Enamel Roughness Changes after Removal of Orthodontic Adhesive

Abstract

:1. Introduction

2. Results

3. Discussion

4. Materials and Methods

4.1. Preparation of Specimens

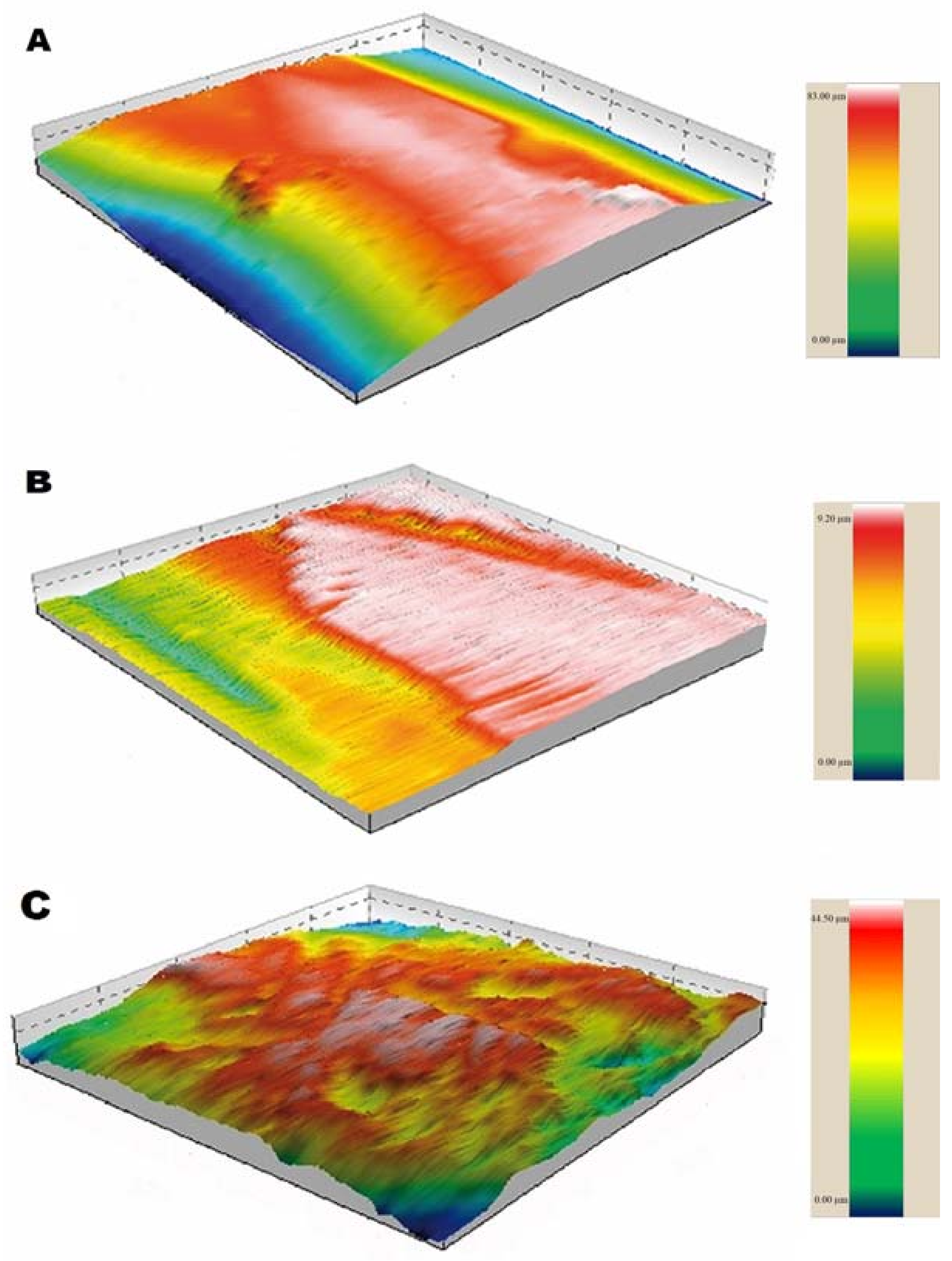

4.2. Roughness Test

- the average roughness (Ra), which is the arithmetic mean of all absolute distances;

- the root mean square of roughness (Rq), which is the distribution of height related to a median line;

- the average height between the five peaks and valleys with the highest and lowest profile points (Rz);

- the flattening of the profile (Rku), whether the angle of the peaks and valleys is sharp (>3) or obtuse (<3); and

- the symmetry of the profile (Rsk), verifying the predominance of peaks (+) and valleys (−).

