Inapparent Strengthening Effect of Twin Interface in Cu/Pd Multilayered Films with a Large Lattice Mismatch

Abstract

:1. Introduction

2. Simulation Details

3. Results and Discussions

3.1. Characterization of Interfaces

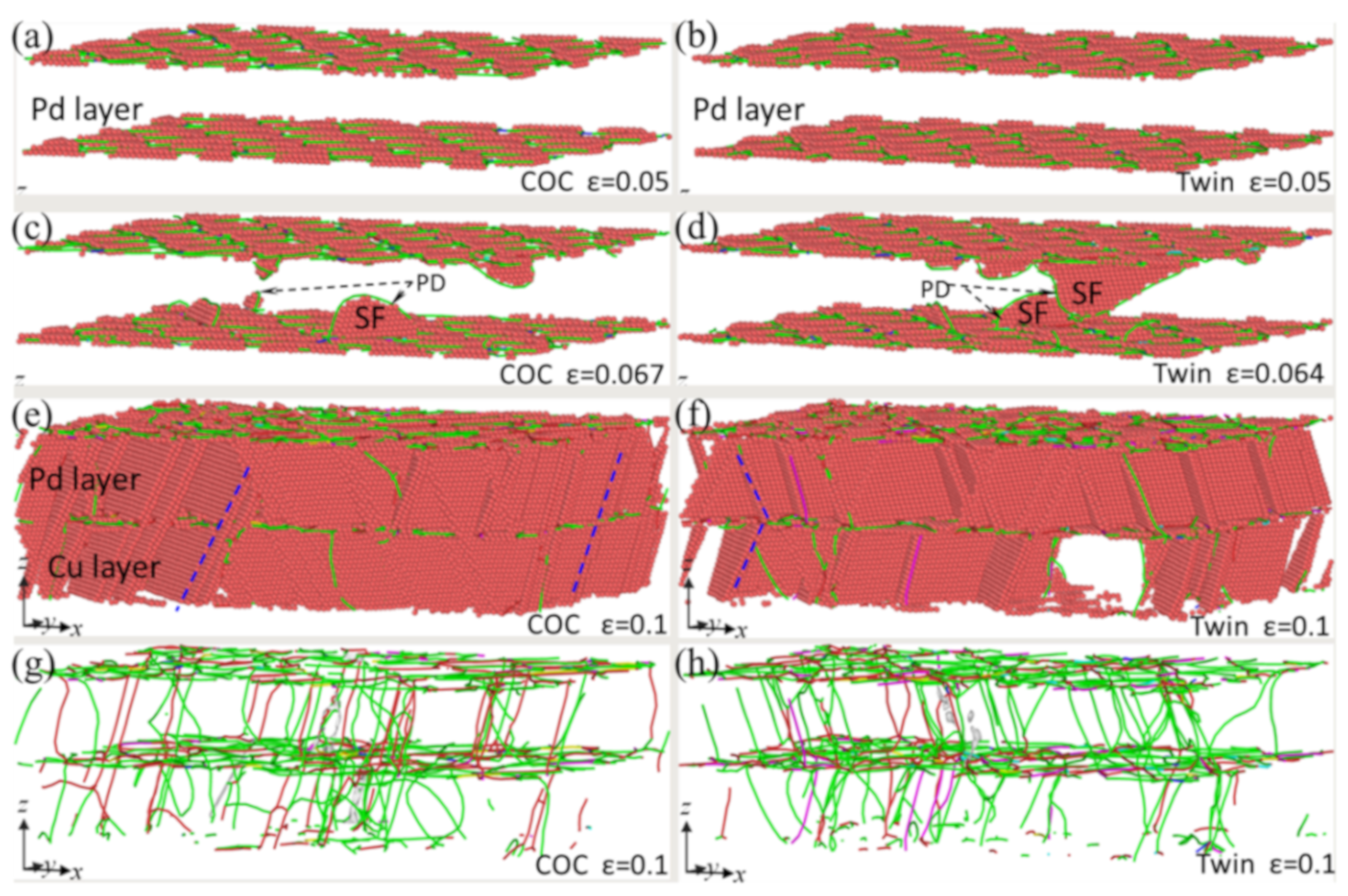

3.2. Deformation Behaviors

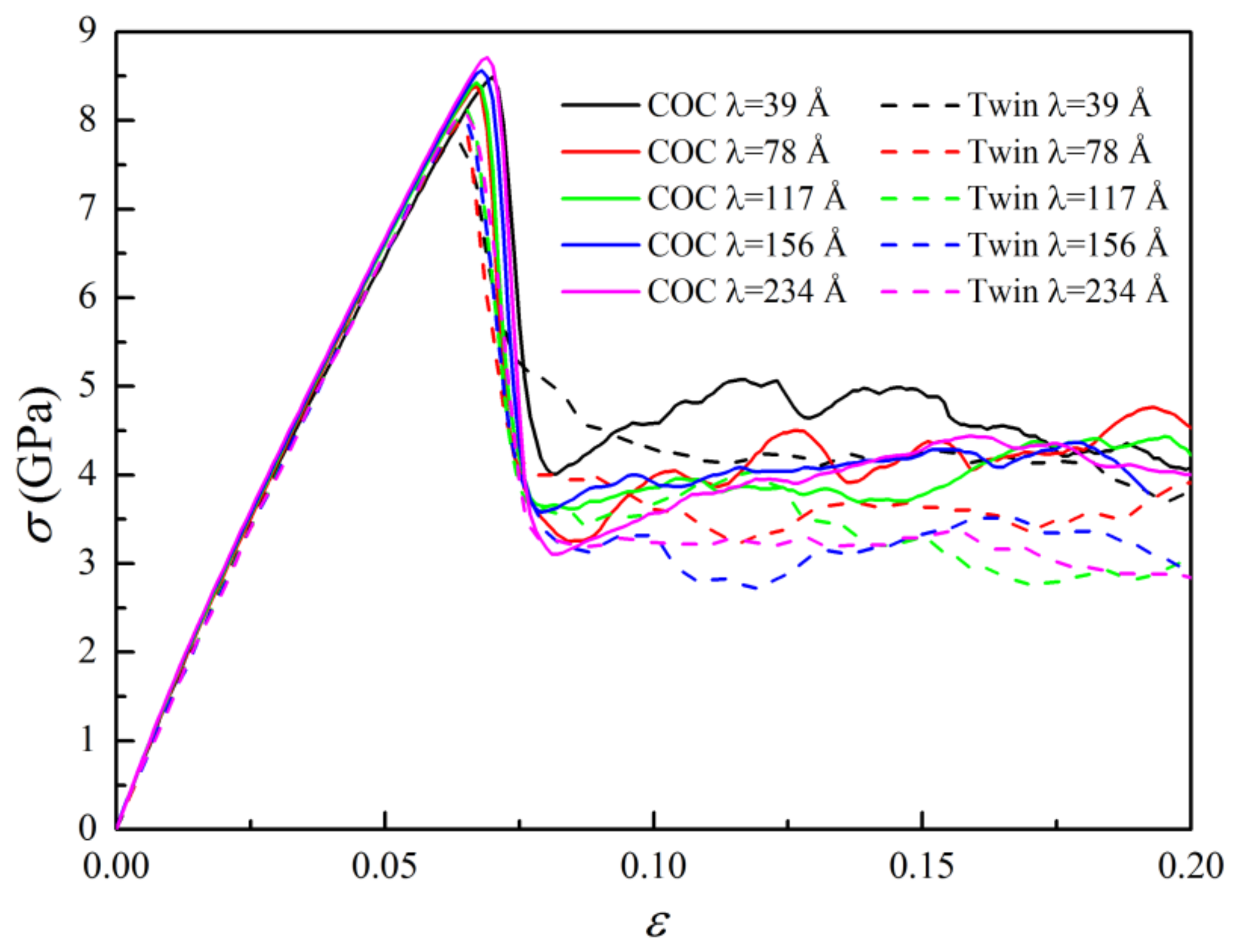

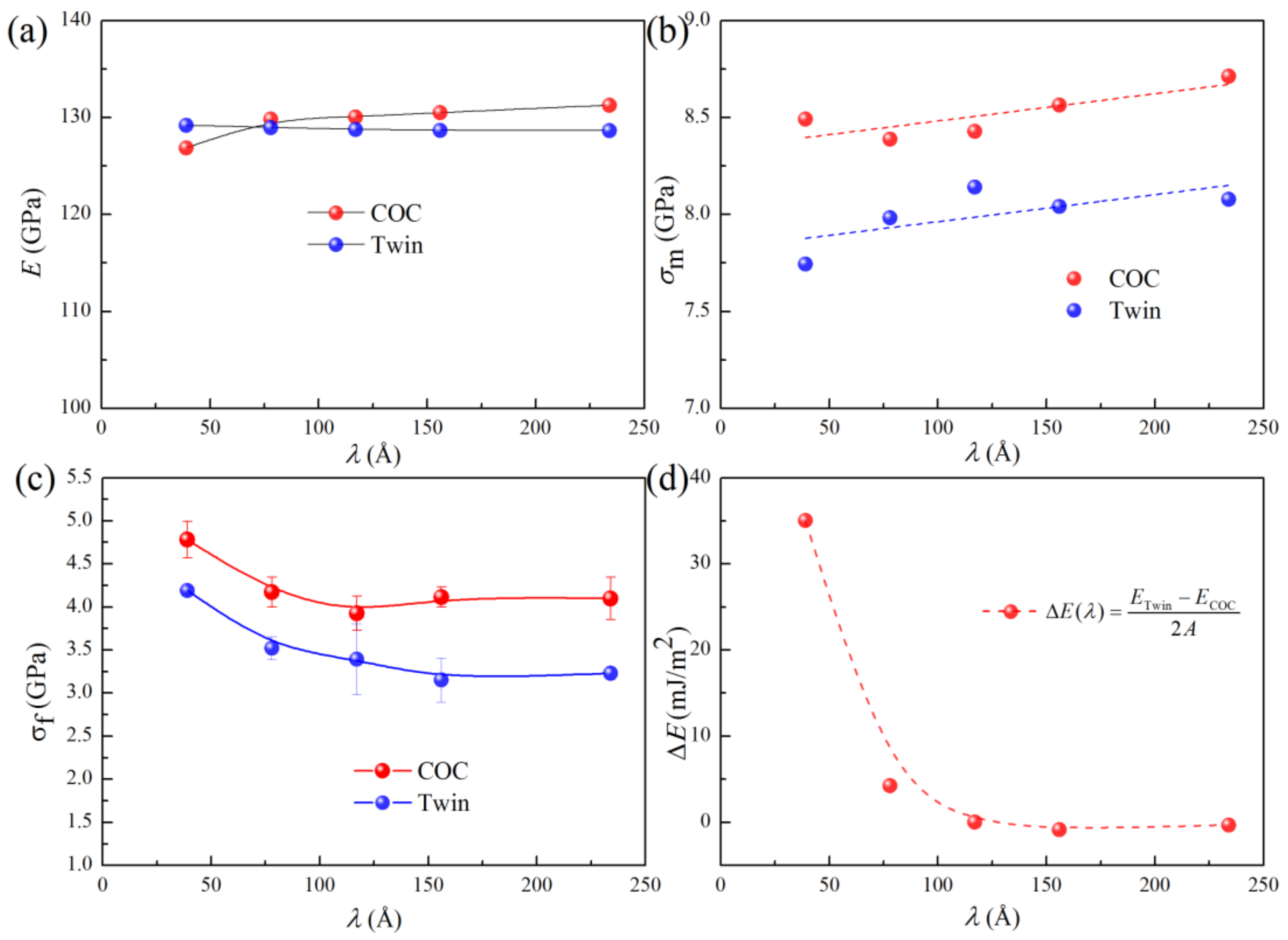

3.3. Effects of the Modulation Period

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wei, S.Y.; Zhang, L.F.; Zheng, S.J.; Wang, X.P.; Wang, J.W. Deformation-induced interfacial transition zone in Cu/V nanolamellar multilayers. Scr. Mater. 2019, 159, 104–108. [Google Scholar] [CrossRef]

