Evaluation of Nutritional and Technological Attributes of Whole Wheat Based Bread Fortified with Chia Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Single-Screw Extrusion

2.2. Raw Materials and Additives

2.3. Bread Preparation

2.4. Theoretical Nutritional Value Calculation

2.5. Moisture Content Analysis

2.6. Textural Analysis

2.7. Crumb Color Analysis

2.8. Sensory Evaluation Analysis

2.9. Total Phenolic Content (TPC) and Trolox Equivalent Antioxidant Capacity (TEAC) Determination

2.10. Statistical Analysis

3. Results

3.1. Nutritional Analysis of Bread

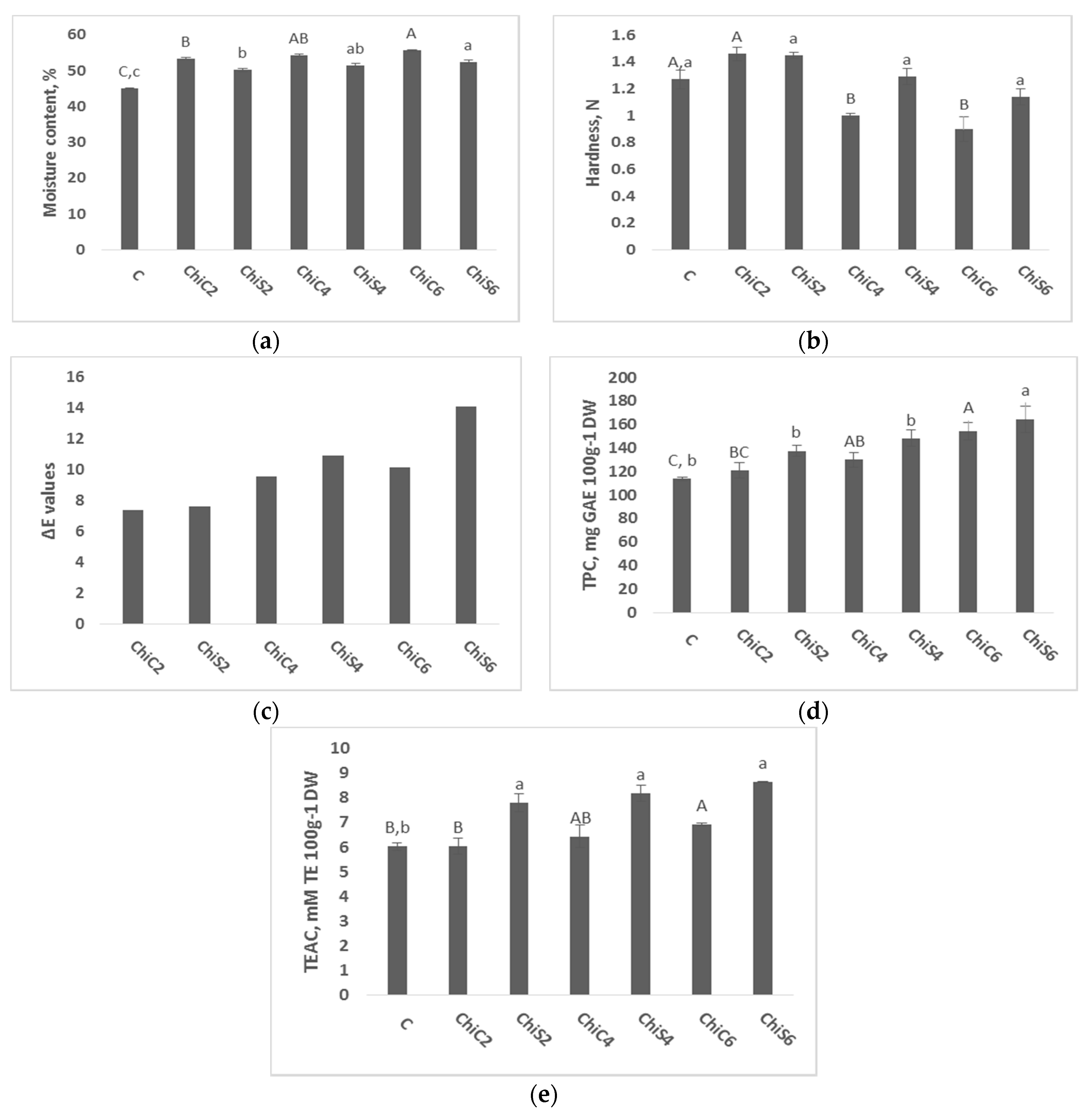

3.2. Bread Moisture Content

3.3. Bread Hardness Analysis

3.4. Bread Color Analysis

3.5. Bread Sensory Analysis

3.6. TPC and TEAC Analysis of Bread

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Viswanathan, K.; Ho, P. Fortification of white flat bread with sprouted red kidney bean (Phaseolus vulgaris). Acta Sci. Pol. Technol. Aliment 2014, 13, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Youseff, R.; Soubh, L.; Alassaf, Z. Detection of vegetable oils adulteration using desmethylsterols composition. Int. J. Pharm. Sci. Rev. Res. 2014, 28, 229–233. [Google Scholar]

