing systems on the performance of timber packs: Static and dynamic considerations. J. S. Afr. Inst. Min. Metall. 1995, 96, 41–46. [Google Scholar]

- Dison, L.; Smith, A.C.S. Cempaks: Stope and gully supports. In Proceedings of the 6th International Symposium on Ground Support in Mining and Civil Engineering Construction, Cape Town, South Africa, 31 March–3 April 2008; Stacey, T.R., Malan, D.F., Eds.; Southern African Institute of Mining and Metallurgy: Cape Town, South Africa, 2008; pp. 289–298. [Google Scholar]

- Mining Product Developments. Available online: http://www.miningproducts.co.za/mining-products.html (accessed on 19 March 2020).

- Skrzypkowski, K. Strengthening the room excavation through the use of additional support in the form of wooden props in underground ore copper mines. Bull. Inst. Non-Ferr. Met. 2017, 62, 10–15. [Google Scholar] [CrossRef]

- Strata Worldwide. Available online: https://www.strataworldwide.com (accessed on 12 March 2020).

- Kushwaha, A.; Singh, S.K.; Tewari, S.; Sinha, A. Empirical approach for designing of support system in mechanized coal pillar mining. Int. J. Rock Mech. Min. 2010, 47, 1063–1078. [Google Scholar] [CrossRef]

- Li, Y.; Li, K.; Feng, X.; Cai, M. Development and evaluation of artificial expandable pillars for hard rock mining. Int. J. Rock Mech. Min. 2018, 110, 68–75. [Google Scholar] [CrossRef]

- Luan, H.; Jiang, Y.; Lin, H.; Li, G. Development of a New Gob-Side Entry-Retaining Approach and Its Application. Sustainability 2018, 10, 470. [Google Scholar] [CrossRef]

- Hadjigeorgiu, J.; Habiyaremye, F.; Lessard, J.S.; Andrieux, P. An investigation into the behavior of shotcrete pillars. In Rock Support and Reinforcement Practice in Mining; Villaescusa, E., Windsor, C.R., Thompson, A., Eds.; Balkema: Rotterdam, The Netherlands, 1999; pp. 183–192. [Google Scholar]

- Kang, H.; Lv, H.; Zhang, X.; Gao, F.; Wu, Z.; Wang, Z. Evaluation of the Ground Response of a Pre-driven Longwall Recovery Room Supported by Concrete Cribs. Rock Mech. Rock Eng. 2016, 49, 1025–1040. [Google Scholar] [CrossRef]

- Cao, S.; Zheng, D.; Yilmaz, E.; Yin, Z.; Xue, G.; Yang, F. Strength development and microstructure characteristics of artificial concrete pillar considering fiber type and content effects. Constr. Build. Mater. 2020, 256, 119408. [Google Scholar] [CrossRef]

- Skrzypkowski, K. The influence of dimension of mining crib model filled by waste rock on the course of load—Displacement characteristic. Bull. Miner. Energy Econ. Res. Inst. Pol. Acad. Sci. 2017, 99, 131–141. [Google Scholar]

- Korzeniowski, W.; Skrzypkowski, K.; Szumiński, A.; Zagórski, K. Laboratory investigations of the load capacity and load-strain characteristics of four-point cribs filled with waste rocks. Bull. Inst. Non-Ferr. Met. 2015, 60, 303–308. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Zagórska, A. Flexibility and load-bearing capacity of roof bolting as functions of mounting depth and hole diameter. Energies 2019, 12, 3754. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Zagórska, A. Adjustment of the Yielding System of Mechanical Rock Bolts for Room and Pillar Mining Method in Stratified Rock Mass. Energies 2020, 13, 2082. [Google Scholar] [CrossRef]

- Malan, D.F.; Napier, J.A.L. Rockburst support in shallow-dipping tabular stopes at great depth. Int. J. Rock Mech. Min. 2018, 112, 302–312. [Google Scholar] [CrossRef]

- Polish Geological Institute. Available online: https://www.pgi.gov.pl/en (accessed on 26 April 2020).

- State Mining Authority. Ordinance Minister of Environment of July 1, 2015 on the Geological Documentation of a Mineral Deposit, Excluding Hydrocarbons. Available online: http://www.wug.gov.pl/english/polish_law (accessed on 1 May 2020).

- Skrzypkowski, K. Crib in Mining Industry. Poland Patent PL233119B1, 30 September 2019. [Google Scholar]

- Skrzypkowski, K. The influence of room and pillar method geometry on the deposit utilization rate and rock bolt load. Energies 2019, 12, 4770. [Google Scholar] [CrossRef]

- Rocscience. Available online: https://www.rocscience.com (accessed on 11 May 2020).

