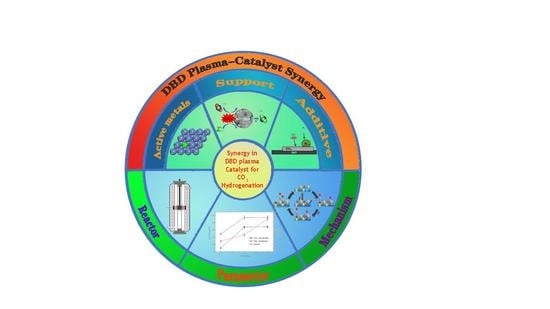

Dielectric Barrier Discharge Plasma-Assisted Catalytic CO2 Hydrogenation: Synergy of Catalyst and Plasma

Abstract

:1. Introduction

2. Overview of Plasma and Catalyst–Plasma Hybrid System

3. Synergy in Catalyst–Plasma (DBD) Hybrid System

3.1. Active Metal and DBD Plasma

3.2. Support and DBD Plasma

3.3. Additive and DBD Plasma

4. Operation Parameter

4.1. Voltage/Power/Temperature/SIE (Specific Input Energy)

4.2. GHSV (Gas Hourly Space Velocity)

4.3. Feed Ratio

5. Reactor Configuration

6. Reaction Mechanism

7. Conclusive Remarks and Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, M.; Yi, Y.; Wang, L.; Guo, H.; Bogaerts, A. Hydrogenation of Carbon Dioxide to Value-Added Chemicals by Heterogeneous Catalysis and Plasma Catalysis. Catalysts 2019, 9, 275. [Google Scholar] [CrossRef] [Green Version]

- Anoop, N.; Sundaramurthy, S.; Jha, J.M.; Chandrabalan, S.; Singh, N.; Verma, J.; Parvatalu, D.; Katti, S. Plasma catalysis: A feasible solution for carbon dioxide valorization? Clean Technol. Envir. 2021, 23, 2789–2811. [Google Scholar] [CrossRef]

- Irish, J.L.; Sleath, A.; Cialone, M.A.; Knutson, T.R.; Jensen, R.E. Simulations of Hurricane Katrina (2005) under sea level and climate conditions for 1900. Clim. Chang. 2014, 122, 635–649. [Google Scholar] [CrossRef]

- Bobicki, E.R.; Liu, Q.; Xu, Z.; Zeng, H. Carbon capture and storage using alkaline industrial wastes. Prog. Energy Combust. Sci. 2012, 38, 302–320. [Google Scholar] [CrossRef]

- Rahman, F.A.; Aziz, M.M.A.; Saidur, R.; Wan, W.A.; Hainin, M.R.; Putrajava, R.; Hassan, N.A. Pollution to solution: Capture and sequestration of carbon dioxide (CO2) and its utilization as a renewable energy source for a sustainable future. Renew. Sustain. Energy Rev. 2017, 71, 112–126. [Google Scholar] [CrossRef]

- Snoeckx, R.; Bogaerts, A. Plasma technology—a novel solution for CO2 conversion? Chem. Soc. Rev. 2017, 46, 5805–5863. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, H.; Mu, Y.; Xu, S.; Xu, S.; Hardacre, C.; Fan, X. Recent advances in non-thermal plasma (NTP) catalysis towards C1 chemistry. Chin. J. Chem. Eng. 2020, 28, 2010–2021. [Google Scholar] [CrossRef]

- Xu, S.; Chen, S.; Hardacre, C.; Fan, X. Non-thermal plasma catalysis for CO2 conversion and catalyst design for the process. J. Phys. D Appl. Phys. 2021, 54, 233001. [Google Scholar] [CrossRef]

- Ashok, J.; Ang, M.L.; Kawi, S. Enhanced activity of CO2 methanation over Ni/ CeO2–ZrO2 catalysts: Influence of preparation methods. Catal. Today 2017, 281, 304–311. [Google Scholar] [CrossRef]

- Ashok, J.; Pati, S.; Hongmanorom, P.; Zhang, T.; Chen, J.; Kawi, S. A review of recent catalyst advances in CO2 methanation processes. Catal. Today 2020, 356, 471–489. [Google Scholar] [CrossRef]

- Bian, Z.; Chan, Y.M.; Yu, Y.; Kawi, S. Morphology dependence of catalytic properties of Ni/CeO2 for CO2 methanation:a kinetic and mechanism study. Catal. Today 2020, 347, 31–38. [Google Scholar] [CrossRef]

- Dewangan, N.; Hui, W.M.; Jayaprakash, S.; Bawah, A.-R.; Poerjoto, A.J.; Jie, T.; Ashok, J.; Hidajat, K.; Kawi, S. Recent progress on layered double hydroxide (LDH) derived metal-based catalysts for CO2 conversion to valuable chemicals. Catal. Today 2020, 356, 490–513. [Google Scholar] [CrossRef]

- Hongmanorom, P.; Ashok, J.; Zhang, G.; Bian, Z.; Wai, M.H.; Zeng, Y.; Xi, S.; Borgna, A.; Kawi, S. Enhanced performance and selectivity of CO2 methanation over phyllosilicate structure derived Ni–Mg/SBA-15 catalysts. Appl. Catal. B Environ. 2021, 282, 119564. [Google Scholar] [CrossRef]

- Pati, S.; Ashok, J.; Dewangan, N.; Chen, T.; Kawi, S. Ultra-thin (similar to 1 µm) Pd–Cu membrane reactor for coupling CO2 hydrogenation and propane dehydrogenation applications. J. Membr. Sci. 2020, 595, 117496. [Google Scholar] [CrossRef]

- Yu, Y.; Bian, Z.; Song, F.; Wang, J.; Zhong, Q.; Kawi, S. Influence of calcination temperature on activity and selectivity of Ni–CeO2 and Ni–Ce0.8Zr0.2O2 catalysts for CO2 methanation. Top. Catal. 2018, 61, 1514–1527. [Google Scholar] [CrossRef]

