Study of Nano-Mechanical, Electrochemical and Raman Spectroscopic Behavior of Al6061-SiC-Graphite Hybrid Surface Composite Fabricated through Friction Stir Processing

Abstract

:1. Introduction

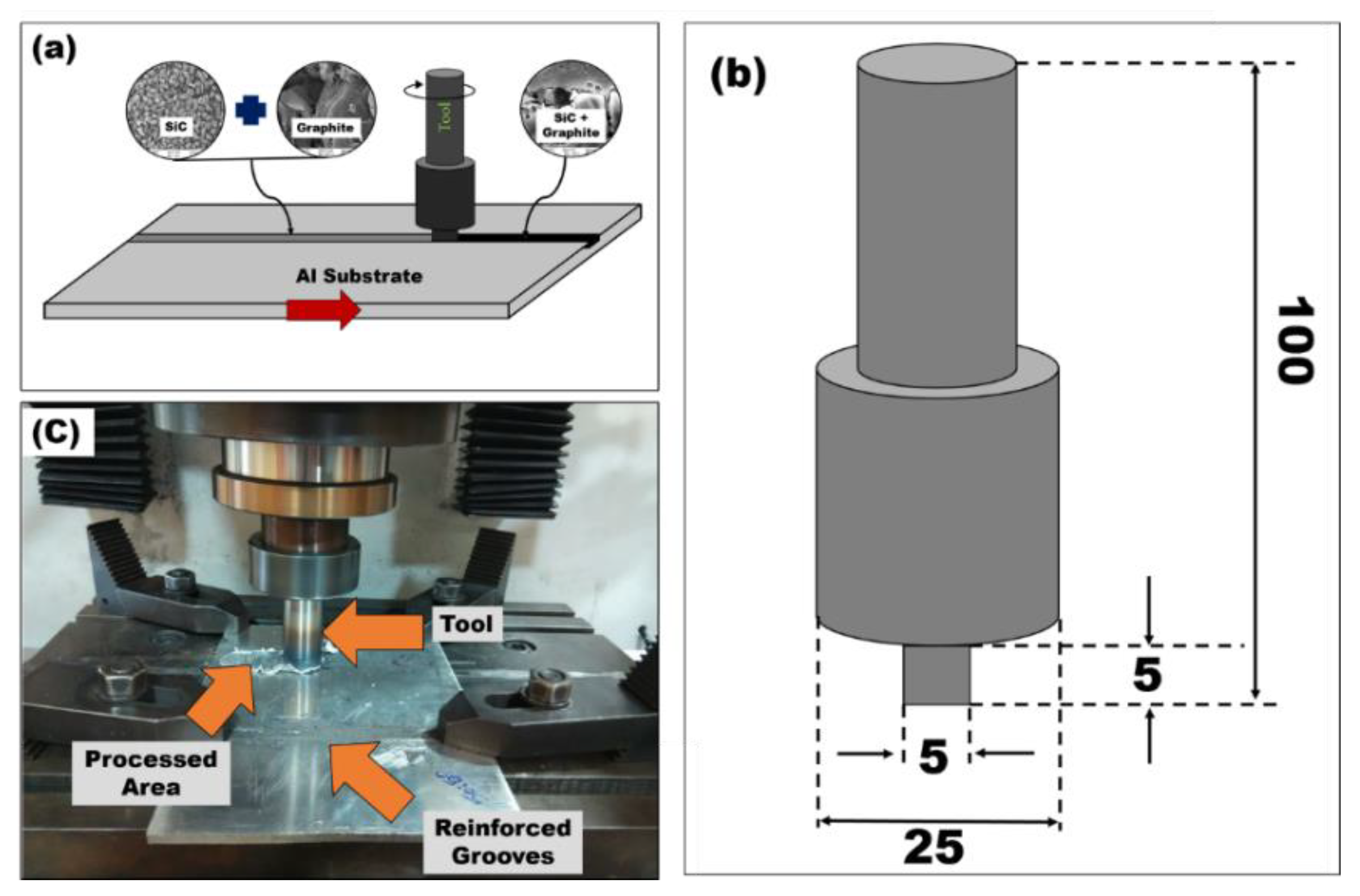

2. Materials and Methods

3. Results and Discussions

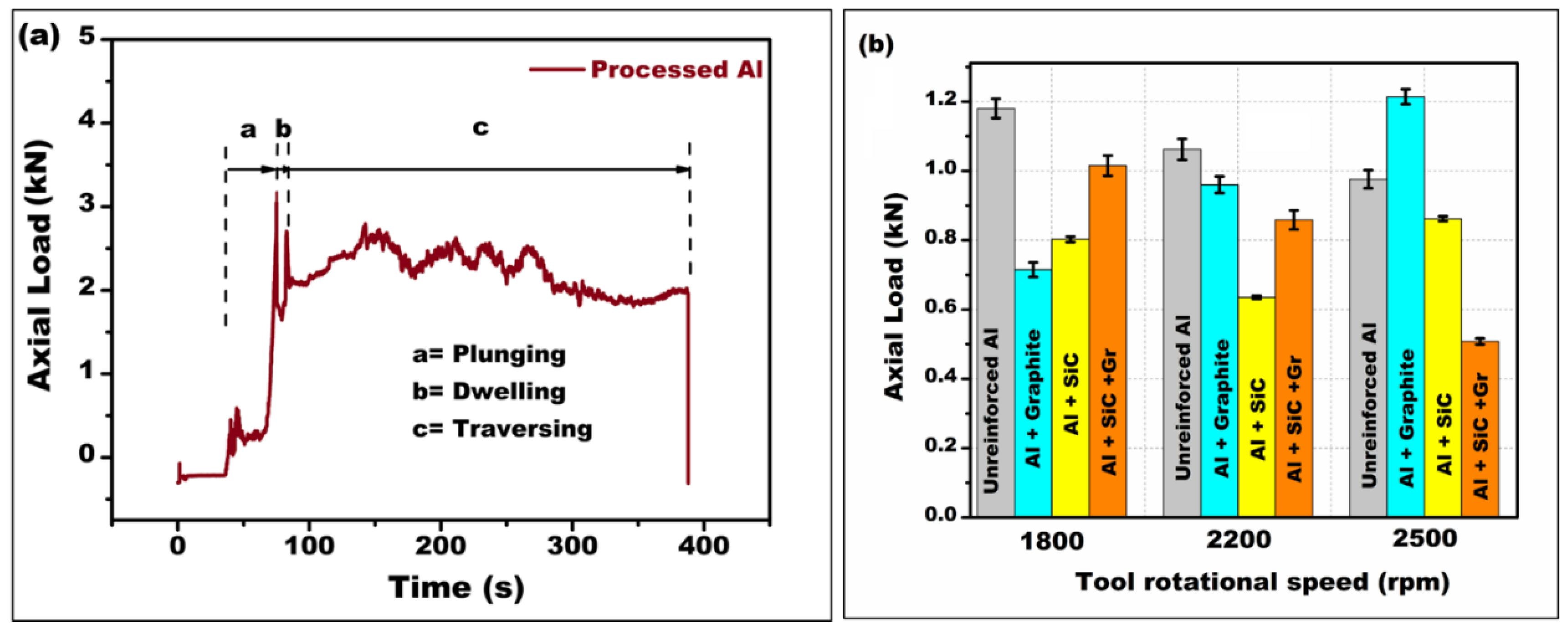

3.1. Axial Force Variation

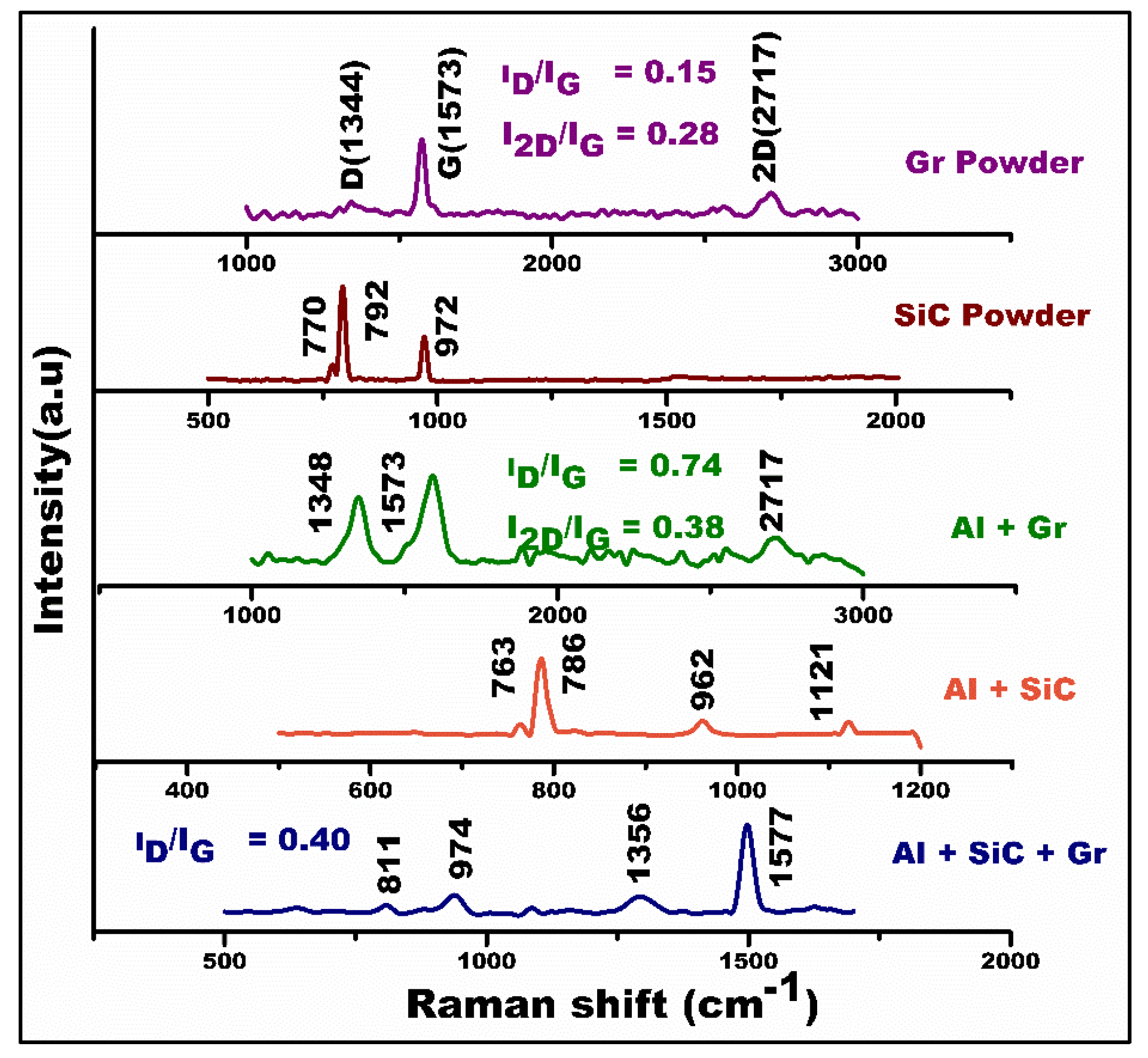

3.2. Raman Spectroscopy

3.3. X-Ray Diffraction

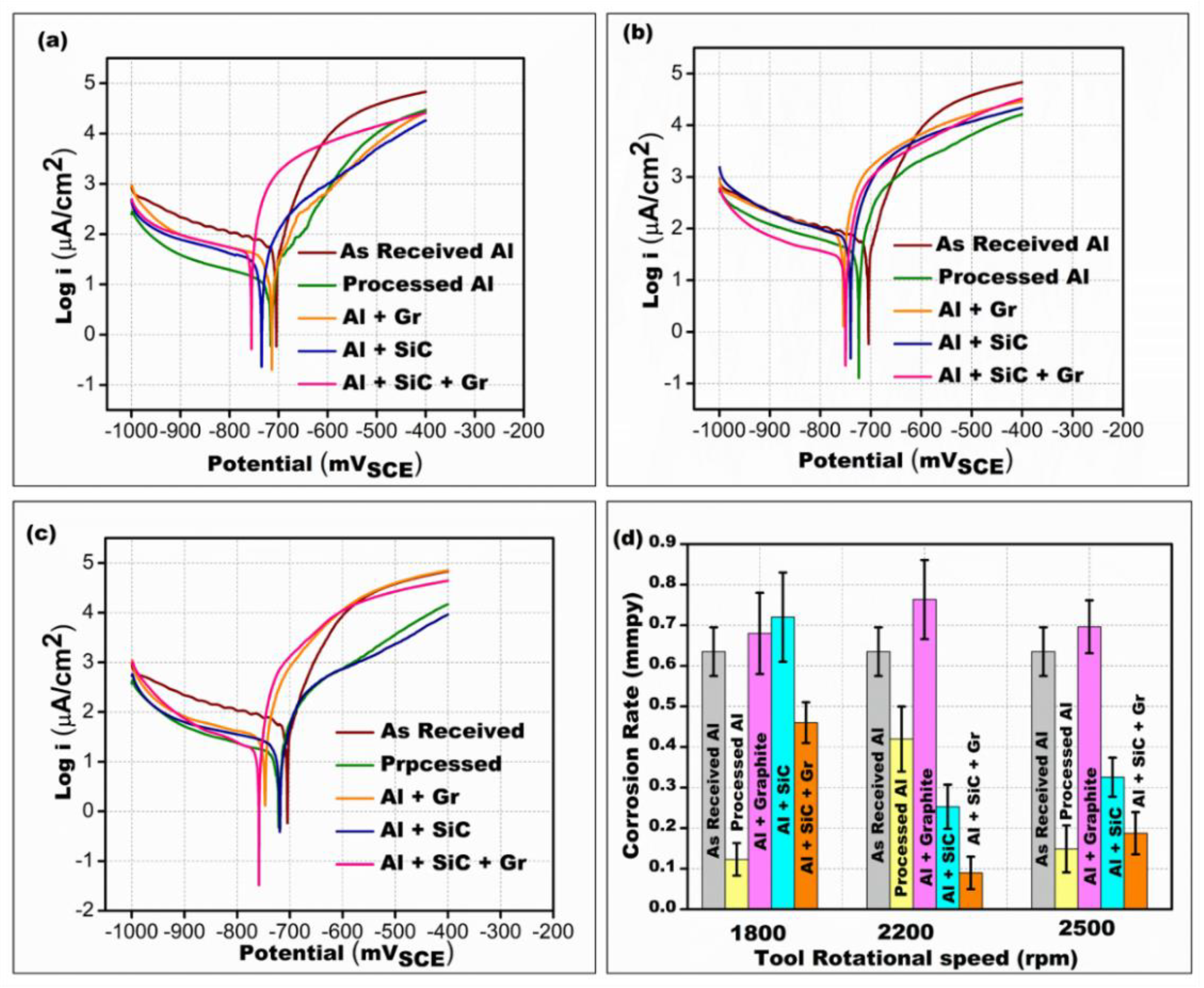

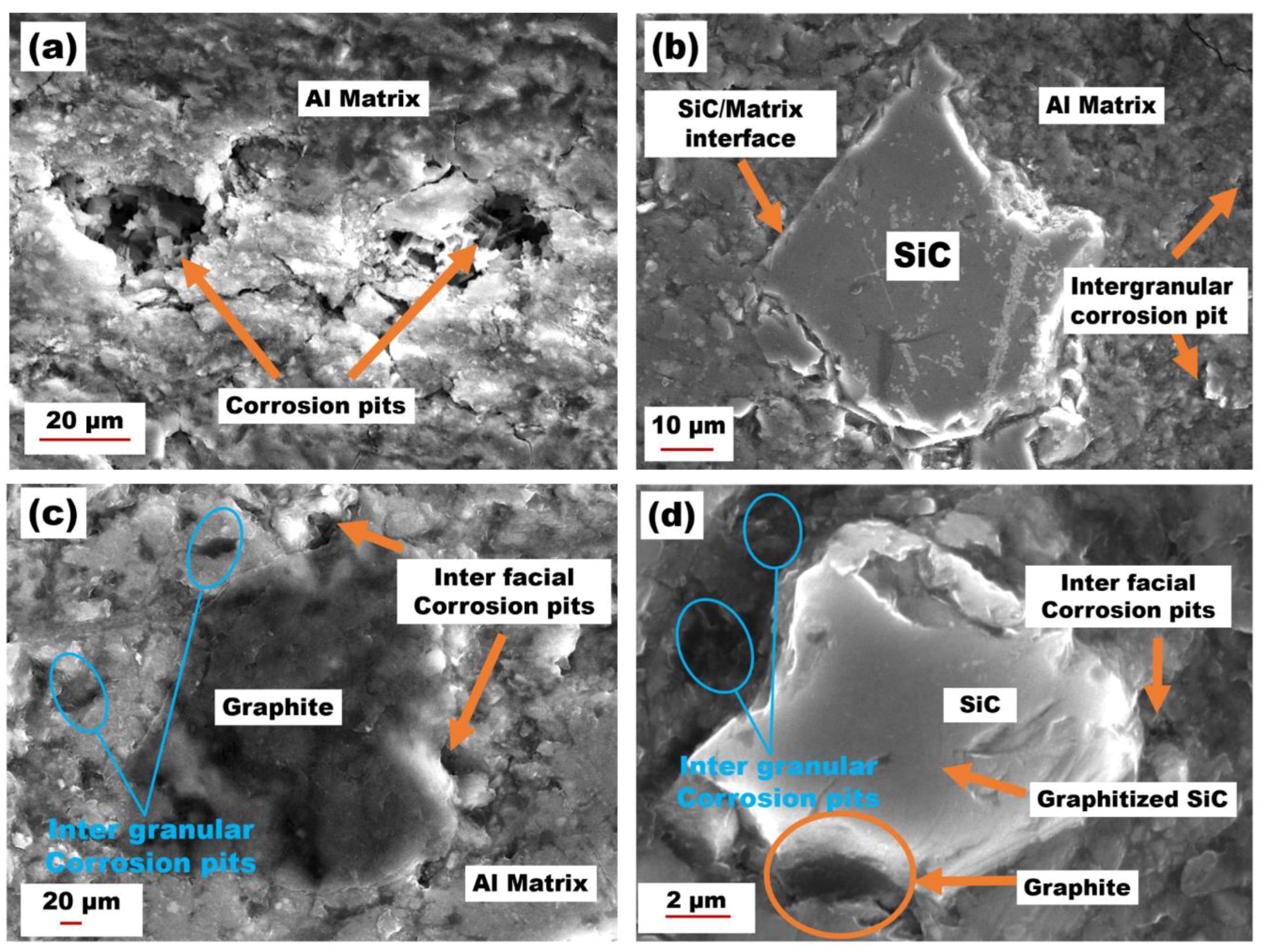

3.4. Electrochemical Behaviour

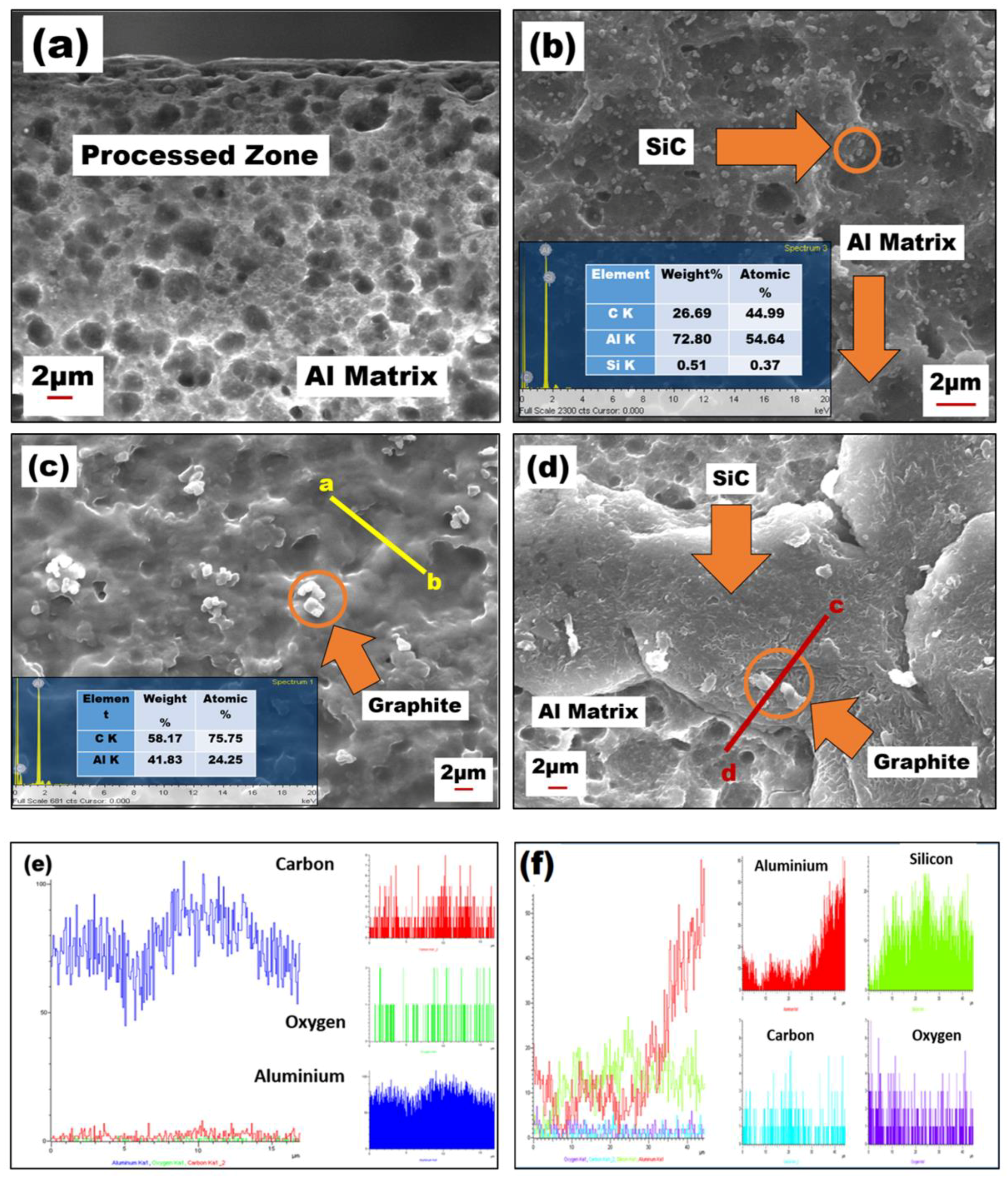

3.5. Microstructural Characterization

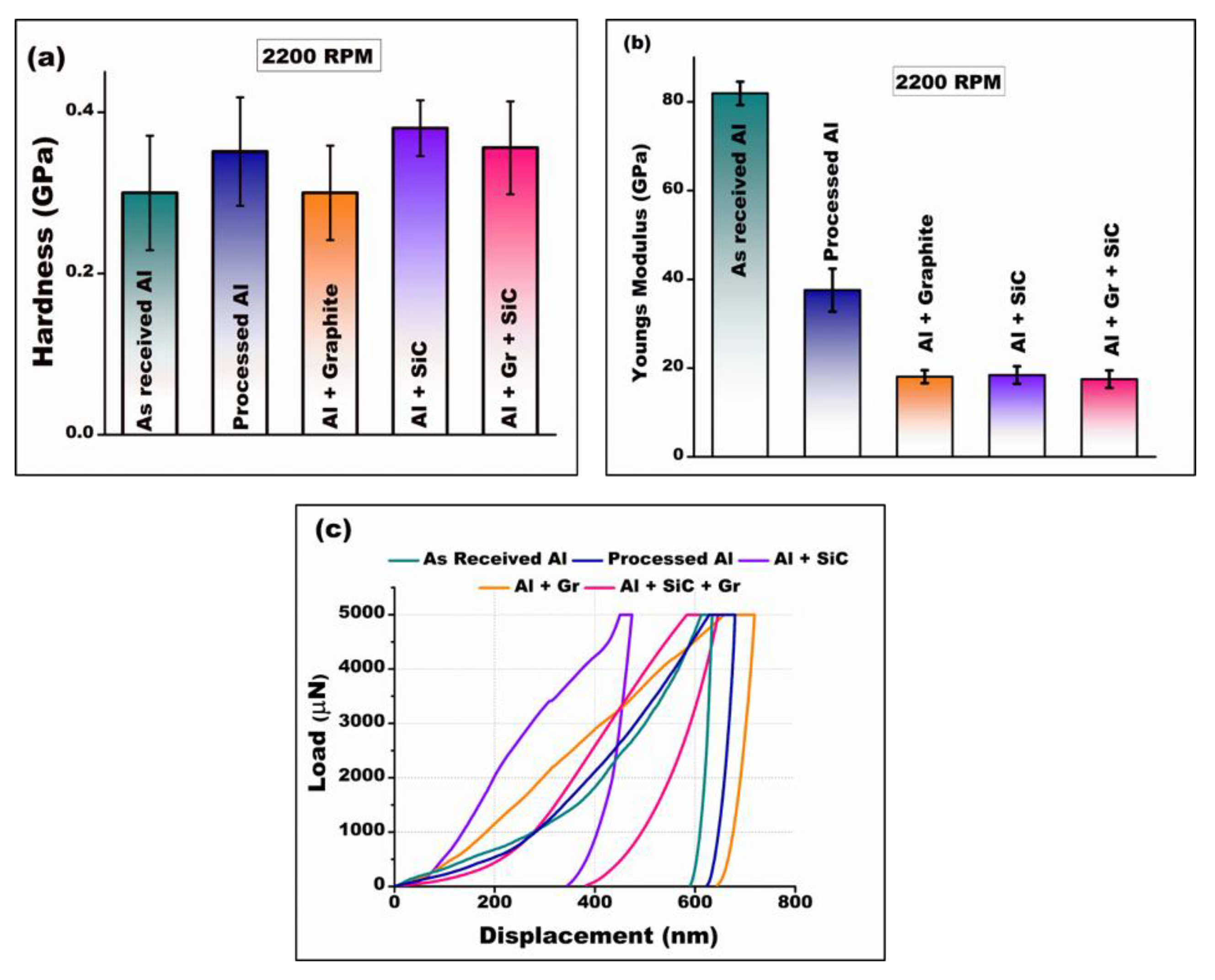

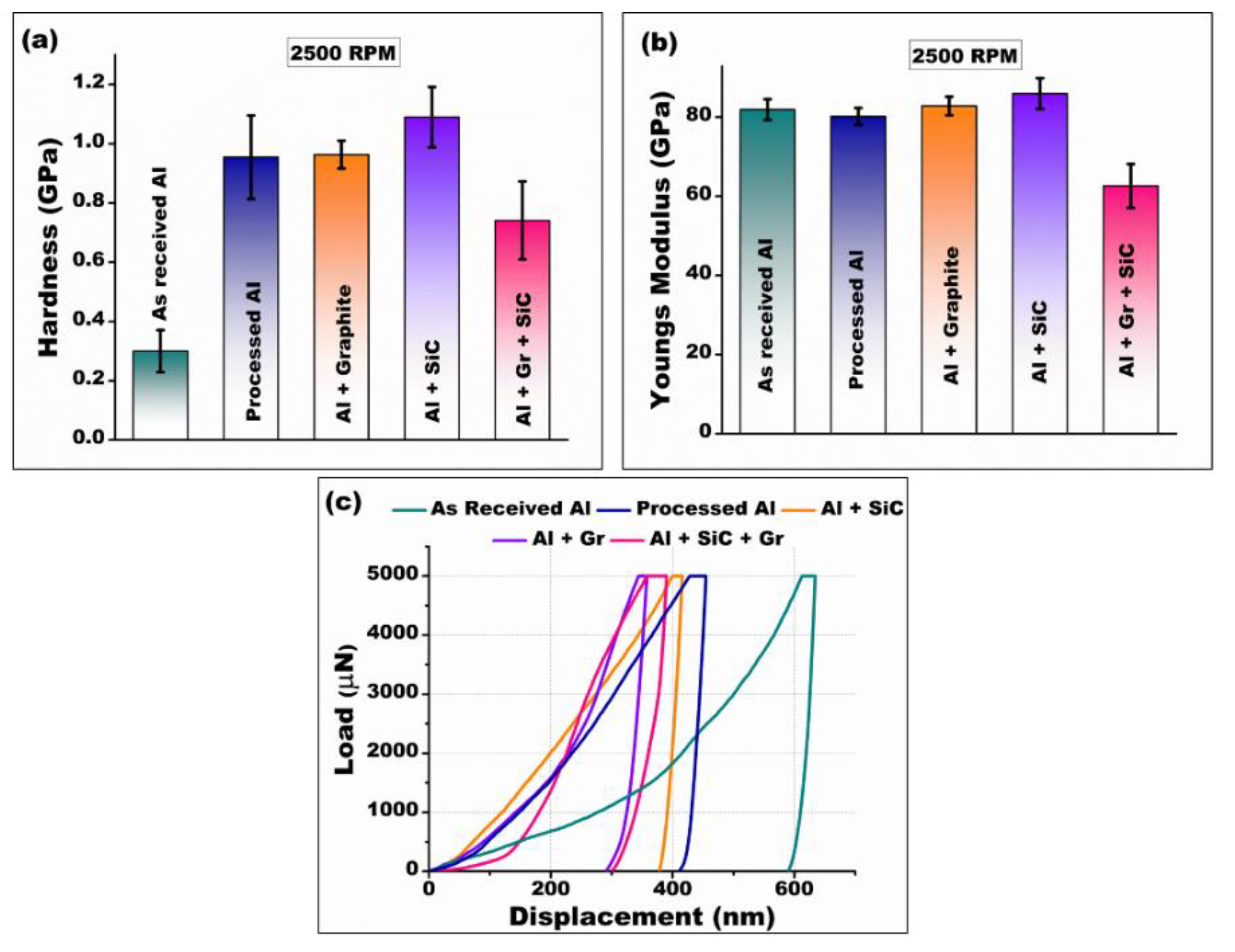

3.6. Nanomechanical Behaviour

4. Conclusions

- The mean axial force during FSP is increased in the case of Al-graphite mono composite due to the high thermal conductivity possessed by graphite;

