Improving MMS Performance during Infrastructure Surveys through Geometry Aided Design

Abstract

:1. Introduction

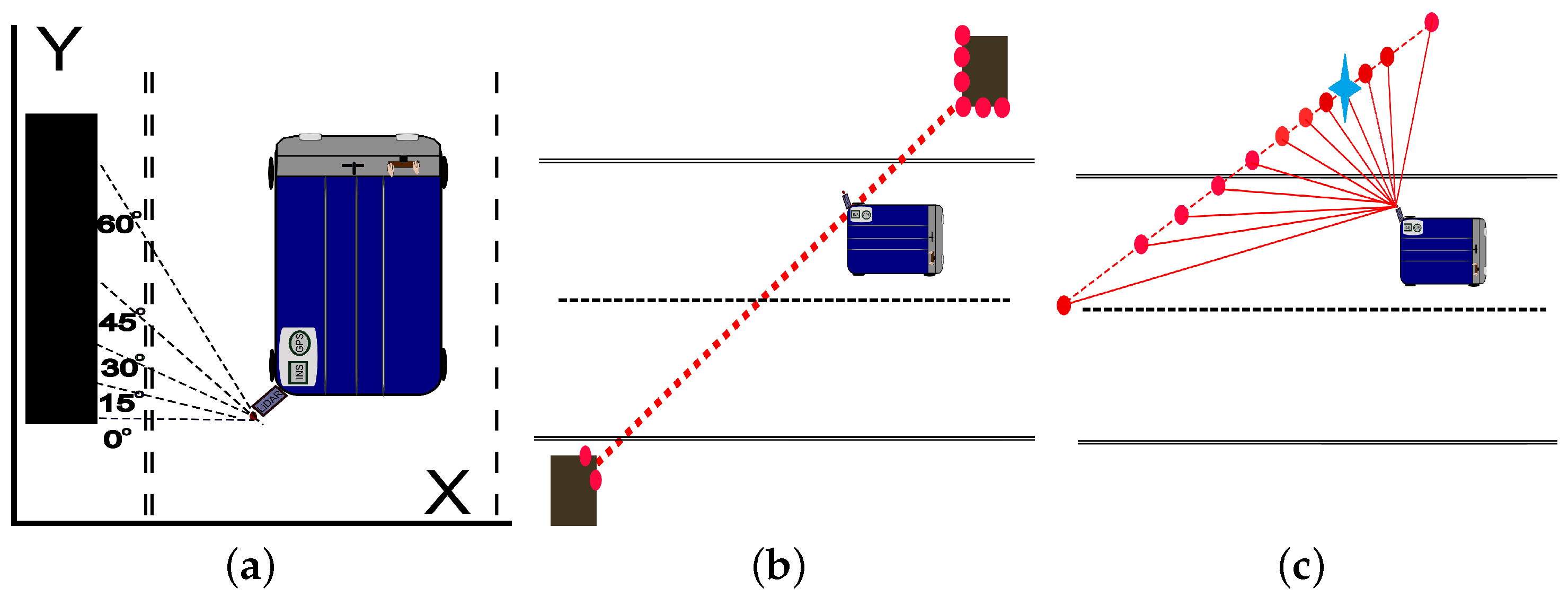

- Utilising both axes of the MMS for the second scanner to reduce scan range.

- Increasing the length of scan profile that intersects with a target by changing the vertical orientation of the scanner.

