Influence of NC Program Quality and Geometric Errors of Rotary Axes on S-Shaped Machining Test Accuracy

Abstract

:1. Introduction

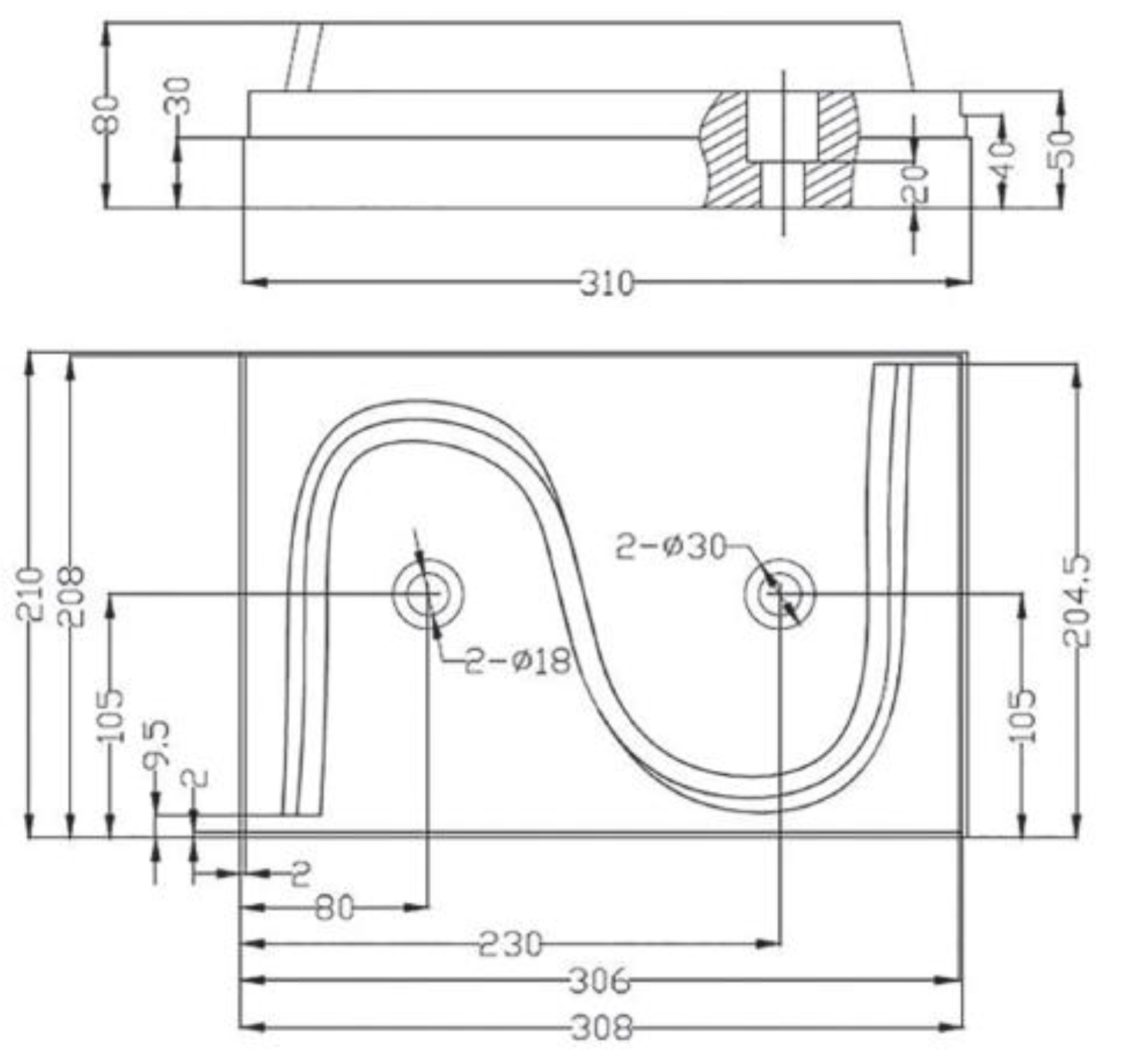

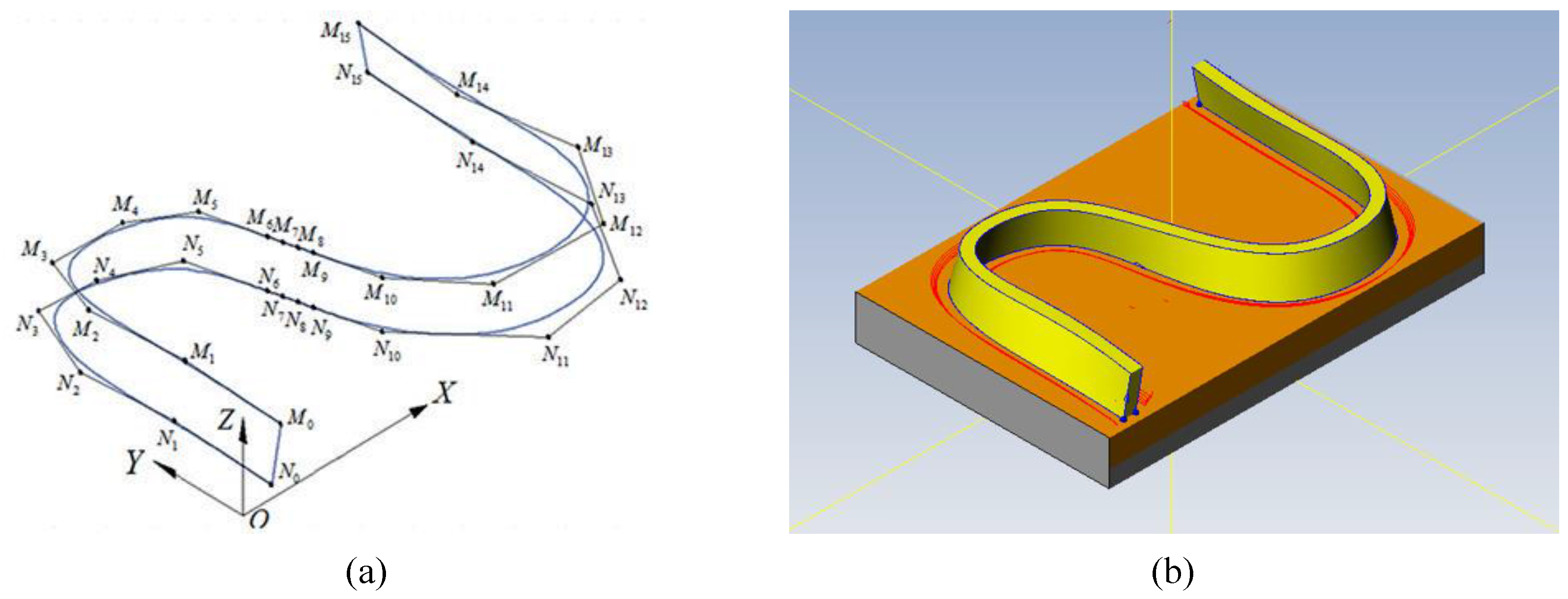

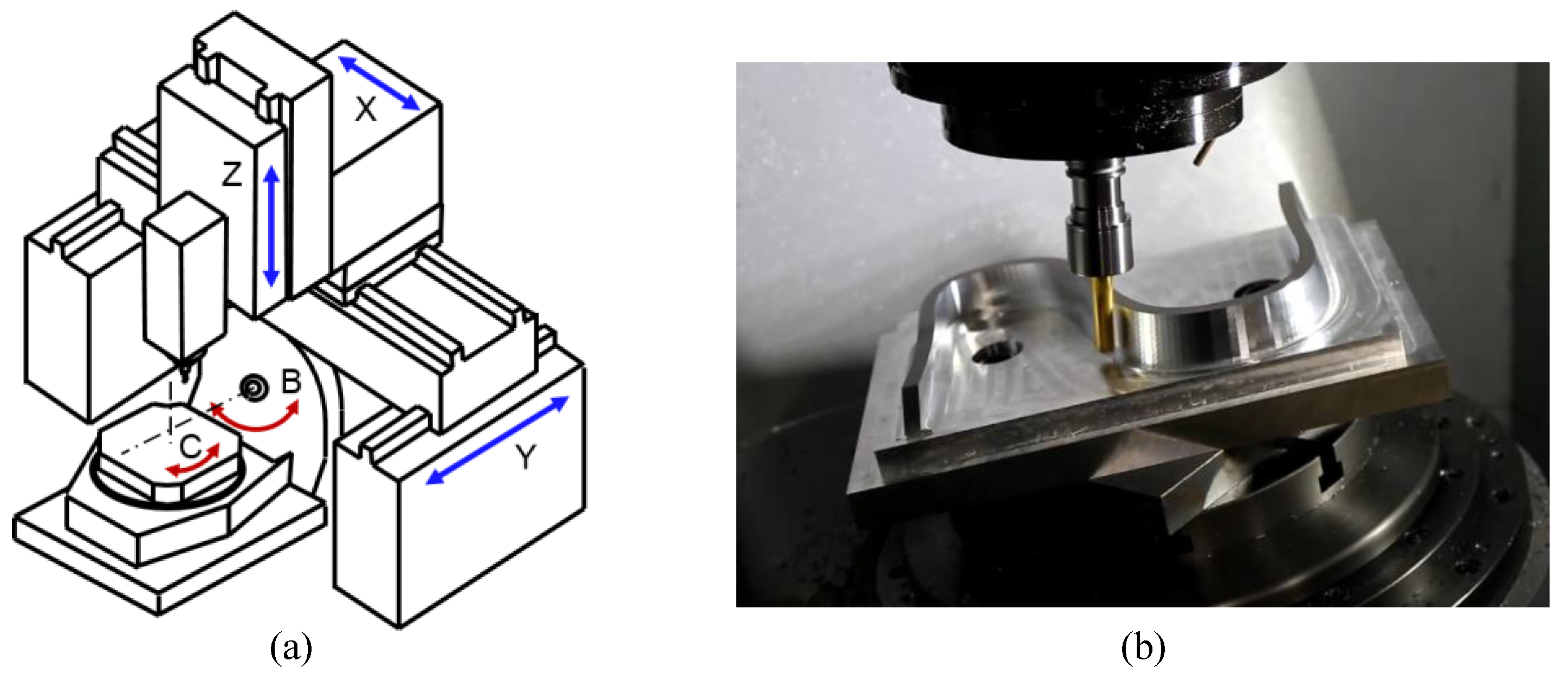

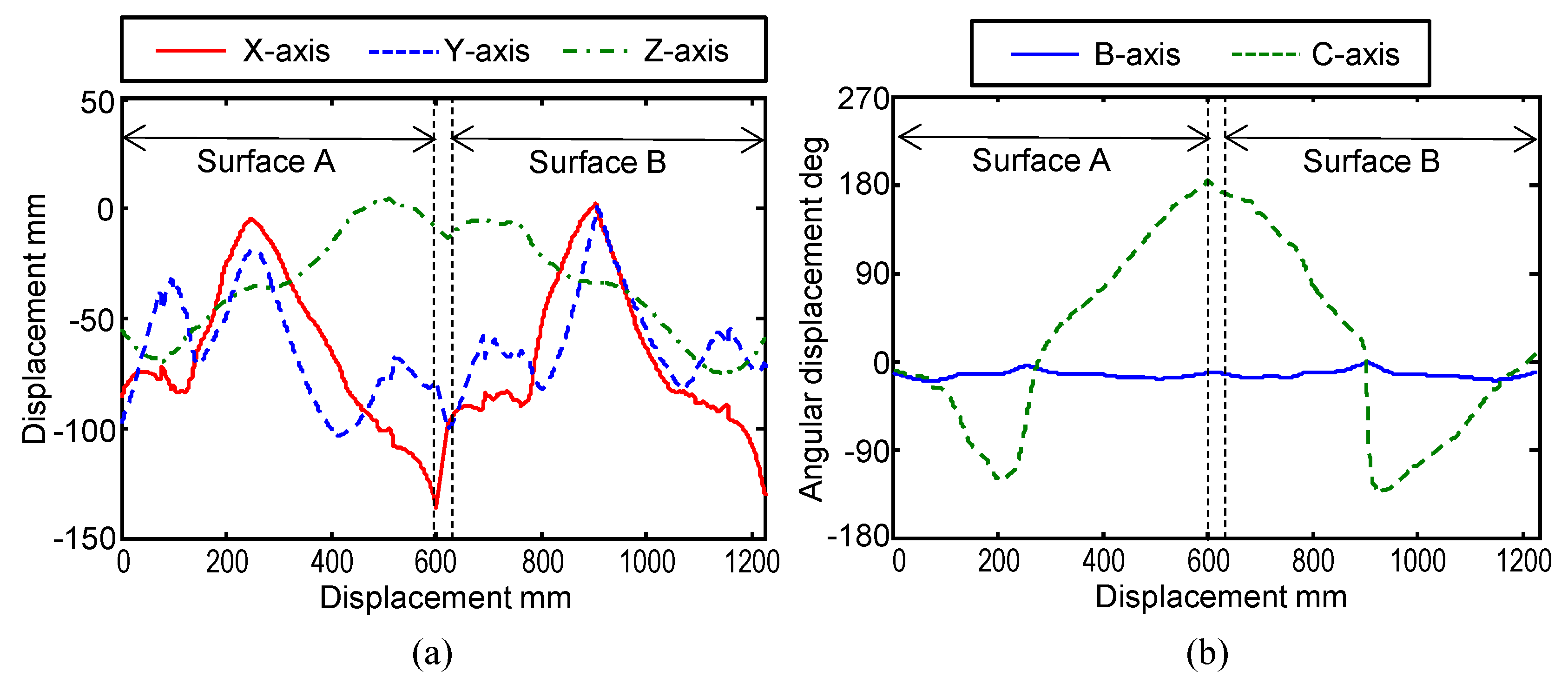

2. S-Shaped Machining Test and Simulation

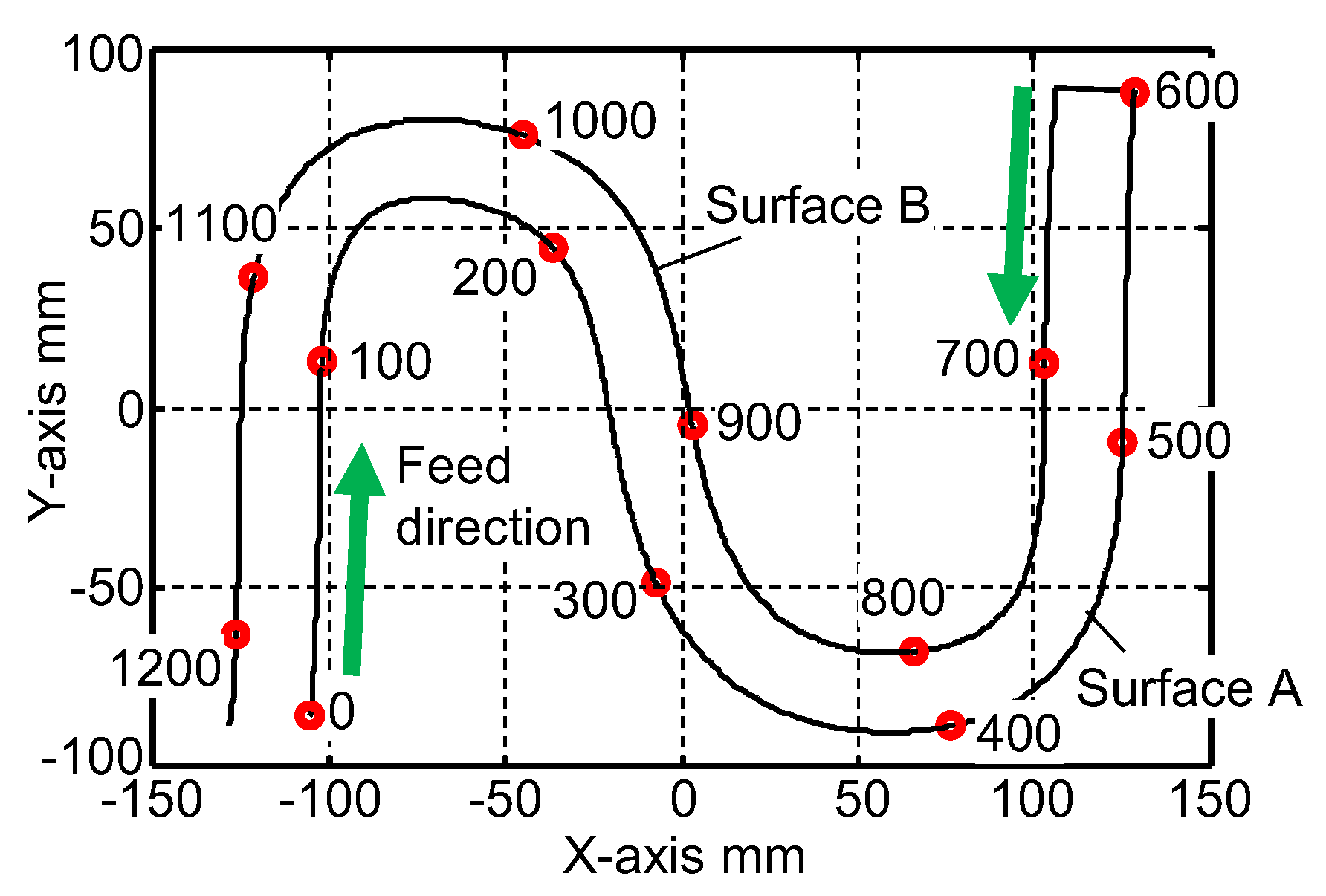

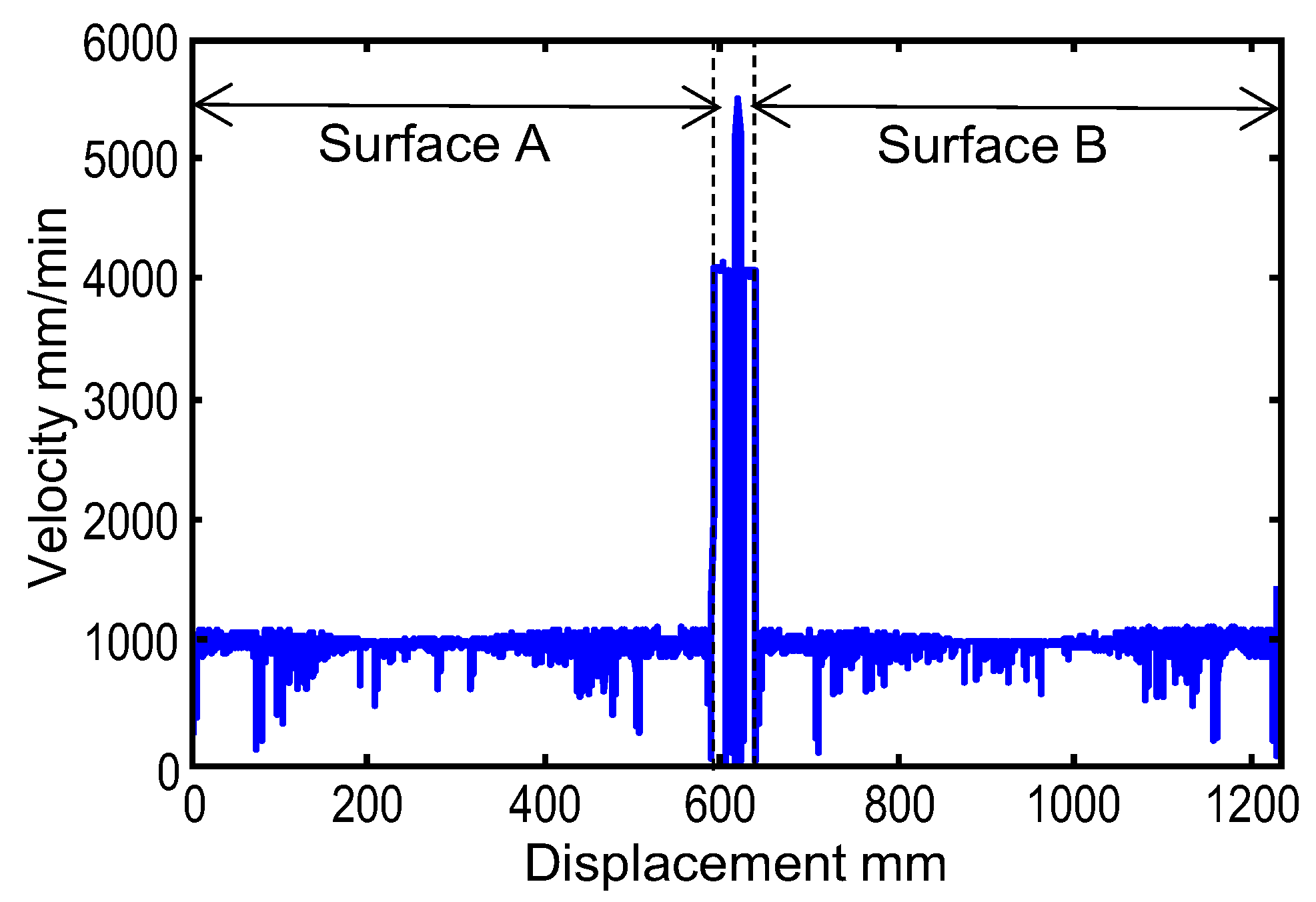

3. Feed Motion in the S-Shaped Machining Test

