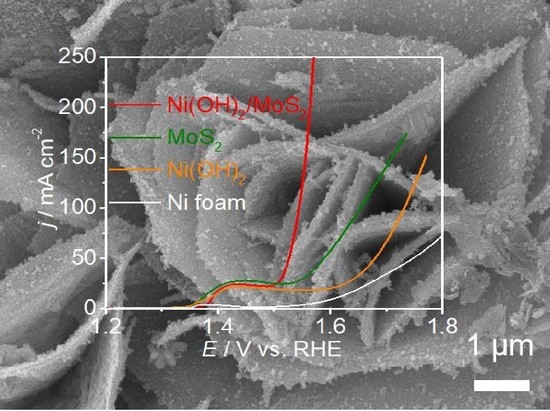

Coupling Interface Construction of Ni(OH)2/MoS2 Composite Electrode for Efficient Alkaline Oxygen Evolution Reaction

Abstract

:1. Introduction

2. Results

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Materials Synthesis

4.3. Materials Characterizations

4.4. Electrochemical Characterizations

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.-J.; Li, M.-Y.; Li, X.; Bao, W.-W.; Jin, C.-Q.; Feng, X.-H.; Liu, G.; Yang, C.-M.; Zhang, N.-N. Chromium-modified ultrathin CoFe LDH as high-efficiency electrode for hydrogen evolution reaction. Nanomaterials 2022, 12, 1227. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Liu, Y.-M.; Zhang, J.-J.; Yan, B.; Jin, C.-Q.; Dou, J.-J.; Li, M.-Y.; Feng, X.-H.; Liu, G. No Annealing Synthesis of Ordered Intermetallic PdCu Nanocatalysts for Boosting Formic Acid Oxidation. Chem. Mater. 2022, 34, 1385–1391. [Google Scholar] [CrossRef]

- Lao, J.; Li, D.; Jiang, C.-L.; Luo, R.; Peng, H.; Qi, R.-J.; Lin, H.-C.; Huang, R.; Waterhouse, G.I.N.; Luo, C.H. Efficient overall water splitting using nickel boride-based electrocatalysts. Int. J. Hydrog. Energy 2020, 45, 28616–28625. [Google Scholar] [CrossRef]

- Wang, J.-S.; Zhang, Z.-F.; Song, H.-R.; Zhang, B.; Liu, J.; Shai, X.-X.; Miao, L. Water dissociation kinetic-oriented design of nickel sulfides via tailored dual sites for efficient alkaline hydrogen evolution. Adv. Funct. Mater. 2021, 31, 2008578. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, Q.; Chen, Q.; Hou, X.; Peng, W.; Li, Y.; Zhang, F.; Xia, Q.; Fan, X. Coupling LaNiO3 Nanorods with FeOOH Nanosheetsfor Oxygen Evolution Reaction. Catalysts 2022, 12, 594. [Google Scholar] [CrossRef]

- Ai, T.-T.; Wang, H.-H.; Bao, W.-W.; Feng, L.-L.; Zou, X.-Y.; Wei, X.-L.; Ding, L.; Deng, Z.-F.; Rao, B. Fe-V synergistic doping effect of hierarchical Ni3S2 oblate-nanorod arrays for efficient electrocatalytic oxygen evolution reaction. Chem. Eng. J. 2022, 450, 138358. [Google Scholar] [CrossRef]

- Liu, S.-Q.; Wen, H.-R.; Guo, Y.; Zhu, Y.-W.; Fu, X.-Z.; Sun, R.; Wong, C.-P. Amorphous Ni(OH)2 encounter with crystalline CuS in hollow spheres: A mesoporous nano-shelled heterostructure for hydrogen evolution electrocatalysis. Nano Energy 2018, 44, 7–14. [Google Scholar] [CrossRef]

- Xiao, G.; Chen, W.; Cai, Y.; Zhang, S.; Wang, D.; Cai, D. FacileSynthesis of Sulfate-IntercalatedCoFe LDH Nanosheets Derived fromTwo-Dimensional ZIF-9(III) forPromoted Oxygen Evolution Reaction. Catalysts 2022, 12, 688. [Google Scholar] [CrossRef]