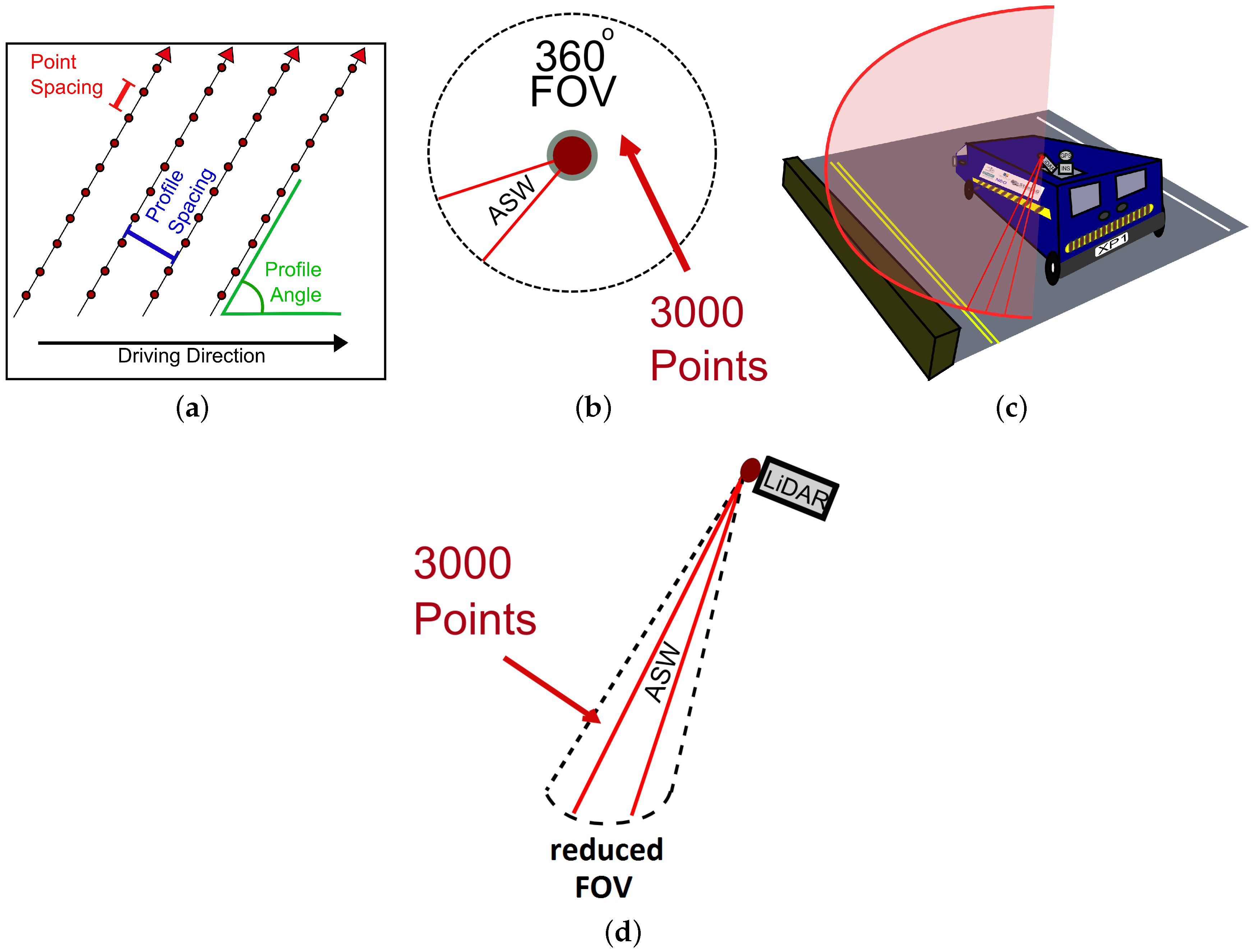

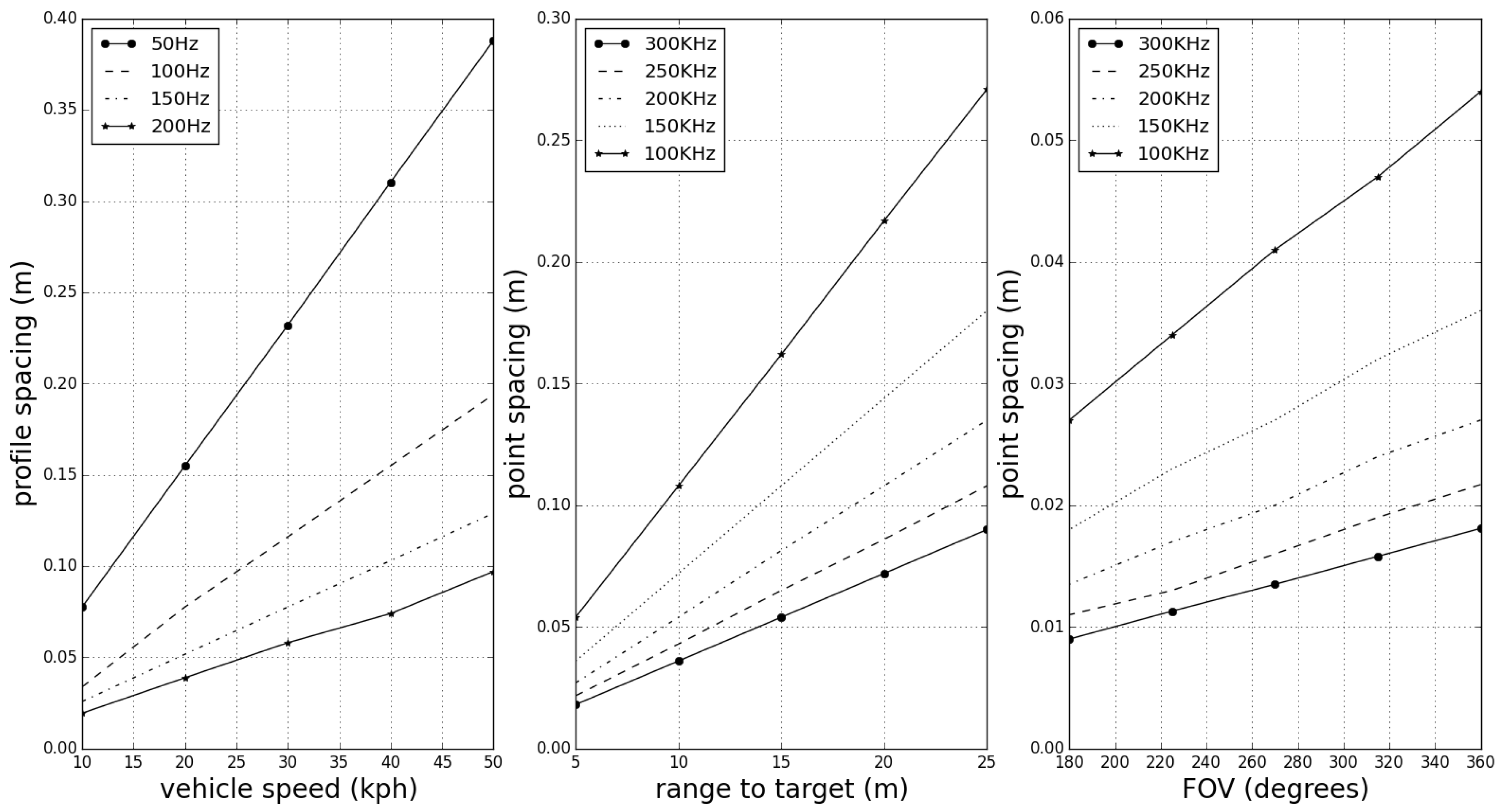

- Limiting the Field of View (FOV) of the scanner to decrease the angular step width between subsequent laser pulses.

