Journal Description

Machines

Machines

is an international, peer-reviewed, open access journal on machinery and engineering published monthly online by MDPI. The IFToMM is affiliated with Machines and its members receive a discount on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, SCIE (Web of Science), Inspec, and other databases.

- Journal Rank: JCR - Q2 (Engineering, Mechanical) / CiteScore - Q1 (Control and Optimization)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 16.9 days after submission; acceptance to publication is undertaken in 2.4 days (median values for papers published in this journal in the first half of 2025).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

- Journal Cluster of Mechanical Manufacturing and Automation Control: Aerospace, Automation, Drones, Journal of Manufacturing and Materials Processing, Machines, Robotics and Technologies.

Impact Factor:

2.5 (2024);

5-Year Impact Factor:

2.6 (2024)

Latest Articles

Towards Sustainable Manufacturing: Particle Emissions in Milling Post-Processing of 3D-Printed Titanium Alloy

Machines 2025, 13(11), 1051; https://doi.org/10.3390/machines13111051 (registering DOI) - 13 Nov 2025

Abstract

Electron beam melting (EBM) is an additive manufacturing method that enables the manufacturing of metallic parts. EBM-printed parts require post-processing to meet the surface quality and dimensional accuracy requirements. Machining is one approach that is beneficial for achieving these requirements. However, during machining,

[...] Read more.

Electron beam melting (EBM) is an additive manufacturing method that enables the manufacturing of metallic parts. EBM-printed parts require post-processing to meet the surface quality and dimensional accuracy requirements. Machining is one approach that is beneficial for achieving these requirements. However, during machining, particles are emitted and can affect the environment and the operator’s health. This study aims to investigate the concentration of particles emitted during the milling of 3D-printed Ti6Al4V alloy produced by EBM. First, the influence of machining speed and cutting fluids, namely flood and minimum quantity lubricant (MQL), on particle emissions was statistically investigated. Then, the standby time required for the operator to safely open the machine door and interact with the machine within the machining area was studied. In this regard, two scenarios were proposed. In the first scenario, the machine door is open immediately after machining, and the operator waits until the particle concentration is acceptable. In the second, the machine door will be opened only when the particle concentration is acceptable. Statistical findings revealed that cutting fluids have a significant impact on particle emissions, exhibiting distinct patterns for both fine and coarse particles. Irrespective of the scenario, MQL results in higher particle concentration peaks and larger particle sizes, and the operator needs a longer standby time before interacting with the machine. For instance, the standby time in MQL is 328% more than that of the flood system. This study provides insight into sustainable manufacturing by taking into account social factors such as worker health and safety.

Full article

(This article belongs to the Section Industrial Systems)

►

Show Figures

Open AccessArticle

To Boldly Go: Redefining Mobility with Thrust-Augmented Rocker-Bogie CanBots for Simulated Planetary Exploration

by

Carrington Chun and Muhammad Hassan Tanveer

Machines 2025, 13(11), 1050; https://doi.org/10.3390/machines13111050 (registering DOI) - 13 Nov 2025

Abstract

This research presents the first known example of a Thrust-Augmented Rocker Bogie (TARB). As a robust and passive mechanisms, the rocker bogie suspension system has seen widespread application in ground-based robotic planetary exploration rovers. However, with the first demonstration of a multirotor on

[...] Read more.

This research presents the first known example of a Thrust-Augmented Rocker Bogie (TARB). As a robust and passive mechanisms, the rocker bogie suspension system has seen widespread application in ground-based robotic planetary exploration rovers. However, with the first demonstration of a multirotor on Mars, there is clearly a need to expand the locomotion capacity for planetary rovers. The TARB builds on the existing flight heritage of the rocker rogie but also innovatively combines the system with a multirotor configuration. The combined homogeneous mobility solution can successfully demonstrate multimodal mobility including in terrestrial, aerial, and hybrid forms of locomotion. The prototype TARB developed for this research was constructed in the form of a CanBot. CanBots provide a means to test space-oriented rover technologies with earth-based analogues. Three prototype multimodal CanBots are described in this work, with each showing improvements in mobility and overall design robustness. Laboratory validation of the final TARB-equipped CanBot showed that it could utilize the rocker-bogie system to engage complicated terrestrial terrains while also maintaining the capacity to fly as an aerial vehicle. The laboratory testing also indicated that the CanBot could climb significantly steeper slopes when employing the TARB in a hybrid mode, successfully climbing slopes of 60 degrees, demonstrating static stability on inclines of up to 90 degrees, and successfully navigating along fully inverted surfaces.

Full article

(This article belongs to the Section Robotics, Mechatronics and Intelligent Machines)

►▼

Show Figures

Figure 1

Open AccessArticle

Experimental Evaluation of Milling Post-Processing on the Surface Quality of MEX-Printed Carbon Fiber-Reinforced PLA Composites

by

Abdullah Yahia AlFaify

Machines 2025, 13(11), 1049; https://doi.org/10.3390/machines13111049 - 13 Nov 2025

Abstract

This study explores the machinability of Material Extrusion (MEX) printed parts made from carbon fiber-reinforced polylactic acid (PLA). MEX-printed parts typically exhibit high surface roughness, necessitating post-processing to enhance their quality. In this work, milling was used as a post-processing method to improve

[...] Read more.

