Developing Ubiquitous Sensor Network Platform Using Internet of Things: Application in Precision Agriculture

Abstract

:1. Introduction

2. Related Work

- Initial expectations and advantages promised unfulfilled. The farming community strongly endorse the adoption of PA technology to manage variability within paddocks. Nevertheless they have become frustrated with the technology, lack of support mainly, and this is the main impediment for PA to be adopted [11]. At a practical level, farmers need to gain the confidence in how to deal with variability and work in partnership with PA specialists

- Complexity of technology and incompatibility of components. The rate of adoption of PA is expected to continue to rise based on greater awareness of the benefits of the technology. There are constraints to adapt the technical issues with equipment and software and the incompatibility of equipment with existing farm operations [12].

- Lack of products. The PA integration has been delayed, in part, due to the lack of products that bring together engineering and agronomics. In [13] this situation has been presented. One solution (proposed in this paper) is to integrate data collection, data processing, and management actions.

- High costs in start-up and maintenance of the facility. There are high start-up and maintenance costs in PA adoption, in some cases with a risk of insufficient return on the investment. In [14], German farmers were interviewed about their experiences with PA technology and their attitudes and barriers towards it, the majority of the interviewed farmers hesitated to introduce PA techniques mainly because of the high costs of the technology.

2.1. IoT Precision Agriculture

2.2. First Conclusions

- Current proposals use conventional automated systems on web services.

- Different PA IoT models are proposed using three levels: control, communication and application layer (cloud services). These models have yet to be put into practice and tested with real applications.

- Agricultural production controlled by agronomist and methods to develop low-cost prototypes are not available.

- Response time controlled on multi-protocol integration is unusual.

- Industrial applications are available. High costs, and the high-level of expertise required for controlling and maintaining are some of the characteristics of these applications.

3. Network Platform: Design and Development

- Short polling: method where the client periodically connect the server (new data are available to communicate). This is the simplest solution to code. It is not recommended in real time.

- Long polling: the client performs the request and the server do not respond until it has something to send. This enables real-time push notifications from the cloud to devices. This technique consumes more energy and also risks the loss of the connection.

- Adapted protocols: to use newer protocols like Constrained Application Protocol (CoAp) or Message Queue Telemetry Transport (MQTT), designed to provide low latency, small packet sizes and stable communication over weak networks. These protocols provide a two-way communication channel, which in turn supports push notifications. This makes them good choices for IoT projects requiring the ability to control connected devices in real time. Firmware libraries and examples for embedded devices, normally using HTTP-based connections, are required for developing new applications.

- MQTT is a publish-subscribe messaging protocol developed for resource-constrained devices, a model already in use by enterprises worldwide, and can work with legacy systems.

- All messages have a topic path composed of words separated by slashes. A common form is /place/device-type/device-id/measurement-type/status. The subscribers may use wild-cards to subscribe to all measurements coming from a specific class of device.

- The bandwidth requirements are extremely low, and the nature of the protocol makes it very energy-efficient.

- Defunct nodes are easily discovered: A publisher can register a «last will and testament» which the MQTT server sends to the subscribers of a topic after a certain time-out.

- The programming interface is very simple, and the client memory footprint is small, making it especially suitable for embedded devices.

- Three Quality of Service (QoS) levels provide reliable operations.

3.1. Platform Design: Analysis and Requirements

- Low-cost elements and low-power consumption of all devices installed improve the establishment and development.

- Standard communication protocols to develop open and reusable applications.

- Easy access and maintenance. Users are not specialized in information technologies; this can improve its acceptability.

- Support the integration of new smart control modules (modularity and scalability).

- To ensure interoperability when new devices are required.

- Non-proprietary hardware-software to reduce dependences.

- Things. Today there are millions of things (sensors/actuators and devices found in commercial and industrial settings) connected directly through wireless networks and accessing the Internet. Usually, the IoT solutions have things filtered and managed using data locally and/or connected to gateways that provide extended functionality. Basic devices are tagged like things. Each thing has data that can be shared in the Internet.

- Local Gateway. Most of existing things were not designed to connect to the Internet and cannot share data with the cloud. To resolve this difficulty gateways act as intermediaries between things and the cloud, providing the needed connectivity, security, and manageability.

