Experimental and Numerical Evaluation of the Mechanical Behavior of Strongly Anisotropic Light-Weight Metallic Fiber Structures under Static and Dynamic Compressive Loading

Abstract

:1. Introduction

2. Results

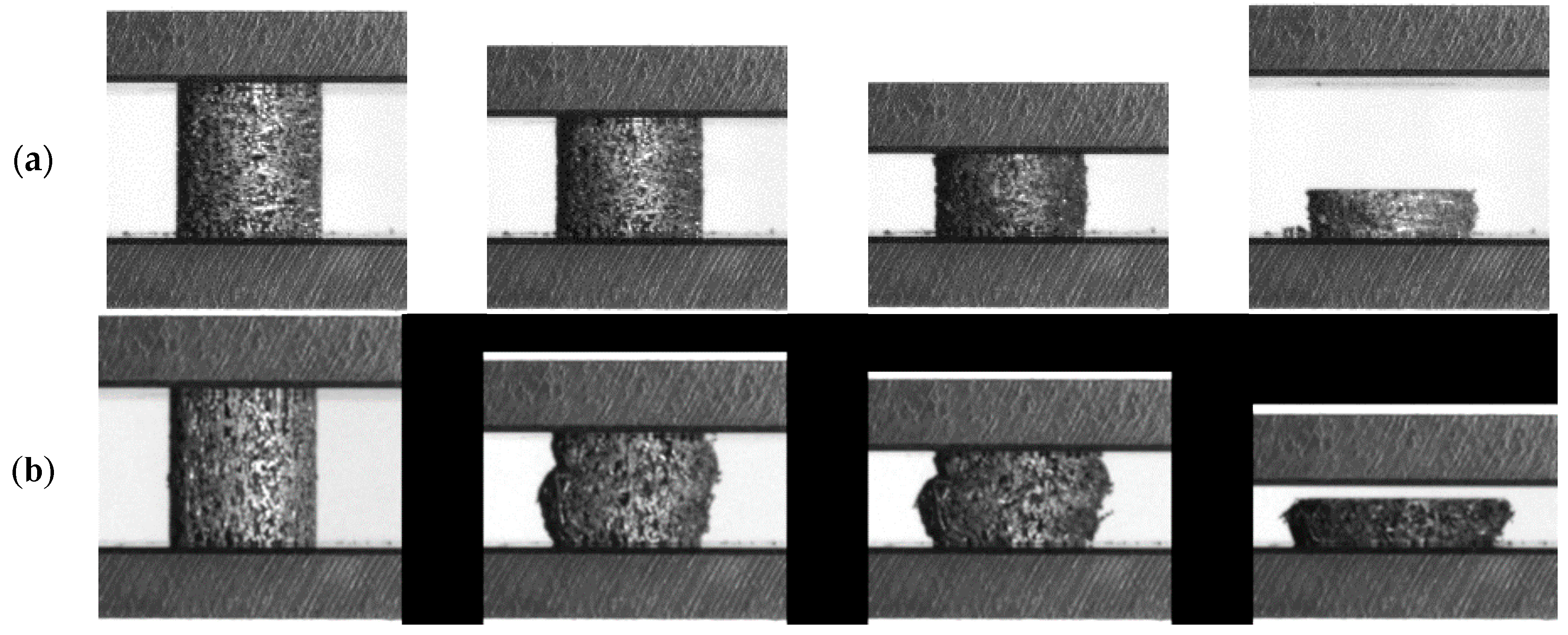