This study explores the machinability of Material Extrusion (MEX) printed parts made from carbon fiber-reinforced polylactic acid (PLA). MEX-printed parts typically exhibit high surface roughness, necessitating post-processing to enhance their quality. In this work, milling was used as a post-processing method to improve the surface finish. Response surface methodology (RSM) experimental design was employed to investigate the effects of cutting velocity, feed rate, and depth of cut on the surface quality of the machined surfaces. Results showed that the as-built MEX-printed sample exhibited a high average surface roughness (Sa) of ~7.982 µm, indicating the need for post-processing. Post-processing milling considerably enhances the Sa by reducing it to ~1.621 µm under the optimal condition. Statistical findings showed that all considered factors have significant influence on the Sa, with feed rate as the most influential one, contributing to 47.63% of the total variation. The Sa values varied from 1.834 µm to 4.146 µm due to changes in the considered factors. Increasing feed rate leads to the emergence of cavities and ridges along the deposited filaments associated with brittle removal mechanism, resulting in higher surface roughness.

Full article

(This article belongs to the Special Issue Recent Advances in Surface Integrity with Machining and Milling)

►▼

Show Figures

Figure 1

Open AccessArticle

A Health-Aware Fuzzy Logic Controller Optimized by NSGA-II for Real-Time Energy Management of Fuel Cell Electric Commercial Vehicles

by

Juan Du, Xuening Zhang, Shanglin Wang and Xiaodong Liu

Machines 2025, 13(11), 1048; https://doi.org/10.3390/machines13111048 - 13 Nov 2025

Abstract

This study introduces a health-aware fuzzy logic (FL) energy management strategy (EMS) for fuel cell electric commercial vehicles (FCECVs) that aimed to improve energy efficiency and extending fuel cell system (FCS) lifespan. The FL-based EMS was developed using vehicle power demand and battery

[...] Read more.

This study introduces a health-aware fuzzy logic (FL) energy management strategy (EMS) for fuel cell electric commercial vehicles (FCECVs) that aimed to improve energy efficiency and extending fuel cell system (FCS) lifespan. The FL-based EMS was developed using vehicle power demand and battery state of charge (SOC) as inputs, with the FCS power change rate as the output, aiming to mitigate degradation induced by abrupt load transitions. A multi-objective optimization framework was established to optimize the fuzzy logic controller (FLC) parameters, achieving a balanced trade-off between fuel economy and FCS longevity. The non-dominated sorting genetic algorithm-II (NSGA-II) was utilized for optimization across various driving cycles, with average Pareto-optimal solutions employed for real-time application. Performance evaluation under standard and stochastic driving cycles benchmarked the proposed strategy against dynamic programming (DP), charge-depletion charge-sustaining (CD-CS), conventional FL strategies, and a non-optimized baseline. Results demonstrated an approximately

(This article belongs to the Special Issue Energy Storage and Conversion of Electric Vehicles)

►▼

Show Figures

Figure 1

Open AccessArticle

The Influence of Suspension Elastokinematics on Vehicle Handling and Stability

by

Albert Basiul, Vidas Žuraulis, Robertas Pečeliūnas and Saugirdas Pukalskas

Machines 2025, 13(11), 1047; https://doi.org/10.3390/machines13111047 - 12 Nov 2025

Abstract

This study investigates the influence of suspension elastokinematics on vehicle handling and stability through a combined research of experimental testing and numerical simulation. Laboratory tests were conducted on the front suspension of a Mercedes-Benz S320 using a quarter-car test rig equipped with specialized

[...] Read more.

This study investigates the influence of suspension elastokinematics on vehicle handling and stability through a combined research of experimental testing and numerical simulation. Laboratory tests were conducted on the front suspension of a Mercedes-Benz S320 using a quarter-car test rig equipped with specialized sensors to measure wheel displacements, steering angles, camber, and accelerations. Complementary dynamic tests were carried out under real driving conditions, including braking in a turn and “fishhook” maneuvers, to capture suspension behavior under critical operating scenarios. Based on the experimental data, an MSC Adams/Car multibody simulation model was used, incorporating varying stiffness values of suspension elastomeric elements that replicated progressive aging and degradation effects. The simulation results were compared with experimental data to validate the model’s predictive capability. Key findings indicate that reductions in elastomer stiffness significantly affect wheel kinematics, vehicle yaw response, and lateral acceleration, particularly during high-intensity maneuvers. The results underline the critical importance of accounting for elastomeric component degradation in suspension modeling to ensure vehicle safety and performance over the operational lifespan. The developed methodology demonstrates the effectiveness of integrating experimental measurements with advanced simulation tools to assess elastokinematic effects on vehicle dynamics.

Full article

(This article belongs to the Special Issue Advances in Vehicle Suspension System Optimization and Control)

►▼

Show Figures

Figure 1

Open AccessArticle

Slot Number Optimization for Motorcycle Traction Motor Considering Driving Duty Cycle

by

Yang Gu, Hui Yi, Huimin Ouyang, Lei Mei, Qiang Sun and Zichong Zhu

Machines 2025, 13(11), 1046; https://doi.org/10.3390/machines13111046 - 12 Nov 2025

Abstract

Due to their compact dimensions, high torque density, high efficiency, and superior flux-weakening capabilities, permanent magnet synchronous machines with tooth-coil winding (TC-PMSMs) are highly suitable for low-power electric transportation applications. This study incorporates the actual duty cycle of an electric motorcycle in the

[...] Read more.