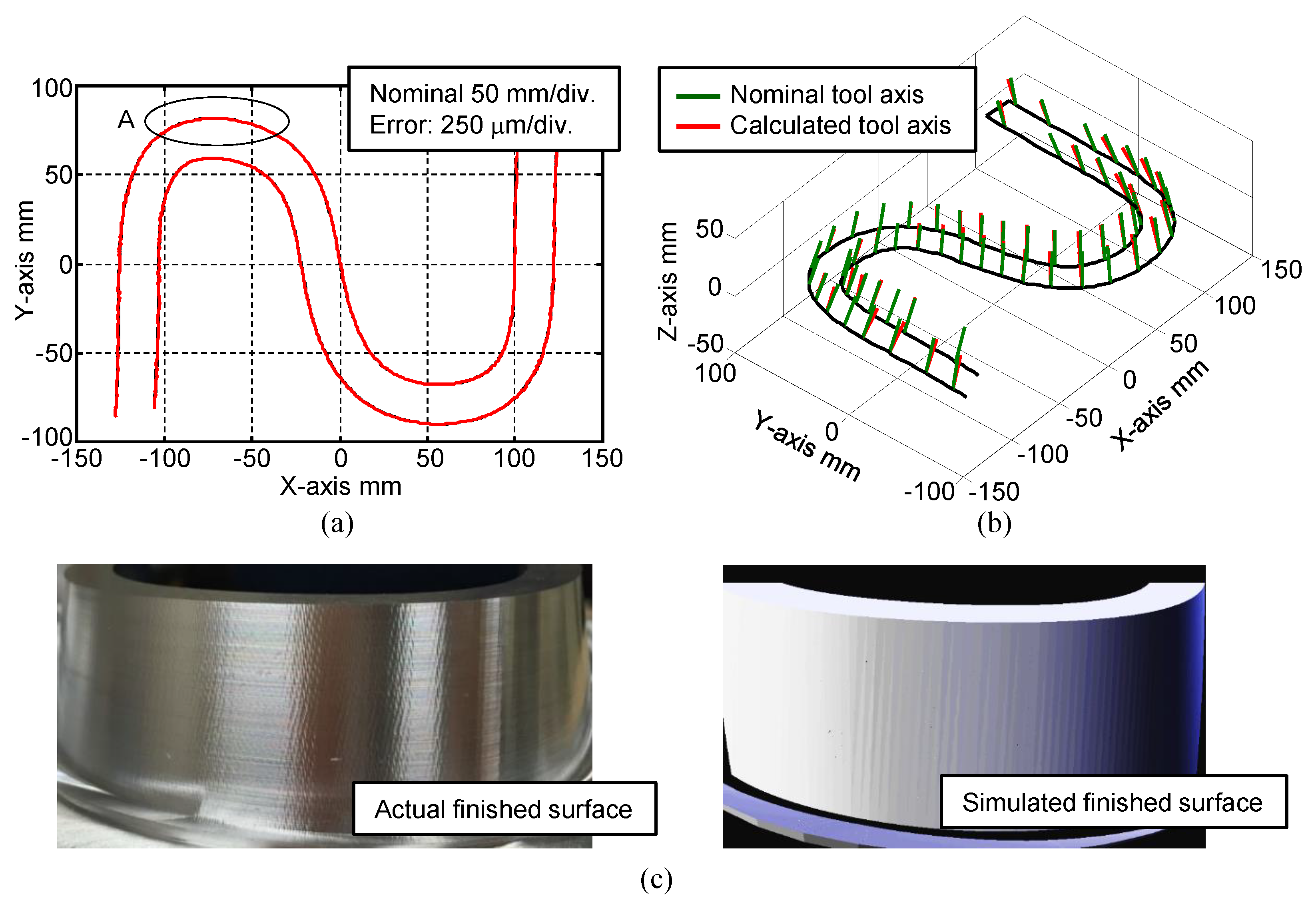

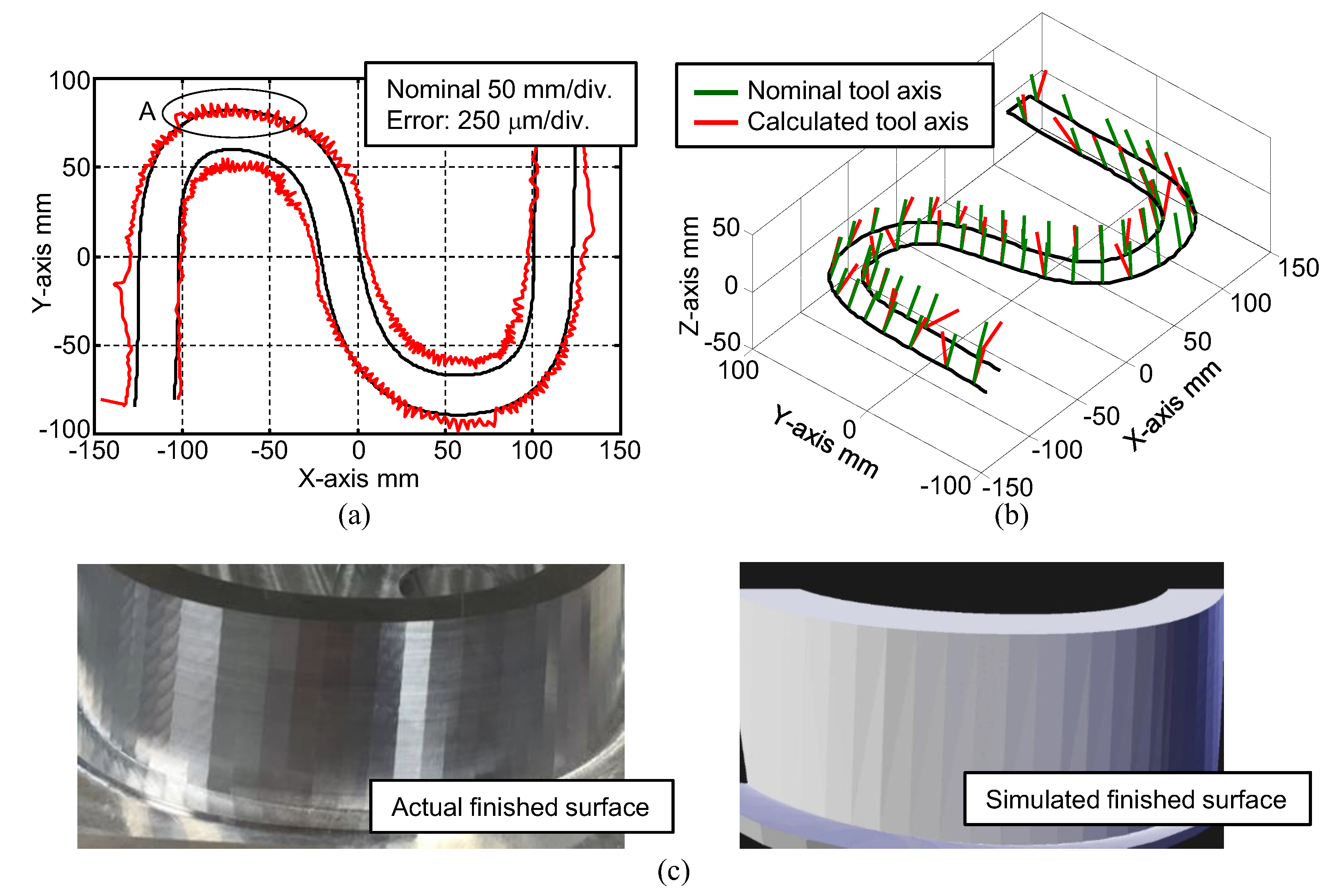

4. Influence of NC Program Quality

5. Influence of Geometric Errors

6. Conclusions

- (1)

- The finished shape of the machined surface in the S-shaped machining test, is strongly influenced by the quality of NC programs. Thus, machine operators must exercise care to ensure that the desired level of quality of NC programs has been appropriately set prior to using the facility.

