Microstructural and Microhardness Evolution from Homogenization and Hot Isostatic Pressing on Selective Laser Melted Inconel 718: Structure, Texture, and Phases

Abstract

:1. Introduction

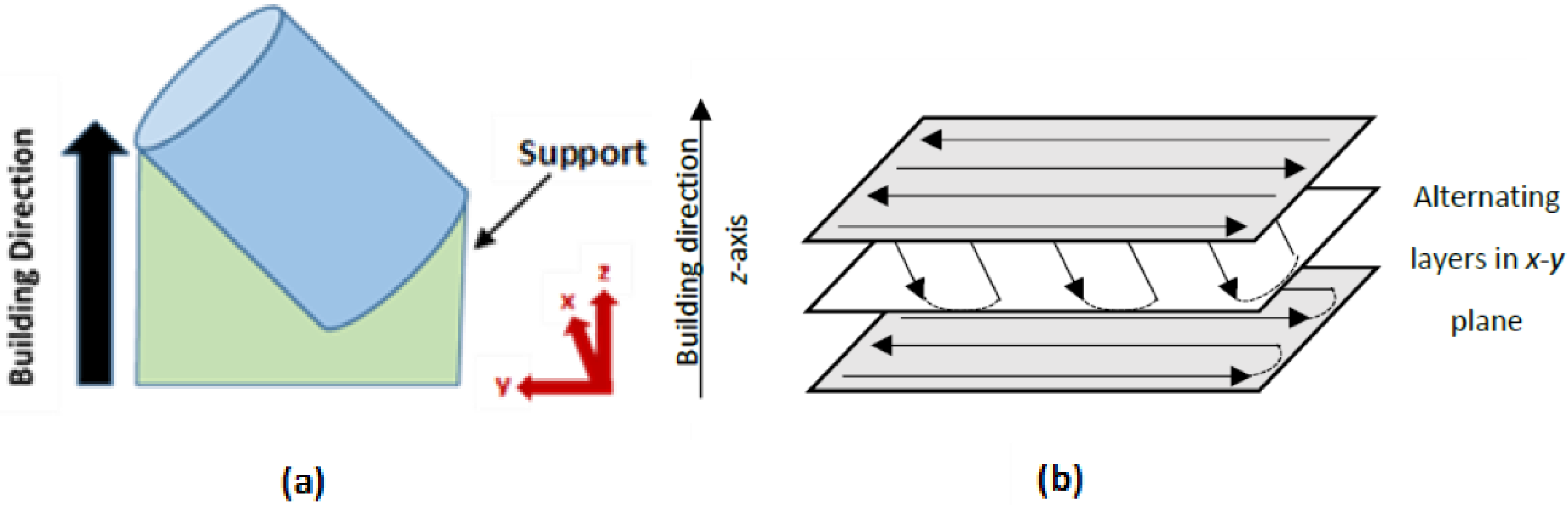

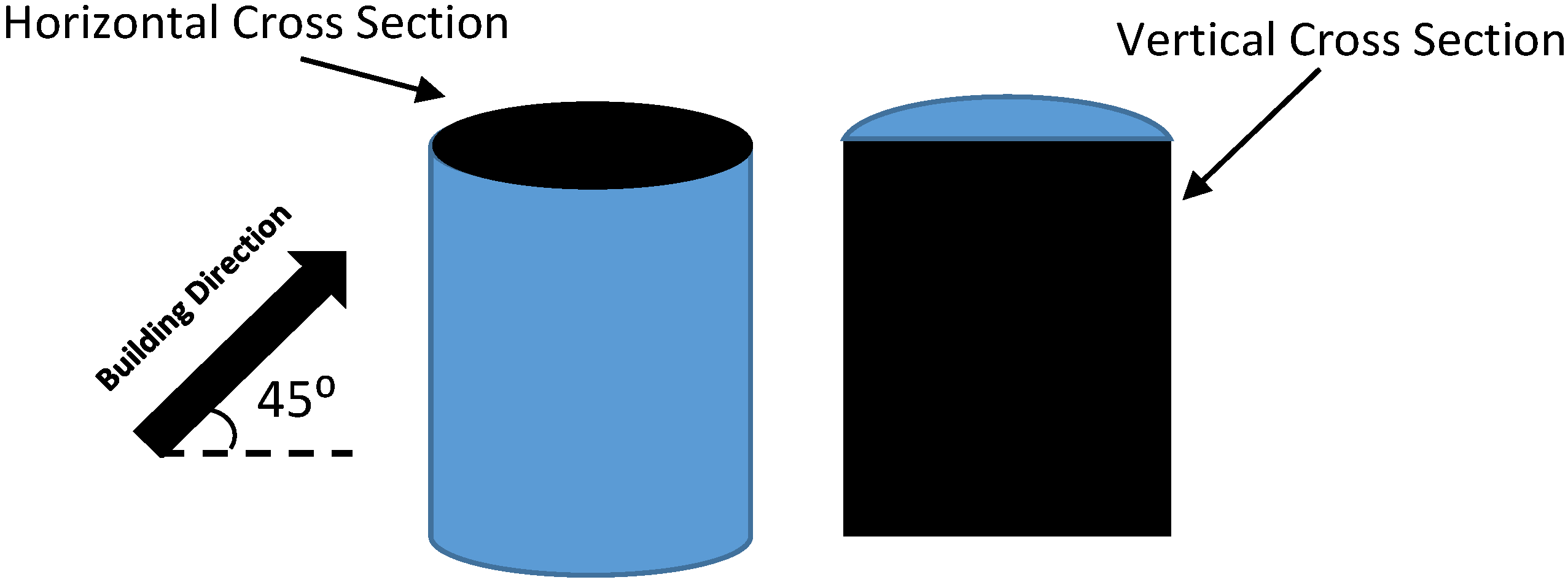

2. Materials and Methods

3. Results and Discussion