Due to their compact dimensions, high torque density, high efficiency, and superior flux-weakening capabilities, permanent magnet synchronous machines with tooth-coil winding (TC-PMSMs) are highly suitable for low-power electric transportation applications. This study incorporates the actual duty cycle of an electric motorcycle in the optimization of the slot number for the drive machine. The proposed methodology addresses the shortcomings of conventional design strategies, which typically consider only a limited set of operating points, leading to suboptimal round-trip efficiency under real driving conditions. Firstly, the influence of slot number on torque output, electromagnetic losses, and flux-weakening performance is examined for 10-pole TC-PMSMs using finite element analysis. Subsequently, the optimal slot number is identified by integrating the real duty cycle of the drive motor into the evaluation. To verify the accuracy and effectiveness of the analytical results and design approach, prototypes of stator assemblies with varying slot numbers were fabricated and experimentally tested.

Full article

(This article belongs to the Section Electrical Machines and Drives)

►▼

Show Figures

Figure 1

Open AccessArticle

Ball Mill Load Classification Method Based on Multi-Scale Feature Collaborative Perception

by

Saisai He, Zhihong Jiang, Wei Huang, Lirong Yang and Xiaoyan Luo

Machines 2025, 13(11), 1045; https://doi.org/10.3390/machines13111045 - 12 Nov 2025

Abstract

Against the backdrop of intelligent manufacturing, the ball mill, as a key energy-consuming piece of equipment, requires an accurate perception of its load state, which is crucial for optimizing production efficiency and ensuring operational safety. However, its vibration signals exhibit typical nonlinear and

[...] Read more.

Against the backdrop of intelligent manufacturing, the ball mill, as a key energy-consuming piece of equipment, requires an accurate perception of its load state, which is crucial for optimizing production efficiency and ensuring operational safety. However, its vibration signals exhibit typical nonlinear and non-stationary characteristics, intertwined with complex noise, posing significant challenges to high-precision identification. A core contradiction exists in existing diagnostic methods: convolution network-based methods excel at capturing local features but overlook global trends, while Transformer-type models, although capable of capturing long-range dependencies, tend to “average out” critical local transient information during modeling. To address this dilemma, this paper proposes a new paradigm for multi-scale feature collaborative perception. This paradigm is implemented through an innovative deep learning architecture—the Residual Block-Swin Transformer Network (RB-SwinT). This architecture subtly achieves hierarchical and in-depth integration of the powerful global context modeling capability of Swin Transformer and the excellent local detail refinement capability of the residual module (ResBlock), enabling synchronous and efficient representation of both the macro trends and micro mutations of signals. On the experimental dataset covering nine types of fine operating conditions, the overall recognition accuracy of the proposed method reaches as high as 96.20%, which is significantly superior to a variety of mainstream models. To further verify the model’s generalization ability, this study was tested on the CWRU public bearing fault dataset, achieving a recognition accuracy of 99.36%, which outperforms various comparative methods such as SAVMD-CNN. This study not only provides a reliable new technical approach for ball mill load identification but also demonstrates its practical application value in indicating critical operating conditions and optimizing production operations through an in-depth analysis of the physical connotations of each load level. More importantly, its “global-local” collaborative modeling concept opens up a promising technical path for processing a broader range of complex industrial time-series data.

Full article

(This article belongs to the Section Advanced Manufacturing)

►▼

Show Figures

Figure 1

Open AccessArticle

Design and Development of an Autonomous Mobile Robot for Unstructured Indoor Environments

by

Ameur Gargouri, Mohamed Karray, Bechir Zalila and Mohamed Ksantini

Machines 2025, 13(11), 1044; https://doi.org/10.3390/machines13111044 - 12 Nov 2025

Abstract

This research work presents the design and the development of a cost-effective autonomous mobile robot for locating misplaced objects within unstructured indoor environments. The tools integrated into the proposed system for perception and localization are a hardware architecture equipped with LiDAR, an inertial

[...] Read more.

This research work presents the design and the development of a cost-effective autonomous mobile robot for locating misplaced objects within unstructured indoor environments. The tools integrated into the proposed system for perception and localization are a hardware architecture equipped with LiDAR, an inertial measurement unit (IMU), and wheel encoders. The system also includes an ROS2-based software stack enabling autonomous navigation via the NAV2 framework and Adaptive Monte Carlo Localization (AMCL). For real-time object detection, a lightweight YOLO11n model is developed and implemented on a Raspberry Pi 4 to enable the robot to identify common household items. The robot’s motion control is achieved by a fuzzy logic-enhanced PID controller that dynamically modifies gain values based on navigation conditions. Remote supervision, task management, and real-time status monitoring are provided by a user-friendly Flutter-based mobile application. Simulations and real-world experiments demonstrate the robustness, modularity, and responsiveness of the robot in dynamic environments. This robot achieves a 3 cm localization error and a 95% task execution success rate.