2. Background and Related Work

2.1. MMS Types

2.2. System Benchmarking

2.3. MIMIC

3. Enabling MMS Performance Improvements through Geometry Aided System Design

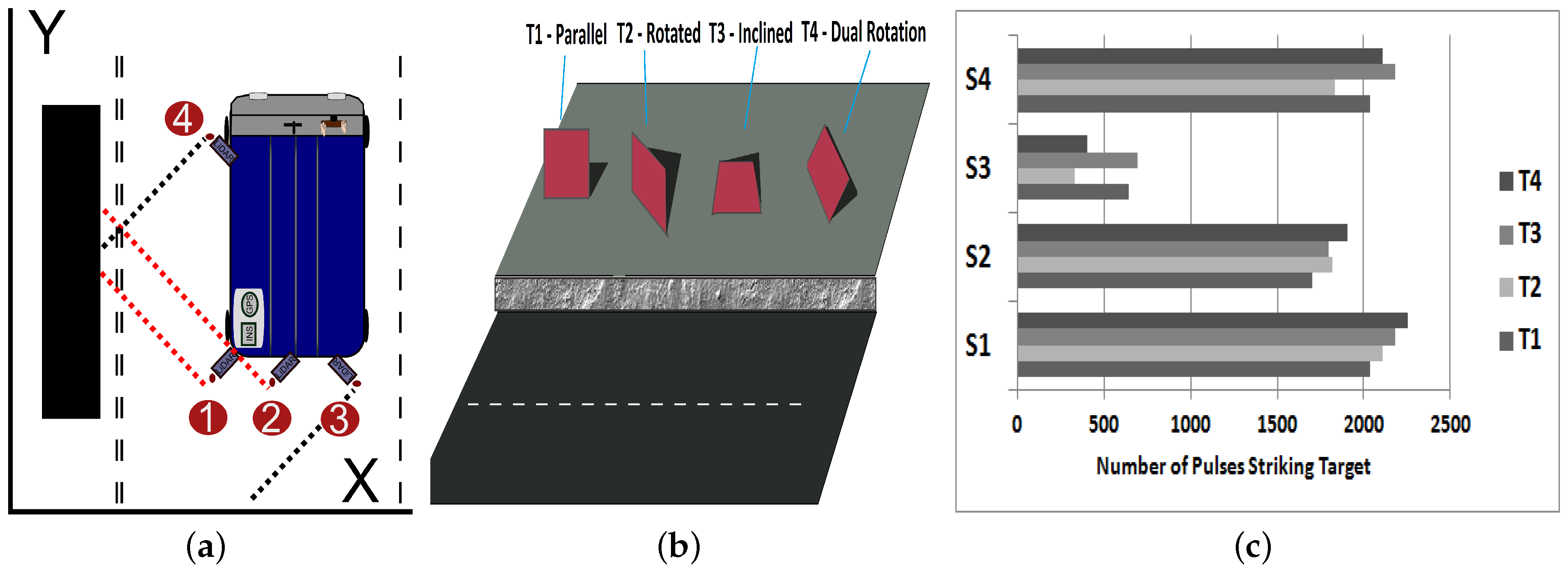

3.1. Scanner Position

3.1.1. Offset Scanner on Vehicle X Axis (Position 1 and 2)

3.1.2. Common Commercial Dual Scanner Configuration (Position 1 and 3)

3.1.3. Proposed Option—Utilising Vehicle Y Axis (Position 1 and 4)

3.2. Enabling Use of Lower Specification Scanner through Field of View Manipulation

- Meas-set-prg (“300 kHz”)—sets the measurement programme for the scanner at 300 kHz

- Scn-set-Scan (20.0, 60.0, 0.013) specifies a 2D, 40 scan at 300 kHz enabling a decreased increment of 0.013 degrees between each pulse increasing point density

- Limiting the FOV could result in incomplete scan coverage of an area. In the example illustrated in Figure 3c the scanner is assigned a dual axis rotation and the FOV is limited to 180. With this configuration, the road under the vehicle is not surveyed.

- A low FOV could also potentially decrease the ASW below the smallest selectable ASW for that piece of hardware. For example, the minimum quoted possible ASW for a Riegl VQ250 is 0.001. This may become an issue at lower FOVs and for this reason 180 is the cut-off for these tests.