- Sullivan, P.; O’Flaherty, J.; Brunton, N.; Arendt, E.; Gallagher, E. The utilisation of barley middlings to add value and health benefits to white breads. J. Food Eng. 2011, 105, 493–502. [Google Scholar] [CrossRef]

- Poinot, P.; Arvisenet, G.; Grua-Priol, J.; Fillonneau, C.; Mezaize, S.; De Lamballerie, M.; Le-Bail, A.; Prost, C. Advances in the understanding of the chemical reactions responsible for bread flavour quality. Czech J. Food Sci. 2009, 27, S54–S57. [Google Scholar] [CrossRef]

- Ghorbel, R.E.; Kamoun, A.; Neifar, M.; Chaabouni, S.E. Optimization of new flour improver mixing formula by surface response methodology. J. Food Process Eng. 2010, 33, 234–256. [Google Scholar] [CrossRef]

- Sayed-Ahmad, B.; Straumite, E.; Sabovics, M.; Kruma, Z.; Merah, O.; Saad, Z.; Hijazi, A.; Talou, T. Effect of addition of fennel (Foeniculum vulgare L.) on quality of protein bread. Proc. Lat. Acad. Sci. Sect. B. Nat. Exact Appl. Sci. 2017, 71, 509–514. [Google Scholar] [CrossRef]

- Capitani, M.I.; Spotorno, V.; Nolasco, S.M.; Tomás, M.C. Physicochemical and functional characterization of by-products from chia (Salvia hispanica L.) seeds of Argentina. LWT Food Sci. Technol. 2012, 45, 94–102. [Google Scholar] [CrossRef]

- Ayerza, R. The seed’s protein and oil content, fatty acid composition, and growing cycle length of a single genotype of chia (Salvia hispanica L.) as affected by environmental factors. J. Oleo Sci. 2009, 58, 347–354. [Google Scholar] [CrossRef] [PubMed]

- Coelho, M.S.; Salas-Mellado, M. Effects of substituting chia (Salvia hispanica L.) flour or seeds for wheat flour on the quality of the bread. LWT Food Sci. Technol. 2015, 60, 729–736. [Google Scholar] [CrossRef]

- Ixtaina, V.Y.; Nolasco, S.M.; Tomás, M.C. Physical properties of chia (Salvia hispanica L.) seeds. Ind. Crops Prod. 2008, 28, 286–293. [Google Scholar] [CrossRef]

- Iglesias-Puig, E.; Haros, M. La chía en Europa: El nuevo ingrediente en productos de panadería. Aliment. Rev. Tecnol. Hig. Aliment. 2011, 420, 73–77. [Google Scholar]

- Marineli, R.S.; Moraes, E.A.; Lenquiste, S.A.; Godoy, A.T.; Eberlin, M.N.; Maróstica, M.R., Jr. Chemical characterization and antioxidant potential of Chilean chia seeds and oil (Salvia hispanica L.). LWT Food Sci. Technol. 2014, 59, 1304–1310. [Google Scholar] [CrossRef]

- Sriti, J.; Neffati, M.; Msaada, K.; Talou, T.; Marzouk, B. Biochemical characterization of coriander cakes obtained by extrusion. J. Chem. 2013. [Google Scholar] [CrossRef]

- Sriti, J.; Talou, T.; Faye, M.; Vilarem, G.; Marzouk, B. Oil extraction from coriander fruits by extrusion and comparison with solvent extraction processes. Ind. Crops Prod. 2011, 33, 659–664. [Google Scholar] [CrossRef]

- Tetens, I. Opinion on the safety of ‘Chia seeds (Salvia hispanica L.) and ground whole Chia seeds’ as a food ingredient. EFSA J. 2009, 7, 996. [Google Scholar]

- Hrusková, M.; Svec, I. Chemical, rheological and bread characteristics of wheat flour influence by different forms of chia (Salvia hispanica L.). Emirates J. Food Agric. 2015, 27, 872–877. [Google Scholar] [CrossRef]