- Yan, Q.; Liu, Z.; Bai, X.; Zhang, X.; Gao, R.; Yuan, W.; Chen, Z.; Li, Z.; Li, Y. In situ formed edge-rich Ni3S2-NiOOH heterojunctions for oxygen evolution reaction. J. Electrochem. Soc. 2022, 169, 054532. [Google Scholar] [CrossRef]

- Liang, Z.-J.; Lu, Y.-C. Critical role of redox mediator in suppressing charging instabilities of lithium−oxygen batteries. J. Am. Chem. Soc. 2016, 138, 7574–7583. [Google Scholar] [CrossRef]

- Zhang, M.-L.; Zhan, Y.-Q.; Ye, L.; Guo, B.-W.; Gong, Y.-Q. Hierarchically constructed Ag nanowires shelled with ultrathin Co-LDH nanosheets for advanced oxygen evolution reaction. Appl. Catal. B 2021, 298, 120601. [Google Scholar] [CrossRef]

- Du, X.-Q.; Ma, G.-Y.; Zhang, X.-S. Oxygen vacancy-confined CoMoO4@CoNiO2 nanorod arrays for oxygen evolution with improved performance. Dalton Trans. 2019, 48, 10116–10121. [Google Scholar] [CrossRef]

- Fei, B.; Chen, Z.-L.; Liu, J.-X.; Xu, H.-B.; Yan, X.-X.; Qing, H.-L.; Chen, M.; Wu, R.B. Ultrathinning nickel sulfide with modulated electron density for efficient water splitting. Adv. Energy Mater. 2020, 10, 2001963. [Google Scholar] [CrossRef]

- Zhang, J.-J.; Yang, C.-M.; Jin, C.-Q.; Bao, W.-W.; Nan, R.-H.; Hu, L.; Liu, G.; Zhang, N.-N. Hierarchical iron molybdate nanostructure array for efficient water oxidation through optimizing electron density. Chem. Commun. 2021, 57, 3563–3566. [Google Scholar] [CrossRef]

- Wang, X.; Liu, W.; Wang, J.-N.; Li, C.-M.; Zheng, R.K.; Zhang, H.X.; Liu, J.Q.; Zhang, X.W. Cobalt and vanadium co-doped FeOOH nanoribbons: An iron-rich electrocatalyst for efficient water oxidation. Mater. Chem. Front. 2021, 5, 6485–6490. [Google Scholar] [CrossRef]

- Sun, F.-Z.; Li, C.-Q.; Li, B.; Lin, Y.-Q. Amorphous MoSx developed on Co(OH)2 nanosheets generating efficient oxygen evolution catalyst. J. Mater. Chem. A 2017, 5, 23103–23114. [Google Scholar] [CrossRef]

- Gu, L.-F.; Li, C.-F.; Zhao, J.-W.; Xie, L.-J.; Wu, J.-Q.; Ren, Q.; Li, G.-R. Dual modulation of lattice strain and charge polarization induced by Co(OH)2/Ni(OH)2 interfaces for efficient oxygen evolution catalysis. J. Mater. Chem. A 2021, 9, 13279–13287. [Google Scholar] [CrossRef]

- Cao, Q.-H.; Luo, M.; Huang, Y.-T.; Liu, Q.; Kong, X.-X.; Lei, J.-L.; Jiang, Z.; Wang, J.H. Temperature and doping-tuned coordination environments around electroactive centers in Fe-doped α(β)-Ni(OH)2 for excellent water splitting. Sustain. Energy Fuels 2020, 4, 1522–1531. [Google Scholar] [CrossRef]

- Shi, D.-W.; Zhang, L.-Y.; Zhang, N.-D.; Zhang, Y.-W.; Yu, Z.-G.; Gong, H. Boosted electrochemical property from surface engineering of ultrathin interlaced Ni(OH)2 nanosheets with Co(OH)2 quantum dot modification. Nanoscale 2018, 10, 10554–10563. [Google Scholar] [CrossRef]

- Aguilera, L.; Leyet, Y.; Almeida, A.; Moreira, J.A.; de la Cruz, J.P.; Milán-Garcés, E.A.; Passos, R.R.; Pocrifka, L.A. Electrochemical preparation of Ni(OH)2/CoOOH bilayer films for application in energy storage devices. J. Alloys Compd. 2021, 874, 159858. [Google Scholar] [CrossRef]

