Long-Wavelength InAs/GaAs Quantum-Dot Light Emitting Sources Monolithically Grown on Si Substrate

Abstract

:1. Introduction

2. Quantum Dot Lasers on Si Substrates

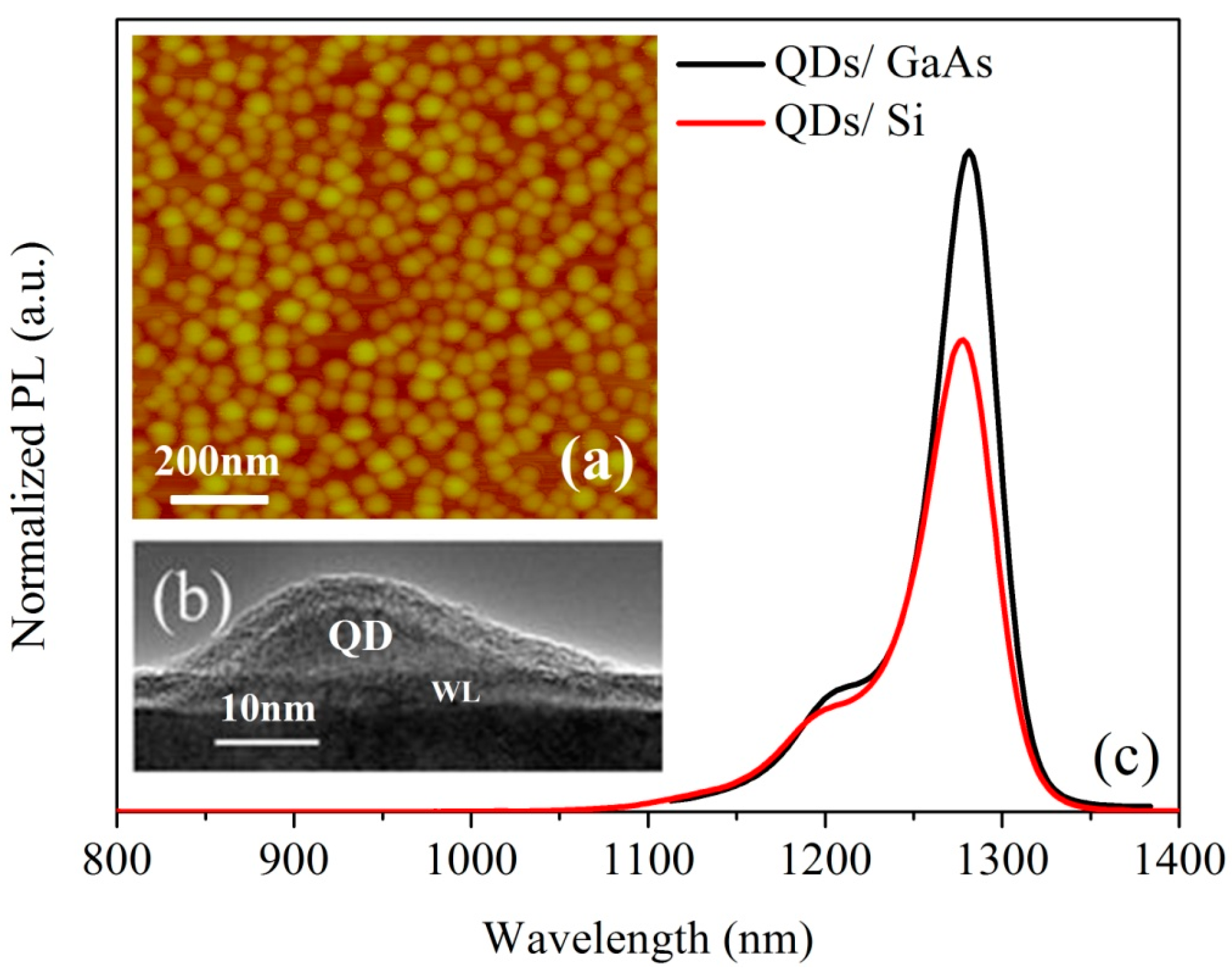

2.1. MBE Growth and Effect of InAlAs/GaAs SLSs on the Quality of III-V Material Grown on Si Substrates

2.2. Device Fabrication of Si-Based Lasers