- The presence of residual stresses in the fabricated composite is confirmed by noteworthy Raman peak shift. The existence of edge disorder in graphite crystal is also noticed. FSP also leads to the exfoliation of graphite towards single-layer graphene;

- The mechanical properties are improved due to particle reinforcement, and optimum uniform properties are obtained at a tool rotational speed of 2200 rpm when processed at 25 mm/min;

- The hybrid composite revealed best electrochemical properties when fabricated at 2200 rpm. The improved corrosion resistance is attributed to the decrease in interfacial and intergranular corrosion due to graphite layer and grain refinement, respectively;

- From XRD analysis, no formation of any intermetallic compounds was observed in any of the composite formulations;

- It could be summarized that the analysis presented herein provides encouraging results for utilizing friction stir processing as a fabrication tool for Al-SiC-graphite hybrid surface composites.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Hassan, A.M.; Almomani, M.; Qasim, T.; Ghaithan, A. Effect of Processing parameters on friction stir welded aluminum matrix composites wear behavior. Mater. Manuf. Process. 2012, 27, 1419–1423. [Google Scholar] [CrossRef]

- Basavarajappa, S. Tool wear in turning of graphitic hybrid metal matrix composites. Mater. Manuf. Process. 2009, 24, 484–487. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W.; McFadden, S.X.; Mara, N.A.; Mukherjee, A.K. High strain rate superplasticity in a friction stir processed 7075 Al alloy. Scr. Mater. 1999, 42, 163–168. [Google Scholar] [CrossRef]