4.3. Bonding, Adhesive Removal, and Final Roughness Test

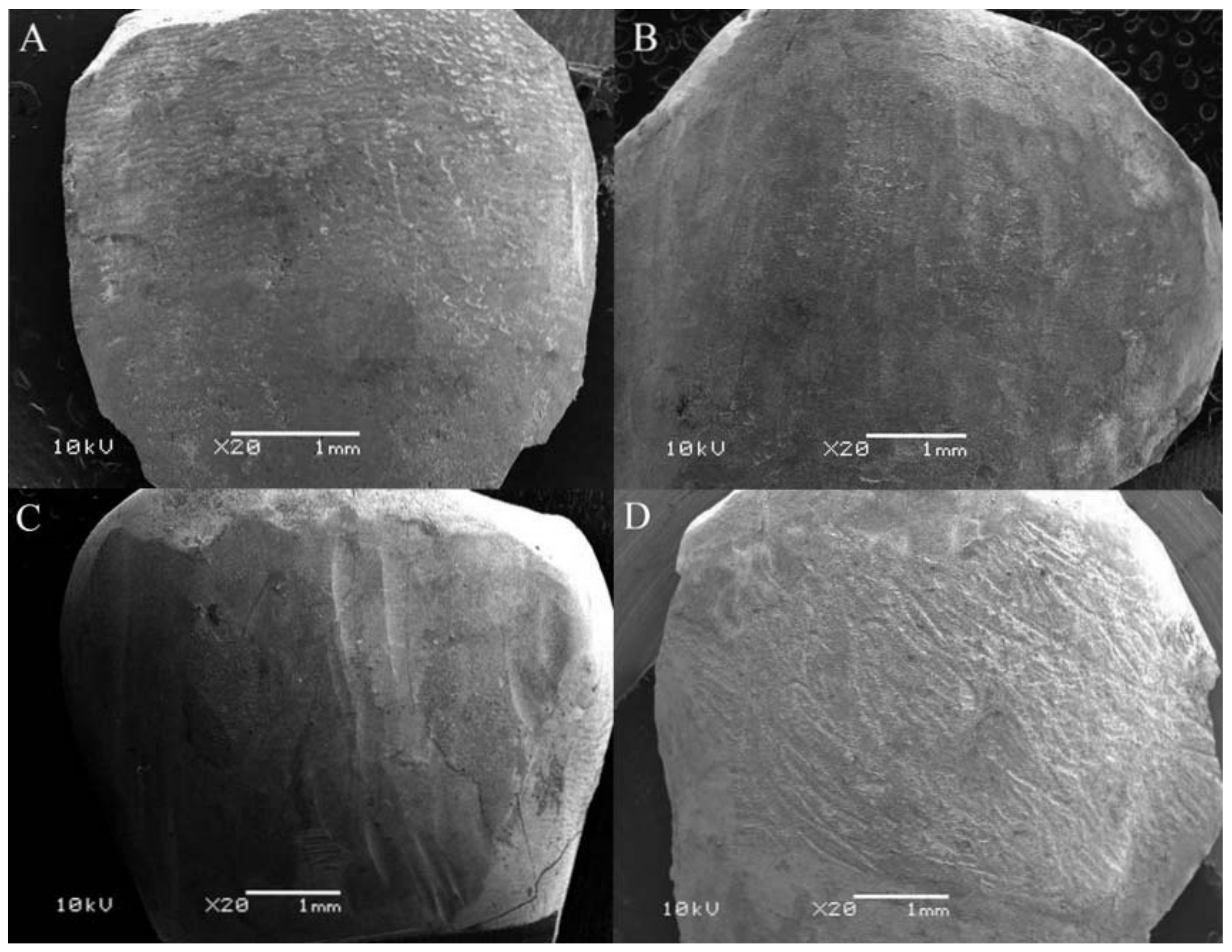

4.4. Micromorphological Analysis

4.5. Satistical Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zarrinnia, K.; Eid, N.M.; Kehoe, M.J. The effect debonding of different techniques on the enamel surface: An in vitro qualitative study. Am. J. Orthod. Dentofac. Orthop. 1995, 108, 284–293. [Google Scholar] [CrossRef]