- Yu, Y.; Chan, Y.M.; Bian, Z.; Song, F.; Wang, J.; Zhong, Q.; Kawi, S. Enhanced performance and selectivity of CO2 methanation over g-C3N4 assisted synthesis of Ni–CeO2 catalyst: Kinetics and DRIFTS studies. Int. J. Hydrog. Energy 2018, 43, 15191–15204. [Google Scholar] [CrossRef]

- Poerjoto, A.J.; Ashok, J.; Dewangan, N.; Kawi, S. The role of lattice oxygen in CO2 hydrogenation to methanol over La1–xSrxCuO catalysts. J. CO2 Util. 2021, 47, 101498. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, W.; Li, K.; Zheng, Y.; Xie, Z.; Na, W.; Chen, J.G.; Wang, H. Strong Evidence of the Role of H2O in Affecting Methanol Selectivity from CO2 Hydrogenation over Cu–ZnO–ZrO2. Chem 2020, 6, 419–430. [Google Scholar] [CrossRef]

- Li, Z.; Deng, Y.; Dewangan, N.; Hu, J.; Wang, Z.; Tan, X.; Liu, X.; Kawi, S. High Temperature Water Permeable Membrane Reactors for CO2 Utilization. Chem. Eng. J. 2021, 420, 129834. [Google Scholar] [CrossRef]

- Hongmanorom, P.; Ashok, J.; Chirawatkul, P.; Kawi, S. Interfacial synergistic catalysis over Ni nanoparticles encapsulated in mesoporous ceria for CO2 methanation. Appl. Catal. B Environ. 2021, 297, 120454. [Google Scholar] [CrossRef]

- Ashok, J.; Das, S.; Dewangan, N.; Hongmanorom, P.; Wai, M.H.; Kawi, S. Conversion of CO2 to C-1 chemicals: Catalyst design, kinetics and mechanism aspects of the reactions. Catal. Today 2020, 358, 3–29. [Google Scholar]

- Wai, M.H.; Ashok, J.; Dewangan, N.; Das, S.; Xi, S.; Borgna, A.; Kawi, S. Influence of Surface Formate Species on Methane Selectivity for Carbon Dioxide Methanation over Nickel Hydroxyapatite Catalyst. ChemCatChem 2020, 12, 6410–6419. [Google Scholar] [CrossRef]

- Gao, X.; Li, J.; Zheng, M.; Cai, S.; Zhang, J.; Askari, S.; Dewangan, N.; Ashok, J.; Kawi, S. Recent progress in anti-coking Ni catalysts for thermo-catalytic conversion of greenhouse gases. Process Saf. Environ. 2021, 156, 598–616. [Google Scholar] [CrossRef]

- Wang, W.; Wang, S.; Ma, X.; Gong, J. Recent advances in catalytic hydrogenation of carbon dioxide. Chem. Soc. Rev. 2011, 40, 3703–3727. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Yi, Y.; Guo, H.; Tu, X. Atmospheric pressure and room temperature synthesis of methanol through plasma–catalytic hydrogenation of CO2. ACS Catal. 2018, 8, 90–100. [Google Scholar] [CrossRef]

- Eliasson, B.; Kogelschatz, U.; Xue, B.; Zhou, L.-M. Hydrogenation of carbon dioxide to methanol with a discharge-activated catalyst. Ind. Eng. Chem. Res. 1998, 37, 3350–3357. [Google Scholar] [CrossRef]

- De Bie, C.; van Dijk, J.; Bogaerts, A. CO2 hydrogenation in a dielectric barrier discharge plasma revealed. J. Phys. Chem. C 2016, 120, 25210–25224. [Google Scholar] [CrossRef]

- Zhao, B.; Liu, Y.; Zhu, Z.; Guo, H.; Ma, X. Highly selective conversion of CO2 into ethanol on Cu/ZnO/Al2O3 catalyst with the assistance of plasma. J. CO2 Util. 2018, 24, 34–39. [Google Scholar] [CrossRef]

- Dębek, R.; Azzolina-Jury, F.; Travert, A.; Maug, F. A review on plasma-catalytic methanation of carbon dioxide—Looking for an efficient catalyst. Renew. Sust. Energ. Rev. 2019, 116, 109427. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, Z.; Das, S.; Kawi, S. Reforming of tar from biomass gasification in a hybrid catalysis–plasma system: A review. Appl. Catal. B Environ. 2019, 250, 250–272. [Google Scholar] [CrossRef]

- Li, Z.; Lin, Q.; Li, M.; Cao, J.; Liu, F.; Pan, H.; Wang, Z.; Kawi, S. Recent advances in process and catalyst for CO2 reforming of methane. Renew. Sust. Energ. Rev. 2020, 134, 110312. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, Z.; Das, S.; Xi, S.; Kawi, S. LaNiO3 as a precursor of Ni/La2O3 for reverse water–gas shift in DBD plasma: Effect of calcination temperature. Energy Convers. Manag. 2020, 206, 112475. [Google Scholar] [CrossRef]

- Ashok, J.; Kawi, S. Low-temperature biomass tar model reforming over perovskite materials with DBD plasma: Role of surface oxygen mobility. Energ. Convers. Manag. 2021, 248, 114802. [Google Scholar] [CrossRef]

- Kawi, S.; Ashok, J.; Dewangan, N.; Pati, S.; Chen, J. Recent Advances in Catalyst Technology for Biomass Tar Model Reforming: Thermal, Plasma and Membrane Reactors. Waste Biomass Valori. 2021. [Google Scholar] [CrossRef]

- Liu, L.; Das, S.; Chen, T.; Dewangan, N.; Ashok, J.; Xi, S.; Borgna, A.; Li, Z.; Kawi, S. Low temperature catalytic reverse water-gas shift reaction over perovskite catalysts in DBD plasma. Appl. Catal. B Environ. 2020, 265, 118573. [Google Scholar] [CrossRef]

