A Variable Control Chart under the Truncated Life Test for a Weibull Distribution

Abstract

:1. Introduction

2. Proposed Chart and Its Average Run Length (ARLs)

- It is assumed that the quality characteristic of interest follows a Weibull distribution.

- The shape parameter of the Weibull distribution is assumed to be known.

- When the process is shifted, the scale parameter is changed to , where is a shift constant and is the scale parameter for the in-control process. The shape parameter remains unchanged when the process is shifted.

- Failure times are measured during the time truncated life test.

- Step 1

- Take a sample of size at each subgroup from the production process. Put them on test until the specified time .

- Step 2

- Obtain the time to failure of item i (denoted by ). Set if item i does not fail by time . Calculate statistics .

- Step 3

- Obtain , is average of . Declare the process as in-control if or as out-of-control if , where represents the control limit.

2.1. Distribution of Control Statistics and In-Control Average Run Length (ARL)

2.2. Out of Control ARL

- Prefix the value of .

- The value is obtained such that .

- As increases, we note to decrease for the same shift in process. This seems reasonable because the number of failures observed increases as increases.

- For a fixed , as decreases, also decreases because the true mean time to a failure decreases.

- For other fixed parameters, as increases from 50 to 100, the behavior of remains quite similarly, which is a desirable feature.

- For other fixed parameters, as increases from 0.5 to 2, decreases.