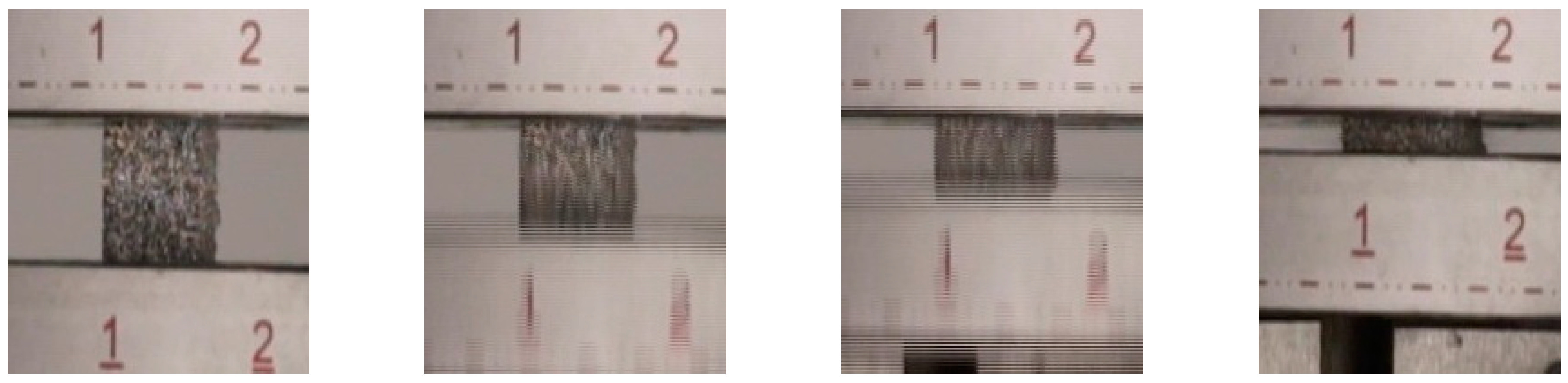

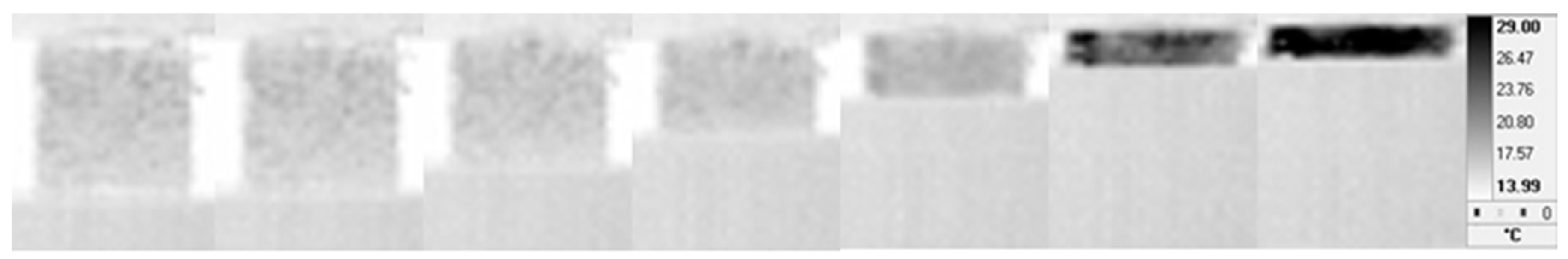

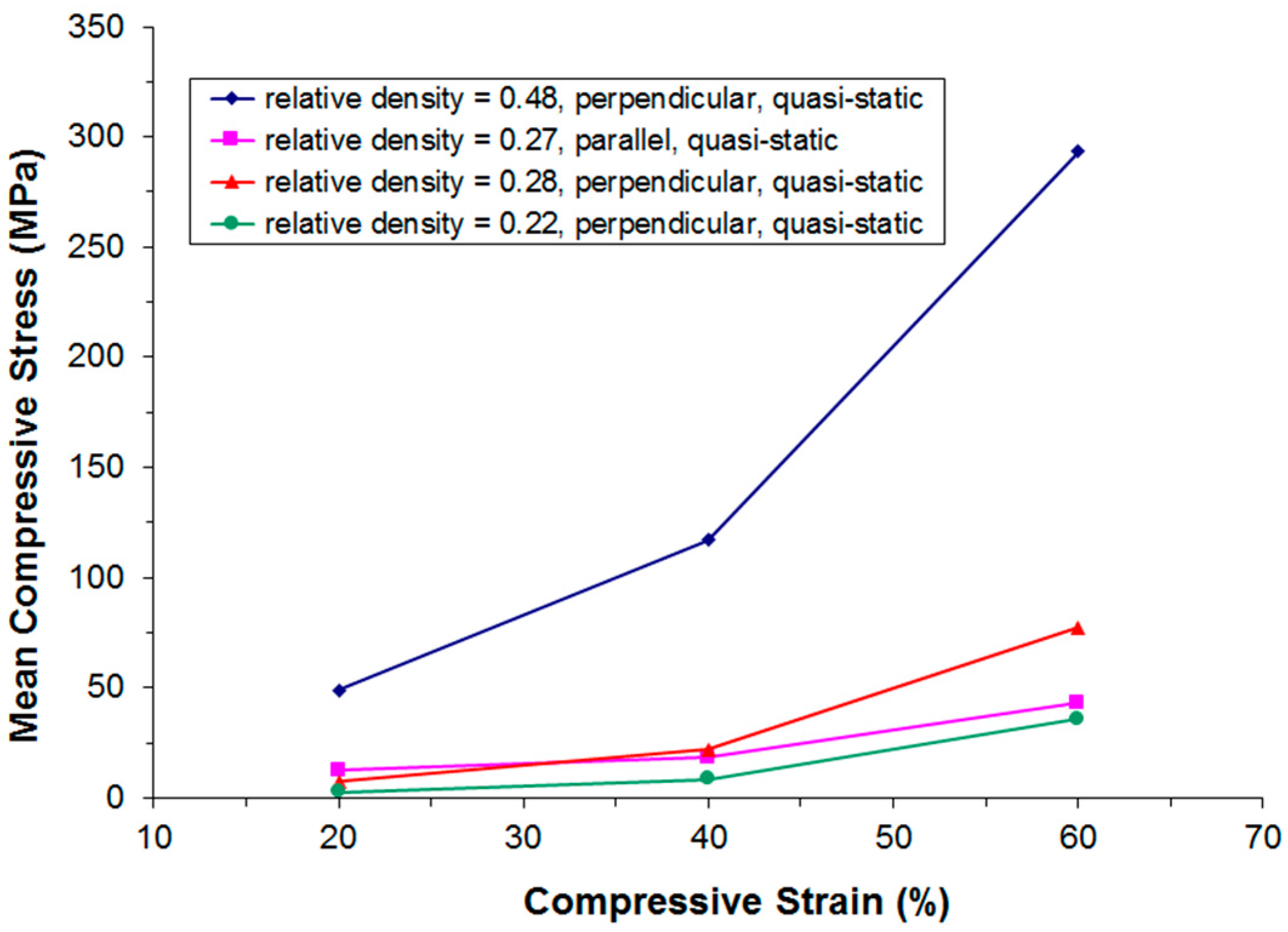

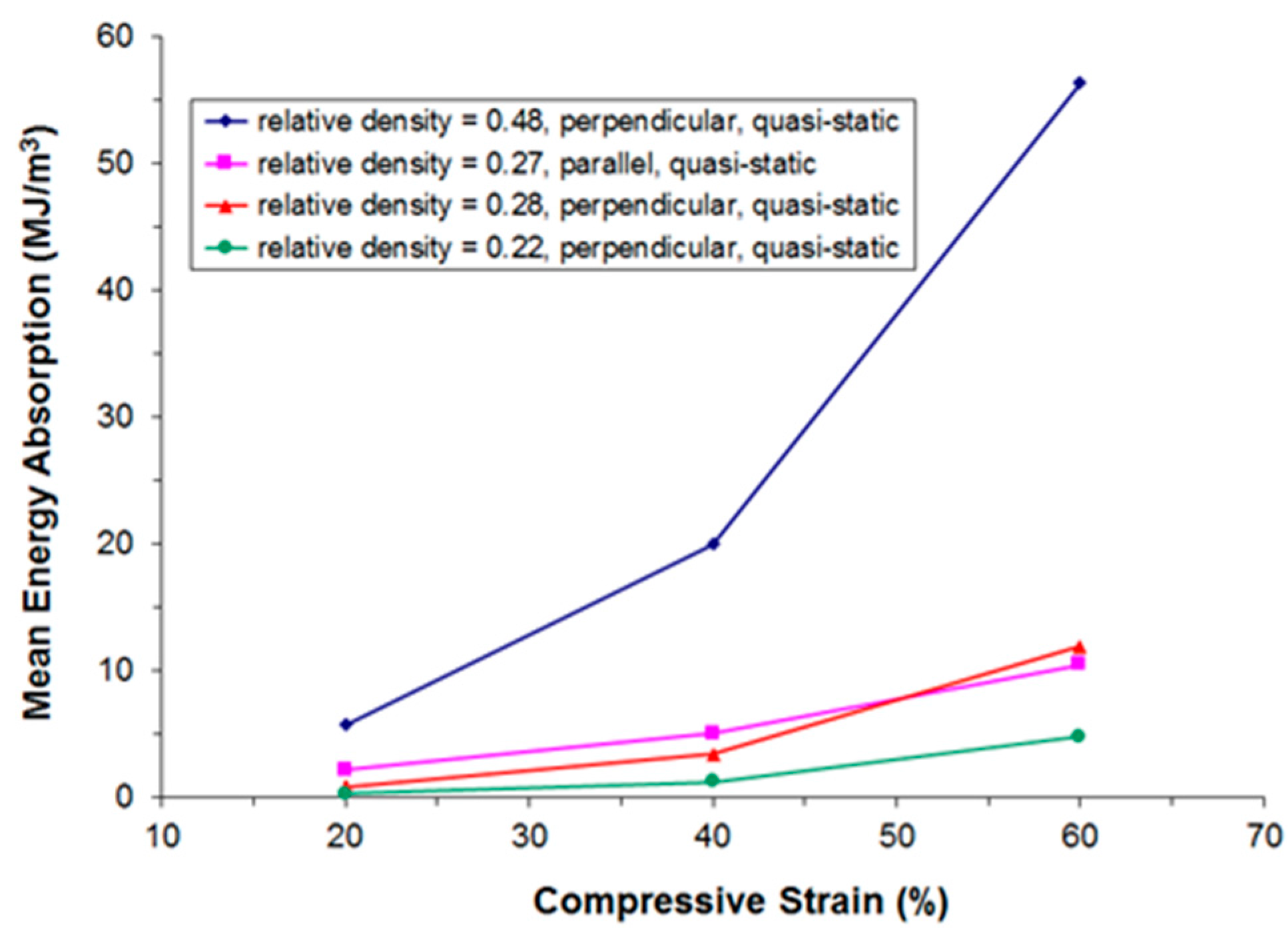

2.1. Quasi-Static Test Results

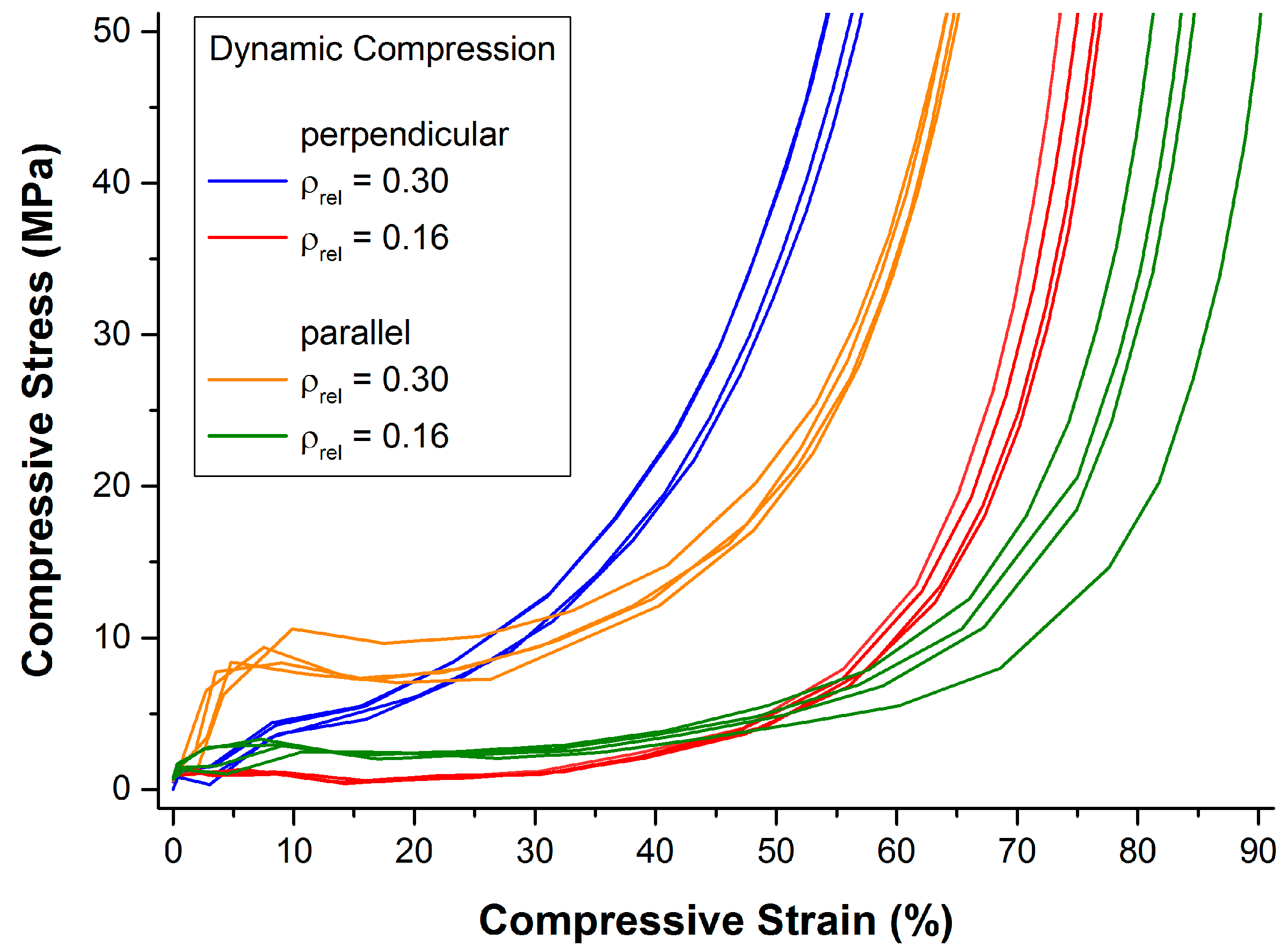

