1. Introduction

A great deal of research has been published regarding different methodologies, raw materials, and catalysts for obtaining biodiesel from vegetable oils. In fact, four procedures have been described to convert vegetable oils in an energy source, which are the direct use of the vegetable oil; the generation of biodiesel through a micro-emulsion process; by thermal cracking (pyrolysis) or catalytic cracking; and transesterification [

1]. Nowadays, transesterification is recognized as the most viable and globally applied technology among the different biodiesel processing methodologies [

2]. Homogeneous catalysts are conventionally used due to their high activity; however, this process requires feedstocks free of fatty acids and water to avoid the formation of soaps. Besides wastewater generation and the consumption of the catalyst upon reaction, the separation of glycerol and the free fatty esters and the purification steps increase costs. Nevertheless, heterogeneous acid catalysis promotes both the transesterification and esterification reactions simultaneously, using low-quality and non-edible feedstocks with free fatty acids and moisture [

3].

In fact, heterogeneous catalysts are known to improve the transesterification process by eliminating the extra processing costs involved in homogeneous catalysis, as well as reducing the generation of pollutants. Moreover, the solid catalysts might be easy to recover and are reusable, leading to a cost-effective green process. Solid acid catalysts are an alternative to heterogeneous base catalysts and non-recyclable homogeneous alkaline and acid catalysts. These catalysts present several advantages, such as being insensitive to free fatty acids, being able to avoid the biodiesel washing step, and the ability to catalyze simultaneous esterification and transesterification reactions, as previously mentioned.

In recent years, the use of polyoxometalate compounds and heteropoly acids (HPAs) as catalysts has been promising [

3,

4]. The basic structure of HPAs consist of a central tetrahedron surrounded by octahedral metal–oxygen. For instance, the Keggin and-Wells-Dawson -type heteropoly anions are represented as XM

12O

40n− and X

2M

18O

62n−, where X represents the central atom, such as Si

+4 or P

+5, and M is a metal ion (generally, W

+6 or Mo

+6) [

5,

6]. HPAs exhibit strong Brønsted acidity and also Lewis acid sites, which makes them suitable to catalyze both esterification and transesterification types of reactions. Most of the studies about the production of biodiesel from HPAs have been carried out mainly investigating the Keggin-structured HPA in its different forms. For instance, Keggin heteropolyacids, such as H

3PW

12O

40, H

4SiW

12O

40, H

3PMo

12O

40, and H

4SiMo

12O

40, are catalytically active in the synthesis of biodiesel. Alsalme et al. reported that H

3PW

12O

40 lead to high conversions in the reaction of esterification of hexanoic acid and the transesterification of ethyl propionate and ethyl hexanoate with methanol at 60 °C with a 1:20 substrate/methanol molar ratio. The reactions were carried out with 1 wt% of H

3PW

12O

40 and H

4SiW

12O

40 as catalysts, and conversions between 77 and 86% were obtained after 6 h in the transesterification reactions [

7].

Sepúlveda et al. carried out the esterification of oleic acid with methanol and an oleic acid/HPA ratio of 94 g/g (0.03 g HPA), obtaining a 40% conversion in 10 h at 25 °C. Additionally, when 0.1 g is used, nearly 80% conversion is obtained [

8].

The low specific surface areas and solubility in polar media are disadvantages of Keggin-type HPA. Therefore, different supports (silica, activated carbons, zeolites, mesoporous materials, polymers, and metal oxides) have been used to immobilize the heteropoly acids [

3]. In this context, the esterification of palmitic acid with methanol was studied, using heteropoly acids immobilized on SBA-15 as catalysts. After 6 h of reaction at 60 °C, the palmitic acid conversions were 92%, 57%, and 45%, with H

3PW

12O

40/SBA-15, H

4SiW

12O

40/SBA-15, and H

3PMo

12O

40/SBA-15, respectively [

9]. Later on, the esterification of oleic acid and the transesterification of soybean oil with methanol using a catalyst containing 30 wt% of H

4SiW

12O

40 supported over zeolite Hβ were reported. The optimum conditions were found at a molar ratio oleic acid (alcohol 1:20 and 100 mg of catalyst per 0.01 mol of oleic acid at 60 °C during 10 h) and a molar ratio oil (alcohol 1:4 and 200 mg of catalyst per 5 g of oil at 65 °C and 8 h). The catalyst exhibits high activity for the esterification and transesterification, providing conversions of 86% and 95%, respectively [

10].