3. Simulation Study

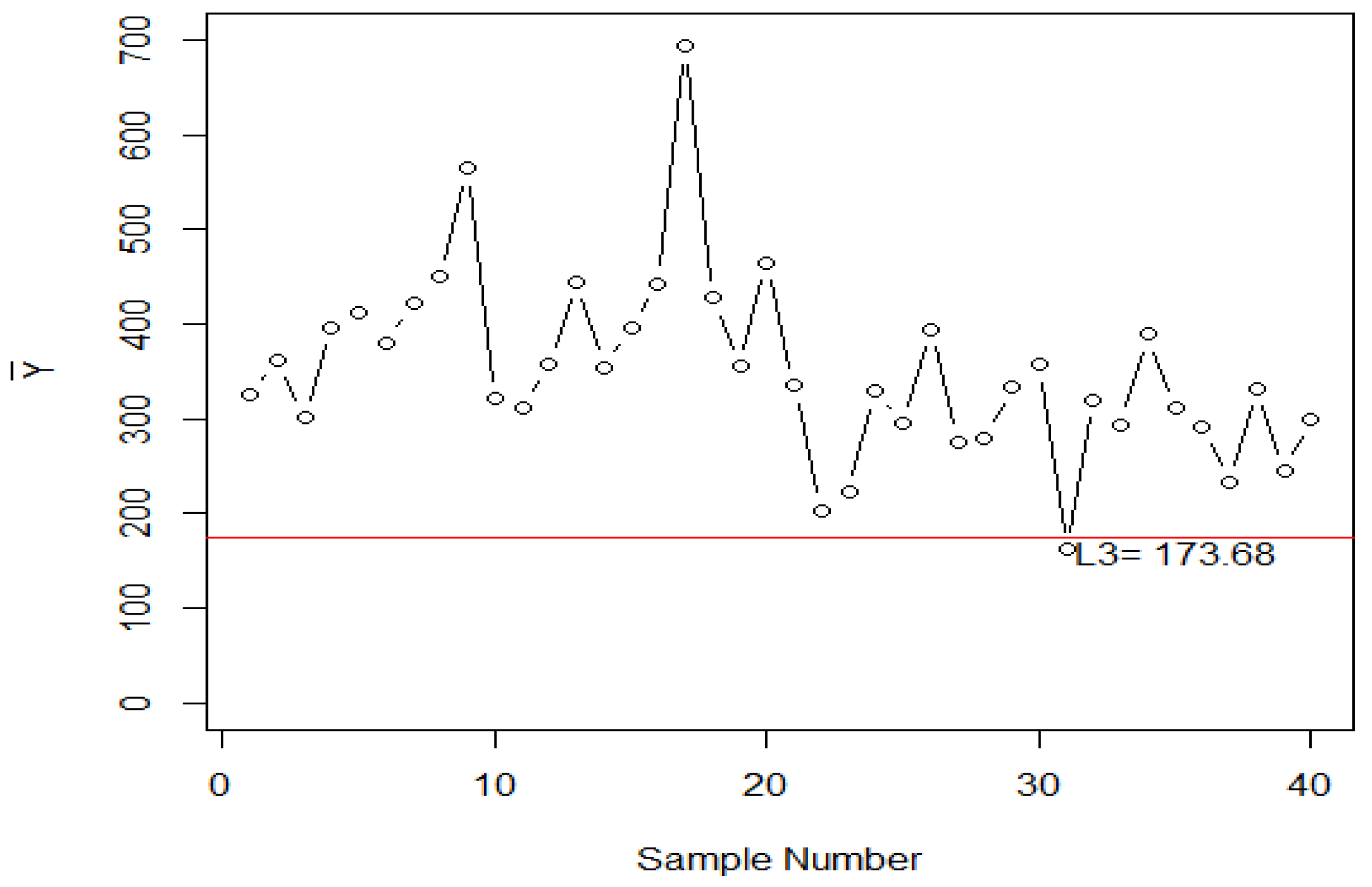

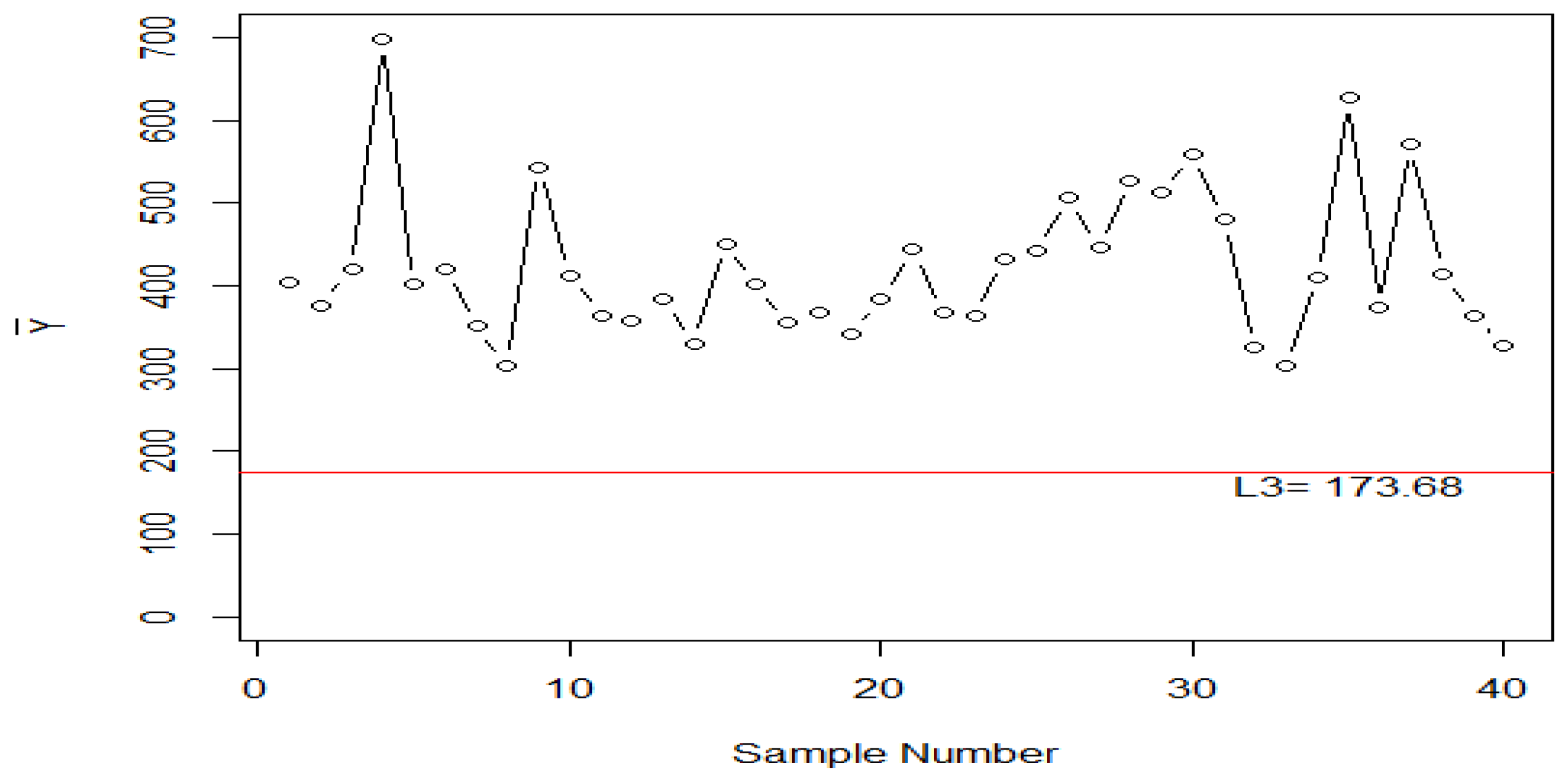

4. Real Example

- 404, 377, 420, 698, 402, 421, 352, 303, 544, 413, 365, 359, 383, 330, 451, 402, 355, 368, 342, 383, 444, 368, 364, 433, 443, 508, 447, 528, 512, 559, 481, 325, 303, 410, 628, 373, 571, 414, 364, 328.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Derya, K.; Canan, H. Control Charts for Skewed Distributions: Weibull, Gamma, and Lognormal. Metodoloski Zvezki 2012, 9, 95–106. [Google Scholar]

- Al-Oraini, H.A.; Rahim, M. Economic statistical design of X control charts for systems with Gamma (λ, 2) in-control times. Comput. Ind. Eng. 2002, 43, 645–654. [Google Scholar] [CrossRef]

- Amin, R.W.; Reynolds, M.R., Jr.; Saad, B. Nonparametric quality control charts based on the sign statistic. Commun. Stat.-Theor. Methods 1995, 24, 1597–1623. [Google Scholar] [CrossRef]

- Chang, Y.S.; Bai, D.S. Control charts for positively-skewed populations with weighted standard deviations. Qual. Reliab. Eng. Int. 2001, 17, 397–406. [Google Scholar] [CrossRef]

- Chen, F.; Yeh, C. Economic statistical design of non-uniform sampling scheme X bar control charts under non-normality and Gamma shock using genetic algorithm. Expert Syst. Appl. 2009, 36, 9488–9497. [Google Scholar] [CrossRef]

- McCracken, A.; Chakraborti, S. Control charts for joint monitoring of mean and variance: An overview. Qual. Technol. Quant. Manag. 2013, 10, 17–35. [Google Scholar] [CrossRef]