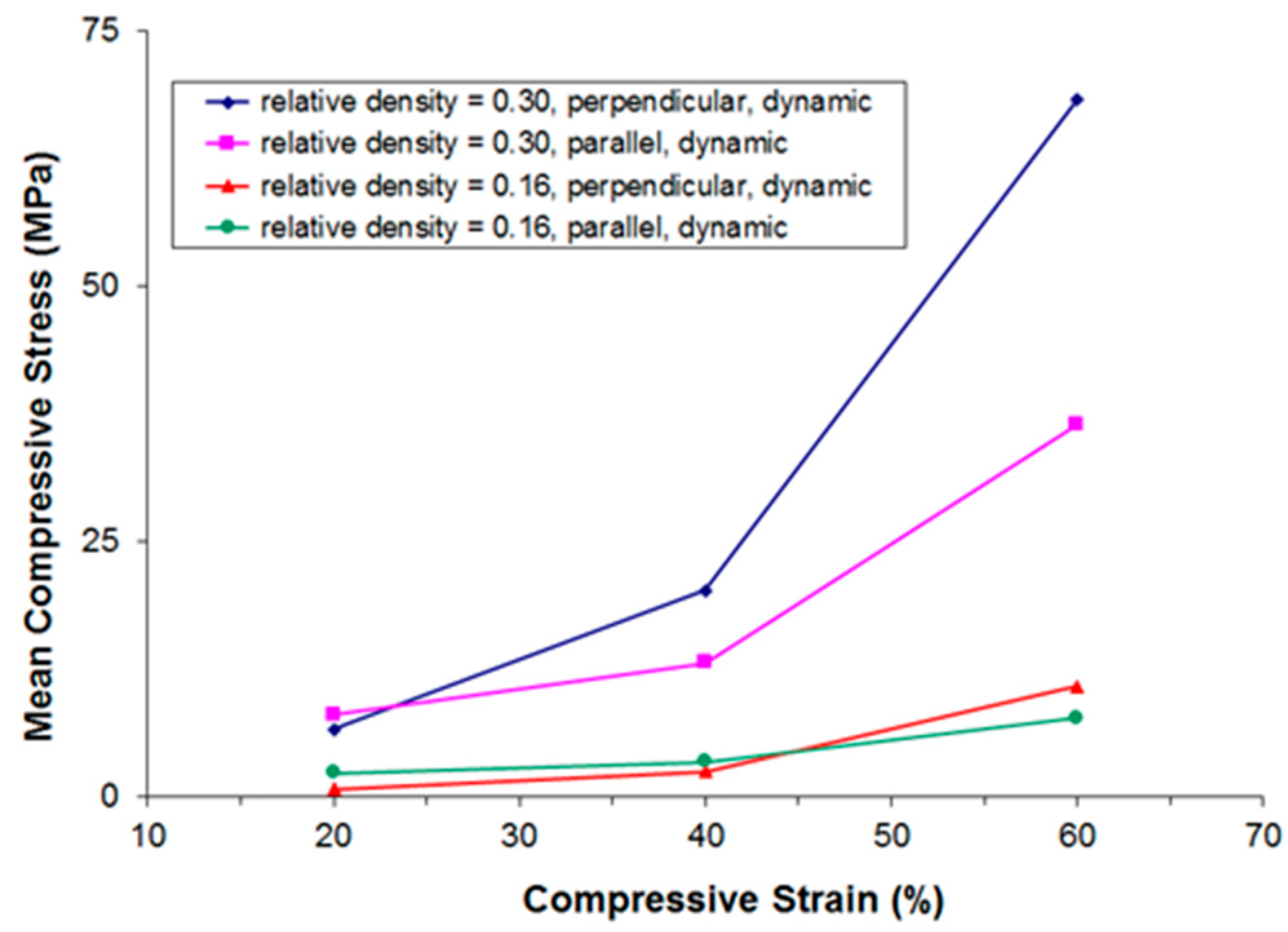

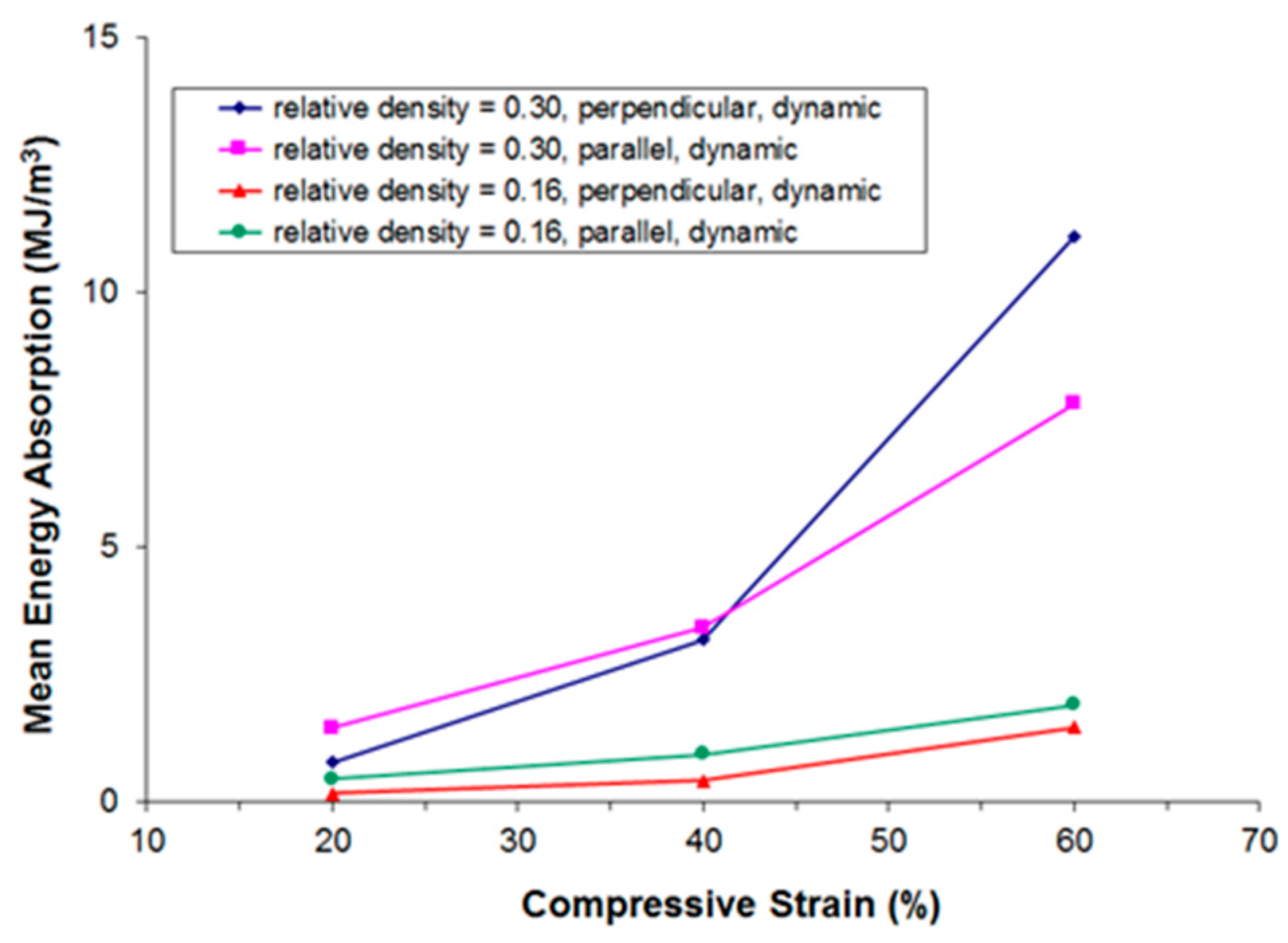

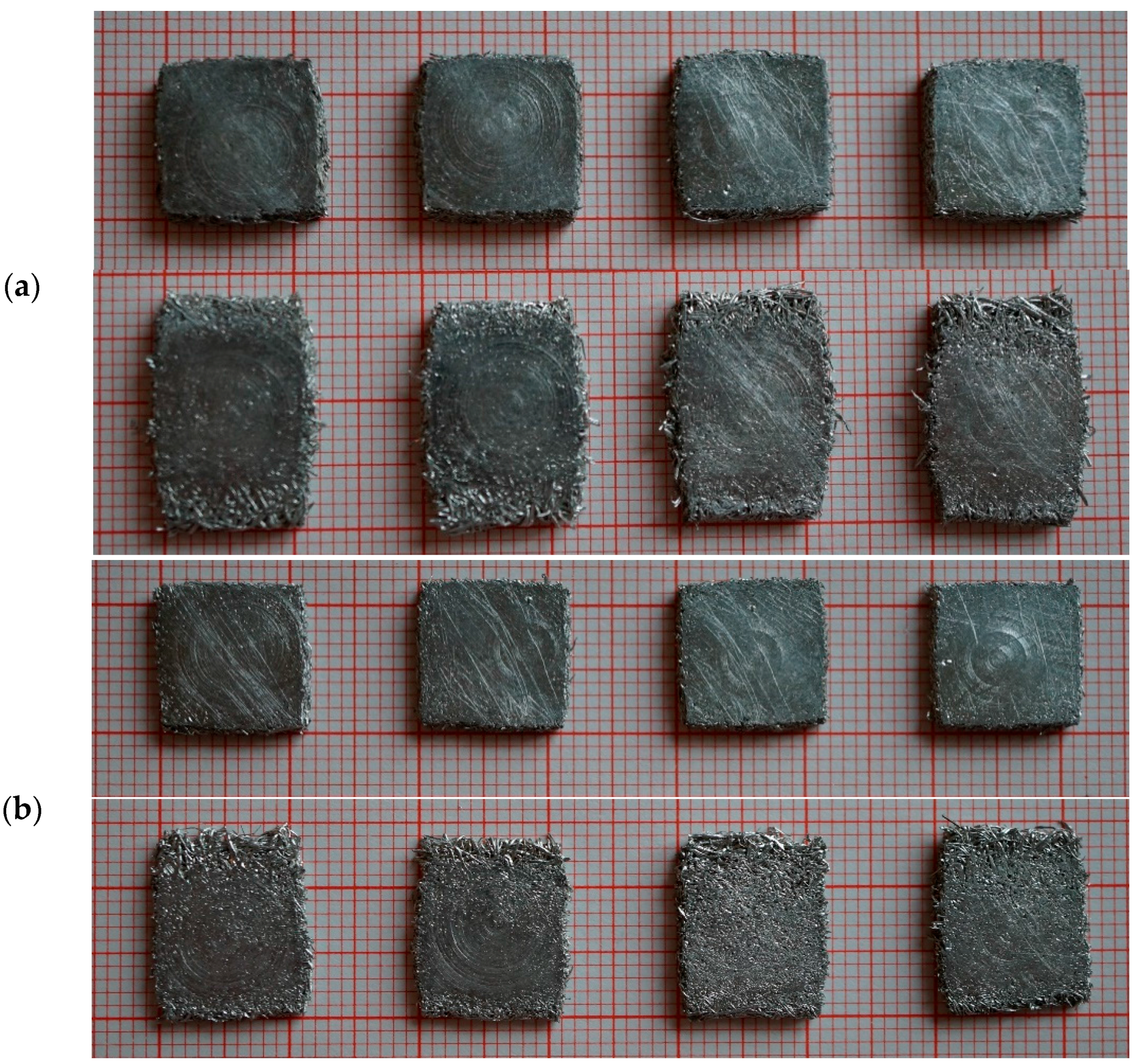

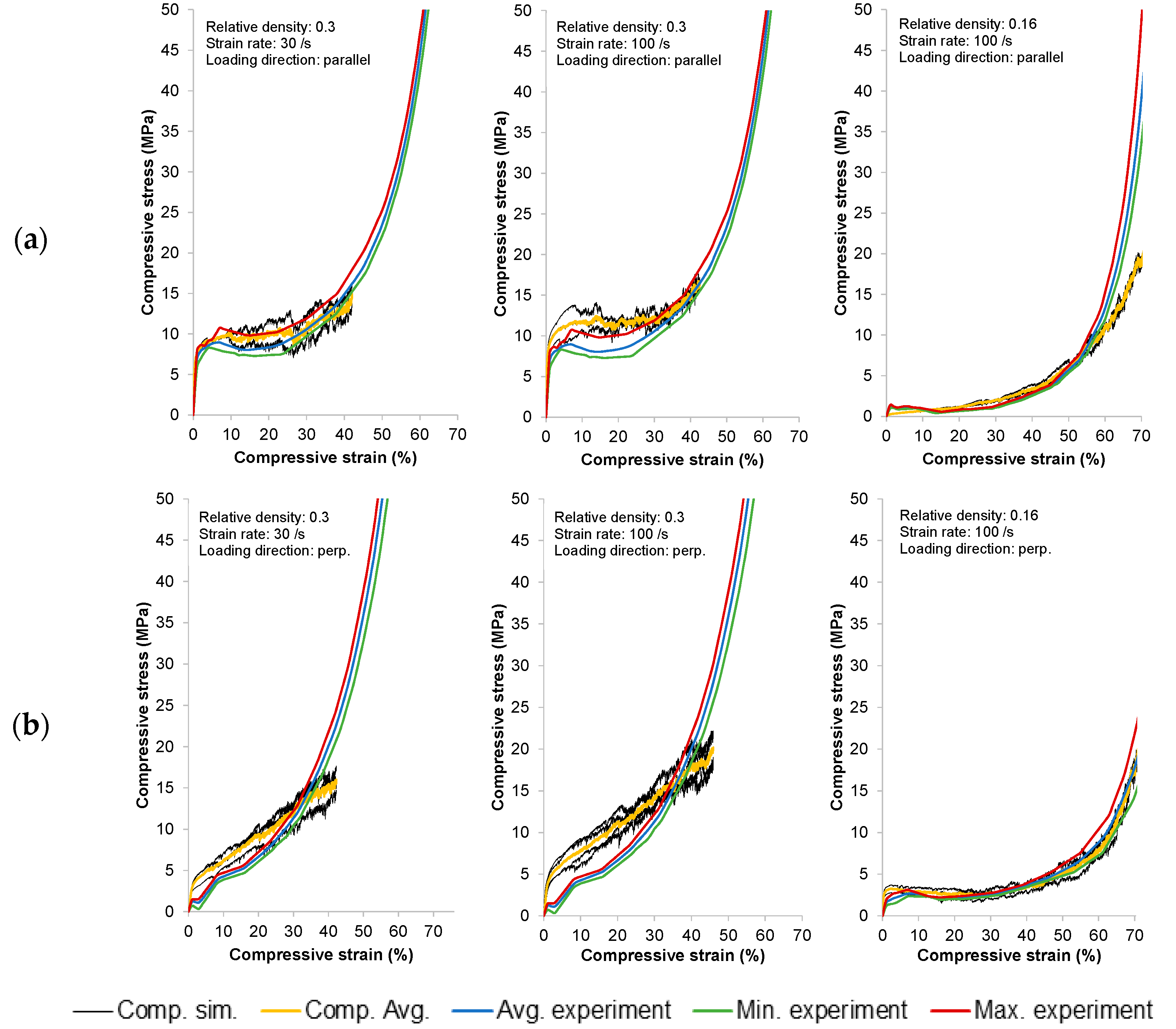

2.2. Dynamic Test Results

3. Discussion

3.1. Mechanical Behavior

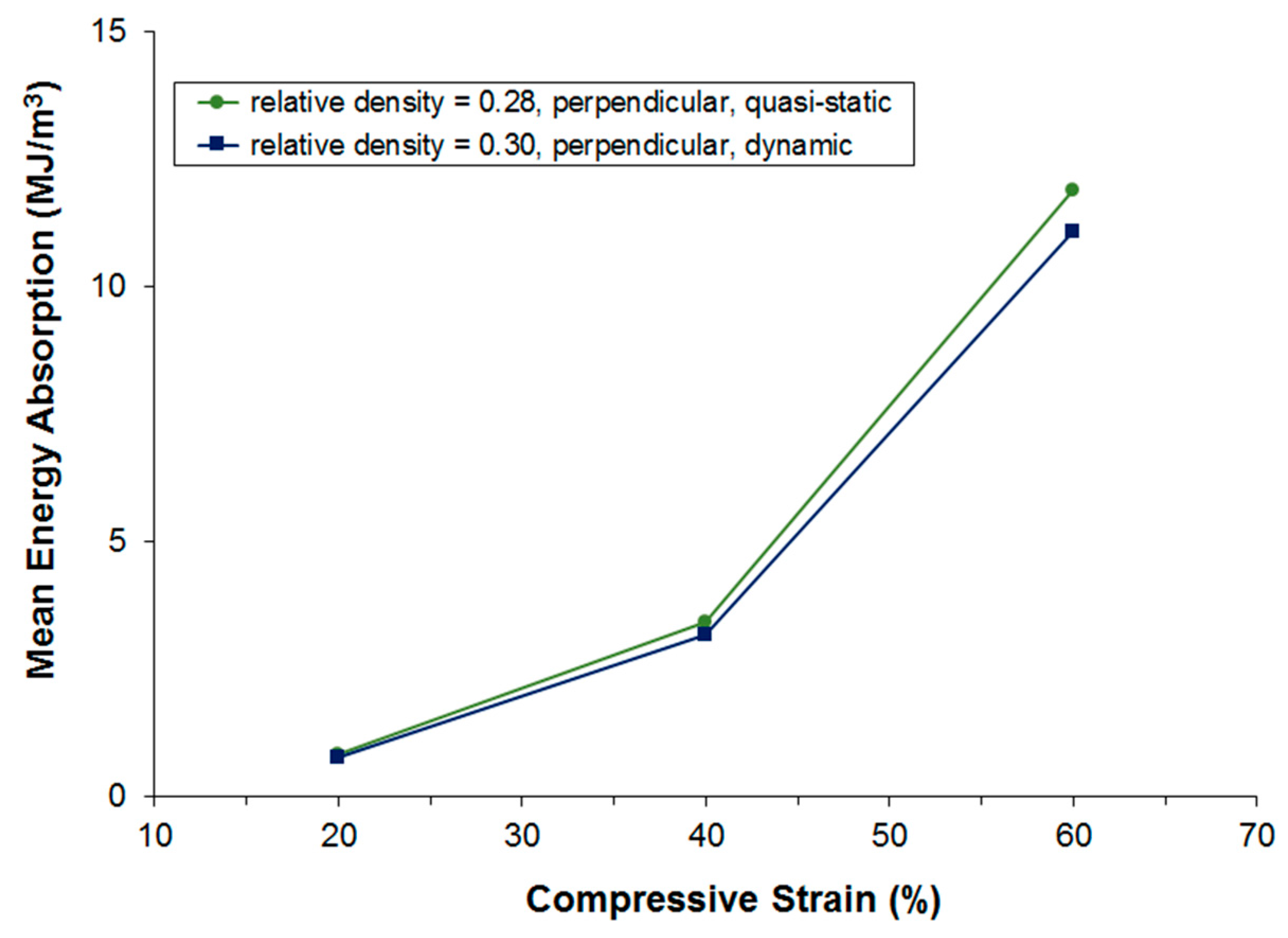