- Network and Cloud. Cloud infrastructure contains large pools of virtualized servers and storage that are networked together. IoT solutions run applications that analyse and manage data from devices and sensors in order to generate services that produce information used in decision making.

3.2. Platform Development

- Analysis: agronomist and Information and Communication Technologies (ICT) technicians should set the basic goals for the project. Scenarios, objectives and technical needs are identified in this phase.

- Design requirements: there are requirements already established on the IoT platform (low-cost, interoperability, standard communication protocols, easy access and maintenance, modularity and scalability and non-proprietary dependences). In this phase, these requirements are related with the requirements of the agricultural installation analysed. A design based in things and its requirements (compute and communication) is proposed by agricultural and ICT technicians. Things and agricultural processes are defined.

- Ubiquitous sensor network: sensors/actuators (things) and its communication/processing capabilities should be clearly defined. Also, the intermediary (network access nodes) collecting information from a group of things must be proposed. These nodes facilitate the USN network access, communicating with a control centre or with external entities. In this phase the architecture of communication layer is proposed.

- Control Processes: agricultural activities with basic and advanced rules between things are specified by agronomists. A technology platform (middleware) to enable the effective use of a USN in the particular application is proposed by ICT technicians. Control rules and things relationships are modelled.

- Edge computing: enables analytic and knowledge generation at the source of the data. In this work, is the layer between data sources and cloud data centers where M2M protocol, control, data processing and web services are integrated. Edge computing pushes applications, data and processes away from embedded nodes that control USN to the logical extremes of a cloud network.

- Cloud services: monitoring, processing and analytic services, among others, can be designed in this phase using Internet technologies. Query and analytic layers are also defined. Things and services are transparent because both cloud and stand-alone cloud use the same paradigms, technologies and protocols.

- Test and validation: things, control processes, USN, Internet communication and Cloud applications are tested and validated in real scenarios.

3.3. Platform Architecture

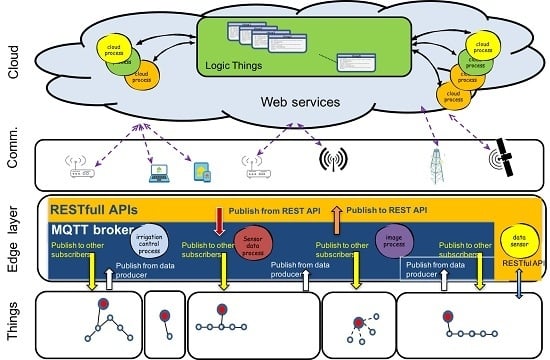

3.4. Integration of Protocols: M2M, Edge Computing and Web Services

- REST/Publisher MQTT: shows the Process-Publisher publishing the update resulting from an HTTP PUT to update the resource. In general, a create operation could also result in the publishing of a topic. A Process publishes a topic when an HTTP PUT is received. Examples of this operations can be manual control, rules settings, cloud-services request, etc..

- Subscriber MQTT/REST: shows how the Process-Subscriber creates a subscription in the broker, which updates the REST endpoint when a message is published from the broker on the topic corresponding to the resource path. Process performs HTTP GET operation when a topic subscribed is updated.

- Subscriber MQTT/publisher MQTT: shows Real-Time operations performed by a control process using only MQTT protocol. MQTT allows devices to send (publish) information about a given topic to a server that functions as an MQTT message broker. The broker then pushes the information out to those clients that have previously been subscribed to the topics. The design principles of MQTT is to minimise network bandwidth and device resource requirements whilst also attempting to ensure reliability and some degree of assurance of delivery. These principles make MQTT a good M2M choice for IoT and mobile apps.

- REST/GET-POST: REST API are libraries, resources and specifies the structure of the data that will be exchanged between different devices and the Server-Cloud. Restful API talks HTTP (the same protocol browsers use to communicate with web pages), the standard way to communicate in the World Wide Web. The RESTful API supports four HTTP methods: GET, POST, PUT and DELETE.

4. Experimental Prototype

- Low-cost deployment: sensors/actuators (temperature, moisture, PH, EC, Luminosity, electro-valves, pumps, lamps) technology used are not expensive. Controllers and sink nodes (routers) are embedded devices with hardware of widespread use.