- Xiang, M.Z.; Liao, Y.; Wang, K.; Lu, G.; Chen, J. Shock-induced plasticity in semi-coherent {111} Cu-Ni multilayers. Int. J. Plast. 2018, 103, 23–38. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.; Li, Q.; Zhang, J.; Ye, H.; Zhang, H.; Shen, L. Hetero interface and twin boundary mediated strengthening in nano-twinned Cu//Ag multilayered materials. Nanotechnology 2017, 28, 415705. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Yuan, H.Z.; Liang, X.Q.; Zhang, J.Y.; Liu, G.; Sun, J. Size dependence of buckling strains of Cr films, Cu films and Cu/Cr multilayers on compliant substrates. Scr. Mater. 2018, 146, 1–4. [Google Scholar] [CrossRef]

- Xiang, H.G.; Li, H.T.; Fu, T.; Zhu, W.B.; Huang, C.; Yang, B.; Peng, X.H. Shock-induced stacking fault pyramids in Ni/Al multilayers. Appl. Surf. Sci. 2018, 427, 219–225. [Google Scholar] [CrossRef]

- Zhang, C.; Feng, K.; Li, Z.; Lu, F.; Huang, J.; Wu, Y. Microstructure and mechanical properties of sputter deposited Ni/Ni3Al multilayer films at elevated temperature. Appl. Surf. Sci. 2016, 378, 408–417. [Google Scholar] [CrossRef]

- Zhou, Q.; Hua, D.P.; Du, Y.; Ren, Y.; Kuang, W.W.; Xia, Q.S.; Bhardwaj, V. Atomistic study of atomic structures and dislocation nucleation at Al/Al2Cu interfaces. Int. J. Plast. 2019, 120, 115–126. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, K.M.; Hay, J.; Fu, E.G.; Zhang, X. The effect of coherent interface on strain-rate sensitivity of highly textured Cu/Ni and Cu/V multilayers. Scr. Mater. 2019, 162, 33–37. [Google Scholar] [CrossRef]

- Eftink, B.P.; Mara, N.A.; Kingstedt, O.T.; Safarik, D.; Wang, S.; Lambros, J.; Robertson, I.M. Deformation response of cube-on-cube and non-coherent twin interfaces in AgCu eutectic under dynamic plastic compression. Mater. Sci. Eng. A 2018, 712, 313–324. [Google Scholar] [CrossRef]

- Yu, W.S.; Wu, L.P.; Shen, S.P. Adhesion properties of Cu(111)/alpha-quartz (0001) interfaces: A molecular dynamics study. Mater. Sci. Eng. A 2017, 695, 239–248. [Google Scholar] [CrossRef]

- An, M.R.; Deng, Q.; Su, M.J.; Song, H.Y.; Li, Y.L. Dependence of deformation mechanisms on layer spacing in multilayered Ti/Al composite. Mater. Sci. Eng. A 2017, 684, 491–499. [Google Scholar] [CrossRef]

- Gao, F.S.; Peng, X.H.; Huang, C.; Yue, X.; Yang, B.; Sun, S.; Fu, T. Modulation period dependent mechanical properties of Cu/Fe metallic multilayered films. Aip Adv. 2018, 8, 045208. [Google Scholar] [CrossRef]