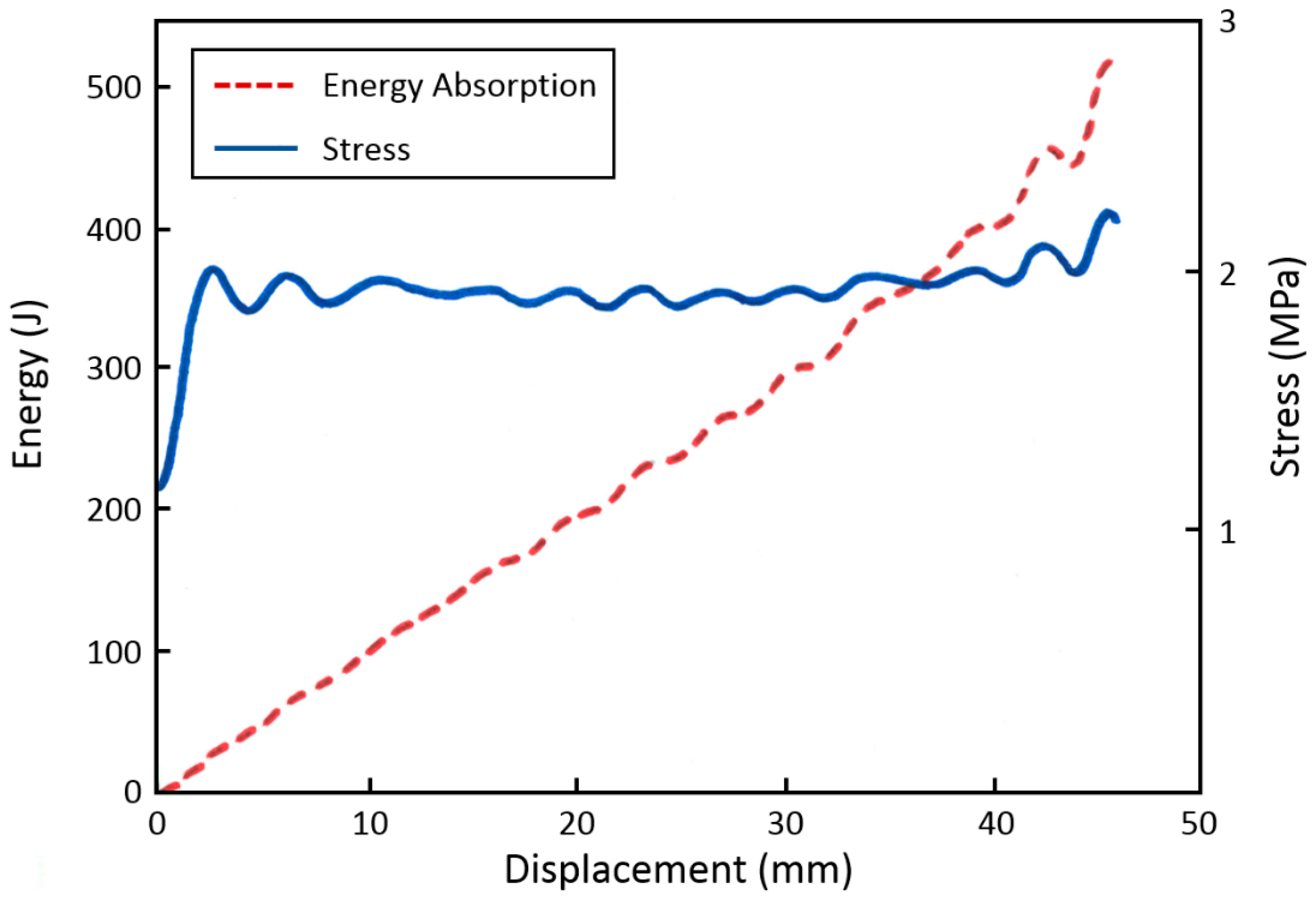

3.2. Comparison with High-Density Polymer Foam

- Sample dia. 80 mm, length 75 mm

- Foam density 110 kg/m3

- Drop tower test speed 7 m/s, punch weight 40 kg

- Fiber material AlCu5, relative sample density 0.16, absolute sample density 480 kg/m3

- Calculated volume specific energy absorption up to 40% deformation amounts to 0.41 MJ/m3 at a maximum stress of 2.26 MPa. This is reasonably close to the plateau stress value of the polymer foam

