1. Introduction

In recent years, the demand for conductive polymer composites has increased dramatically due to their potential application in many areas, including as electromagnetic interference shielding materials, self-regulated heating materials, antistatic coatings, semiconductors, batteries and pressure sensors etc. Different types of conductive fillers, such as carbon black (CB) and metallic powders (Ni, Al, Cu, etc.) have been extensively investigated to effectively improve the electrical conductivity of rubbers and insulating polymers [

1]. Electrically conductive chlorosulfonated polyethylene (CSM) composites are widely used in electronic sectors in power distribution, audio, and telephone applications as packaging and semi-conductive polymeric materials due to their good weather resistance, good electrical properties and good aging resistance. The preparation of different types of electrically conductive polymer composites filled with various conductive fillers has already been reported by several researchers [

2]. The electrical properties of conductive composites depend mainly on how well the fillers disperse within the matrices, the relevant properties of the filler (e.g., particle size, surface area, aggregate structure and surface activity) and polymer-filler interactions. The incorporation of filler into a polymer enhances the mechanical properties of the final product, and also decreases the cost of the end product. The relation between electrical and mechanical properties of conductive polymer composites has also been the subject of recent research [

1,

2]. Polymer/metal composites are extrinsic electrical conductivity materials, and the electrical properties of polymer/metal composites have been the subject of many papers. However, less work has been concerned with the correlations among rheological, mechanical and electrical features [

3].

Wiriya et al. [

1] reported that a binary composite containing 50 phr carbon black in natural rubber was a superior conductive composite for a pressure sensor, based on its balance of compression set and electrical conductivity. They also found that at the same total filler content, a third metal component filler decreases the electrical conductivity of the binary composites and deteriorates the compression set of the composites. Aleksandra et al. [

4] reported on the capacitive properties of polypyrrole/activated carbon composite which can be effectively used in super capacitors and/or batteries. Xiangyang et al. [

5] reported on development of a conductive polymer matrix composite with low concentration of the conductive filler by coating process.

Recently, there has been an increase in the use of thermally conductive polymeric composites, where polymers filled with thermally conductive fillers effectively dissipate heat generated by electronic components. The life time of electronic devices is directly dependent on the management of heat. To improve the thermal conductivity of a polymeric material, polymer matrices are usually filled with highly thermally conductive fillers like metal powders, ceramic powders and carbon-based materials. Polymer composites filled with thermally conductive particles have advantages due to their easy processability, low cost, and durability to the corrosion. In particular, carbon-based 1-dimensional nanomaterials such as carbon nanotube (CNT) and carbon nanofiber (CNF) have gained much attention for their excellent thermal conductivity, corrosion resistance and low thermal expansion coefficient in comparison to metals [

6]. The composites made by incorporating powdery metal fillers into polymers combine the advantages of metals and plastics. Therefore, conductive polymer composites are also essential to some electrical applications, where their properties are relevant in situations such as the discharge of static electricity, heat conduction, electromagnetic interference shields and switching [

7]. A high level of electrical conductivity is obtained when a continuous conducting path is formed at a critical concentration of conductive filler particles. This concentration is called the percolation threshold. A melt-blending or coating process is often used to disperse the conductive particles into the polymer matrix, as conductive filler dispersion (or the coating on the polymer) is the most important stage in the preparation of conducting polymers [

5].

Rungsima et al. [

8] worked on carbon filler-reinforced polypropylene composites by injection-molding technique for a bipolar plate application. They reported that the orientation of carbon fibers in composites is affected by the injection flow geometry. Ritu et al. [

9] worked on conducting polymer composites of polyvinyl-pyrrolidone (PVP) with potassium hydroxide (KOH). They used solution-cast techniques to prepare composites, and investigated the structural and mechanical properties of the polymer composite specimen. The results revealed that the conductivity and hardness of the polymer composite increased with the concentration of KOH. Kristin et al. [

10] investigated PVC composites incorporating multi-walled carbon nanotubes (MWCNT) by three roll mill techniques for use in antistatic coatings. They reported that CNT contents ≤0.5% are sufficient for use in antistatic coatings. Remo et al. [