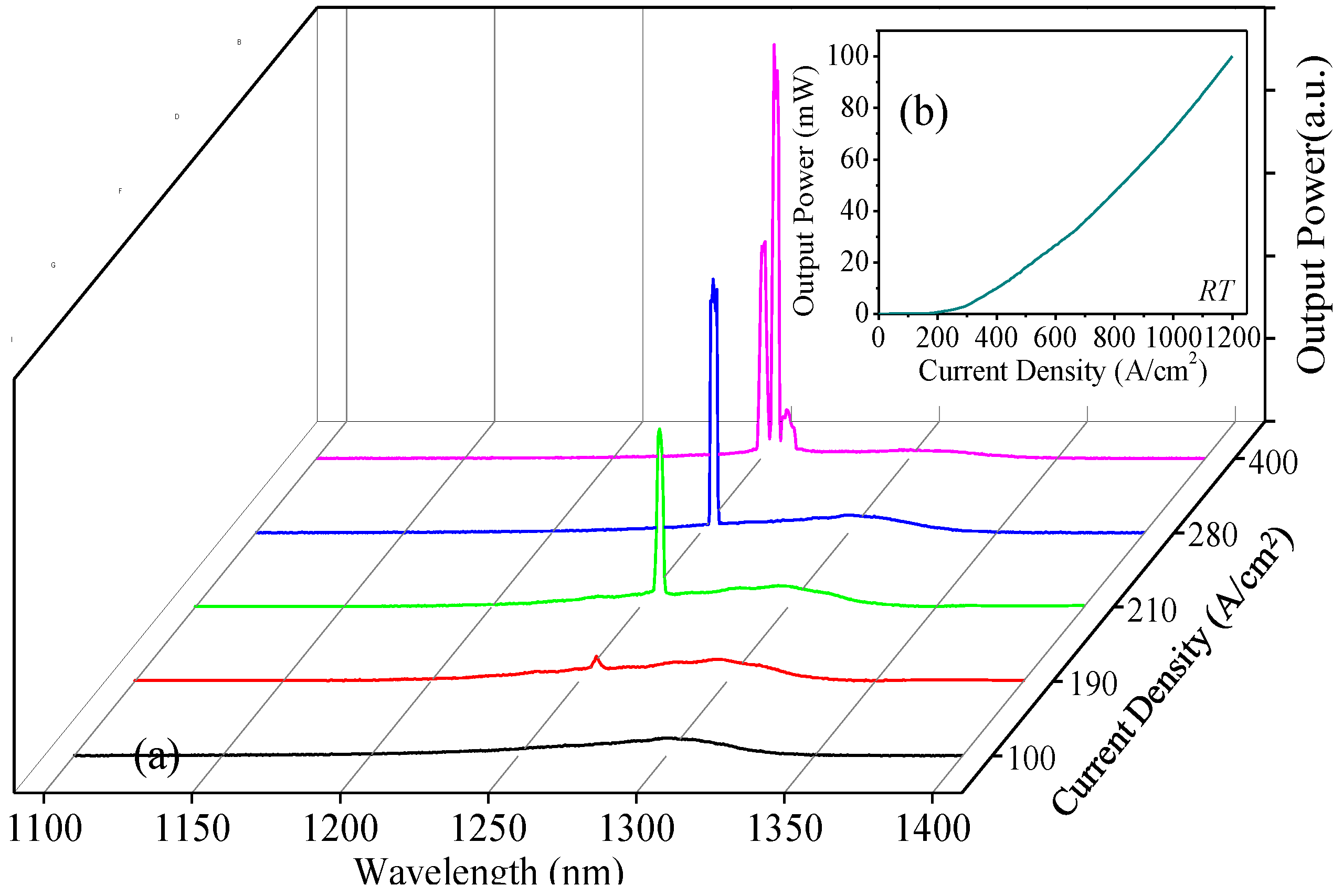

2.3. Results and Discussion

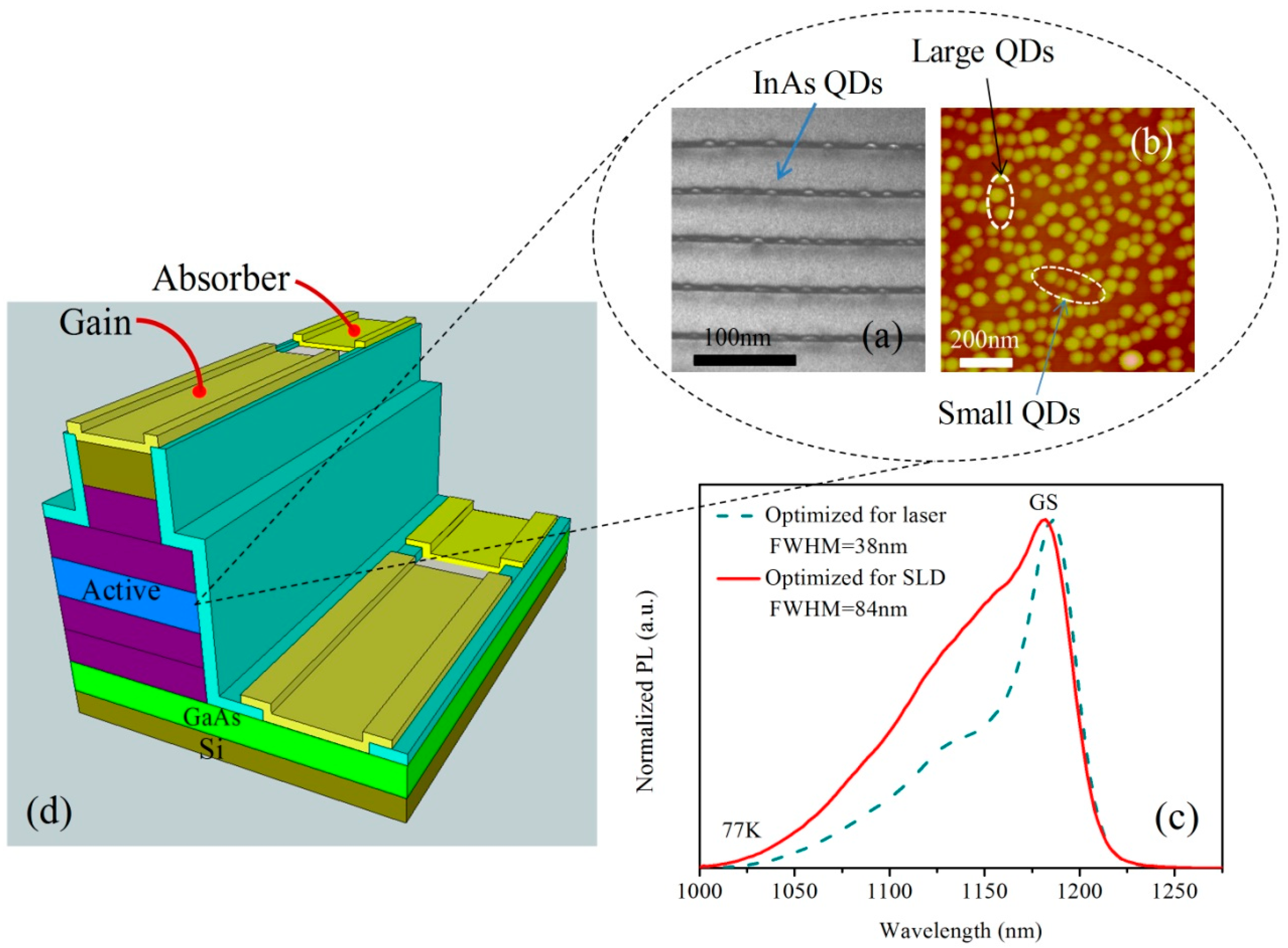

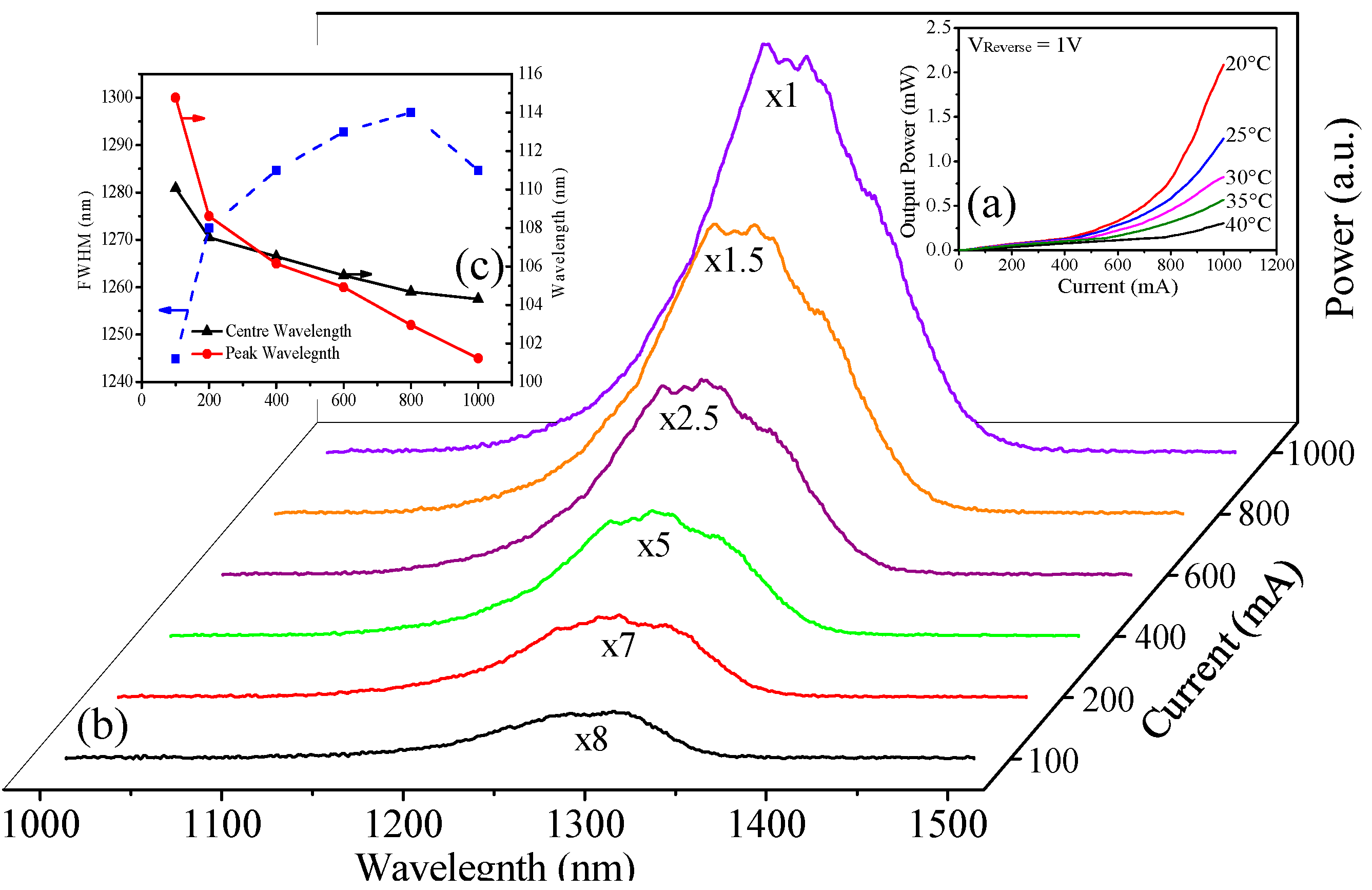