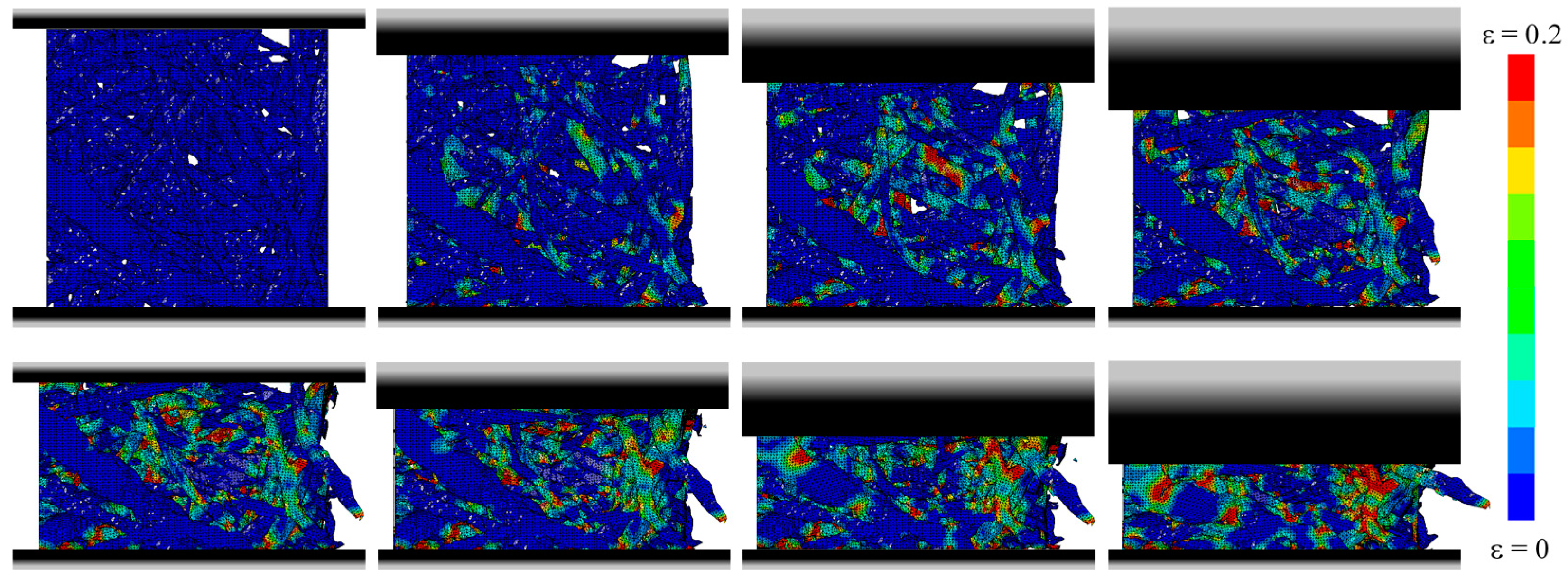

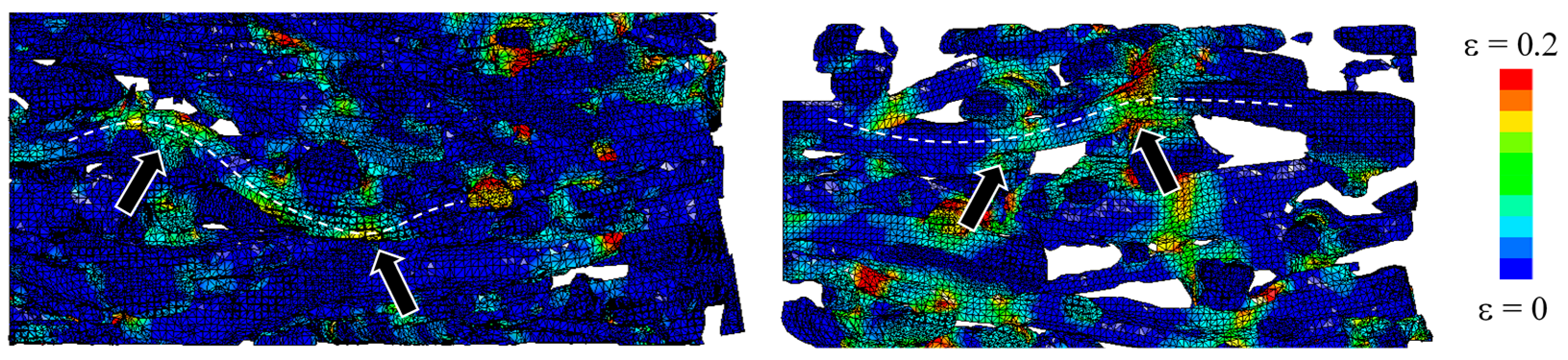

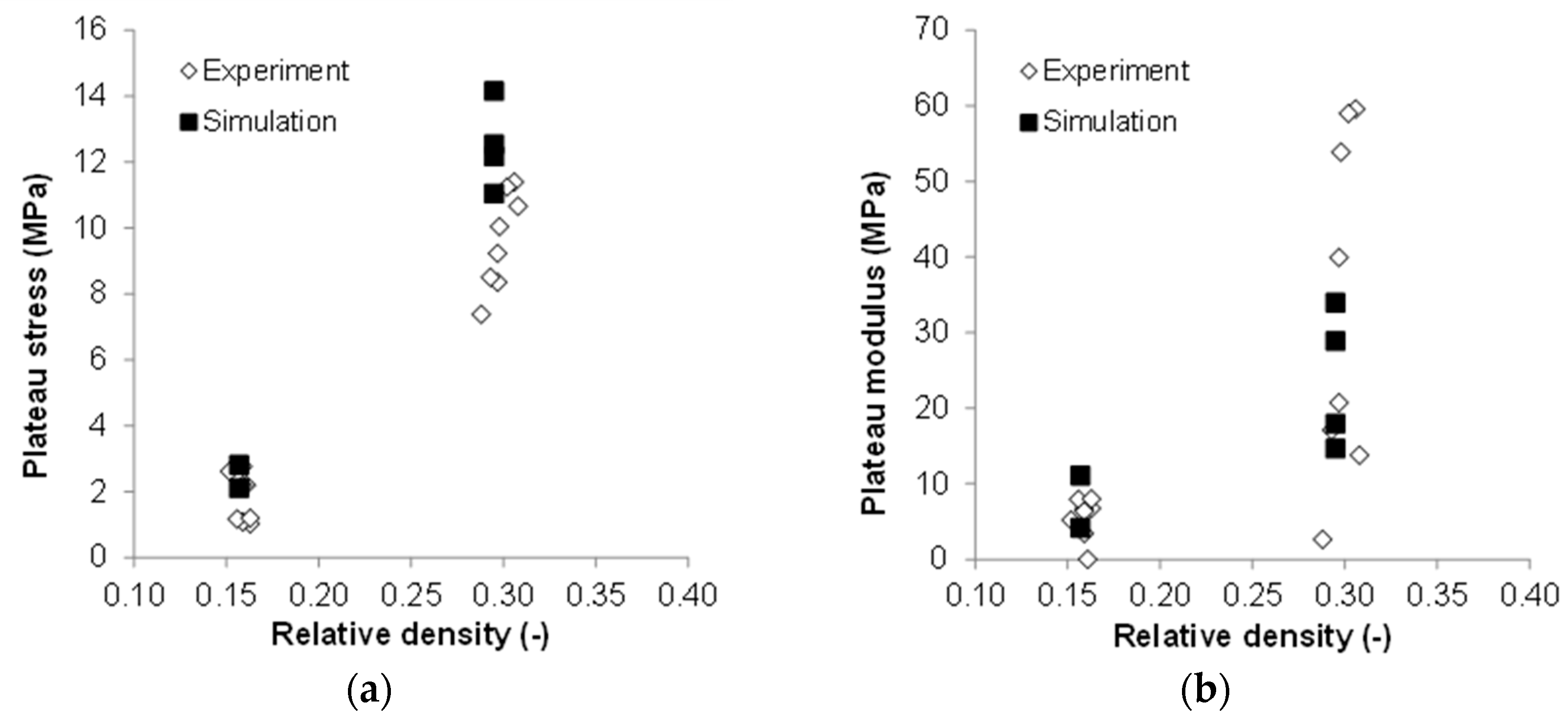

3.3. Numerical Results

4. Materials and Methods

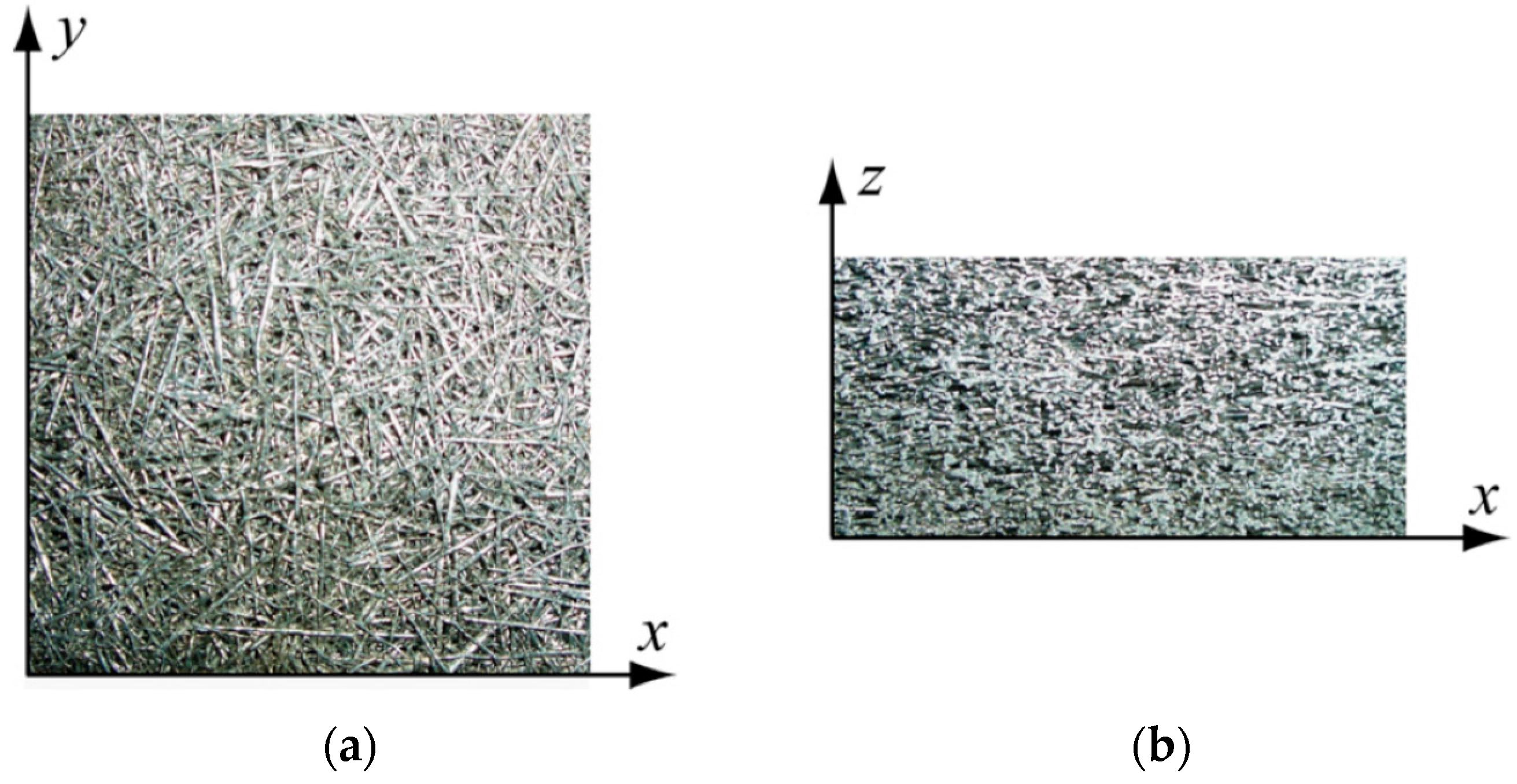

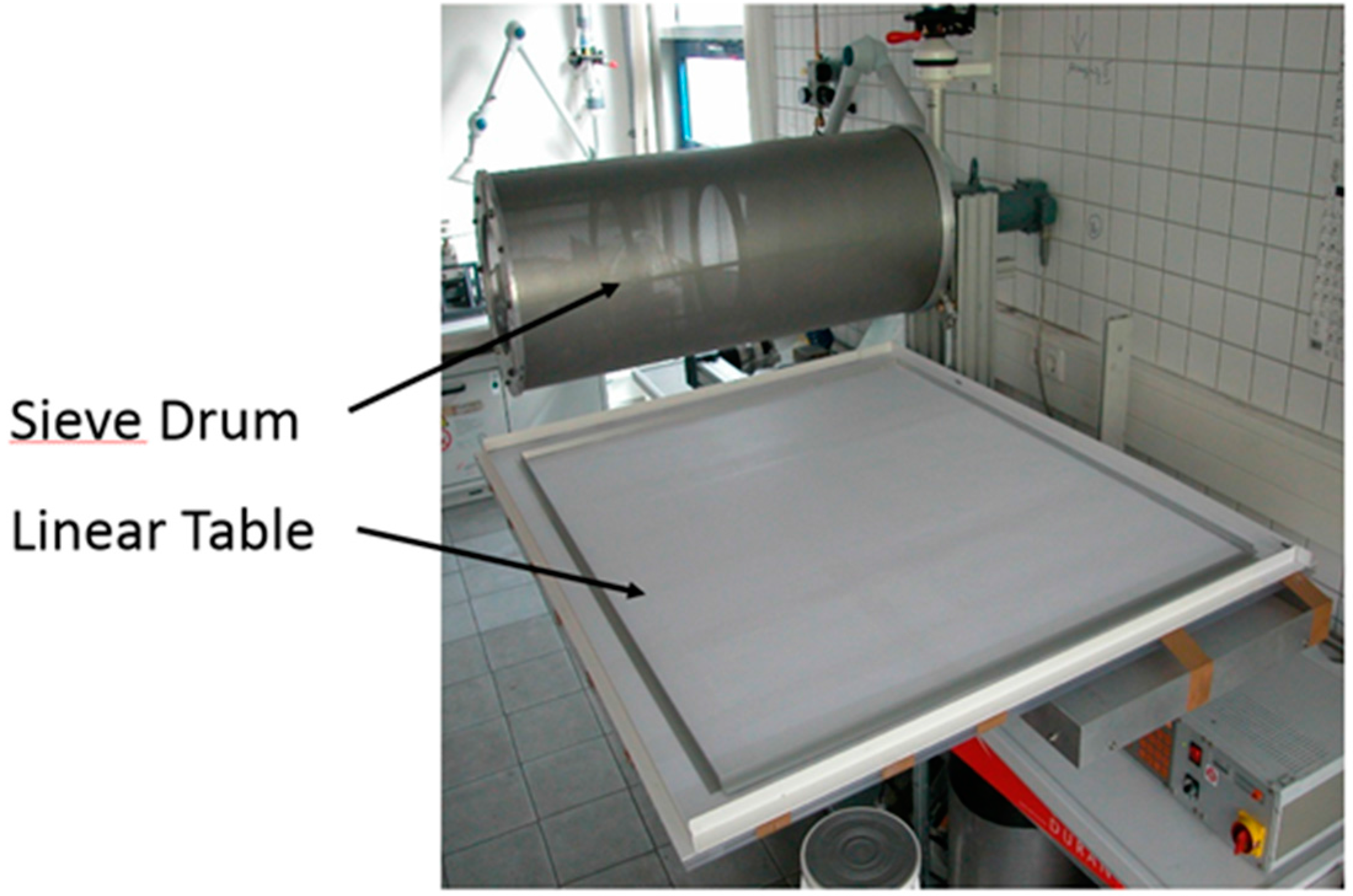

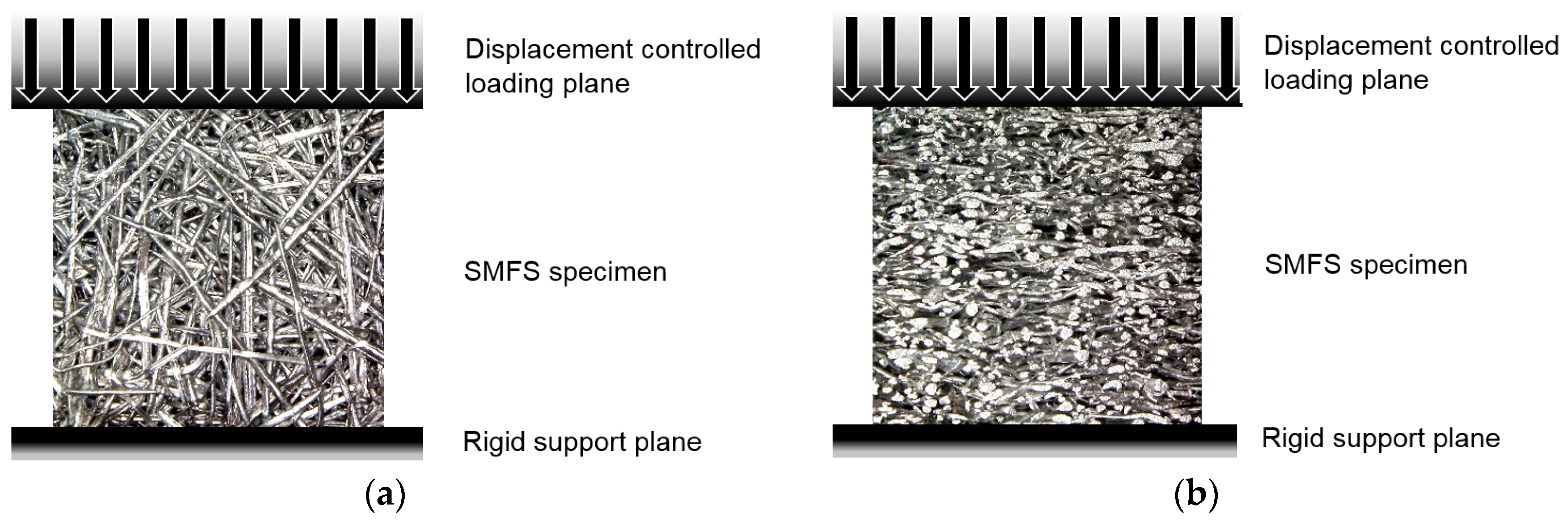

4.1. Sample Manufacturing

4.2. Quasi-Static and Dynamic Test Procedure

4.3. Numerical Methods

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Veyhl, C.; Fiedler, T.; Jehring, U.; Andersen, O.; Bernthaler, T.; Belova, I.V.; Murch, G.E. On the mechanical properties of sintered metallic fibre structures. Mater. Sci. Eng. A 2013, 562, 83–88. [Google Scholar] [CrossRef]