11] worked and reported on conducting composites of multi-walled carbon nanotubes (MWCNTs) and ionic liquid (IL)-funtionalized nano fillers (IL-f-MWCNTs) with ethylene octane copolymers (EOC). They observed that MWCNTs and IL-f-MWCNTs were both effective in increasing the storage modulus, tensile modulus, stress-at-break, and electrical conductivity of EOC-based nanocomposites with increasing nano filler content. Bahaa et al. [

12] studied the effect of filler content on DC electrical properties of zinc powders filled polyvinyl chloride composites. They reported that the DC electrical conductivity of the polyvinyl chloride increases with increasing zinc concentrations and temperature. Cheng-Ho et al. [

13] reported on rigid and conductive PVC/CB composites prepared by Haake torque rheometer. They observed that the rigidity of the PVC/CB composite increased with an increase in CB content, thus also increasing the electrical and mechanical properties. Saad et al. [

14] worked on the electrical and mechanical properties of polyvinyl chloride (PVC) mixed with electrically conductive additives, and reported that a carbon black (CB)-filled PVC–CB system containing a high CB content possesses a much higher electrical conductivity, but a higher CB loading causes deterioration of the mechanical properties.

Jinhong et al. [

15] provided a review of the electrical, thermal and mechanical properties of graphene/polymer composites fabricated by solution-casting method. They also provided guidance for stimulating the development of wider applications for conductive polymer composites and nano composites in structural, functional and electrical areas. Conductive filler-filled thermoplastic composites and nanocomposites could also be used for structural and functional applications in spite of the present predominance of electrical applications [

15,

16]. Carbon fiber-reinforced polymer composites have been demonstrated to have many applications in diverse fields, including the aerospace and automotive industries, and related to engineering components such as bearings, gears, fan blades, and chassis structures, due to their ability to obtain a synergetic effect when combining the toughness of the thermoplastic polymer with the stiffness and strength of carbon fibers [

17]. Recently, extensive studies have focused on the effect of carbon fibers for developing conductive thermoplastic composites [

18]. Tailorable properties provide applications for conductive carbon-based composite materials in many industries as electronic and constructional components: in microelectronics, antistatic, electrostatic dissipation, in electromagnetic shield fabrication, for aircraft structures, aircraft brakes, concrete structures, etc. [

18,

19,

20]. Very few research works were found on carbon black-reinforced thermoplastic composites through compression-molding processing techniques for electrically conductive applications. Carbon black-based conductive composites produced by compression-molding processing techniques can be used in a wide range of applications in the structural and electrical areas. Selection of composite materials for the proper end-use application also depends on the desired mechanical and electrical properties. In this research, carbon black (CB) was used to reinforce thermoplastic polymer polyvinyl chloride (PVC) in order to prepare CB-PVC composites using different wt fractions of CB by compression-molding technique. This research work focuses on the manufacturing process and the properties of the CB-PVC composites in order to determine their potentialities in both electrical and structural applications. Thus, the aim and objective of this work is to assess the effect of CB loading on the electrical and tensile properties of compression-molded CB-PVC composites. The influence of CB content on the structure of CB-PVC composites was also studied by ATR-FTIR spectroscopic analyses and microstructural analyses.