3. Quantum Dot SLDs on Si Substrates

3.1. Experimental Procedure

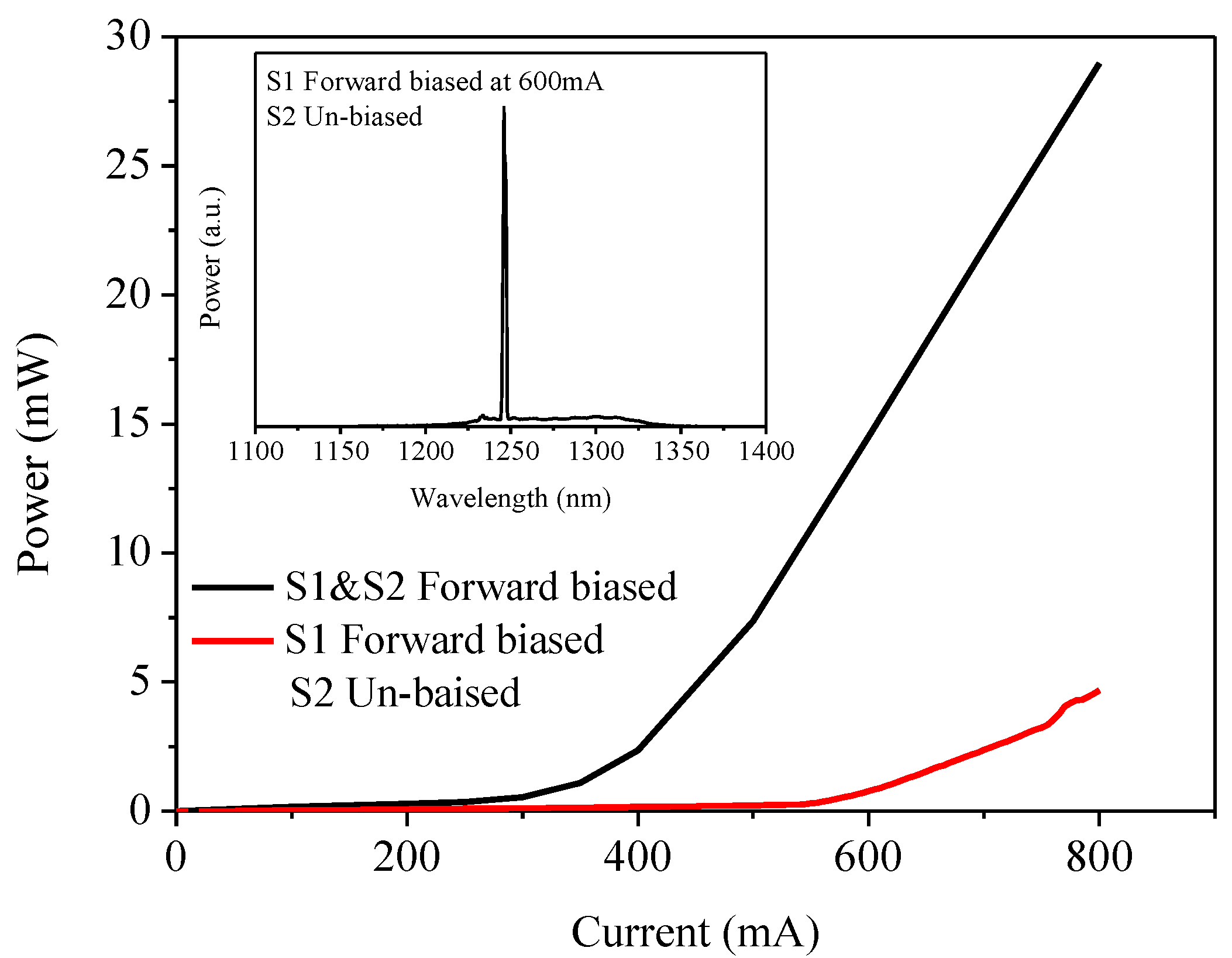

3.2. Results and Discussion

4. Conclusion

Acknowledgments

Author Contributions

Conflict of Interest

References

- Liang, D.; Bowers, J.E. Recent progress in lasers on silicon. Nat. Photonics 2010, 4, 511–517. [Google Scholar]