3.1. Microstructural Characterization

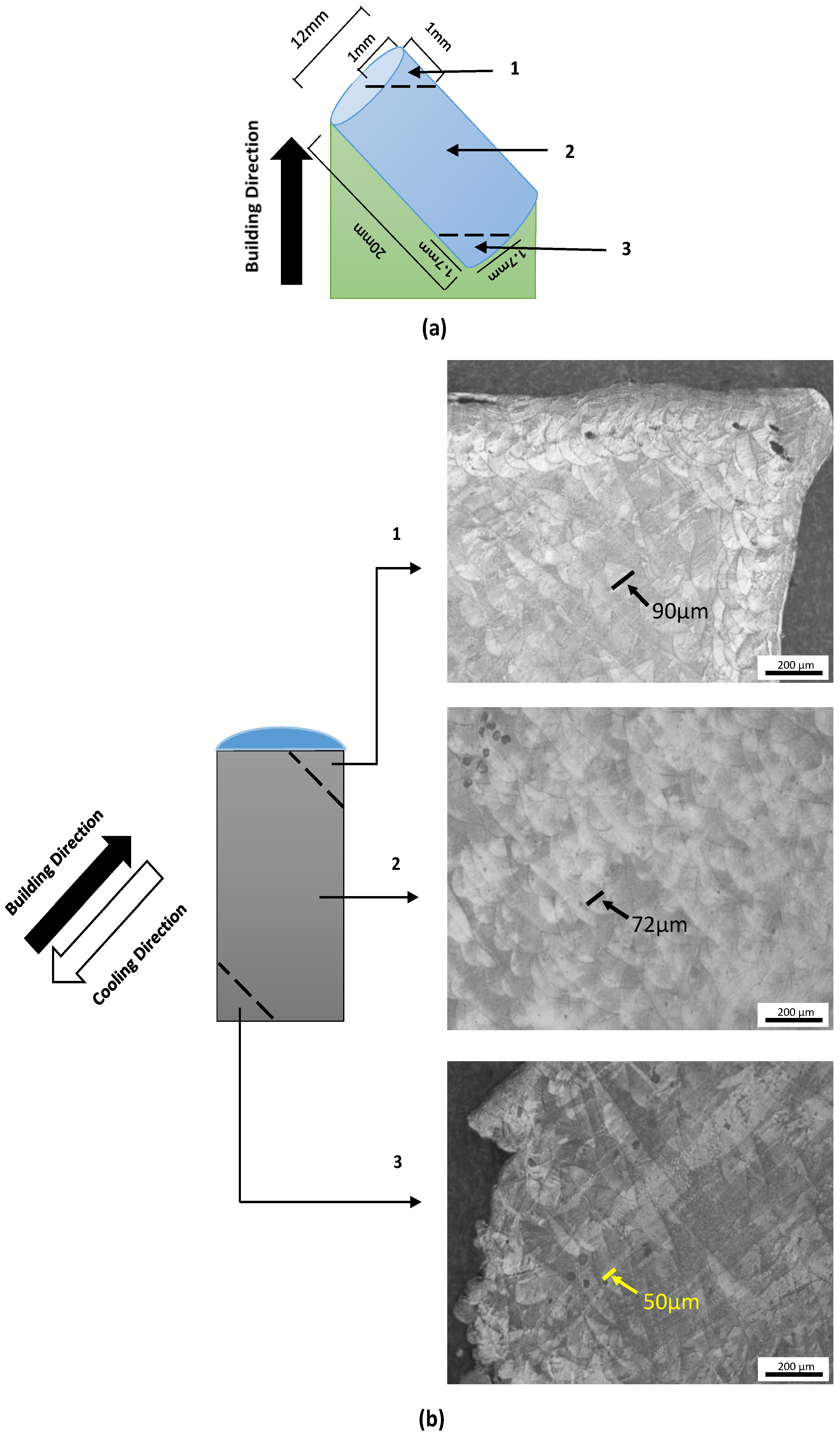

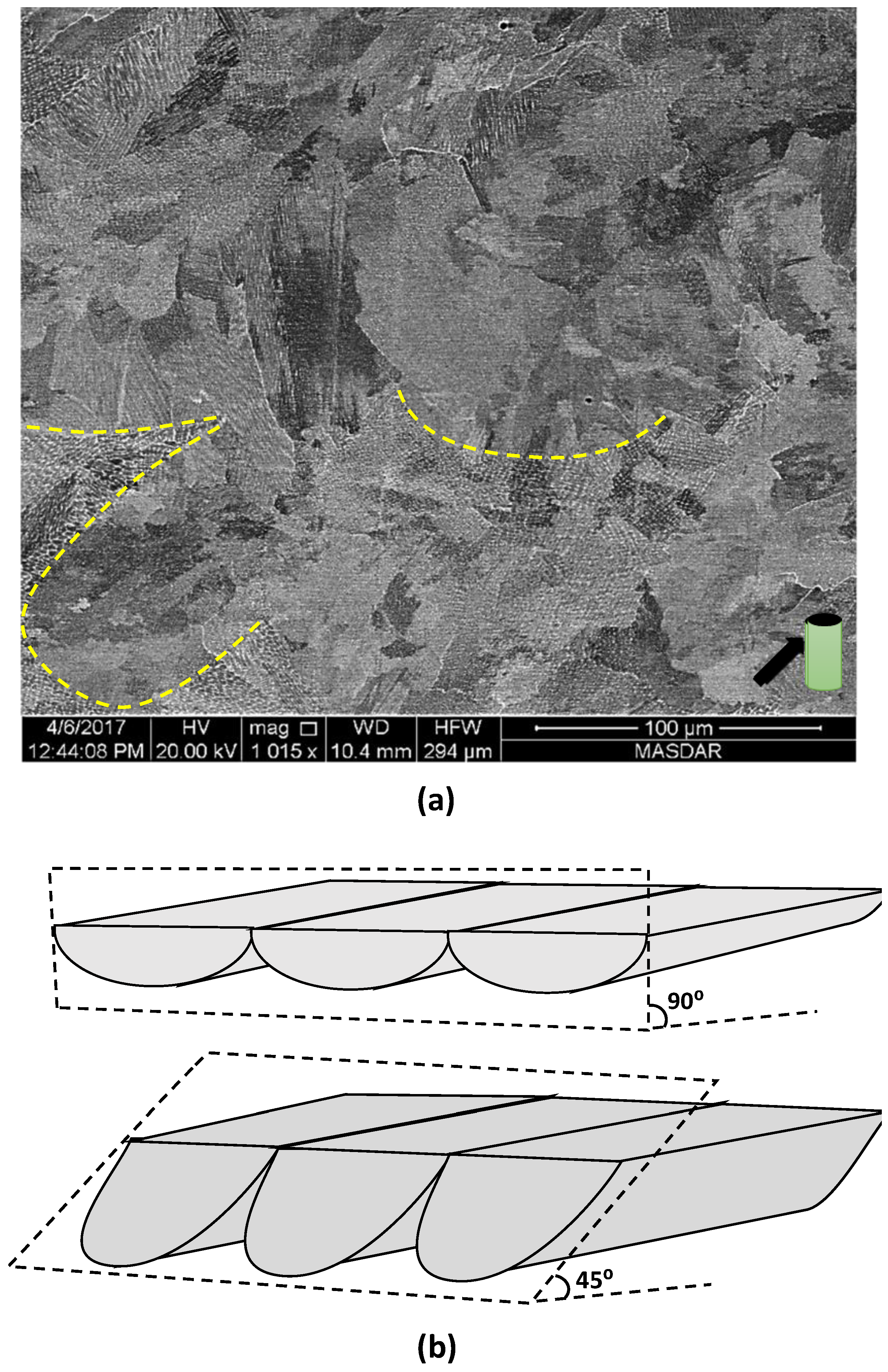

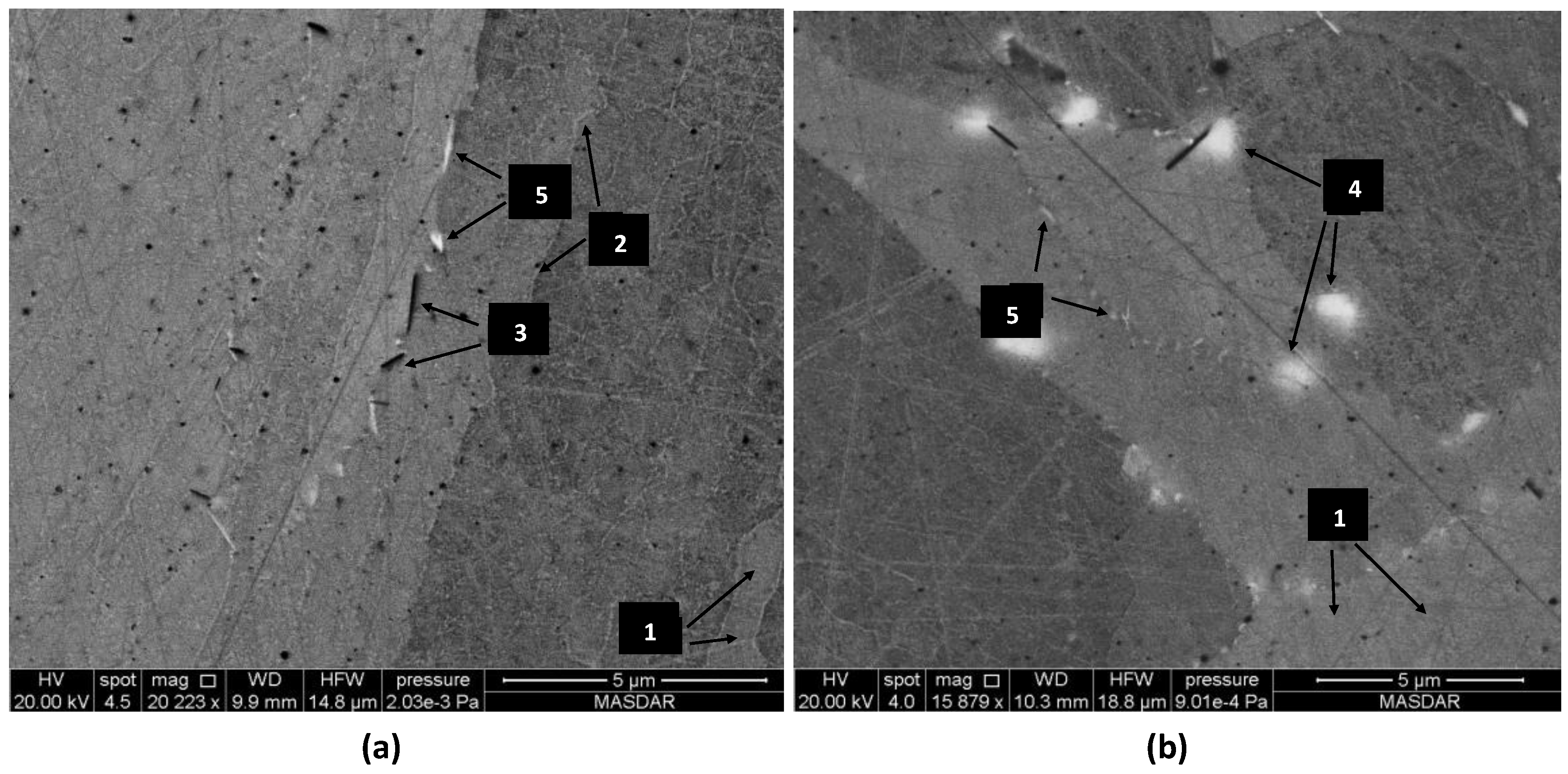

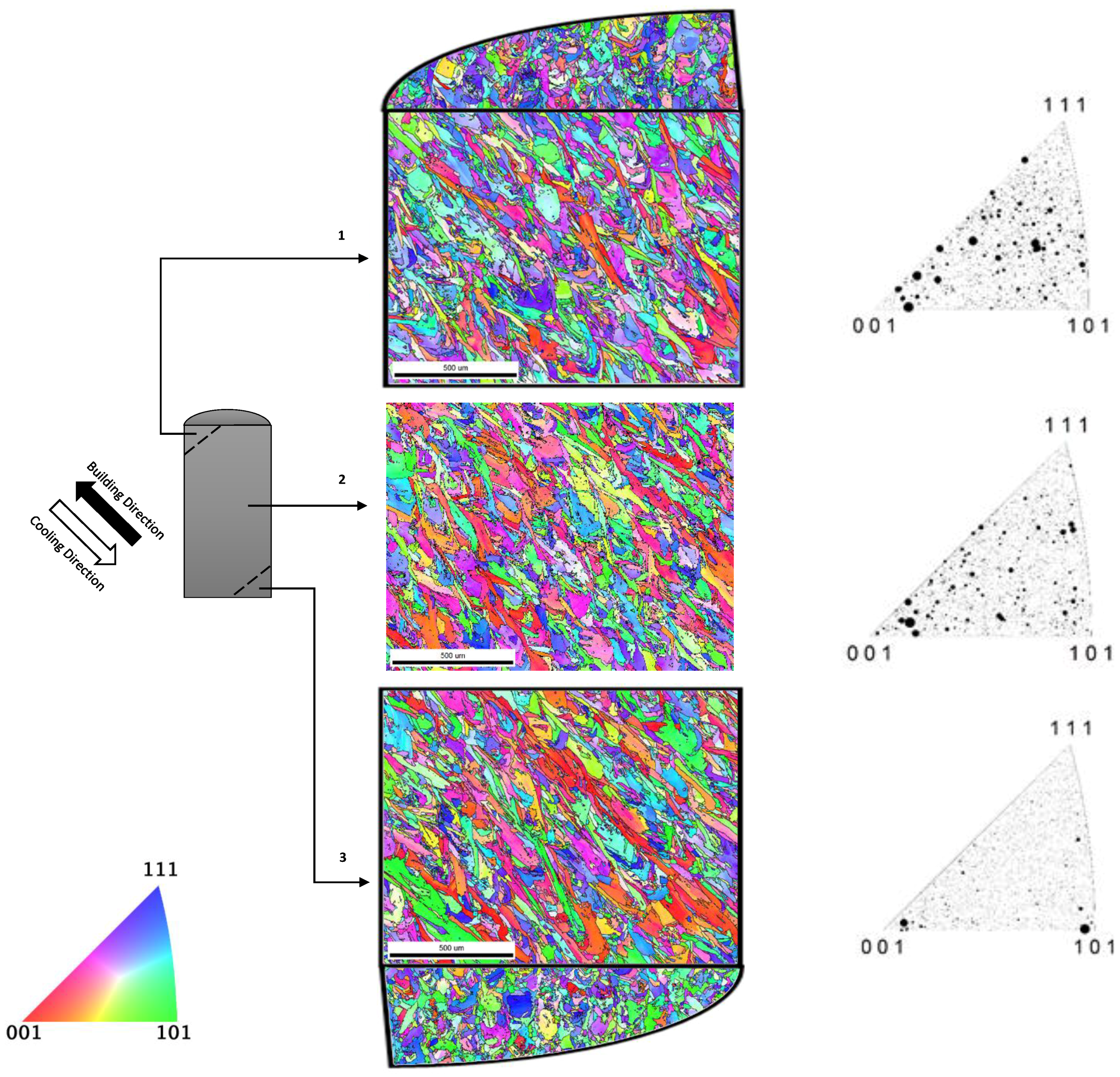

3.1.1. Microstructure of the As-Printed Inconel 718

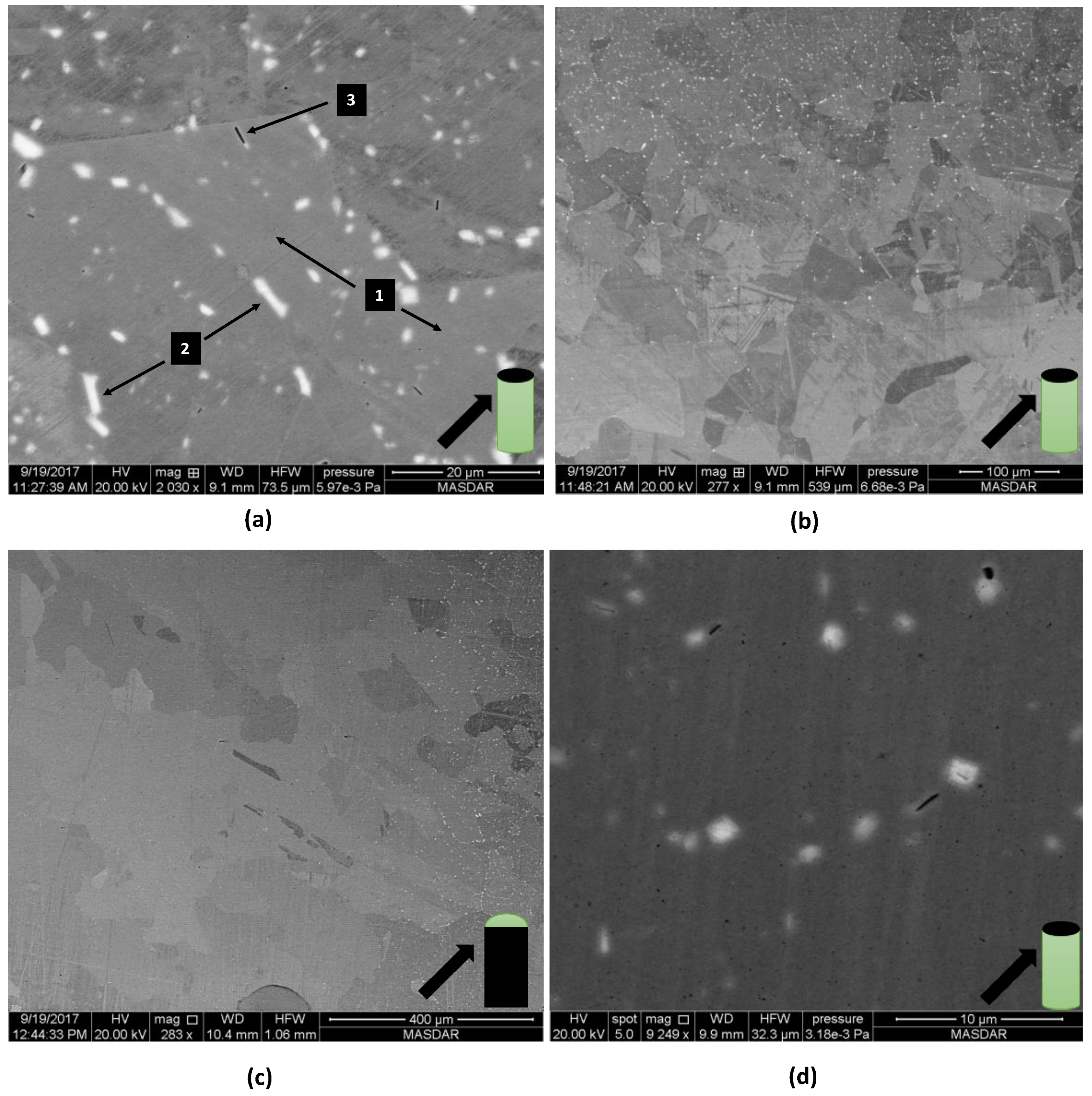

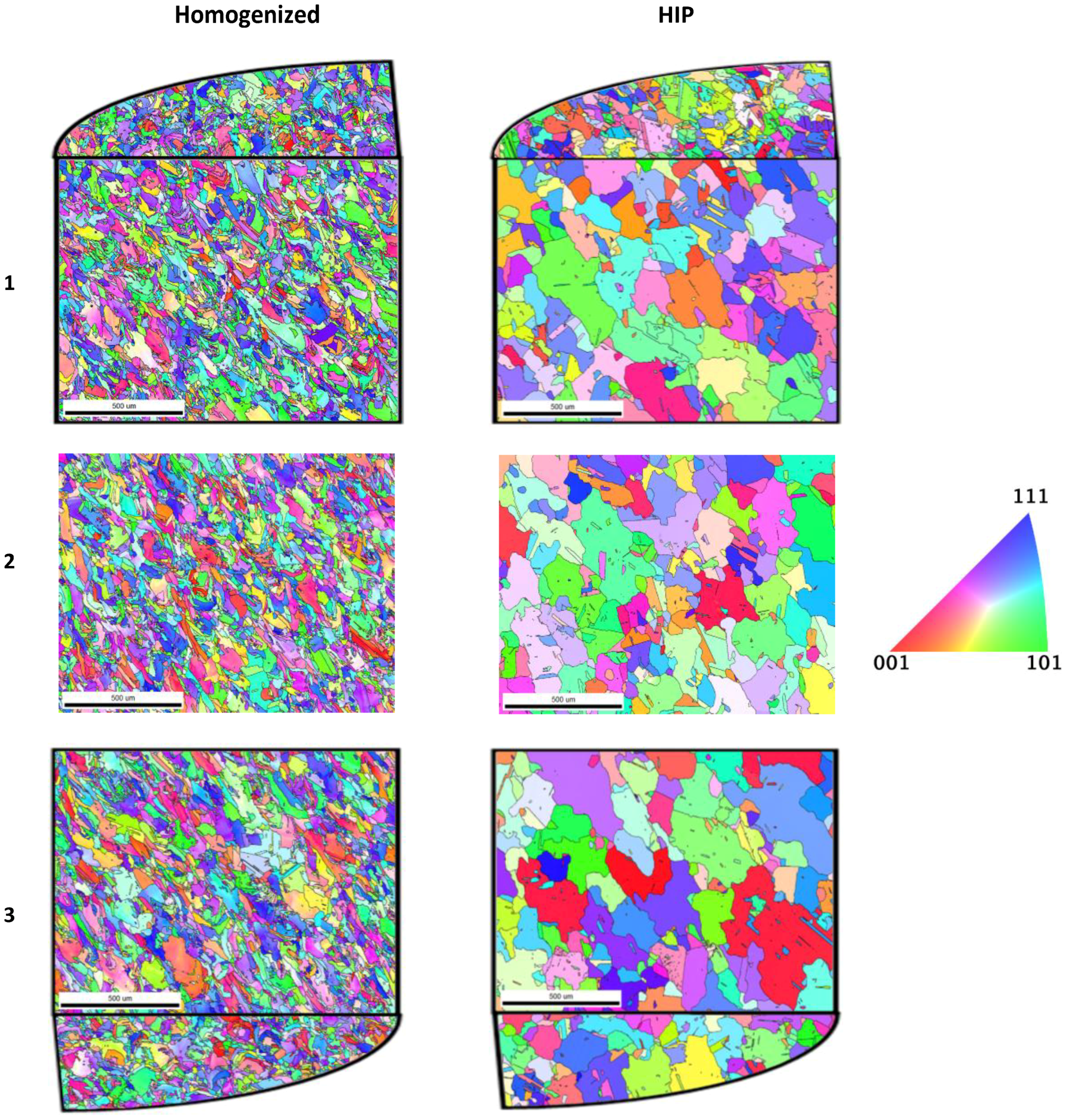