Later, the esterification of oleic acid and the transesterification of soybean oil with methanol using a catalyst containing 30 wt% of H

4SiW

12O

40 supported over zeolite Hβ and catalyzed with H

3PW

12O

40/Ta

2O

5 was reported. The optimum conditions found were a molar ratio oleic acid (alcohol 1:20 and 100 mg of catalyst per 0.01 mol of oleic acid at 60 °C during 10 h) and a molar ratio oil (alcohol 1:4 and 200 mg of catalyst per 5 g of oil at 65 °C and 8 h). The catalyst exhibits high activity for the esterification and transesterification, supplying maximum conversions of 86% and 95%, respectively. This reaction was carried out with 2 wt% of catalyst, a ratio of alcohol/oil equal to 90, 65 °C, and 24 h time reaction [

10].

The phosphotungstic Wells-Dawson heteropolyacid H

6P

2W

18O

62·xH

2O is another heteropoly compound with multiple applications as a recyclable catalyst in acid and redox heterogeneous processes [

5,

11]. Nevertheless, to our knowledge, there are only two publications regarding the use of such materials in the heterogeneous synthesis of biodiesel. In this context, Matkovic et al. reported the catalytic performance of bulk and transition metal oxide-supported phosphotungstic Wells-Dawson heteropolyacid 18% HPA/TiO

2, the insoluble cesium salt of the Wells-Dawson heteropoly anion Cs

2H

4P

2W

18O

62 in the esterification of oleic acid with methanol towards methyl oleate. Additionally, the commercial biocatalyst Novozym

®435 (immobilized lipase B of

Candida antarctica) and a self-supported lipase of vegetable origin obtained from the latex

Araujia sericifera (ASL) were studied. The authors demonstrated that the HPA dispersed over titanium dioxide catalyzed the esterification of the fatty acid in a heterogeneous fashion, with the highest activity (6.4 μmol mg

−1 h

−1 at 85 °C) among the inorganic materials [

12]. The second report regarding the investigation of a Wells-Dawson type of material was published recently by Narenji-Sani et al. [

13]. A novel material based on the phosphotungstic Wells-Dawson heteropolyacid embedded in a framework of a zeolite functionalized with imidazole, named [H

6-nP

2W

18O

62n−/ZIF(H

nHis.)

+n], with a 40.5 wt% of HPA loading, was studied. This nanomaterial proved active in the esterification of oleic, lauric, myristic, stearic, and palmitic acids with methanol at conversions ranging from 78% to 98% in four hours of reaction at 25 °C.

The thorough revision of the literature demonstrates that the phosphotungstic Wells-Dawson heteropolyacid has been scarcely explored as a catalytic material in the esterification of fatty acids. Besides, the catalytic performance of that HPA in the transesterification of vegetable oils (a more complex substrate than FFAs) has not been investigated to date. In view of those observations, the present contribution is devoted to assess the catalytic activity of bulk and supported phosphotungstic Wells-Dawson heteropolyacid and heteropoly salts in the heterogeneous transesterification of waste cooking oil (WCO).

2. Results and Discussion

2.1. Screening of Heteropolyacid-Based Materials as Catalysts in the Esterification of Fatty Acids

Revision of the literature demonstrates that there is a lack of information regarding the catalytic activity of complex phosphotungstic compounds, such as the Wells-Dawson type of heteropolyacids in the transesterification of triglycerides towards fatty acid methyl esters. In this context, the activity of a series of phosphotungstic Wells-Dawson-based materials (both bulk and dispersed on an oxide support) were screened in the esterification of oleic acid with methanol as a first approach to establish which were more suitable in the transesterification of waste cooking oil. These chosen materials will allow comparison between bulk and supported HPA and to obtain insights in the influence of the structure of the dispersed heteropolyacid (monolayer vs. crystals) and the amount of Brønsted and Lewis acid sites, as will be discussed later on in this section.

As a first step, the specific activity of the Wells-Dawson phosphotungstic heteropoly acid H

6P

2W

18O

62·28.5H

2O bulk and supported on titanium oxide (4% and 42% HPA/TiO

2), along with derived polyoxometal salts, were investigated in the esterification of oleic acid with methanol. Particularly, Mn

3.4P

2W

18O

62·31H

2O and Ni

4.6P

2W

18O

62·2.7H

2O (named WDMn and WDNi, respectively) transition metal Wells-Dawson heteropoly salts were investigated.

Table 1 presents the specific surface area, surface HPA density, and the elemental analysis of those materials. It is worth mentioning that a thoroughly spectroscopic characterization of those materials was published previously by some of the authors; therefore, it is not presented in this investigation [

14,

15].

The esterification of oleic acid is usually a reaction test that provides a fairly good estimation of the potentiality to catalyze more complex substrates such as a vegetable oil.

Table 2 shows the screened materials and the ratio between the concentration of Brønsted and Lewis acid sites (when available from previous investigations published by some of the authors) along with the oil: methanol molar ratio, extension of the reaction (hours), and specific activity at 85 °C. The specific activity is the result of subtracting the conversion of the catalyzed esterification of oleic acid and the conversion without catalyst obtained in the blank experiments. In this context, those cases of null specific activity (see

Table 2) mean that the conversion detected in the catalyzed reaction did not exceed the one determined in the non-catalyzed homogenous esterification.