- Standard communication protocols and non-proprietary hardware-software. USN networks use WIFI, Bluetooth Low Energy (BLE) and serial bus protocols as support to develop communication services.

- Easy access and maintenance: sensors/actuators and devices are easy to identify, connect and maintain.

- Control processes and edge computing layer development: basic control processes work in local network. Some analytic, storage and user interfaces are distributed in stand-alone cloud and internet services.

- Support for integration of new smart control modules and interoperability: web services protocols (REST, HTTP, MQTT, etc.) and open source hardware-software paradigms allow to program new modules which can be easily integrated. Interoperability between things is assured using IoT applications.

- Provide support for agronomist use, maintenance, settings and basic extensions.

- Analyse agronomist feedback.

- USN1. Monitor water tank using: PH, EC and Temperature sensors. This node control nutrients using electro-valves. This sensor network is managed by an embedded device type 2 (Table 3).

- USN2. Monitor radiance using: radiance and luminosity sensor. Monitor soil and environmental conditions using: temperature, soil moisture, humidity and flow sensors. This node controls the electro-valve irrigation and illumination control relay. This sensor network is managed by an embedded device type 1 (Table 3).

- USN3. Monitor greenhouse climate using: temperature, humidity sensors. Takes images with embedded camera. This node control automated windows and air conditioning system. This sensor network is managed by an embedded device type 1 (Table 3).

MQTT, Edge Layer and RESTful Integration

5. Results and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gebbers, R.; Adamchuk, V.I. Precision agriculture and food security. Science 2010, 327, 828–831. [Google Scholar] [CrossRef] [PubMed]

- Mulla, D.J. Twenty five years of remote sensing in precision agriculture: Key advances and remaining knowledge gaps. Biosyst. Eng. 2013, 114, 358–371. [Google Scholar] [CrossRef]

- Resh, H.M. Hydroponic Food Production: A Definitive Guidebook for the Advanced Home Gardener and the Commercial Hydroponic Grower; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Zhang, N.; Wang, M.; Wang, N. Precision agriculture. A worldwide overview. Comput. Electron. Agric. 2002, 36, 113–132. [Google Scholar] [CrossRef]

- Baggio, A. Wireless sensor networks in precision agriculture. In ACM Workshop on Real-World Wireless Sensor Networks (REALWSN 2005); Citeseer: Stockholm, Sweden, 2005. [Google Scholar]

- Zhang, W.; Kantor, G.; Singh, S. Demo abstract: Integrated wireless sensor/actuator networks in an agricultural application. In Proceedings of the 2nd International Conference on Embedded Networked Sensor Systems, ACM SenSys, Baltimore, MD, USA, 3–5 November 2004.

- Burrell, J.; Brooke, T.; Beckwith, R. Vineyard computing: Sensor networks in agricultural production. IEEE Pervasive Comput. 2004, 3, 38–45. [Google Scholar] [CrossRef]

- McBratney, A.; Whelan, B.; Ancev, T.; Bouma, J. Future directions of precision agriculture. Precis. Agric. 2005, 6, 7–23. [Google Scholar] [CrossRef]

- Chu, M.; Haussecker, H.; Zhao, F. Scalable information-driven sensor querying and routing for ad hoc heterogeneous sensor networks. Int. J. High Perform. Comput. Appl. 2002, 16, 293–313. [Google Scholar] [CrossRef]

- Pablo, J.; Zarco-Tejada, N.H.; Loudjani, P. Precision Agriculture: An Opportunity for EU Farmers; Joint Research Centre (JRC) of the European Commission: Brussels, Belgium, 2010. [Google Scholar]

- Mandel, R.; Lawes, R.; Robertson, M. What’s preventing growers from implementing precision agriculture (PA)? Available online: https://grdc.com.au/uploads/documents/WA%20Crop%20updates%202011%20Barriers%20to%20PA%20adoption.pdf (accessed on 10 April 2016).