- Yang, W.M.C.; Tsakalakos, T.; Hilliard, J.E. Enhanced elastic modulus in composition-modulated gold-nickel and copper-palladium foils. J. Appl. Phys. 1977, 48, 876–879. [Google Scholar] [CrossRef]

- Davis, B.M.; Seidman, D.N.; Moreau, A.; Ketterson, J.B.; Mattson, J.; Grimsditch, M. “Supermodulus effect” in Cu/Pd and Cu/Ni superlattices. Phys. Rev. B 1991, 43, 9304–9307. [Google Scholar] [CrossRef]

- Fu, T.; Peng, X.; Feng, C.; Zhao, Y.; Wang, Z. MD simulation of growth of Pd on Cu (1 1 1) and Cu on Pd (1 1 1) substrates. Appl. Surf. Sci. 2015, 356, 651–658. [Google Scholar] [CrossRef]

- Subedi, S.; Beyerlein, I.J.; LeSar, R.; Rollett, A.D. Strength of nanoscale metallic multilayers. Scr. Mater. 2018, 145, 132–136. [Google Scholar] [CrossRef]

- Zhou, Q.; Huang, P.; Liu, M.B.; Wang, F.; Xu, K.W.; Lu, T.J. Grain and interface boundaries governed strengthening mechanisms in metallic multilayers. J. Alloy. Compd. 2017, 698, 906–912. [Google Scholar] [CrossRef]

- Wang, F.; Holec, D.; Oden, M.; Mucklich, F.; Abrikosov, I.A.; Tasnadi, F. Systematic ab initio investigation of the elastic modulus in quaternary transition metal nitride alloys and their coherent multilayers. Acta Mater. 2017, 127, 124–132. [Google Scholar] [CrossRef]

- Wei, M.Z.; Cao, Z.H.; Meng, X.K. Interfacial structures governed plastic deformation behaviors in metallic multilayers. Acta Metall. Sin. Engl. Lett. 2016, 29, 199–204. [Google Scholar] [CrossRef] [Green Version]

- Kong, Y.; Shen, L.M.; Shen, Y.G.; Chen, Z. Interfacial effect on strengthening nanoscale metallic multilayers-a combined hall-petch relation and atomistic simulation study. Mater. Sci. Eng. A 2016, 663, 29–37. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Q.; Shao, S.; Misra, A. Strength and plasticity of nanolaminated materials. Mater. Res. Lett. 2016, 5, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Fu, T.; Zhang, Z.J.; Peng, X.H.; Weng, S.Y.; Miao, Y.H.; Zhao, Y.B.; Fu, S.Y.; Hu, N. Effects of modulation periods on mechanical properties of V/VN nano-multilayers. Ceram. Int. 2019, 45, 10295–10303. [Google Scholar] [CrossRef]

- Wang, J.; Misra, A. An overview of interface-dominated deformation mechanisms in metallic multilayers. Curr. Opin. Solid State Mater. Sci. 2011, 15, 20–28. [Google Scholar] [CrossRef]

- Weng, S.; Fu, T.; Peng, X.; Chen, X. Anisotropic phase transformation in B2 crystalline CuZr alloy. Nanoscale Res. Lett. 2019, 14, 283. [Google Scholar] [CrossRef] [PubMed]

- Weng, S.; Ning, H.; Fu, T.; Hu, N.; Wang, S.; Huang, K.; Peng, X.; Qi, H.J.; Yan, C. Anisotropic and asymmetric deformation mechanisms of nanolaminated graphene/Cu composites. Nano Mater. Sci. 2019, 1, 121–130. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, L.; Yu, W.; Shen, S.; Fu, T. Structure and shear response of <001> tilt grain boundary in titanium nitride. Ceram. Int. 2019, 45, 5531–5546. [Google Scholar] [CrossRef]