3. Results and Discussion

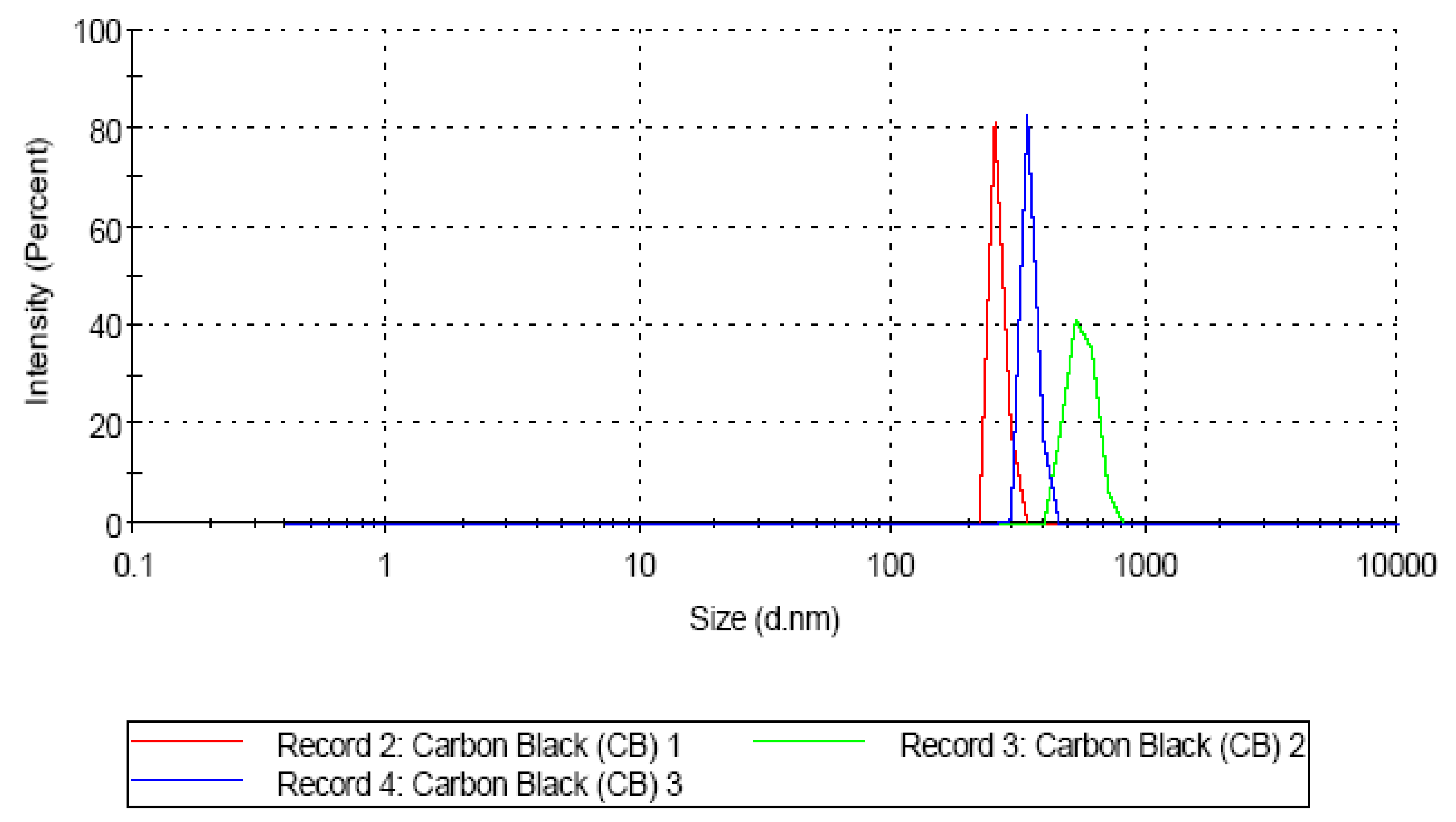

In this work, conductive polymer composites were prepared, and their electrical and mechanical properties were studied. PVC polymers in the 100–177 µm size range were used as matrix materials. Nirvana et al. [

18] reported on three types of PVC-based conductive composites, with carbon black, carbon fiber and synthetic graphite, respectively. They reported that carbon black was more effective than carbon fiber and synthetic graphite at low weight fractions. In this research, carbon black (CB) was used as a conductive ingredient to prepare conductive composites. The particle size of CB used in this research was measured, and was found to be 2705 nm or 2.70 µm (

Figure 1).The conductivity of the composites depends on the shape, particle size and properties of the conductive fillers applied [

18].