- Kawi, S.; Kathiraser, Y.; Ni, J.; Oemar, U.; Li, Z.; Saw, E.T. Progress in Synthesis of Highly Active and Stable Nickel-Based Catalysts for Carbon Dioxide Reforming of Methane. ChemSusChem 2015, 8, 3556–3575. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, D.H.; Kim, T. Enhancement of methanation of carbon dioxide using dielectric barrier discharge on a ruthenium catalyst at atmospheric conditions. Catal. Today 2017, 293–294, 97–104. [Google Scholar] [CrossRef]

- Bogaerts, A.; Kozák, T.; van Laer, K.; Snoeckx, R. Plasma-based conversion of CO2: Current status and future challenges. Faraday Discuss. 2015, 183, 217–232. [Google Scholar] [CrossRef]

- Gao, X.; Lin, Z.; Li, T.; Huang, L.; Zhang, J.; Askari, S.; Dewangan, N.; Ashok, J.; Kawi, S. Recent Developments in Dielectric Barrier Discharge Plasma-Assisted Catalytic Dry Reforming of Methane over Ni-Based Catalysts. Catalysts 2021, 11, 455. [Google Scholar] [CrossRef]

- Yuan, H.; Zhu, X.; Han, J.; Wang, H.; Ge, Q. Rhenium-promoted selective CO2 methanation on Ni-based catalyst. J. CO2 Util. 2018, 26, 8–18. [Google Scholar] [CrossRef]

- Kattel, S.; Yan, B.; Chen, J.G.; Liu, P. CO2 hydrogenation on Pt, Pt/SiO2 and Pt/TiO2: Importance of synergy between Pt and oxide support. J. Catal. 2016, 343, 115–126. [Google Scholar] [CrossRef] [Green Version]

- Bogaerts, A.; Neyts, E.; Gijbels, R.; Van der Mullen, J. Gas discharge plasmas and their applications. Spectrochim. Acta Part B 2002, 57, 609–658. [Google Scholar] [CrossRef]

- Chen, H.L.; Lee, H.M.; Chen, S.H.; Chang, M.B.; Yu, S.J.; Li, S.N. Removal of Volatile Organic Compounds by Single-Stage and Two-Stage Plasma Catalysis Systems: A Review of the Performance Enhancement Mechanisms, Current Status, and Suitable Applications. Environ. Sci. Technol. 2009, 43, 2216–2227. [Google Scholar] [CrossRef]

- Patil, B.S.; Cherkasov, N.; Lang, J.; Ibhadon, A.O.; Hessel, V.; Wang, Q. Low temperature plasma–catalytic NOx synthesis in a packed DBD reactor: Effect of support materials and supported active metal oxides. Appl. Catal. B Environ. 2016, 194, 123–133. [Google Scholar] [CrossRef] [Green Version]

- Suttikul, T.; Nuchdang, S.; Rattanaphra, D.; Phalakornkule, C. Influence of Operating Parameters, Al2O3 and Ni/Al2O3 Catalysts on Plasma Assisted CO2 Reforming of CH4 in a Parallel Plate Dielectric Barrier Discharge for High H2/CO Ratio Syngas Production. Plasma Chem. Plasma Process. 2020, 40, 1445–1463. [Google Scholar] [CrossRef]

- Whitehead, J.C. Plasma–catalysis: The known knowns, the known unknowns and the unknown unknowns. J. Phys. D Appl. Phys. 2016, 49, 243001. [Google Scholar] [CrossRef]

- Ahmad, F.; Lovell, E.C.; Masood, H.; Cullen, P.J.; Ostrikov, K.K.; Scott, J.A.; Amal, R. Low-temperature CO2 methanation: Synergistic effects in plasma–Ni hybrid catalytic system. ACS Sustain. Chem. Eng. 2020, 8, 1888–1898. [Google Scholar] [CrossRef]

- Neyts, E.C. Plasma–surface interactions in plasma catalysis. Plasma Chem. Plasma Process. 2015, 36, 185–212. [Google Scholar] [CrossRef]

- Mikhail, M.; Wang, B.; Jalain, R.; Cavadias, S.; Tatoulian, M.; Ognier, S.; Gálvez, M.E.; da Costa, P. Plasma–catalytic hybrid process for CO2 methanation: Optimization of operation parameters. React. Kinet. Mech. Catal. 2019, 126, 629–643. [Google Scholar] [CrossRef]

- Debek, R.; Wierzbicki, D.; Motak, M.; Galvez, M.E.; Costa, P.D.; Azzolina-Jury, F. Operando FT-IR study on basicity improvement of Ni(Mg,Al)O hydrotalcite-derived catalysts promoted by glow plasma discharge. Plasma Sci. Technol. 2019, 21, 045503. [Google Scholar] [CrossRef]

- Dębek, R.; Azzolina-Jury, F.; Travert, A.; Maugé, F.; Thibault-Starzyk, F. Low-pressure glow discharge plasma-assisted catalytic CO2 hydrogenation – the effect of metal oxide support on the performance of the Ni-based catalyst. Catal. Today 2019, 337, 182–194. [Google Scholar] [CrossRef]

- Parastaev, A.; Hoeben, W.F.L.M.; van Heesch, B.E.J.M.; Kosinov, N.; Hensen, E.J.M. Temperature-programmed plasma surface reaction: An approach to determine plasma–catalytic performance. Appl. Catal. B Environ. 2018, 239, 168–177. [Google Scholar] [CrossRef]

- Men, Y.-L.; Liu, Y.; Wang, Q.; Luo, Z.-H.; Shao, S.; Li, Y.-B.; Pan, Y.-X. Highly dispersed Pt-based catalysts for selective CO2 hydrogenation to methanol at atmospheric pressure. Chem. Eng. Sci. 2019, 200, 167–175. [Google Scholar] [CrossRef]

