Additive Manufacturing: Alloy Design and Process Innovations

A topical collection in Materials (ISSN 1996-1944). This collection belongs to the section "Manufacturing Processes and Systems".

Viewed by 282368Editors

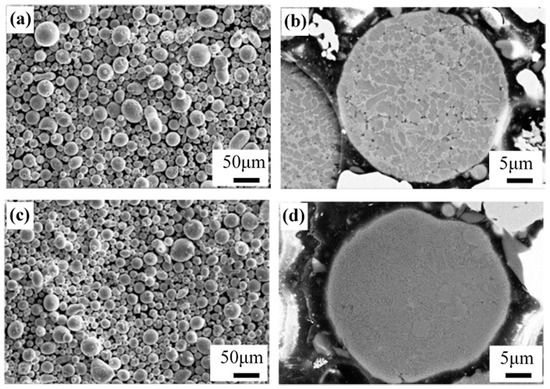

Interests: powder metallurgy; additive manufacturing; selective laser melting; meta-stable materials; amorphous alloys

Special Issues, Collections and Topics in MDPI journals

Interests: additive manufacturing; Al-based alloys; powder metallurgy; meta-stable materials; structure–property correlation in metals

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

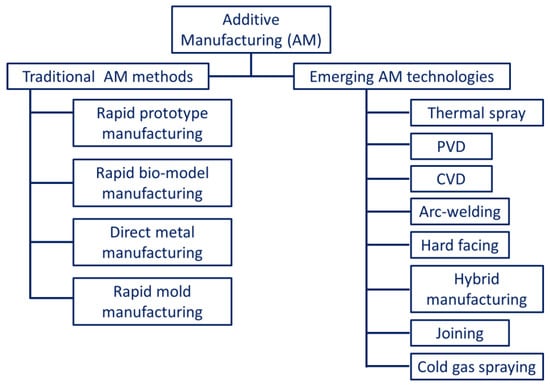

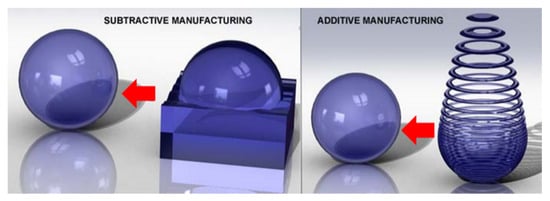

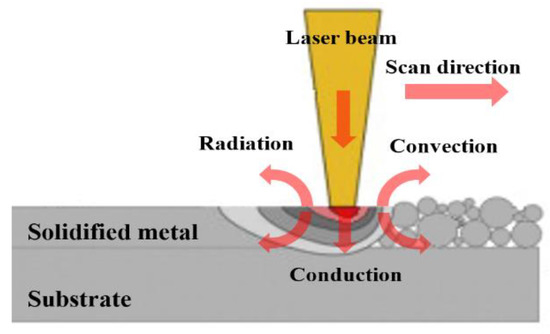

Additive manufacturing (AM) is revolutionizing the manufacturing sector, especially for the production of metallic components with added functionality, including complex or intricate geometries, conformal cooling channels, and for production of highly-customized parts with small production cycles. In addition, there is the possibility for materials saving and weight reduction of the components in automobile and aerospace sectors, helping in reducing fuel consumption and promoting a green environment. The AM field is undergoing rapid developments with new improvements and innovations taking place at a very short period of times. However, the AM field faces several challenges before it may be adapted completely in an industrial environment like the process capabilities, the material aspects including the microstructure formation and properties and the process cycle. It is, therefore, necessary to devote attention to focus the research and development activities in the field of AM and to promote the industrialization process. This includes production of powder, properties of powder, AM process developments, alloy systems used for the AM process, post-processing of the components, etc., are some of them. This Special Issue will be devoted to disseminate expert views and article contributions on the developments and innovations in the field of AM along with the design of alloys specific to additive manufacturing processes.