3.1.2. Microstructural Development of Heat Treated Inconel 718

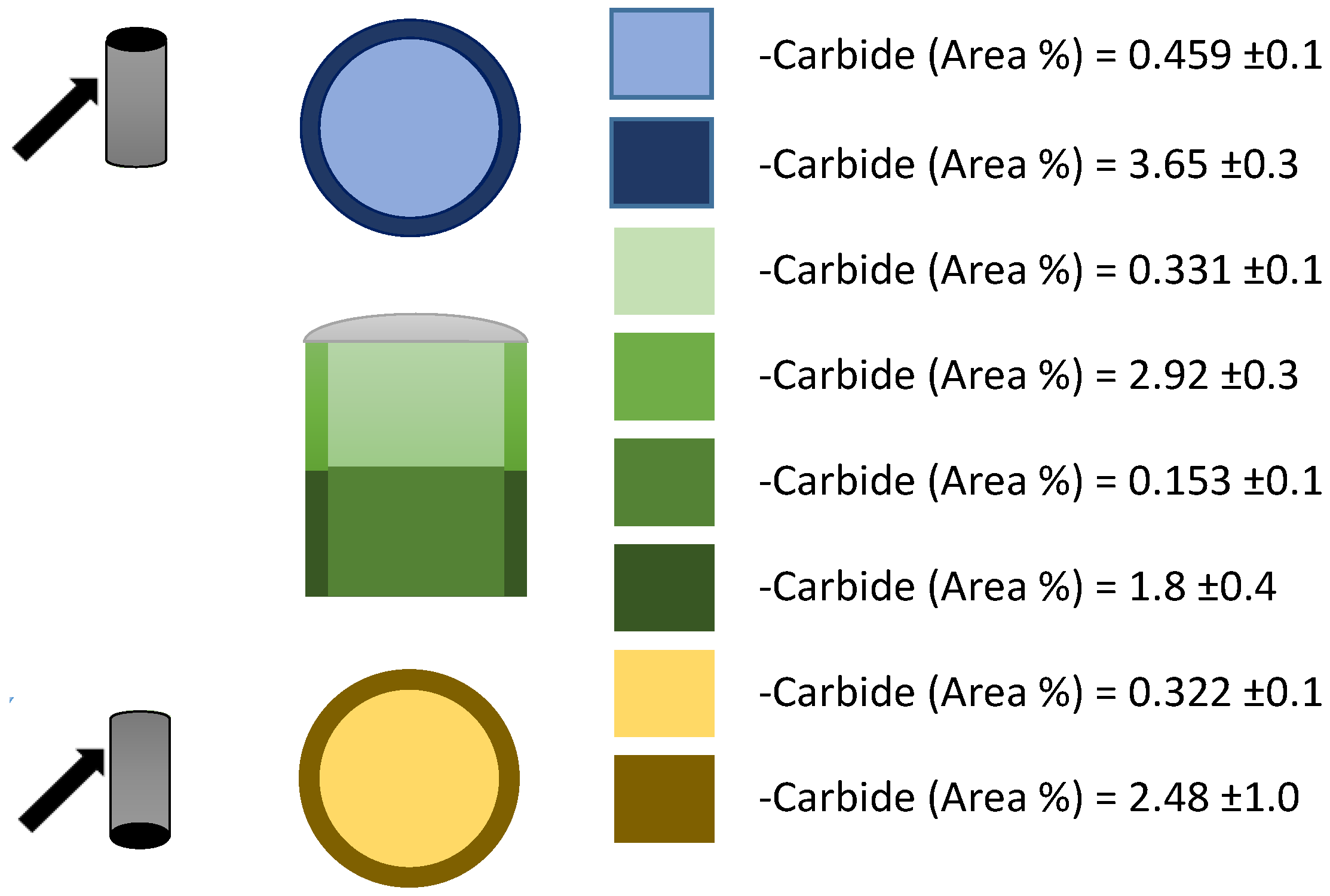

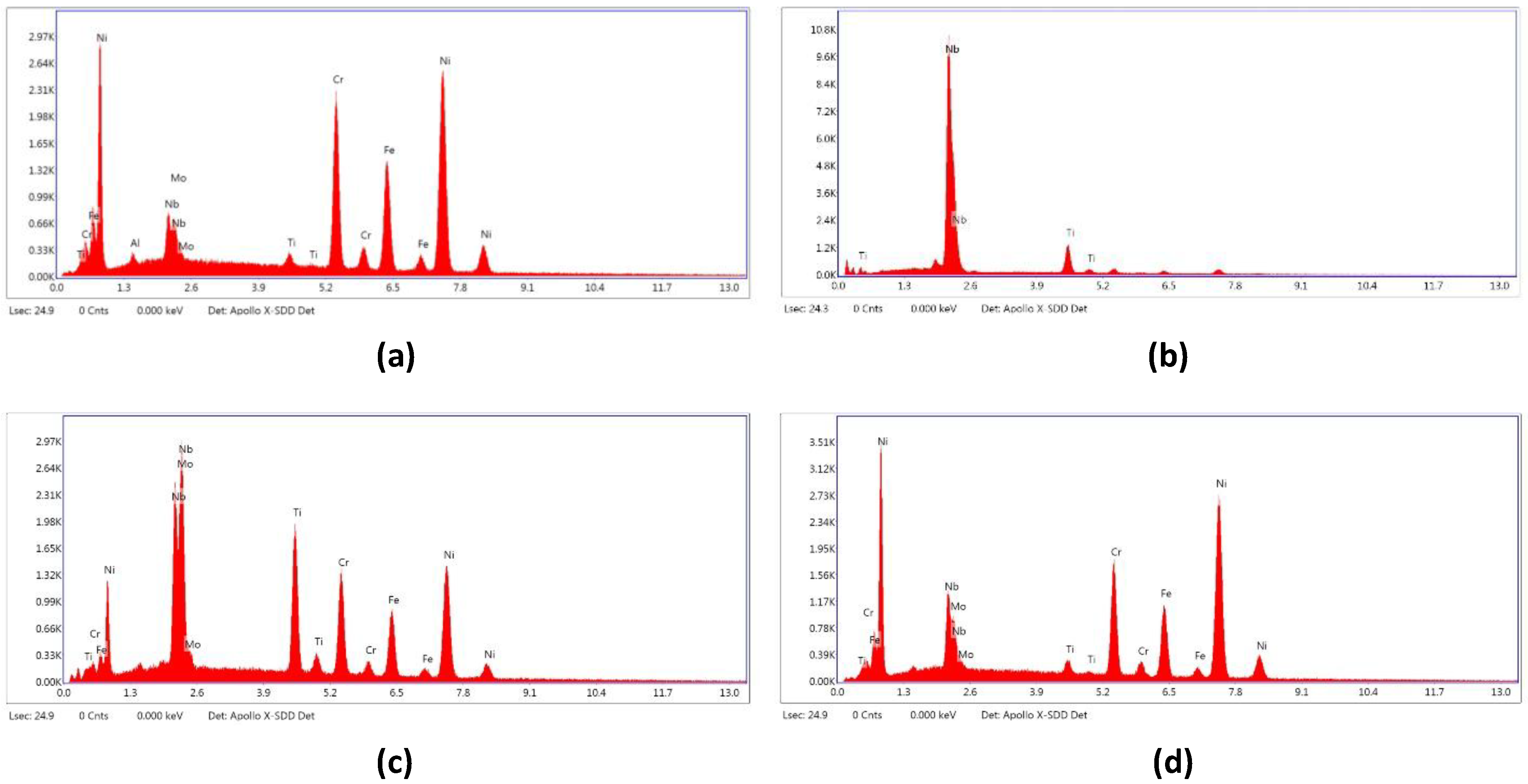

3.2. Phase Analysis of Heat-Treated Inconel 718

3.3. Evolution of Structure, Phases, and Texture

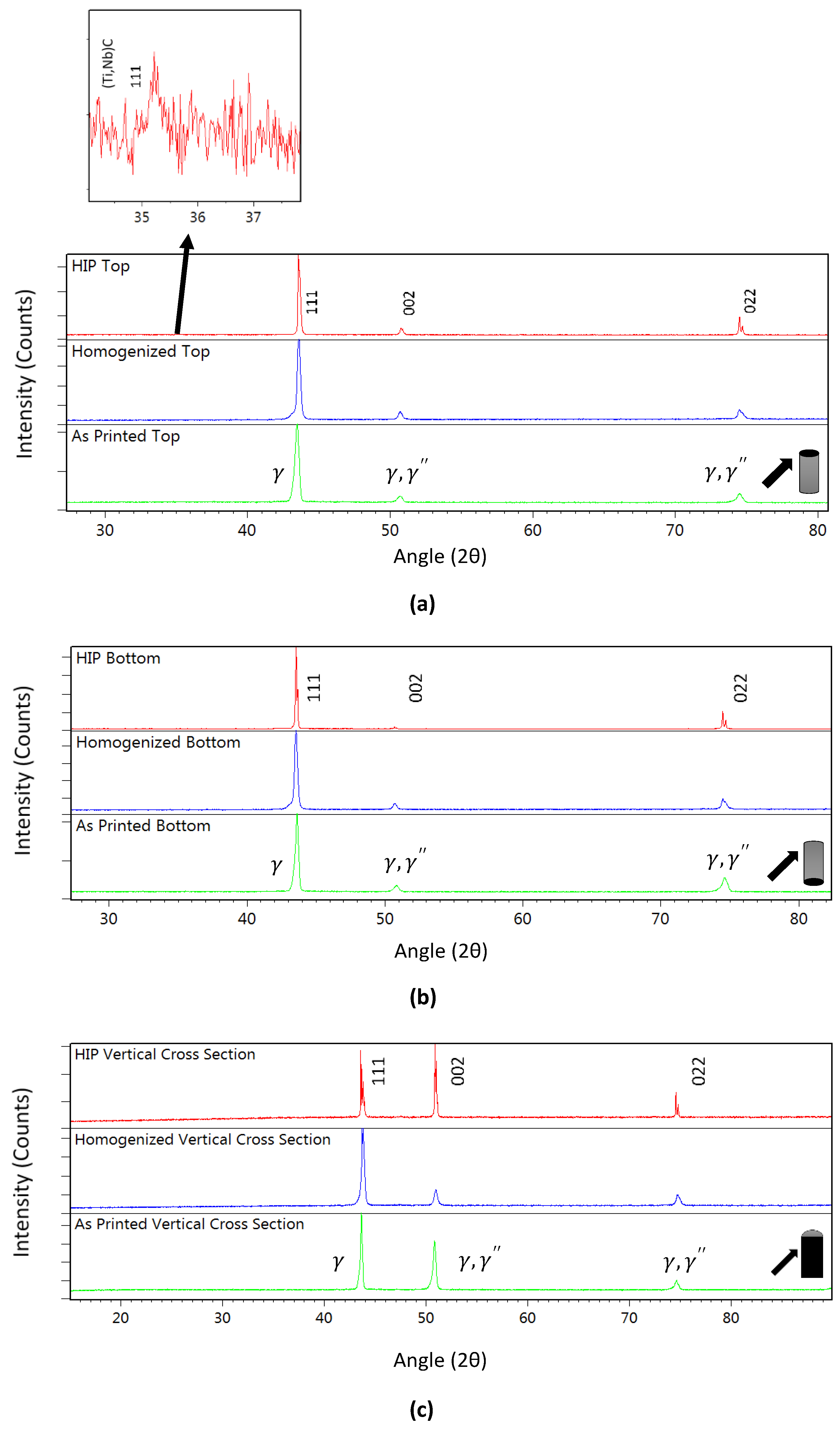

3.3.1. XRD Analysis of Structure and Phases

3.3.2. Evolution of Structure and Texture

3.4. Vickers Microhardness Measurements

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wang, X.; Gong, X.; Chou, K. Review on Powder-Bed Laser Additive Manufacturing of Inconel 718 Parts. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloy. Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Qi, H.; Azer, M.; Ritter, A. Studies of standard heat treatment effects on microstructure and mechanical properties of laser net shape manufactured INCONEL 718. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 2410–2422. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, K.; Gao, M.; Li, X.; Chen, X.; Zeng, X. The microstructure and mechanical properties of deposited-IN718 by selective laser melting. J. Alloy. Compd. 2012, 513, 518–523. [Google Scholar] [CrossRef]

- Debarbadillo, J.J.; Mannan, S.K. Alloy 718 for oilfield applications. JOM 2012, 64, 265–270. [Google Scholar] [CrossRef]