- Robertson, M.J.; Llewellyn, R.S.; Mandel, R.; Lawes, R.; Bramley, R.G.V.; Swift, L.; Metz, N.; O’Callaghan, C. Adoption of variable rate fertiliser application in the Australian grains industry: Status, issues and prospects. Precis. Agric. 2011, 13, 181–199. [Google Scholar] [CrossRef]

- Kitchen, N.R. Emerging technologies for real-time and integrated agriculture decisions. Comput. Electron. Agric. 2008, 61, 1–3. [Google Scholar] [CrossRef]

- Reichardt, M.; Jürgens, C. Adoption and future perspective of precision farming in Germany: Results of several surveys among different agricultural target groups. Precis. Agric. 2008, 10, 73–94. [Google Scholar] [CrossRef]

- Becker, T.; Kluge, M.; Schalk, J.; Tiplady, K.; Paget, C.; Hilleringmann, U.; Otterpohl, T. Autonomous sensor nodes for aircraft structural health monitoring. IEEE Sens. J. 2009, 9, 1589–1595. [Google Scholar] [CrossRef]

- Hu, J.; Shen, L.; Yang, Y.; Lv, R. Design and implementation of wireless sensor and actor network for precision agriculture. In Proceedings of the 2010 IEEE International Conference on Wireless Communications, Networking and Information Security (WCNIS), Beijing, China, 25–27 June 2010; pp. 571–575.

- Dargie, W.W.; Poellabauer, C. Fundamentals of Wireless Sensor Networks: Theory and Practice; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Zhao, J.C.; Zhang, J.F.; Feng, Y.; Guo, J.X. The study and application of the IOT technology in agriculture. In Proceedings of the 2010 3rd IEEE International Conference on Computer Science and Information Technology (ICCSIT), Chengdu, China, 9–11 July 2010.

- Hwang, J.; Shin, C.; Yoe, H. Study on an agricultural environment monitoring server system using wireless sensor networks. Sensors 2010, 10, 11189–11211. [Google Scholar] [CrossRef] [PubMed]

- Åkerberg, J.; Gidlund, M.; Björkman, M. Future research challenges in wireless sensor and actuator networks targeting industrial automation. In Proceedings of the 2011 9th IEEE International Conference on Industrial Informatics (INDIN), Caparica, Lisbon, Portugal, 26–29 July 2011; 2011; pp. 410–415. [Google Scholar]

- Mostefaoui, S.K. Advances in Ubiquitous Computing: Future Paradigms and Directions; IGI Global: Hershey, PA, USA, 2008. [Google Scholar]

- Kaloxylos, A.; Eigenmann, R.; Teye, F.; Politopoulou, Z.; Wolfert, S.; Shrank, C.; Dillinger, M.; Lampropoulou, I.; Antoniou, E.; Pesonen, L.; et al. Farm management systems and the Future Internet era. Comput. Electron. Agric. 2012, 89, 130–144. [Google Scholar] [CrossRef]

- Tech-Student, M. A Literature Study on Agricultural Production System Using IoT as Inclusive Technology. Int. J. Innov. Technol. Res. 2016, 4, 1. [Google Scholar]

- Yan-e, D. Design of Intelligent Agriculture Management Information System Based on IoT. In Proceedings of the 2011 International Conference on Intelligent Computation Technology and Automation (ICICTA), Shenzhen, China, 28–29 March 2011.

- Bing, F. Research on the agriculture intelligent system based on IOT. In Proceedings of the 2012 International Conference on Image Analysis and Signal, Hangzhou, China, 9–11 November 2012; pp. 1–4.

- Li, S. Application of the Internet of Things Technology in Precision Agriculture IRrigation Systems. In Proceedings of the 2012 International Conference on Computer Science and Service System, Nanjing, China, 11–13 August 2012; pp. 1009–1013.

- Lee, M.; Hwang, J.; Yoe, H. Agricultural Production System Based on IoT. In Proceedings of the 2013 IEEE 16th International Conference on Computational Science and Engineering, Sydney, Australia, 3–5 December 2013; pp. 833–837.

- Dan, L.; Xin, C.; Chongwei, H.; Liangliang, J. Intelligent Agriculture Greenhouse Environment Monitoring System Based on IOT Technology. In Proceedings of the 2015 International Conference on Intelligent Transportation, Big Data and Smart City (ICITBS), Halong Bay, Vietnam, 19–20 December 2015; pp. 487–490.

- ADVANTECH. Intelligent Agricultural Solutions. Available online: http://waplus.advantech.com (accessed on 10 April 2016).

- Libelium platform. Available online: http://www.libelium.com/libeliumworld/agriculture/ (accessed on 10 April 2016).