- Chen, S.-R.; Yin, Z.-H.; Cui, M.; Liu, X.; Xiong, J.-B.; Li, Y.-Q.; Ma, T.L. Interface engineering of transitional metal sulfides-MoS2 heterostructure composites as effective electrocatalysts for water-splitting. J. Mater. Chem. A 2021, 9, 2070–2092. [Google Scholar]

- Mansingh, S.; Das, K.K.; Parida, K. HERs in an acidic medium over MoS2 nanosheets: From fundamentals to synthesis and the recent progress. Sustain. Energy Fuels 2021, 5, 1952–1987. [Google Scholar] [CrossRef]

- Ren, Y.-X.; Zhu, S.-L.; Liang, Y.-Q.; Li, Z.-Y.; Wu, S.-L.; Chang, C.-T.; Luo, S.-Y.; Cui, Z.D. Hierarchical Ni3S4@MoS2 nanocomposites as efficient electrocatalysts for hydrogen evolution reaction. J. Mater. Sci. 2021, 95, 70–77. [Google Scholar] [CrossRef]

- Wang, H.-M.; Li, C.-H.; Fang, P.-F.; Zhang, Z.-L.; Zhang, J.-Z. Synthesis, properties, and optoelectronic applications of two-dimensional MoS2 and MoS2-based heterostructures. Chem. Soc. Rev. 2018, 47, 6101–6127. [Google Scholar] [CrossRef]

- Jung, H.-Y.; Chae, M.-J.; Park, J.-H.; Song, Y.-I.; Ro, J.-C.; Suh, S.-J. Effect of platinum group metals on MoS2 nanosheets for a high-performance hydrogen evolution reaction catalyst. ACS Appl. Energy Mater. 2021, 4, 10748–10755. [Google Scholar] [CrossRef]

- Huang, J.-B.; Jiang, Y.; An, T.-Y.; Cao, M.-H. Increasing the active sites and intrinsic activity of transition metal chalcogenide electrocatalysts for enhanced water splitting. J. Mater. Chem. A 2020, 8, 25465–25498. [Google Scholar] [CrossRef]

- Yu, F.; Yu, L.; Mishra, I.-K.; Yu, Y.; Ren, Z.-F.; Zhou, H.-Q. Recent developments in earth-abundant and non-noble electrocatalysts for water electrolysis. Mater. Today Phys. 2018, 7, 121–138. [Google Scholar] [CrossRef]

- Huang, Y.-Z.; Huang, J.-C.; Xu, K.S.; Geng, R.-R. Constructing NiSe2@MoS2 nano-heterostructures on a carbon fiber paper for electrocatalytic oxygen evolution. RSC Adv. 2021, 11, 26928–26936. [Google Scholar] [CrossRef]

- Jin, Q.; Liu, N.; Dai, C.-N.; Xu, R.-N.; Wu, B.; Yu, G.-Q.; Chen, B.-H.; Du, Y.-Z. H2-Directing Strategy on In Situ Synthesis of Co-MoS2 with Highly Expanded Interlayer for Elegant HER Activity and its Mechanism. Adv. Energy Mater. 2020, 10, 2000291. [Google Scholar] [CrossRef]

- Tang, B.-S.; Yu, Z.-G.; Seng, H.-L.; Zhang, N.-D.; Liu, X.-X.; Zhang, Y.-W.; Yang, W.-F.; Gong, H. Simultaneous edge and electronic control of MoS2 nanosheets through Fe doping for an efficient oxygen evolution reaction. Nanoscale 2018, 10, 20113–20119. [Google Scholar] [CrossRef] [PubMed]

- Guan, S.-D.; Fu, X.-L.; Lao, Z.-Z.; Jin, C.-H.; Peng, Z.-J. NiS–MoS2 hetero-nanosheet array electrocatalysts for efficient overall water splitting. Sustain. Energy Fuels 2019, 3, 2056–2066. [Google Scholar] [CrossRef]

- Yu, M.-Q.; Moon, G.H.; Castillo, R.G.; DeBeer, S.; Weidenthaler, C.; Tüysüz, H. Dual role of silver moieties coupled with ordered mesoporous cobalt oxide towards electrocatalytic oxygen evolution reaction. Angew. Chem. Int. Ed. 2020, 132, 16687–16695. [Google Scholar]