- Izquierdo, B.; Plaza, S.; Sánchez, J.A.; Pombo, I.; Ortega, N. Numerical prediction of heat affected layer in the EDM of aeronautical alloys. Appl. Surf. Sci. 2012, 259, 780–790. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2. [Google Scholar] [CrossRef]

- Hague, R.; Campbell, I.; Dickens, P. Implications on design of rapid manufacturing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2003, 217, 25–30. [Google Scholar] [CrossRef] [Green Version]

- Campbell, R.I.; Hague, R.J.; Sener, B.; Wormald, P.W. The Potential for the Bespoke Industrial Designer. Des. J. 2003, 6, 24–34. [Google Scholar] [CrossRef]

- Choi, J.P.; Shin, G.H.; Yang, S.; Yang, D.Y.; Lee, J.S.; Brochu, M.; Yu, J.H. Densification and microstructural investigation of Inconel 718 parts fabricated by selective laser melting. Powder Technol. 2017, 310, 60–66. [Google Scholar] [CrossRef]

- Amato, K.N.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.W.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Chlebus, E.; Gruber, K.; Kuźnicka, B.; Kurzac, J.; Kurzynowski, T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater. Sci. Eng. A 2015, 639, 647–655. [Google Scholar] [CrossRef]

- Mostafa, A.; Rubio, I.P.; Brailovski, V.; Jahazi, M.; Medraj, M. Structure, texture and phases in 3D printed IN718 alloy subjected to homogenization and HIP treatments. Metals 2017, 7, 196. [Google Scholar] [CrossRef]

- Thijs, L.; Sistiaga, M.L.M.; Wauthle, R.; Xie, Q.; Kruth, J.P.; van Humbeeck, J. Strong morphological and crystallographic texture and resulting yield strength anisotropy in selective laser melted tantalum. Acta Mater. 2013, 61, 4657–4668. [Google Scholar] [CrossRef]

- Segersäll, M.; Moverare, J.J. Crystallographic orientation influence on the serrated yielding behavior of a single-crystal superalloy. Materials 2013, 6, 437–444. [Google Scholar] [CrossRef] [PubMed]

- Segersäll, M.; Moverare, J.J.; Simonsson, K.; Johansson, S. Deformation and damage mechanisms during thermomechanical fatigue of a single-crystal superalloy in the and directions. Superalloys 2012, 215–223. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Heurtebise, V.; Riemslag, T.; Popovich, A.A.; Sufiiarov, V.S. Creep and Thermomechanical Fatigue of Functionally Graded Inconel 718 Produced by Additive Manufacturing. In TMS 2018 147th Annual Meeting & Exhibition Supplemental Proceedings; Springer: Berlin/Heidelberg, Germany, 2018; pp. 85–97. [Google Scholar]

- Parimi, L.L.; Ravi, G.; Clark, D.; Attallah, M.M. Microstructural and texture development in direct laser fabricated IN718. Mater. Charact. 2014, 89, 102–111. [Google Scholar] [CrossRef]

- Zhang, D.; Niu, W.; Cao, X.; Liu, Z. Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel 718 superalloy. Mater. Sci. Eng. A 2015, 644, 32–40. [Google Scholar] [CrossRef]

- Tucho, W.M.; Cuvillier, P.; Sjolyst-Kverneland, A.; Hansen, V. Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after solution heat treatment. Mater. Sci. Eng. A 2017, 689, 220–232. [Google Scholar] [CrossRef]

- EOS Gmbh Electro Optical Systems. EOS Nickelalloy Inconel 718 Datasheet; EOS Gmbh: Krailling, Germany, 2014. [Google Scholar]

- Smith, D.H.; Bicknell, J.; Jorgensen, L.; Patterson, B.M.; Cordes, N.L.; Tsukrov, I.; Knezevic, M. Microstructure and mechanical behavior of direct metal laser sintered Inconel alloy 718. Mater. Charact. 2016, 113, 1–9. [Google Scholar] [CrossRef]

- Rasband, W.S. ImageJ; U. S. National Institutes of Health: Bethesda, MD, USA, 2012. Available online: https://imagej.nih.gov/ij/ (accessed on 16 May 2018).

- Degen, T.; Sadki, M.; Bron, E.; König, U.; Nénert, G. The HighScore suite. Powder Diffr. 2014, 29, S13–S18. [Google Scholar] [CrossRef]

- Pierre, V. Pearson’s Crystal Data, Crystal Structure Database for Inorganic Compounds (on CD-ROM); ASM International: Materials Park, OH, USA, 2010. [Google Scholar]

- Campanelli, S.L.; Casalino, G.; Contuzzi, N.; Ludovico, A.D. Taguchi optimization of the surface finish obtained by laser ablation on selective laser molten steel parts. Procedia CIRP 2013, 12, 462–467. [Google Scholar] [CrossRef]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 105, 160–170. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Agius, D.; Kourousis, K.; Wallbrink, C. A Review of the As-Built SLM Ti-6Al-4V Mechanical Properties towards Achieving Fatigue Resistant Designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, Y.; Sun, S.; Zhang, H. Selective laser melting of Al-8.5Fe-1.3V-1.7Si alloy: Investigation on the resultant microstructure and hardness. Chin. J. Aeronaut. 2015, 28, 564–569. [Google Scholar] [CrossRef]

- Zhou, X.; Li, K.; Zhang, D.; Liu, X.; Ma, J.; Liu, W.; Shen, Z. Textures formed in a CoCrMo alloy by selective laser melting. J. Alloy. Compd. 2015, 631, 153–164. [Google Scholar] [CrossRef]

- Liu, L.; Zhai, C.; Lu, C.; Ding, W.; Hirose, A.; Kobayashi, K.F. Study of the effect of Delta phase on hydrogen embrittlement of Inconel 718 by notch tensile tests. Corros. Sci. 2005, 47, 355–367. [Google Scholar] [CrossRef]

- Koul, A.K.; Au, P.; Bellinger, N.; Thamburaj, R.; Wallace, W.; Immarigeon, J.P. Development of a Damage Tolerant Microstructure for Inconel 718 Turbine Disc Material. Superalloys 1988, 3–10. [Google Scholar] [CrossRef]

- Rao, G.A.; Kumar, M.; Srinivas, M.; Sarma, D.S. Effect of solution treatment temperature on microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718. Mater. Sci. Technol. 2004, 20, 1161–1170. [Google Scholar] [CrossRef]

- Mitchell, A.; Schmalz, A.J.; Schvezov, C.; Cockcroft, S.L. The Precipitation of Primary Carbides in Alloy 718. Superalloys 1994, 65–78. [Google Scholar] [CrossRef]

