Effect of Laser Remelting and Simultaneous Application of Ultrasonic Vibrations during Laser Melting on the Microstructural and Tribological Properties of Laser Clad Al-SiC Composites

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

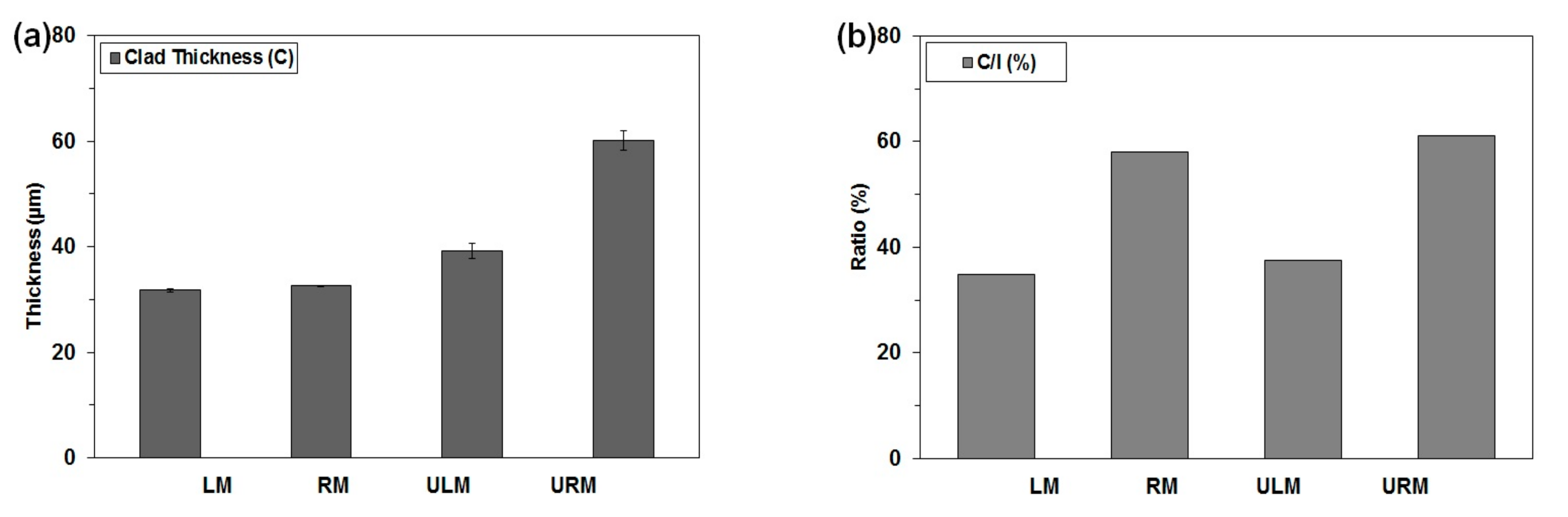

3.1. Clad Layer Characteristics

3.2. XRD Characterization

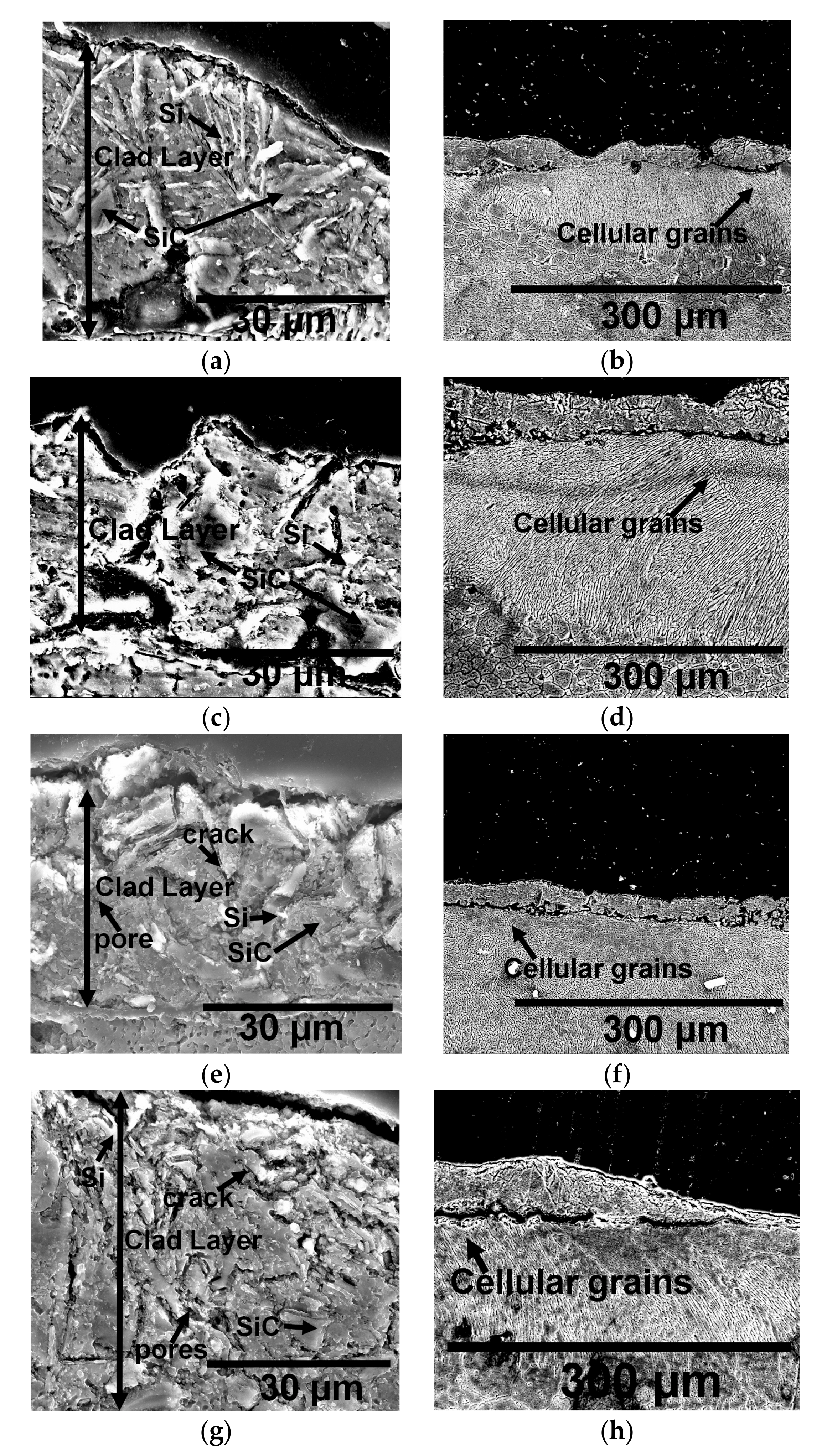

3.3. Microstructural Characterization

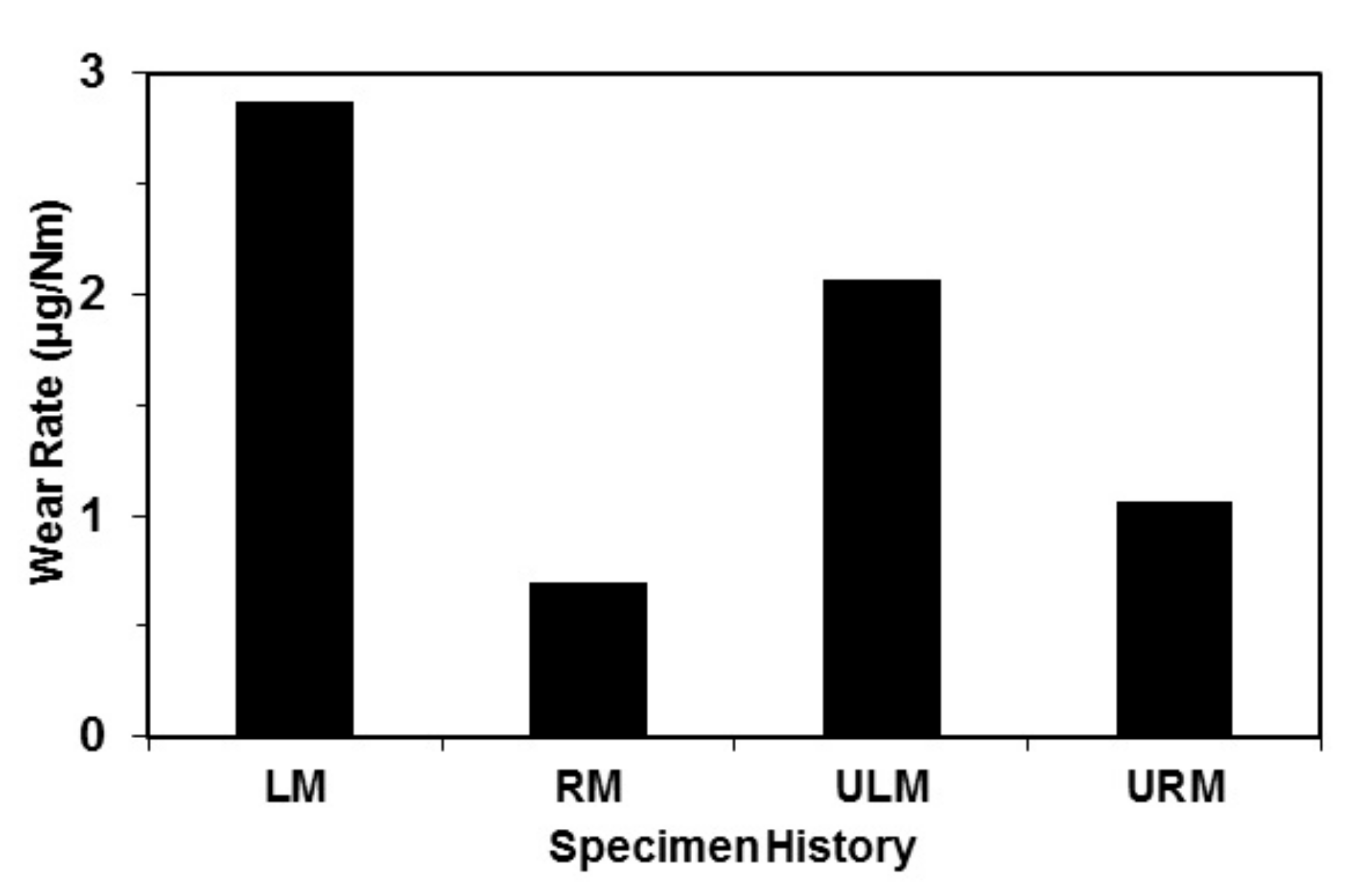

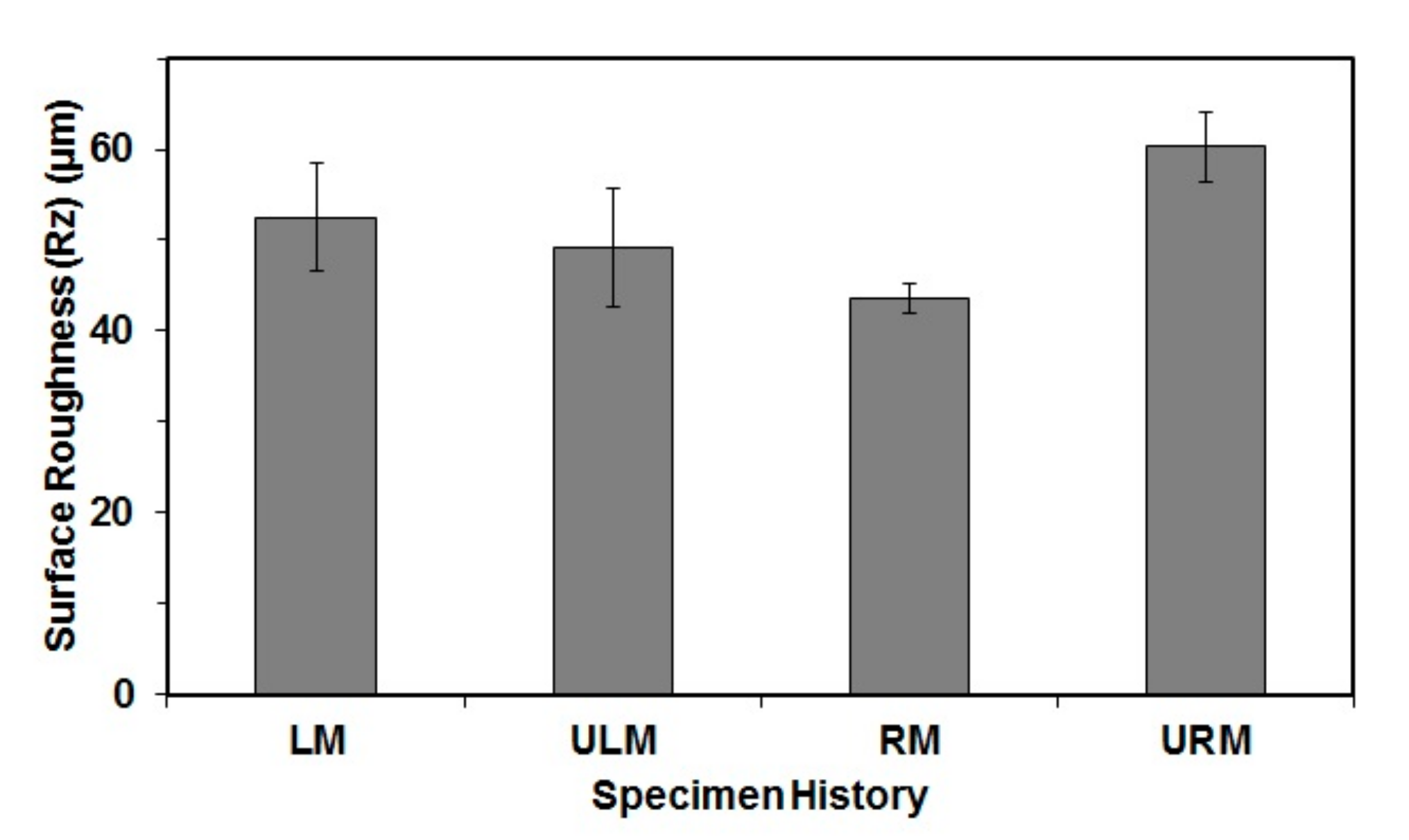

3.4. Tribological Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wan, Y.; Xue, Q. Effect of phosphorus-containing additives on the wear of aluminum in the lubricated aluminum-on-steel contact. Tribol. Lett. 1996, 2, 37–45. [Google Scholar] [CrossRef]