- Yen, F.Y.; Chong, K.M.B.; Ha, L.M. Synthetic-type control charts for time-between-events monitoring. PLoS ONE 2013, 8, e65440. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, S.; Riaz, M.; Abbasi, S.A.; Lin, Z. On efficient median control charting. J. Chin. Inst. Eng. 2014, 37, 358–375. [Google Scholar] [CrossRef]

- Abujiya, M.R.; Riaz, M.; Lee, M.H. Enhanced Cumulative Sum Charts for Monitoring Process Dispersion. PLoS ONE 2015, 10, e0124520. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, I.M.; Viles, E. Design of R control chart assuming a gamma distribution. Econ. Qual. Control 2001, 16, 199–204. [Google Scholar] [CrossRef]

- Lio, Y.; Park, C. A bootstrap control chart for inverse Gaussian percentiles. J. Stat. Comput. Simul. 2010, 80, 287–299. [Google Scholar] [CrossRef]

- Huang, X.; Pascual, F. ARL-unbiased control charts with alarm and warning lines for monitoring Weibull percentiles using the first-order statistic. J. Stat. Comput. Simul. 2011, 81, 1677–1696. [Google Scholar] [CrossRef]

- Lio, Y.L.; Tsai, T.-R.; Aslam, M.; Jiang, N. Control charts for monitoring Burr type-X percentiles. Commun. Stat.-Simul. Comput. 2014, 43, 761–776. [Google Scholar] [CrossRef]

- Aslam, M.; Azam, M.; Jun, C.-H. A new control chart for exponential distributed life using EWMA. Trans. Inst. Meas. Control 2015, 37, 205–210. [Google Scholar] [CrossRef]

- Aslam, M.; Jun, C.-H. Attribute Control Charts for the Weibull Distribution under Truncated Life Tests. Qual. Eng. 2015, 27, 283–288. [Google Scholar] [CrossRef]

- Aslam, M.; Khan, N.; Jun, C.-H. A control chart for time truncated life tests using Pareto distribution of second kind. J. Stat. Comput. Simul. 2016, 86, 2113–2122. [Google Scholar] [CrossRef]

