Refractive Index Measurement of Liquids Based on Microstructured Optical Fibers

Abstract

:1. Introduction

2. Overview of Refractometer-Based Microstructured Fibers

2.1. Interferometric-Based MOF Configurations

2.2. Resonance-Based MOF Configurations

| Structure Device | RI Range | RI Sensitivity | Resolution (RIU) | Reference |

|---|---|---|---|---|

| Fiber tip | 1.38–1.44 | - | 2.9 × 10−4 | [23,24] |

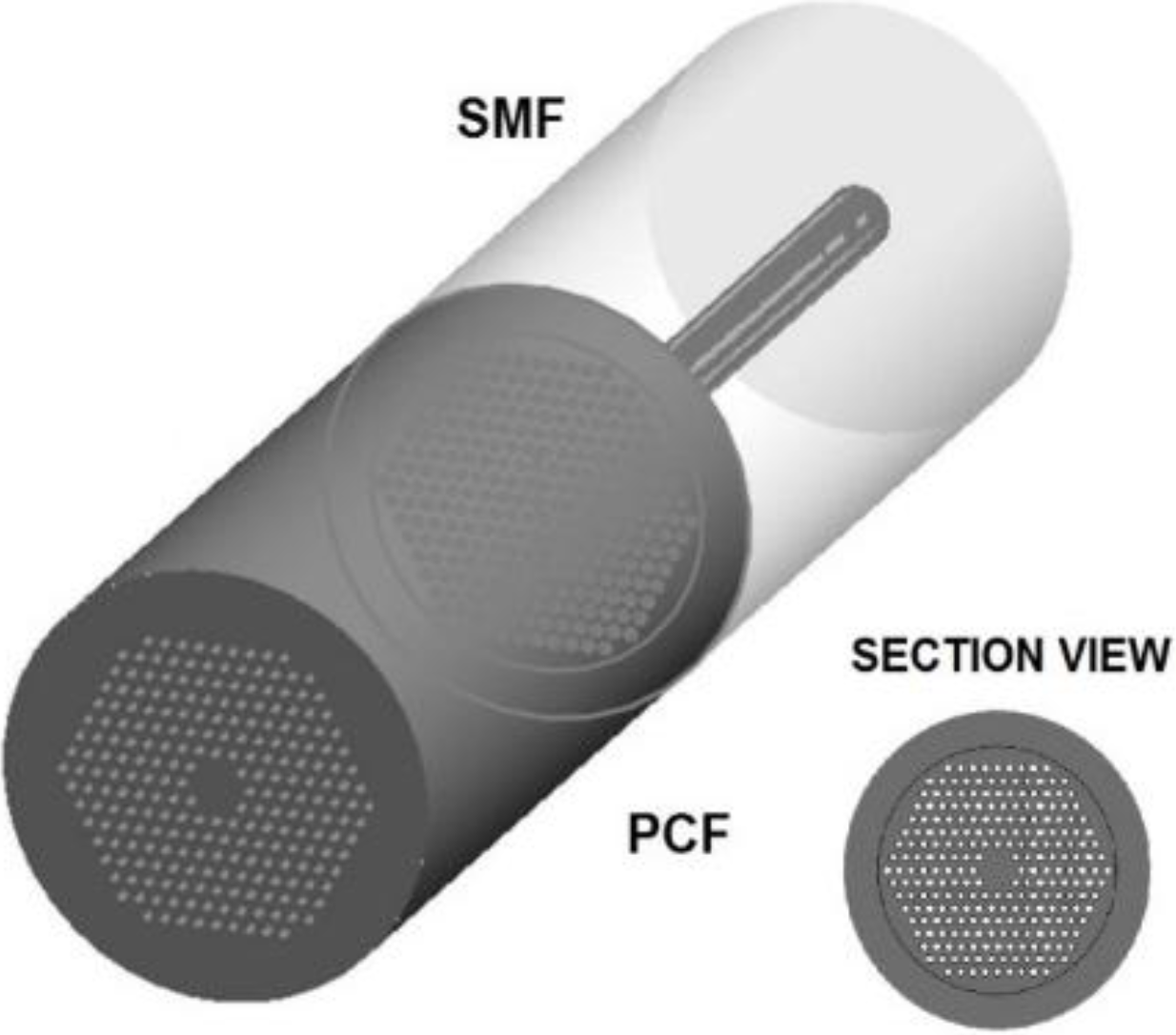

| SMF/ large-mode area PCF | 1.33–1.38 | 2 × 10−3 | ||

| Fabry-Perot fiber tip | 1.32–1.44 | 4.59/RI | 2 × 10−5 | [25] |

| SMF/endlessly singlemode PCF/SMF | ||||

| Fabry-Perot fiber tip | 1.332–1.427 | –11.27/RIU (Fast Fourier Transform) | 2 × 10−4 | [26] |