- Romankiewicz, D.; Hassoon, W.H.; Cacak-Pietrzak, G.; Sobczyk, M.; Wirkowska-Wojdyła, M.; Ceglińska, A.; Dziki, D. The effect of chia seeds (Salvia hispanica L.) addition on quality and nutritional value of wheat bread. J. Food Qual. 2017. [Google Scholar] [CrossRef]

- Steffolani, E.; De la Hera, E.; Pérez, G.; Gómez, M. Effect of chia (Salvia hispanica L.) addition on the quality of gluten-free bread. J. Food Qual. 2014, 37, 309–317. [Google Scholar] [CrossRef]

- Ayerza, R.; Coates, W. Ground chia seed and chia oil effects on plasma lipids and fatty acids in the rat. Nutr. Res. 2005, 25, 995–1003. [Google Scholar] [CrossRef]

- El-Demery, M.; Mahmoud, K.F.; Bareh, G.F.; Albadawy, W. Effect of fortification by full fat and defatted flaxseed Flour sensory properties of wheat bread and lipid profile laste. Int. J. Microbiol. Appl. Sci. 2015, 4, 581–598. [Google Scholar]

- Sayed-Ahmad, B.; Talou, T.; Saad, Z.; Hijazi, H.; Cerny, M.; Chokr, A.; Kanaan, H.; Merah, O. Fennel seed oil and by-products characterization and their potential applications. Ind. Crops Prod. 2018, 111, 92–98. [Google Scholar] [CrossRef]

- Cereals and Cereal Products-Determination of Moisture Content-Reference Method (ISO 712:2009). Available online: https://www.sis.se/api/document/preview/71901/ (accessed on 5 July 2018).

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar]

- Yu, L.; Nanguet, A.L.; Beta, T. comparison of antioxidant properties of refined and whole wheat flour and bread. Antioxidants 2013, 2, 370–383. [Google Scholar] [CrossRef] [PubMed]

- Justo, M.B.; Alfaro, A.D.C.; Aguilar, E.C.; Guzmán, K.; Da Mota Zanella, Z. Desarrollo de pan integral con soya, chía, linaza y ácido fólico como alimento funcional para la mujer. Arch. Latinoam. Nutr. 2007, 57, 14–20. [Google Scholar]

- Anderson, J.W.; Baird, P.; Davis, R.H., Jr.; Ferreri, S.; Knudtson, M.; Koraym, A.; Waters, V.; Williams, C.L. Health benefits of dietary fiber. Nutr. Rev. 2009, 67, 188–205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vázquez-Ovando, A.; Rosado-Rubio, G.; Chel-Guerrero, L.; Betancur-Ancona, D. Physicochemical properties of a fibrous fraction from chia (Salvia hispanica L.). LWT Food Sci. Technol. 2009, 42, 168–173. [Google Scholar]

- Iglesias-Puig, E.; Haros, M. Evaluation of performance of dough and bread incorporating chia (Salvia hispanica L.). Eur. Food Res. Technol. 2013, 237, 865–874. [Google Scholar] [CrossRef]

- Ugwuona, F.U.; Suwaba, S. Effects of defatted jack bean flour and jack bean protein concentrate on physicochemical and sensory properties of bread. Niger. Food J. 2013, 31, 25–32. [Google Scholar] [CrossRef]

- Kučerová, J.; Šottníková, V.; Nedomová, Š. Influence of dietary fibre addition on the rheological and sensory properties of dough and bakery products. Czech J. Food Sci. 2013, 31, 340–346. [Google Scholar] [CrossRef]

- Dick, M.; Costa, T.M.; Gomaa, A.; Subirade, M.; Rios Ade, O.; Flôres, S.H. Edible film production from chia seed mucilage: Effect of glycerol concentration on its physicochemical and mechanical properties. Carbohydr. Polym. 2015, 130, 198–205. [Google Scholar] [CrossRef] [PubMed]

- Eduardo, M.; Svanberg, U.; Ahrné, L. Effect of hydrocolloids and emulsifiers on the shelf-life of composite cassava-maize-wheat bread after storage. Food Sci. Nutr. 2016, 4, 636–644. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akhtar, S.; Anjum, F.M.; Rehman, S.U.; Sheikh, M.A.; Farzana, K. Effect of fortification on physico-chemical and microbiological stability of whole wheat flour. Food Chem. 2008, 110, 113–119. [Google Scholar] [CrossRef] [PubMed]

- Serrem, C.A.; de Kock, H.L.; Taylor, J.R. Nutritional quality, sensory quality and consumer acceptability of sorghum and bread wheat biscuits fortified with defatted soy flour. Int. J. Food Sci. Technol. 2011, 46, 74–83. [Google Scholar] [CrossRef]