4. Test Systems

4.1. System 1—MIMIC+

4.2. System 2—PRR+

4.3. System 3—Mirror+

5. Benchmarking MMS Performance

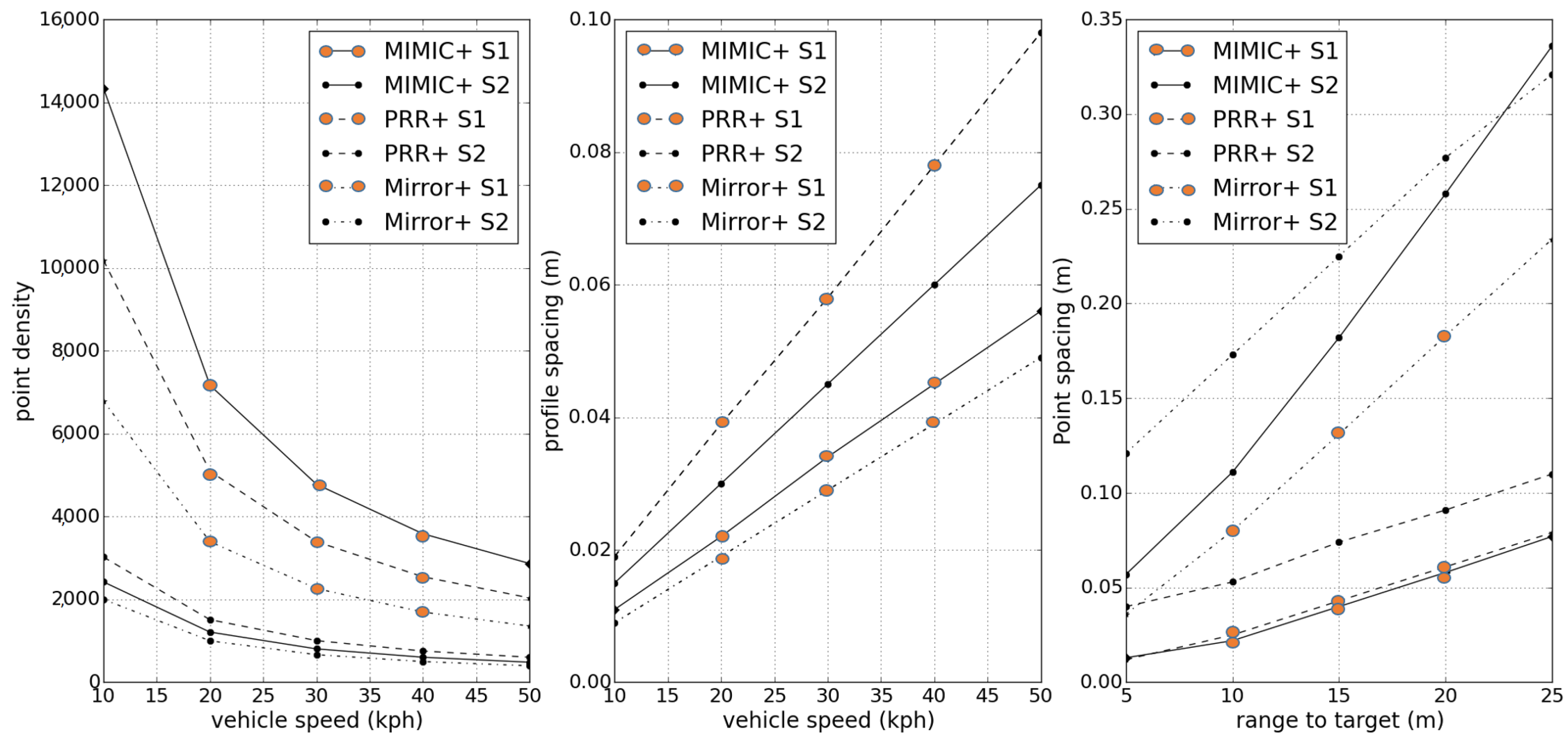

5.1. Test 1—2D Targets

5.2. Small Features

5.2.1. Test 2—Profile Spacing

5.2.2. Test 3—Point Spacing

5.3. Angled Targets

5.3.1. Test 4—Structures

- Face (i): The high PRR scanners display the highest point density on each face, however Scanner 1 on MIMIC+ is capable of capturing 11% more points than the same scanner on PRR+ because of its application of GAD. The high PRR scanners are each capable of over twice the number of points than the Mirror+ scanners.

- Face (ii): For each MMS, the point density is higher for this face of the target because it is visible to both scanners and it also has a lower range to target. GAD has enabled MIMIC+ to once again outperform the other two systems as it is capable of returning 37% more points than the higher specification PRR+ MMS for Face (ii).

- Face (iii): This target face is only visible to Scanner 2 on each of the MMSs. The low point density is due to the negative horizontal scanner rotation of Scanner 2 on the PRR+ and the Mirror+ and the scanner offset. In these tests, Scanner 2 on the PRR+ exhibits a higher point density than Scanner 2 on the other systems because of the higher PRR, returning over three times (327%) the point density of the Scanner 2 on the MIMIC+ MMS. Scanner 2 on Mirror+ also exhibits a higher point density than Scanner 2 on MIMIC+, returning 89% more points. Despite the decreased range to target arising from the recommended scanner position on MIMIC+, Scanner 2 on this MMS has underperformed in these tests in relation to Scanner 2 on the Mirror+.