| SMF/ PCF/SMF | ||||

| Directional coupler architecture using a solid-core PCF | 1.50 @ 25 °C | 38,000 nm/RIU @ 52 °C | 4.6 × 10−7 | [27] |

| Interferometric fiber tip | 1.410–1.430 | 850 nm/RIU | - | [28] |

| PCF/coreless silica fiber | ||||

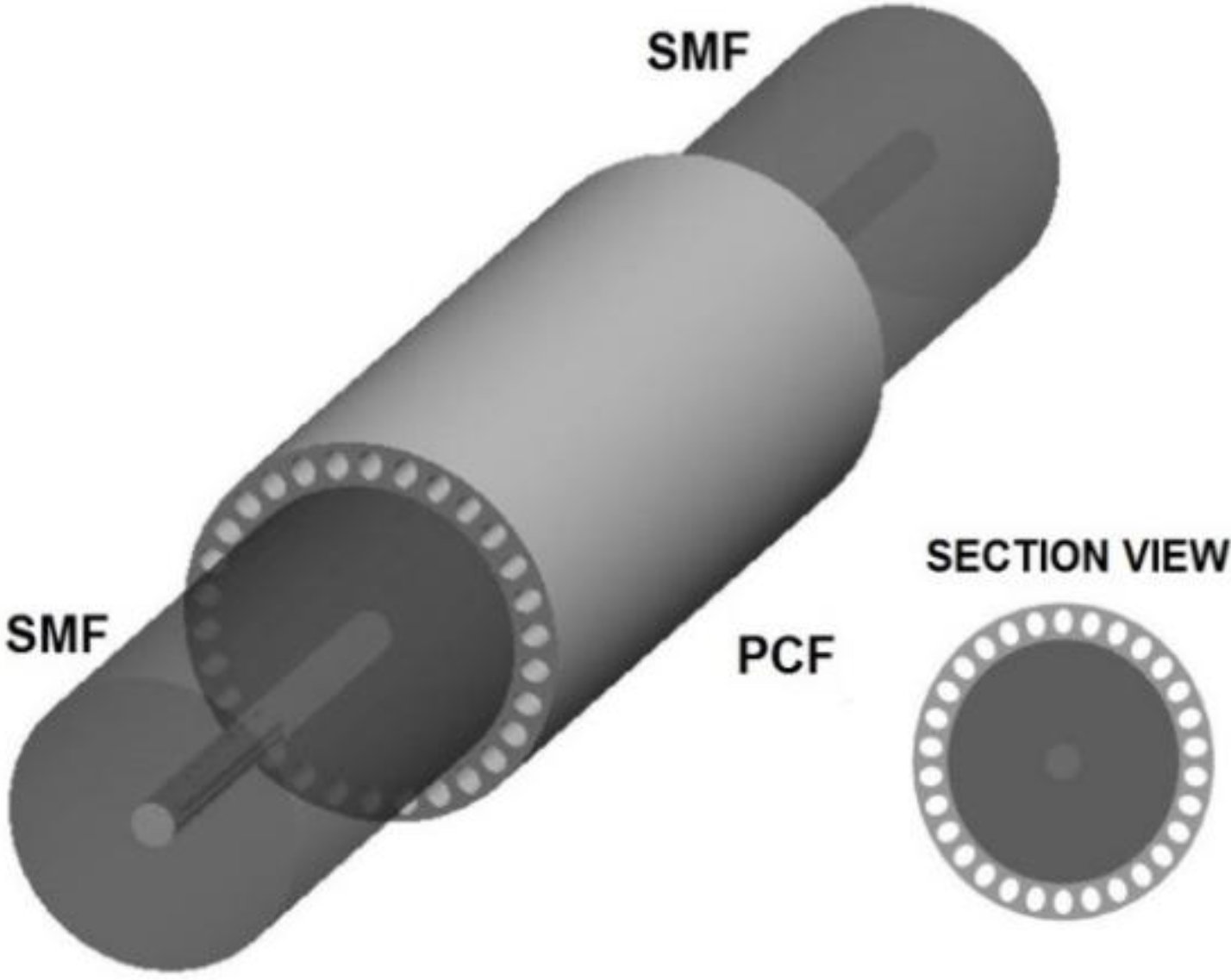

| SMF/Hollow-core PCF/SMF | 1.35–1.39 | 24.5 nm/RIU | 8.1 × 10−4 | [29] |

| 1.39–1.43 | 46.5 nm/RIU | 4.3 × 10−4 | ||

| SMF/large-core air-clad PCF/SMF | 1.3196–1.3171 | 800 nm/RIU | 3.4 × 10−5 | [30] |

| Dual-core PCF (microstructured and solid cores) | 1.33 | 8500 nm/RIU | 2.02 × 10−6 | [31] |

| Dual-core MOF (Ge-doped and side-hole cores) | 1.5–1.66 | 3259 nm/RIU (TM01) | - | [32] |

| 3183 nm/RIU (TE01) | ||||

| 2956 nm/RIU (HE21) | ||||

| Intermodal PCF interferometer | 1.340 | 70 μW/RIU | - | [33] |

| 1.360 | 679 W/RIU | 1.5 × 10−5 | ||

| Mach–Zehnder interferometer | 1.3515–1.360 | 101.25 nm/RIU | 2.9 × 10−4 | [34] |

| SMF/PCF with collapsed air holes in the splice region /SMF | ||||

| Microcell based on an endless single-mode PCF | 1.3 | 9100 nm/RIU | - | [37] |

| Two-core chirped MOF | 1.42 | 300/RIU | 3 × 10−6 | [38] |

| SPR-based solid-core gold-coated honeycomb PCF | 1.33 | 2800 nm/RIU | 3.6 × 10−5 | [39] |

| LPG written in a large-mode area PCF | 1.33 | 1500 nm/RIU | 2 × 10−5 | [40] |

| LPG written in an endlessly singlemode PCFfilled with water | 1.33–1.35 | - | 4.42 × 10−7 | [41] |

| SPR-based on a PCF with a central air hole coated with gold | 1.37–1.41 | 5500 nm/RIU | 10−6 | [42,43] |