- Weibull, W. A statistical distribution function of wide applicability. J. App. Mech. 1951, 18, 293–297. [Google Scholar]

- Zweben, C. Designer’s corner. Is there a size effect in composites? Composites 1994, 25, 451–454. [Google Scholar] [CrossRef]

- Esterhuizen, G.S.; Dolinar, D.R.; Ellenberger, J.L. Pillar strength in underground stone mines in the United States. Int. J. Rock Mech. Min. 2011, 48, 42–50. [Google Scholar] [CrossRef]

- Deghan, S.; Shahriar, K.; Maarefvand, P.; Goshtasbi, K. 3-D numerical modelling of Domino failure of hard rock pillars in Fetr6 Chromite Mine, Iran, and comparison with empirical methods. J. Cent. South Univ. 2013, 20, 541–549. [Google Scholar] [CrossRef]

- Verma, A.K. A comparative study of various empirical methods to estimate the factor of safety of coal pillars. Am. J. Mining Metall. 2014, 2, 17–22. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, S.-E.; Deng, K.-Z.; Fan, H.-D. Long-Term Stability Evaluation and Pillar Design Criterion for Room-and-Pillar Mines. Energies 2017, 10, 1644. [Google Scholar] [CrossRef]

- Jessu, K.V.; Spearing, A.J.S.; Sharifzadeh, M. A Parametric Study of Blast Damage on Hard Rock Pillar Strength. Energies 2018, 11, 1901. [Google Scholar] [CrossRef]

- Martin, C.D.; Maybee, W.G. The strength of hard-rock pillars. Int. J. Rock Mech. Min. 2000, 37, 1239–1246. [Google Scholar] [CrossRef]

- Van der Merwe, J.N. Coal pillar strength analysis based on size at the time of failure. J. S. Afr. Inst. Min. Metall. 2019, 119, 681–691. [Google Scholar] [CrossRef]

- Hadley, D.G.G.; Grant, F. Stope and pillar design for the Elliot Lake uranium mines. Can. Inst. Min. Metall. Bull. 1972, 65, 37–44. [Google Scholar]

- London Metal Exchange. Available online: https://www.lme.com/en-GB/Metals/Non-ferrous/ (accessed on 2 July 2020).

| Crib Model | Maximal Load F/kN | Vertical Displacement Δl/mm (at Maximal Load) | Average Specific Deformation ε/% | ||||

|---|---|---|---|---|---|---|---|

| From | To | Average | From | To | Average | ||

| Four-point | 56.5 | 65.2 | 60.9 | 63.9 | 73 | 70.3 | 35.15 |

| Six-point | 172 | 194 | 183 | 74.5 | 81.7 | 78.8 | 39.40 |

| Eight-point | 222 | 235 | 227 | 80.7 | 86.8 | 83.3 | 41.65 |

| Four-point filled with waste rocks | 271 | 295 | 283 | 72 | 79.1 | 76.1 | 38.05 |

| Case | Principal Stresses Occurring in the Inter-Room Pillar /MPa | ||

|---|---|---|---|

| No | Descriptions | Minimal | Maximal |

| R1 | Rock pillars and empty rooms | 3.25 | 3.50 |

| R2 | Rock pillars and rooms filled with hydraulic sand filling | 3.10 | 3.13 |

| R3 | Rock pillars replaced by wooden cribs filled with waste rocks and empty rooms | 3.60 | 3.90 |

| R4 | Rock pillars replaced by wooden cribs filled with waste rocks and rooms filled with hydraulic sand filling | 3.19 | 3.21 |

| Compressibility C/% | Four-Point Crib | Six-Point Crib | Eight-Point Crib | Four-Point Crib with Waste Rocks |

|---|---|---|---|---|

| Stiffness S/kN/mm | ||||

| 10 | 1.25 | 2 | 2.45 | 1.65 |

| 20 | 0.87 | 1.46 | 1.85 | 1.67 |

| 30 | 0.75 | 1.40 | 1.80 | 2.30 |

| 40 | 0.77 | 2.05 | 2.60 | 3.72 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skrzypkowski, K. Decreasing Mining Losses for the Room and Pillar Method by Replacing the Inter-Room Pillars by the Construction of Wooden Cribs Filled with Waste Rocks. Energies 2020, 13, 3564. https://doi.org/10.3390/en13143564

Skrzypkowski K. Decreasing Mining Losses for the Room and Pillar Method by Replacing the Inter-Room Pillars by the Construction of Wooden Cribs Filled with Waste Rocks. Energies. 2020; 13(14):3564. https://doi.org/10.3390/en13143564

Chicago/Turabian StyleSkrzypkowski, Krzysztof. 2020. "Decreasing Mining Losses for the Room and Pillar Method by Replacing the Inter-Room Pillars by the Construction of Wooden Cribs Filled with Waste Rocks" Energies 13, no. 14: 3564. https://doi.org/10.3390/en13143564

APA StyleSkrzypkowski, K. (2020). Decreasing Mining Losses for the Room and Pillar Method by Replacing the Inter-Room Pillars by the Construction of Wooden Cribs Filled with Waste Rocks. Energies, 13(14), 3564. https://doi.org/10.3390/en13143564