- Kuo, Y.-L.; Kakehi, K. Influence of Powder Surface Contamination in the Ni-Based Superalloy Alloy718 Fabricated by Selective Laser Melting and Hot Isostatic Pressing. Metals 2017, 7, 367. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Gaytan, S.M.; Ramirez, D.A.; MacHado, B.I.; Shindo, P.W.; Martinez, J.L.; Medina, F.; Wooten, J.; Ciscel, D.; et al. Microstructural architecture, microstructures, and mechanical properties for a nickel-base superalloy fabricated by electron beam melting. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 3491–3508. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Amato, K.N.; Gaytan, S.M.; Hernandez, J.; Ramirez, D.A.; Shindo, P.W.; Medina, F.; Wicker, R.B. Fabrication of metal and alloy components by additive manufacturing: Examples of 3D materials science. J. Mater. Res. Technol. 2012, 1, 42–54. [Google Scholar] [CrossRef]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide, 2nd ed.; ASM International: Geauga County, OH, USA, 2002. [Google Scholar]

- Muralidharan, B.G.; Shankar, V. Weldability of Inconel 718—A Review; Indira Gandhi Centre for Atomic Research: Tamil Nadu, India, 1996; pp. 1–30. [Google Scholar]

- Manikandan, S.G.K.; Sivakumar, D.; Rao, K.P.; Kamaraj, M. Laves phase in alloy 718 fusion zone—Microscopic and calorimetric studies. Mater. Charact. 2015, 100, 192–206. [Google Scholar] [CrossRef]

- Azadian, S.; Wei, L.Y.; Warren, R. Delta phase precipitation in inconel 718. Mater. Charact. 2004, 53, 7–16. [Google Scholar] [CrossRef]

- Idell, Y.; Levine, L.E.; Allen, A.J.; Zhang, F.; Campbell, C.E.; Olson, G.B.; Gong, J.; Snyder, D.R.; Deutchman, H.Z. Unexpected δ-phase formation in additive-manufactured Ni-based superalloy. JOM 2016, 68, 950–959. [Google Scholar] [CrossRef]

- Jouiad, M.; Marin, E.; Devarapalli, R.S.; Cormier, J.; Ravaux, F.; le Gall, C.; Franchet, J.M. Microstructure and mechanical properties evolutions of alloy 718 during isothermal and thermal cycling over-aging. Mater. Des. 2016, 102, 284–296. [Google Scholar] [CrossRef]

- Sjoberg, G.; Ingesten, N.G.; Carlson, R.G. Grain Boundary δ-phase Morphologies. Carbides and Notch Rupture Sensitivity of Cast Alloy 718. Superalloys 1991. [Google Scholar] [CrossRef]

- Maity, T.; Chawake, N.; Kim, J.T.; Eckert, J.; Prashanth, K.G. Anisotropy in local microstructure—Does it affect the tensile properties of the SLM samples? Manuf. Lett. 2018, 15, 33–37. [Google Scholar] [CrossRef]

| Reference #’s (Figure 6) | Phase | Nb | Mo | Ti | Cr | Fe | Ni |

|---|---|---|---|---|---|---|---|

| 1 | γ-phase | 4.56 | 2.6 | 1.08 | 19.77 | 18.33 | 52.99 |

| 2 | γ″-phase | Below detection limits | |||||

| 3 | δ-phase | 11.22 | 9.41 | 18.15 | 16.41 | 12.99 | 31.82 |

| 4 | MC-type carbide | 76.22 | - | 23.78 | - | - | - |

| 5 | Laves | 6.05 | 1.54 | 1.8 | 18.29 | 15.12 | 57.21 |

| EDS Error (%) | 6.5 | 9.1 | 8.6 | 3.8 | 4.5 | 2.8 | |

| Phases | As-Printed | Homogenized | HIP | |||

|---|---|---|---|---|---|---|

| Top | Bottom | Top | Bottom | Top | Bottom | |

| γ (CrNi) | 96.3% | 97.7% | 100% | 100% | 99.8% | 99.9% |

| γ″ (Ni3Nb) | 3.7% | 2.3% | 0.0% | 0.0% | 0.0% | 0.0% |

| (Ti, Nb)C | - | - | - | - | 0.2% | 0.1% |

| Horizontal Cross-Section | Vertical Cross-Section | ||||

|---|---|---|---|---|---|

| (3) Bottom | (1) Top | (3) Bottom | (2) Middle | (1) Top | |

| As-printed | |||||

| Diameter (µm): | 39.4 | 41.5 | 65.2 | 56.1 | 55.2 |

| Standard Deviation: | 2.4 | 2.5 | 54.8 | 36.1 | 36.7 |

| Grain Aspect Ratio: | 0.392 | 0.371 | 0.253 | 0.275 | 0.277 |

| Standard Deviation: | 0.115 | 0.121 | 0.132 | 0.124 | 0.121 |

| Homogenized | |||||

| Diameter (µm): | 38.5 | 40.4 | 54.2 | 43.7 | 44.7 |

| Standard Deviation: | 2.2 | 2.5 | 36.4 | 25.7 | 28.0 |

| Grain Aspect Ratio: | 0.397 | 0.409 | 0.333 | 0.339 | 0.348 |

| Standard Deviation: | 0.122 | 0.118 | 0.128 | 0.123 | 0.127 |

| HIP | |||||

| Diameter (µm): | 153.5 | 69.9 | 200.7 | 154.8 | 153.2 |

| Standard Deviation: | 14.3 | 4.9 | 111.0 | 74.1 | 77.1 |

| Grain Aspect Ratio: | 0.436 | 0.404 | 0.419 | 0.399 | 0.415 |

| Standard Deviation: | 0.109 | 0.119 | 0.102 | 0.113 | 0.105 |

| Horizontal Cross-Section | Vertical Cross-Section | ||

|---|---|---|---|

| Bottom | Top | ||

| As-printed | |||

| Hardness (HV): | 211.3 ± 12.6 | 204.9 ± 21.0 | 236.9 ± 11.2 |

| Homogenized | |||

| Hardness (HV): | 289.1 ± 15.9 | 260.0 ± 41.4 | 282.6 ± 16.6 |

| HIP | |||

| Hardness (HV): | 181.1 ± 13.8 | 175.7 ± 5.2 | 180.5 ± 7.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seede, R.; Mostafa, A.; Brailovski, V.; Jahazi, M.; Medraj, M. Microstructural and Microhardness Evolution from Homogenization and Hot Isostatic Pressing on Selective Laser Melted Inconel 718: Structure, Texture, and Phases. J. Manuf. Mater. Process. 2018, 2, 30. https://doi.org/10.3390/jmmp2020030

Seede R, Mostafa A, Brailovski V, Jahazi M, Medraj M. Microstructural and Microhardness Evolution from Homogenization and Hot Isostatic Pressing on Selective Laser Melted Inconel 718: Structure, Texture, and Phases. Journal of Manufacturing and Materials Processing. 2018; 2(2):30. https://doi.org/10.3390/jmmp2020030

Chicago/Turabian StyleSeede, Raiyan, Ahmad Mostafa, Vladimir Brailovski, Mohammad Jahazi, and Mamoun Medraj. 2018. "Microstructural and Microhardness Evolution from Homogenization and Hot Isostatic Pressing on Selective Laser Melted Inconel 718: Structure, Texture, and Phases" Journal of Manufacturing and Materials Processing 2, no. 2: 30. https://doi.org/10.3390/jmmp2020030