- Davis, J.R. Surface Engineering for Corrosion and Wear Resistance; ASM International: Materials Park, OH, USA, 2001. [Google Scholar]

- Rehn, L.E.; Picraux, S.; Wiedersich, H. Surface alloying by Ion, Electron and Laser Beams; ASM International: Metals Park, OH, USA, 1986. [Google Scholar]

- Dahotre, N.B.; Harimkar, S. Laser Fabrication and Machining of Materials; Springer Science & Business Media: New York, NY, USA, 2008. [Google Scholar]

- Majumdar, J.D.; Chandra, B.R.; Manna, I. Friction and wear behavior of laser composite surfaced aluminium with silicon carbide. Wear 2007, 262, 641–648. [Google Scholar] [CrossRef]

- Man, H.; Kwok, C.; Yue, T. Cavitation erosion and corrosion behaviour of laser surface alloyed MMC of SiC and Si3N4 on Al alloy AA6061. Surf. Coat. Technol. 2000, 132, 11–20. [Google Scholar] [CrossRef]

- Kadolkar, P.; Dahotre, N.B. Variation of structure with input energy during laser surface engineering of ceramic coatings on aluminum alloys. Appl. Surf. Sci. 2002, 199, 222–233. [Google Scholar] [CrossRef]

- Man, H.; Zhang, S.; Cheng, F.; Yue, T. In situ synthesis of tic reinforced surface MMC on Al6061 by laser surface alloying. Scr. Mater. 2002, 46, 229–234. [Google Scholar] [CrossRef]

- Hu, C.; Barnard, L.; Mridha, S.; Baker, T. The role of SiC particulate and Al2O3 (saffil) fibers in several alloys during the formation of in situ MMCs developed by laser processing. J. Mater. Process. Technol. 1996, 58, 87–95. [Google Scholar] [CrossRef]

- Vreeling, J.; Ocelık, V.; Pei, Y.; van Agterveld, D.T.L.; De Hosson, J.T.M. Laser melt injection in aluminum alloys: On the role of the oxide skin. Acta Mater. 2000, 48, 4225–4233. [Google Scholar] [CrossRef]

- Gingu, O.; Mangra, M.; Orban, R. In-situ production of Al/SiCp composite by laser deposition technology. J. Mater. Process. Technol. 1999, 89, 187–190. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Chandra, B.R.; Nath, A.; Manna, I. Compositionally graded SiC dispersed metal matrix composite coating on Al by laser surface engineering. Mater. Sci. Eng. A 2006, 433, 241–250. [Google Scholar] [CrossRef]

- Liu, X.; Osawa, Y.; Takamori, S.; Mukai, T. Grain refinement of AZ91 alloy by introducing ultrasonic vibration during solidification. Mater. Lett. 2008, 62, 2872–2875. [Google Scholar] [CrossRef]

- Biswas, S.; Alavi, S.H.; Harimkar, S.P. Laser surface melting of Ti–6Al–4V under the influence of ultrasonic vibrations. Mater. Lett. 2015, 159, 470–473. [Google Scholar] [CrossRef]