- Liao, F.; Wu, X.P.; Zheng, J.; Li, M.M.J.; Kroner, A.; Zeng, Z.; Hong, X.; Yuan, Y.; Gong, X.Q.; Tsang, S.C.E. A promising low pressure methanol synthesis route from CO2 hydrogenation over Pd@Zn core–shell catalysts. Green Chem. 2017, 19, 270–280. [Google Scholar] [CrossRef]

- Zeng, Y.; Tu, X. Plasma–catalytic hydrogenation of CO2 for the cogeneration of CO and CH4 in a dielectric barrier discharge reactor: Effect of argon addition. J. Phys. D Appl. Phys. 2017, 50, 184004. [Google Scholar] [CrossRef]

- Zhang, S.; Li, L.; Zhao, S.; Sun, Z.; Luo, J. Construction of Interpenetrated Ruthenium Metal–Organic Frameworks as Stable Photocatalysts for CO2 Reduction. Inorg. Chem. 2015, 54, 8375–8379. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Zhang, X.; Dong, M.; Zhao, J.; Di, L. Plasma-assisted Ru/Zr-MOF catalyst for hydrogenation of CO2 to methane. Plasma Sci. Technol. 2019, 21, 044004. [Google Scholar] [CrossRef]

- Lan, L.; Wang, A.; Wang, Y. CO2 hydrogenation to lower hydrocarbons over ZSM-5-supported catalysts in a dielectric-barrier discharge plasma reactor. Catal. Commun. 2019, 130, 105761. [Google Scholar] [CrossRef]

- Wang, J.; AlQahtani, M.S.; Wang, X.; Knecht, S.D.; Bilén, S.G.; Song, C.; Chu, W. One-step plasma-enabled catalytic carbon dioxide hydrogenation to higher hydrocarbons: Significance of catalyst-bed configuration. Green Chem. 2021, 23, 1642–1647. [Google Scholar] [CrossRef]

- Chen, H.; Mu, Y.; Shao, Y.; Chansai, S.; Xiang, H.; Jiao, Y.; Hardacre, C.; Fan, X. Nonthermal plasma (NTP) activated metal–organic frameworks (MOFs) catalyst for catalytic CO2 hydrogenation. AIChE J. 2020, 66, e16853. [Google Scholar] [CrossRef]

- Bacariza, M.C.; Biset-Peiró, M.; Graça, I.; Guilera, J.; Morante, J.; Lopes, J.M.; Andreu, T.; Henriques, C. DBD plasma-assisted CO2 methanation using zeolite-based catalysts: Structure composition–reactivity approach and effect of Ce as promoter. J. CO2 Util. 2018, 26, 202–211. [Google Scholar] [CrossRef]

- Biset-Peiró, M.; Guilera, J.; Zhang, T.; Arbiol, J.; Andreu, T. On the role of ceria in Ni–Al2O3 catalyst for CO2 plasma methanation. Appl. Catal. A Gen. 2019, 575, 223–229. [Google Scholar] [CrossRef]

- Chen, H.; Mu, Y.; Shao, Y.; Chansai, S.; Xu, S.; Stere, C.E.; Xiang, H.; Zhang, R.; Jiao, Y.; Hardacre, C.; et al. Coupling non-thermal plasma with Ni catalysts supported on BETA zeolite for catalytic CO2 methanation. Catal. Sci. Technol. 2019, 9, 4135–4145. [Google Scholar] [CrossRef]

- Wierzbicki, D.; Moreno, M.V.; Ognier, S.; Motak, M.; Grzybek, T.; Da Costa, P.; Gálvez, M.E. Ni-Fe layered double hydroxide derived catalysts for non-plasma and DBD plasma-assisted CO2 methanation. Int. J. Hydrog. Energy 2020, 45, 10423–10432. [Google Scholar] [CrossRef]

- Mikhail, M.; Da Costa, P.; Amouroux, J.; Cavadias, S.; Tatoulian, M.; Ognier, S.; Gálvez, M.E. Effect of Na and K impurities on the performance of Ni/CeZrOx catalysts in DBD plasma–catalytic CO2 methanation. Fuel 2021, 306, 121639. [Google Scholar] [CrossRef]

- Kattel, S.; Yan, B.; Yang, Y.; Chen, J.G.; Liu, P. Optimizing Binding Energies of Key Intermediates for CO2 Hydrogenation to Methanol over Oxide-Supported Copper. J. Am. Chem. Soc. 2016, 138, 12440–12450. [Google Scholar] [CrossRef] [PubMed]

- Xiao, S.; Zhang, Y.; Gao, P.; Zhong, L.; Li, X.; Zhang, Z.; Wang, H.; Wei, W.; Sun, Y. Highly efficient Cu-based catalysts via hydrotalcite-like precursors for CO2 hydrogenation to methanol. Catal. Today 2017, 281, 327–336. [Google Scholar] [CrossRef]

- Behrens, M.; Studt, F.; Kasatkin, I.; Kühl, S.; Hävecker, M.; Abild-Pedersen, F.; Zander, S.; Girgsdies, F.; Kurr, P.; Kniep, B.-L.; et al. The Active Site of Methanol Synthesis over Cu/ZnO/Al2O3 Industrial Catalysts. Science 2012, 336, 893–897. [Google Scholar] [CrossRef]

- Fichtl, M.B.; Schumann, J.; Kasatkin, I.; Jacobsen, N.; Behrens, M.; Schlögl, R.; Muhler, M.; Hinrichsen, O. Counting of Oxygen Defects versus Metal Surface Sites in Methanol Synthesis Catalysts by Different Probe Molecules. Angew. Chem. Int. Ed. 2014, 53, 7043–7047. [Google Scholar] [CrossRef]