- Stephens, W.; Hess, T. Systems approaches to water management research. Agric. Water Manag. 1999, 40, 3–13. [Google Scholar] [CrossRef]

- Architectural Considerations in Smart Object Networking. Available online: http://ubidots.com/home-ubidots.html (accessed on 10 April 2016).

- Ubidots IoT platform. Available online: https://www.ietf.org/mail-archive/web/ietf-announce/current/msg13921.html (accessed on 10 April 2016).

- Thingspeak IoT platform. Available online: https://thingspeak.com (accessed on 10 April 2016).

- Zatar IoT platform. Available online: http://www.zatar.com (accessed on 10 April 2016).

- Echelon IoT platform. Available online: http://www.echelon.com/izot-platform (accessed on 10 April 2016).

- Xively IoT platform. Available online: https://xively.com (accessed on 10 April 2016).

- Cai, J.; Liu, Y.; Lei, T.; Pereira, L.S. Estimating reference evapotranspiration with the FAO Penman–Monteith equation using daily weather forecast messages. Agric. For. Meteorol. 2007, 145, 22–35. [Google Scholar] [CrossRef]

| Characteristics | Sensor/Actuator and Control Layer | Communication Layer | Application Layer | Theoretical/Experimental Development |

|---|---|---|---|---|

| Model for PA on IoT based on the key technologies: Sensors, IoT paradigms, Cloud-Computing, Mobile-Computing and Big-Data analysis [22,23,24] | Different sensors are used: Temperature, Humidity, Soil Moisture, etc. and central server is proposed for data processing | Mobile and Wireless sensor networks like Zigbee, Bluetooth, WIFI. Wired serial bus protocols | Web services: database, data analysis, graphic interfaces | Theoretical models: concepts and architectures. No experiments on real production |

| Control Agriculture system for production, irrigation, climate, etc. Different technologies are used in the system, such as sensors, RFID, industrial control and so on [25,26] | Deploy different kinds of sensors. Control plant with "IF THEN" rules in embedded devices | Wireless Sensor Network based in nodes Zigbee, 3G and wireless gateway | Cloud services Not deployed | Experimental control and preliminary tests |

| Monitoring system to analyse crop environment, and the method to improve the efficiency of decision making by analysing statistics. [27,28] | IoT sensors: soil, PH, humidity, temperature, etc. | Wireless gateway and IoT sensor | Monitoring and statistic analysis using internet and web services | Preliminary tests based in monitoring agricultural production and simulation |

| Scientific or Industrial systems based in integration of internet and web services on automation and industrial control. Proprietary Systems designed for monitoring or large production plants [19,29,30] | Sensors and Industrial control | Ethernet and industrial control protocols, wireless, gateway, modem, etc. | Software control and data acquisition systems (SCADA), Human Machine Interface, web services | Proprietary systems proposed for large production. Ad-hoc systems |

| Analysis and Design Requirements | Things and Control Processes | |

|---|---|---|

| crop | Hydroponically grown plants have the same general requirements as field-grown plants. The major difference is the method by which the plants are supported and the inorganic elements necessary for growth and development are supplied: Temperature, light, water, oxygen, mineral nutrients and support are the control parameters. | sensor/things: agricultural-processes: |

| soil | In a garden the plant roots are surrounded by soil that supports the growing plant. A hydroponically grown plant must be artificially supported, usually with string or stakes. Soil moisture must be monitored. | sensor/things: agricultural-processes: |

| climate | Plants grow well only within a limited temperature range. Temperatures that are too high or too low will result in abnormal development and reduced production. Warm-season vegetables and most flowers grow best between 15 and 25 ºC. All vegetable plants and many flowers require large amounts of sunlight. Special plant-growth lamps can be used to grow. Relative humidity should be between upper and lower limits. | sensor/things: actuator/things: agricultural-processes: |

| water | A controlled (time and flow) irrigation is necessary. If the aggregate is not kept sufficiently moist, the plant roots will dry out and some will die. PH and Electro-Conductivity (EC) are variables that need to be controlled. | sensor/things: actuator/things: agricultural-processes: |

| nutrients | Soil-less growing requires complete and effective hydroponic nutrient solutions. Liquid nutrients (nitrogen, phosphorus, potassium) are prepared by agronomist. | sensor/things: |

