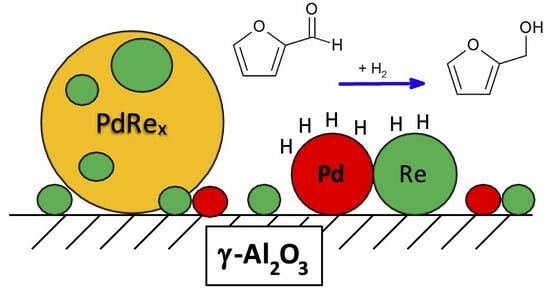

Palladium-Rhenium Catalysts for Selective Hydrogenation of Furfural: Influence of Catalyst Preparation on Structure and Performance

Abstract

:1. Introduction

2. Results and Discussion

2.1. Catalyst Characterization

2.2. Furfural Hydrogenation Catalysis

3. Materials and Methods

3.1. Catalyst Preparation

3.2. TPR and TPHD

3.3. CO and H2 Chemisorption

3.4. CO DRIFTS

3.5. Raman Spectroscopy

3.6. HAADF-STEM-EDX

3.7. Furfural Hydrogenation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, K.Y.; Koso, S.; Kubota, T.; Nakagawa, Y.; Tomishige, K. Chemoselective Hydrogenolysis of Tetrahydropyran-2-methanol to 1,6-Hexanediol over Rhenium-Modified Carbon-Supported Rhodium Catalysts. Chemcatchem 2010, 2, 547–555. [Google Scholar] [CrossRef]

- Koso, S.; Nakagawa, Y.; Tomishige, K. Mechanism of the hydrogenolysis of ethers over silica-supported rhodium catalyst modified with rhenium oxide. J. Catal. 2011, 280, 221–229. [Google Scholar] [CrossRef]

- Chia, M.; Pagan-Torres, Y.J.; Hibbitts, D.; Tan, Q.H.; Pham, H.N.; Datye, A.K.; Neurock, M.; Davis, R.J.; Dumesic, J.A. Selective Hydrogenolysis of Polyols and Cyclic Ethers over Bifunctional Surface Sites on Rhodium–Rhenium Catalysts. J. Am. Chem. Soc. 2011, 133, 12675–12689. [Google Scholar] [CrossRef]

- Koso, S.; Furikado, I.; Shimao, A.; Miyazawa, T.; Kunimori, K.; Tomishige, K. Chemoselective hydrogenolysis of tetrahydrofurfuryl alcohol to 1,5-pentanediol. Chem. Comm. 2009, 2035–2037. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; He, D.H.; Li, Z.P. Hydrogenolysis of bioglycerol to 1,2-propanediol over Ru/CeO2 catalysts: Influence of CeO2 characteristics on catalytic performance. Catal. Comm. 2008, 9, 2489–2495. [Google Scholar] [CrossRef]

- Ma, L.; He, D.H. Hydrogenolysis of Glycerol to Propanediols Over Highly Active Ru–Re Bimetallic Catalysts. Top. Catal. 2009, 52, 834–844. [Google Scholar] [CrossRef]

- Takeda, Y.; Nakagawa, Y.; Tomishige, K. Selective hydrogenation of higher saturated carboxylic acids to alcohols using a ReOx–Pd/SiO2 catalyst. Catal. Sci. Technol. 2012, 2, 2221–2223. [Google Scholar] [CrossRef]

- Shimao, A.; Koso, S.; Ueda, N.; Shinmi, Y.; Furikado, I.; Tomishige, K. Catalytic glycerol hydrogenolysis to 1,3-propanediol in a gas–solid fluidized bed. Chem. Lett. 2009, 38, 540–541. [Google Scholar] [CrossRef]

- Koso, S.; Watanabe, H.; Okumura, K.; Nakagawa, Y.; Tomishige, K. Preferential CO Oxidation in a H2-Rich Stream on Pt−ReOx/SiO2: Catalyst Structure and Reaction Mechanism. J. Phys. Chem. C 2012, 116, 3079–3090. [Google Scholar] [CrossRef]

- Ly, B.K.; Minh, D.P.; Pinel, C.; Besson, M.; Tapin, B.; Epron, F.; Especel, C. Effect of Addition Mode of Re in Bimetallic Pd–Re/TiO2 Catalysts Upon the Selective Aqueous-Phase Hydrogenation of Succinic Acid to 1,4-Butanediol. Top. Catal. 2012, 55, 466–473. [Google Scholar] [CrossRef]

- Mabry, M.A.; Prichard, W.W.; Ziemecki, S.B. Process for Making Tetrahydrofuran and 1,4-Butanediol Using Pd/Re Hydrogenation Catalyst. U.S. Patent 4,550,185, 29 October 1985. [Google Scholar]