Full article

(This article belongs to the Special Issue Recent Developments in Machine Design, Automation and Robotics, Second Edition)

►▼

Show Figures

Figure 1

Open AccessArticle

Study on the Influence of the Mechanical Characteristics of the Cutting-Type Anti-Climbing Energy Absorber on the Collision Behavior of the GFRP Head Cover for Subways

by

Xuan Liu, Ping Xu, Yifan Hu, Ying Gao and Dongtao Wang

Machines 2025, 13(11), 1043; https://doi.org/10.3390/machines13111043 - 12 Nov 2025

Abstract

Anti-climbing energy absorbers (AEAs) are often installed at the ends of subway vehicles to prevent climbing in the event of a head-on collision or rear-end collision, thereby improving safety performance. To reduce the air resistance of the vehicle during operation, the AEA is

[...] Read more.

Anti-climbing energy absorbers (AEAs) are often installed at the ends of subway vehicles to prevent climbing in the event of a head-on collision or rear-end collision, thereby improving safety performance. To reduce the air resistance of the vehicle during operation, the AEA is usually wrapped with the GFRP head cover. However, the collision behavior of the head cover during a collision requires further research. The effects of mechanical properties of cutting anti-climbing energy absorbers (CAEAs) on the collision behavior of glass fiber reinforced polymer (GFRP) head covers for subway vehicles are investigated in this study. Firstly, the force–displacement curve of the CAEA was obtained through a dynamic impact test, and the finite element (FE) model of the CAEA with a GFRP head cover was constructed and verified. Subsequently, the effects of the four mechanical characteristics of the CAEA (i.e., initial peak crushing force (IPCF), platform force, compaction force, and eccentric height difference) on the collision behavior of the GFRP head cover were systematically analyzed. The results show that the increase in IPCF improves the energy absorption of CAEA, but that damage and stress concentration of the head cover at the moving end also occur. The increase in platform force induced the premature fracture of the GFRP head cover. The collision behavior of the head cover reaches a critical value when the compaction force is between 2500 and 3000 kN. Increasing the eccentric height difference between the anti-climbing teeth weakens the cutting energy absorption efficiency of CAEA and changes its deformation mode. This study can provide important insights into the design and optimization of anti-climbing energy absorbers for subway vehicles, and has important engineering value for improving the durability of the head cover and the collision safety of the vehicle.

Full article

(This article belongs to the Section Advanced Manufacturing)

►▼

Show Figures

Figure 1

Open AccessArticle

A Woven Soft Wrist-Gripper Composite End-Effector with Variable Stiffness: Design, Modeling, and Characterization

by

Pan Zhou, Yangzuo Liu, Junxi Chen, Haoyuan Chen, Haili Li and Jiantao Yao

Machines 2025, 13(11), 1042; https://doi.org/10.3390/machines13111042 - 11 Nov 2025

Abstract

Soft robots often suffer from insufficient load capacity due to the softness of their materials. Existing variable stiffness technologies usually introduce rigid components, resulting in decreased flexibility and complex structures of soft robots. To address these challenges, this work proposes a novel wrist-gripper

[...] Read more.

Soft robots often suffer from insufficient load capacity due to the softness of their materials. Existing variable stiffness technologies usually introduce rigid components, resulting in decreased flexibility and complex structures of soft robots. To address these challenges, this work proposes a novel wrist-gripper composite soft end-effector based on the weaving jamming principle, which features a highly integrated design combining structure, actuation, and stiffness. This end-effector is directly woven from pneumatic artificial muscles through weaving technology, which has notable advantages such as high integration, strong performance designability, lightweight construction, and high power density, effectively reconciling the technical trade-off between compliance and load capacity. Experimental results demonstrate that the proposed end-effector exhibits excellent flexibility and multi-degree-of-freedom grasping capabilities. Its variable stiffness function enhances its ability to resist external interference by 4.77 times, and its grasping force has increased by 1.7 times, with a maximum grasping force of 102 N. Further, a grasping force model for this fiber-reinforced woven structure is established, providing a solution to the modeling challenge of highly coupled structures. A comparison between theoretical and experimental data indicates that the modeling error does not exceed 7.8 N. This work offers a new approach for the design and analysis of high-performance, highly integrated soft end-effectors, with broad application prospects in unstructured environment operations, non-cooperative target grasping, and human–robot collaboration.

Full article

(This article belongs to the Section Robotics, Mechatronics and Intelligent Machines)

►▼

Show Figures

Figure 1

Open AccessArticle

Solid Lubricants for the Wheel–Rail Interface: Practical Experience and Computational Estimation of Their Effects

by

Tomáš Michálek, Petr Voltr, Stanislava Liberová and Jiří Šlapák

Machines 2025, 13(11), 1041; https://doi.org/10.3390/machines13111041 - 11 Nov 2025

Abstract

This paper deals with solid lubricants for the wheel–rail interface; the topic is viewed from two different but complementary perspectives. By means of simulations, the potential contribution of these lubricants, applied for purposes of wheel flange lubrication on curved tracks, to the reduction

[...] Read more.

This paper deals with solid lubricants for the wheel–rail interface; the topic is viewed from two different but complementary perspectives. By means of simulations, the potential contribution of these lubricants, applied for purposes of wheel flange lubrication on curved tracks, to the reduction in the wheel–rail wear level is estimated. Further, the relationship between frictional work in wheel–rail contact and guiding forces is investigated. The aim of this paper is to contribute to the knowledge of a physical basis for this relationship and to help understand the capability of these quantities to quantify the damaging effects of running vehicles on curved tracks. The mechanism of the observed increase in quasi-static guiding force on the leading wheel with lubricated wheel flanges is described in detail, using different quantities characterizing the steady running of a vehicle through a curve. The limitation of the contribution of wheel flange lubrication to the reduction in total frictional power on all wheels of the vehicle is also explained. In the second part, attention is paid to a practical assessment of the performance of solid lubricant samples using the testing methodology of the European standards EN 15427-2-1 and EN 16028. The aim of this part of the paper is to summarize the authors’ experience with twin-disc machine measurements, showing imperfections in the standardized testing methodology, as well as the significantly different performance of various solid lubricant samples, which is influenced by many factors. Based on their experience, further research on solid lubricant performance using wheel–rail roller rigs is outlined.