- (2)

- Each individual geometric error of the rotary axes traces stepwise trajectories around the 900-mm mark on Surface B because the C-axis rotates rapidly around that point.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ibaraki, S.; Knapp, W. Indirect Measurement of Volumetric Accuracy for Three-axis and Five-axis Machine Tools: A Review. Int. J. Autom. Technol. 2012, 6, 110–124. [Google Scholar] [CrossRef]

- ISO 230-1: Test Code for Machine Tools–Part 1: Geometric Accuracy of Machines Operating under No-load or Quasi-Static Conditions; International Organization for Standardization: Geneva, Switzerland, 2012.

- Tsutsumi, M.; Saito, A. Identification and Compensation of Systematic Deviations Particular to 5-axis Machining Centers. Int. J. Mach. Tools Manuf. 2003, 43, 771–780. [Google Scholar] [CrossRef]

- Tsutsumi, M.; Saito, A. Identification of Angular and Positional Deviations Inherent to 5-axis Machining Centers with a Tilting-rotary Table by Simultaneous Four-axis Control Movements. Int. J. Mach. Tools Manuf. 2004, 44, 1333–1342. [Google Scholar] [CrossRef]

- Tsutsumi, M.; Tone, S.; Kato, N.; Sato, R. Enhancement of Geometric Accuracy of Five-axis Machining Centers based on Identification and Compensation of Geometric Deviations. Int. J. Mach. Tools Manuf. 2013, 68, 11–20. [Google Scholar] [CrossRef]

- Bringmann, B.; Knapp, W. Model-based ‘Chace-the-ball’ Calibration of a 5-axis Machining Center. CIRP Ann. Manuf. Technol. 2006, 55, 531–534. [Google Scholar] [CrossRef]

- Weikert, S. R-test, A New Device for Accuracy Measurements on Five Axis Machine Tools. CIRP Ann. Manuf. Technol. 2004, 53, 429–432. [Google Scholar] [CrossRef]

- ISO 10791-6: Test Conditions for Machining Centres—Part 6: Accuracy of Speeds and Interpolations; International Organization for Standardization: Geneva, Switzerland, 2014.