- Studt, F.; Sharafutdinov, I.; Abild-Pedersen, F.; Elkjar, C.F.; Hummelshoj, J.S.; Dahl, S.; Chorkendorff, I.; Norskov, J.K. Discovery of a Ni–Ga catalyst for carbon dioxide reduction to methanol. Nat. Chem. 2014, 6, 320–324. [Google Scholar] [CrossRef] [PubMed]

- Feliz, M.Q.; Polaert, I.; Ledoux, A.; Fernandez, C.; Azzolina-Jury, F. Influence of ionic conductivity and dielectric constant of the catalyst on DBD plasma-assisted CO2 hydrogenation into methanol. J. Phys. D Appl. Phys. 2021, 54, 334003. [Google Scholar] [CrossRef]

- Zeng, Y.; Tu, X. Plasma–Catalytic CO2 Hydrogenation at Low Temperatures. IEEE T. Plasma Sci. 2016, 44, 405–411. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Cundari, T.R.; Wilson, A.K. Reaction mechanism of the reverse water–gas shift reaction using first-row middle transition metal catalysts L’M (M = Fe, Mn, Co): A computational study. Inorg. Chem. 2011, 50, 8782–8789. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Gong, J. Methanation of carbon dioxide: An overview. Front. Chem. Sci. Eng. 2011, 5, 2–10. [Google Scholar]

- Saeidi, S.; Aishah, N.; Amin, S.; Rahimpour, M.R. Hydrogenation of CO2 to valueadded products—A review and potential future developments. Biochem. Pharmacol. 2014, 5, 66–81. [Google Scholar]

- Vosoughi, V.; Dalai, A.K.; Abatzoglou, N.; Hu, Y. Performances of promoted cobalt catalysts supported on mesoporous alumina for Fischer–Tropsch synthesis. Appl. Catal. A Gen. 2017, 547, 155–163. [Google Scholar] [CrossRef]

- Azzolina-Jury, F.; Bento, D.; Henriques, C.; Thibault-Starzyk, F. Chemical Engineering Aspects of Plasma-Assisted CO2 hydrogenation over Nickel Zeolites under Partial Vacuum. J. CO2 Util. 2017, 22, 97–109. [Google Scholar] [CrossRef]

- Benrabbah, R.; Cavaniol, C.; Liu, H.; Ognier, S.; Cavadias, S.; Gálvez, M.E.; Da Costa, P. Plasma DBD Activated Ceria–Zirconia-Promoted Ni-Catalysts for Plasma Catalytic CO2 hydrogenation at Low Temperature. Catal. Commun. 2017, 89, 73–76. [Google Scholar] [CrossRef] [Green Version]

- Bal, K.M.; Huygh, S.; Bogaerts, A.; Neyts, E.C. Effect of Plasma-Induced Surface Charging on Catalytic Processes: Application to CO2 activation. Plasma Sources mnopSci. Technol. 2018, 27, 024001. [Google Scholar] [CrossRef]

- Kim, J.; Abbott, M.S.; Go, D.B.; Hicks, J.C. Enhancing C−H Bond Activation of Methane via Temperature-Controlled, Catalyst−Plasma Interactions. ACS Energy Lett. 2016, 1, 94–99. [Google Scholar] [CrossRef]

- Jiang, N.; Qiu, C.; Guo, L.; Shang, K.; Lu, N.; Li, J.; Zhang, Y.; Wu, Y. Plasma-Catalytic Destruction of Xylene over Ag–Mn Mixed Oxides in a Pulsed Sliding Discharge Reactor. J. Hazard. Mater. 2019, 369, 611–620. [Google Scholar] [CrossRef]

- Mehta, P.; Barboun, P.; Go, D.B.; Hicks, J.C.; Schneider, W.F. Catalysis Enabled by Plasma Activation of Strong Chemical Bonds: A Review. ACS Energy Lett. 2019, 4, 1115–1133. [Google Scholar] [CrossRef]

- Wang, X.; Shi, H.; Szanyi, J. Controlling Selectivities in CO2 Reduction through Mechanistic Understanding. Nat. Commun. 2017, 8, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Shirazi, M.; Bogaerts, A.; Neyts, E.C. A DFT Study of H-Dissolution into the Bulk of a Crystalline Ni(111) Surface: A Chemical Identifier for the Reaction Kinetics. Phys. Chem. Chem. Phys. 2017, 19, 19150–19158. [Google Scholar] [CrossRef] [Green Version]

- Shirazi, M.; Neyts, E.C.; Bogaerts, A. DFT Study of Ni-Catalyzed Plasma Dry Reforming of Methane. Appl. Catal. B Environ. 2017, 205, 605–614. [Google Scholar] [CrossRef]

- Butterworth, T.; Elder, R.; Allen, R. Effects of Particle Size on CO2 reduction and Discharge Characteristics in a Packed Bed Plasma Reactor. Chem. Eng. J. 2016, 293, 55–67. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.R.; Neyts, E.C.; Bogaerts, A. Influence of the Material Dielectric Constant on Plasma Generation inside Catalyst Pores. J. Phys. Chem. C 2016, 120, 25923–25934. [Google Scholar] [CrossRef]

- Jwa, E.; Lee, S.B.; Lee, H.W.; Mok, Y.S. Plasma-assisted catalytic methanation of CO and CO2 over Ni–zeolite catalysts. Fuel Process. Technol. 2013, 108, 89–93. [Google Scholar] [CrossRef]

- Chen, H.; Goodarzi, F.; Mu, Y.; Chansai, S.; Mielby, J.J.; Mao, B.; Sooknoi, T.; Hardacre, C.; Kegnæs, S.; Fan, X. Effect of metal dispersion and support structure of Ni/silicalite-1 catalysts on non-thermal plasma (NTP) activated CO2 hydrogenation. Appl. Catal. B Environ. 2020, 272, 119013. [Google Scholar] [CrossRef]