- Wang, Y.-Z.; Liu, S.-S.; Hao, X.-F.; Luan, S.-R.; You, H.-H.; Zhou, J.-S.; Song, D.-D.; Wang, D.; Li, H.; Gao, F.-M. Surface reorganization engineering of the N dopant MoS2 construction heterostructures MoOx@N-doped MoS2-x by in-situ electrochemical oxidation activated for an efficient oxygen evolution reaction. J. Mater. Chem. A 2019, 7, 10572–10580. [Google Scholar] [CrossRef]

- Priamushko, T.; Guillet-Nicolas, R.; Yu, M.; Doyle, M.; Weidenthaler, C.; Tüysüz, H.; Kleitz, F. Nanocast mixed Ni–Co–Mn oxides with controlled surface and pore structure for electrochemical oxygen evolution reaction. ACS Appl. Energy Mater. 2020, 3, 5597–5609. [Google Scholar] [CrossRef]

- Yang, Y.-Q.; Zhang, K.; Lin, H.-L.; Li, X.; Chan, H.-C.; Yang, L.-C.; Gao, Q.S. MoS2−Ni3S2 heteronanorods as efficient and stable bifunctional electrocatalysts for overall water splitting. ACS Catal. 2017, 7, 2357–2366. [Google Scholar] [CrossRef]

- Zou, X.; Liu, Y.-P.; Li, G.-D.; Wu, Y.-Y.; Liu, D.-P.; Li, W.; Li, H.-W.; Wang, D.; Zhang, J.Y.; Zou, X.X. Ultrafast formation of amorphous bimetallic hydroxide films on 3D conductive sulfide nanoarrays for large-current-density oxygen evolution electrocatalysis. Adv. Mater. 2017, 29, 1700404. [Google Scholar] [CrossRef]

- Li, X.; Kou, Z.-K.; Xi, S.-B.; Zang, W.-J.; Yang, T.; Zhang, L.; Wang, J. Porous NiCo2S4/FeOOH nanowire arrays with rich sulfide/hydroxide interfaces enable high OER activity. Nano Energy 2020, 78, 105230. [Google Scholar] [CrossRef]

- Li, S.-M.; Yu, Y.-M.; Sun, X.-Y.; Ding, X.-F.; Yang, H.-F.; Pan, S.-B.; Wang, L.X.; Zhang, Q.T. Enhanced electronic interaction in hemin@Ni(OH)2 composite for efficient electrocatalytic oxygen evolution. J. Alloys Compd. 2022, 892, 161780. [Google Scholar] [CrossRef]

- Dua, X.-Q.; Yang, Z.; Li, Y.; Gong, Y.-Q.; Zhao, M. Controlled synthesis of Ni(OH)2/Ni3S2 hybrid nanosheet arrays as highly active and stable electrocatalysts for water splitting. J. Mater. Chem. A 2018, 6, 6938–6946. [Google Scholar] [CrossRef]

- Xi, W.-G.; Yan, G.; Tan, H.-Q.; Xiao, L.-G.; Cheng, S.-H.; Khan, S.-U.; Wang, Y.-H.; Lia, Y.G. Superaerophobic P-doped Ni(OH)2/NiMoO4 hierarchical nanosheet arrays grown on Ni foam for electrocatalytic overall water splitting. Dalton Trans. 2018, 47, 8787–8793. [Google Scholar] [CrossRef]

- Lu, Y.-K.; Liu, C.-C.; Xing, Y.-Y.; Xu, Q.; Hossain, A.M.S.; Jiang, D.-L.; Li, D.; Zhu, J.-J. Synergistically integrated Co9S8@NiFe-layered double hydroxide core-branch hierarchical architectures as efficient bifunctional electrocatalyst for water splitting. J. Colloid Interf. Sci. 2021, 604, 680–690. [Google Scholar] [CrossRef]

- Su, L.; Cui, X.-Z.; He, T.; Zeng, L.-M.; Tian, H.; Song, Y.-L.; Qi, K.; Xia, B.-Y. Surface reconstruction of cobalt phosphide nanosheets by electrochemical activation for enhanced hydrogen evolution in alkaline solution. Chem. Sci. 2019, 10, 2019–2024. [Google Scholar] [CrossRef] [Green Version]