- Lee, J.W.; Shichijo, H.; Tsai, H.L.; Matyi, R.J. Defect reduction by thermal annealing of GaAs layers grown by molecular beam epitaxy on Si substrates. Appl. Phys. Lett. 1987, 50, 31–33. [Google Scholar]

- Masselink, W.T.; Henderson, T.; Klem, J.; Fischer, R.; Pearah, P.; Morkoç, H.; Hafich, M.; Wang, P.D.; Robinson, G.Y. Optical properties of GaAs on (100) Si using molecular beam epitaxy. Appl. Phys. Lett. 1984, 45, 1309–1311. [Google Scholar] [CrossRef]

- Metze, G.M.; Choi, H.K.; Tsaur, B.-Y. Metal-semiconductor field-effect transistors fabricated in GaAs layers grown directly on Si substrates by molecular beam epitaxy. Appl. Phys. Lett. 1984, 45, 1107–1109. [Google Scholar] [CrossRef]

- Wang, T.; Liu, H.; Lee, A.; Pozzi, A.; Seeds, A. 1.3-μm InAs/GaAs quantum-dot lasers monolithically grown on Si substrates. Opt. Express 2011, 19, 11381–11386. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Lee, A.; Tutu, F.; Seeds, A.; Liu, H.; Groom, K.; Hogg, R.A. The effect of growth temperature of GaAs nucleation layer on InAs/GaAs quantum dots monolithically grown on Ge substrates. Appl. Phys. Lett. 2012, 100, 052113–1–052113–3. [Google Scholar] [CrossRef]

- Fischer, R.; Neuman, D.; Zabel, H.; Morkoç, H.; Chai, C.; Otsuka, N. Dislocation reduction in epitaxial GaAs on Si(100). Appl. Phys. Lett. 1986, 43, 1223–1225. [Google Scholar] [CrossRef]

- Tang, M.; Chen, S.; Wu, J.; Jiang, Q.; Dorogan, V.G.; Benamara, M.; Mazur, Y.I.; Salamo, G.J.; Seeds, A.; Liu, H. 1.3-μm InAs/GaAs quantum-dot lasers monolithically grown on Si substrates using InAlAs/GaAs dislocation filter layers. Opt. Express 2014, 22, 11528–11535. [Google Scholar] [CrossRef] [PubMed]

- Ward, T.; Sánchez, A.M.; Tang, M.; Wu, J.; Liu, H.; Dunstan, D.J.; Beanland, R. Design rules for dislocation filters. J. Appl. Phys. 2014, 116, 063508–1–063508–10. [Google Scholar] [CrossRef]

- Tang, M.; Wu, J.; Chen, S.; Jiang, Q.; Seeds, A.; Liu, H.; Dorogan, V.G.; Benamara, M.; Mazur, Y.I.; Salamo, G. Optimisation of the dislocation filter layers in 1.3-μm InAs/GaAs quantum-dot lasers monolithically grown on Si substrates. J. IET Optoelectronics 2015, 9, 61–64. [Google Scholar] [CrossRef]

- Liu, H.; Childs, D.; Badcock, T.J.; Groom, K.M.; Sellers, I.R.; Mopkinson, M.; Hogg, R.A.; Robbins, D.J.; Mowbray, D.J.; Skolnick, M.S. High-performance three-layer 1.3-μm InAs-GaAs quantum-dot lasers with very low continuous-wave room-temperature threshold currents. IEEE Photon. Technol. Lett. 2005, 17, 1139–1141. [Google Scholar] [CrossRef]

- Liu, H.; Wang, T.; Jiang, Q.; Hogg, R.; Tutu, F.; Pozzi, F.; Seeds, A. Long-wavelength InAs/GaAs quantum-dot laser diode monolithically grown on Ge substrate. Nat. Photon. 2011, 5, 416–419. [Google Scholar] [CrossRef]