This first set of assays was performed at 85 °C, since preliminary investigations reported by some of the authors evidenced that the phosphotungstic Wells-Dawson heteropolyacid was active in the esterification of oleic acid at that temperature under a 1:1 oleic acid: methanol molar ratio [

16]. In fact, the results presented in

Table 2 somehow evidence a correlation between the Brønsted/Lewis acid sites ratio and catalytic activity. In fact, the oxide-supported HPA, possessing a higher concentration of Brønsted acid sites and resulting in more activity than the heteropoly salts.

The latter have Lewis acid sites due to the presence of manganese and nickel that deplete the amount of -OH species [

15]. Now, regarding bulk and supported HPA, it is interesting to compare the specific activity of 8.6 mg of bulk and 10 mg of supported HPA (from the 42% HPA/TiO

2). It is clear that the supported HPA presents a similar activity (142.80 for supported vs. 180.89 µmol. mg

−1 h

−1 for bulk HPA) for a lower oleic acid: methanol molar ratio (1:3 vs. 1:7) and a shorter reaction time (1 h vs. 3 h) than the bulk HPA. In addition, the bulk materials (both HPA and salts) dissolve in the alcohol, which is in contrast with the supported materials, catalyzing a homogeneous type of reaction and avoiding the possibility of recovery and reuse. Finally, it is worth noticing that the mass of supported catalysts plays a role on the catalytic activity. In this context, the comparison of the specific activity of 9.3–10.6 mg vs. 14–20 mg of active supported HPA at a 1:7 oleic acid: methanol molar ratio and 1–3 h of reaction time demonstrates that the higher the amount of supported HPA, the lower the activity.

The observation that the 4% HPA/TiO

2 was inactive, compared with the 42% HPA/TiO

2, is attributed to the nature of the structure of the HPA. Previous investigations by some of the authors demonstrated that the phosphotungstic heteropolyacid supported on TiO

2 at low loading (from 0.7 to 1.0 mg m

−2) is dispersed as a monolayer of isolated HPA units [

14]. However, at loadings exceeding 2.5 mg m

−2, the HPA forms crystals on titania with a similar structure as the bulk type of material.

Figure 1 shows the infrared spectra of the 42% HPA/TiO

2 along with the spectra of bulk HPA and TiO

2 oxide support for comparison. The signal at 1080 cm

−1 is assigned to the vibration of the P-O bond within the phosphotungstic cage of the anion P

2W

18O

626− structure and is the fingerprint of the phosphotungstic Wells-Dawson heteropolyacid. The signals at 1618 cm

−1 and 1666 cm

−1 correspond to physisorbed water molecules and crystallized water molecules, respectively [

14]. Finally, the broad band at 3244 cm

−1 is attributed to O–H vibrations.

The infrared spectra of transition metal oxide-supported HPA possesses the characteristic features of bulk phosphotungstic Wells-Dawson HPA. The observation that the heteropolyacid is dispersed as crystals onto the oxide support is further corroborated with the analysis through scanning electron microscopy shown in

Figure 2.

The images of 42% HPA/TiO2 show needle-type crystals of the phosphotungstic heteropolyacid dispersed on the surface of bigger, rounded-type structures of titania oxide. In addition, the mapping of titanium and tungsten through electron dispersive microprobe evidenced a uniform dispersion of the heteropolyacid onto the oxide support.

In this context, it is important to stress that the crystalline HPA presents the so-called pseudo-liquid or bulk-type I catalysis that accounts for the diffusion of the reactants in the tridimensional lattice of the heteropolyacid (rather than in the pores of the materials) [

17]. In fact, the 42% HPA/TiO

2 material possesses a specific surface area of 26.80 m

2 g

−1, with pores of 19.0 nm in width and a scarce pore volume of 0.099 cm

3 g

−1. Besides, the tridimensional structure of this type of material is a network of heteropolyanions interacting with water molecules through hydrogen bridges that, in turn, generate tunnels in between the anions. The thermogravimetric analysis of the heteropolyacid shown in

Figure 3 evidences the presence of water molecules in the HPA structure. The desorption of loosely bonded water occurs from R.T. to about 143 °C and involves, typically, 26.5 water molecules per one heteropoly anion. A second desorption (from 143 °C to 335 °C) involves 2 molecules of water per heteropoly anion unit [

12,

15]. The overall process accounts for 28.5 water molecules per heteropolyanion, providing a molecular formula equal to H

6P

2W

18O

62·28.5 H

2O.

The network of tunnels of the HPA due to the presence of water molecules allows the reactants to go through the whole structure of the HPA, accessing more active sites than in the case of a surface type of catalysis. This is the mechanism that takes place in a bidimensional arrangement of heteropolyacid molecules, such as in the monolayer coverage of the 4% HPA/TiO2.