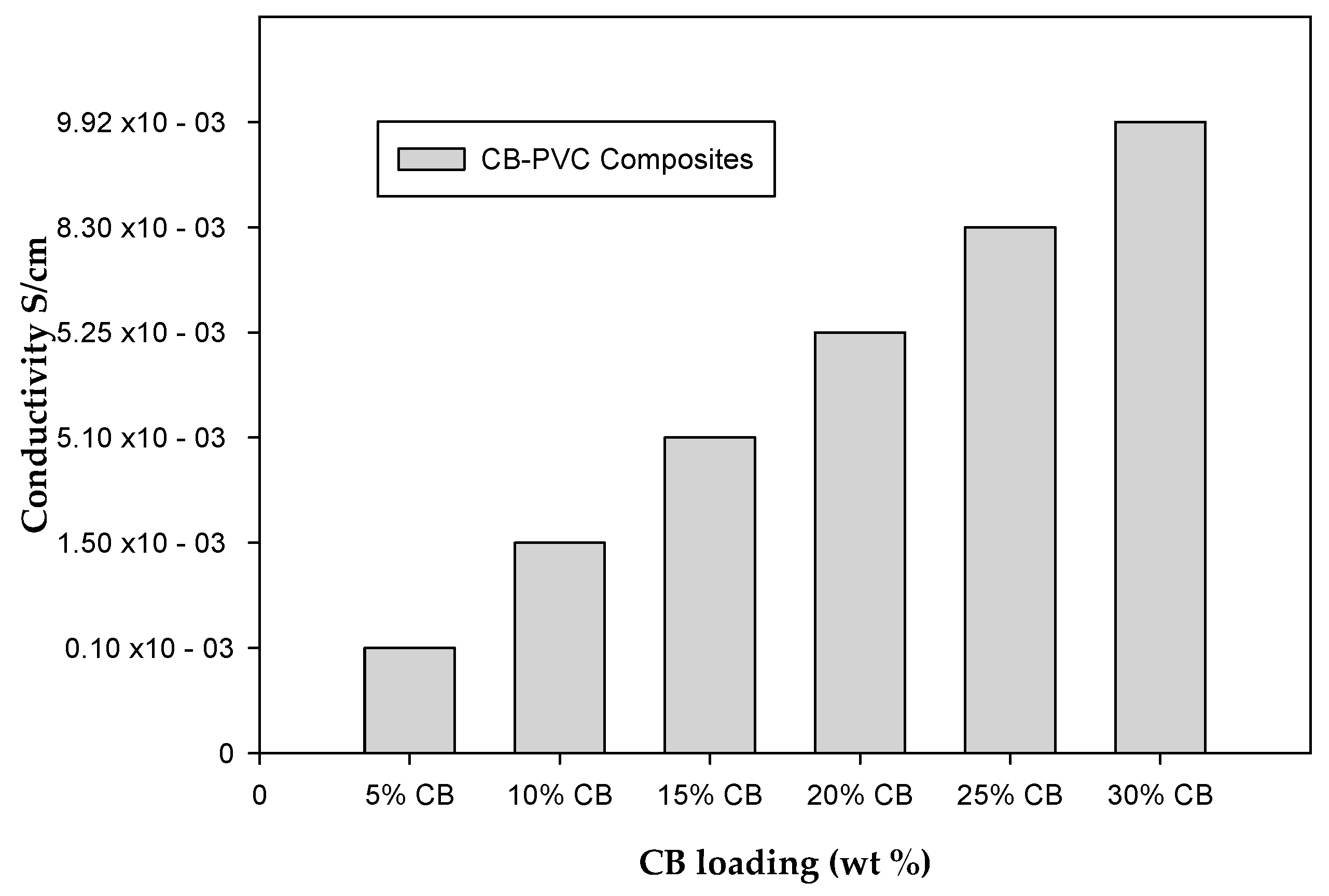

The DC conductivity of the prepared CB-PVC compression-molded composites was measured by applying four probe methods at room temperature. The results of DC conductivity obtained in this study are presented in

Figure 2. It is observed from

Figure 2 that the DC conductivity of the composites increases with increasing CB loading. The electrical conductivity of the composites increases with increasing the conductive filler content [

9,

12,

21]. Bahaa [

22] stated that the increase in conductivity with increased concentration of conductive filler was due to the increase in the charge carriers, which increase with increasing filler contact. These filler contact networks generate electrical contacts and enhance the conductivity. In this research, the DC conductivity (σ

dc) of 100% PVC was found to be 0 S·cm

−1, or could be so small that it was undetectable with the setup used.