- Berbon, P.B.; Bingel, W.H.; Mishra, R.S.; Bampton, C.C.; Mahoney, M.W. Friction stir processing: A tool to homogenize nanocomposite aluminum alloys. Scr. Mater. 2001, 44, 61–66. [Google Scholar] [CrossRef]

- Karthikeyan, L.; Senthilkumar, V.S.; Balasubramanian, V.; Natarajan, S. Mechanical property and microstructural changes during friction stir processing of cast aluminum 2285 alloy. Mater. Des. 2009, 30, 2237–2242. [Google Scholar] [CrossRef]

- Li, J.L.; Xiong, Y.C.; Wang, X.D.; Yan, S.J.; Yang, C.; He, W.W.; Chen, J.Z.; Wang, S.Q.; Zhang, X.Y.; Dai, S.L. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling. Mater. Sci. Eng. A 2015, 626, 400–405. [Google Scholar] [CrossRef]

- Mahmoud, T.S. Effect of friction stir processing on electrical conductivity and corrosion resistance of AA6063-T6 Al alloy. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2008, 222, 1117–1123. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W. Friction stir processing: A new grain refinement technique to achieve high strain rate superplasticity in commercial alloys. Mater. Sci. Forum 2001, 357, 507–514. [Google Scholar] [CrossRef]

- Patel, V.V.; Badheka, V.; Kumar, A. Influence of friction stir processed parameters on superplasticity of Al-Zn-Mg-Cu alloy. Mater. Manuf. Process. 2016, 31, 1573–1582. [Google Scholar] [CrossRef]

- Verdera, D.; Valle, J.A.; Rey, P.; Gesto, D.; Fernández, A.; Ruano, Ó.A. Effect of friction stir processing parameters on the mechanical properties of cast magnesium alloy AZ91. Open Ind. Manuf. Eng. 2010, 2972, 1–5. [Google Scholar] [CrossRef]

- Cavaliere, P.; De Marco, P.P. Friction stir processing of AM60B magnesium alloy sheets. Mater. Sci. Eng. A 2007, 462, 393–397. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y.; Charit, I. Friction Stir Processing: A novel technique for fabrication of surface composite. Mater. Sci. Eng. A 2003, 341, 307–310. [Google Scholar] [CrossRef]

- Morisada, Y.; Fujii, H.; Nagaoka, T.; Fukusumi, M. Effect of friction stir processing with SiC particles on microstructure and hardness of AZ31. Mater. Sci. Eng. A 2006, 433, 50–54. [Google Scholar] [CrossRef]

- Wang, W.; Shi, Q.Y.; Liu, P.; Li, H.K.; Li, T. A novel way to produce bulk SiCp reinforced aluminum Metal matrix composites by friction stir processing. J. Mater. Process. Technol. 2009, 209, 2099–2103. [Google Scholar] [CrossRef]

- Sahraeinejad, S.; Izadi, H.; Haghshenas, M.; Gerlich, A.P. Fabrication of metal matrix composites by friction stir processing with different particles and processing parameters. Mater. Sci. Eng. A 2015, 626, 505–513. [Google Scholar] [CrossRef]