| SPR-based on a gold-coated wagon wheel MOF | 1.33–1.36 | - | 6.5 × 10−6 | [44] |

| Rounded tip-based PCF | 1.337–1.395 | 262.28 nm/RIU | - | [45] |

| FBG written in a MOF | 1.4–1.44 | 15, 21 and 45 nm/RIU (first three-order modes) | 2.2 to 6.7 × 10−5 | [46] |

| SPR-based grapefruit PCF filled with different numbers of silver nanowires | 1.33–1.335 | 2400 nm/RIU | 4.51 × 10−5 | [47] |

| SPR-based on a closed-form multi-core holey fiber | 1.33–1.42 | 2929.39 nm/RIU | - | [48] |

| 1.43–1.53 | 9231.27 nm/RIU | |||

| SMF/tapered-PCF/SMF | 1.33–1.34 | 1629 nm/RIU | - | [49] |

| Etched two-core MOF | 1.3160–1.3943 | 3119 nm/RIU | - | [50] |

| FBG written in exposed-core MOF | 1.3–1.4 | 1.1 nm/RIU | - | [51] |

3. Conclusions

Acknowledgments

Conflict of Interest

References

- Pereira, D.A.; Frazão, O.; Santos, J.L. Fibre Bragg grating sensing system for simultaneous measurement of salinity and temperature. Opt. Eng. 2004, 43, 299–304. [Google Scholar]

- Osorio, J.H.; Mosquera, L.; Gouveia, C.J.; Biazoli, C.R.; Hayashi, J.G.; Jorge, P.A.S.; Cordeiro, C.M.B. High sensitivity LPG Mach-Zehnder sensor for real-time fuel conformity analysis. Meas. Sci. Technol. 2013, 24, 015102. [Google Scholar] [CrossRef]

- Jiménez-Márquez, F.; Vázquez, J.; Úbeda, J.; Sánchez-Rojas, J.L. Low-cost and portable refractive optoelectronic device for measuring wine fermentation kinetics. Sens. Actuators B Chem. 2013, 178, 316–323. [Google Scholar] [CrossRef]