- Xiang, S.; Altintas, Y. Modeling ad Compensation of Volumetric Errors for Five-axis Machine Tools. Int. J. Mach. Tools Manuf. 2016, 101, 65–78. [Google Scholar] [CrossRef]

- NAS 979: National Aerospace Standard; Aerospace Industries Association of America: Washington, DC, USA, 1969.

- ISO 10791-7: Test Conditions for Machining Centres—Part 7: Accuracy of Finished Test Pieces; International Organization for Standardization: Geneva, Switzerland, 2014.

- Kato, N.; Tsutsumi, M.; Sato, R. Analysis of Circular Trajectory Equivalent to Cone-frustum Milling in Five-axis Machining Centers Using Motion Simulator. Int. J. Mach. Tools Manuf. 2013, 64, 1–11. [Google Scholar] [CrossRef]

- Kato, N.; Tsutsumi, M.; Tsuchihashi, Y.; Sato, R.; Ihara, Y. Sensitivity Analysis in Ball Bar Measurement of Three-Dimensional Circular Movement Equivalent to Cone-Frustum Cutting in Five-Axis Machining Centers. J. Adv. Mech. Des. Syst. Manuf. 2013, 7, 317–332. [Google Scholar] [CrossRef]

- ISO 10791-7: 2014/DAM 1. Test Conditions for Machining Centres—Part 7: Accuracy of Finished Test Pieces; AMENDMENT 1; International Organization for Standardization: Geneva, Switzerland, 2016.

- Senatore, J.; Moniès, F.; Rubio, W. 5-Axis flank milling of sculptured surfaces. In Machining of Complex Sculptured Surfaces; Springer: Berlin, Germany, 2012; pp. 33–65. [Google Scholar]

- Sprott, K.; Ravani, B. Cylindrical Milling of Ruled Surfaces. Int. J. Adv. Manuf. Technol. 2008, 38, 649–656. [Google Scholar] [CrossRef]

- Bo, P.; Bartoň, M.; Plakhotnik, D.; Pottmannd, H. Towards Efficient 5-axis Flank CNC Machining of Free-form Surfaces via Fitting Envelopes of Surfaces of Revolution. Comput. Aided Des. 2016, 79, 1–11. [Google Scholar] [CrossRef]

- Wang, W.; Jiang, Z.; Tao, W.; Zhuang, W. A New Test Part to Identify Performance of Five-axis Machine Tool–Part I: Geometrical and Kinematic Characteristics of S Part. Int. J. Adv. Manuf. Technol. 2015, 79, 729–738. [Google Scholar] [CrossRef]

- Wang, W.; Jiang, Z.; Li, Q.; Tao, W. A New Test Part to Identify Performance of Five-axis Machine Tool–Part II: Validation of S Part. Int. J. Adv. Manuf. Technol. 2015, 79, 739–756. [Google Scholar] [CrossRef]

- Jiang, Z.; Ding, J.; Song, Z.; Du, L.; Wang, W. Modeling and Simulation of Surface Morphology Abnormality of ‘S’ Test Piece Machined by Five-axis CNC Machine Tool. Int. J. Adv. Manuf. Technol. 2016, 85, 2745–2759. [Google Scholar] [CrossRef]

- Nakai, T.; Ihara, Y. Study on the “S” Shaped Test Piece of 5-Axis Machining Center. In Proceedings of the 9th International Conference on Leading Edge Manufacturing in 21st Century, Hiroshima, Japan, 13–17 November 2017. [Google Scholar]

- Sato, R.; Sato, Y.; Shirase, K.; Campatelli, G.; Scippa, A. Finished Surface Simulation Method to Predicting the Effects of Machine Tool Motion Errors. Int. J. Autom. Technol. 2014, 6, 801–810. [Google Scholar] [CrossRef]

- Hasegawa, S.; Sato, R.; Shirase, K. Influence of Geometric and Dynamic Synchronous Errors onto Machined Surface in 5-axis Machining Center. J. Adv. Mech. Des. Syst. Manuf. 2016, 10. [Google Scholar] [CrossRef]

