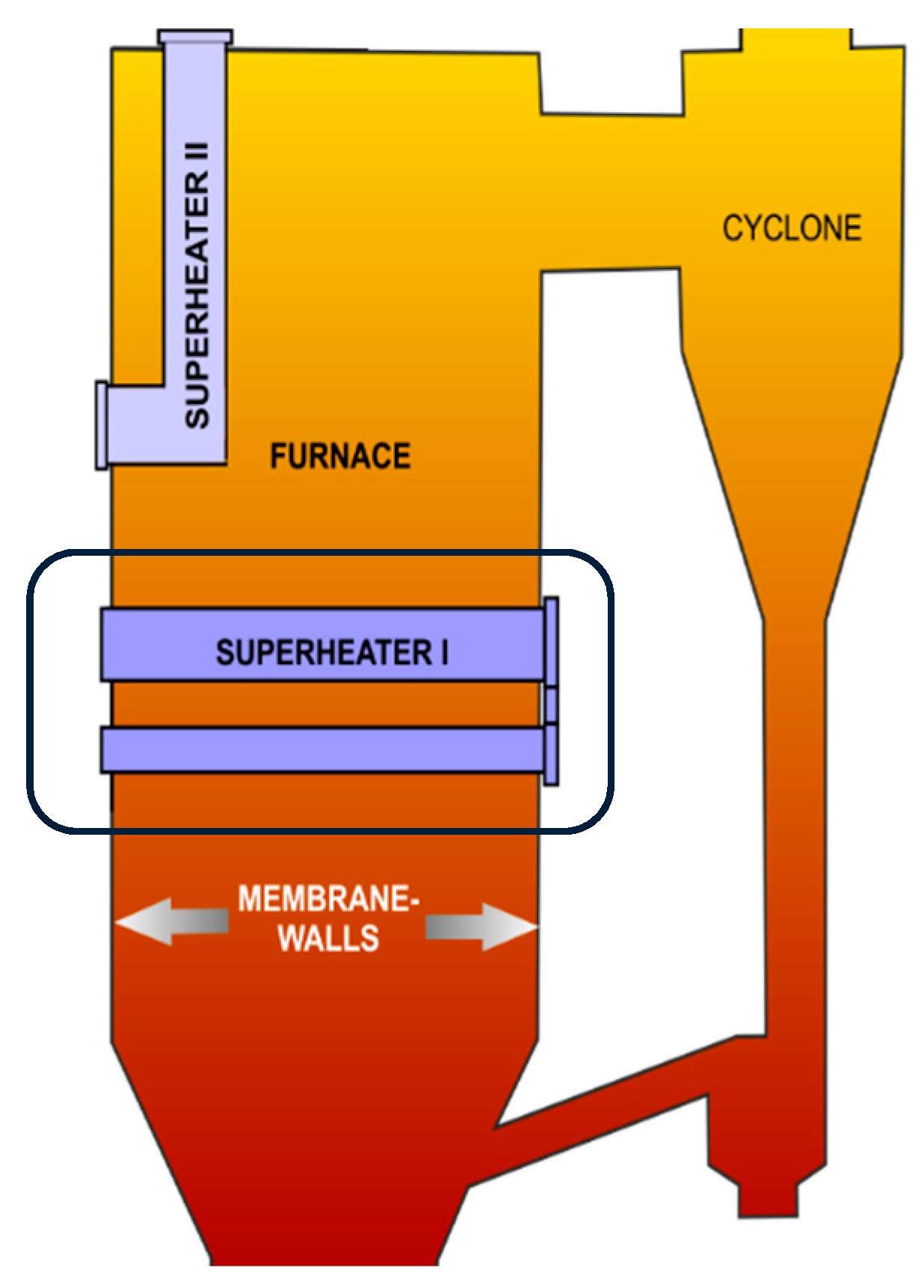

Heat Transfer Performance in a Superheater of an Industrial CFBC Using Fuzzy Logic-Based Methods