2.2. Fine-Tuning of the Operative Conditions towards Application in Complex Substrates: Nonlinear Surface Fitting Analysis

The influence of the amount of catalyst, the oleic acid: methanol molar ratio, time of reaction, stirring speed, temperature, and the stability of the catalytic material (that is, the desorption of the active phase out of the oxide support) in the esterification of oleic acid catalyzed with 42% HPA/TiO2 was deeply investigated through a nonlinear surface fitting analysis.

Figure 4 shows the influence of both the amount of catalyst and the excess of methanol in the specific activity of the esterification of the fatty acid with methanol catalyzed with 42% HPA/TiO

2. In particular, the excess of methanol accounts for the mols of methanol in excess, with respect to the stoichiometric 1:1 oleic acid: methanol molar ratio. Then, the molar ratio 1:1, 1:3, and 1:7 correspond to cero, 2 mols, and 6 mols, respectively, in excess.

The nonlinear surface fitting graph clearly indicates that the best catalytic performances are reached with 16 mg to 24 mg of the catalyst (10 mg of HPA) under a molar ratio of reactants’ oleic acid: methanol above 1:1 and below 1:7, with the optimum ratio being equal to 1:3. In addition, either a high amount of catalyst, along with a stoichiometric molar ratio of reactants, or a great excess of methanol are detrimental to the catalytic activity. The first scenario evidences that an excess of alcohol is required to shift the equilibrium towards the products, while the second observation might be related to the desorption of the active phase towards the liquid media, as will be discussed later on.

Figure 5 shows the dependence of the specific activity of the esterification with the speed of stirring and the temperature at a fixed amount of the catalyst (42% HPA/TiO

2), corresponding to 24 mg and 1:3 oleic acid: methanol molar ratio, that are within the optimum observed in the previous assay. The surface response undoubtedly demonstrates that a high stirring speed (above 600 rpm) is required to overcome diffusional restrictions. Moreover, the optimum temperature is about 60 °C, which is below the boiling point of methanol, avoiding the rapid volatilization of the alcohol from the reaction media.

Finally,

Figure 6 presents the concentration of tungsten (from the desorption of the HPA out of the titania support) detected in the reaction media when the esterification of oleic acid with methanol was performed at various temperatures and times of reaction, with a fixed amount of catalyst (24 mg) and speed of stirring (150 rpm). The desorption of the active HPA phase is greatly influenced by the temperature and increases continuously from 60 °C towards 85 °C, regardless of the extension of the reaction. Nevertheless, the maximum concentration of tungsten leached towards the reaction media was 9.8 ppm, which corresponds only to 2.9% of the mass of supported HPA. Further investigation of the leaching of HPA in a more complex reaction media (i.e., the transesterification of waste cooking oil with methanol) under higher stirring speeds than that assayed above was also performed, as is presented in the next section.

2.3. Supported Phosphotungstic Wells-Dawson Acid as a Potential Catalyst for Transesterification of Waste Cooking Oil WCO

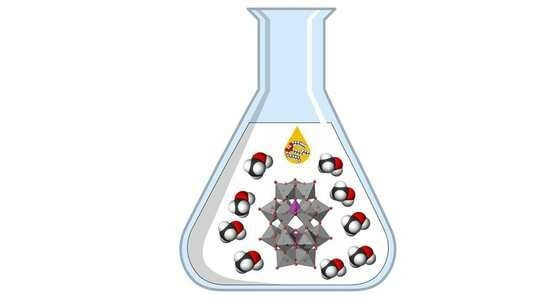

The results obtained through the oleic acid esterification with methanol indicate that 42% HPA/TiO2 is suitable to catalyze the transesterification of more complex substrates such as waste cooking oil (WCO from now on). In particular, the transesterification of used sunflower oil (a typical oil used in household and restaurants) with methanol was investigated. As a first approach, the optimum operative conditions obtained with the reaction test (esterification of oleic acid with methanol) were used to assay the transesterification of WCO with methanol catalyzed with 42% HPA/TiO2. In this context, it is worth noticing that the optimum molar ratio is equal to 1:3 oleic acid: methanol, which considers an excess of 2 mols of alcohol per mol of fatty acid, which was increased to 1:9 in order to maintain a similar excess of alcohol and accounting for the fact that the triglycerides possess three ester bonds, suitable to react with methanol.

Scheme 1 shows the typical transesterification of a triglyceride where the three ester bonds form fatty acid methyl esters (FAME, also known as biodiesel) and glycerol. In addition, molar ratios of WCO: methanol below and above 1:9 were also assayed for comparison.