- Lee, A.; Jiang, Q.; Tang, M.; Seed, A.; Liu, H. Continuous-wave InAs/GaAs quantum-dot laser diodes monolithically grown on Si substrate with low threshold current densities. Opt. Express 2012, 20, 22181–22187. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.D.; Jiang, Q.; Tang, M.; Zhang, Y.; Seeds, A.J.; Liu, H. InAs/GaAs quantum-dot lasers monolithically grown on Si, Ge, and Ge-on-Si substrates. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1901107–1–1901107–7. [Google Scholar] [CrossRef]

- Liu, A.Y.; Zhang, C.; Norman, J.; Snyder, A.; Lubyshev, D.; Fastenau, J.M.; Liu, A.W.; Gossard, A.C.; Bowers, J.E. High performance continuous wave 1.3 μm quantum dot lasers on silicon. Appl. Phys. Lett. 2014, 104, 041104–1–041104–4. [Google Scholar] [CrossRef]

- Chen, S.; Tang, M.; Jiang, Q.; Wu, J.; Dorogan, V.G.; Benamara, M.; Mazur, Y.I.; Salamo, G.J.; Seeds, A.; Liu, H. 1.3-μm InAs/GaAs quantum-dot laser monolithically grown on Si Substrates operating over 100°C. Electron. Lett. 2014, 50, 1467–1468. [Google Scholar] [CrossRef]

- Chen, S.; Tang, M.; Wu, J.; Jiang, Q.; Dorogan, V.G.; Benamara, M.; Mazur, Y.I.; Salamo, G.J.; Smowton, P.; Seeds, A.; Liu, H. InAs/GaAs Quantum-Dot Superluminescent Light-Emitting Diode Monolithically Grown on a Si Substrate. ACS Photonics 2014, 1, 638–642. [Google Scholar] [CrossRef]

- Wu, J.; Lee, A.; Tang, M.; Zhang, Y.; Seeds, A.; Liu, H. Electrically pumped continuous-wave 1.3-µm InAs/GaAs quantum dot lasers monolithically grown on Si substrates. IET Optoelectronics 2014, 8, 20–24. [Google Scholar] [CrossRef]

- Burns, W.K.; Chen, C.; Moeller, R.P. Depolarization in a single-mode optical fiber. J. Lightw. Technol. 1983, LT1, 98–105. [Google Scholar] [CrossRef]

- Huang, D.; Swanson, E.A.; Lin, C.P.; Shuman, J.S.; Stinson, W.G.; Chang, W.; Hee, M.R.; Flotte, T.; Gregory, K.; Puliafito, C.A.; et al. Optical Coherence Tomography. Science 1991, 254, 1178–1181. [Google Scholar] [CrossRef] [PubMed]

- Park, S.F.; Lee, C.H.; Jeong, K.T.; Park, H.J.; Ahn, J.G.; Song, K.H. Fiber-to-the-Home Services Based on Wavelength-Division-Multiplexing Passive Optical Network. J. Lightw. Technol. 2004, 22, 2582–2591. [Google Scholar] [CrossRef]

- Ebiko, Y.; Muto, S.; Suzuki, D.; Itoh, S.; Shiramine, K.; Haga, T.; Nakata, Y.; Yokoyama, N. Island Size Scaling in InAs/GaAs Self-Assembled Quantum Dots. Phys. Rev. Lett. 1998, 80, 2650–2653. [Google Scholar] [CrossRef]

- Liu, H.; Sellers, I.; Badcock, T.; Mowbray, D.; Skolnick, M.; Groom, K.; Gutierrez, M.; Hopkinson, M.; Ng, J.; David, J. Improved performance of 1.3 μm multilayer InAs quantum-dot lasers using a high-growth temperature GaAs spacer layer. Appl. Phys. Lett. 2004, 85, 704–706. [Google Scholar] [CrossRef]