- Whitehead, J.C. Plasma–catalysis: Is it just a question of scale? Front. Chem. Sci. Eng. 2019, 13, 264–273. [Google Scholar] [CrossRef] [Green Version]

- Christensen, P.A.; Ali, A.H.B.M.; Mashhadani, Z.T.A.W.; Carroll, M.A.; Martin, P.A. The Production of Ketene and C5O2 from CO2, N2 and CH4 in a Non-thermal Plasma Catalysed by Earth-Abundant Elements: An In-Situ FTIR Study. Plasma Chem. Plasma Process. 2018, 38, 461–484. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.; Liu, Y.; Zhao, B.; Wang, Z.; Wang, Y.; Liu, C.-J. Methanation over Ni/SiO2: Effect of the catalyst preparation methodologies. Int. J. Hydrog. Energy 2013, 38, 2283–2291. [Google Scholar] [CrossRef]

- Fan, Z.; Sun, K.; Rui, N.; Zhao, B.; Liu, C.-J. Improved activity of Ni/MgAl2O4 for CO2 methanation by the plasma decomposition. J. Energy Chem. 2015, 24, 655–659. [Google Scholar] [CrossRef]

- Neyts, E.C.; Bogaerts, A. Understanding plasma catalysis through modelling and simulation—A review. J. Phys. D Appl. Phys. 2014, 47, 224010. [Google Scholar] [CrossRef]

- Butterworth, T.; Allen, R.W.K. Plasma–catalyst interaction studied in a single pellet DBD reactor: Dielectric constant effect on plasma dynamics. Plasma Sources Sci. Technol. 2017, 26, 065008. [Google Scholar] [CrossRef]

- Mei, D.; Zhu, X.; He, Y.-L.; Yan, J.D.; Tu, X. Plasma-assisted conversion of CO2 in a dielectric barrier discharge reactor: Understanding the effect of packing materials. Plasma Sources Sci. Technol. 2014, 24, 015011. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Kim, H.-H.; van Laer, K.; Bogaerts, A. Streamer propagation in a packed bed plasma reactor for plasma catalysis applications. Chem. Eng. J. 2018, 334, 2467–2479. [Google Scholar] [CrossRef]

- Nilsson, M.; Jozsa, P.; Pettersson, L.J. Evaluation of Pd-based catalysts and the influence of operating conditions for autothermal reforming of dimethyl ether. Appl. Catal. B Environ. 2007, 76, 42–50. [Google Scholar] [CrossRef]

- Kuld, S.; Thorhauge, M.; Falsig, H.; Elkjær, C.F.; Helveg, S.; Chorkendorff, I.; Sehested, J. Quantifying the promotion of Cu catalysts by ZnO for methanol synthesis. Science 2016, 352, 969–974. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.; Sun, Y.; Wang, B.; Xiao, H.; Wu, J.; Chen, L.; Fu, M.; Ye, D. Effect of plasma on catalytic conversion of CO2 with hydrogen over Pd/ZnO in a dielectric barrier discharge reactor. J. Phys. D Appl. Phys. 2019, 52, 244001. [Google Scholar] [CrossRef]

- Jo, S.; Kim, T.; Lee, D.H.; Kang, W.S.; Song, Y.-H. Effect of the electric conductivity of a catalyst on methane activation in a dielectric barrier discharge reactor. Plasma Chem. Plasma Process. 2014, 34, 175–186. [Google Scholar] [CrossRef]

- Nizio, M.; Albarazi, A.; Cavadias, S.; Amouroux, J.; Galvez, M.E.; Da Costa, P. Hybrid plasma–catalytic methanation of CO2 at low temperature over ceria zirconia supported Ni catalysts. Int. J. Hydrog. Energy 2016, 41, 11584–11592. [Google Scholar] [CrossRef] [Green Version]

- Pan, Q.; Peng, J.; Wang, S.; Wang, S. In situ FTIR spectroscopic study of the CO2 methanation mechanism on Ni/Ce0.5Zr0.5O2. Catal. Sci. Technol. 2014, 4, 502–509. [Google Scholar] [CrossRef]

- Aldana, P.A.U.; Ocampo, F.; Kobl, K.; Louis, B.; Thibault-Starzyk, F.; Daturi, M.; Bazin, P.; Thomas, S.; Roger, A.C. Catalytic CO2 valorization into CH4 on Ni-based ceria–zirconia. Reaction mechanism by operando IR spectroscopy. Catal. Today 2013, 215, 201–207. [Google Scholar] [CrossRef]

- Nizio, M.; Benrabbah, R.; Krzak, M.; Debek, R.; Motak, M.; Cavadias, S.; Gálvez, M.E.; Da Costa, P. Low temperature hybrid plasma–catalytic methanation over Ni–Ce–Zr hydrotalcite-derived catalysts. Catal. Commun. 2016, 83, 14–17. [Google Scholar] [CrossRef] [Green Version]

- Yang, Q.; Zhang, H.-Y.; Wang, L.; Zhang, Y.; Zhao, J. Ru/UiO-66 catalyst for the reduction of nitroarenes and tandem reaction of alcohol oxidation/Knoevenagel condensation. ACS Omega 2018, 3, 4199–4212. [Google Scholar] [CrossRef] [PubMed]

- Cavka, J.H.; Jakobsen, S.; Olsbye, U.; Guillou, N.; Lamberti, C.; Bordiga, S.; Lillerud, K.P. A new zirconium inorganic building brick forming metal organic frameworks with exceptional stability. J. Am. Chem. Soc. 2008, 130, 13850–13851. [Google Scholar] [CrossRef] [PubMed]

- Hester, P.; Xu, S.; Liang, W.; Al-Janabi, N.; Vakili, R.; Hill, P.; Muryn, C.A.; Chen, X.; Martin, P.A.; Fan, X. On thermal stability and catalytic reactivity of Zr-based metal–organic framework (UiO-67) encapsulated Pt catalysts. J. Catal. 2016, 340, 85–94. [Google Scholar] [CrossRef]

