Stretchable Material for Microfluidic Applications †

Abstract

:1. Introduction

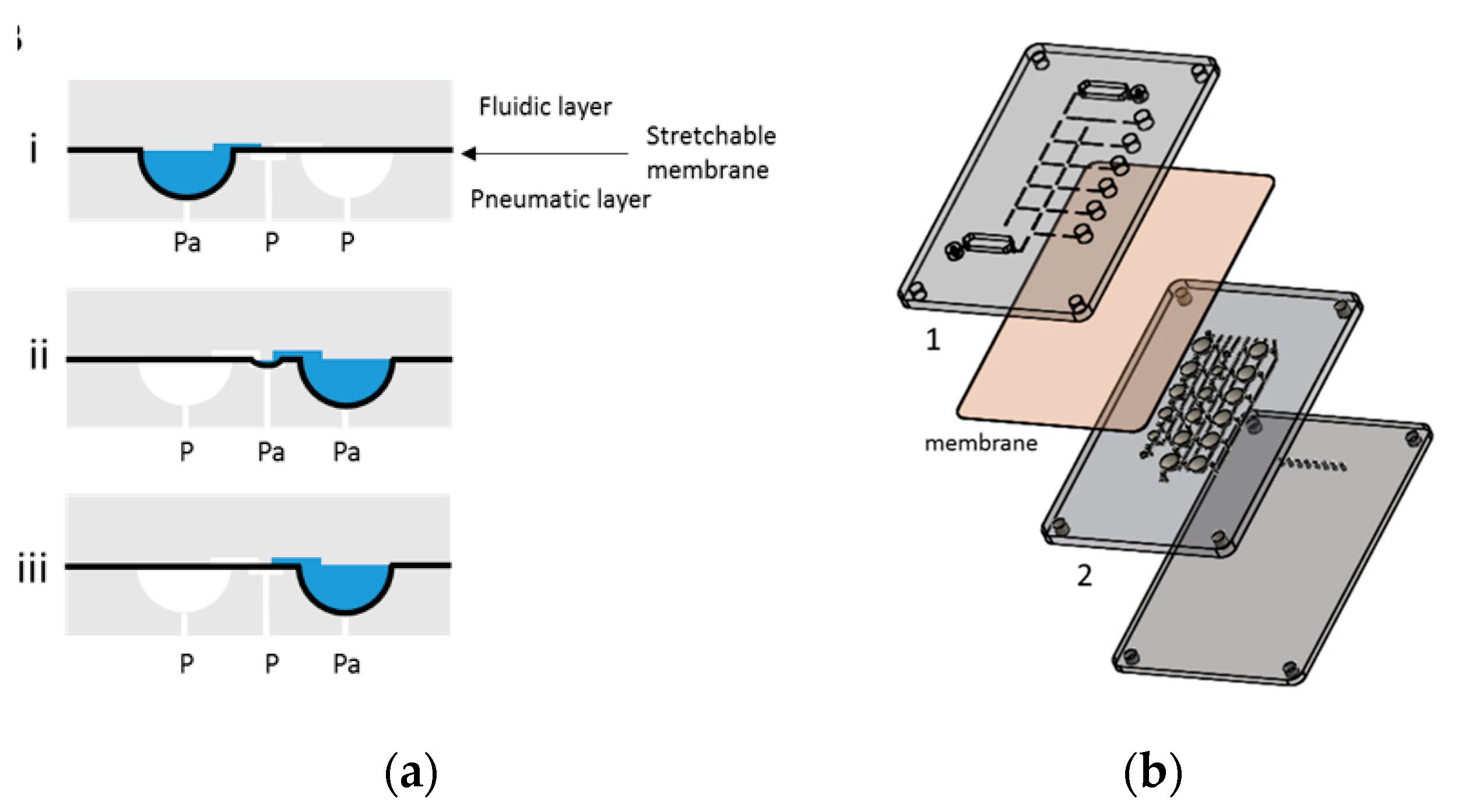

2. Material and Methods

3. Results and Discussion

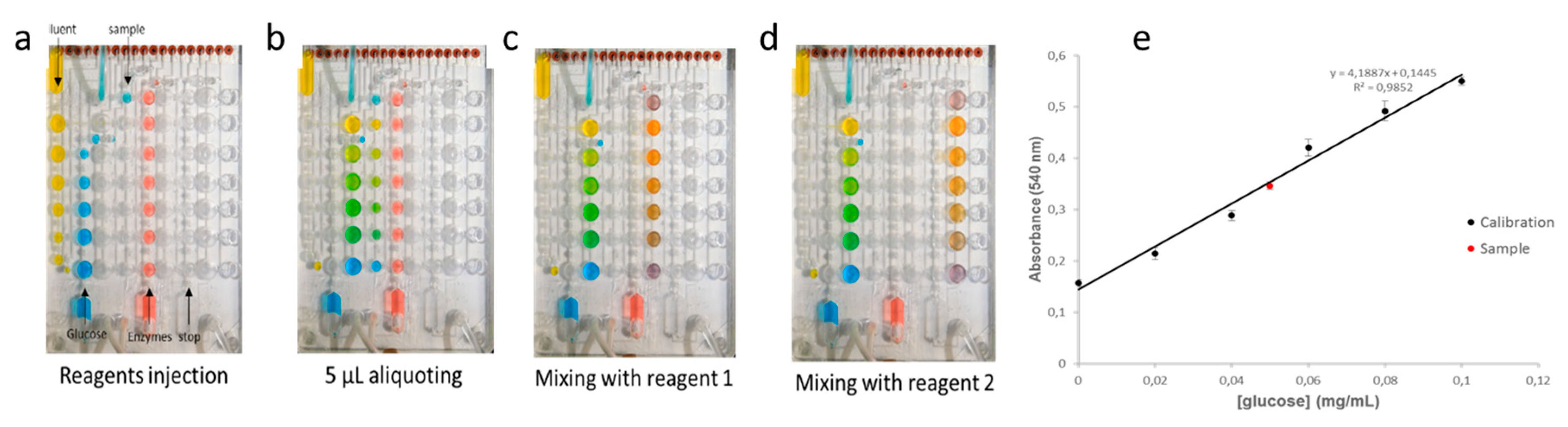

3.1. Enzymatic Assay Validation Using Stretchable Digital Microfluidics

3.2. Foam-Based Device for Point of Care Applications

4. Conclusions

Conflicts of Interest

References

- Unger, M.A.; Chou, H.P.; Thorsen, T.; Scherer, A.; Quake, S.R. Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 2000, 288, 113–116. [Google Scholar] [CrossRef] [PubMed]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef] [PubMed]

- Pineda, F.; Bottausci, F.; Icard, B.; Malaquin, L.; Fouillet, Y. Using electrofluidic devices as hyper-elastic strain sensors: Experimental and theoretical analysis. Microelectron. Eng. 2015, 144, 27–31. [Google Scholar] [CrossRef]

- Gropplero, G.; Davoust, L.; Arnoux, S.; Fouillet, Y.; Revol-Cavalier, F. Foam-based microfluidics: experiments and modeling with lumped elements. Microfluid. Nanofluid. 2016, 20. [Google Scholar] [CrossRef]

| Material | Maximum Elongation | Young Modulus |

|---|---|---|

| PDMS | 7 to 40% | 0.8–3 MPa |

| Ecoflex 00-30 | 900% | 170 Pa |

| Dragon skin | 760% | 560 kPa |

| Bulpren PPI90 | 350% | ~22 kPa (elastic phase) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fouillet, Y.; Parent, C.; Gropplero, G.; Davoust, L.; Achard, J.L.; Revol-Cavalier, F.; Verplanck, N. Stretchable Material for Microfluidic Applications. Proceedings 2017, 1, 501. https://doi.org/10.3390/proceedings1040501

Fouillet Y, Parent C, Gropplero G, Davoust L, Achard JL, Revol-Cavalier F, Verplanck N. Stretchable Material for Microfluidic Applications. Proceedings. 2017; 1(4):501. https://doi.org/10.3390/proceedings1040501

Chicago/Turabian StyleFouillet, Yves, Charlotte Parent, Giacomo Gropplero, Laurent Davoust, Jean Luc Achard, Frédéric Revol-Cavalier, and Nicolas Verplanck. 2017. "Stretchable Material for Microfluidic Applications" Proceedings 1, no. 4: 501. https://doi.org/10.3390/proceedings1040501