- Aslam, M.; Arif, O.H.; Jun, C.-H. An Attribute Control Chart Based on the Birnbaum-Saunders Distribution Using Repetitive Sampling. In IEEE Access; IEEE: Washington, DC, USA, 2016. [Google Scholar]

- Aslam, M.; Arif, O.H.; Jun, C.-H. An attribute control chart for a Weibull distribution under accelerated hybrid censoring. PLoS ONE 2017, 12, e0173406. [Google Scholar] [CrossRef] [PubMed]

- Arif, O.-H.; Aslam, M.; Jun, C.-H. EWMA np Control Chart for the Weibull Distribution. J. Test. Eval. 2016, 45, 1022–1028. [Google Scholar] [CrossRef]

- Khan, N.; Aslam, M.; Kim, K.-J.; Jun, C.-H. A mixed control chart adapted to the truncated life test based on the Weibull distribution. Oper. Res. Decis. 2017, 27, 43–55. [Google Scholar]

- Shafqat, A.; Hussain, J.; Al-Nasser, A.D.; Aslam, M. Attribute control chart for some popular distributions. Commun. Stat.-Theor. Methods 2018, 47, 1978–1988. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

| 0.1 | 0.2 | 0.4 | 0.5 | 0.7 | 0.9 | 1 | 1.5 | |

| L | 1.45 | 1.80 | 2.15 | 2.25 | 2.39 | 2.47 | 2.51 | 2.60 |

| c | ARL1 | |||||||

| 1 | 371.89 | 370.16 | 370.03 | 370.20 | 370.32 | 370.00 | 370.15 | 370.37 |

| 0.9 | 206.44 | 198.53 | 193.29 | 192.28 | 191.36 | 191.09 | 191.28 | 192.92 |

| 0.8 | 111.78 | 103.82 | 98.36 | 97.24 | 96.19 | 95.91 | 96.03 | 97.43 |

| 0.7 | 58.89 | 52.83 | 48.67 | 47.80 | 46.94 | 46.69 | 46.72 | 47.57 |

| 0.6 | 30.11 | 26.12 | 23.40 | 22.82 | 22.23 | 22.02 | 22.01 | 22.41 |

| 0.5 | 14.92 | 12.56 | 10.96 | 10.61 | 10.24 | 10.09 | 10.07 | 10.20 |

| 0.4 | 7.18 | 5.90 | 5.05 | 4.86 | 4.65 | 4.56 | 4.54 | 4.55 |

| 0.3 | 3.40 | 2.78 | 2.38 | 2.28 | 2.18 | 2.12 | 2.11 | 2.09 |

| 0.2 | 1.67 | 1.43 | 1.27 | 1.24 | 1.20 | 1.18 | 1.17 | 1.16 |

| 0.1 | 1.04 | 1.01 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| a | ||||||||

| 0.1 | 0.2 | 0.4 | 0.5 | 0.7 | 0.9 | 1 | 1.5 | |

| L | 2.05 | 2.55 | 3.04 | 3.18 | 3.38 | 3.50 | 3.54 | 3.68 |

| c | ARL1 | |||||||

| 1 | 370.08 | 370.09 | 370.40 | 370.05 | 370.20 | 370.03 | 370.04 | 370.04 |

| 0.9 | 205.51 | 198.49 | 193.48 | 192.21 | 191.31 | 191.10 | 191.23 | 192.75 |

| 0.8 | 111.32 | 103.81 | 98.45 | 97.21 | 96.16 | 95.92 | 96.00 | 97.35 |

| 0.7 | 58.67 | 52.82 | 48.71 | 47.78 | 46.93 | 46.69 | 46.71 | 47.53 |

| 0.6 | 30.02 | 26.12 | 23.42 | 22.81 | 22.22 | 22.02 | 22.01 | 22.39 |

| 0.5 | 14.88 | 12.55 | 10.97 | 10.61 | 10.24 | 10.09 | 10.07 | 10.20 |

| 0.4 | 7.16 | 5.90 | 5.05 | 4.86 | 4.65 | 4.56 | 4.53 | 4.55 |

| 0.3 | 3.39 | 2.78 | 2.38 | 2.28 | 2.18 | 2.12 | 2.11 | 2.09 |

| 0.2 | 1.67 | 1.43 | 1.27 | 1.24 | 1.20 | 1.18 | 1.17 | 1.16 |

| 0.1 | 1.04 | 1.01 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.1 | 0.2 | 0.4 | 0.5 | 0.7 | 0.9 | 1 | 1.5 | |