- Biswas, S.; Allison, S.; Alavi, S.H.; Harimkar, S.P. Effect of simultaneous application of ultrasonic vibrations during laser surface melting on electrochemical properties of 2024 aluminum alloy. Adv. Mater. Proc. 2017, 2, 675–678. [Google Scholar]

- Legay, M.; Gondrexon, N.; Le Person, S.; Boldo, P.; Bontemps, A. Enhancement of heat transfer by ultrasound: Review and recent advances. Int. J. Chem. Eng. 2011, 2011, 670108. [Google Scholar] [CrossRef]

- Jian, X.; Xu, H.; Meek, T.; Han, Q. Effect of power ultrasound on solidification of aluminum A356 alloy. Mater. Lett. 2005, 59, 190–193. [Google Scholar] [CrossRef]

- Harimkar, S.P.; Dahotre, N.B. Crystallographic and morphological textures in laser surface modified alumina ceramic. J. Appl. Phys. 2006, 100, 024901. [Google Scholar] [CrossRef]

- Li, R.; Ferreira, M.G.S.; Almeida, A.; Vilar, R.; Watkins, K.G.; McMahon, M.A.; Steen, W.M. Localized corrosion of laser surface melted 2024-T351 aluminium alloy. Surf. Coat. Technol. 1996, 81, 290–296. [Google Scholar] [CrossRef]

- Simchi, A.; Godlinski, D. Effect of sic particles on the laser sintering of Al–7Si–0.3 Mg alloy. Scr. Mater. 2008, 59, 199–202. [Google Scholar] [CrossRef]

- Ehrström, J.; Kool, W. Production of rapidly solidified Al/SiC composites. J. Mater. Sci. 1988, 23, 3195–3201. [Google Scholar] [CrossRef]

- Anandkumar, R.; Almeida, A.; Colaço, R.; Vilar, R.; Ocelik, V.; De Hosson, J.T.M. Microstructure and wear studies of laser clad Al-Si/SiC (p) composite coatings. Surf. Coat. Technol. 2007, 201, 9497–9505. [Google Scholar] [CrossRef]

- Wang, W.; Ajersch, F.; Löfvander, J. Si phase nucleation on SiC particulate reinforcement in hypereutectic Al-Si alloy matrix. Mater. Sci. Eng. A 1994, 187, 65–75. [Google Scholar] [CrossRef]

- Jiang, J.; Arnell, R. The effect of substrate surface roughness on the wear of dlc coatings. Wear 2000, 239, 1–9. [Google Scholar] [CrossRef]

- Guha, D.; Chowdhuri, S.R. The effect of surface roughness on the temperature at the contact between sliding bodies. Wear 1996, 197, 63–73. [Google Scholar] [CrossRef]

- Gandra, J.; Vigarinho, P.; Pereira, D.; Miranda, R.; Velhinho, A.; Vilaça, P. Wear characterization of functionally graded Al–SiC composite coatings produced by friction surfacing. Mater. Des. 2013, 52, 373–383. [Google Scholar] [CrossRef]

| Processing Conditions Sample ID | Laser Melting | Laser Remelting | |||

|---|---|---|---|---|---|

| Vibration Amplitude (%) | Scan Speed (mm·s−1) | Vibration Amplitude (%) | Scan Speed (mm·s−1) | ||

| Laser processed without vibrations | LM | - | 10 | - | - |

| RM | - | 10 | - | 3.33 | |

| Laser processed with vibrations | ULM | 80 | 10 | - | - |

| URM | - | 10 | 80 | 3.33 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biswas, S.; Alavi, S.H.; Harimkar, S.P. Effect of Laser Remelting and Simultaneous Application of Ultrasonic Vibrations during Laser Melting on the Microstructural and Tribological Properties of Laser Clad Al-SiC Composites. J. Compos. Sci. 2017, 1, 13. https://doi.org/10.3390/jcs1020013

Biswas S, Alavi SH, Harimkar SP. Effect of Laser Remelting and Simultaneous Application of Ultrasonic Vibrations during Laser Melting on the Microstructural and Tribological Properties of Laser Clad Al-SiC Composites. Journal of Composites Science. 2017; 1(2):13. https://doi.org/10.3390/jcs1020013

Chicago/Turabian StyleBiswas, Sourabh, S. Habib Alavi, and Sandip P. Harimkar. 2017. "Effect of Laser Remelting and Simultaneous Application of Ultrasonic Vibrations during Laser Melting on the Microstructural and Tribological Properties of Laser Clad Al-SiC Composites" Journal of Composites Science 1, no. 2: 13. https://doi.org/10.3390/jcs1020013