- Zibaii, M.I.; Kazemi, A.; Latifi, H.; Azar, M.K.; Hosseini, S.M.; Ghezelaiagh, M.H. Measuring bacterial growth by refractive index tapered fiber optic biosensor. J. Photochem. Photobiol. B Biol. 2010, 3, 313–320. [Google Scholar] [CrossRef]

- Zibaii, M.I.; Latifi, H.; Karami, M.; Gholami, M.; Hosseini, S.M.; Ghezelayagh, M.H. Non-adiabatic tapered optical fiber sensor for measuring the interaction between alpha-amino acids in aqueous carbohydrate solution. Meas. Sci. Technol. 2010, 21, 105801. [Google Scholar] [CrossRef]

- Meeten, G.H.; North, A.N. Refractive index measurement of turbid colloidal fluids by transmission near the critical angle. Meas. Sci. Technol. 1991, 2, 441–447. [Google Scholar] [CrossRef]

- Rheims, J.; Koser, J.; Wriedt, T. Refractive-index measurements in the near-IR using an Abbe refractometer. Meas. Sci. Technol. 1997, 8, 601–605. [Google Scholar] [CrossRef]

- Jorge, P.A.S.; Silva, S.O.; Gouveia, C.; Tafulo, P.; Coelho, L.; Caldas, P.; Viegas, D.; Rego, G.; Baptista, J.M.; Santos, J.L.; et al. Fiber Optic-Based Refractive Index Sensing at INESC Porto. Sensors 2012, 12, 8371–8389. [Google Scholar] [CrossRef] [PubMed]

- Cooper, P.R. Refractive-index measurements of liquids used in conjunction with optical fibers. Appl. Opt. 1983, 22, 3070–3072. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Subrahmanyam, T.V.B.; Sharma, A.D.; Thyagarajan, K.; Pal, B.P.; Goyal, I.C. Novel refractometer using a tapered optical fiber. Electron. Lett. 1984, 20, 534–535. [Google Scholar] [CrossRef]

- Meyer, M.S.; Eesley, G.L. Optical fiber refractometer. Rev. Sci. Instrum. 1987, 58, 2047–2048. [Google Scholar] [CrossRef]

- Kim, C.-B.; Su, C.B. Measurement of the refractive index of liquids at 1.3 and 1.5 micron using a fiber optic Fresnel ratio meter. Meas. Sci. Technol. 2004, 15, 1683–1686. [Google Scholar] [CrossRef]

- Jorgenson, R.C.; Yee, S.S. A fiber-optic chemical sensor based on surface plasmon resonance. Sens. Actuators B Chem. 1993, 12, 213–220. [Google Scholar] [CrossRef]

- Bhatia, V.; Vengsarkar, A.M. Optical fiber long-period grating sensors. Opt. Lett. 1996, 21, 692–694. [Google Scholar] [CrossRef] [PubMed]

- Asseh, A.; Sandgren, S.; Ahlfeldt, H.; Sahlgren, B.; Edwall, G. Fiber optical Bragg refractometer. Fiber Integr. Opt. 1998, 17, 51–62. [Google Scholar] [CrossRef]

- Wang, Q.; Farrell, G. All-fiber multimode-interference based refractometer sensor: Proposal and design. Opt. Lett. 2006, 31, 317–319. [Google Scholar] [CrossRef] [PubMed]

- Silva, S.F.O.; Frazão, O.; Caldas, P.; Santos, J.L.; Araújo, F.M.; Ferreira, L.A. Optical fibre refractometer based on a Fabry-Pérot interferometer. Opt. Eng. 2008, 47, 054403. [Google Scholar] [CrossRef]

- Fini, J.M. Microstructure fibres for optical sensing in gases and liquids. Meas. Sci. Technol. 2004, 15, 1120–1128. [Google Scholar] [CrossRef]

- Cordeiro, C.M.B.; Franco, M.A.R.; Chesini, G.; Barretto, E.C.S.; Lwin, R.; Cruz, C.H.B.; Large, M.C.J. Microstructured-core optical fibre for evanescent sensing applications. Opt. Exp. 2006, 14, 13056–13066. [Google Scholar] [CrossRef]