- Ducheyne, P.; Aernoudt, E.; De Meester, P. The mechanical behavior of porous austenitic stainless steel fibre structures. J. Mater. Sci. 1978, 13, 2650–2658. [Google Scholar] [CrossRef]

- Clyne, T.; Markaki, A.; Tan, J. Mechanical and magnetic properties of metal fibre networks, with and without a polymeric matrix. Compos. Sci. Technol. 2005, 65, 2492–2499. [Google Scholar] [CrossRef]

- Tsarouchas, D.; Markaki, A.E. Extraction of fibre network architecture by X-ray tomography and prediction of elastic properties using an affine analytical model. Acta Mater. 2011, 59, 6989–7002. [Google Scholar] [CrossRef]

- Deshpande, V.S.S.; Fleck, N.A.A. High strain rate compressive behavior of aluminum alloy foams. Int. J. Impact Eng. 2000, 24, 277–298. [Google Scholar] [CrossRef]

- Crash Absorption Structure for Formula Ford. Available online: http://www.rohacell.com/product/rohacell/en/about/downloads/technical-literature/pages/default.aspx (accessed on 15 January 2016).

- Andersen, O.; Meinert, J.; Studnitzky, T.; Stephani, G.; Kieback, B. Highly heat conductive open-porous aluminum fibre based parts for advanced heat transfer applications. Materwiss. Werksttech. 2012, 43, 328–333. [Google Scholar] [CrossRef]

- Wouterse, A.; Luding, S.; Philipse, A.P. On contact numbers in random rod packings. Granular Matter 2009, 11, 169–177. [Google Scholar] [CrossRef]

- Mechanical Testing of Metals–Ductility testing–Compression Test for Porous and Cellular Metals; ISO 13314:2011; ISO: Geneva, Switzerland, 15 December 2011.

- Vesenjak, M.; Sulong, M.A.; Krstulović-Opara, L.; Borovinšek, M.; Mathier, V.; Fiedler, T. Dynamic compression of aluminum foam derived from infiltration casting of salt dough. Mech. Mater. 2015, 93, 96–108. [Google Scholar] [CrossRef]

- Pastor, M.L.; Balandraud, X.; Grédiac, M.; Robert, J.L. Applying infrared thermography to study the heating of 2024-T3 aluminum specimens under fatigue loading. Infrared Phys. Technol. 2008, 51, 505–515. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring—A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Krstulović-Opara, L.; Surjak, M.; Vesenjak, M.; Tonković, Z.; Kodvanj, J.; Domazet, Ž. Comparison of infrared and 3D digital image correlation techniques applied for mechanical testing of materials. Infrared Phys. Technol. 2015, 73, 166–174. [Google Scholar] [CrossRef]

- Vesenjak, M.; Krstulović-Opara, L.; Ren, Z. Characterization of irregular open-cell cellular structure with silicone pore filler. Polym. Test. 2013, 32, 1538–1544. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L.; Ren, Z. Static and dynamic axial crush performance of in-situ foam-filled tubes. Compos. Struct. 2015, 124, 128–139. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L.; Anžel, I.; Ferreira, J.M.F. Manufacturing and bending behavior of in situ foam-filled aluminum alloy tubes. Mater. Des. 2015, 66, 532–544. [Google Scholar] [CrossRef]

- Vesenjak, M.; Gačnik, F.; Krstulović-Opara, L.; Ren, Z. Mechanical properties of advanced pore morphology foam elements. Mech. Adv. Mater. Struct. 2014, 22, 359–366. [Google Scholar] [CrossRef]

- Fiedler, T.; Taherishargh, M.; Krstulović-Opara, L.; Vesenjak, M. Dynamic compressive loading of expanded perlite/aluminum syntactic foam. Mater. Sci. Eng. A 2015, 626, 296–304. [Google Scholar] [CrossRef]

- Vesenjak, M.; Hokamoto, K.; Sakamoto, M.; Nishi, T.; Krstulović-Opara, L.; Ren, Z. Mechanical and microstructural analysis of unidirectional porous (Unipore) copper. Mater. Des. 2015, 90, 867–880. [Google Scholar] [CrossRef]

- Veyhl, C.; Belova, I.V.; Murch, G.E.; Fiedler, T. Finite element analysis of the mechanical properties of cellular aluminum based on micro-computed tomography. Mater. Sci. Eng. A 2011, 528, 4550–4555. [Google Scholar] [CrossRef]

- Vesenjak, M.; Veyhl, C.; Fiedler, T. Analysis of anisotropy and strain rate sensitivity of open-cell metal foam. Mater. Sci. Eng. A 2012, 541, 105–109. [Google Scholar] [CrossRef]

- Sulong, M.A.; Vesenjak, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Compressive properties of Advanced Pore Morphology (APM) foam elements. Mater. Sci. Eng. A 2014, 607, 498–504. [Google Scholar] [CrossRef]

- Veyhl, C.; Fiedler, T.; Andersen, O.; Meinert, J.; Bernthaler, T.; Belova, I.V.; Murch, G.E. On the thermal conductivity of sintered metallic fibre structures. Int. J. Heat Mass Transf. 2012, 55, 2440–2448. [Google Scholar] [CrossRef]

- Hallquist, J. LS-DYNA Keyword User’s Manual; Livermore Software Technology Corporation: Livermore, CA, USA, 2007. [Google Scholar]

| Quasi-Static Test Samples | Dynamic Test Samples - Mean Relative Density 0.3 | Dynamic Test Samples - Mean Relative Density 0.16 | |

|---|---|---|---|

| Composition | AlCu5 | AlCu5 | AlCu5 |

| Bulk Density (g/cm3) | 3.0 | 3.0 | 3.0 |

| Mean Fiber Length (mm) | 7.6 | 9.6 | 8.6 |

| Mean Equivalent Fiber Diameter 1 (µm) | 125 | 170 | 110 |

| Number of Specimens | Average Sample Weight (g) | Average Relative Density | Direction of Loading with Respect to Main Fiber Orientation |

|---|---|---|---|

| 4 | 0.92 | 0.30 | perpendicular |

| 4 | 0.91 | 0.30 | parallel |

| 4 | 0.46 | 0.16 | perpendicular |

| 4 | 0.46 | 0.16 | parallel |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andersen, O.; Vesenjak, M.; Fiedler, T.; Jehring, U.; Krstulović-Opara, L. Experimental and Numerical Evaluation of the Mechanical Behavior of Strongly Anisotropic Light-Weight Metallic Fiber Structures under Static and Dynamic Compressive Loading. Materials 2016, 9, 398. https://doi.org/10.3390/ma9050398

Andersen O, Vesenjak M, Fiedler T, Jehring U, Krstulović-Opara L. Experimental and Numerical Evaluation of the Mechanical Behavior of Strongly Anisotropic Light-Weight Metallic Fiber Structures under Static and Dynamic Compressive Loading. Materials. 2016; 9(5):398. https://doi.org/10.3390/ma9050398

Chicago/Turabian StyleAndersen, Olaf, Matej Vesenjak, Thomas Fiedler, Ulrike Jehring, and Lovre Krstulović-Opara. 2016. "Experimental and Numerical Evaluation of the Mechanical Behavior of Strongly Anisotropic Light-Weight Metallic Fiber Structures under Static and Dynamic Compressive Loading" Materials 9, no. 5: 398. https://doi.org/10.3390/ma9050398