| l3 | 4.32 | 7.88 | 13.44 | 15.61 | 19.05 | 21.53 | 22.49 | 25.39 |

| c | ARL1 | |||||||

| 1 | 370.49 | 370.04 | 370.05 | 370.04 | 370.02 | 370.02 | 370.00 | 370.03 |

| 0.9 | 160.24 | 140.34 | 121.26 | 115.86 | 109.00 | 105.29 | 104.19 | 103.22 |

| 0.8 | 69.80 | 54.24 | 41.14 | 37.75 | 33.62 | 31.43 | 30.77 | 29.92 |

| 0.7 | 30.74 | 21.55 | 14.70 | 13.06 | 11.14 | 10.13 | 9.81 | 9.30 |

| 0.6 | 13.78 | 8.94 | 5.69 | 4.97 | 4.14 | 3.71 | 3.57 | 3.30 |

| 0.5 | 6.36 | 3.97 | 2.51 | 2.21 | 1.86 | 1.69 | 1.63 | 1.50 |

| 0.4 | 3.10 | 1.98 | 1.38 | 1.26 | 1.14 | 1.09 | 1.07 | 1.04 |

| 0.3 | 1.67 | 1.22 | 1.03 | 1.02 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.2 | 1.11 | 1.01 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.1 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| a | ||||||||

| 0.1 | 0.2 | 0.4 | 0.5 | 0.7 | 0.9 | 1 | 1.5 | |

| l3 | 8.63 | 15.75 | 26.87 | 31.22 | 38.09 | 43.05 | 44.98 | 50.77 |

| c | ARL1 | |||||||

| 1 | 370.11 | 370.15 | 370.00 | 370.00 | 370.02 | 370.01 | 370.01 | 370.01 |

| 0.9 | 160.10 | 140.38 | 121.25 | 115.85 | 109.00 | 105.29 | 104.19 | 103.21 |

| 0.8 | 69.75 | 54.25 | 41.14 | 37.75 | 33.62 | 31.43 | 30.77 | 29.92 |

| 0.7 | 30.72 | 21.55 | 14.70 | 13.06 | 11.14 | 10.13 | 9.81 | 9.30 |

| 0.6 | 13.77 | 8.94 | 5.69 | 4.97 | 4.14 | 3.71 | 3.57 | 3.30 |

| 0.5 | 6.36 | 3.97 | 2.51 | 2.21 | 1.86 | 1.69 | 1.63 | 1.50 |

| 0.4 | 3.10 | 1.98 | 1.37 | 1.26 | 1.14 | 1.09 | 1.07 | 1.04 |

| 0.3 | 1.67 | 1.22 | 1.03 | 1.02 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.2 | 1.11 | 1.01 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.1 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.1 | 0.2 | 0.4 | 0.5 | 0.7 | 0.9 | 1 | 1.5 | |

| l3 | 10.50 | 27.97 | 69.43 | 90.44 | 129.08 | 160.79 | 173.68 | 211.26 |

| c | ARL1 | |||||||

| 1 | 370.72 | 370.42 | 370.06 | 370.00 | 370.02 | 370.08 | 370.05 | 370.01 |

| 0.9 | 141.52 | 116.13 | 88.08 | 79.62 | 68.53 | 62.25 | 60.30 | 58.10 |

| 0.8 | 56.58 | 39.16 | 23.78 | 19.89 | 15.29 | 12.91 | 12.18 | 11.10 |

| 0.7 | 23.78 | 14.36 | 7.50 | 6.00 | 4.36 | 3.56 | 3.32 | 2.88 |

| 0.6 | 10.57 | 5.83 | 2.89 | 2.33 | 1.74 | 1.48 | 1.40 | 1.25 |

| 0.5 | 5.01 | 2.70 | 1.47 | 1.27 | 1.09 | 1.03 | 1.02 | 1.00 |

| 0.4 | 2.58 | 1.50 | 1.06 | 1.02 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.3 | 1.50 | 1.07 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.2 | 1.07 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.1 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.1 | 0.2 | 0.4 | 0.5 | 0.7 | 0.9 | 1 | 1.5 | |