- Faltermeier, A.; Rosentritt, M.; Reicheneder, C.; Behr, M. Discolouration of orthodontic adhesives Caused by food dyes and ultraviolet light. Eur. J. Orthod. 2008, 30, 89–93. [Google Scholar] [CrossRef] [PubMed]

- Eliades, T.; Gioka, C.; Eliades, G.; Makou, M. Enamel surface roughness following debonding using two resin grinding methods. Eur. J. Orthod. 2004, 26, 333–338. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quirynen, M. The clinical meaning of the surface roughness and the surface-free energy of intra-oral hard substrata on the microbiology of the supra- and subgingival plaque: Results of in vitro and in vivo experiments. J. Dent. 1994, 22 (Suppl. 1), S13–S16. [Google Scholar] [CrossRef]

- Kakaboura, A.; Fragouli, M.; Rahiotis, C.; Silikas, N. Evaluation of surface characteristics of dental composites using profilometry, scanning electron, atomic force microscopy and gloss-meter. J. Mater. Sci. Mater. Med. 2007, 18, 155–163. [Google Scholar] [CrossRef] [PubMed]

- Sfondrini, M.F.; Scribante, A.; Fraticelli, D.; Roncallo, S.; Gandini, P. Epidemiological survey of different clinical techniques of orthodontic bracket debonding and enamel polishing. J. Orthod. Sci. 2015, 4, 123–127. [Google Scholar] [PubMed]

- Hosein, I.; Sherriff, M.; Ireland, A.J. Enamel loss during bonding, debonding, and cleanup with use of a self-etching primer. Am. J. Orthod. Dentofac. Orthop. 2004, 126, 717–724. [Google Scholar] [CrossRef]

- Karan, S.; Kircelli, B.H.; Tasdelen, B. Enamel surface roughness after debonding-comparison of two different burs. Angle Orthod. 2010, 80, 1081–1088. [Google Scholar] [CrossRef] [PubMed]

- Howell, S.; Weekes, W.T. An electron microscopic evaluation of the enamel surface subsequent to various debonding procedures. Aust. J. Dent. 1990, 35, 245–252. [Google Scholar] [CrossRef]

- Kim, S.; Park, W.; Son, W.; Ahn, H.; Ro, J.; Kim, Y. Enamel surface evaluation after removal of orthodontic composite remnants by intraoral sandblasting: A three-dimensional surface profilometry study. Am. J. Dentofac. Orthop. Orthod. 2007, 132, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Garg, R.; Dixit, P.; Khosla, T.; Gupta, P.; Kalra, H.; Kumar, P. Enamel surface roughness after debonding: A comparative study using three different burs. J. Contemp. Dent. Pract. 2018, 19, 521–526. [Google Scholar] [CrossRef] [PubMed]

- Faria-Júnior, É.; Guiraldo, R.; Berger, S.; Correr, A.; Correr-Sobrinho, L.; Contreras, E.; Lopes, M. In-vivo evaluation of the surface roughness and morphology of enamel after bracket removal and polishing by different techniques. Am. J. Orthod. Dentofac. Orthop. 2015, 147, 324–329. [Google Scholar] [CrossRef] [PubMed]

- Radlanski, R.J. A new carbide finishing bur for bracket debonding. J. Orthop. Orofac. 2001, 62, 296–304. [Google Scholar] [CrossRef]

- Brauchli, L.M.; Baumgartner, M.S.; Ball, J.; Wichelhaus, A. Roughness of different enamel surface after bonding and debonding procedures. An in vitro study. J. Orthop. Orofac. 2011, 72, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Zachrisson, B.U.; Arthun, J. Enamel surface appearance after various debonding techniques. Am. J. Orthod. 1979, 75, 121–137. [Google Scholar] [CrossRef]

- Borges, C.F.M.; Magne, P.; Pfender, E.; Heberlein, J. Dental diamond burs made with the new technology. J. Prosthet. Dent. 1999, 82, 73–79. [Google Scholar] [CrossRef]

- Cehreli, Z.C.; Lakshmipathy, M.; Yazici, R. Effect of different techniques on the splint removal human enamel surface roughness: The three-dimensional optical profilometry analysis. Traumat Dent. 2008, 24, 177–182. [Google Scholar] [CrossRef] [PubMed]