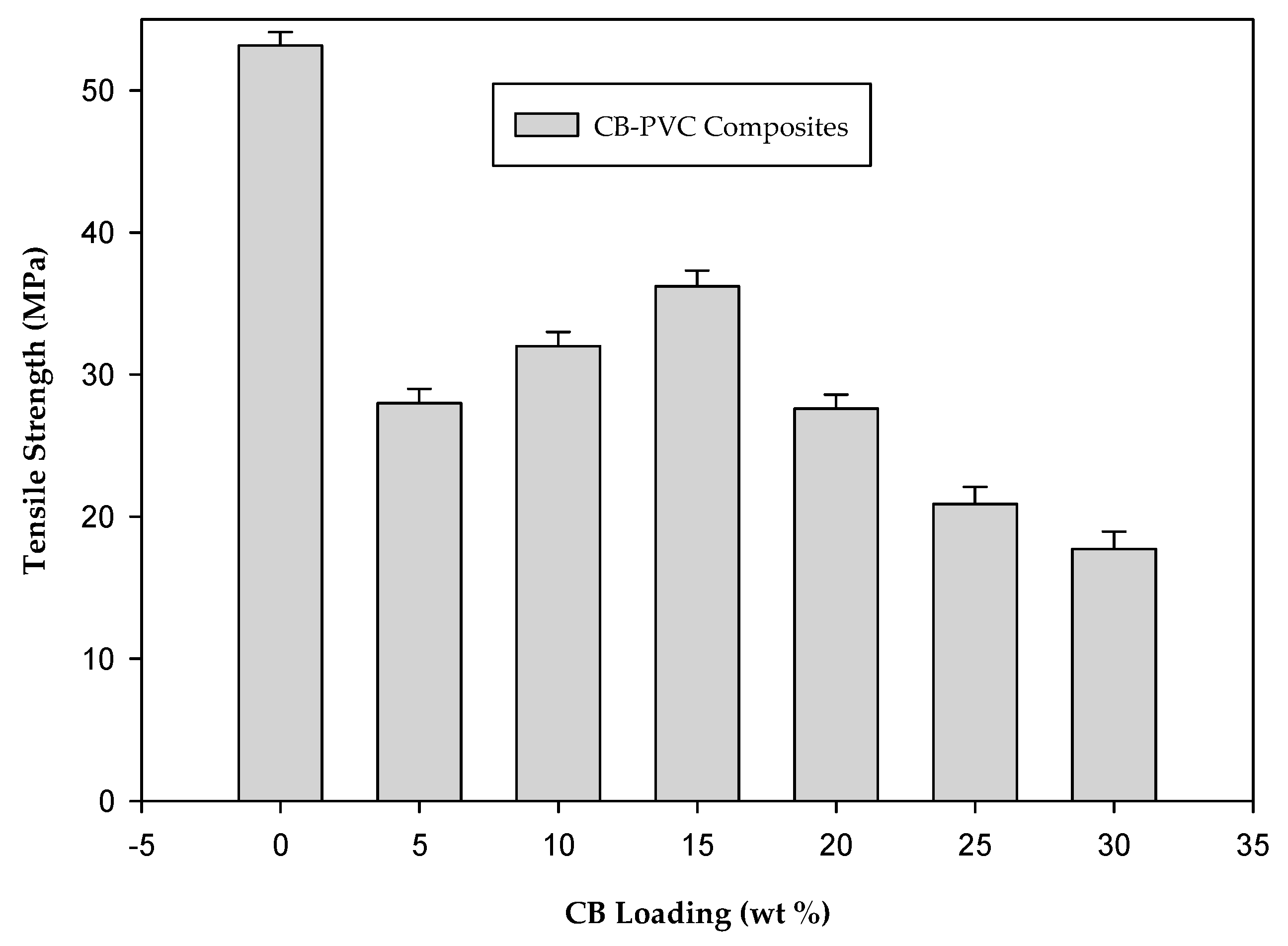

Tensile strength and elongation-at-break of the different types of CB-PVC composites were determined following the ASTM method described in the experimental section. The tensile strengths of the CB-PVC compression-molded composites are presented in

Figure 3. It is found from

Figure 3 that the tensile strength of 100% PVC composite is higher than that of all CB-PVC composites. The lower tensile strength of the CB-PVC composite system is due to the inability of the filler particles to transfer the applied stress for weak interfacial adhesion between the filler and matrix molecules [