Full article

(This article belongs to the Section Friction and Tribology)

►▼

Show Figures

Figure 1

Open AccessArticle

Chain-Based Outlier Detection: Interpretable Theories and Methods for Complex Data Scenarios

by

Huiwen Dong, Meiliang Liu, Shangrui Wu, Qing-Guo Wang and Zhiwen Zhao

Machines 2025, 13(11), 1040; https://doi.org/10.3390/machines13111040 - 11 Nov 2025

Abstract

Outlier detection is a critical task in the intelligent operation and maintenance (O&M) of transportation equipment, as it helps ensure the safety and reliability of systems like high-speed trains, aircraft, and intelligent vehicles. Nearest neighbor-based detectors generally offer good interpretability, but often struggle

[...] Read more.

Outlier detection is a critical task in the intelligent operation and maintenance (O&M) of transportation equipment, as it helps ensure the safety and reliability of systems like high-speed trains, aircraft, and intelligent vehicles. Nearest neighbor-based detectors generally offer good interpretability, but often struggle with complex data scenarios involving diverse data distributions and various types of outliers, including local, global, and cluster-based outliers. Moreover, these methods typically rely on predefined contamination, which is a critical parameter that directly determines detection accuracy and can significantly impact system reliability in O&M environments. In this paper, we propose a novel chain-based theory for outlier detection with the aim to provide an interpretable and transparent solution for fault detection. We introduce two methods based on this theory: Cascaded Chain Outlier Detection (CCOD) and Parallel Chain Outlier Detection (PCOD). Both methods identify outliers through sudden increases in chaining distances, with CCOD being more sensitive to local data distributions, while PCOD offers higher computational efficiency. Experimental results on synthetic and real-world datasets demonstrate the superior performance of our methods compared to existing state-of-the-art techniques, with average improvements of 11.3% for CCOD and 14.5% for PCOD.

Full article

(This article belongs to the Section Machines Testing and Maintenance)

►▼

Show Figures

Figure 1

Open AccessArticle

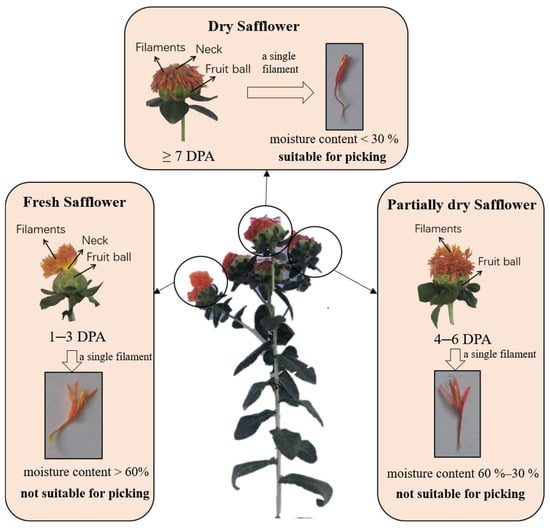

Design and Experiment of a Roller-Brush Type Harvesting Device for Dry Safflower Based on Plant Clamping and Pose Adjustment

by

Chunjiao Ma, Haifeng Zeng, Yun Ge, Guotao Li, Botao He and Yangyang Guo

Machines 2025, 13(11), 1039; https://doi.org/10.3390/machines13111039 - 11 Nov 2025

Abstract

To address the challenges of low efficiency and high damage rates in dryland safflower harvesting, a roller-brush type harvesting device was developed. The design was developed following a detailed analysis of the spatial distribution and mechanical characteristics of safflower plants. The pose adjustment

[...] Read more.

To address the challenges of low efficiency and high damage rates in dryland safflower harvesting, a roller-brush type harvesting device was developed. The design was developed following a detailed analysis of the spatial distribution and mechanical characteristics of safflower plants. The pose adjustment process begins with helical grooves clamping and contacting the plant stem. The propulsion action of the helix then forces the stem to undergo a predetermined deflection displacement. The optimal picking pose occurs when the plant’s longitudinal axis is perpendicular to the rotational axis of the picking roller brush. In this position, the picking roller brush shears the filaments at the necking zone through gentle contact with the fruit balls. This mechanism transforms the traditional pull-off separation into a low-damage shear-separation mode. The Box–Behnken test was designed to find the optimal combination of parameters for picking: picking roller brush speed of 282.5 r/min, roller brush spacing of 3.7 mm, and brush bristle diameter of 0.1 mm. Verification tests showed the picking, damage and fruit injury rates were 92.4%, 7.1% and 1.2%, respectively, with standard deviations of 5.42%, 0.51%, and 0.08%. The harvesting efficiency reached 0.053 hm2/h, 8.48 to 12.01 times higher than manual harvesting.