- Bollen, C.M.; Lambrechts, P.; Quirynen, M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature. Dent. Mater. 1997, 13, 258–269. [Google Scholar] [CrossRef]

- Yoda, I.; Koseki, H.; Tomita, M.; Shida, T.; Horiuchi, H.; Sakoda, H.; Osaki, M. Effect of surface roughness of biomaterials on Staphylococcus epidermidis adhesion. BMC Microbiol. 2014, 14, 234. [Google Scholar] [CrossRef] [PubMed]

- Radlanski, R.J.; Best, T. New carbide finishing burs to reduce polishing efforts of light-cured restorations. Quintessence Int. 2007, 38, e555–e563. [Google Scholar] [PubMed]

- Ryf, S.; Flury, S.; Palaniappan, S.; Lussi, A.; Van Meerbeek, B.; Zimmerli, B. Enamel loss and adhesive remnants following various brackets removal and clean-up procedures in vitro. Eur. J. Orthod. 2012, 34, 25–32. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Chen, L.; Huang, X. Effects of various debonding and adhesive clearance methods on enamel surface: An in vitro study. BMC Oral Health 2017, 17, 58. [Google Scholar] [CrossRef] [PubMed]

- Retief, D.H.; Denys, F.R. Finishing of enamel surfaces after debonding of orthodontics attachments. Angle Orthod. 1979, 49, 1–10. [Google Scholar] [PubMed]

- Ireland, A.J.; Hosein, I.; Sheriff, M. Enamel loss at bond-up, debond and clean-up following the use of conventional light-cured composite and resin modified glass polyalkenoate cement. Eur. J. Orthod. 2005, 27, 413–419. [Google Scholar] [CrossRef] [PubMed]

- Andrews, J.; Hagan, J.; Armbruster, P.; Ballard, R. Comparison of traditional orthodontic polishing systems with novel non-orthodontic methods for residual adhesive removal. Aust. Orthod. J. 2016, 32, 41–47. [Google Scholar] [PubMed]

- Webb, B.; Koch, J.; Hagan, J.; Ballard, R.; Armbruster, P. Enamel surface roughness of preferred debonding and polishing protocols. J. Orthod. 2016, 43, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Özer, T.; Başaran, G.; Kama, J.D. Surface roughness of the restored enamel after orthodontic treatment. Am. J. Orthod. Dentofac. Orthop. 2010, 137, 368–374. [Google Scholar] [CrossRef] [PubMed]

- Whitehead, S.A.; Shearer, A.C.; Watts, D.C.; Wilson, N.H.F. Comparison of two stylus methods for measuring surface texture. Dent. Mater. 1999, 15, 79–86. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). Dental Materials–Testing of Adhesion to Tooth Structure, 2nd ed.; ISO 11405; International Organization for Standardization: Geneva, Switzerland, 2003. [Google Scholar]

- International Organization for Standardization (ISO). Geometrical Products Specifications (GPS)—Surface Texture: Profile Method—Nominal Characteristics of Contact (Stylus) Instruments; ISO 3274; International Organization for Standardization: Geneva, Switzerland, 1996. [Google Scholar]

- Taylor Hobson Ltd. Exploring Surface Roughness: A Fundamental Guide to the Measurement of Surface Finish, 7th ed.; Taylor Hobson Ltd.: Leicester, UK, 2011; pp. 1–100. [Google Scholar]

- Schuler, F.S.; van Waes, H. SEM-evaluation of enamel surfaces after removal of fixed orthodontic appliances. Am. J. Dent. 2003, 16, 390–394. [Google Scholar] [PubMed]

| Parameter | Group | Initial Mean ± SD | p Value | Final Mean ± SD | p Value | Dunn †† |