- Michalska, A.; Amigo-Benavent, M.; Zielinski, H.; Dolores del Castillo, M. Effect of bread making on formation of Maillard reaction products contributing to the overall antioxidant activity of rye bread. J. Cereal Sci. 2008, 48, 123–132. [Google Scholar] [CrossRef]

- Mohd-Ali, N.; Yeap, S.W.; Ho, W.Y.; Beh, B.K.; Tan, S.W.; Tan, S.G. The promising future of chia, Salvia hispanica L. J. Biomed. Biotechnol. 2012. [Google Scholar] [CrossRef] [PubMed]

- Matthäus, A. Antioxidant activity of extracts obtained from residues of different oilseeds. J. Agric. Food Chem. 2002, 50, 3444–3452. [Google Scholar] [CrossRef] [PubMed]

- Chlopicka, J.; Pasko, P.; Gorinstein, S.; Jedryas, A.; Zagrodzki, P. Total phenolic and total flavonoid content, antioxidant activity and sensory evaluation of pseudocereal breads. LWT Food Sci. Technol. 2012, 46, 548–555. [Google Scholar] [CrossRef]

- Sayed Ahmad, B.; Talou, T.; Straumite, E.; Sabovics, M.; Kruma, Z.; Saad, Z.; Hijazi, A.; Merah, O. Protein bread fortification with cumin and caraway seeds and by-products flour. Foods 2018, 7. [Google Scholar] [CrossRef] [PubMed]

| Color | Nutrients, g 100 g−1 | Energy Value, 100 g−1 | Sensory Evaluation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Bread Samples | L* | a* | b* | Carbohydrates | Protein | Fiber | Fat | kcal | Mean Hedonic Values |

| Control (C) | 61.08 a ± 2.06 | 0.47 d ± 0.69 | 20.32 a ± 1.96 | 25.59 | 21.37 | 4.96 | 0.97 | 210.49 | 3.39 |

| 2% of chia seed powder (ChiS2) | 54.00 b ± 1.73 | 1.54 c ± 0.04 | 17.68 ab ± 0.79 | 25.75 | 21.63 | 5.07 | 1.29 | 223.19 | 3.73 |

| 4% of chia seed powder (ChiS4) | 51.88 b ± 0.09 | 2.18 c ± 0.21 | 14.65 b ± 0.01 | 25.92 | 21.61 | 5.18 | 1.61 | 235.77 | 3.55 |

| 6% of chia seed powder (ChiS6) | 48.84 b ± 1.89 | 4.30 b ± 0.18 | 14.48 b ± 0.07 | 26.08 | 21.60 | 5.29 | 1.92 | 248.41 | 3.68 |

| 2% of chia cakes (ChiC2) | 54.47 b ± 0.32 | 3.84 b ± 0.41 | 20.33 a ± 0.91 | 26.04 | 21.74 | 5.20 | 1.01 | 221.45 | 3.68 |

| 4% of chia cakes (ChiC4) | 52.55 b ± 0.20 | 4.67 b ± 0.01 | 18.99 a ± 1.28 | 26.49 | 21.83 | 5.43 | 1.06 | 232.41 | 3.65 |

| 6% of chia cakes (ChiC6) | 52.69 b ± 1.30 | 5.99 a ± 0.44 | 18.56 a ± 0.35 | 26.94 | 21.92 | 5.66 | 1.11 | 243.37 | 3.58 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayed-Ahmad, B.; Talou, T.; Straumite, E.; Sabovics, M.; Kruma, Z.; Saad, Z.; Hijazi, A.; Merah, O. Evaluation of Nutritional and Technological Attributes of Whole Wheat Based Bread Fortified with Chia Flour. Foods 2018, 7, 135. https://doi.org/10.3390/foods7090135

Sayed-Ahmad B, Talou T, Straumite E, Sabovics M, Kruma Z, Saad Z, Hijazi A, Merah O. Evaluation of Nutritional and Technological Attributes of Whole Wheat Based Bread Fortified with Chia Flour. Foods. 2018; 7(9):135. https://doi.org/10.3390/foods7090135

Chicago/Turabian StyleSayed-Ahmad, Bouchra, Thierry Talou, Evita Straumite, Martins Sabovics, Zanda Kruma, Zeinab Saad, Akram Hijazi, and Othmane Merah. 2018. "Evaluation of Nutritional and Technological Attributes of Whole Wheat Based Bread Fortified with Chia Flour" Foods 7, no. 9: 135. https://doi.org/10.3390/foods7090135