Determination of Egg Number Added to Special Pasta by Means of Cholesterol Contained in Extracted Fat Using GC-FID

Abstract

:1. Introduction

2. Materials and Methods

2.1. Equipment

2.2. Sampling

2.3. Preparation of Samples for Analysis

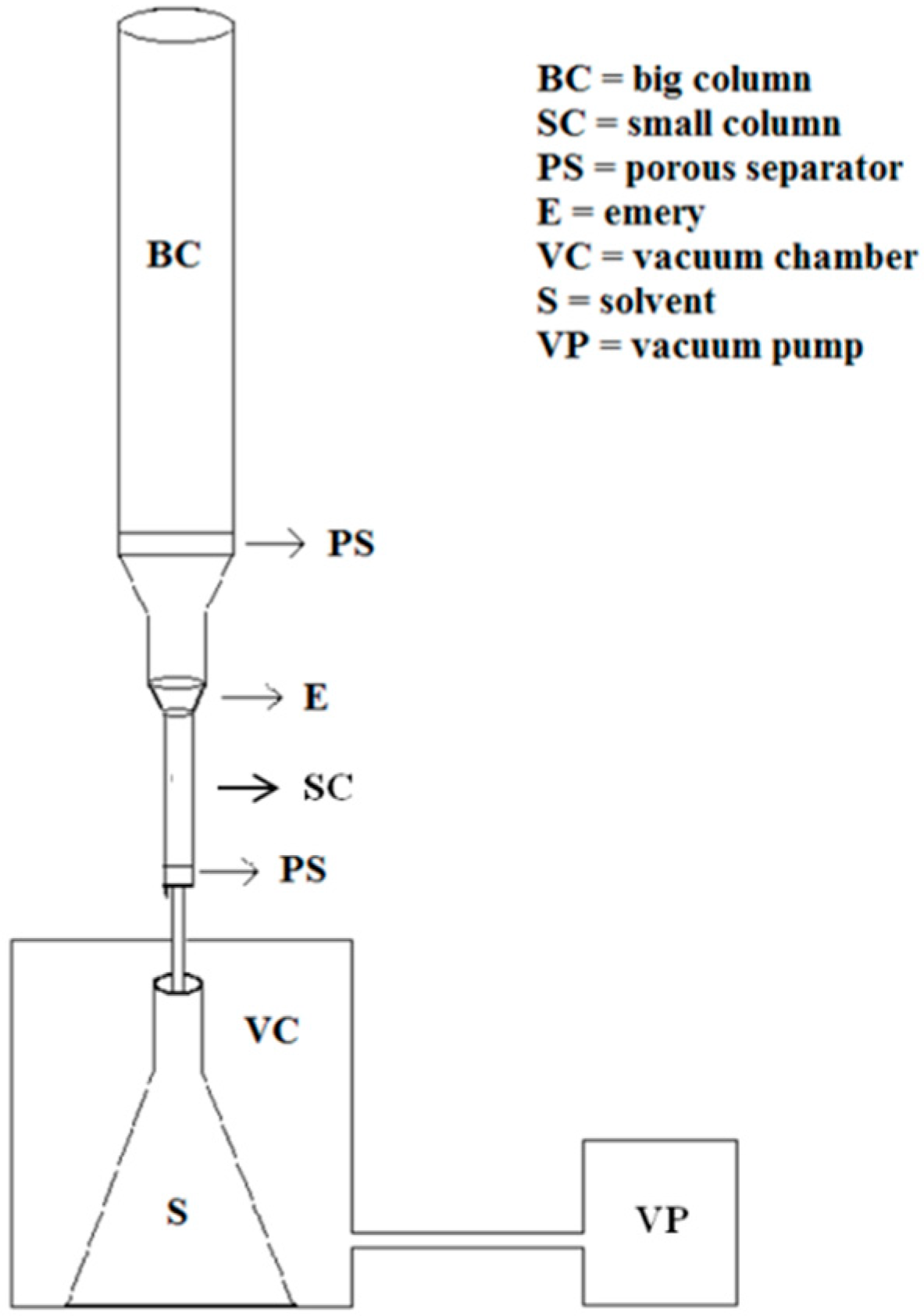

2.3.1. Analysis of Pasta Samples

2.3.2. Analysis of Lyophilized Yolk

2.4. Chromatographic Conditions

2.5. Analytical Validation

3. Results and Discussion

3.1. Determination of the Number of Eggs According to Muntoni’s Method