Table 3 shows the conversion, yield towards fatty acid methyl ester FAME, selectivity towards monoglycerides MG, diglycerides DG, and glycerol, and the acidity index of the transesterification of sunflower waste cooking oil (20.0 g) with methanol catalyzed with 24 mg of 42% HPA/TiO

2 at 60 °C and under stirring at 650 rpm, which corresponds to the optimum conditions determined with the test reaction. Various WCO: methanol molar ratios (1:7, 1:9, and 1:12) and times of reactions (3, 6, and 24 h) were assayed. The best catalytic performance was reached at the operative conditions that were concluded through the application of the nonlinear surface fitting methodology in the esterification of oleic acid with methanol. This observation evidences that the application of the test reaction was a reliable pathway towards the optimization of the operative conditions in this particular case. In fact, there is 27.5% of conversion of the glycerides towards FAME and glycerol at 3 h of reaction with a 1:9 WCO: methanol molar ratio. Additionally, the acidity index indicates the presence of free fatty acids in the reaction media.

The conversion decreases when the amount of alcohol is below (1:7 molar ratio) or above (1:12 molar ratio) 2 mol in excess, with respect to the stoichiometric molar ratio. Again, as discussed in the previous section, a certain excess of alcohol is necessary to shift the equilibrium towards the esters. The low conversion and the appearance of monoglycerides and diglycerides at a 1:7 WCO: methanol molar ratio provide proofs of an incomplete transesterification of the triglycerides.

In addition, a certain solubility of the HPA is also expected under a great excess of alcohol. In conclusion, the molar ratio of the substrates is a key factor in the transesterification of WCO catalyzed with the phosphotungstic HPA.

Further assays were performed, increasing the amount of 42% HPA/TiO

2 in order to investigate the influence of the amount of catalyst in the conversion of WCO. In fact, the amount of catalyst was increased from 24.0 mg (10.0 mg of active HPA) to 49.6 mg, corresponding to 19.7 mg of active HPA (i.e., 100% more HPA than before), that is, 0.25 wt.% of catalyst and a HPA: WCO weight ratio equal to 9.8 × 10

−4 (20.0 g of oil and 49.6 mg of catalyst corresponding to 19.7 mg of active HPA). The 1:9 WCO: methanol molar ratio, the temperature at 60 °C, stirring speed at 650 rpm, and the time of reaction (3 h) was kept without modifications, as assayed before. In addition, reuse of the catalyst was also explored.

Table 4 presents the results of conversion, yield, selectivity, and acidity index obtained in these assays.

The results presented in

Table 4 show a boost in the conversion of triglycerides and yield towards FAME and a decrease in the acidity index upon increasing the amount of catalyst. The observation that the conversion increases with the increase of the amount of HPA looks to be in contradiction with the results obtained in the esterification of oleic acid. Nevertheless, the increase in the amount of heteropolyacid also increases the amount of active acid sites that might be required to catalyze a more complex substrate, such as the triglycerides with three times the amount of methanol compared with a free fatty acid. Typically, the mechanism of the homogeneous acid catalyzed transesterification of triglycerides involves the protonation of the carbonyl group by the acid catalyst, followed by the nucleophilic attack of the alcohol that forms a tetrahedral intermediate. Then, the proton migrates and the intermediate breaks down, generating ester and glycerol, and regenerates the catalyst. This sequence is repeated for each of the three carbonyl groups of the triglyceride, requiring three protons. However, more recently, alternative mechanisms have been proposed when solid catalysts are used. Reinoso et al. demonstrated that the energetically favored mechanism of the transesterification of triglycerides with methanol catalyzed with zinc carboxylate involves the coordination of alcohol with Zn

2+ to form an alkoxide group Zn-OCH

3 in a first step [

18]. Then, the triglyceride adsorbs to the alkoxy species through a polarized carbonyl group. Actually, the formation of alkoxides on phosphotungstic heteropolyacids is a feasible mechanism, since these materials catalyze the dehydration of methanol to form dimethyl ether and isopropanol to form propylene, which requires chemisorbed alkoxide species to proceed [

19].

The successive reuse of the catalyst evidences that the conversion and yield diminish about 11%. This fairly low percentage somehow indicates that the catalyst does not deactivate during reaction. In fact, this observation might be attributed either to the loss of catalyst during the stage of recovery and/or to the dissolution of the active phase in the reaction media.

Figure 7 shows the images of the catalyst after the reuses at a similar magnification as the ones before reaction (see

Figure 2). The comparison of the images demonstrates that several reuses of the HPA/TiO

2 in the transesterification of WCO does not significantly modify the surface texture of the materials. Nevertheless, the elemental analysis through EDS shows a significant amount of carbon (15 wt%), which somehow makes unreliable the quantification of tungsten and titanium as performed on 42% HPA/TiO

2 before reaction.