7,

23,

24]. It is also found from

Figure 3 that the tensile strengths of the CB-PVC composites increase with increasing CB content up to a CB loading of 15 wt %, and then decrease. This may be due to vander Waals force between CB molecules in the CB-PVC composites. The distance between the CB molecules decreases at higher loading of CB, so they tend to stack together due to the vander Waals force in the composites. This tendency of CB reduces their uniform dispersion and load transfer in the CB-PVC composites. As a result, tensile strength of the CB-PVC composites decreases at CB loadings greater than 15 wt %. A similar observation was reported by Jinhong et al. [

15]. Enoki et al. [

25] reported that when a component with low molecular weight is increased in a matrix, then the tensile strength decreases. Sahai et al. [

26] worked on and reported the effect of particle size and concentration of fly ash on the mechanical properties of polyphenylene oxide composites. They reported on the effect of particle size on tensile behavior, and stated that filler agglomerate with lower particle size at higher concentration reduced the tensile strength of composites with a filler loading above 10 wt %. Bikiaris [

27] reported on multi-walled carbon nanotube (MWCNT)/polypropylene (PP) nanocomposites, and this review also stated that at low content, MWCNTs act as reinforcement agents, increasing the tensile strength of nanocomposites, but that at higher MWCNT contents, the size of aggregates increases and the formed aggregates act as mechanical failure concentrators. Thus, MWCNTs/PP nanocomposites exhibiting their mechanical performance at concentrations of 2–2.5 wt %, while with a further increase of MWCNT content, the tensile strength of PP/MWCNTs nanocomposites decreases. In this research, the lower particle size CB fillers may have a tendency to agglomerate at high filler contents of more than 15 wt %, resulting in improper bonding between the CB and the PVC, such that the tensile strength of CB-PVC composites decreases with the addition of CB above 15 wt %. At low CB content (5–15 wt %), partial tensile strain can be transferred to CB embedded in the PVC matrix under tensile stress, which leads to an increase in tensile strength [