5.3.2. Test 5—Cylinders

- Firstly, except for one instance with the PRR+ on Face (i), none of the MMSs used in these benchmarking tests can return the required number of on a cylindrical target at 15 m horizontal range.

- Performance in terms of drops significantly between 5 m and 10 m horizontal range for narrow vertical targets. The number of approximately halves as the range doubles. The PRR+ MMS returned the most points for each cylinder face in these tests, but only returns a maximum of 5 at 10 m range.

- At the shortest measurement range, 5 m, the Mirror+ MMS returns 4 , whereas the PRR+ returns 8. Eight potentially provide a better definition of the object in the point cloud.

- Scanner 2 on MIMIC+ fails these tests as it was not capable of capturing the three points on the scan profile for Face (iii), however Scanner 1 has returned a high number of points on the two other faces and therefore this is not essential.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Puente, I.; González-Jorge, H.; Martínez-Sánchez, J.; Arias, P. Review of mobile mapping and surveying technologies. Measurement 2013, 46, 2127–2145. [Google Scholar] [CrossRef]

- Graham, L. Mobile mapping systems overview. Photogramm. Eng. Remote Sens. 2010, 76, 222–228. [Google Scholar]

- McElhinney, C.; Kumar, P.; Cahalane, C.; McCarthy, T. Initial results from European Road Safety Inspection (EURSI) mobile mapping project. In Proceedings of the ISPRS Commission V Technical Symposium, Newcastle, UK, 21–24 June 2010.

- Becker, S.; Haala, N. Grammar supported facade reconstruction from mobile LiDAR mapping. In Proceedings of the ISPRS CMRT09, Paris, France, 3–4 September 2009; pp. 229–234.

- Hammoudi, K.; Dornaika, F.; Paparoditis, N. Extracting building footprints from 3D point clouds using terrestrial laser scanning at street level. In Proceedings of the ISPRS CMRT09, Paris, France, 3–4 September 2009; pp. 65–70.

- Kumar, P.; McCarthy, T.; McElhinney, C. Automated road extraction from terrestrial based mobile laser scanning system using the GVF snake model. In Proceedings of the European Laser Mapping Forum—‘ELMF 2010’, The Hague, The Netherlands, 30 November–1 December 2010.

- Kumar, P.; McElhinney, C.; McCarthy, T. Utilizing terrestrial mobile laser scanning data attributes for road edge extraction with the GVF snake model. In Proceedings of the 7th International Symposium on Mobile Mapping Technology (MMT’11), Cracow, Poland, 13–16 June 2011.

- Pu, S.; Vosselman, G. Extracting windows from terrestrial laser scanning. In Proceedings of the ISPRS Workshop on Laser Scanning 2007 and SilviLaser 2007, Espoo, Finland, 12–14 September 2007; Volume 36, pp. 320–325.

- Pu, S.; Rutzinger, M.; Vosselman, G.; Elberink, S.O. Recognizing basic structures from mobile laser scanning data for road inventory studies. ISPRS J. Photogramm. Remote Sens. 2011, 66, S28–S39. [Google Scholar] [CrossRef]

- Brenner, C. Global localization of vehicles using local pole patterns. In Pattern Recognition; Denzler, J., Notni, G., Süße, H., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2009; Volume 5748, pp. 61–70. [Google Scholar]

- Kukko, A.; Jaakkola, A.; Lehtomaki, M.; Kaartinen, H.; Chen, Y. Mobile mapping system and computing methods for modelling of road environment. In Proceedings of the 2009 Joint Urban Remote Sensing Event, Shanghai, China, 20–22 May 2009.