Table 5 shows the concentration of tungsten (from the phosphotungstic heteropolyacid) found in the reaction media in the transesterification of WCO with methanol at 60 °C, under stirring at 650 rpm and various amounts of catalysts and times of reaction. Additionally, the maximum theoretical concentration of tungsten that would be detected upon dissolution of the whole amount of supported HPA is presented for comparison.

The results evidenced that 19–25% of tungsten (a similar range if expressed in terms of H6P2W18O62·28.5 H2O) is detected in the reaction media, regardless of the time of reaction (3 h, 6 h, or 24 h of reaction) or the molar ratio of reactants. In fact, a similar result was obtained with 2 mol (1:9 WCO: methanol molar ratio) and 5 mol in excess of methanol (1:18 WCO: methanol molar ratio). The remaining loading of HPA supported on TiO2 after the active phase leaching in the reaction media is around 31% (11 mg m−2). Even though the loss of the active phase is somehow related to the decrease in catalytic activity upon the reuses of the catalyst, it still remains an active material whose HPA loading is well above the monolayer coverage.

The catalytic performance of the 42% HPA/TiO

2 was compared with other heteropolyacid based catalysts in the esterification of free fatty acids and the transesterification of oils with methanol that appear in the literature over a period of 10 years. It is worth noticing that the information presented in

Table 6 of the Keggin-type HPA-based catalysts is focused on those materials synthesized through a similar methodology as the one presented in this contribution (incipient wetness impregnation of a transition metal oxide with the HPA). Most of the investigations are devoted to the phosphotungstic Keggin type of heteropolyacids and only two of them refer to the transesterification of WCO. Besides, there is only one investigation, reported by Narenji-Sani et al., regarding bulk and a novel catalyst based on phosphotungstic Wells-Dawson-type heteropolyacid. The performance of the catalytic system investigated in this work is clearly higher than the bulk counterpart and it is fairly similar to the phosphotungstic Wells-Dawson heteropolyacid embedded in a framework of a zeolite H

6P

2W

18O

62/ZIF (His.) [

13]. The conversion and yield towards FAME of 42% HPA/TiO

2 are lower than the supported Keggin-type heteropolyacid. Nevertheless, a higher weight percentage of catalyst and methanol excess was used in the investigation of the Keggin materials, which would explain such differences.

3. Materials and Methods

3.1. Materials

Sodium tungstate dihydrate (Sigma-Aldrich, Burlington, MA, USA, 99%), Ammonium chloride (J.T. Baker, Temixco, Mexico, 99.6%), Hydrochloric acid (Anedra, Troncos del Talar, Argentina, 37%), o-Phosphoric acid (Riedel-de Haën, Charlotte, NC, USA, 85%), and titanium dioxide anatase (Aeroxide® P-18 Evonik Ind., Esse, Germany, 43.93 m2 g−1) were used.

Oleic acid (Anedra, Troncos del Talar, Argentina, 81.2%), Potassium hydroxide (Carlo Erba, Milan, Italy, 85%), methanol (Cicarelli, San Lorenzo, Santa Fe, Argentina, 99.5%), and toluene (Dorwil, Grand Bourg, Argentina, 99.5%) were also employed.

Waste cooking oil (WCO) was prepared from commercial sunflower oil (Cañuelas, produced in Buenos Aires, Argentina). This oil was used for frying household meals at 170 °C five times. The WCO is composed of 0.3% of monoglycerides MG, 1.3% of diglycerides DG, 98% of triglycerides TG, and 0.7% of free fatty acids FFA (acidity index equal to 0.7).

3.2. Synthesis of the Phosphotungstic Heteropoly Acid and Derived Salts

The HPA was synthesized through the ion exchange of the phosphotungstic Wells–Dawson ammonium salt (NH

4)

6P

2W

18O

62·13H

2O with an ion exchange resin. The details have been reported previously in the literature [

22].

The synthesis of (NH

4)

6P

2W

18O

62·13H

2O was carried out according to a modified version of the methodology described by Mbomekalle [

23]. To perform this reaction, 150 g of Na

2WO

4·2H

2O was placed in a flask with 175 mL of distilled water, and 125 mL of a solution of 4 M HCl was added slowly under vigorous stirring. When a translucent solution was obtained, 125 mL of 4 M H

3PO

4 was aggregated and was heated reflux for 24 h. After that, 53.5 g of NH

4Cl was added and the resulting solid was filtered. The solid was dissolved in 300 mL of distilled water and was heated at 80 °C in a glycerin bath; then, it was cooled and filtered.

The heteropoly salts were synthesized by replacing the protons of the HPA by the transition metals using a technique reported previously [

15,

24]. An aqueous solution of the HPA and the metal nitrate (nickel nitrate and manganese nitrate) were mixed and heated under magnetic stirring until dry and the solid obtained was calcined.