Full article

(This article belongs to the Section Machine Design and Theory)

►▼

Show Figures

Figure 1

Open AccessArticle

Design-Orientated Optimization and Motion Planning of a Parallel Platform for Improving Performance of an 8-DOF Hybrid Surgical Robot

by

Asna Kalsoom, Muhammad Faizan Shah, Zareena Kausar, Faizan Khan Durrani, Syed Zahid Hussain and Muhammad Umer Farooq

Machines 2025, 13(11), 1038; https://doi.org/10.3390/machines13111038 - 9 Nov 2025

Abstract

The emergence of surgical robots has revolutionized complex operations, improving precision, lowering operating risks, and shortening recovery periods. Given the merits, an eight degrees of freedom (DOF) hybrid surgical robot (HSR) has been proposed, which leverages the benefits of both serial and parallel

[...] Read more.

The emergence of surgical robots has revolutionized complex operations, improving precision, lowering operating risks, and shortening recovery periods. Given the merits, an eight degrees of freedom (DOF) hybrid surgical robot (HSR) has been proposed, which leverages the benefits of both serial and parallel manipulators. However, its performance is hindered by the constrained range of motion of its parallel platform. To address the issue, this research presents a systematic approach for designing and optimizing the proposed HSR. The first step is the design of the HSR, followed by a multi-stage design analysis of its parallel platform, concentrating on kinematic, geometrical, and singularity analysis. Higher values of the condition number indicate singular configurations in the platform’s workspace, highlighting the need for an optimized design. For optimization of the platform, performance parameters like global condition number (GCN), actuator forces, and stiffness are identified. Initially, the design is optimized by targeting GCN only through a genetic algorithm (GA). This approach compromised the other parameters and raised the need for simultaneous optimization employing a non-dominated sorting genetic algorithm (NSGA II). It offered a better trade-off between performance parameters. To further assess the working of the optimized parallel platform, workspace analysis and motion planning of a predefined trajectory have been performed.

Full article

(This article belongs to the Special Issue Mechanical Design of Parallel Manipulators)

►▼

Show Figures

Figure 1

Open AccessArticle

Stress–Strain Evolution and Multi-Pass Process Optimization in Mandrel-Free Hot Spinning of Wind Tunnel Nozzles

by

Piyao Liu, Linsen Song, Zhenhui Li, Wei Liang, Ziwei Jiang, Xiaosha Tang, Qiang Gao and Shuang Guo

Machines 2025, 13(11), 1037; https://doi.org/10.3390/machines13111037 - 9 Nov 2025

Abstract

Traditional manufacturing methods of wind tunnel nozzles are often cumbersome, time-consuming, and costly. The study of spinning forming technology for wind tunnel nozzles provides a pathway to improve manufacturing efficiency while reducing both cost and production cycle. However, when processing alloy steel (20MnMo),

[...] Read more.

Traditional manufacturing methods of wind tunnel nozzles are often cumbersome, time-consuming, and costly. The study of spinning forming technology for wind tunnel nozzles provides a pathway to improve manufacturing efficiency while reducing both cost and production cycle. However, when processing alloy steel (20MnMo), challenges arise due to large deformation, high-temperature loading, and complex wall-thickness control. To address these issues, this work proposes a die-less multi-pass hot spinning process. A three-dimensional dynamic explicit finite element model was developed to simulate the stress–strain evolution during multi-pass spinning. In the first pass, an L9 orthogonal experimental design was applied to analyze the influence of spinning parameters on forming stress and plastic deformation capacity, thereby determining the optimal combination of workpiece rotation speed, axial feed, and radial feed rates. The optimized design strategy was subsequently extended to ten passes. Based on simulation results, hot spinning experiments were conducted, followed by precision machining of the nozzle’s inner and outer surfaces. Inspection results indicated that the deviations in contour and wall thickness between simulation predictions and actual specimens were both less than 0.5%. This study establishes an integrated process route combining numerical simulation, hot spinning, and finishing, providing both theoretical support and practical guidance for the high-precision and high-stability manufacturing of complex thin-walled nozzle structures.

Full article

(This article belongs to the Section Machine Design and Theory)

►▼

Show Figures

Figure 1

Open AccessArticle

Genetic Algorithm-Based Optimization of Velocity Profiles for Multi-Robot Collision Avoidance

by

Luca Marseglia, Alberto Vale and Giuseppe Di Gironimo

Machines 2025, 13(11), 1036; https://doi.org/10.3390/machines13111036 - 9 Nov 2025

Abstract

Efficient coordination of multiple mobile robots is essential in automated systems, especially when robots must follow predefined paths while avoiding collisions. This paper proposes a centralized optimization framework using Genetic Algorithms to optimize the velocity profiles of a system of robots without altering

[...] Read more.

Efficient coordination of multiple mobile robots is essential in automated systems, especially when robots must follow predefined paths while avoiding collisions. This paper proposes a centralized optimization framework using Genetic Algorithms to optimize the velocity profiles of a system of robots without altering their paths. The goal is to minimize task completion time and energy consumption while ensuring collision avoidance. Three Genetic Algorithm-based methods are introduced: Maximum Velocity Optimization, Slow-Down Segment Single-Objective Optimization and Slow-Down Segment Multi-Objective Optimization. The first method adjusts each robot’s maximum velocity along its entire path, whereas the second introduces a slow-down segment only at the start of its path. While these two approaches only optimize task completion time, the third method contains a multi-objective formulation, producing solutions that balance time and energy. Methods such as Brute-Force and Prioritized Planning were used as baseline methods for comparison. Simulation results indicate that the proposed strategies significantly outperform the baseline methods. Furthermore, the second method achieves better results than the first by introducing more targeted velocity adjustments, while the third further enhances flexibility by offering a range of trade-offs between task completion time and energy consumption. Scalability and computational cost remain critical challenges, especially as the number of robots increases.