Abstract

:1. Introduction

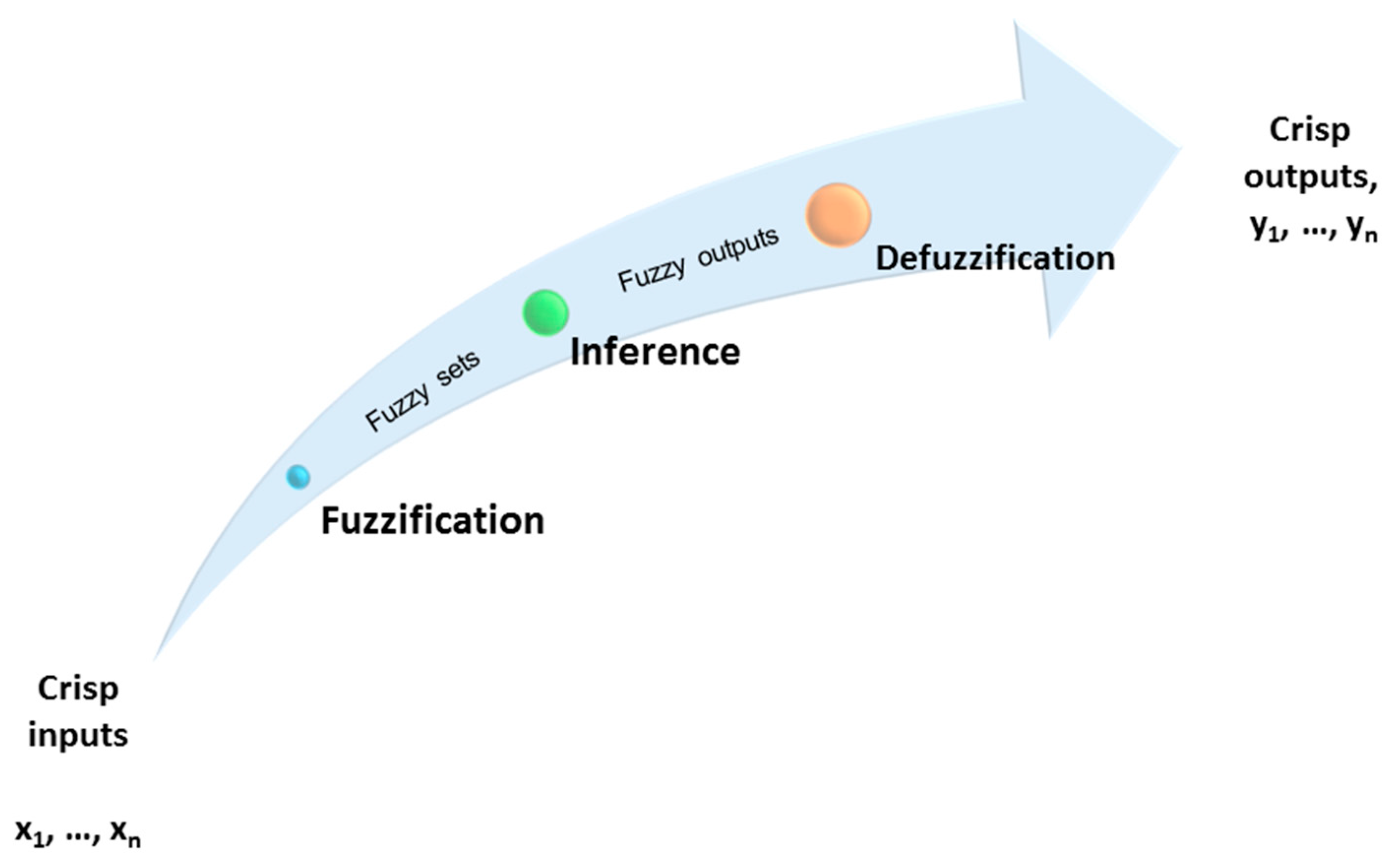

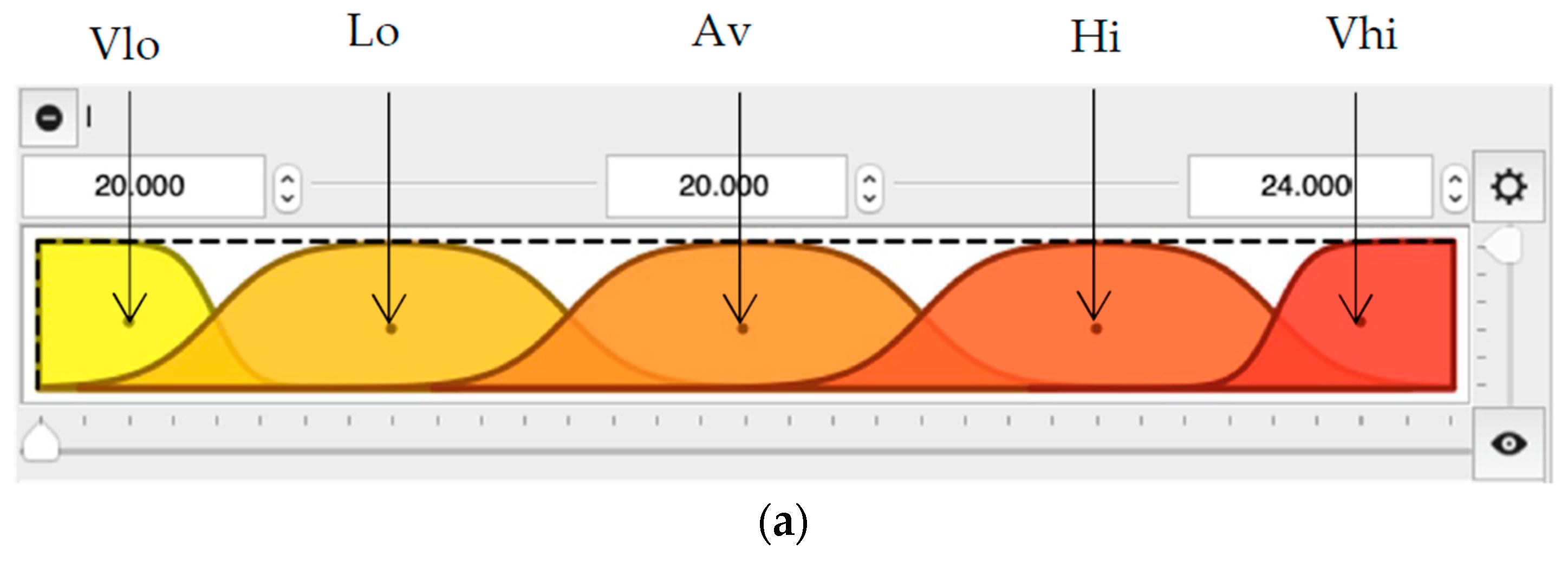

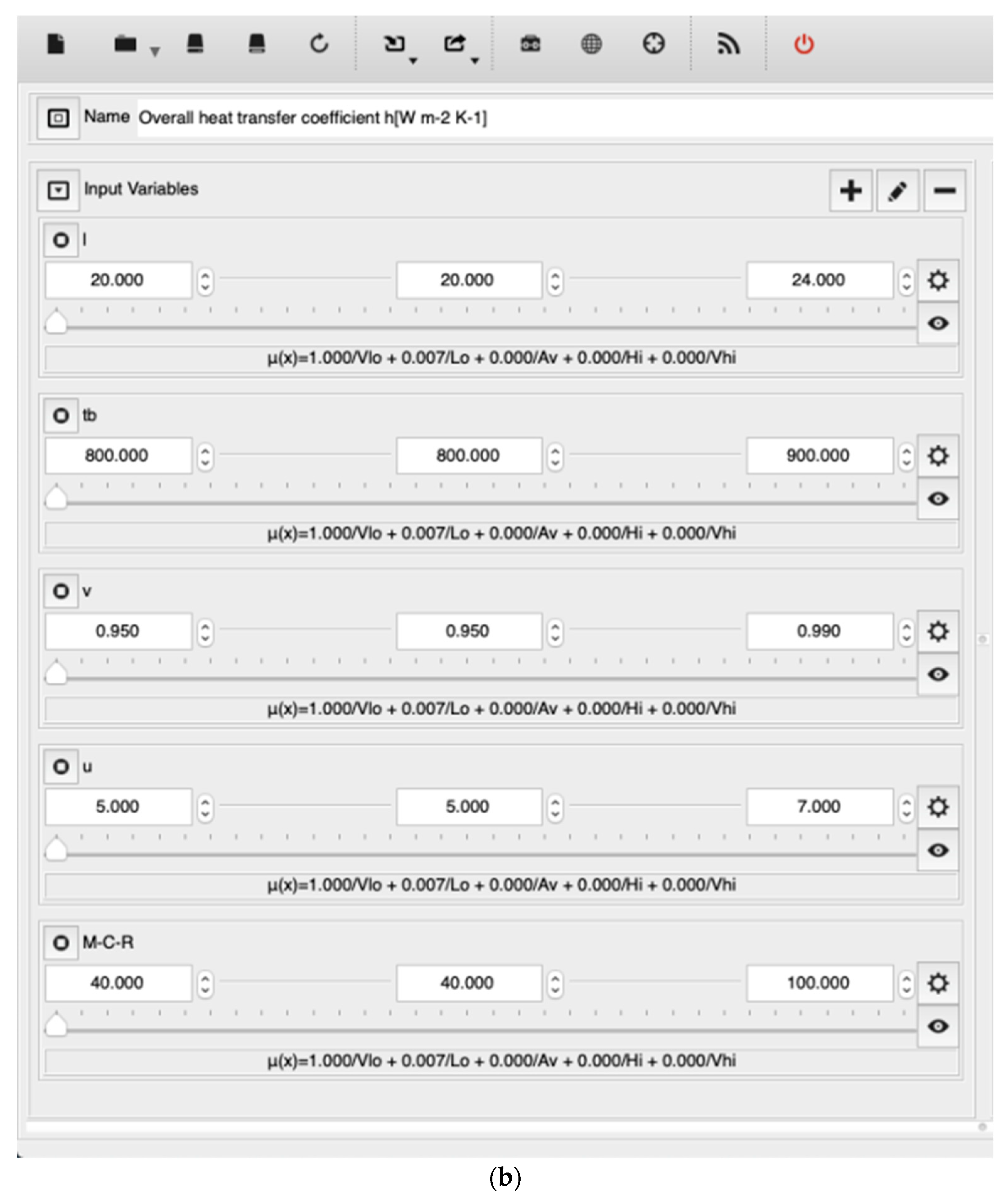

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Funding

Conflicts of Interest

Nomenclature

| k | overall heat transfer coefficient, W/(m2⋅K) |

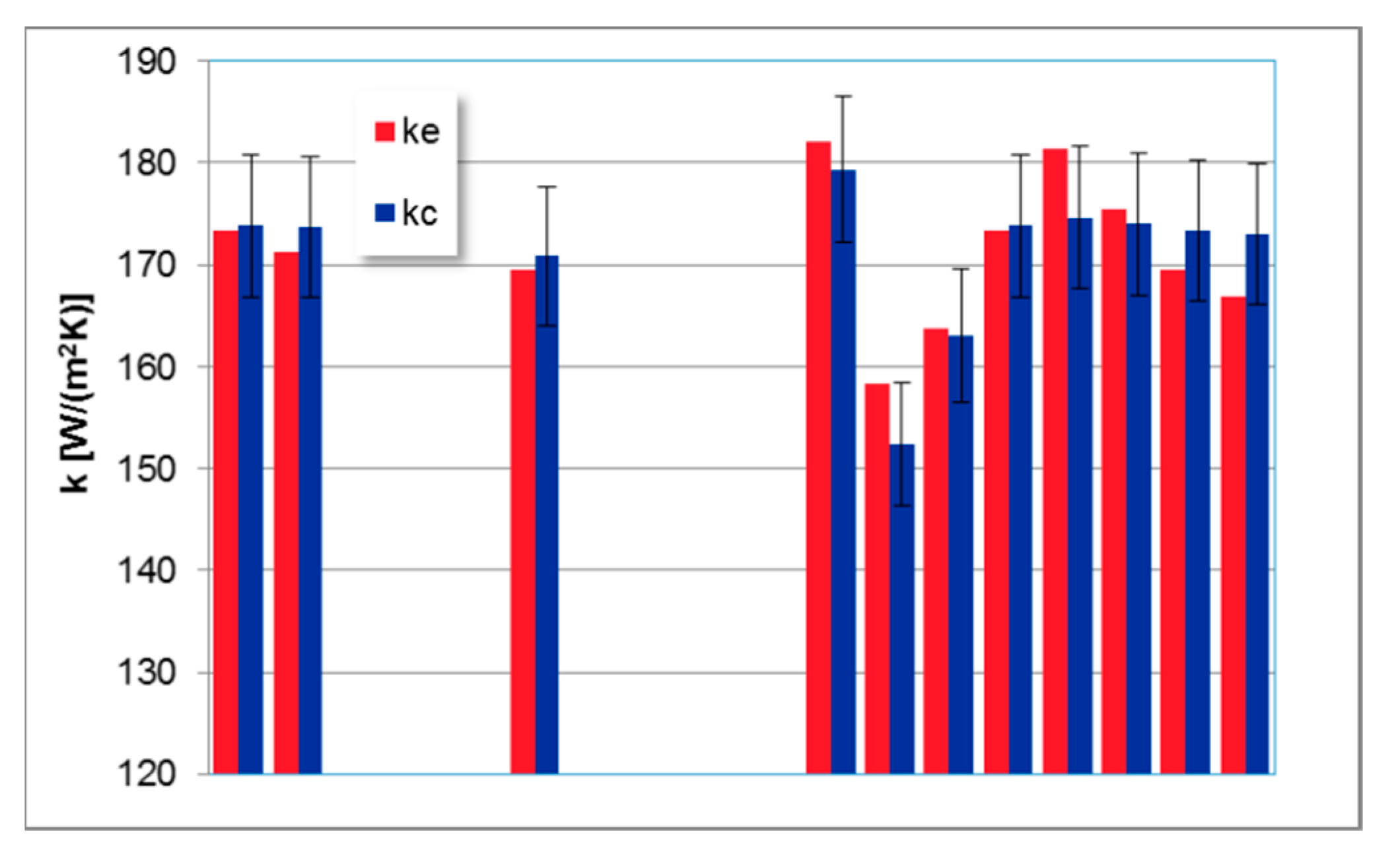

| kc | overall heat transfer coefficient, predicted (calculated), W/(m2⋅K) |

| ke | overall heat transfer coefficient, desired (measured), W/(m2⋅K) |

| xi | an i-th crisp input |

| M-C-R | maximum continuous rating, % |

| μ (xi) | a membership degree |

| yi | an i-th crisp output |

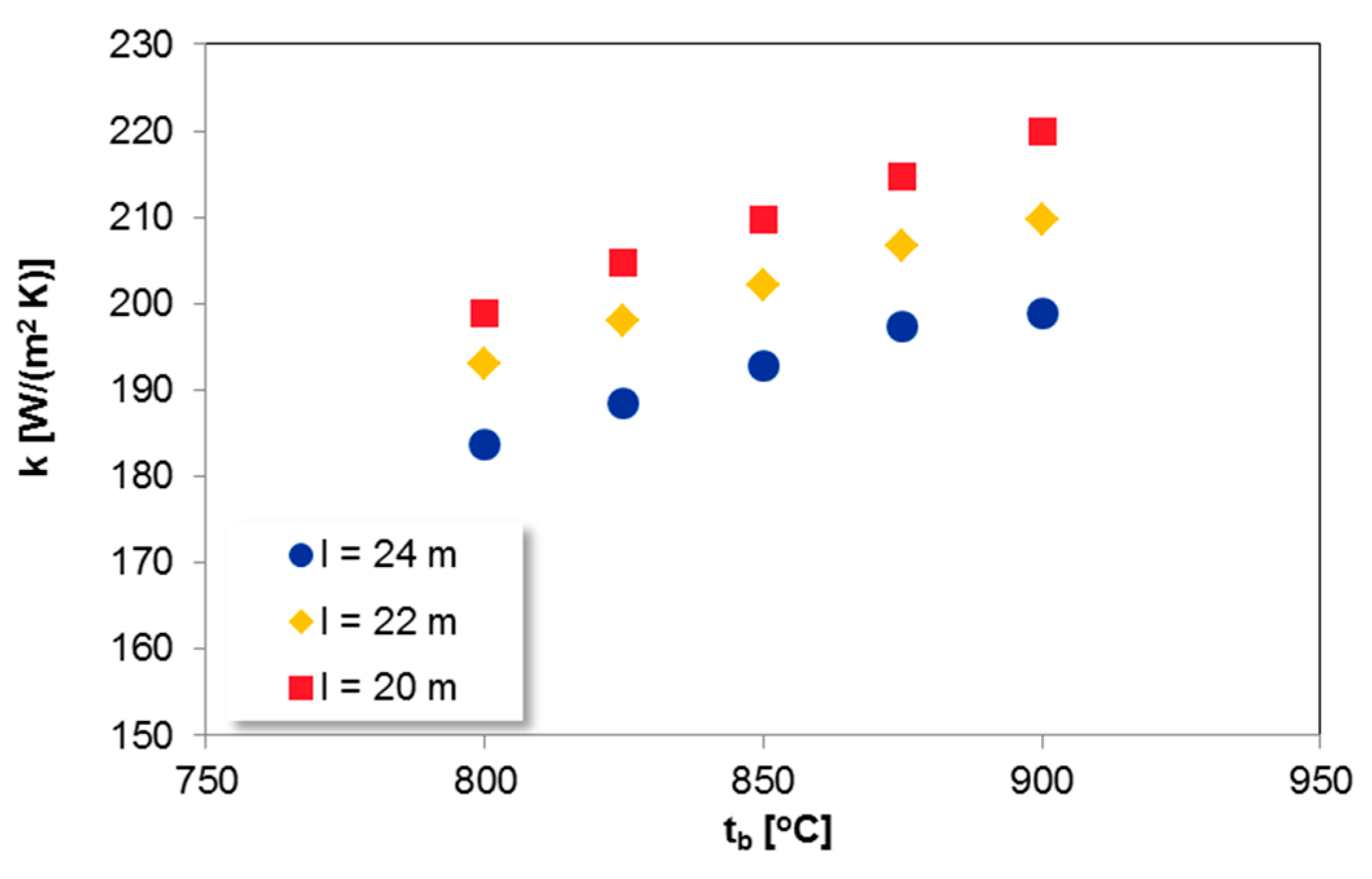

| tb | fluidized-bed temperature, °C |

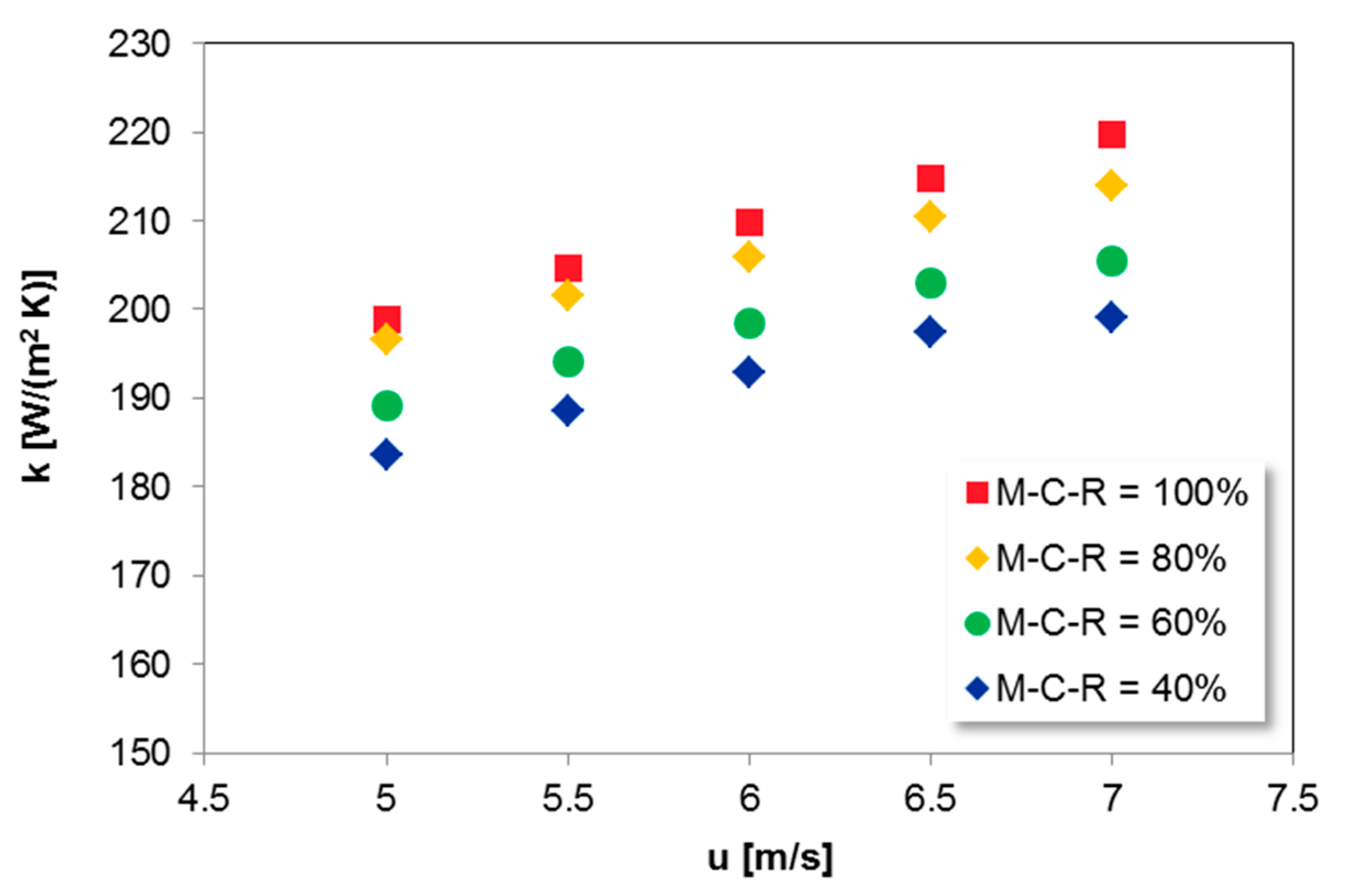

| u | velocity, m/s |

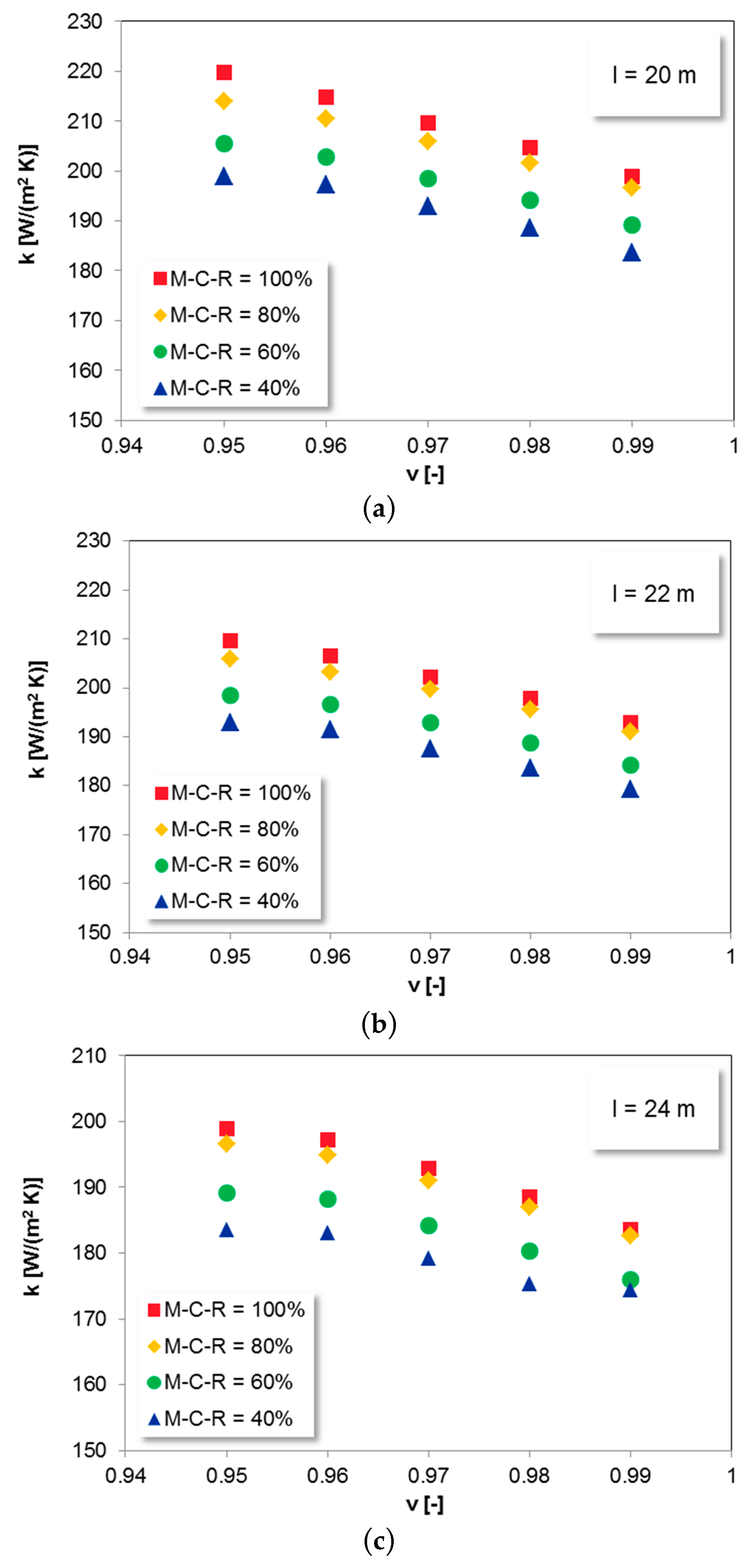

| v | voidage |

| l | the height above the grid, m |