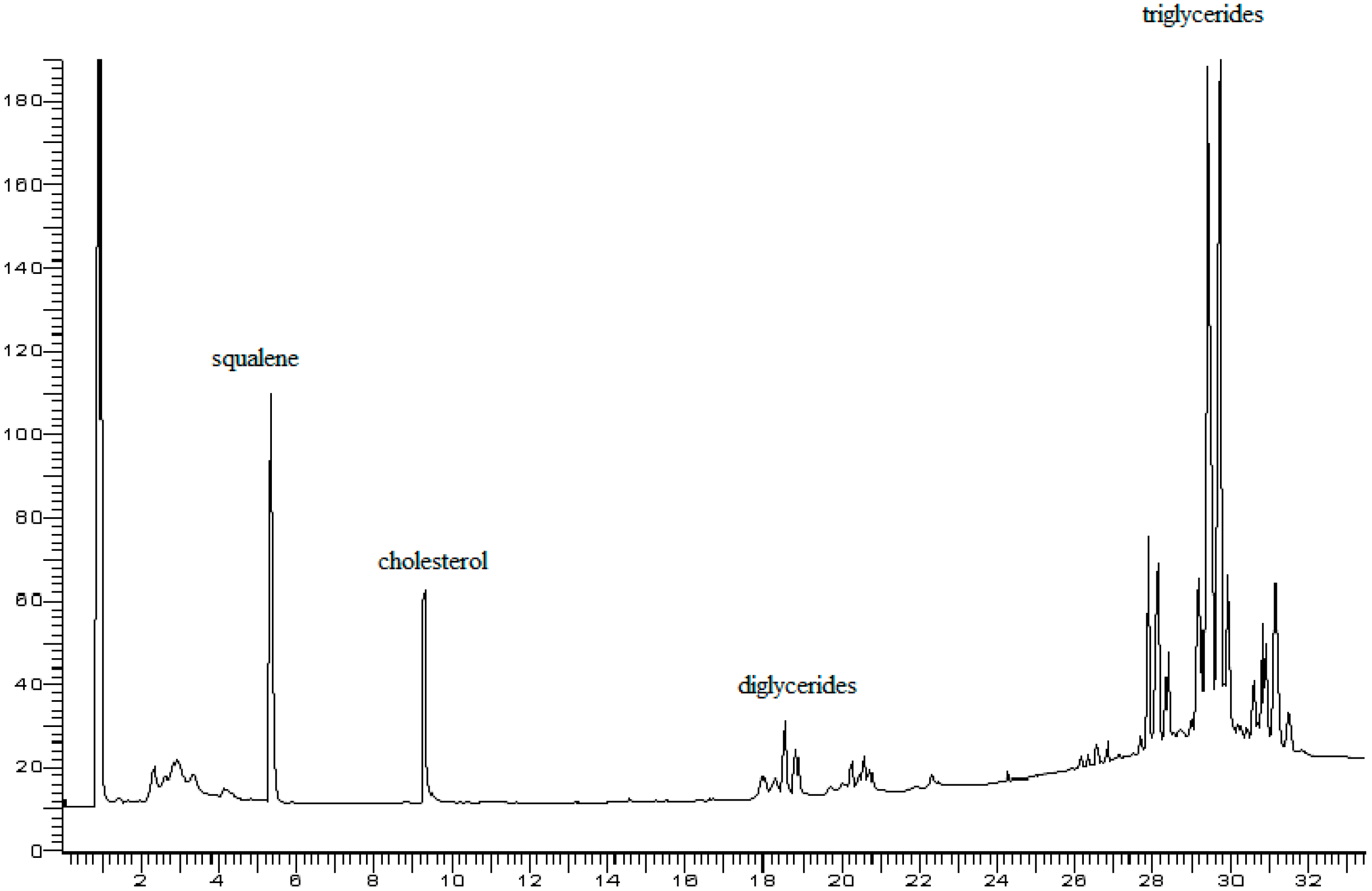

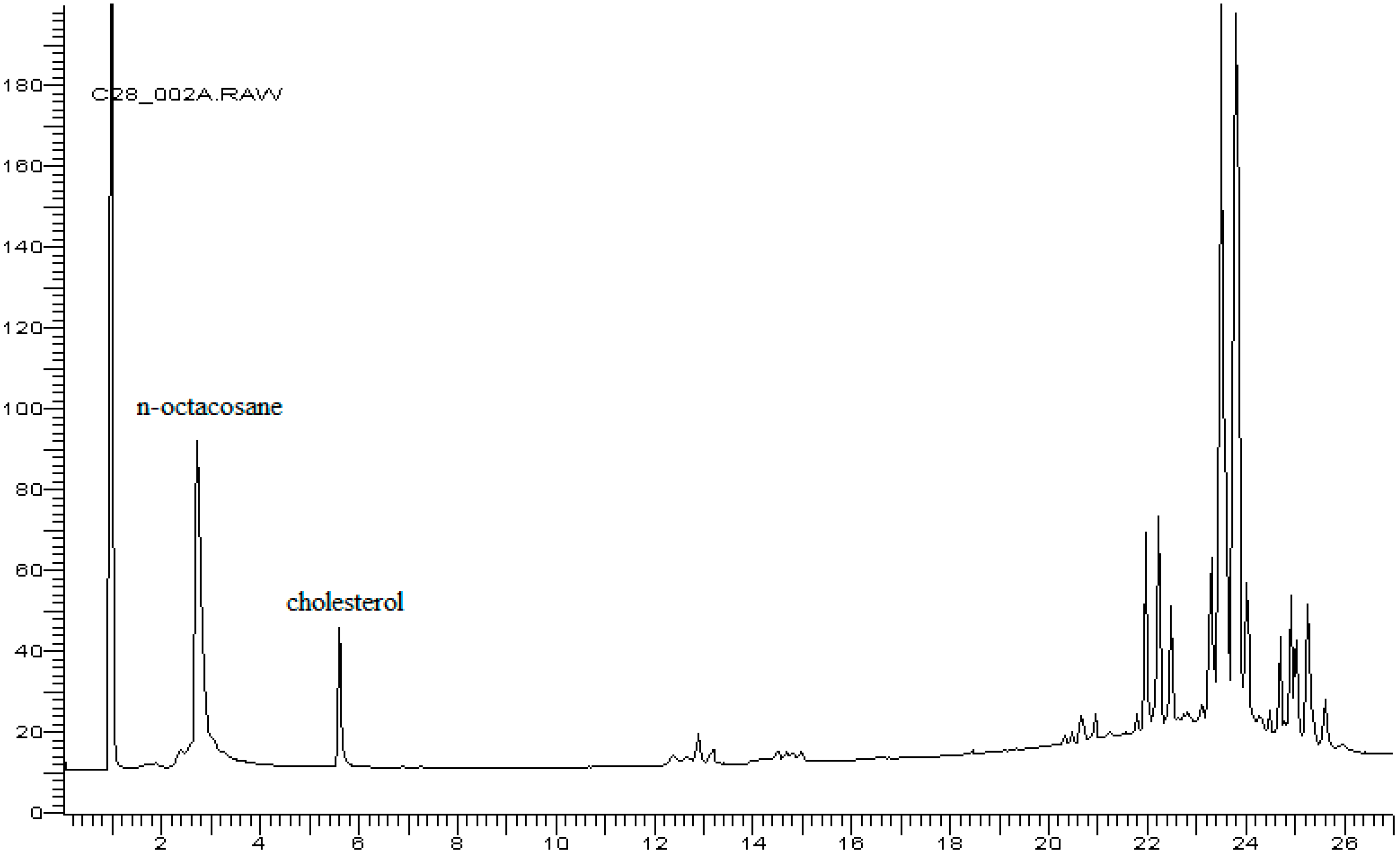

3.2. Determination of the Number of Eggs According to the New Method

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kill, R.; Turnbull, K. Pasta and Semolina Technology; John Wiley and Sons: Ames, IA, USA, 2008. [Google Scholar]

- Sissons, M. Role of durum wheat composition on the quality of pasta and bread. Food 2008, 2, 75–90. [Google Scholar]

- Fuad, T.; Prabhasankar, P. Role of ingredients in pasta product quality: A review on recent developments. Crit. Rev. Food Sci. 2010, 50, 787–798. [Google Scholar] [CrossRef] [PubMed]

- Giacco, R.; Vitale, M.; Riccardi, G. Pasta: Role in diet. In The Encyclopedia of Food and Health; Caballero, B., Finglas, P., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; Volume 4, pp. 242–245. [Google Scholar]

- Presidential Decree. Decree of the President of the Republic (DPR) of Italy; Gazzetta Ufficiale della Repubblica Italiana: Rome, Italy, 2001.