Full article

(This article belongs to the Section Automation and Control Systems)

►▼

Show Figures

Figure 1

Open AccessArticle

Performance Analysis and Optimization of a Bio-Inspired Spider-Web-Shaped Energy Absorbing Component for Legged Landers

by

Xueao Liu, Hui Wang, Kai Yang, Bin Zhang, Xuecong Wang, Kaiting Liu and Shiming Zhou

Machines 2025, 13(11), 1035; https://doi.org/10.3390/machines13111035 - 8 Nov 2025

Abstract

Inspired by the structural characteristics of natural spider webs, a simplified configuration composed of multi-layer regular polygons was developed to design a novel energy absorbing component for legged landers. To investigate its compressive energy-absorption behavior, a parameterized finite element model (FEM) was established.

[...] Read more.

Inspired by the structural characteristics of natural spider webs, a simplified configuration composed of multi-layer regular polygons was developed to design a novel energy absorbing component for legged landers. To investigate its compressive energy-absorption behavior, a parameterized finite element model (FEM) was established. By integrating optimized Latin hypercube experimental design with the FEM, the energy absorption characteristics under varying structural parameters were evaluated. Based on the FEM results, response surface methodology was employed to construct surrogate models that capture the mapping relationships between design parameters and performance indices. Using these surrogate models, the energy-absorbing component was optimized under three different ranges of average buffering force. Three optimized components with distinct average buffering forces were selected and connected in series, and their force–displacement responses during compression were computed through finite element simulations. The obtained response curves were incorporated into a multibody dynamics model of a Mars lander to verify performance, demonstrating that the lander can achieve effective soft landing.

Full article

(This article belongs to the Section Machine Design and Theory)

►▼

Show Figures

Figure 1

Open AccessArticle

Optimization Design of Blade Profile Parameters of Low-Speed and High-Torque Turbodrill Based on GA-LSSVM-MOPSO-TOPSIS Method

by

Yulin Gao, Yu Wang, Guosong Chen, Jia Yan, Lingrong Kong and Yuzuo Lu

Machines 2025, 13(11), 1034; https://doi.org/10.3390/machines13111034 - 7 Nov 2025

Abstract

The exploration and development of deep marine resources are faced with the problems of poor drill ability and serious wellbore instability in high temperature and high-pressure formations. The bottom hole dynamic drilling tool with low vibration characteristics is the best choice for deep

[...] Read more.

The exploration and development of deep marine resources are faced with the problems of poor drill ability and serious wellbore instability in high temperature and high-pressure formations. The bottom hole dynamic drilling tool with low vibration characteristics is the best choice for deep well drilling. The output torque of the turbodrill is relatively small, which limits its application potential. In this study, intelligent optimization algorithms are used to improve the blade shape design to improve its output torque. Firstly, based on the moment of momentum theorem, the key blade profile parameters and range affecting the output characteristics of the turbodrill are analyzed and summarized. Subsequently, the five-order polynomial method and UG software (version 10.0) are used to complete the three-dimensional configuration of the bent-twisted blade. Then, based on the GA-LSSVM-MOPSO-TOPSIS intelligent optimization algorithm, the two-dimensional and three-dimensional modeling design parameters under the optimal hydraulic performance are optimized, and the accuracy of the intelligent optimization algorithm and parameters is verified by CFD simulation analysis. The results show that the hydraulic efficiency of only 4.9% is sacrificed, and the output torque is increased by 36.61%, which significantly improves the hydraulic performance of the turbodrill and provides guidance for the design of low-speed and high-torque turbodrills.

Full article

(This article belongs to the Section Machines Testing and Maintenance)

►▼

Show Figures

Figure 1

Open AccessArticle

A Framework for Testing and Evaluation of Automated Valet Parking Using OnSite and Unity3D Platforms

by

Ouchan Chen, Lei Chen, Junru Yang, Hao Shi, Lin Xu, Haoran Li, Weike Lu and Guojing Hu

Machines 2025, 13(11), 1033; https://doi.org/10.3390/machines13111033 - 7 Nov 2025

Abstract

Automated valet parking (AVP) is a key component of autonomous driving systems. Its functionality and reliability need to be thoroughly tested before road application. Current testing technologies are limited by insufficient scenario coverage and lack of comprehensive evaluation indices. This study proposes an

[...] Read more.