|---|---|---|---|---|---|---|

| Ra | 1 | 2.09 ± 0.75 | 0.1563 | 2.73 ± 1.08 | <0.001 | A |

| 2 | 2.01 ± 0.78 | - | 3.36 ± 1.46 † | - | B | |

| 3 | 2.43 ± 0.61 | - | 3.82 ± 0.62 † | - | C | |

| Rq | 1 | 2.57 ± 0.89 | 0.0989 | 3.51 ± 1.53 | <0.001 | A |

| 2 | 2.55 ± 1.01 | - | 4.34 ± 1.94 † | - | B | |

| 3 | 3.05 ± 0.81 | - | 4.79 ± 0.78 † | - | C | |

| Rz | 1 | 7.35 ± 2.47 | 0.0611 | 11.28 ± 5.47 † | <0.001 | A |

| 2 | 7.32 ± 3.41 | - | 13.04 ± 5.51 † | - | A | |

| 3 | 7.90 ± 2.33 | - | 17.99 ± 3.02 † | - | B | |

| Rku | 1 | 2.96 ± 1.23 | 0.3734 | 3.40 ± 1.38 | 0.3965 | - |

| 2 | 3.26 ± 1.51 | - | 3.56 ± 1.49 | - | - | |

| 3 | 3.01 ± 1.12 | - | 3.06 ± 0.73 | - | - | |

| Rsk | 1 | −0.22 ± 0.63 | 0.1556 | −0.32 ± 0.58 | 0.1354 | - |

| 2 | −0.43 ± 0.70 | - | −0.32 ± 0.67 | - | - | |

| 3 | −0.34 ± 0.66 | - | −0.16 ± 0.42 | - | - |

| Roughness Parameter | Group | Initial Mean ± SD | p Value | Final Mean ± SD | p Value | Dunn †† |

|---|---|---|---|---|---|---|

| Ra | 1 | 2.04 ± 0.60 | 0.0610 | 1.21 ± 0.59 † | <0.001 | A |

| 2 | 1.80 ± 0.62 | 0.91 ± 0.28 † | A | |||

| 3 | 2.04 ± 0.54 | 3.08 ± 0.72 † | B | |||

| Rq | 1 | 2.58 ± 0.78 | 0.0568 | 1.73 ± 0.94 † | <0.001 | A |

| 2 | 2.27 ± 0.84 | 1.23 ± 0.44 † | B | |||

| 3 | 2.57 ± 0.70 | 3.95 ± 0.91 † | C | |||

| Rz | 1 | 8.58 ± 2.79 | 0.0832 | 6.66 ± 3.32 † | <0.001 | A |

| 2 | 7.46 ± 2.75 | 4.58 ± 1.56 † | B | |||

| 3 | 8.64 ± 2.36 | 17.19 ± 3.40 † | C | |||

| Rku | 1 | 3.67 ± 3.33 | 0.8477 | 5.59 ± 2.41 † | <0.001 | A |

| 2 | 2.94 ± 0.81 | 5.34 ± 2.73 † | A | |||

| 3 | 3.05 ± 1.19 | 3.51 ± 0.93 | B | |||

| Rsk | 1 | 0.09 ± 0.90 | 0.0558 | −0.13 ± 0.94 | <0.001 | A |

| 2 | 0.12 ± 0.47 | 0.80 ± 1.02 † | B | |||

| 3 | −0.34 ± 0.49 | −0.31 ± 0.39 | C |

| Groups | Score 0 | Score 1 | Score 2 | Score 3 |

|---|---|---|---|---|

| Healthy | 07 | 03 | - | - |

| 5-blade | 03 | 05 | 02 | - |

| 30-blade | - | 04 | 06 | - |

| CVD | - | - | 01 | 09 |

| Group | Mean (±SD) a | Minimum | Maximum |

|---|---|---|---|

| 5-bladed | 75.5 (±29.6) A | 33 | 136 |

| 30-bladed | 59.2 (±17.8) AB | 32 | 93 |

| CVD | 54.8 (±22.9) B | 28 | 114 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Degrazia, F.W.; Genari, B.; Ferrazzo, V.A.; Santos-Pinto, A.D.; Grehs, R.A. Enamel Roughness Changes after Removal of Orthodontic Adhesive. Dent. J. 2018, 6, 39. https://doi.org/10.3390/dj6030039

Degrazia FW, Genari B, Ferrazzo VA, Santos-Pinto AD, Grehs RA. Enamel Roughness Changes after Removal of Orthodontic Adhesive. Dentistry Journal. 2018; 6(3):39. https://doi.org/10.3390/dj6030039

Chicago/Turabian StyleDegrazia, Felipe Weidenbach, Bruna Genari, Vilmar Antonio Ferrazzo, Ary Dos Santos-Pinto, and Renésio Armindo Grehs. 2018. "Enamel Roughness Changes after Removal of Orthodontic Adhesive" Dentistry Journal 6, no. 3: 39. https://doi.org/10.3390/dj6030039