The heteropoly acid was supported on TiO2 (Aeroxides P-18 Evonik Ind., 43.93 m2 g−1) by means of incipient wetness impregnation. The impregnation of the HPA over TiO2 was carried out by dissolution of heteropoly acid in distilled water. The samples were dried at 100 °C for 1 h and calcined at 300 °C for 4 h.

3.3. Characterization of the Materials

The presence of the Wells-Dawson structure was confirmed through the infrared analysis. The samples were diluted with KBr and pressed in a conventional wafer for FTIR analysis. Spectra were collected in the 4000 to 400 cm−1 range (+/− 2 cm−1 resolution) with a Bruker Vertex 70 equipment (Billerica, MA, USA). The infrared analysis was recorded with 60 scans in the absorption mode.

X-ray microanalysis EDS was applied to quantify the amount of tungsten, oxygen, phosphorous, and titanium, in order to calculate the amount of H6P2W18O62·xH2O dispersed on the titania support. The analysis was performed to the HPA, supported on TiO2 fixed on an aluminum sample holder using silver-based paint to avoid any contamination with carbon. The analysis was carried out at 0.6 Torr and 20 kV with an equipment EDAX SS Apollo 40 (Mahwah, NJ, USA) coupled to an ESEM microscope FEI Quanta 200. In addition, the surface texture of those materials in powder form was analyzed from 300× to 8000× magnification under low vacuum conditions in the scanning electron microscope named before.

The sample of the used catalyst was pretreated previous to the analysis through scanning electron microscopy. After the reuse assays, the reaction medium was centrifuged to separate the catalyst. The solid was washed with n-heptane and filtered, then dried at 30 °C for 24 h and at 100 °C for 2 h.

The amount of water of hydration of the heteropolyacid and the heteropoly salts was determined through thermal gravimetric analysis. The analysis was carried out with Shimadzu TGA 50 equipment (Tokyo, Japan). Typically, 2.000 to 6.000 mg of each material was placed into an aluminum sample pan and heated from R.T. to 750 °C at 10 °C min−1 under helium flowing at 50 mL min−1.

The specific surface area, along with the average pore volume and size of the materials, were determined through the conventional Brunauer-Emmett and Teller method with Micromeritics ASAP 2020 equipment (Norcross, GA, USA). Additionally, the experimental data was adjusted to the BJH model adsorption isotherm.

The concentration of tungsten in the reaction media was determined through inductive coupled plasma ICP-OES in Shimadzu ICPE-9800 (Tokyo, Japan), according to the EPA 6010 normative. The samples were subjected to an acid digestion in a microwave digester QLAB Pro Question Technologies Corp. (Mississauga, Canada) with nitric acid (Merck, Darmstadt, Germany, pro-analysis) at 400 W, 200 °C, for 15 min, according to US EPA SW-3052 normative.

3.4. Esterification of Oleic Acid and Transesterification of WCO

In order to compare the specific activity of HPA with its salts in the esterification of oleic acid, reactions with H6P2W18O62·28.5H2O (HPA), Mn3.4P2W18O62·31H2O, and Ni4.6P2W18O62·2.7H2O were carried out using methanol as acyl donor. The reactions were performed in a flask under magnetic stirring in a glycerin bath and connected with a refrigerant.

Firstly, the bulk Wells-Dawson heteropoly acid and salts were assayed in the esterification of oleic acid with methanol at 85 °C and 150 rpm. For this, 20.0 g of oleic acid were mixed with 200 mg of catalyst and methanol with an oleic acid: methanol molar ratio equal to 1:1, 1:3 and 1:7 and using different reaction times (1, 3, and 24 h).

Subsequently, the specific activity of the HPA supported on titanium oxide (4% and 42% HPA/TiO2) were studied and compared with the HPA bulk. The reactions were carried out at 85 °C and 150 rpm with 20.0 g of oleic acid and methanol using different amounts of catalyst (8.6 mg for HPA bulk, 200 mg of 4% HPA/TiO2, which corresponds to 8.6 mg of active HPA and 16, 24, 32, and 48.4 mg of 42% HPA/TiO2 that belong to 6.8, 10, 14, and 20.2 mg of active HPA, respectively). The oleic acid: methanol molar ratios used were 1:1, 1:3, and 1:7, and 3 h of reaction time.

In addition, various temperatures (60, 65, 70, and 85 °C) and stirring speeds (150, 350, and 650 rpm) were assayed at 1 and 3 h of reaction.

The transesterification of waste cooking oil was investigated by reacting the used sunflower oil with methanol and 42% HPA/TiO2 as catalyst. The optimal temperature and magnetic stirring used were those found in the oleic acid esterification studies (60 °C and 650 rpm). The transesterifications were carried out with 20.0 g of used oil and 24 and 49.6 mg of catalyst (corresponding to 10.0 mg and 19.7 mg of active HPA, respectively), and the WCO: methanol molar ratios were 1:7, 1:9, 1:12, and 1:18 and 3, 6, and 24 h reaction times.