| b | fluidized-bed |

References

- Cengel, Y.A.; Boles, M.A. Thermodynamics: An Engineering Approach, 8th ed.; McGraw-Hill Education: New York, NY, USA, 2015. [Google Scholar]

- Gungor, A. Second law analysis of heat transfer surfaces in circulating fluidized beds. Appl. Energy 2009, 86, 1344–1353. [Google Scholar] [CrossRef]

- Rincón Tabares, J.S.; Perdomo-Hurtado, L.; Aragón, J.L. Study of Gasketed-Plate Heat Exchanger performance based on energy efficiency indexes. Appl. Therm. Eng. 2019, 159, 113902. [Google Scholar] [CrossRef]

- Naphon, P. Second law analysis on the heat transfer of the horizontal concentric tube heat exchanger. Int. Commun. Heat Mass Transf. 2006, 33, 1029–1041. [Google Scholar] [CrossRef]

- Kotowicz, J.; Brzęczek, M. Comprehensive multivariable analysis of the possibility of an increase in the electrical efficiency of a modern combined cycle power plant with and without a CO2 capture and compression installations study. Energy 2019, 175, 1100–1120. [Google Scholar] [CrossRef]

- Kotowicz, J.; Brzęczek, M. Analysis of increasing efficiency of modern combined cycle power plant: A case study. Energy 2018, 153, 90–99. [Google Scholar] [CrossRef]

- Basu, P. Circulating Fluidized Bed Boilers: Design, Operation and Maintenance; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-319-06172-6. [Google Scholar]

- Shah, M.M. General correlation for maximum heat transfer to surfaces submerged in gas-fluidized beds. Chem. Eng. Sci. 2018, 185, 127–140. [Google Scholar] [CrossRef]

- Abdelmotalib, H.M.; Youssef, M.A.M.; Hassan, A.A.; Youn, S.B.; Im, I.-T. Heat transfer process in gas–solid fluidized bed combustors: A review. Int. J. Heat Mass Transf. 2015, 89, 567–575. [Google Scholar] [CrossRef]

- Taler, J.; Taler, D. Measurement of heat flux and heat transfer coefficient. In Heat Flux: Processes, Measurement Techniques and Applications; Cirimele, G., D’Elia, M., Eds.; Nova Science Publishers: New York, NY, USA, 2012; pp. 1–103. [Google Scholar]

- Taler, J.; Taler, D.; Ludowski, P. Measurements of local heat flux to membrane water walls of combustion chambers. Fuel 2014, 115, 70–83. [Google Scholar] [CrossRef]

- Bolea, I.; Romeo, L.M.; Pallarès, D. Heat transfer in the external heat exchanger of oxy-fuel fluidized bed boilers. Appl. Therm. Eng. 2014, 66, 75–83. [Google Scholar] [CrossRef]

- Sun, P.; Hui, S.; Gao, Z.; Zhou, Q.; Tan, H.; Zhao, Q.; Xu, T. Experimental investigation on the combustion and heat transfer characteristics of wide size biomass co-firing in 0.2 MW circulating fluidized bed. Appl. Therm. Eng. 2013, 52, 284–292. [Google Scholar] [CrossRef]