| energy | Monitoring energy consumption and controlling photovoltaic generation enables powering devices only when needed. The energy balance of the activity (processes and things) must be analysed. | sensor/things: actuator/things: agricultural-processes: |

| cloud service | Storage, analytic and user interfaces must be designed. Tables and graphs with statistical data show data in real time. IoT resources store principal data. Subsequent analysis generate information about the growing process | things: cloud-processes: |

| Capabilities | ||||

|---|---|---|---|---|

| Processing | Programming | Communication/Control | Storage | |

| Type1: RaspberryPi  | ARM Cortex-A7 CPU 900 MHz Memory 1GB | Linux C/C++ and Python APIs libraries | WIFI and USB SPI and MQTT protocol GPIO and A/D modul | micro SD 16 GB |

| Type2: Photon IoT  | ARM Cortex-M3 CPU 120 MHz 1MB flash, 128KB RAM | C language APIs libraries | WIFI and USB SPI and MQTT protocol GPIO and A/D ports | - |

| Type 3: SmartPhone  | SoC μ Processor CPU ≥ 900 MHz Memory ≥ 1GB | Android/iOS Objective C Java libraries | WIFI and USB Bluetooth 4G LTE | - |

| Type 4: WIFI router  | SoC μ Processor | - | WIFI Bluetooth 4G LTE | - |

| Cloud-server: IoT ubidots  | Push Data from any Internet-Enabled Device | REST API HTTP request Python, Java, C, PHP, Node and Ruby lib. | Internet connection Analysis and visualisation Trigger actions: e-mail, SMS and WebHook | Data storage |

| Water temperature graphic obtained. This sensor is included in USN1 and embedded device type 2. This chart is useful in water nutrient process. |

| Control dashboard and state indicator. These actuators are included in USN3 (manual control). Automatic control is implemented in embedded device type 1. |

| Events with trigger actions can be programmed by agronomist. An SMS can be mailed when data sensor reaches a fixed value. E-mail also can be used. |

| Days 0–10 vegetative stage | Days 10–15 emergence stage | Days 15–2 cotyledon | Days 20–25 unifoliolate nodes |

|  |  |  |

| Irrigation actual (Total liters) = 20 L/m | Average Temperature = C | ||

| Irrigation theoretic (Total liters ) = 25 L/m | Average water PH = | ||

| Evapo-transpiration (ETP) FAO equation | Average water EC = 1000 S/cm | ||

| Energy used = 60 Wh/m/day | Solar irradiance = 4 kWh/m/day (NASA HOMER web) | ||

| Reduction in water consumption = 20% | |||

|  |  |  |

| Problems | Solutions | Technological results | |

| Initial expectations unfulfilled Complexity of technology Incompatibility of components Lack of products High costs | Develop a reference model based in IoT paradigms and USN resources Standard components (devices, sensors, actuators) with low cost PA processes automated with software and languages standard Graphics Interfaces use simple and universal access Tools, facilities and resources create for agronomist and users needs New products are created integrating technological resources | GUI interfaces used on Internet New ways of data access Low-cost deployment Users can interact and created conditional statements PA information in near real time | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrández-Pastor, F.J.; García-Chamizo, J.M.; Nieto-Hidalgo, M.; Mora-Pascual, J.; Mora-Martínez, J. Developing Ubiquitous Sensor Network Platform Using Internet of Things: Application in Precision Agriculture. Sensors 2016, 16, 1141. https://doi.org/10.3390/s16071141

Ferrández-Pastor FJ, García-Chamizo JM, Nieto-Hidalgo M, Mora-Pascual J, Mora-Martínez J. Developing Ubiquitous Sensor Network Platform Using Internet of Things: Application in Precision Agriculture. Sensors. 2016; 16(7):1141. https://doi.org/10.3390/s16071141

Chicago/Turabian StyleFerrández-Pastor, Francisco Javier, Juan Manuel García-Chamizo, Mario Nieto-Hidalgo, Jerónimo Mora-Pascual, and José Mora-Martínez. 2016. "Developing Ubiquitous Sensor Network Platform Using Internet of Things: Application in Precision Agriculture" Sensors 16, no. 7: 1141. https://doi.org/10.3390/s16071141