- Kitson, M.; Williams, P.S. Platinum Group Metal Alloy Catalysts for Hydrogenation of Carboxylic Acids and Their Anhydrides to Alcohols and/or Esters. U.S. Patent 5,149,680, 22 September 1992. [Google Scholar]

- Malinowski, A.; Juszczyk, W.; Bonarowska, M.; Pielaszek, J.; Karpinski, Z. Pd-Re/Al2O3: Characterization and catalytic activity in hydrodechlorination of CCl2F2. J. Catal. 1998, 177, 153–163. [Google Scholar] [CrossRef]

- Bonarowska, M.; Malinowski, A.; Karpinski, Z. Hydrogenolysis of C–C and C–Cl bonds by Pd–Re/Al2O3 catalysts. Appl. Catal. A 1999, 188, 145–154. [Google Scholar] [CrossRef]

- Juszczyk, W.; Karpinski, Z. Hydrocarbon reactions on Pd–Re/Al2O3 catalysts. Appl. Catal. A 2001, 206, 67–78. [Google Scholar] [CrossRef]

- Meitzner, G.; Via, G.H.; Lytle, F.W.; Sinfelt, J.H. Structure of bimetallic clusters. Extended x-ray absorption fine structure (EXAFS) of Pt–Re and Pd–Re clusters. J. Chem. Phys. 1987, 87, 6354–6363. [Google Scholar] [CrossRef]

- Ziemecki, S.B.; Michel, J.B.; Jones, G.A. Hydride formation as a measure of alloying in bimetallic systems containing Palladium. React. Sol. 1986, 2, 187–202. [Google Scholar] [CrossRef]

- Ziemecki, S.B.; Jones, G.A.; Michel, J.B. Effect of Phosphorus Content in Nickel Phosphide Catalysts Studied by XAFS and Other Techniques. J. Catal. 1986, 99, 207–217. [Google Scholar] [CrossRef]

- Latusek, M.P.; Spigarelli, B.P.; Heimerl, R.M.; Holles, J.H. Correlation of H2 heat of adsorption and ethylene hydrogenation activity for supported Re@Pd overlayer catalysts. J. Catal. 2009, 263, 306–314. [Google Scholar] [CrossRef]

- Skoglund, M.D.; Holles, J.H. Overlayer bimetallic catalysts or particle size effects? A comparison of Re@ Pd catalysts with different particle sizes. Catal. Lett. 2013, 143, 966–974. [Google Scholar] [CrossRef]

- Thompson, S.T.; Lamb, H.H. Palladium–Rhenium Catalysts for Selective Hydrogenation of Furfural: Evidence for an Optimum Surface Composition. ACS Catal. 2016, 6, 7438–7447. [Google Scholar] [CrossRef]

- Kammert, J.D.; Chemburkar, A.; Miyake, N.; Neurock, M.; Davis, R.J. Reaction Kinetics and Mechanism for the Catalytic Reduction of Propionic Acid over Supported ReOx Promoted by Pd. ACS Catal. 2011, 11, 1435–1455. [Google Scholar] [CrossRef]

- Otto, K.; Hubbard, C.P.; Weber, W.H.; Graham, G.W. Raman spectroscopy of palladium oxide on γ-alumina applicable to automotive catalysts: Nondestructive, quantitative analysis; oxidation kinetics; fluorescence quenching. App. Catal. B 1992, 1, 317–327. [Google Scholar] [CrossRef]

- Baylet, A.; Marecot, P.; Duprez, D.; Castellazzi, P.; Groppi, G.; Forzatti, P. In situ Raman and in situ XRD analysis of PdO reduction and Pd0 oxidation supported on γ-Al2O3 catalyst under different atmospheres. Phys. Chem. Chem. Phys. 2011, 13, 4607–4613. [Google Scholar] [CrossRef] [PubMed]

- Hardcastle, F.D.; Wachs, I.E.; Horsley, J.A.; Via, G.H. The structure of surface rhenium oxide on alumina from laser raman spectroscopy and x-ray absorption near-edge spectroscopy. J. Mol. Catal. 1988, 46, 15–36. [Google Scholar] [CrossRef]

- Vuurman, M.A.; Wachs, I.E. In situ Raman spectroscopy of alumina-supported metal oxide catalysts. J. Phys. Chem. 1992, 96, 5008–5016. [Google Scholar] [CrossRef]

- Kim, D.S.; Wachs, I.E. Surface rhenium oxide-support interaction for supported Re2O7 catalysts. J. Catal. 1993, 141, 419–429. [Google Scholar] [CrossRef]

- McBride, J.R.; Hass, K.C.; Weber, W.H. Resonance-Raman and lattice-dynamics studies of single-crystal PdO. Phys. Rev. B 1991, 44, 5016–5028. [Google Scholar] [CrossRef]