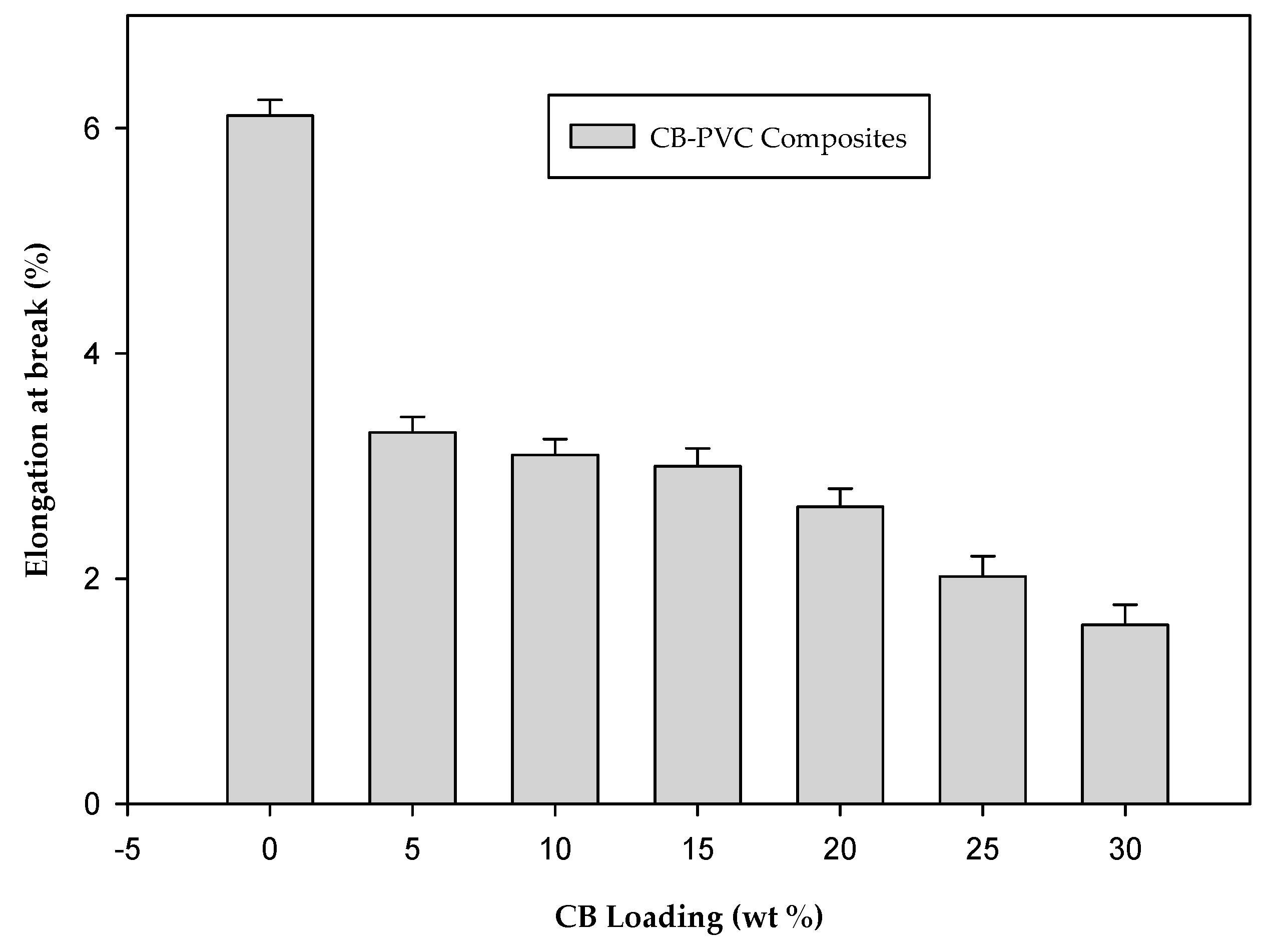

27]. However, elongation-at-break of the CB-PVC composites decreases with increasing PVC content (

Figure 4). Elongation is the percentage increase in original length (strain) of a specimen as a result of tensile force (stress) being applied to the specimen [

28]. It also indicates that the toughness or ductility of the CB-PVC composites decreases with increasing CB loading. The error bars of

Figure 3 and 4 show the standard deviation of tensile strength and elongation-at-break for all of the composites. The low standard deviations found in each group of composites indicate good uniformity between the samples. These small standard deviations of composites are due to variations in the sample manufacturing processes [

29].