Scientific contributions are invited from scientists, researchers, engineers and industry to disseminate recent inventions and developments in the field of AM. The potential topics include but not limited to:

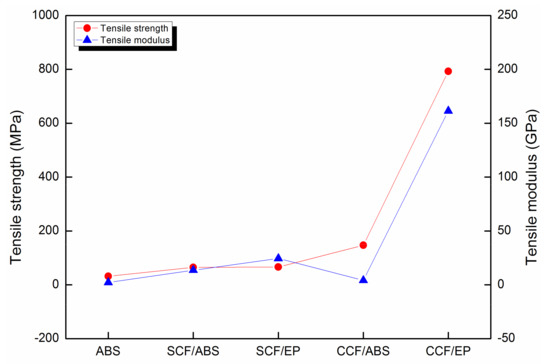

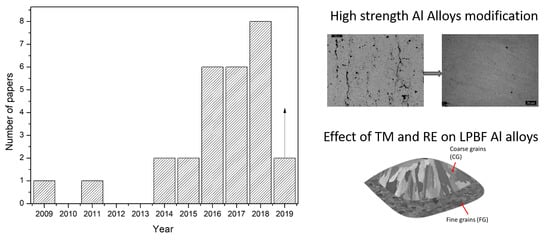

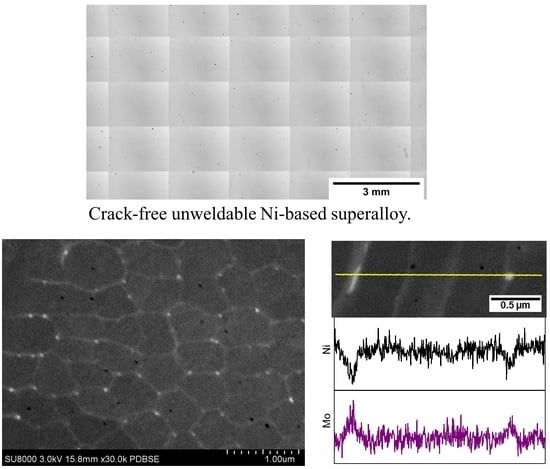

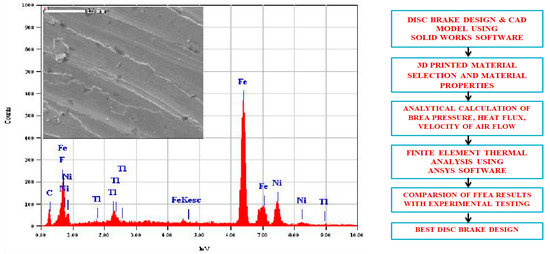

- Alloy systems and alloy development

- Next generation 4D printing

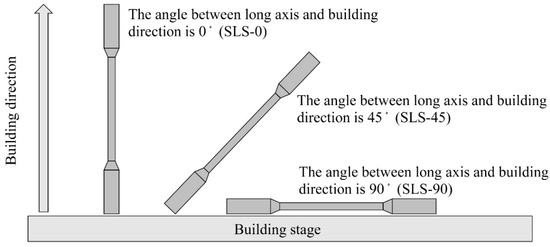

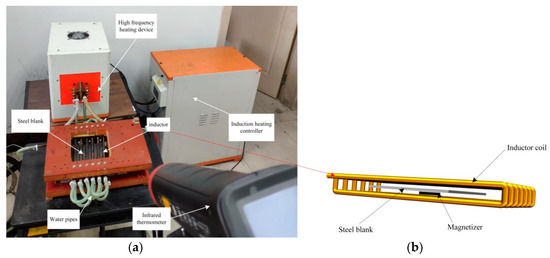

- Innovation in processing strategies

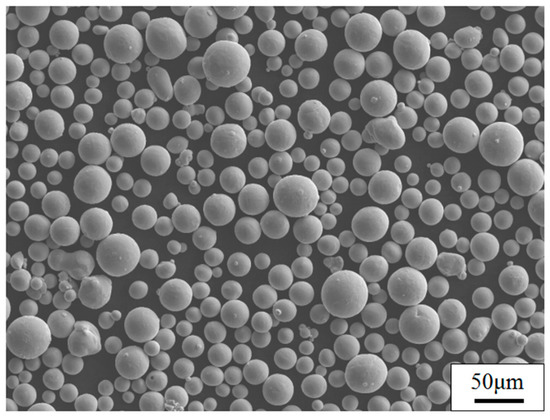

- Innovation and advancement in powder production

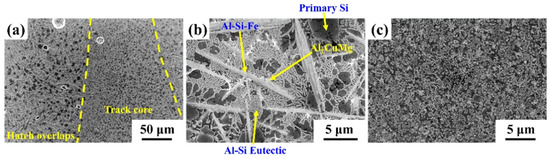

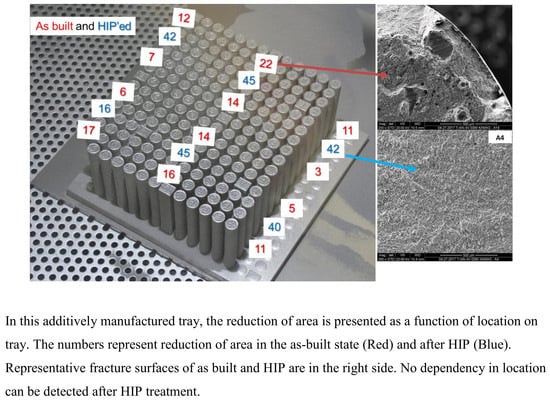

- Microstructure and property correlation

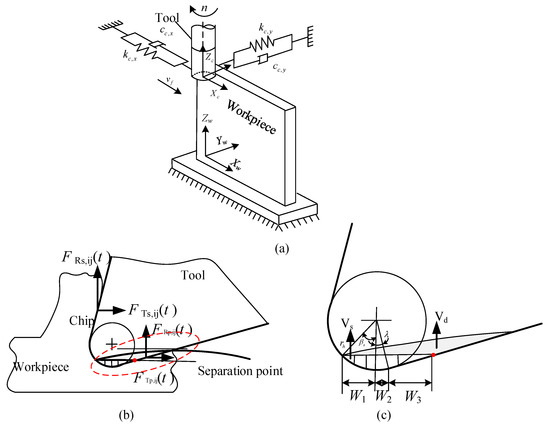

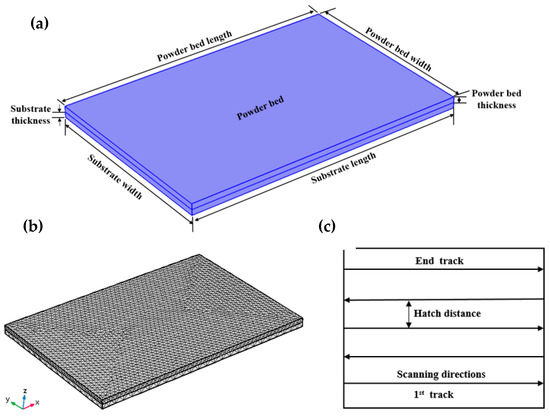

- Numerical simulation

- Defect and failure analysis

- Industrialization of the process