| Tool Type | Square-End Mill |

|---|---|

| Tool diameter | 13 mm |

| Number of flutes | 2 |

| Workpiece material | A7075 |

| Radial depth of cut | 0.1 mm |

| Feed rate | 1000 mm/min |

| Spindle speed | 5000 rpm |

| Symbol | Description |

|---|---|

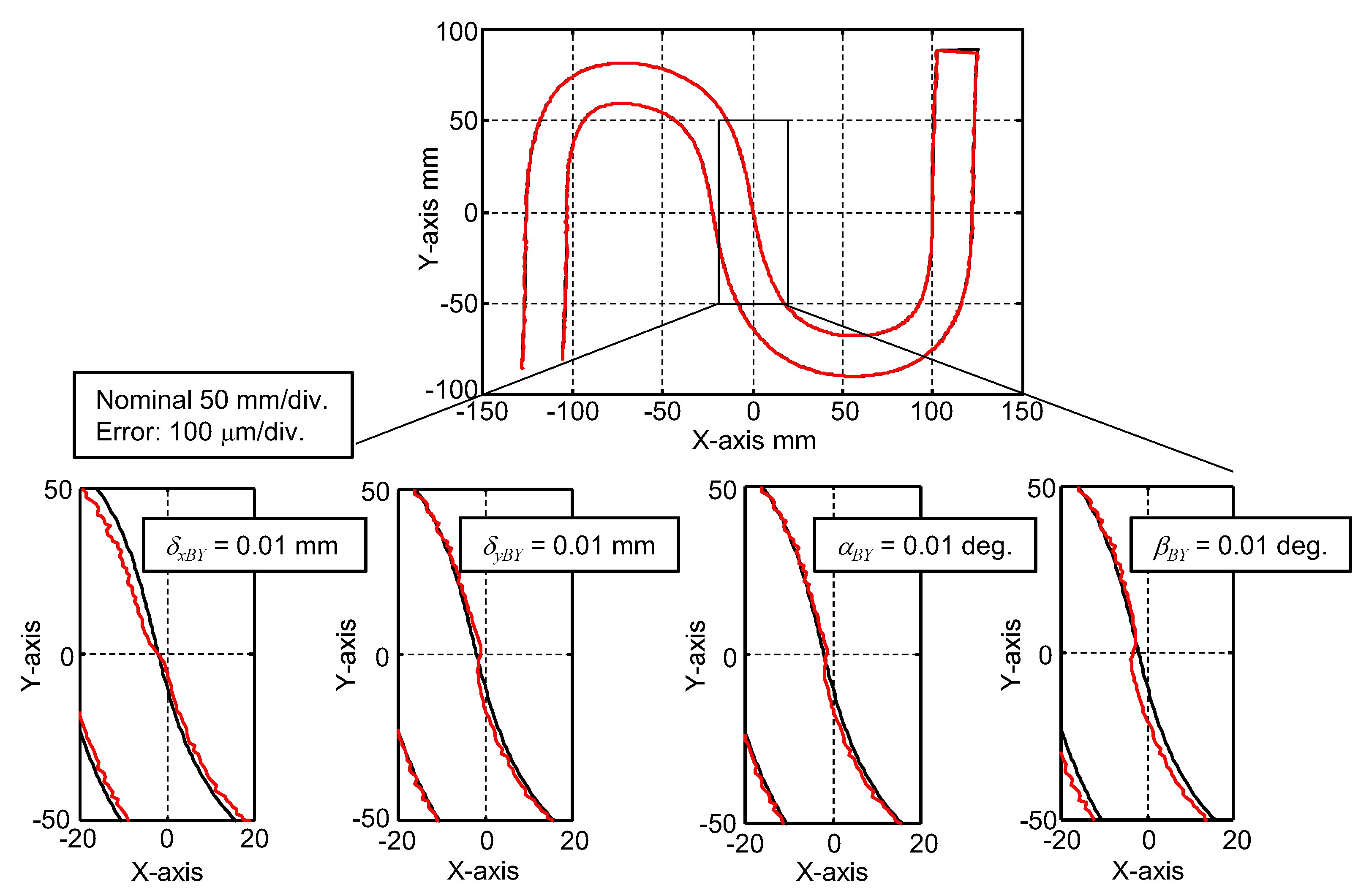

| δxBY | Position error of the B-axis average line along X-axis |

| δyBY | Position error of the C-axis average line along Y-axis |

| δzBY | Position error of the B-axis average line along Z-axis |

| δxCB | Offset between B- and C-axis average lines along X-axis |

| αCB | Squareness error between B- and C-axis in the X–Y plane |

| αBY | Parallelism between the C-axis average line and Z-axis motion in the Y–Z plane |

| βBY | Parallelism between the C-axis average line and Z-axis motion in the Z–X plane |

| γBY | Parallelism between the B-axis average line and Y-axis motion in the X–Y plane |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sato, R.; Shirase, K.; Ihara, Y. Influence of NC Program Quality and Geometric Errors of Rotary Axes on S-Shaped Machining Test Accuracy. J. Manuf. Mater. Process. 2018, 2, 21. https://doi.org/10.3390/jmmp2020021

Sato R, Shirase K, Ihara Y. Influence of NC Program Quality and Geometric Errors of Rotary Axes on S-Shaped Machining Test Accuracy. Journal of Manufacturing and Materials Processing. 2018; 2(2):21. https://doi.org/10.3390/jmmp2020021

Chicago/Turabian StyleSato, Ryuta, Keiichi Shirase, and Yukitoshi Ihara. 2018. "Influence of NC Program Quality and Geometric Errors of Rotary Axes on S-Shaped Machining Test Accuracy" Journal of Manufacturing and Materials Processing 2, no. 2: 21. https://doi.org/10.3390/jmmp2020021