- Corma, A.; García, H.; Llabrés i Xamena, F.X. Engineering metal organic frameworks for heterogeneous catalysis. Chem. Rev. 2010, 110, 4606–4655. [Google Scholar] [CrossRef]

- Xu, S.; Chansai, S.; Stere, C.; Inceesungvorn, B.; Goguet, A.; Wangkawong, K.; Rebecca Taylor, S.F.; Al-Janabi, N.; Hardacre, C.; Martin, P.A.; et al. Sustaining metal–organic frameworks for water–gas shift catalysis by non-thermal plasma. Nat. Catal. 2019, 2, 142–148. [Google Scholar] [CrossRef] [Green Version]

- Rani, P.; Srivastava, R. Tailoring the catalytic activity of metal organic frameworks by tuning the metal center and basic functional sites. New J. Chem. 2017, 41, 8166–8177. [Google Scholar] [CrossRef]

- Teeparthi, S.R.; Awin, E.W.; Kumar, R. Dominating role of crystal structure over defect chemistry in black and white zirconia on visible light photocatalytic activity. Sci. Rep. 2018, 8, 5541. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, A.; Ying, W.; Zhang, H.; Ma, H.; Fang, D. Ni–Al2O3 catalysts prepared by solution combustion method for syngas methanation. Catal. Commun. 2012, 17, 34–38. [Google Scholar] [CrossRef]

- Tada, S.; Shimizu, T.; Kameyama, H.; Haneda, T.; Kikuchi, R. Ni/CeO2 catalysts with high CO2 methanation activity and high CH4 selectivity at low temperatures. Int. J. Hydrog. Energy 2011, 37, 5527–5531. [Google Scholar] [CrossRef]

- Pan, Q.; Peng, J.; Sun, T.; Wang, S.; Wang, S. Insight into the reaction route of CO2 methanation: Promotion effect of medium basic sites. Catal. Commun. 2014, 45, 74–78. [Google Scholar] [CrossRef]

- Azzolina-Jury, F.; Thibault-Starzyk, F. Mechanism of Low Pressure Plasma-Assisted CO2 Hydrogenation Over Ni-USY by Microsecond Time-resolved FTIR Spectroscopy. Top. Catal. 2017, 60, 1709–1721. [Google Scholar] [CrossRef]

- Rahmani, F.; Haghighi, M.; Estifaee, P. Synthesis and characterization of Pt/Al2O3–CeO2 nanocatalyst used for toluene abatement from waste gas streams at low temperature: Conventional vs. plasma–ultrasound hybrid synthesis methods. Microporous Mesoporous Mater. 2014, 185, 213–223. [Google Scholar] [CrossRef]

- Liu, X.; Wang, M.; Zhou, C.; Zhou, W.; Cheng, K.; Kang, J.; Zhang, Q.; Deng, W.; Wang, Y. Selective transformation of carbon dioxide into lower olefins with a bifunctional catalyst composed of ZnGa2O4 and SAPO-34. Chem. Commun. 2017, 54, 140–143. [Google Scholar] [CrossRef] [PubMed]

- Shinde, V.M.; Madras, G. Nanostructured Pd modified Ni/CeO2 catalyst for water gas shift and catalytic hydrogen combustion reaction. Appl. Catal. B Environ. 2013, 132–133, 28–38. [Google Scholar] [CrossRef]

- Bian, L.; Zhang, L.; Xia, R.; Li, Z. Enhanced low-temperature CO2 methanation activity on plasma-prepared Ni-based catalyst. J. Nat. Gas. Sci. Eng. 2015, 27, 1189–1194. [Google Scholar] [CrossRef]

- Ray, D.; Chawdhury, P.; Bhargavi, K.V.S.S.; Thatikonda, S.; Lingaiah, N.; Subrahmanyam, C. Ni and Cu oxide supported γ-Al2O3 packed DBD plasma reactor for CO2 activation. J. CO2 Util. 2021, 44, 101400. [Google Scholar] [CrossRef]

- Schild, C.; Wokaun, A.; Baiker, A. Surface species in CO2 methanation over amorphous palladium/zirconia catalysts. J. Mol. Catal. 1991, 69, 347–357. [Google Scholar] [CrossRef]

- Wang, X.; Shi, H.; Kwak, J.H.; Szanyi, J. Mechanism of CO2 Hydrogenation on Pd/Al2O3 Catalysts: Kinetics and Transient DRIFTS–MS Studies. ACS Catal. 2015, 5, 6337–6349. [Google Scholar] [CrossRef]

- Mikhail, M.; Da Costa, P.; Amouroux, J.; Cavadias, S.; Tatoulian, M.; Ognier, S.; Gálvez, M.E. Electrocatalytic behaviour of CeZrOx-supported Ni catalysts in plasma assisted CO2 methanation. Catal. Sci. Technol. 2020, 10, 4532–4543. [Google Scholar] [CrossRef]

- Ramakers, M.; Michielsen, I.; Aerts, R.; Meynen, V.; Bogaerts, A. Effect of Argon or Helium on the CO2 Conversion in a Dielectric Barrier Discharge. Plasma Process. Polym. 2015, 12, 755–763. [Google Scholar] [CrossRef]

- Zhang, Y.-P.; Ma, P.-S.; Zhu, X.; Liu, C.-J.; Shen, Y. A novel plasma-treated Pt/NaZSM-5 catalyst for NO reduction by methane. Catal. Commun. 2004, 5, 35–39. [Google Scholar] [CrossRef]

- Amouroux, J.; Cavadias, S. Electrocatalytic reduction of carbon dioxide under plasma DBD process. J. Phys. D Appl. Phys. 2017, 50, 465501. [Google Scholar] [CrossRef] [Green Version]