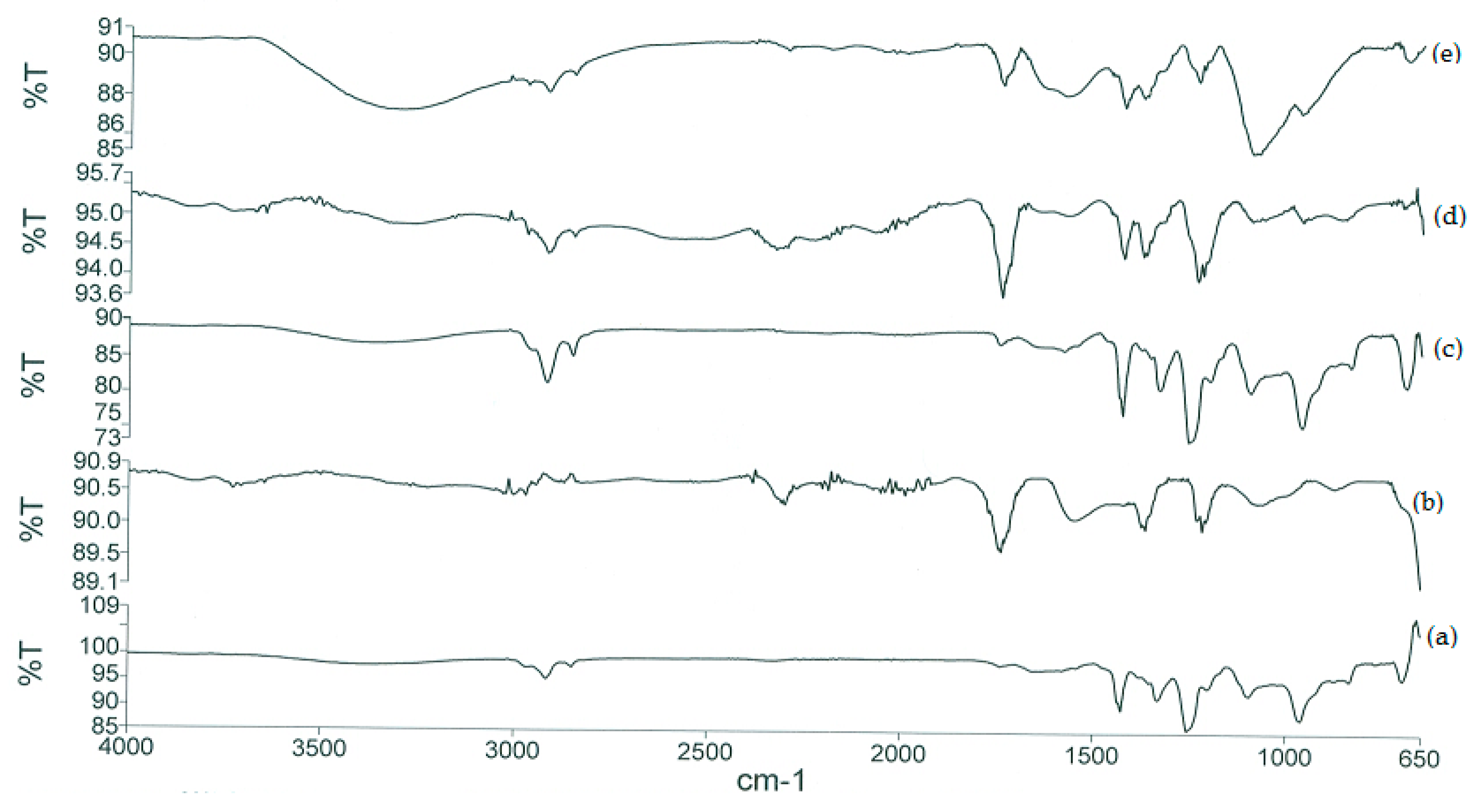

The structures of the CB-PVC composites were studied by ATR-FTIR spectroscopic analysis. ATR-FTIR spectra of the PVC, CB and three types CB-PVC composites are presented in

Figure 5. Anjalin [

30] also reported on the structure of a multi-walled carbon nanotube (MWCNT)-filled poly (vinylidene fluoride) (PVDF) nanocomposite by FTIR spectroscopic analysis. In

Figure 5a, the characteristic bands of PVC found at 2916 and 1426 cm

−1 are due to the CH

2 stretch. The bands at 1330, 1253 and at 695 cm

−1 are related to the CH bend out of phase, the CH bend into phase, and the C–Cl bonds respectively. From

Figure 5b, it is observed that the characteristic bands of CB found at 1739, 1578 and 1365 cm

−1 are due to the C=O, C–O and C–C bond vibrations, respectively. An almost identical FT-IR spectrum of carbon was reported by Meytij et al. [

19]. All of these characteristic bands of CB and PVC are found in the CB-PVC composites in

Figure 5c–e, respectively. The broad band near 3400 cm

−1 in

Figure 5e indicates the presence of hydroxyl groups on the carbon surface. The hydroxyl groups came from water that had been absorbed by the carbon black [

19].The peak intensity of the hydroxyl groups increased from10 wt % CB-PVC composite to 30 wt % CB-PVC composite with increasing CB content. It is also found from the ATR-FTIR spectra of the CB-PVC composites that the intensity of CB increases with increasing of CB loading in the composites, except for the 30 wt % CB-PVC composite. In 30 wt % CB-PVC composite, the peak intensity of both CB and PVC decreases, but the peak intensity of the hydroxyl group increases due to the presence of more CB.

Microstructural characterization of CB, PVC particles, 100 wt %PVC and 30 wt % CB-PVC composites were performed by optical microscopy. Dispersion of the filler particles in the composites was evaluated by optical microscopic images analysis [

12,

22,

31,

32]. In this work, the microscopic structures of all ingredients and the filler dispersion in the composites were observed by microscopic image analysis. The 100 times magnified images of PVC (125–177 µm) and CB (2.70 µm) particles are shown in

Figure 6a,b, respectively. It is clear from the figures that the CB and PVC are mixtures of different sizes of particles. The tiny pieces of 100% PVC and 30 wt % CB-PVC composites were examined using the microscope to observe the microstructure and filler dispersion. The microstructural images of 100 wt % PVC and 30 wt % CB-PVC composites at 100 times magnification are shown in

Figure 7a,b, respectively. The microsturctural analysis of the composites indicates a good dispersion of CB throughout the PVC.