| l3 | 29.69 | 79.11 | 196.38 | 255.81 | 365.10 | 454.78 | 491.26 | 597.52 |

| c | ARL1 | |||||||

| 1 | 370.53 | 370.08 | 370.17 | 370.00 | 370.00 | 370.00 | 370.01 | 370.00 |

| 0.9 | 141.46 | 116.05 | 88.10 | 79.61 | 68.52 | 62.24 | 60.30 | 58.10 |

| 0.8 | 56.56 | 39.14 | 23.78 | 19.89 | 15.29 | 12.90 | 12.18 | 11.10 |

| 0.7 | 23.78 | 14.35 | 7.50 | 6.00 | 4.36 | 3.56 | 3.32 | 2.88 |

| 0.6 | 10.57 | 5.83 | 2.89 | 2.33 | 1.74 | 1.48 | 1.40 | 1.25 |

| 0.5 | 5.01 | 2.70 | 1.47 | 1.27 | 1.09 | 1.03 | 1.02 | 1.00 |

| 0.4 | 2.58 | 1.50 | 1.06 | 1.02 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.3 | 1.50 | 1.07 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.2 | 1.07 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.1 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.1 | 0.2 | 0.4 | 0.5 | 0.7 | 0.9 | 1 | 1.5 | |

| l3 | 24.25 | 93.32 | 336.83 | 493.78 | 832.31 | 1150.16 | 1286.31 | 1659.85 |

| c | ARL1 | |||||||

| 1 | 389.83 | 373.30 | 370.04 | 370.08 | 370.04 | 370.02 | 370.03 | 370.01 |

| 0.9 | 133.38 | 103.35 | 70.29 | 60.00 | 46.42 | 38.84 | 36.53 | 34.42 |

| 0.8 | 50.14 | 32.53 | 16.66 | 12.77 | 8.41 | 6.33 | 5.73 | 4.93 |

| 0.7 | 20.67 | 11.69 | 5.06 | 3.73 | 2.39 | 1.82 | 1.67 | 1.41 |

| 0.6 | 9.34 | 4.83 | 2.06 | 1.60 | 1.19 | 1.06 | 1.03 | 1.00 |

| 0.5 | 4.62 | 2.34 | 1.20 | 1.07 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.4 | 2.50 | 1.38 | 1.01 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.3 | 1.51 | 1.05 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.2 | 1.08 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.1 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| r0 = 370; β = 1.5; u0 = 100 | ||||||||

| a | ||||||||

| 0.1 | 0.2 | 0.4 | 0.5 | 0.7 | 0.9 | 1 | 1.5 | |

| l3 | 97.02 | 373.31 | 1347.30 | 1975.12 | 3329.23 | 4600.66 | 5145.24 | 6639.42 |

| c | ARL1 | |||||||

| 1 | 373.80 | 370.47 | 370.01 | 370.06 | 370.01 | 370.01 | 370.01 | 370.00 |

| 0.9 | 128.96 | 102.73 | 70.29 | 59.99 | 46.42 | 38.84 | 36.53 | 34.42 |

| 0.8 | 48.83 | 32.38 | 16.66 | 12.77 | 8.41 | 6.33 | 5.73 | 4.93 |

| 0.7 | 20.27 | 11.65 | 5.06 | 3.73 | 2.39 | 1.82 | 1.67 | 1.41 |

| 0.6 | 9.21 | 4.82 | 2.06 | 1.60 | 1.19 | 1.06 | 1.03 | 1.00 |

| 0.5 | 4.57 | 2.34 | 1.20 | 1.07 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.4 | 2.49 | 1.38 | 1.01 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.3 | 1.51 | 1.05 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.2 | 1.08 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 0.1 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, N.; Aslam, M.; Khan, M.Z.; Jun, C.-H. A Variable Control Chart under the Truncated Life Test for a Weibull Distribution. Technologies 2018, 6, 55. https://doi.org/10.3390/technologies6020055

Khan N, Aslam M, Khan MZ, Jun C-H. A Variable Control Chart under the Truncated Life Test for a Weibull Distribution. Technologies. 2018; 6(2):55. https://doi.org/10.3390/technologies6020055

Chicago/Turabian StyleKhan, Nasrullah, Muhammad Aslam, Muhammad Zahir Khan, and Chi-Hyuck Jun. 2018. "A Variable Control Chart under the Truncated Life Test for a Weibull Distribution" Technologies 6, no. 2: 55. https://doi.org/10.3390/technologies6020055