The reuse of 42% HPA/TiO2 in the reaction of WCO with methanol was studied under the best conditions found (60 °C, 650 rpm, 3 h, WCO: methanol molar ratio 1:9, 49.6 mg of catalyst). In order to recover all the catalyst, the reaction medium was centrifuged and the solid phase (corresponding to HPA/TiO2) was reused. This procedure was performed at least twice.

3.5. Acidity Index and Quantification of Mono-, Di-, and Triglycerides, Glycerol

The acidity index was determined according to the European normative EN 14104 as follows. The reaction mixture of the transesterification of the WCO was centrifuged to separate the aqueous and oil phases. This procedure was not necessary in the particular case of the determination of the acidity index of the esterification of oleic acid.

The oil phase (1.00 g) was diluted in 10.00 mL of a neutralized mixture of ethanol and toluene (1:1). Then, it was titrated with a solution of KOH 0.100 M in ethanol and phenolphthalein as indicator.

The acidity index

AI was calculated with the following equation:

where,

MKOH is the molecular weight of potassium hydroxide KOH;

VKOH is the volume (in mL) of the solution of potassium hydroxide;

CKOH is the molar concentration (in mol L

−1) of KOH, and

Wsample is the weight of the oil phase in grams.

The determination of mono-, di-, and triglycerides was performed through gas chromatography, according to the ASTM D6584 normative. Equipment consisting of GC-2010 Plus Tracera (Shimadzu Corporation, Tokyo, Japan) with a BID detector, a capillary column MEGA-Biodiesel 105 (15 m × 0.32 mm × 0.10 μm), and helium as carrier gas, was used. The samples (100 mg) were pretreated, adding 100 µL of tricaprin as stock solution and 100 µL of N-methyl-N-(trimethylsilyl)trifluoroacetamide (MSTFA). This mixture was stirred and further diluted with n-heptane (8 mL).

The analysis was performed under a temperature program that starts at 50 °C, then goes to 180 °C at a rate of 15 °C min

−1, raises to 230 °C at 7 °C min

−1, and, finally, to 350 °C, at 30 °C min

−1. The injector and detector temperatures were kept at 350 °C and the volume of the injected sample was 1 μL [

25].

The subtraction of the initial amounts of triglycerides in the WCO and the amount after reaction allowed calculating the triglycerides converted towards methyl esters and glycerol. In fact, the amount of FAME equals three times that of glycerol. It is worth noticing that the amount of mono- and diglycerides produced in the transesterification with methanol catalyzed with the materials studied in this investigation is negligible.

The amount of free fatty acids (in mols) of the starting WCO and after the reaction was calculated through the acidity index. Then, the subtraction of these data allowed calculating the yield towards FFA.

In turn, the conversion of oleic acid was expressed in terms of specific activity as the micromols of converted oil per mass of catalyst (that is, supported HPA or amount of salt in mg) per hours of reaction.

3.6. Analysis of the Results with the Response Surface Methodology RSM

A nonlinear analysis approach was applied to analyze the experimental data obtained to study the relationship between excess of methanol, catalyst amount, and specific activity.

The model proposed is presented in

Figure 4 and Equation (2):

where,

X represents the excess of methanol measured in mol,

Y is the catalyst amount in mg, and

Z is the specific activity in micromol mg

−1 h

−1. The coefficients obtained after fitting were

with coefficients

and

.

The experimental data obtained for the temperature, stirring speed, and specific activity (shown in the

Figure 5) were fitted using a second-order model. Equation (3) represents the quadratic model, where

X is the temperature in Celsius degrees,

Y is the stirring speed measured in rpm, and

Z is the specific activity in micromol mg

−1 h

−1:

The coefficients Z0, A, B, C, D, and E of the proposed model were obtained after an adjustment:

Z0 = −1629.26739; A = 43.73342; B = 1.7111; C = −0,2508; D = 8.30906 × 10−4; and E = −0.03197, with adjustment coefficients equal to: and .

On the other hand, for the case studied of temperature, time, and tungsten concentration (shown in

Figure 6) a second-order model was also applied to approach the experimental data. In this context, the nonlinear fitted surface is given for Equation (4):

where,

X is the temperature in Celsius degrees,

Y is time measured in hours, and

Z represents the tungsten concentration in ppm. The coefficients

A,

B,

C, and

D were obtained after fitting:

A = 0.00193;

B = −0.11043;

C = −0.06691; and

D = 61.13596, with adjustment coefficients equal to:

and

.

From the obtained experimental data, a nonlinear surface was constructed, which fits them using the Levenberg-Marquardt Algorithm (LMA). The LMA is an iterative procedure that solves a damped least square problem using nonlinear algorithms developed for the optimization of nonlinear functions. In all cases, the fitting of data and the graphics were performed using the software Origin 2022b.