- Cunniff, P. Official Methods of Analysis of AOAC International, 20th ed.; George, W.L., Ed.; Association of Official Analytical Chemists: Rockville, MD, USA, 2016. [Google Scholar]

- AACC International. Methods 44-15.02, 66–50.01 and 76-31.01. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 1999. [Google Scholar]

- Muntoni, F.; Tiscornia, E.; Tassi-Micco, C. La gas cromatografia nella chimica dei cereali. Nota IV: II dosaggio delle uova nelle paste alimentari. Rassegna Diritto Tecnica Della Alimentazione 1966, 1, 29–36. [Google Scholar]

- Dinh, T.; Thompson, L. Cholesterol: Properties, processing effects, and determination. Encycl. Food Health 2016, 60–69. [Google Scholar] [CrossRef]

- Herron, K.L.; Fernandez, M.L. Are the current dietary guidelines regarding egg consumption appropriate? J. Nutr. 2004, 134, 187–190. [Google Scholar] [CrossRef] [PubMed]

- Naviglio, D.; Gallo, M.; Le Grottaglie, L.; Scala, C.; Ferrara, L.; Santini, A. Determination of cholesterol in Italian chicken eggs. Food Chem. 2012, 132, 701–708. [Google Scholar] [CrossRef]

- USDA (United Stated Department of Agriculture). Nutrient Database for Standard Reference; USDA: Washington, DC, USA, 2000.

- Mozaffarian, D. Dietary and policy priorities for cardiovascular disease, diabetes, and obesity: A comprehensive review. Circulation 2016, 133, 187–225. [Google Scholar] [CrossRef] [PubMed]

- Djoussé, L.; Kamineni, A.; Nelson, T.L.; Carnethon, M.; Mozaffarian, D.; Siscovick, D.; Mukamal, K.J. Egg consumption and risk of type 2 diabetes in older adults. Am. J. Clin. Nutr. 2010, 92, 422–427. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fernandez, M.L. Effects of eggs on plasma lipoproteins in healthy populations. Food Funct. 2010, 1, 156–160. [Google Scholar] [CrossRef] [PubMed]

- Ballesteros, M.N.; Valenzuela, F.; Robles, A.E.; Artalejo, E.; Aguilar, D.; Andersen, C.J.; Valdez, H.; Fernandez, M.L. One egg per day improves inflammation when compared to an oatmeal-based breakfast without increasing other cardiometabolic risk factors in diabetic patients. Nutrients 2015, 7, 3449–3463. [Google Scholar] [CrossRef] [PubMed]

- Missimer, A.; DiMarco, D.; Vergara-Jimenez, M.; Murillo, G.; Creighton, B.; Andersen, C.; Fernandez, M.L. Intake of 2 eggs or oatmeal for breakfast does not increase biomarkers for heart disease while eggs improve liver enzymes and raise HDL cholesterol in young healthy individuals. FASEB J. 2015, 29, 274.2. [Google Scholar]

- DiMarco, D.M.; Missimer, A.; Murillo, A.G.; Lemos, B.S.; Malysheva, O.V.; Caudill, M.A.; Blesso, C.N.; Fernandez, M.L. Intake of up to 3 eggs/day increases HDL cholesterol and plasma choline while plasma trimethylamine-N-oxide is unchanged in a healthy population. Lipids 2017, 52, 255–263. [Google Scholar] [CrossRef] [PubMed]

- Blesso, C.N.; Andersen, C.J.; Bolling, B.W.; Fernandez, M.L. Egg intake improves carotenoid status by increasing plasma HDL cholesterol in adults with metabolic syndrome. Food Func. 2013, 4, 213–221. [Google Scholar] [CrossRef] [PubMed]

- Naviglio, D.; Raia, C. Application of a HRGC method on capillary column Rtx 65-TG for triglyceride analysis to monitor butter purity. Anal. Lett. 2003, 36, 3063–3094. [Google Scholar] [CrossRef]

- Christie, W.W. Preparation of ester derivatives of fatty acids for chromatographic analysis. Adv. Lipid Method 1993, 2, e111. [Google Scholar]

- Nota, G.; Naviglio, D.; Romano, R.; Luongo, D.; Spagna Musso, S. Un metodo rapido per la determinazione del numero delle uova nelle paste speciali. Riv. Ital. Sostanze Grasse 1994, 71, 417–420. [Google Scholar]

- Boselli, E.; Velazco, V.; Caboni, M.F.; Lercker, G. Pressurized liquid extraction of lipids for the determination of oxysterols in egg-containing food. J. Chromatogr. 2001, 917, 239–244. [Google Scholar] [CrossRef]

- Dinh, T.T.; Thompson, L.D.; Galyean, M.L.; Brooks, J.C.; Patterson, K.Y.; Boylan, L.M. Cholesterol content and methods for cholesterol determination in meat and poultry. Compr. Rev. Food Sci. Food Saf. 2011, 10, 269–289. [Google Scholar] [CrossRef]