- Huang, C.; Peng, X.; Yang, B.; Zhao, Y.; Weng, S.; Fu, T. Investigation of interaction between dislocation loop and coherent twin boundary in Bcc Ta film during nanoindentation. Nanomaterials 2017, 7, 375. [Google Scholar] [CrossRef] [Green Version]

- Fu, T.; Peng, X.H.; Zhao, Y.B.; Feng, C.; Huang, C.; Li, Q.B.; Wang, Z.C. Md simulation of effect of crystal orientations and substrate temperature on growth of Cu/Ni bilayer films. Appl. Phys. A 2016, 122, 67. [Google Scholar] [CrossRef]

- Shao, S.; Akasheh, F.; Wang, J.; Liu, Y. Alternative misfit dislocations pattern in semi-coherent FCC {100} interfaces. Acta Mater. 2018, 144, 177–186. [Google Scholar] [CrossRef]

- Shao, S.; Wang, J. Relaxation mechanisms, structure and properties of semi-coherent interfaces. Metals 2015, 5, 1887–1901. [Google Scholar] [CrossRef]

- Shao, S.; Wang, J. Relaxation, structure, and properties of semicoherent interfaces. JOM 2016, 68, 242–252. [Google Scholar] [CrossRef]

- Shao, S.; Wang, J.; Beyerlein, I.J.; Misra, A. Glide dislocation nucleation from dislocation nodes at semi-coherent {1 1 1} Cu-Ni interfaces. Acta Mater. 2015, 98, 206–220. [Google Scholar] [CrossRef] [Green Version]

- Weng, S.; Ning, H.; Hu, N.; Yan, C.; Fu, T.; Peng, X.; Fu, S.; Zhang, J.; Xu, C.; Sun, D.; et al. Strengthening effects of twin interface in Cu/Ni multilayer thin films-a molecular dynamics study. Mater. Des. 2016, 111, 1–8. [Google Scholar] [CrossRef]

- Baskes, M.I. Application of the embedded-atom method to covalent materials: A semiempirical potential for silicon. Phys. Rev. Lett. 1987, 59, 2666–2669. [Google Scholar] [CrossRef]

- Lee, B.J.; Baskes, M.I. Second nearest-neighbor modified embedded-atom-method potential. Phys. Rev. B 2000, 62, 8564–8567. [Google Scholar] [CrossRef]

- Lee, B.J.; Shim, J.H.; Baskes, M.I. Semiempirical atomic potentials for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, Al, and Pb based on first and second nearest-neighbor modified embedded atom method. Phys. Rev. B 2003, 68, 144112. [Google Scholar] [CrossRef]

- Liu, Y.; Bufford, D.; Rios, S.; Wang, H.; Chen, J.; Zhang, J.Y.; Zhang, X. A formation mechanism for ultra-thin nanotwins in highly textured Cu/Ni multilayers. J. Appl. Phys. 2012, 111, 073526. [Google Scholar] [CrossRef]

- Liu, Y.; Bufford, D.; Wang, H.; Sun, C.; Zhang, X. Mechanical properties of highly textured cu/ni multilayers. Acta Mater. 2011, 59, 1924–1933. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Stukowski, A. Structure identification methods for atomistic simulations of crystalline materials. Model. Simul. Mater. Sci. Eng. 2012, 20, 045021. [Google Scholar] [CrossRef]

- Hoover, W.G. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 1985, 31, 1695–1697. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hoover, W.G. Constant-pressure equations of motion. Phys. Rev. A 1986, 34, 2499–2500. [Google Scholar] [CrossRef] [PubMed]

- Plimpton, S. Fast parallel algorithms for short-range molecular-dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Bachurin, D.V.; Gumbsch, P. Accommodation processes during deformation of nanocrystalline palladium. Acta Mater. 2010, 58, 5491–5501. [Google Scholar] [CrossRef]