- Lehtomäki, M.; Jaakkola, A.; Hyyppä, J.; Kukko, A.; Kaartinen, H. Detection of vertical pole-like objects in a road environment using vehicle-based laser scanning data. Remote Sens. 2010, 2, 641–664. [Google Scholar] [CrossRef]

- Kaartinen, H.; Hyyppä, J.; Gülch, E.; Vosselman, G.; Hyyppä, H.; Matikainen, L.; Hofmann, A.D.; Mäder, U.; Persson, A. Accuracy of 3D City Models: EuroSDR comparison. In Proceedings of the International Archives of Photogrammetry, Remote Sensing and Spatial Information Sciences, Enschede, The Netherlands, 12–14 September 2005; pp. 227–232.

- Yoo, H.; Goulette, F.; Senpauroca, J.; Lepere, G. Simulation based comparative analysis for the design of laser terresttrial mobile mapping. In Proceedings of the 6th International Symposium on Mobile Mapping Technology, Sao Paulo, Brazil, 21–24 July 2009; pp. 839–854.

- Bolzon, G.; Caroti, G.; Piemonte, A. Accuracy check of road’s cross slope evaluation using MMS vehicle. In Proceedings of the 5th International Symposium on Mobil Mapping Technology, Padua, Italy, 28–31 May 2007; pp. 127–132.

- Florida Department of Transport. Terrestrial Mobile LiDAR Surveying and Mapping Guidelines; Florida Department of Transport: Tallahassee, FL, USA, 2012.

- Yen, K.S.; Ravani, B.; Lasky, T.A. LiDAR for Data Efficiency; University of California: Oakland, CA, USA, 2011. [Google Scholar]

- Olsen, M.J.; Roe, G.V.; Glennie, C.; Persi, F.; Reedy, M.; Hurwitz, D.; Williams, K.; Tuss, H.; Squellati, A.; Knodler, M. NCHRP 15–44 Guidelines for the Use of Mobile LiDAR in Transportation Applications; NCHRP: Washington, DC, USA, 2013. [Google Scholar]

- Trimble. Trimble MX8 Mobile Mapping System; Trimble: Sunnyvale, CA, USA, 2010. [Google Scholar]

- Optech. Optech Lynx M1 and V200 System Specifications; Optech: Vaughan, ON, Canada, 2012. [Google Scholar]

- RIEGL. Dual Scanner Data Sheet Riegl VMX-450; RIEGL: Horn, Austria, 2016. [Google Scholar]

- Laser Mapping. StreetMapper Brochure; Technical Report; 3D Laser Mapping: Nottingham, UK, 2012. [Google Scholar]

- Kukko, A.; Andrei, C.; Salminen, V.; Kaartinen, H.; Chen, Y.; Rönnholm, P.; Hyyppä, H.; Hyyppä, J.; Chen, R.; Haggrén, H.; et al. Road environment mapping system of the finnish geodetic institute-FGI roamer. In Proceedings of the ISPRS Workshop on Laser Scanning 2007 and SilviLaser 2007, Espoo, Finland, 12–14 September 2007; pp. 241–247.

- Hesse, C.; Kutterer, H. A mobile mapping system using kinematic terrestrial laser scanning (KTLS) for image acquisition. In Proceedings of the 8th Conference on Optical 3-D Measurement Techniques, Zurich, Switzerland, 9–12 July 2007; pp. 134–141.

- Lohani, B.; Mishra, R. Generating LiDAR data in laboratory: LiDAR simulator. In Proceedings of the ISPRS Workshop on Laser Scanning 2007 and SilviLaser 2007, Espoo, Finland, 12–14 September 2007; Volume 52, pp. 12–14.

- Kukko, A.; Hyyppä, J. Small-footprint laser scanning simulator for system validation, error assessment and algorithm development. Photogramm. Eng. Remote Sens. 2009, 75, 1177–1189. [Google Scholar] [CrossRef]

- Kaartinen, H.; Hyyppä, J.; Kukko, A.; Jaakkola, A.; Hyyppä, H. Benchmarking the performance of mobile laser scanning systems using a permanent test field. Sensors 2012, 12, 12814–12835. [Google Scholar] [CrossRef]

- Cahalane, C.; McCarthy, T.; McElhinney, C. MIMIC: Mobile mapping point density calculator. In Proceedings of the 3rd International Conference on Computing for Geospatial Research and Applications, Reston, VA, USA, 1–3 July 2012.