- Yang, J.; Bhattacharya, P.; Mi, Z. High-Performance In0.5Ga0.5 As/GaAs Quantum-Dot Lasers on Silicon With Multiple-Layer Quantum-Dot Dislocation Filters. IEEE Trans. Electron. Dev. 2007, 54, 2849–2855. [Google Scholar] [CrossRef]

- Gourley, P.L.; Drummond, T.J.; Doyle, B.L. Dislocation filtering in semiconductor superlattices with lattice-matched and lattice-mismatched layer materials. Appl. Phys. Lett. 1986, 49, 1101–1103. [Google Scholar] [CrossRef]

- Shchekin, O.; Deppe, D. 1.3 μm InAs quantum dot laser with To=161 K from 0 to 80 °C. Appl. Phys. Lett. 2002, 80, 3277–3279. [Google Scholar] [CrossRef]

- Sugawara, M.; Usami, M. Quantum dot devices: Handling the heat. Nat. Photon. 2009, 3, 30–31. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Hogg, R.A.; Lv, X.Q.; Wang, Z.G. Self-assembled quantum-dot superluminescent light-emitting diodes. Adv. Opt. Photon. 2010, 2, 201–228. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, K.; Zhang, Z.; Orchard, J.; Childs, D.T.D.; Hugues, M.; Wada, O.; Hogg, R.A. Hybrid Quantum Well/Quantum Dot Structure for Broad Spectral Bandwidth Emitters. IEEE J. Select. Topics Quantum Electron. 2013, 19. [Google Scholar] [CrossRef]

- Jiang, Q.; Tang, M.; Chen, S.; Wu, J.; Seeds, A.; Liu, H. InAs/GaAs quantum-dot superluminescent diodes monolithically grown on a Ge substrate. Opt. Express 2014, 22, 23242–23248. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Rossetti, M.; Fiore, A.; Occhi, L.; Velez, C. Wide emission spectrum from superluminescent diodes with chirped quantum dot multilayers. Electron. Lett. 2005, 41, 41–43. [Google Scholar] [CrossRef]

- Zhou, K.; Jiang, Q.; Zhang, Z.; Chen, S.; Liu, H.; Lu, Z.; Kennedy, K.; Matcher, S.; Hogg, R.A. Quantum dot selective area intermixing for broadband light sources. Opt. Express 2012, 20, 26950–26957. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Zhou, K.; Zhang, Z.; Childs, D.T.D.; Hugues, M.; Ramsay, A.; Hogg, R.A. Ultra-broad spontaneous emission and modal gain spectrum from a hybrid quantum well/quantum dot laser structure. Appl. Phys. Lett. 2012, 100, 041118. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, K.; Zhang, Z.; Wada, O.; Childs, D.T.D.; Hugues, M.; Jin, X.; Hogg, R.A. Room temperature simultaneous three-state lasing in hybrid quantum well/quantum dot laser. Electron. Lett. 2012, 48, 644–646. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Tang, M.; Wu, J.; Jiang, Q.; Dorogan, V.; Benamara, M.; Mazur, Y.I.; Salamo, G.J.; Liu, H. Long-Wavelength InAs/GaAs Quantum-Dot Light Emitting Sources Monolithically Grown on Si Substrate. Photonics 2015, 2, 646-658. https://doi.org/10.3390/photonics2020646

Chen S, Tang M, Wu J, Jiang Q, Dorogan V, Benamara M, Mazur YI, Salamo GJ, Liu H. Long-Wavelength InAs/GaAs Quantum-Dot Light Emitting Sources Monolithically Grown on Si Substrate. Photonics. 2015; 2(2):646-658. https://doi.org/10.3390/photonics2020646

Chicago/Turabian StyleChen, Siming, Mingchu Tang, Jiang Wu, Qi Jiang, Vitaliy Dorogan, Mourad Benamara, Yuriy I. Mazur, Gregory J. Salamo, and Huiyun Liu. 2015. "Long-Wavelength InAs/GaAs Quantum-Dot Light Emitting Sources Monolithically Grown on Si Substrate" Photonics 2, no. 2: 646-658. https://doi.org/10.3390/photonics2020646