- Brooks, K.P.; Hu, J.; Zhu, H.; Kee, R.J. Methanation of carbon dioxide by hydrogen reduction using the Sabatier process in microchannel reactors. Chem. Eng. Sci. 2007, 62, 1161–1170. [Google Scholar] [CrossRef]

- Ocampo, F.; Louis, B.; Roger, A.-C. Methanation of carbon dioxide over nickel-based Ce0.72Zr0.28O2 mixed oxide catalysts prepared by sol–gel method. Appl. Catal. A Gen. 2009, 369, 90–96. [Google Scholar] [CrossRef]

- Jiang, T.; Li, Y.; Liu, C.-J.; Xu, G.-H.; Eliasson, B.; Xue, B. Plasma methane conversion using dielectric-barrier discharges with zeolite A. Catal. Today 2002, 72, 229–235. [Google Scholar] [CrossRef]

- Abate, S.; Mebrahtu, C.; Giglio, E.; Deorsola, F.; Bensaid, S.; Perathoner, S.; Pirone, R.N.; Centi, G. Catalytic Performance of γ-Al2O3–ZrO2–TiO2–CeO2 Composite Oxide Supported Ni-Based Catalysts for CO2 Methanation. Ind. Eng. Chem. Res. 2016, 55, 4451–4460. [Google Scholar] [CrossRef]

- Chung, W.-C.; Chang, M.-B. Dry reforming of methane by combined spark discharge with a ferroelectric. Energy Convers. Manag. 2016, 124, 305–314. [Google Scholar] [CrossRef] [Green Version]

- Biset-Peiró, M.; Mey, R.; Guilera, J.; Andreu, T. Adiabatic plasma-catalytic reactor configuration: Energy efficiency enhancement by plasma and thermal synergies on CO2 methanation. Chem. Eng. J. 2020, 393, 124786. [Google Scholar] [CrossRef]

- Chen, H.; Mu, Y.; Hardacre, C.; Fan, X. Integration of Membrane Separation with Nonthermal Plasma Catalysis: A Proof-of-Concept for CO2 Capture and Utilization. Ind. Eng. Chem. Res. 2020, 59, 8202–8211. [Google Scholar] [CrossRef]

- Poshusta, J.C.; Tuan, V.A.; Falconer, J.L.; Noble, R.D. Synthesis and permeation properties of SAPO-34 tubular membranes. Ind. Eng. Chem. Res. 1998, 37, 3924–3929. [Google Scholar] [CrossRef]

- Li, S.; Falconer, J.L.; Noble, R.D. SAPO-34 membranes for CO2/CH4 separation. J. Membr. Sci. 2004, 241, 121–135. [Google Scholar] [CrossRef]

- Liao, Y.; Zhong, W.; Qian, M.; Liu, S.; Zhang, J.; Wang, D. Numerical study on the reaction mechanism of CO2 hydrogenation in atmospheric-pressure dielectric barrier discharge. J. Appl. Phys. 2020, 128, 233303. [Google Scholar] [CrossRef]

- Gordon, E.; Ivanov, B.; Perminov, A.; Balalaev, V. A measurement of formation rates and lifetimes of intermediate complexes in reversible chemical reactions involving hydrogen atoms. Chem. Phys. 1978, 35, 79–89. [Google Scholar] [CrossRef]

- Mu, Y.; Xu, S.; Shao, Y.; Chen, H.; Hardacre, C.; Fan, X. Kinetic Study of Nonthermal Plasma Activated Catalytic CO2 Hydrogenation over Ni Supported on Silica Catalyst. Ind. Eng. Chem. Res. 2020, 59, 9478–9487. [Google Scholar] [CrossRef]

| Catalyst | Targeted Product | H2/CO2 | CO2 Conversion (%) | Selectivity (%) | Applied Voltage (kV) | Ref. |

|---|---|---|---|---|---|---|

| Pt/In2O3 | CH3OH | 3 | 37 | 62.6 | 13.3 | [53] |

| Co/CeZrO4 | CH4 | 4 | 70 | 100 | 20 | [52] |

| Co/ZSM-5 | C2-C4 | 3 | 45 | 13.7 | 10 | [58] |

| Ni/Al2O3 | CH4 | 4 | 60 | 97 | 10 | [47] |

| Co/Al2O3 | C2+ | 3 | 74 | 46.5 | 18.5 | [59] |

| Ni/UiO-66 | CH4 | 4 | 85 | 99 | 6.5 | [60] |

| CeNi/Cs–USY | CH4 | 4 | 70 | 95 | 6 | [61] |

| Ni-CeO2/Al2O3 | CH4 | 4 | 70 | 96 | 7.7 | [62] |

| Ni–La/Na–BETA | CH4 | 4 | 85 | 97 | 6 | [63] |

| Ni–Fe/LDH | CH4 | 4 | 72 | 99 | 18 | [64] |

| Ni–Na/CeZrOx | CH4 | 4 | 57.5 | 75.9 | 15 | [65] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Liang, J.; Wu, L.; Wu, L.; Kawi, S. Dielectric Barrier Discharge Plasma-Assisted Catalytic CO2 Hydrogenation: Synergy of Catalyst and Plasma. Catalysts 2022, 12, 66. https://doi.org/10.3390/catal12010066

Gao X, Liang J, Wu L, Wu L, Kawi S. Dielectric Barrier Discharge Plasma-Assisted Catalytic CO2 Hydrogenation: Synergy of Catalyst and Plasma. Catalysts. 2022; 12(1):66. https://doi.org/10.3390/catal12010066

Chicago/Turabian StyleGao, Xingyuan, Jinglong Liang, Liqing Wu, Lixia Wu, and Sibudjing Kawi. 2022. "Dielectric Barrier Discharge Plasma-Assisted Catalytic CO2 Hydrogenation: Synergy of Catalyst and Plasma" Catalysts 12, no. 1: 66. https://doi.org/10.3390/catal12010066