- Troia, B.; Paolicelli, A.; Leonardis, F.D.; Passaro, V.M.N. Photonic Crystals for Optical Sensing: A Review. In Advances in Photonic Crystals; Vittorio, P., Ed.; InTech: Rijeka, Croatia, 2013; pp. 241–295. [Google Scholar]

- Frazão, O.; Santos, J.; Araújo, F.; Ferreira, L. Optical sensing with photonic crystal fibers. Laser Photon. Rev. 2008, 2, 449–459. [Google Scholar] [CrossRef]

- Pinto, A.M.R.; Lopez-Amo, M. Photonic Crystal Fibers for Sensing Applications. J. Sens. 2012, 12, 598178. [Google Scholar]

- Jha, R.; Villatoro, J.; Badenes, G. Ultrastable in reflection photonic crystal fiber modal interferometer for accurate refractive index sensing. Appl. Phys. Lett. 2008, 93, 191106. [Google Scholar] [CrossRef]

- Jha, R.; Villatoro, J.; Badenes, G.; Pruneri, V. Refractometry based on a photonic crystal fiber interferometer. Opt. Lett. 2009, 34, 617–619. [Google Scholar] [CrossRef] [PubMed]

- Rao, Y.-J.; Deng, M.; Duan, D.-W.; Zhu, T. In line fiber Fabry Perot refractive index tip sensor based on endlessly photonic crystal fiber. Sens. Actuators A Phys. 2008, 148, 33–38. [Google Scholar] [CrossRef]