- Shafiei-Zarghani, A.; Kashani-Bozorg, S.F.; Zarei-Hanzaki, A. Microstructures and mechanical properties of Al/Al2O3 surface nano-composite layer produced by friction stir processing. Mater. Sci. Eng. A 2009, 500, 84–91. [Google Scholar] [CrossRef]

- Prakash, T.; Sivasankaran, S.; Sasikumar, P. Mechanical and tribological behaviour of friction-stir-processed Al 6061 aluminium sheet metal reinforced with Al2O3/0.5 Gr hybrid surface nanocomposite. Arab. J. Sci. Eng. 2014, 40, 559–569. [Google Scholar] [CrossRef]

- Zakaria, H.M. Microstructural and corrosion behavior of Al/SiC metal matrix composites. Ain Shams Eng. J. 2014, 5, 831–838. [Google Scholar] [CrossRef]

- Candan, S. Effect of SiC particle size on corrosion behavior of pressure infiltrated Al matrix composites in a NaCl solution. Mater. Lett. 2004, 58, 3601–3605. [Google Scholar] [CrossRef]

- Abbass, M.K.; Hassan, K.S.; Alwan, A.S. Study of corrosion resistance of aluminum alloy 6061/SiC composites in 3.5% NaCl solution. Int. J. Mater. Mech. Manuf. 2015, 3, 31–35. [Google Scholar] [CrossRef]

- Modi, O.P.; Saxena, M.; Prasad, B.K.; Jha, A.K.; Das, S.; Yegneswaran, A.H. Role of alloy matrix and dispersoid on corrosion behavior of cast aluminum alloy composites. Corrosion 1998, 54, 129–134. [Google Scholar] [CrossRef]

- Feng, Z.; Lin, C.; Lin, J.; Luo, J.; Feng, Z.; Lin, C.; Lin, J. Pitting behavior of SiCp/2024 Al metal matrix composites. J. Mater. Sci. 1998, 3, 5637–5642. [Google Scholar] [CrossRef]

- Sherif, E.M.; Almajid, A.A.; Latif, F.H.; Junaedi, H. Effects of graphite on the corrosion behavior of aluminum-graphite composite in sodium chloride solutions. Corrosion 2011, 6, 1085–1099. [Google Scholar]

- Guo, M.L.T.; Tsao, C.-Y.A. Tribological behavior of self-lubricating aluminium/SiC/graphite hybrid composites synthesized by the semi-solid powder-densification method. Compos. Sci. Technol. 2000, 60, 65–74. [Google Scholar] [CrossRef]

- Thapliyal, S.; Dwivedi, D.K. Microstructure evolution and tribological behavior of the solid lubricant based surface composite of cast nickel aluminum bronze developed by friction stir processing. J. Mater. Process. Technol. 2016, 238, 30–38. [Google Scholar] [CrossRef]

- Liu, Y.; Rohatgi, P.K.; Ray, S. Tribological characteristics of aluminum-50 Vol Pct graphite composite. Metall. Trans. A 1993, 24, 151–159. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Sanusi, K.O. Microstructural characteristics, mechanical and wear behaviour of aluminium matrix hybrid composites reinforced with alumina, rice husk ash and graphite. Eng. Sci. Technol. Int. J. 2015, 18, 1–7. [Google Scholar] [CrossRef]

- Saxena, M.; Modi, O.P.; Yegneswaran, A.H.; Rohatgi, P.K. Corrosion characteristics of cast aluminum alloy—3 wt % graphite particulate composites in different environments. Corros. Sci. 1987, 27, 249–256. [Google Scholar] [CrossRef]

- Payan, S.; Le Petitcorps, Y.; Olive, J.-M.; Saadaoui, H. Experimental procedure to analyse the corrosion mechanisms at the carbon/aluminium interface in composite materials. Compos. Part A Appl. Sci. Manuf. 2001, 32, 585–589. [Google Scholar] [CrossRef]

- Devaraju, A.; Kumar, A.; Kumaraswamy, A.; Kotiveerachari, B. Influence of reinforcements (SiC and Al2O3) and rotational speed on wear and mechanical properties of aluminum alloy 6061-T6 based surface hybrid composites produced via friction stir processing. Mater. Des. 2013, 51, 331–341. [Google Scholar] [CrossRef]

- Aruri, D.; Adepu, K.; Adepu, K.; Bazavada, K. Wear and mechanical properties of 6061-T6 aluminum alloy surface hybrid composites [(SiC + Gr) and (SiC + Al2O3)] fabricated by friction stir processing. J. Mater. Res. Technol. 2013, 2, 362–369. [Google Scholar] [CrossRef]

- Shahi, A.; Sohi, M.H.; Ahmadkhaniha, D.; Ghambari, M. In situ formation of Al-Al3Ni composites on commercially pure aluminium by friction stir processing. Int. J. Adv. Manuf. Technol. 2014, 75, 1331–1337. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminium alloy. Mater. Sci. Eng. A 2007, 459, 7–18. [Google Scholar] [CrossRef]

- Lee, W.B.; Yeon, Y.M.; Jung, S.B. Joint properties of friction stir welded AZ31B—H24 magnesium alloy. Mater. Sci. Technol. 2003, 19, 785–790. [Google Scholar] [CrossRef]

- Armeyev, V.Y.; Chapliev, N.I.; Chistyakov, I.M.; Konov, V.I.; Ralchenko, V.G.; Strelnitsky, V.E.; Volkov, V.Y. Direct laser writing of microstructures in diamond-like carbon films. Mater. Manuf. Process. 1993, 8, 9–17. [Google Scholar] [CrossRef]

- Sharma, A.; Sagar, S.; Mahto, R.P.; Sahoo, B.; Pal, S.K.; Paul, J. Surface modification of Al6061 by graphene impregnation through a powder metallurgy assisted friction surfacing. Surf. Coat. Technol. 2018, 337, 12–23. [Google Scholar] [CrossRef]