- Ye, L.; Zhang, Y.-Q.; Wang, L.-M.; Zhao, L.-X.; Gong, Y.-Q. Assembly of ZIF-67 nanoparticles and in situ grown Cu(OH)2 nanowires serves as an effective electrocatalyst for oxygen evolution. Dalton Trans. 2021, 50, 7256–7264. [Google Scholar] [CrossRef]

- Zhang, B.; Qiu, C.-T.; Wang, S.; Gao, H.; Yu, K.-Y.; Zhang, Z.-F.; Ling, X.; Ou, W.; Su, C.-L. Electrocatalytic water-splitting for the controllable and sustainable synthesis of deuterated chemicals. Sci. Bull. 2021, 66, 562–569. [Google Scholar] [CrossRef]

- Xie, C.; Zhang, X.; Matras-Postolek, K.; Yang, P. Hierarchical FeCo/C@Ni(OH)2 heterostructures for enhanced oxygen evolution activity. Electrochim. Acta 2021, 395, 139194. [Google Scholar] [CrossRef]

- Niu, S.-Q.; Sun, Y.-C.; Sun, G.-J.; Rakov, D.; Li, Y.-Z.; Ma, Y.; Chu, J.-Y.; Xu, P. Stepwise electrochemical construction of FeOOH/Ni(OH)2 on Ni foam for enhanced electrocatalytic oxygen evolution. ACS Appl. Energy Mater. 2019, 2, 3927–3935. [Google Scholar] [CrossRef]

- Wu, Q.; Dong, A.; Yang, C.; Ye, L.; Zhao, L.; Jiang, Q. Metal-organic framework derived Co3O4@Mo-Co3S4-Ni3S2 heterostructure supported on Ni foam for overall water splitting. Chem. Eng. J. 2021, 413, 127482. [Google Scholar] [CrossRef]

- Guo, J.-X.; Zhang, K.; Sun, Y.-F.; Zong, Y.-X.; Guo, Z.-Y.; Liu, Q.Y.; Zhang, X.; Xia, Y.-Y. Enhanced hydrogen evolution of MoS2/RGO: Vanadium, nitrogen dopants triggered new active sites and expanded interlayer. Inorg. Chem. Front. 2018, 5, 2092–2099. [Google Scholar] [CrossRef]

- Xiao, L.; Bao, W.W.; Zhang, J.J.; Yang, C.M.; Ai, T.T.; Li, Y.; Wei, X.L.; Jiang, P.; Kou, L.J. Interfacial interaction between NiMoP and NiFe-LDH to regulate the electronic structure toward high-efficiency electrocatalytic oxygen evolution reaction. Int. J. Hydrog. Energy 2022, 47, 9230–9238. [Google Scholar] [CrossRef]

- Gong, Y.; Zhi, Y.; Lin, Y.; Zhou, T.; Li, J.; Jiao, F.; Wang, W. Controlled synthesis of bifunctional particle-like Mo/Mn-NixSy/NF electrocatalyst for highly efficient overall water splitting. Dalton Trans. 2019, 48, 6718–6729. [Google Scholar] [CrossRef]

- Bao, W.-W.; Xiao, L.; Zhang, J.-J.; Jiang, P.; Zou, X.-Y.; Yang, C.-M.; Hao, X.-L.; Ai, T.-T. Electronic and structural engineering of NiCo2O4/Ti electrocatalysts for efficient oxygen evolution reaction. Int. J. Hydrog. Energy 2021, 46, 10259–10267. [Google Scholar] [CrossRef]

- Yu, M.-Q.; Li, X.-J.; Hua, G.-Y. Ultrathin nanosheets constructed CoMoO4 porous flowers with high activity for electrocatalytic oxygen evolution. Chem. Commun. 2015, 51, 14361–14364. [Google Scholar] [CrossRef]

- Dong, C.-L.; Yuan, X.-T.; Wang, X.; Liu, X.-Y.; Dong, W.-J.; Wang, R.-Q.; Duan, Y.-H.; Huang, F.-Q. Rational design of cobalt–chromium layered double hydroxide as a highly efficient electrocatalyst for water oxidation. J. Mater. Chem. A 2016, 4, 11292–11298. [Google Scholar] [CrossRef]