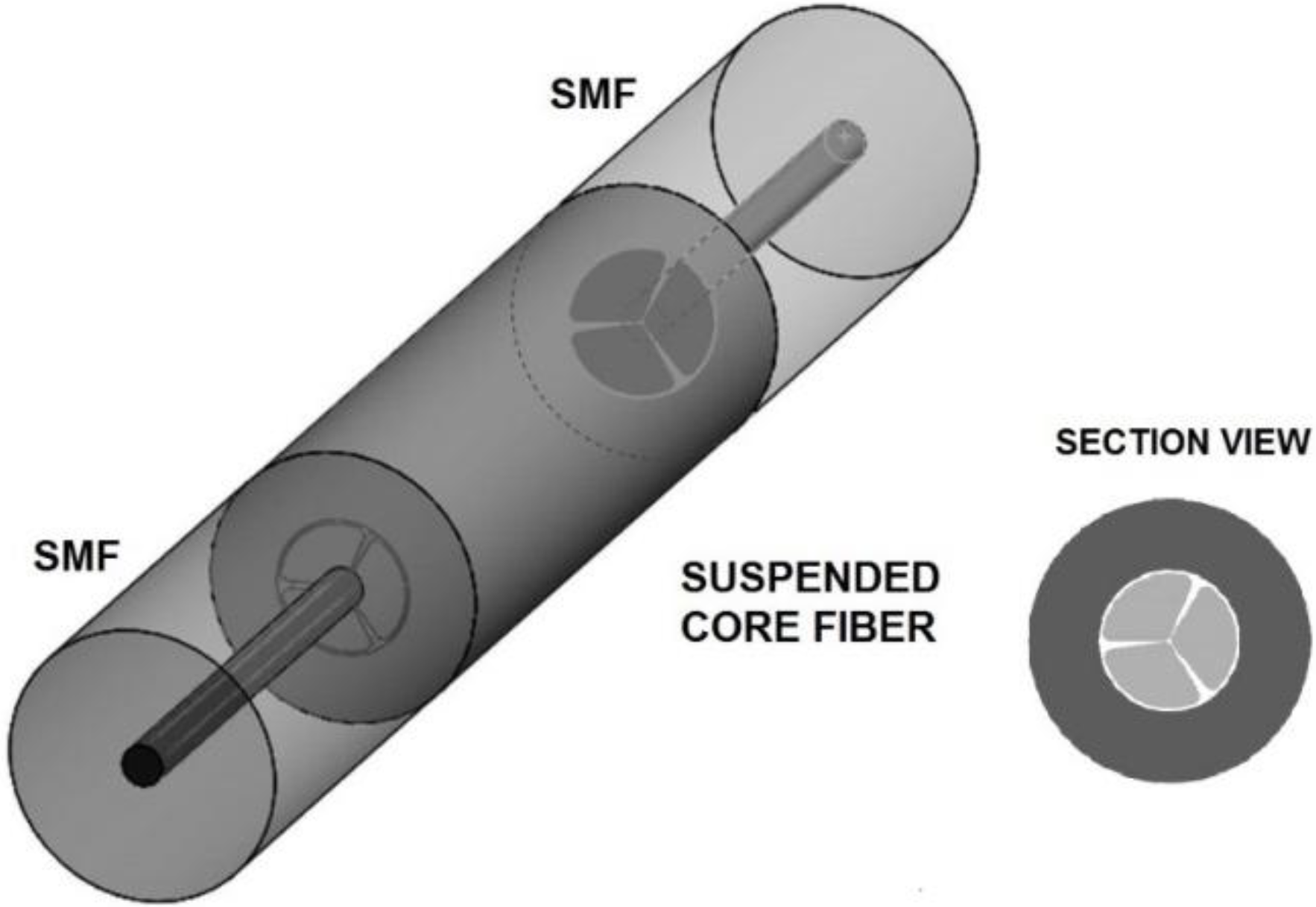

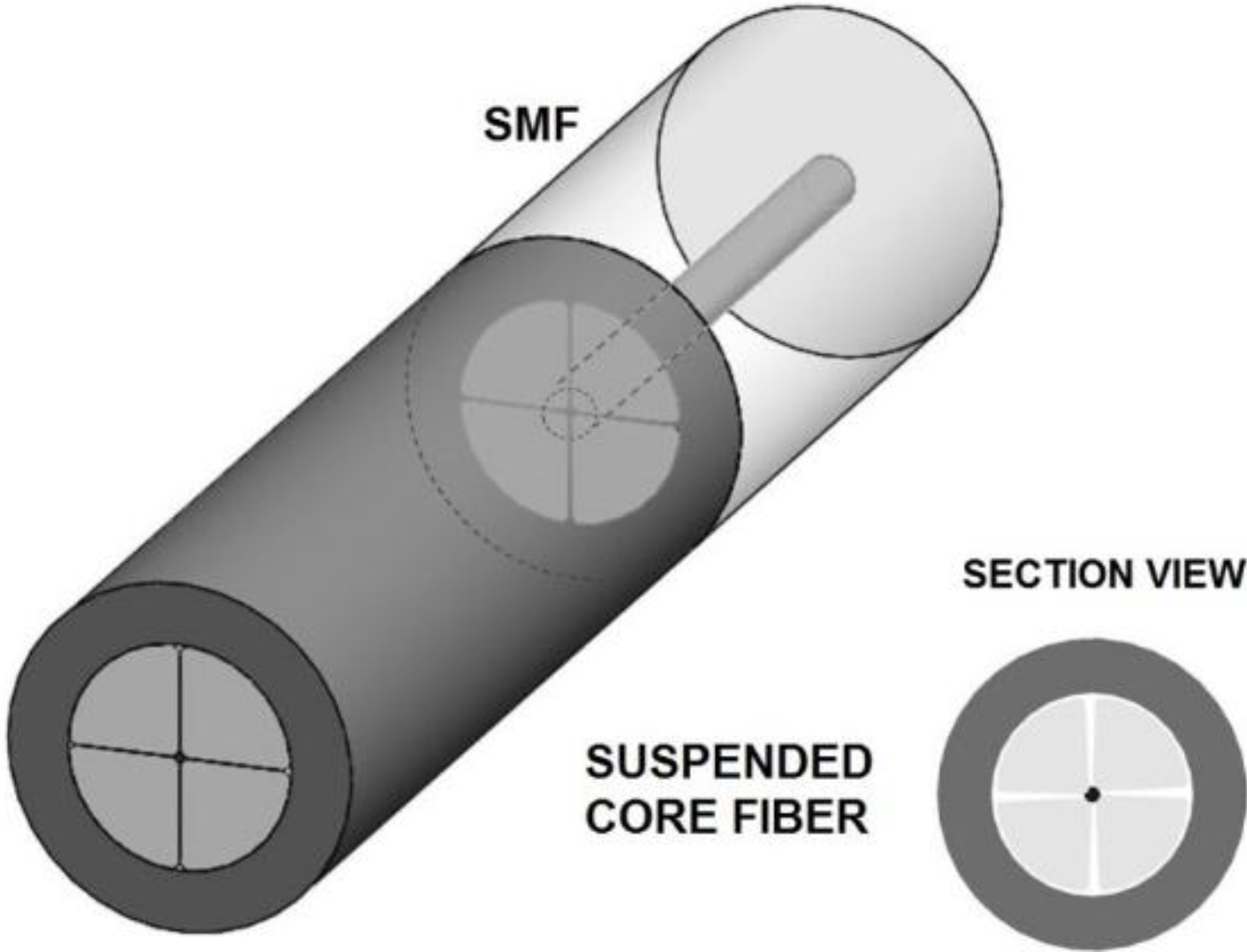

- Frazão, O.; Baptista, J.M.; Santos, J.L.; Kobelke, J.; Schuster, K. Refractive index tip sensor based on Fabry-Perot cavities formed by a suspended core fibre. JEOS:RP 2009, 4, 09041. [Google Scholar] [CrossRef]

- Wu, D.K.C.; Kuhlmey, B.T.; Eggleton, B.J. Ultrasensitive photonic crystal fiber refractive index sensor. Opt. Lett. 2009, 34, 322–324. [Google Scholar] [CrossRef] [PubMed]

- Park, K.S.; Choi, H.Y.; Park, S.J.; Paek, U.-C.; Lee, B.H. Temperature Robust Refractive Index Sensor Based on a Photonic Crystal Fiber Interferometer. IEEE Sens. J. 2010, 10, 1147–1148. [Google Scholar] [CrossRef]

- Gong, H.; Chan, C.C.; Zhang, Y.F.; Wong, W.C.; Dong, X. Miniature refractometer based on modal interference in a hollow-core photonic crystal fiber with collapsed splicing. J. Biomed. Opt. 2011, 16, 017004. [Google Scholar] [CrossRef] [PubMed]

- Silva, S.; Santos, J.L.; Malcata, F.X.; Kobelke, J.; Schuster, K.; Frazão, O. Optical Refractometer based on Large-Core Air-Clad Photonic Crystal fibers. Opt. Lett. 2011, 36, 852–854. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Chen, M.-Y.; Zhang, Y.-K.; Yang, J.-C.; Yao, J.-Q.; Cui, H.-X. Microstructured-core photonic-crystal fiber for ultra-sensitive refractive index sensing. Opt. Express 2011, 19, 4091–4100. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.W.; Schmidt, M.A.; Uebel, P.; Tyagi, H.; Joly, N.Y.; Scharrer, M.; Russell, P.S. Optofluidic refractive-index sensor in step-index fiber with parallel hollow micro-channel. Opt. Express 2011, 19, 8200–8007. [Google Scholar] [PubMed]