- Van Swygenhoven, H.; Derlet, P.M.; Froseth, A.G. Stacking fault energies and slip in nanocrystalline metals. Nat. Mater. 2004, 3, 399–403. [Google Scholar] [CrossRef]

- Fu, T.; Peng, X.H.; Zhao, Y.B.; Li, T.F.; Li, Q.B.; Wang, Z.C. Molecular dynamics simulation of deformation twin in rocksalt vanadium nitride. J. Alloy. Compd. 2016, 675, 128–133. [Google Scholar] [CrossRef]

- Daphalapurkar, N.P.; Ramesh, K.T. Orientation dependence of the nucleation and growth of partial dislocations and possible twinning mechanisms in aluminum. J. Mech. Phys. Solids 2012, 60, 277–294. [Google Scholar] [CrossRef]

- Weng, S.; Ning, H.; Fu, T.; Hu, N.; Zhao, Y.; Huang, C.; Peng, X. Molecular dynamics study of strengthening mechanism of nanolaminated graphene/Cu composites under compression. Sci. Rep. 2018, 8, 3089. [Google Scholar] [CrossRef]

- Fu, T.; Peng, X.; Chen, X.; Weng, S.; Hu, N.; Li, Q.; Wang, Z. Molecular dynamics simulation of nanoindentation on Cu/Ni nanotwinned multilayer films using a spherical indenter. Sci. Rep. 2016, 6, 35665. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Misra, A. Strain hardening in nanolayered thin films. Curr. Opin. Solid State Mater. Sci. 2014, 18, 19–28. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, J.Y.; Zhang, P.; Wang, Y.Q.; Liu, G.; Zhang, G.J.; Sun, J. Fracture behavior and adhesion energy of nanostructured Cu/Mo multilayer films. Mater. Sci. Eng. A 2014, 613, 130–135. [Google Scholar] [CrossRef]

| Element | Ec (eV) | re (Å) | α | A | β(0) | β(1) | β(2) | β(3) | t(0) | t(1) | t(2) | t(3) | Cmin | Cmax | d |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | 3.54 | 2.555 | 5.15 | 0.94 | 3.83 | 1.00 | 6.0 | 2.2 | 1.0 | 2.72 | 3.04 | 1.95 | 1.21 | 2.8 | 0.05 |

| Pd | 3.91 | 2.750 | 6.42 | 0.94 | 2.75 | 5.15 | 6.0 | 2.2 | 1.0 | 4.50 | 1.47 | 4.85 | 1.69 | 2.8 | 0.05 |

| Parameter | Ec (eV) | re (Å) | B (GPa) | d | Cu–Pd–Cu | Pd–Cu–Pd | Cu–Cu–Pd | Pd–Pd–Cu | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cmin | Cmax | Cmin | Cmax | Cmin | Cmax | Cmin | Cmax | |||||

| Value | 3.725 | 2.593 | 106.2 | 0.05 | 0.65 | 1.44 | 0.78 | 1.44 | 1.44 | 2.8 | 1.44 | 2.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, S.; Chen, X.; Yue, X.; Fu, T.; Peng, X. Inapparent Strengthening Effect of Twin Interface in Cu/Pd Multilayered Films with a Large Lattice Mismatch. Nanomaterials 2019, 9, 1778. https://doi.org/10.3390/nano9121778

Weng S, Chen X, Yue X, Fu T, Peng X. Inapparent Strengthening Effect of Twin Interface in Cu/Pd Multilayered Films with a Large Lattice Mismatch. Nanomaterials. 2019; 9(12):1778. https://doi.org/10.3390/nano9121778

Chicago/Turabian StyleWeng, Shayuan, Xiang Chen, Xing Yue, Tao Fu, and Xianghe Peng. 2019. "Inapparent Strengthening Effect of Twin Interface in Cu/Pd Multilayered Films with a Large Lattice Mismatch" Nanomaterials 9, no. 12: 1778. https://doi.org/10.3390/nano9121778