- Dutta, A.; Basu, P. An experimental investigation into the heat transfer on wing walls in a circulating fluidized bed boiler. Int. J. Heat Mass Transf. 2002, 45, 4479–4491. [Google Scholar] [CrossRef]

- Krzywanski, J. Modeling of Energy Systems with Fixed and Moving Porous Media by Artificial Intelligence Methods; University of Warmia and Mazury in Olsztyn: Olsztyn, Poland, 2018; ISBN 978-83-60493-05-2. [Google Scholar]

- Basu, P.; Nag, P.K. Heat transfer to walls of a circulating fluidized-bed furnace. Chem. Eng. Sci. 1996, 51, 1–26. [Google Scholar] [CrossRef]

- Blaszczuk, A.; Nowak, W.; Krzywanski, J. Effect of bed particle size on heat transfer between fluidized bed of group b particles and vertical rifled tubes. Powder Technol. 2017, 316, 111–122. [Google Scholar] [CrossRef]

- Zarzycki, R.; Jędras, J. Numerical analysis of heat exchange process in the biomass carbonisation reactor. MATEC Web Conf. 2019, 252, 05019. [Google Scholar] [CrossRef]

- Zarzycki, R.; Kacprzak, A.; Bis, Z. The Use of Direct Carbon Fuel Cells in Compact Energy Systems for the Generation of Electricity, Heat and Cold. Energies 2018, 11, 3061. [Google Scholar] [CrossRef]

- Chang, J.; Wang, G.; Gao, J.; Zhang, K.; Chen, H.; Yang, Y. CFD modeling of particle–particle heat transfer in dense gas-solid fluidized beds of binary mixture. Powder Technol. 2012, 217, 50–60. [Google Scholar] [CrossRef]

- Madejski, P.; Taler, D. Analysis of temperature and stress distribution of superheater tubes after attemperation or sootblower activation. Energy Convers. Manag. 2013, 71, 131–137. [Google Scholar] [CrossRef]

- Molerus, O.; Wirth, K.E. Heat Transfer in Fluidized Beds; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; ISBN 978-94-011-5842-8. [Google Scholar]

- Yusuf, R.; Halvorsen, B.; Melaaen, M.C. An experimental and computational study of wall to bed heat transfer in a bubbling gas–solid fluidized bed. Int. J. Multiph. Flow 2012, 42, 9–23. [Google Scholar] [CrossRef]

- Molerus, O. Heat transfer in gas fluidized beds part 1. Powder Technol. 1992, 70, 1–14. [Google Scholar] [CrossRef]

- Molerus, O. Heat transfer in gas fluidized beds part 2. Dependence of heat transfer on gas velocity. Powder Technol. 1992, 70, 15–20. [Google Scholar] [CrossRef]

- Molerus, O. Arguments on heat transfer in gas fluidized beds. Chem. Eng. Sci. 1993, 48, 761–770. [Google Scholar] [CrossRef]

- Yang, W.-C. Handbook of Fluidization and Fluid-Particle Systems; CRC Press: Boca Raton, FL, USA, 2003; ISBN 978-0-8247-4836-4. [Google Scholar]

- Breitholtz, C.; Leckner, B.; Baskakov, A.P. Wall average heat transfer in CFB boilers. Powder Technol. 2001, 120, 41–48. [Google Scholar] [CrossRef]

- Ostermeier, P.; Dawo, F.; Vandersickel, A.; Gleis, S.; Spliethoff, H. Numerical calculation of wall-to-bed heat transfer coefficients in Geldart B bubbling fluidized beds with immersed horizontal tubes. Powder Technol. 2018, 333, 193–208. [Google Scholar] [CrossRef]

- Abdelmotalib, H.M.; Ko, D.G.; Im, I.-T. A study on wall-to-bed heat transfer in a conical fluidized bed combustor. Appl. Therm. Eng. 2016, 99, 928–937. [Google Scholar] [CrossRef]

- Sosnowski, M.; Krzywanski, J.; Grabowska, K.; Gnatowska, R. Polyhedral meshing in numerical analysis of conjugate heat transfer. In Proceedings of the EPJ Web of Conferences; Experimental Fluid Mechanics: Makarov, Czech Republic, 2018; Volume 180. [Google Scholar]

- Madejski, P.; Taler, D.; Taler, J. Numerical model of a steam superheater with a complex shape of the tube cross section using Control Volume based Finite Element Method. Energy Convers. Manag. 2016, 118, 179–192. [Google Scholar] [CrossRef]

- Krzywanski, J.; Żyłka, A.; Czakiert, T.; Kulicki, K.; Jankowska, S.; Nowak, W. A 1.5D model of a complex geometry laboratory scale fuidized bed clc equipment. Powder Technol. 2017, 316, 592–598. [Google Scholar] [CrossRef]

- Zylka, A.; Krzywanski, J.; Czakiert, T.; Idziak, K.; Sosnowski, M.; Grabowska, K.; Prauzner, T.; Nowak, W. The 4th Generation of CeSFaMB in numerical simulations for CuO-based oxygen carrier in CLC system. Fuel 2019, 255, 115776. [Google Scholar] [CrossRef]

- Guzmán, G.; De Los Reyes, L.; Noriega, E.; Ramírez, H.; Bula, A.; Fontalvo, A. Thermal Optimization of a Dual Pressure Goswami Cycle for Low Grade Thermal Sources. Entropy 2019, 21, 711. [Google Scholar] [CrossRef]

- Huang, S.; Li, C.; Tan, T.; Fu, P.; Wang, L.; Yang, Y. Comparative Evaluation of Integrated Waste Heat Utilization Systems for Coal-Fired Power Plants Based on In-Depth Boiler-Turbine Integration and Organic Rankine Cycle. Entropy 2018, 20, 89. [Google Scholar] [CrossRef]

- Huang, S.; Li, C.; Tan, T.; Fu, P.; Xu, G.; Yang, Y. An Improved System for Utilizing Low-Temperature Waste Heat of Flue Gas from Coal-Fired Power Plants. Entropy 2017, 19, 423. [Google Scholar] [CrossRef]

- Rangel-Hernandez, V.H.; Damian-Ascencio, C.; Belman-Flores, J.M.; Zaleta-Aguilar, A. Assessing the Exergy Costs of a 332-MW Pulverized Coal-Fired Boiler. Entropy 2016, 18, 300. [Google Scholar] [CrossRef]

- Zhou, W.; Zhao, C.; Duan, L.; Chen, X.; Liu, D. A simulation study of coal combustion under O2/CO2 and O2/RFG atmospheres in circulating fluidized bed. Chem. Eng. J. 2013, 223, 816–823. [Google Scholar] [CrossRef]