- Sahoo, B.; Kumar, R.; Joseph, J.; Sharma, A.; Paul, J. Preparation of aluminium 6063-graphite surface composites by an electrical resistance heat assisted pressing technique. Surf. Coat. Technol. 2017, 309, 563–572. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, V.M.; Mewar, S.; Pal, S.K.; Paul, J. Friction stir processing of Al6061- SiC -graphite hybrid surface composites. Mater. Manuf. Process. 2018, 33, 795–804. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, L.; Koenig, J.L. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, D.; Zhang, J.; Zhang, P.; Shi, X.; Hao, Y. Synthesis of multilayer graphene films on copper by modified chemical vapor deposition. Mater. Manuf. Process. 2015, 30, 711–716. [Google Scholar] [CrossRef]

- Sahoo, B.; Joseph, J.; Sharma, A.; Paul, J. Surface modification of aluminium by graphene impregnation. Mater. Des. 2017, 116, 51–64. [Google Scholar] [CrossRef]

- Borriello, C.; De Maria, A.; Jovic, N.; Montone, A.; Schwarz, M.; Antisari, M.V. Mechanochemical exfoliation of graphite and its polyvinyl alcohol nanocomposites with enhanced barrier properties. Mater. Manuf. Process. 2009, 24, 1053–1057. [Google Scholar] [CrossRef]

- Cullity, B.D.; Weymouth, J.W. Elements of X-ray diffraction. Am. J. Phys. 1957, 25, 394–395. [Google Scholar] [CrossRef]

- Bartolucci, S.F.; Paras, J.; Rafiee, M.A.; Rafiee, J.; Lee, S.; Kapoor, D.; Koratkar, N. Graphene-aluminum nanocomposites. Mater. Sci. Eng. A 2011, 528, 7933–7937. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C.C. Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Yadav, D.; Bauri, R. Nickel particle embedded aluminium matrix composite with high ductility. Mater. Lett. 2010, 64, 664–667. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Jamaati, R.; Niroumand, B.; Toroghinejad, M.R. Manufacturing of high-performance Al356/SiC P composite by CAR process. Mater. Manuf. Process. 2011, 26, 902–907. [Google Scholar] [CrossRef]

- Izadi, H.; Sandstrom, R.; Gerlich, A.P. Grain growth behavior and Hall–Petch strengthening in friction stir processed Al 5059. Metall. Mater. Trans. A 2014, 45, 5635–5644. [Google Scholar] [CrossRef]

- Hihara, L.H.; Latanision, R.M. Galvanic corrosion of aluminum-matrix composites. Corrosion 1992, 48, 546–552. [Google Scholar] [CrossRef]

- Sato, N. The stability of localized corrosion. Corros. Sci. 1995, 37, 1947–1967. [Google Scholar] [CrossRef]

- Soib, M.; Selamat, B.I.N. Corrosion behavior of SiC P/6061 Al metal matrix composites in chloride solutions. Adv. Perform. Mater. 1996, 3, 183–204. [Google Scholar]

- Abdi Behnagh, R.; Besharati Givi, M.K.K.; Akbari, M. Mechanical properties, corrosion resistance, and microstructural changes during friction stir processing of 5083 aluminum rolled plates. Mater. Manuf. Process. 2012, 27, 636–640. [Google Scholar] [CrossRef]

- Zhang, F.; Huang, Y.; Hwang, K.C.; Qu, S.; Liu, C. A Three-dimensional strain gradient plasticity analysis of particle size effect in composite materials. Mater. Manuf. Process. 2007, 22, 140–148. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Rams, J.; Merino, S.; Viejo, F.; Campo, M. Effect of reinforcement coating on the oxidation behavior of AA6061/SiC/20p composite. Oxid. Met. 2005, 63, 215–227. [Google Scholar] [CrossRef]

- Babu, J.; Srinivasan, A.; Kang, C. Nano and macromechanical properties of aluminium (A356) based hybrid composites reinforced with multiwall carbon nanotubes/alumina fiber. J. Compos. Mater. 2017, 51, 1631–1642. [Google Scholar] [CrossRef]

| Material | Tool Rotational Speed (RPM) | ECORR (mV) | ICORR (µA/cm2) |

|---|---|---|---|

| As-received Al | - | −707.37 | 1.77 |

| As-processed Al | 1800 | −715.95 | 1.06 |

| 2200 | −722.68 | 1.59 | |

| 2500 | −722.11 | 1.14 | |

| Al-SiC | 1800 | −741.95 | 1.83 |

| 2200 | −718.79 | 1.37 | |

| 2500 | −739.39 | 1.48 | |

| Al-graphite | 1800 | −754.01 | 1.80 |

| 2200 | −754.30 | 1.85 | |

| 2500 | −754.23 | 1.81 | |

| Al-SiC-graphite | 1800 | −760.29 | 1.60 |

| 2200 | −751.59 | 0.92 | |

| 2500 | −759.65 | 1.24 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma, A.; Mani Sharma, V.; Sahoo, B.; Joseph, J.; Paul, J. Study of Nano-Mechanical, Electrochemical and Raman Spectroscopic Behavior of Al6061-SiC-Graphite Hybrid Surface Composite Fabricated through Friction Stir Processing. J. Compos. Sci. 2018, 2, 32. https://doi.org/10.3390/jcs2020032

Sharma A, Mani Sharma V, Sahoo B, Joseph J, Paul J. Study of Nano-Mechanical, Electrochemical and Raman Spectroscopic Behavior of Al6061-SiC-Graphite Hybrid Surface Composite Fabricated through Friction Stir Processing. Journal of Composites Science. 2018; 2(2):32. https://doi.org/10.3390/jcs2020032

Chicago/Turabian StyleSharma, Abhishek, Vyas Mani Sharma, Baidehish Sahoo, Jomy Joseph, and Jinu Paul. 2018. "Study of Nano-Mechanical, Electrochemical and Raman Spectroscopic Behavior of Al6061-SiC-Graphite Hybrid Surface Composite Fabricated through Friction Stir Processing" Journal of Composites Science 2, no. 2: 32. https://doi.org/10.3390/jcs2020032