- Su, S.C.; Carstens, J.N.; Bell, A.T. A Study of the Dynamics of Pd Oxidation and PdO Reduction by H2 and CH4. J. Catal. 1998, 176, 125–135. [Google Scholar] [CrossRef]

- Mamede, A.S.; Leclercq, G.; Payen, E.; Granger, P.; Grimblot, J. In situ Raman characterisation of surface modifications during NO transformation over automotive Pd-based exhaust catalysts. J. Mol. Struct. 2003, 651, 353–364. [Google Scholar] [CrossRef]

- Arai, T.; Shima, T.; Nakano, T.; Tominaga, J. Thermally-induced optical property changes of sputtered PdOx films. Thin Solid Films 2007, 515, 4774–4777. [Google Scholar] [CrossRef]

- Jiao, L.; Regalbuto, J.R. The synthesis of highly dispersed noble and base metals on silica via strong electrostatic adsorption: I. Amorphous silica. J. Catal. 2008, 260, 329–341. [Google Scholar] [CrossRef]

- Okal, J.; Kepinski, L.; Krajczyk, L.; Tylus, W. Oxidation and redispersion of a low-loaded Re/γ-Al2O3 catalyst. J. Catal. 2003, 219, 362–371. [Google Scholar] [CrossRef]

- Sumner, C.; Burchett, W. Developments in the Pd Catalyzed Hydrogenation of Oxygenated Organic Compounds. Top. Catal. 2012, 55, 480–485. [Google Scholar] [CrossRef]

- McCaulley, J.A. In-situ X-ray absorption spectroscopy studies of hydride and carbide formation in supported palladium catalysts. J. Phys. Chem. 1993, 97, 10372–10379. [Google Scholar] [CrossRef]

- Predel, B.; Madelung, O.E. (Eds.) Landolt-Börnstein—Group IV Physical Chemistry; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Sinfelt, J.H. Bimetallic Catalysts: Discoveries, Concepts, and Applications; John Wiley and Sons: Hoboken, NJ, USA, 1983. [Google Scholar]

- Thompson, S.T.; Lamb, H.H. Catalysts for selective hydrogenation of furfural derived from the double complex salt [Pd(NH3)4](ReO4)2 on γ-Al2O3. J. Catal. 2017, 350, 111–121. [Google Scholar] [CrossRef]

- Chadzynski, G.W.; Kubicka, H. Chemisorption of hydrogen and oxygen on γ-alumina-supported rhenium: Part 1. Chemisorption of hydrogen. Thermochim. Acta 1990, 158, 353–367. [Google Scholar] [CrossRef]

- Giorgi, J.B.; Schroeder, T.; Baumer, M.; Freund, H.J. Study of CO adsorption on crystalline-silica-supported palladium particles. Surf. Sci. 2002, 498, L71–L77. [Google Scholar] [CrossRef]

- Agostini, G.; Pellegrini, R.; Leofanti, G.; Bertinetti, L.; Bertarione, S.; Groppo, E.; Zecchina, A.; Lamberti, C. Determination of the particle size, available surface area, and nature of exposed sites for silica-alumina-supported Pd nanoparticles: A multitechnical approach. J. Phys. Chem. C 2009, 113, 10485–10492. [Google Scholar] [CrossRef]

- Lear, T.; Marshall, R.; Lopez-Sanchez, J.A.; Jackson, S.D.; Klapotke, T.M.; Baumer, M.; Rupprechter, G.; Freund, H.J.; Lennon, D. Hydrogenation catalysis on Pd nanoparticles stabilized by different crosslinked polymers. J. Chem. Phys. 2005, 123, 13. [Google Scholar]

- Daniell, W.; Weingand, T.; Knozinger, H. Redox properties of Re2O7/Al2O3 as investigated by FTIR spectroscopy of adsorbed CO. J. Mol. Catal. 2003, 204, 519–526. [Google Scholar] [CrossRef]

- Bare, S.R.; Kelly, S.D.; Vila, F.D.; Boldingh, E.; Karapetrova, E.; Kas, J.; Mickelson, G.E.; Modica, F.S.; Yang, N.; Rehr, J.J. Experimental (XAS, STEM, TPR, and XPS) and theoretical (DFT) characterization of supported rhenium catalysts. J. Phys. Chem. C 2011, 115, 5740–5755. [Google Scholar] [CrossRef]