- Govindaswamy, R.; Srinivasan, S. Application of Artificial Neural Network for Single Horizontal Bare Tube and Bare Tube Bundles in Gas-Solid (Air-Solid) Fluidized Bed of Small and Large Particles: Heat Transfer Predictions. In Proceedings of the ASME 2013 International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2013; V08AT09A052. [Google Scholar]

- Kamble, L.V.; Pangavhane, D.R.; Singh, T.P. Artificial Neural Network Based Prediction of Heat Transfer from Horizontal Tube Bundles Immersed in Gas–Solid Fluidized Bed of Large Particles. J. Heat Transf. 2015, 137, 012901. [Google Scholar] [CrossRef]

- Krzywanski, J.; Fan, H.; Feng, Y.; Shaikh, A.R.; Fang, M.; Wang, Q. Genetic algorithms and neural networks in optimization of sorbent enhanced H2 production in FB and CFB gasifiers. Energy Convers. Manag. 2018, 171, 1651–1661. [Google Scholar] [CrossRef]

- Krzywanski, J.; Nowak, W. Modeling of heat transfer coefficient in the furnace of CFB boilers by artificial neural network approach. Int. J. Heat Mass Transf. 2012, 55, 4246–4253. [Google Scholar] [CrossRef]

- Karami, A.; Rezaei, E.; Shahhosseni, M.; Aghakhani, M. Fuzzy logic to predict the heat transfer in an air cooler equipped with different tube inserts. Int. J. Therm. Sci. 2012, 53, 141–147. [Google Scholar] [CrossRef]

- Khairul, M.A.; Hossain, A.; Saidur, R.; Alim, M.A. Prediction of heat transfer performance of CuO/water nanofluids flow in spirally corrugated helically coiled heat exchanger using fuzzy logic technique. Comput. Fluids 2014, 100, 123–129. [Google Scholar] [CrossRef]

- Li, L.; Sun, Y. Adaptive Fuzzy Control for Nonlinear Fractional-Order Uncertain Systems with Unknown Uncertainties and External Disturbance. Entropy 2015, 17, 5580–5592. [Google Scholar] [CrossRef] [Green Version]

- Ross, T.J. Fuzzy Logic with Engineering Applications, 3rd ed.; John Wiley: Chichester, UK, 2010; ISBN 978-0-470-74376-8. [Google Scholar]

- Fullér, R. Neural fuzzy systems. In Proceedings of the in Advances in Soft Computing Series; Springer: Berlin/Heidelberg, Germany, 1995; pp. 3–7908. [Google Scholar]

- Sekret, R. Thermal and Flow Conditions and Pollutant Emissions in Large-Scale Circulating Fluidized Bed Boilers; Silesian University of Technology: Gliwice, Silesia, Poland, 2005. [Google Scholar]

- Błaszczuk, A.; Krzywański, J. A comparison of fuzzy logic and cluster renewal approaches for heat transfer modeling in a 1296 t/h CFB boiler with low level of flue gas recirculation. Arch. Thermodyn. 2017, 38, 91–122. [Google Scholar] [CrossRef] [Green Version]

- Muskała, W.; Krzywański, J.; Rajczyk, R.; Cecerko, M.; Kierzkowski, B.; Nowak, W.; Gajewski, W. Investigation of erosion in CFB boilers. Rynek Energii 2010, 2, 97–102. [Google Scholar]

- Krzywanski, J.; Grabowska, K.; Sosnowski, M.; Zylka, A.; Sztekler, K.; Kalawa, W.; Wójcik, T.; Nowak, W. An adaptive neuro-fuzzy model of a re-heat two-stage adsorption chiller. Therm. Sci. 2019, in press. [Google Scholar] [CrossRef]

- Takagi, T.; Sugeno, M. Fuzzy Identification of Systems and Its Applications to Modeling and Control. In Readings in Fuzzy Sets for Intelligent Systems; Dubois, D., Prade, H., Yager, R.R., Eds.; Morgan Kaufmann: Burlington, MA, USA, 1993; pp. 387–403. ISBN 978-1-4832-1450-4. [Google Scholar]

- Krzywanski, J.; Wesolowska, M.; Blaszczuk, A.; Majchrzak, A.; Komorowski, M.; Nowak, W. The Non-Iterative Estimation of Bed-to-Wall Heat Transfer Coefficient in a CFBC by Fuzzy Logic Methods. Procedia Eng. 2016, 157, 66–71. [Google Scholar] [CrossRef] [Green Version]

- Krzywanski, J.; Wesolowska, M.; Blaszczuk, A.; Majchrzak, A.; Komorowski, M.; Nowak, W. Fuzzy logic and bed-to-wall heat transfer in a large-scale CFBC. Int. J. Numer. Methods Heat Fluid Flow 2018, 28, 254–266. [Google Scholar] [CrossRef]

- Brems, A.; Cáceres, G.; Dewil, R.; Baeyens, J.; Pitié, F. Heat transfer to the riser-wall of a circulating fluidised bed (CFB). Energy 2013, 50, 493–500. [Google Scholar] [CrossRef]

- Di Natale, F.; Bareschino, P.; Nigro, R. Heat transfer and void fraction profiles around a horizontal cylinder immersed in a bubbling fluidised bed. Int. J. Heat Mass Transf. 2010, 53, 3525–3532. [Google Scholar] [CrossRef]

- Blaszczuk, A.; Pogorzelec, M.; Shimizu, T. Heat transfer characteristics in a large-scale bubbling fluidized bed with immersed horizontal tube bundles. Energy 2018, 162, 10–19. [Google Scholar] [CrossRef]

- Rabi, J.A.; de Souza Santos, M.L. Incorporation of a two-flux model for radiative heat transfer in a comprehensive fluidized bed simulator part I: Preliminary theoretical investigations. Revista Eng. Térmica 2003, 2, 64–70. [Google Scholar] [CrossRef]

- de Souza-Santos, M.L. Solid Fuels Combustion and Gasification: Modeling, Simulation, and Equipment Operations, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2010; ISBN 978-0-429-14520-9. [Google Scholar]

- Ebert, T.A.; Glicksman, L.R.; Lints, M. Determination of particle and gas convective heat transfer components in a circulating fluidized bed. Chem. Eng. Sci. 1993, 48, 2179–2188. [Google Scholar] [CrossRef]

- Shah, S.; Myöhänen, K.; Kallio, S.; Ritvanen, J.; Hyppänen, T. CFD modeling of gas–solids flow in a large scale circulating fluidized bed furnace. Powder Technol. 2015, 274, 239–249. [Google Scholar] [CrossRef]

- Win, K.K.; Nowak, W.; Matsuda, H.; Hasatani, M.; Bis, Z.; Krzywanski, J.; Gajewski, W. Transport Velocity of Coarse Particles in Multi-Solid Fluidized Bed. J. Chem. Eng. Jpn. 1995, 28, 535–540. [Google Scholar] [CrossRef]