- Carrapiso, A.I.; García, C. Development in lipid analysis: Some new extraction techniques and in situ transesterification. Lipids 2000, 35, 1167–1177. [Google Scholar] [CrossRef] [PubMed]

- Čížková, H.; Prokorátová, V.; Voldřich, M.; Kvasnička, F.; Soukupová, V. Determination of egg content in pasta. Czech J. Food Sci. 2004, 22, 197–203. [Google Scholar] [CrossRef]

- Fodor, M.; Woller, A.; Turza, S.; Szigedi, T. Development of a rapid, non-destructive method for egg content determination in dry pasta using FT-NIR technique. J. Food Eng. 2011, 107, 195–199. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Bucci, R.; Materazzi, S.; Marini, F. Application of near infrared (NIR) spectroscopy coupled to chemometrics for dried egg-pasta characterization and egg content quantification. Food Chem. 2013, 140, 726–734. [Google Scholar] [CrossRef] [PubMed]

- Albuquerque, T.G.; Oliveira, M.B.P.; Sanches-Silva, A.; Costa, H.S. Cholesterol determination in foods: Comparison between high performance and ultra-high performance liquid chromatography. Food Chem. 2016, 193, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Langella, C.; Naviglio, D.; Marino, M.; Gallo, M. Study of the effects of a diet supplemented with active components on lipid and glycemic profiles. Nutrition 2015, 31, 180–186. [Google Scholar] [CrossRef] [PubMed]

- Madzlan, K. Determination of cholesterol in several types of eggs by gas chromatography. J. Trop. Agric. Food Sci. 2008, 36, 205–210. [Google Scholar]

- Dinh, T.T.; Thompson, L.D.; Galyean, M.L.; Brooks, J.C.L.; Boylan, M.L. Determination of total cholesterol in meat and poultry by gas chromatography: Single-laboratory validation. J. AOAC Int. 2012, 95, 472–488. [Google Scholar] [CrossRef] [PubMed]

- Egressy-Molnár, O.; Jókai, Z. Development of a GC-based method for the determination of egg content in dried pasta with the focus on method validation. Acta Aliment. 2011, 40, 23–32. [Google Scholar] [CrossRef]

- Al-Balaa, D.; Rajchl, A.; Grégrová, A.; Ševčík, R.; Čížková, H. DART mass spectrometry for rapid screening and quantitative determination of cholesterol in egg pasta. J. Mass Spectrom. 2014, 49, 911–917. [Google Scholar] [CrossRef] [PubMed]

- Naviglio, D.; Dellagreca, M.; Ruffo, F.; Andolfi, A.; Gallo, M. Rapid analysis procedures for triglycerides and fatty acids as pentyl and phenethyl esters for the detection of butter adulteration using chromatographic techniques. J. Food Qual. 2017, 2017, 9698107. [Google Scholar] [CrossRef]

| Commercial Samples | Percentage of Added Eggs (Label) | Egg Number/kg (*) (Declared) | Cholesterol (mg/kg) | No. Determined Eggs (Min–Max) |

|---|---|---|---|---|

| Sample 1 | 19.36% | 4.8 | 1025 | 4.1–5.9 |

| Sample 2 | 20.30% | 5.1 | 1050 | 4.2–6.0 |

| Sample 3 | 28.30% | 7.9 | 1100 | 4.4–6.3 |

| Sample 4 | 23.87% | 6.3 | 1200 | 4.8–6.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naviglio, D.; Langella, C.; Faralli, S.; Ciaravolo, M.; Salvatore, M.M.; Andolfi, A.; Varchetta, V.; Romano, R.; Gallo, M. Determination of Egg Number Added to Special Pasta by Means of Cholesterol Contained in Extracted Fat Using GC-FID. Foods 2018, 7, 131. https://doi.org/10.3390/foods7090131

Naviglio D, Langella C, Faralli S, Ciaravolo M, Salvatore MM, Andolfi A, Varchetta V, Romano R, Gallo M. Determination of Egg Number Added to Special Pasta by Means of Cholesterol Contained in Extracted Fat Using GC-FID. Foods. 2018; 7(9):131. https://doi.org/10.3390/foods7090131

Chicago/Turabian StyleNaviglio, Daniele, Ciro Langella, Stefano Faralli, Martina Ciaravolo, Maria Michela Salvatore, Anna Andolfi, Vincenzo Varchetta, Raffaele Romano, and Monica Gallo. 2018. "Determination of Egg Number Added to Special Pasta by Means of Cholesterol Contained in Extracted Fat Using GC-FID" Foods 7, no. 9: 131. https://doi.org/10.3390/foods7090131