- Qian, W.; Chan, C.C.; Zhao, C.-L.; Liu, Y.; Li, T.; Hu, L.; Ni, K.; Dong, X. Photonic crystal fiber refractive index sensor based on a fiber Bragg grating demodulation. Sens. Actuators B Chem. 2012, 166–167, 761–765. [Google Scholar] [CrossRef]

- Wong, W.C.; Zhou, W.; Chan, C.C.; Dong, X.; Leong, K.C. Cavity ringdown refractive index sensor using photonic crystal fiber interferometer. Sens. Actuators B Chem. 2012, 161, 108–113. [Google Scholar] [CrossRef]

- Moura, J.P.; Baierl, H.; Auguste, J.-L.; Jamier, R.; Roy, P.; Santos, J.L.; Frazão, O. Evaporation of volatile compounds in suspended-core fibers. Opt. Lett. 2014, 39, 3868–3871. [Google Scholar] [CrossRef] [PubMed]

- Silva, S.O.; Auguste, J.-L.; Jamier, R.; Rougier, S.; Baptista, J.M.; Santos, J.L.; Roy, P.; Frazão, O. Detection of Evaporation Process of Acetone with a Microstructured fibre in a Reflective Configuration. Opt. Eng. Lett. 2014, 53, 080501. [Google Scholar] [CrossRef]

- Wang, C.; Jin, W.; Liao, C.; Ma, J.; Jin, W.; Yang, F.; Ho, H.L.; Wang, Y. Highly birefringent suspended-core photonic microcells for refractive-index sensing. Appl. Phys. Lett. 2014, 105, 061105. [Google Scholar] [CrossRef]

- Torres, P.; Reyes-Vera, E.; Díez, A.; Andrés, M.V. Two-core transversally chirped microstructured optical fiber refractive index sensor. Opt. Lett. 2014, 39, 1593–1596. [Google Scholar] [CrossRef] [PubMed]