- Muskała, W.; Krzywański, J.; Sekret, R.; Nowak, W. Model research of coal combustion in circulating fluidized bed boilers. Chem. Process Eng. 2008, 29, 473–492. [Google Scholar]

- Błasiak, P.; Pietrowicz, S. A numerical study on heat transfer enhancement via mechanical aids. Int. J. Heat Mass Transf. 2019, 140, 203–215. [Google Scholar] [CrossRef]

- Błasiak, P.; Pietrowicz, S. An experimental study on the heat transfer performance in a batch scraped surface heat exchanger under a turbulent flow regime. Int. J. Heat Mass Transf. 2017, 107, 379–390. [Google Scholar] [CrossRef]

- Mirek, P.; Klajny, M. Air nozzle design criteria for protection against the backflow of solids in CFB boilers. Appl. Therm. Eng. 2018, 141, 503–515. [Google Scholar] [CrossRef]

- Mirek, P. Designing of primary air nozzles for large-scale CFB boilers in a combined numerical–Experimental approach. Chem. Eng. Process. Process Intensif. 2011, 50, 694–701. [Google Scholar] [CrossRef]

| Parameter | Values |

|---|---|

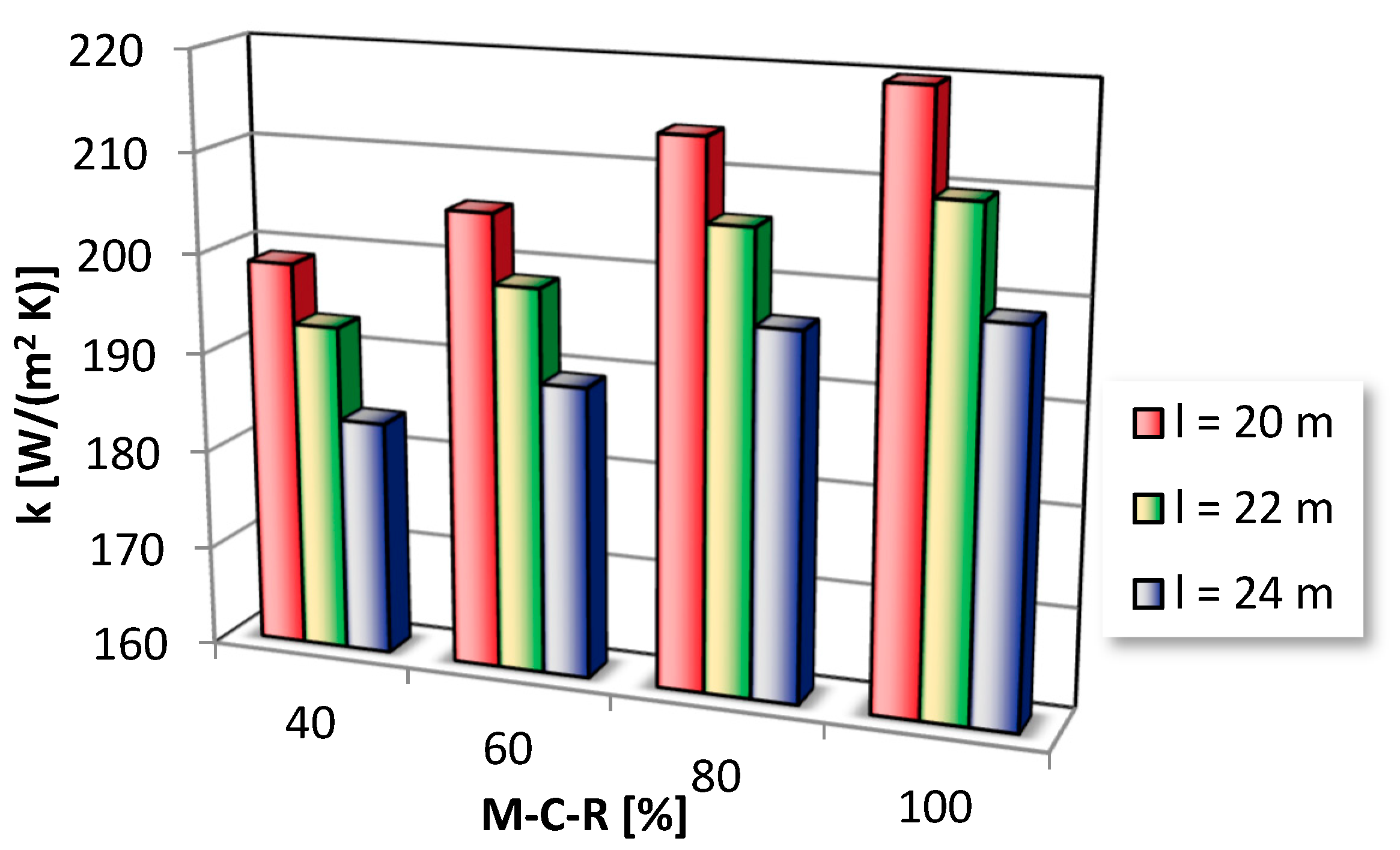

| l, m | 20–24 |

| tb, °C | 800–900 |

| v | 0.95–0.99 |

| u, m/s | 5–7 |

| M-C-R, % | 40–100 |

| k, W/(m2⋅K) | 138–220 |

| Heat Transfer Coefficient, W/(m2K) | Vhi | Hi | Av | Lo | Vlo |

|---|---|---|---|---|---|

| l, m | Vlo | Lo | Av | Hi | Vhi |

| tb, °C | Vhi | Ho | Av | Lo | Vlo |

| v | VLo | Lo | Av | Hi | Vhi |

| u, m/s | Vhi | Hi | Av | Lo | Vlo |

| M-C-R, % | Vhi | Hi | Av | Lo | Vlo |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krzywanski, J. Heat Transfer Performance in a Superheater of an Industrial CFBC Using Fuzzy Logic-Based Methods. Entropy 2019, 21, 919. https://doi.org/10.3390/e21100919

Krzywanski J. Heat Transfer Performance in a Superheater of an Industrial CFBC Using Fuzzy Logic-Based Methods. Entropy. 2019; 21(10):919. https://doi.org/10.3390/e21100919

Chicago/Turabian StyleKrzywanski, Jaroslaw. 2019. "Heat Transfer Performance in a Superheater of an Industrial CFBC Using Fuzzy Logic-Based Methods" Entropy 21, no. 10: 919. https://doi.org/10.3390/e21100919

APA StyleKrzywanski, J. (2019). Heat Transfer Performance in a Superheater of an Industrial CFBC Using Fuzzy Logic-Based Methods. Entropy, 21(10), 919. https://doi.org/10.3390/e21100919