Automated valet parking (AVP) is a key component of autonomous driving systems. Its functionality and reliability need to be thoroughly tested before road application. Current testing technologies are limited by insufficient scenario coverage and lack of comprehensive evaluation indices. This study proposes an AVP testing and evaluation framework using OnSite (Open Naturalistic Simulation and Testing Environment) and Unity3D platforms. Through scenario construction based on field-collected data and model reconstruction, a testing scenario library is established, complying with industry standards. A simplified kinematic model, balancing simulation accuracy and operational efficiency, is applied to describe vehicle motion. A multidimensional evaluation system is developed with completion rate as a primary index and operation performance as a secondary index, which considers both parking efficiency and accuracy. Over 500 AVP algorithms are tested on the OnSite platform, and the testing results are evaluated through the Unity3D platform. The performance of the top 10 algorithms is analyzed. The evaluation platform is compared with CARLA simulation platform and field vehicle testing. This study finds that the framework provides an effective tool for AVP testing and evaluation; a variety of high-level AVP algorithms are developed, but their flexibility in complex dynamic scenarios has limitations. Future research should focus on exploring more sophisticated learning-based algorithms to enhance AVP adaptability and performance in complex dynamic environment.

Full article

(This article belongs to the Special Issue Control and Path Planning for Autonomous Vehicles)

►▼

Show Figures

Figure 1

Open AccessArticle

Analysis of Driver Takeover Performance in Autonomous Vehicles Based on Generalized Estimating Equations

by

Min Duan, Lian Xie, Jianrong Cai, Junru Yang and Haoran Li

Machines 2025, 13(11), 1032; https://doi.org/10.3390/machines13111032 - 7 Nov 2025

Abstract

Current autonomous vehicles require human drivers to take over control during emergencies or in environments the system cannot handle. During other periods, drivers are permitted to engage in non-driving-related tasks. It is essential to investigate how the immersion in non-driving-related tasks affects drivers’

[...] Read more.

Current autonomous vehicles require human drivers to take over control during emergencies or in environments the system cannot handle. During other periods, drivers are permitted to engage in non-driving-related tasks. It is essential to investigate how the immersion in non-driving-related tasks affects drivers’ takeover performance under different scenarios. To address this, a mixed-design simulated driving experiment was conducted with 40 participants, incorporating three non-driving-related tasks (no task, watch video, play game), three takeover request lead times (3 s, 5 s, 7 s), and two obstacle types (dynamic, static). The takeover process was divided into three phases: preparation, obstacle avoidance, and recovery. Analysis of the areas of interest showed that engaging in non-driving-related tasks substantially reduced drivers’ visual attention tothe road ahead during the preparation phase. The Generalized Estimating Equations method was employed to investigate the effects of various factors on takeover performance. Model results showed that scenarios with static obstacles and longer takeover request times led to a significant reduction in mean lane deviation but a significant increase in the standard deviation of lane deviation, suggesting improved lateral control performance. A significant interaction was observed between the watch video task and static obstacles, which corresponded to a notable decrease in the mean vehicle speed during obstacle avoidance. Performance in the recovery phase was strongly predicted by that in the obstacle avoidance phase, indicating that the stability of the avoidance maneuver is a critical determinant of the subsequent recovery. These findings offer valuable insights for managing non-driving-related tasks and setting appropriate takeover request timings in automated driving systems.

Full article

(This article belongs to the Special Issue Control and Path Planning for Autonomous Vehicles)

►▼

Show Figures

Figure 1

Journal Menu

► ▼ Journal Menu-

- Machines Home

- Aims & Scope

- Editorial Board

- Reviewer Board

- Topical Advisory Panel

- Instructions for Authors

- Special Issues

- Topics

- Sections & Collections

- Article Processing Charge

- Indexing & Archiving

- Editor’s Choice Articles

- Most Cited & Viewed

- Journal Statistics

- Journal History

- Journal Awards

- Society Collaborations

- Conferences

- Editorial Office

Journal Browser

► ▼ Journal BrowserHighly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Actuators, Algorithms, BDCC, Future Internet, JMMP, Machines, Robotics, Systems

Smart Product Design and Manufacturing on Industrial Internet

Topic Editors: Pingyu Jiang, Jihong Liu, Ying Liu, Jihong YanDeadline: 31 December 2025

Topic in

Actuators, Automation, Electronics, Machines, Robotics, Eng, Technologies

New Trends in Robotics: Automation and Autonomous Systems

Topic Editors: Maki Habib, Fusaomi NagataDeadline: 31 January 2026

Topic in

Coatings, JMMP, Lubricants, Machines, Materials

Advanced Manufacturing and Surface Technology, 2nd Edition

Topic Editors: Dingding Xiang, Kaiming Wang, Xudong SuiDeadline: 20 March 2026

Topic in

Applied Sciences, Electricity, Electronics, Energies, Machines, Smart Cities, Vehicles, Batteries

Design and Control of Electrical Machines for Electric Vehicles

Topic Editors: Jinhua Du, Xuan WuDeadline: 31 March 2026

Conferences

Special Issues

Special Issue in

Machines

Recent Progress of Thin Wall Machining, 2nd Edition

Guest Editor: Yuwen SunDeadline: 30 November 2025

Special Issue in

Machines

Nonlinear Dynamics in Mechanical Systems, Automation and Control

Guest Editor: Louay S. YousufDeadline: 30 November 2025

Special Issue in

Machines

Trajectory Planning for Autonomous Vehicles: State of the Art

Guest Editor: Yiwen HuangDeadline: 30 November 2025

Special Issue in

Machines

Advances in Dynamics and Vibration Control in Mechanical Engineering

Guest Editor: Ahmed GuerineDeadline: 30 November 2025

Topical Collections

Topical Collection in

Machines

Machines, Mechanisms and Robots: Theory and Applications

Collection Editor: Raffaele Di Gregorio