| Catalyst | Metal Precursor(s) | Pd Loading a (wt.%) | Re Loading a (wt.%) |

|---|---|---|---|

| Pd1-N | Pd(NO3)2 | 0.91 | - |

| Pd3-N | Pd(NO3)2 | 2.66 | - |

| Pd3-TA | Pd(NH3)4(NO3)2 | 2.34 | - |

| Pd3Re5-CI | Pd(NO3)2 and HReO4 | 2.43 | 4.41 |

| Pd3Re5-SI | Pd(NH3)4(NO3)2 and HReO4 | 2.80 | 4.63 |

| Re5Pd3N-SI | HReO4 and Pd(NO3)2 | 2.15 | 5.73 |

| Re5Pd3-SI (350) | NH4ReO4 and Pd(NH3)4(NO3)2 | 2.56 | 4.23 |

| Re5Pd3-SI (400) | NH4ReO4 and Pd(NH3)4(NO3)2 | 2.27 | 4.24 |

| Re5Pd1.5-DCS | Pd(NH3)4(ReO4)2 | 1.42 | 4.65 |

| Re5-H | HReO4 | - | 5.29 |

| Re5-N | NH4ReO4 | - | 4.54 |

| Catalyst | H/Metal Ratio (TPR) 1 | Re Oxidation State (TPR) 2 | H/Pd (TPHD) 4 |

|---|---|---|---|

| Pd3-N | 2.1 | - | 0.32 |

| Pd3-TA | 2.4 | - | 0.13 |

| Pd3Re5-CI | 4.4 | 0.4 | 0.063 |

| Pd3Re5-SI | 3.6 | 0.7 3 | 0.058 |

| Re5Pd3N-SI | 5.0 | 0.7 | 0.18 |

| Re5Pd3-SI (350) | 4.3 | 0.3 | 0.11 |

| Re5Pd3-SI (400) | 4.5 | 0.2 | 0.12 |

| Re5-N | 4.9 | 2.1 | -- |

| Catalyst | CO Chemisorption | H2 Chemisorption | ||||||

|---|---|---|---|---|---|---|---|---|

| 35 °C | 35 °C | 100 °C | ||||||

| CO Uptake a | CO/Metal | H2 uptake a | H/Metal | H/CO | H2 Uptake | H/Metal | H/CO | |

| Pd1-N | 28.5 | 0.333 | 12.7 | 0.297 | 0.89 | 8.8 | 0.204 | 0.62 |

| Pd3-N | 32.4 | 0.130 | 16.7 | 0.133 | 1.03 | 12.4 | 0.100 | 0.76 |

| Pd3-TA | 103 | 0.469 | 45.0 | 0.370 | 0.88 | 34.0 | 0.280 | 0.66 |

| Pd3Re5-CI | 59.0 | 0.127 | 26.7 | 0.115 | 0.90 | 27.3 | 0.117 | 0.92 |

| Pd3Re5-SI | 80.5 | 0.157 | 17.9 | 0.070 | 0.44 | 21.6 | 0.084 | 0.54 |

| Re5Pd3N-SI | 50.5 | 0.099 | n/a | - | - | n/a | - | - |

| Re5Pd3-SI (350) | 96.2 | 0.206 | 20.9 | 0.089 | 0.43 | 26.7 | 0.114 | 0.56 |

| Re5Pd3-SI (400) | 92.6 | 0.210 | 20.3 | 0.092 | 0.44 | 21.1 | 0.096 | 0.46 |

| Pd1.5Re5-DCS | 44.6 | 0.116 | 7.6 | 0.040 | 0.34 | 11.0 | 0.057 | 0.49 |

| Re5-N | 33.8 | 0.139 | 2.3 | 0.019 | 0.14 | 14.5 | 0.119 | 0.86 |

| Catalyst | TOF (min−1) a | |

|---|---|---|

| CO | H | |

| Pd1-N | 10.1 | 11.3 b |

| Pd3-N | 9.1 | 8.9 b |

| Pd3-TA | 3.2 | 3.7 b |

| Pd3Re5-CI | 5.1 | 5.5 |

| Pd3Re5-SI | 20.5 | 38.3 |

| Re5Pd3-SI (350) | 13.6 | 24.5 |

| Re5Pd3-SI (400) | 26.0 | 57.0 |

| Pd1.5Re5-DCS | 29.9 | 60.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thompson, S.T.; Lamb, H.H. Palladium-Rhenium Catalysts for Selective Hydrogenation of Furfural: Influence of Catalyst Preparation on Structure and Performance. Catalysts 2023, 13, 1239. https://doi.org/10.3390/catal13091239

Thompson ST, Lamb HH. Palladium-Rhenium Catalysts for Selective Hydrogenation of Furfural: Influence of Catalyst Preparation on Structure and Performance. Catalysts. 2023; 13(9):1239. https://doi.org/10.3390/catal13091239

Chicago/Turabian StyleThompson, Simon T., and H. Henry Lamb. 2023. "Palladium-Rhenium Catalysts for Selective Hydrogenation of Furfural: Influence of Catalyst Preparation on Structure and Performance" Catalysts 13, no. 9: 1239. https://doi.org/10.3390/catal13091239