- Li, J.; Li, G.-S.; Wang, J.-H.; Xue, C.-L.; Li, X.-S.; Wang, S.; Han, B.-Q.; Yang, M.; Li, L.P. A novel core–double shell heterostructure derived from a metal–organic framework for efficient HER, OER and ORR electrocatalysis. Inorg. Chem. Front. 2020, 7, 191–197. [Google Scholar] [CrossRef]

- Cheng, P.-F.; Yuan, C.; Zhou, Q.-W.; Hu, X.-B.; Li, J.; Lin, X.-Z.; Wang, X.; Jin, M.-L.; Shui, L.-L.; Gao, X.-S.; et al. Core–Shell MoS2@CoO electrocatalyst for water splitting in neural and alkaline solutions. J. Phys. Chem. C 2019, 123, 5833–5839. [Google Scholar] [CrossRef]

- He, F.; Liu, Y.-J.; Ca, Q.-H.; Zhao, J.-X. Size-dependent electrocatalytic activity of ORR/OER on palladium nanoclusters anchored on defective MoS2 monolayers. New J. Chem. 2020, 44, 16135–16143. [Google Scholar]

- Nai, J.-W.; Yin, H.-J.; You, T.-T.; Zheng, L.-R.; Zhang, J.; Wang, P.-X.; Jin, Z.; Tian, Y.; Liu, J.Z.; Tang, Z.Y.; et al. Efficient electrocatalytic water oxidation by using amorphous Ni-Co double hydroxides nanocages. Adv. Energy Mater. 2015, 5, 1401880. [Google Scholar] [CrossRef]

- Hu, H.; Guan, B.-Y.; Xia, B.-Y.; Lou, X.-W. Designed formation of Co3O4/NiCo2O4 double-shelled nanocages with enhanced pseudocapacitive and electrocatalytic properties. J. Am. Chem. Soc. 2015, 137, 5590–5595. [Google Scholar] [CrossRef]

- Paliwala, M.; Meher, S. Study of “Ni-doping” and “open-pore microstructure” as physico-electrochemical stimuli towards the electrocatalytic efficiency of Ni/NiO for the oxygen evolution reaction. New J. Chem. 2020, 44, 17507–17517. [Google Scholar] [CrossRef]

- Dileep, N.; Vineesh, T.; Sarma, P.; Chalil, M.; Prasad, C.; Shaijumon, M. Electrochemically Exfoliated β-Co(OH)2 Nanostructures for enhanced oxygen evolution electrocatalysis. ACS Appl. Energy Mater. 2020, 3, 1461–1467. [Google Scholar] [CrossRef]

- Yan, K.-L.; Sheng, M.-L.; Sun, X.-D.; Song, C.; Cao, Z.; Sun, Y.-J. Microwave synthesis of ultrathin nickel hydroxide nanosheets with Iron incorporation for electrocatalytic water oxidation. ACS Appl. Energy Mater. 2019, 2, 1961–1968. [Google Scholar]

- Mohanty, B.; Ghorbani-Asl, M.; Kretschmer, S.; Ghosh, A.; Guha, P.; Panda, S.; Jena, B.; Krasheninnikov, A.; Jena, B.K. MoS2 quantum dots as efficient catalyst materials for the oxygen evolution reaction. ACS Catal. 2018, 8, 1683–1689. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Ouyang, X.; Wei, X.-L.; Bao, W.-W.; Feng, X.-H.; Zhang, J.-J. Coupling Interface Construction of Ni(OH)2/MoS2 Composite Electrode for Efficient Alkaline Oxygen Evolution Reaction. Catalysts 2022, 12, 966. https://doi.org/10.3390/catal12090966

Liu G, Ouyang X, Wei X-L, Bao W-W, Feng X-H, Zhang J-J. Coupling Interface Construction of Ni(OH)2/MoS2 Composite Electrode for Efficient Alkaline Oxygen Evolution Reaction. Catalysts. 2022; 12(9):966. https://doi.org/10.3390/catal12090966

Chicago/Turabian StyleLiu, Ge, Xuezhi Ouyang, Xue-Ling Wei, Wei-Wei Bao, Xiao-Hua Feng, and Jun-Jun Zhang. 2022. "Coupling Interface Construction of Ni(OH)2/MoS2 Composite Electrode for Efficient Alkaline Oxygen Evolution Reaction" Catalysts 12, no. 9: 966. https://doi.org/10.3390/catal12090966