This Special Issue looks forward to receiving submissions in any form, including review articles, regular research articles, and short communications. Both experimental and theoretical studies are of interest.

Prof. Dr. Konda Gokuldoss Prashanth

Prof. Dr. Zhi Wang

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- Alloy Systems and Alloy Development

- Next generation 4D printing

- Innovation in Processing Strategies

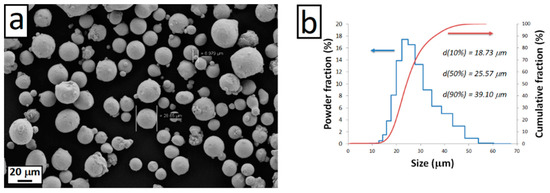

- Innovation and Advancement in Powder Production

- Microstructure and property correlation

- Numerical Simulation

- Defect and Failure Analysis

- Industrialization of the process

Related Special Issues

- Additive Manufacturing Methods and Modeling Approaches in Materials (10 articles)

- Progress in Metal Additive Manufacturing and Metallurgy in Materials (12 articles)

- Additive Manufacturing Materials and Their Applications in Materials (21 articles)

- Characterization and Properties of Materials Produced by Additive Manufacturing in Materials (11 articles)

- Hybrid Additive Manufacturing and Machining Machine-Tools and Processes in Materials (13 articles)