- Cahalane, C.; McCarthy, T.; McElhinney, C. Mobile mapping system performance: An initial investigation into the effect of vehicle speed on laser scan lines. In Proceedings of the Remote Sensing & Photogrammety Society Annual Conference—‘From the Sea-Bed to the Cloudtops’, Cork, Ireland, 1–3 September 2010.

- Cahalane, C.; McElhinney, C.; McCarthy, T. Mobile mapping system performance: An analysis of the effect of laser scanner configuration and vehicle velocity on scan profiles. In Proceedings of the European laser Mapping Forum—‘ELMF 2010’, The Hague, The Netherlands, 30–31 November 2010.

- Cahalane, C.; McElhinney, C.; McCarthy, T. Calculating the effect of dual-axis scanner rotations and surface orientation on scan profiles. In Proceedings of the 7th International Symposium on Mobile Mapping Technology (MMT’11), Cracow, Poland, 13–16 June 2011.

- Cahalane, C.; McElhinney, C.; Lewis, P.; McCarthy, T. Calculation of target-specific point distribution for 2D mobile laser scanners. Sensors 2014, 14, 9471–9488. [Google Scholar] [CrossRef] [PubMed]

- Cahalane, C.; McElhinney, C.; Lewis, P.; McCarthy, T. MIMIC: An innovative methodology for determining mobile laser scanning system point density. Remote Sens. 2014, 6, 7857–7877. [Google Scholar]

- Cahalane, C.; Lewis, P.; McElhinney, C.; McCarthy, T. Optimising mobile mapping system laser scanner orientation. ISPRS Int. J. Geo-Inf. 2015, 4, 302–319. [Google Scholar] [CrossRef]

- Shepard, D. A two-dimensional interpolation function for irregularly-spaced data. In Proceedings of the 23rd National Conference ACM, Las Vegas, NV, USA, 27–29 August 1968; pp. 517–524.

| System | Scanner | Hrot | VRot | PRR | FOV | ASW | |

|---|---|---|---|---|---|---|---|

| MIMIC+ | Geom1 | 45 | 60 | 100 Hz | 300 kHz | 360 | 0.12 |

| FOV1 | 135 | 60 | 75 Hz | 27.075 kHz | 180 | 0.99 | |

| PRR+ | PRR1 | 45 | 45 | 100 Hz | 300 kHz | 360 | 0.12 |

| PRR2 | 45 | 60 | 100 Hz | 300 kHz | 360 | 0.12 | |

| Mirror+ | Mirror1 | 45 | 45 | 200 Hz | 200 kHz | 360° | 0.36 |

| Mirror2 | 45 | 60 | 200 Hz | 200 kHz | 360 | 0.36 |

| Test | Characteristic | Surface | Target | Dimensions | Variable |

|---|---|---|---|---|---|

| 1 | Point Density | 2D | Planar | 2 m × 1 m | Velocity |

| 2 | Profile Spacing | 2D | Planar | 2 m × 1 m | Velocity |

| 3 | Point Spacing | 2D | Planar | 2 m × 1 m | Range |

| 4 | Point Density | 3D | Structure | 2 m × 2 m | Velocity |

| 5 | Points Per Profile | 3D | Cylinder | 0.1 m × 2 m | Range |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cahalane, C.; Lewis, P.; McElhinney, C.P.; McNerney, E.; McCarthy, T. Improving MMS Performance during Infrastructure Surveys through Geometry Aided Design. Infrastructures 2016, 1, 5. https://doi.org/10.3390/infrastructures1010005

Cahalane C, Lewis P, McElhinney CP, McNerney E, McCarthy T. Improving MMS Performance during Infrastructure Surveys through Geometry Aided Design. Infrastructures. 2016; 1(1):5. https://doi.org/10.3390/infrastructures1010005

Chicago/Turabian StyleCahalane, Conor, Paul Lewis, Conor P. McElhinney, Eimear McNerney, and Tim McCarthy. 2016. "Improving MMS Performance during Infrastructure Surveys through Geometry Aided Design" Infrastructures 1, no. 1: 5. https://doi.org/10.3390/infrastructures1010005