- Hassani, A.; Gauvreau, B.; Fehri, M.F.; Kabashin, A.; Skorobogatiy, M. Photonic Crystal Fiber and Waveguide-Based Surface Plasmon Resonance. Electromagnetics 2008, 28, 198–213. [Google Scholar] [CrossRef]

- Rindorf, L.; Bang, O. Highly sensitive refractometer with a photonic-crystal-fiber long-period grating. Opt. Lett. 2008, 33, 563–565. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Zhu, Y.; Du, H. Long-period gratings inscribed in air- and water-filled photonic crystal fiber for refractometric sensing of aqueous solution. Appl. Phys. Lett. 2008, 92, 044105. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, Y.; Pan, S.; Shum, P.; Yan, M.; Leviatan, Y.; Li, C. A selectively coated photonic crystal fiber based surface plasmon resonance sensor. J. Opt. 2010, 12, 015005. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, L.; Zhou, C.; Yu, X.; Liu, H.; Liu, D.; Zhang, Y. Microstructured fiber based plasmonic index sensor with optimized accuracy and calibration relation in large dynamic range. Opt. Commun. 2011, 284, 4161–4166. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, C.; Xia, L.; Yu, X.; Liu, D. Wagon wheel fiber based multichannel plasmonic sensor. Opt. Express 2011, 19, 22863–22873. [Google Scholar] [CrossRef] [PubMed]

- Wong, W.C.; Chan, C.C.; Chen, L.H.; Tou, Z.Q.; Leong, K.C. Highly sensitive miniature photonic crystal fiber refractive index sensor based on mode field excitation. Opt. Lett. 2011, 36, 1731–1733. [Google Scholar] [CrossRef] [PubMed]

- Zhang, A.P.; Yan, G.; Gao, S.; He, S.; Kim, B.; Im, J.; Chung, Y. Microfluidic refractive-index sensors based on small-hole microstructured optical fiber Bragg gratings. Appl. Phys. Lett. 2011, 98, 221109. [Google Scholar] [CrossRef]

- Lu, Y.; Hao, C.-J.; Wu, B.-Q.; Huang, X.-H.; Wen, W.-Q.; Fu, X.-Y.; Yao, J.-Q. Grapefruit Fiber Filled with Silver Nanowires Surface Plasmon Resonance Sensor in Aqueous Environments. Sensors 2012, 12, 12016–12025. [Google Scholar] [CrossRef] [PubMed]

- Shuai, B.; Xia, L.; Zhang, Y.; Liu, D. A multi-core holey fiber based plasmonic sensor with large detection range and high linearity. Opt. Express 2012, 20, 5974–5986. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Qiu, S.-J.; Chen, Y.; Xu, F.; Lu, Y.-Q. Ultra-Sensitive Refractive Index Sensor with Slightly Tapered Photonic Crystal Fiber. IEEE Photon. Technol. Lett. 2012, 24, 1771–1774. [Google Scholar] [CrossRef]

- Guzmán-Sepúlveda, J.R.; Guzman-Cabrera, R.; Torres-Cisneros, M.; Sánchez-Mondragón, J.J.; May-Arrioja, D.A. A Highly Sensitive Fiber Optic Sensor Based on Two-Core Fiber for Refractive Index Measurement. Sensors 2013, 13, 14200–14213. [Google Scholar] [CrossRef] [PubMed]

- Warren-Smith, S.C.; Monro, T.M. Exposed core microstructured optical fiber Bragg gratings-refractive index sensing. Opt. Express 2014, 22, 1480–1489. [Google Scholar] [CrossRef] [PubMed]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, S.; Roriz, P.; Frazão, O. Refractive Index Measurement of Liquids Based on Microstructured Optical Fibers. Photonics 2014, 1, 516-529. https://doi.org/10.3390/photonics1040516

Silva S, Roriz P, Frazão O. Refractive Index Measurement of Liquids Based on Microstructured Optical Fibers. Photonics. 2014; 1(4):516-529. https://doi.org/10.3390/photonics1040516

Chicago/Turabian StyleSilva, Susana, Paulo Roriz, and Orlando Frazão. 2014. "Refractive Index Measurement of Liquids Based on Microstructured Optical Fibers" Photonics 1, no. 4: 516-529. https://doi.org/10.3390/photonics1040516